Abstract

The Hanging Temple, a representative of a traditional wooden structure in northern China, is affixed to the cliff and closely connected to the rock, complicating its structural analysis due to uneven foundation height and irregular lateral stiffness. This paper adopts a simplified simulation method based on shear plastic hinge Dougong (DG), modified mortise–tenon joint (MTJ), and compressive constitutive model of wood for the example of a Hanging Temple in northern China. A finite element model of the Hanging Temple was established based on field research and mapping results. Its structural dynamic response to rare earthquakes was studied in depth to assess the structure’s seismic performance. The results show that the simplified simulation method can accurately and effectively simulate the plastic behavior of DG and MTJ. Under 3D ground motion excitation, structural deformation, and stresses were mainly concentrated at the foundations’ embedded ends. In particular, the dynamic response of the bottom columns and cantilever beams is most significant. The Hanging Temple’s force situation differs from that of general wooden structures. The existence of cantilever beams leads to the vertical asymmetry of the structure, which causes the uneven distribution of stiffness (the Y-direction stiffness is much more minor than the X-direction stiffness), and the middle columns, which are connected to multiple beams and DG, become the primary distribution points of stiffness, and are subject to large eccentric loads and tensile stresses, especially at the top of the columns where they are connected to the DG, which bear more internal forces in transferring and dispersing seismic forces. Historical wooden structures are a significant part of the world’s architectural heritage. Establishing an accurate seismic performance assessment model to evaluate these historical buildings is still challenging. This study provides an effective method and basis for seismic performance assessment and modeling of ancient wooden structures.

Similar content being viewed by others

Introduction

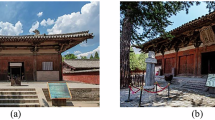

In China’s existing architectural heritage, wooden structures occupy the majority of buildings, which are still well preserved despite repeated earthquakes and typhoons1, which fully reflects the good structural performance of ancient Chinese wooden structures, which is related to structural materials, framing forms, MTJ structures, etc. For example, the Hanging Temple (see Fig. 1), a traditional wooden structure of architectural heritage in northern China, looks like a miniature temple hanging in the air from a distance, which is breathtaking. The Hanging Temple was built in 491 AD, more than 1,500 years ago. Its bottom is about 90 meters above the ground, equivalent to the height of the Statue of Liberty in the United States. This unique temple, a fusion of Buddhism, Taoism, and Confucianism, combines mechanics, esthetics, and religion. It showcases the splendid culture and civilized history of ancient peoples. Seismic performance assessment and a detailed understanding of their current state are crucial to ensuring these structures can be passed on to future generations2. However, accurate numerical modeling (e.g., finite element models) for seismic assessment remains challenging due to the complexity of component simulation methods and the uncertainty of structural conditions. Therefore, the priority is the methodology for accurate modeling.

Accurate finite element models provide reliable estimates of structural behavior and reduce costs and time3,4. For historic wooden structures, the DG and the MTJ, the main energy-consuming components, are critical components of the overall finite element model. In the past, Wang et al.5 and Jiang et al.6 modeled DGs and MTJs using solid units, mainly for component-level analysis. However, for finite element analyses of integral ancient wooden structures, the DG and MTJ are usually reduced to a model consisting of six independent springs7,8,9. Yue et al. experimentally investigated the semi-rigid properties of various MTJs10. At the same time, Li et al. developed a simulation method for MTJs using multilinear plastic linking units with 12 degrees of freedom11. However, due to the large number of units and poor convergence, applying the solid unit simulation methods of DG and MTJ to the numerical simulation of the whole structure is complex. Also, the semi-rigid spring method does not apply to DG, which consists of a complex combination of multi-layer components and cannot be accurately simulated by a single element12. To solve these problems, a simplified method for DGs and MTJs that visually and accurately expresses their properties is needed.

Establishing wood constitutive models has been a hot research topic for scholars at home and abroad, and significant results have been achieved. Gharib et al.’s existing macroscopic constitutive models were identified as empirical, elastic, elastoplastic, fracture, continuum damage, progressive damage, and combined plasticity damage models13. Empirical models are usually established by directly fitting the test results. However, they cannot reflect the physical nature of the mechanical behavior of wood and are only applicable to uniaxial loading states but not to complex loading states. Plastic modeling has become increasingly popular due to its broad applicability. Sirumbalzapata et al.14 proposed a constitutive model that takes into account plastic deformation and degradation of cyclic stiffness and strength, which is capable of simulating orthotropic and anisotropic elasticity, tensile and compressive strength differences in different directions, anisotropic plasticity, and isotropic hardening. Wang et al.15 considered plastic deformation in a progressive damage model. This model can calculate the isotropic hardening and anisotropic damage of wood. More studies are needed on the tensile and compressive constitutive model of timber for traditional wooden structures in buildings. In this paper, based on the experimental data of Chen et al.16, the moment hinge and axial hinge of wood are simulated and corrected concerning the literature17,18,19 to establish the tensile and compressive constitutive model of wood.

In this study, a simplified simulation method based on shear plastic hinge DG, modified MTJ, and compressive constitutive model of wood, combined with the results of field research and mapping, was used to establish a finite element model of the Hanging Temple and evaluate its seismic performance. This paper aims to establish an accurate and effective seismic performance assessment model for wooden architectural heritage. It is a new exploration of the seismic performance study of traditional wooden buildings in northern China and provides a theoretical basis for their routine maintenance and reinforcement.

Hanging Temple

Description

The Hanging Temple is a representative building of the MTJ structure. MTJ, the classic Chinese wooden structure connection method, has a strict limit on member number and length20,21. In this paper, a Hanging Temple in northern China is taken as a research object to explore its seismic performance. As shown in Fig. 2, based on the literature22,23 and surveying and mapping drawings, the Hanging Temple was built on a cliff 90 m above the ground. The beams and columns were connected by mortise and tenon joints (i.e., MTJ), and the upper and lower beams and columns were closely linked to the cantilever beams, forming an overall wooden frame structure, which enhanced structural rigidity and proved its structural reasonableness after many earthquakes in the millennium. Buddha statues in the Hanging Temple differ from general Buddha statues because they weigh less than 3 kg each, which is ‘customized’ for the temple. Considering the stability of the temple, the ancients chose the internal foundation of the temple on the protruding rock instead of the overhanging part. The natural gravity of the whole temple lies on the roof, which the Hanging Temple artisans cleverly disperse. The choice of six upper cantilever beams, each upper cantilever beam with a top beam between the columns to support open through the frame structure to disperse the gravity of the roof, and the bottom beams of most of the support in the rock, the force of relative stability, the principle of this is the pre-stressing in modern engineering24.

Establishment of a finite element model

Model method of MTJ

The MTJ of the Hanging Temple is simulated using the linking units in SAP2000. As shown in Fig. 3, after on-site research and mapping, it is known that the MTJ of the Hanging Temple are dovetail joints22, and information about the tenon and mortise is detailed in the relevant literature23. The following will select the experimental results of dovetail joints for simulation. The experimental model used in the experiment is a scaled model, and the scale of the dovetail joint is 1:3.52. The experimental results need to be corrected according to the similarity relationship, and the relationship between the experimental model and the original structure can be obtained by referring to the literature25,26 shown in Table 1. The cantilever beam and the column are connected using a tenon and mortise joint (i.e., MTJ).

The MTJ connection in traditional wooden buildings is semi-rigid between rigid and articulated joints. In this paper, an “M–θ “ simplified skeleton curve for MTJ studied by Chun et al.27 is used, as shown in Fig. 4.

The connection properties of the linking unit in the node area of the wooden structure are adopted as a multi-linear plastic linking unit, and the pivot point hysteresis model is used to simulate the MTJ. The linking unit has 12 degrees of freedom. The analysis assumes that the two bending degrees of freedom around the local Z-axis are semi-rigid properties, and the other 10 degrees of freedom are considered rigid connections. The eigenvalues of the MTJ model for the dovetail joint are shown in Table 2.

Model method of Dougong

The dougong (hereafter referred to as DG), shown in Fig. 5a, is a unique structural component of wooden architectural heritage and is extremely important in traditional wooden structures. The height of the DG is about 20% of the entire floor. The DG consists of dougs and kungs. The kung is the horizontal component with a double-bowed arm, whereas the doug is the vertical component connecting the kungs of each floor. The DG can transfer loads from the roof and floors to the ground. It also dissipates much energy through earthquake friction20,28. The damage modes are mainly shear damage from connecting tenon nails and compression damage between tenon nails. Relevant literature shows that although solid and friction contact units can accurately simulate DGs, the modeling is complicated and needs better convergence, which makes it challenging to apply to irregularly shaped Hanging Temple structures. Researchers proposed a simplified DG method based on multiple elastic–plastic hinges12, but it still complicates the modeling process as each DG contains about 20 plastic hinges. Therefore, this study improves the simplified simulation method of DGs based on the method of Li et al.12, which is based on shear plastic hinges and improves efficiency while guaranteeing accuracy. The DGs consume much energy through shear friction and extrusion, which can be simulated with shear plastic hinges in SAP2000. Specifically, the DG at each level can be simplified as multiple beams connected in series, horizontal members such as Kung can be simplified and omitted, and vertical members such as Doug are simplified as beams with shear plastic hinges in the middle (as shown in Fig. 5b). The initial dimensions of the doug can be determined according to the equivalent stiffness of the DG, and wooden beams with orthotropic anisotropy are used in this paper.

The hysteresis characteristics of the DG can be determined by three main parameters: the hysteresis type, the force–displacement relationship of the plastic hinge, and the yield force and displacement. To determine the hysteresis type, the force–displacement relationship (skeleton curve) was established based on the force characteristics of the DG and described by a three-broken line model with key points (Δs, Ps), (Δu, Pu) and (Δm, Pm), as shown in Fig. 6a. Since the DG layers are connected in series, the proportionality of the force–displacement curves of each layer remains constant. The hysteresis parameters of each DG layer can be determined by adjusting the yield force and displacement. In SAP2000, the plastic hinge is assumed to be a rigid plastic hinge, so the coordinates of point B are (0, 1). By entering the proportionality of force–displacement curves in SAP2000, the coordinates of points C–E are shown in Fig. 6b.

It is assumed that each Kung in the DG is identical and connected to the dougs, therefore, the hysteretic properties of each doug are the same. Ki denotes the stiffness of the dougs in the ith layer of the DG, which can be described as:

Where \(K\) is the stiffness of each doug, \({n}_{{i}}\) is the number of dougs in the ith layer of the DG, and \({\alpha }_{i}\) is the stiffness reduction coefficient for the ith DG layer. The force acting on the kung will be reduced due to spatial effects, and \({\alpha }_{i}\) is related to the number of dougs and the length of the kung. The different doug layers are connected by a series of connections. Therefore, the relationship between the total equivalent stiffness of the DG (\({K}_{e}\)) and the stiffness of each DG can be described as follows:

Where \({K}_{e}\) is the total equivalent stiffness of the DG, which can be calculated from the experimentally obtained hysteresis parameters of the whole DG, and m is the number of layers of the doug. The relationship between \({K}_{e}\) and \({K}_{i}\) can be described by substituting Eq. (2) into Eq. (1):

Since the DG layers are connected in series and the yield force remains constant, the yield displacement of each layer shear plastic hinge in Fig. 5b can be found by the following equation:

Where \({\Delta }_{s}\) is the yield displacement of the whole DG. The yield force and yield displacement of each DG are also obtained. Finally, the hysteresis parameters, the proportionality in the force–displacement curves of the DGs, the yield forces and displacements, and the type of hysteresis are entered into SAP2000.

This method is summarized as follows: (1) experimental determination of the hysteresis parameters for the entire Dougong (DG); (2) calculation of the proportional relationship between the force–displacement curve and the total stiffness of the DG (i.e., \({K}_{e}\)); (3) computation of the stiffness for each layer (i.e., \({K}_{i}\)); and (4) acquisition of the yield force and displacement, which are then applied to the beam’s plastic hinge. Table 3 shows the characteristic parameters of DG.

Model method for the plastic hinges of wood structure

Currently, there are fewer studies on plastic hinges for wooden structures. In this paper, based on the experimental data of Chen et al.16, the moment hinges and axial hinges of the wood used are simulated. The plastic hinge constitutive relationship of wood is shown in Fig. 7: σten-yield is the tensile yield stress, εten-yield is the tensile yield strain, σcom-yield is the compressive yield stress, εcom-yield is the compressive yield strain, and εcom-max is the compressive ultimate strain. The tensile and compressive constitutive model of wood has the whole curve divided into four stages. The tensile and compressive phases are divided into elastic and plastic sections. In SAP2000, the material constitutive model can be determined by custom hinge or default hinge in two ways. The method used in this paper is to set the default hinge first and then make custom modifications. The constitutive model (axial hinge) for compressive resistance of wood parallel to the grain is referred to in the related literature17. σcom-yield = 36 Mpa, σcom-max = 41= Mpa, εcom-yield = 0.04, εcom-max = 0.0469, and the stresses after the compressive limit are taken as 35 Mpa approximately, σten-yield = 70 Mpa, εten-yield = 0.01. The correction of the moment hinge parameters was carried out in the wooden beam experiment19,22,23. For example, the dimensions of the beam were 180 mm high, 120 mm wide, and 1300 mm long. From the experimental data, it is known that the yield load of the timber beam is 1.21 kN m, the yield deflection is 12 mm, the yield angle is 0.06, the ultimate load is 1.35 kN m, the ultimate deflection is 19 mm, and the ultimate angle is 0.1. Accordingly, it is worth noting that the reduced scale model of 1:3.52 is used in the literature. It is similar to the cross-sectional area and length of the timber beams in this paper, so the experimental data are used to correct the timber moment hinge and axial hinge.

Finite element model of the entire structure

As a convenient and practical tool for numerical structural performance assessment, the Finite Element Method is particularly effective when dealing with complex historic buildings. Finite element models for historic buildings need to be highly accurate and efficient. For an understanding of the dynamic characteristics of the Hanging Temple, an assessment of its seismic performance, and the development of a theoretical basis and technical reference for future strengthening, modeling was carried out using SAP2000 finite element software.

The Hanging Temple is a three-story wooden structure attached to a rock slope. It has a width of 13.2 m, a length of 21.6 m, and a rectangular layout. The first floor is 6 m tall, and the remaining floors are 8 m. The arrangement of the structure, the members’ self-weight, and the members’ geometric dimensions are determined according to field mapping and measurement results. The Hanging Temple’s timber material is northern Chinese larch22, which is orthogonal and anisotropic. The dimensions of the column-beam structure are given in Fig. 8 below. Wood properties are taken from Table 429. The rock slope is considered an elastic body for calculation because the sliding damage of the slope under seismic load is not considered. The material mechanical parameters of the rock slope model are shown in Table 5. According to the Load code for the design of building structures (article 6.2.3)30, the standard value of the Hanging Temple’s roof live load is qK = 0.7 kN/m2, and the standard value of floor dead load is gK1 = 2.0 kN/m2.

According to the code ‘Technical code for maintenance and strengthening of ancient timber buildings’31, when calculating the value of dead load for the roof, the following loads need to be taken into account: structural self-weight, roof live load, wind load, snow load, and seismic effects. Buddha statues in the Hanging Temple differ from general Buddha statues because they weigh less than 3 kg each. Therefore, these statues’ impact on the Hanging Temple’s dynamic performance is negligible. At the same time, factors such as the material’s density and thickness and the building’s geographical location should be considered. Considering the above factors, the standard value of roof dead load is qK = 3.5 kN/m2, and the standard value of floor live load is qK1 = 3.5 kN/m2. The strength of the material is taken according to the ‘Code for Design of Wooden Structures’32, and the discount factor suggested by the code33 is considered comprehensively. According to the regulations, the design strength of timber is discounted when the building is constructed ≥500 years from now. After discounting, the modulus of elasticity of the timber is taken as 6750 N/mm2, the flexural strength is determined as 7.7 N/mm2, the compressive strength of the parallel to the grain is taken as 7.5 N/mm2, the shear strength of the parallel to the grain is taken as 0.98 N/mm2, the compressive strength of the cross-grain is determined as 1.35 N/mm2, and the Poisson’s ratio is 0.3. Hanging Temple is a spatial structural system, and the structure mainly consists of columns, beams, DGs, and other components. In SAP2000, beams, columns, and other components use line units, and columns, rock foundations, cantilever beams, and rock foundations are simulated through articulated. In the Hanging Temple model, the beam-column joints are MTJ, mainly dovetail joints, simulated by the linking units above. The beam in tandem represents the DG with a shear plastic hinge in the middle. Accordingly, the finite element model of the Hanging Temple is established, as shown in Fig. 9.

Selection of ground motions

According to the code ‘Technical code for maintenance and strengthening of ancient timber buildings’31, when calculating the value of dead load for the roof, the following loads need to be taken into account: structural self-weight, roof live load, wind load, snow According to Article 5.1.2 of the Code for Seismic Design of Buildings (GB50011-2010)34, the selection of ground movement should take into account the type of building site and the design seismic groups, and the acceleration time–history curves of actual vital earthquake records and artificial simulations should be used. This paper selects five natural ground motions from the U.S. Pacific Earthquake Center. GM-Tool software generates two artificial ground motions, with a total of seven ground motions, and the acceleration ratios of the three-directional seismic components are adjusted according to the ratio of 1:0.85:0.65. The ground motion information is shown in Table 6, in which the bottom shear force of the structure obtained from the computation of each time–history curve should be at least 65% of the computation result of the vibration pattern decomposition reaction spectrum method. The average value of structural bottom shear obtained from the seven time–history curves should be at least 80% of the result of the vibration pattern decomposition reaction spectrum method, so the ground vibration selected in this study is reasonable and effective and meets the code requirements. Since the seismic intensity of the area is VIII degrees, the peak acceleration of ground motion is adjusted to the rare earthquake level of 400 cm/s2. The acceleration response spectra are shown in Fig. 10.

Seismic dynamic response analysis of the Hanging Temple under rare earthquakes

Modal analysis of the Hanging Temple

A modal analysis was carried out to study the dynamic characteristics of the Hanging Temple structure to derive the intrinsic frequency and the first 10 orders of vibration patterns of the structure and its modal coefficients (refer to Table 7). X is the horizontal east–west direction (longitudinal), Y is the horizontal north–south direction (transverse), and Z is the vertical direction. In the table, UX% is the percentage of mass participation in the X-direction, SumUX% is the cumulative percentage of mass participation in the X-direction, RX% is the percentage of mass participation in the direction of torsion around the x-axis, RY% is the percentage of mass participation in the direction of torsion around the y-axis, and RZ% is the percentage of mass participation in the direction of torsion around the z-axis.

It can be seen that the natural vibration period of the first three stages of the Hanging Temple structure is 1.84 s, 1.35 s, and 0.99 s. The first stage of the first mode is 7.91% for UX, 82.72% for UY, 0.04% for UZ, and 0.09% for RZ, and the first order modes of UX + UY> RZ and UY> UX, which indicate that the first mode of the structure belongs to Y-direction horizontal vibration, The second vibration mode is 4.03% for UX, 15.48% for UY, 0.05% for UZ, 0.00% for RZ, and UX + UY> RZ and UY> UX, which indicates that the second vibration mode of the structure also belongs to the Y-direction horizontal vibration, the third vibration mode is 3.76% for UX, 0.01% for UY, 2.78% for UZ, and 5.88% for RZ, which indicates that the third vibration mode is the torsion around the z-axis. After the fourth-order mode, there are more complex flat and torsional coupled vibrations. This suggests that the mode shapes in the Y direction play a dominant role in the dynamic response of the structure. In addition, the X-direction and the torsional Rz-direction contribute negligibly to the dynamic response of the structure due to the longitudinal restraint provided by the cantilever beams connected ted to the rock slopes, which control the X-direction displacement of the structure while limiting the torsion of the structure. The period ratio of the structure is the ratio of the lateral stiffness to the torsional stiffness of the building, which can express the relative relationship between the two. From Table 7, the first torsional period of the Hanging Temple is 0.99 s, the first translational period is 1.84 s, and the period ratio is 0.99/1.84 = 0.538. The smaller period indicates the Hanging Temple’s structural arrangement is relatively regular. It is not easy to have a large torsional deformation under seismic action. Table 7 shows that the Y-direction translational natural vibration frequency of the Hanging Temple is smaller than the X-direction translational natural vibration frequency of the Hanging Temple, which shows the difference in the stiffness distribution of the Hanging Temple structure along the two directions, and the Y-direction stiffness is smaller than the X-direction stiffness. The first three orders of the Hanging Temple modal vibration patterns are shown in Fig. 11. From the results of the modal analysis, it can be seen that the most prone to deformation of the Hanging Temple is north–south vibration (Y-direction), followed by east–west (X-direction) vibration and torsion (RZ-direction) vibration.

Analysis of the time–history of the Hanging Temple

The seismic parameters of the Hanging Temple are taken as mentioned before. Firstly, the seismic time–history analysis is carried out in the north–south direction (i.e., Y-direction), where the stiffness of the Hanging Temple is minor, and the damping ratio of the structure is taken as 0.05. From the results of the modal analysis of the Hanging Temple, it can be seen that the Y-direction stiffness is smaller than the X-direction stiffness, and this paper first conducts the displacement time–history analysis of the Y-direction, where the stiffness of the Hanging Temple is small, to get the most unfavorable seismic response. Figure 12a, b shows the structure’s Y- and X-direction deformation responses. From the lateral deformation response distribution results, the lateral deformation of the lower part of the Hanging Temple and its girders in the Y-direction is small. In contrast, the lateral deformation of the top floor and its girders at the side span locations is large. Due to the existence of cantilever beams connected to the rock slope, the lateral deformation in the X direction is much smaller than that in the Y direction, and the maximum lateral deformation in the X direction occurs at the eaves of the top floor. It can be seen that the lateral deformation of the roof of the Hanging Temple and its beams is larger at the side span position and eaves.

This study investigates the maximum displacement response of the Hanging Temple structure under seismic action in the context of a three-way rare earthquake of degree VIII. As a macro-control indicator of the seismic capacity of the structure, the purpose of the calculation is to ensure that the structure has sufficient stiffness. Under three-dimensional ground motion excitation, the inter-story displacement angle of the Hanging Temple is shown in Fig. 13, and according to the code for the design of wooden structures32, the elastic–plastic inter-story displacement angle of the wooden structure is limited to 1/50 under rare earthquakes. It can be seen from the figure that the maximum inter-story displacement angle of the Hanging Temple structure under rare earthquakes is 1/205, which is much smaller than the limit value stipulated by the code, and it has a sufficient seismic safety reserve. Due to the existence of cantilever beams, the stiffness of the second floor of the Hanging Temple is the largest. The other floors are relatively small, resulting in a decreasing and then increasing trend of the inter-story displacement angle from the first floor to the roof floor.

The overall deformation response of the Hanging Temple under 3D rare earthquake excitation is shown in Fig. 14. It is shown that the deformation of the structure is mainly concentrated at the unequal foundation’s embedded end, i.e., the column end of the first floor and the cantilever beams at each floor have the most considerable deformation. Additionally, there is a large deformation at the side span locations of the top floor and its beams. Therefore, health monitoring and maintenance should be carried out in these critical areas.

Structural stress and shear analysis of the Hanging Temple

The allowable tensile strength of the timber of the Hanging Temple is 8.5 MPa. Based on the comparison of the time–history curves, the maximum main stress cloud diagram during a rare earthquake is obtained, as shown in Fig. 15. The maximum primary stress of the Hanging Temple is 9.6 MPa, which exceeds the allowable tensile strength of wood of 8.5 MPa. This indicates that tensile cracking in a rare earthquake may damage the wooden structure.

A stress cloud diagram of the structural section under a rare earthquake was analyzed to identify the most dangerous parts (as shown in Fig. 16). In a rare earthquake, the stresses on many members exceeded the allowable strength of the wood. Some of the members had exceeded the limit substantially, destroying the structure. The members subjected to large stresses include all the middle columns on the first floor, most of the DGs and some of the edge columns, and the tops of the corner columns. The Hanging Temple’s stress situation differs from that of general wooden structures. The existence of cantilever beams leads to vertical asymmetry of the structure, which in turn causes uneven distribution of stiffness, especially at the top of the columns connecting the DG parts, which should be paid particular attention to in the daily maintenance process. At the same time, the middle column connects several beams and DGs, which is the main distribution point for structural stiffness. It, therefore, bears a larger internal force when transferring and dispersing the seismic force. In the process of seismic wave input, the principal stresses of the corner columns and edge columns are smaller than those of the middle columns, which indicates that during seismic action, the earthquake damage to the corner columns and edge columns is effectively reduced by vibration dissipation through the vibration isolation of the arch of the middle columns. In addition, the mechanical properties of the dougong are different in different directions, and the arrangement directions of the dougongs connected to the middle columns and the dougongs connected to the edge columns are different. Due to the cantilever beam’s presence, the structure’s dynamic response in the Y-direction is much greater than in the X-direction. Therefore, the DG plays an essential role in the energy consumption in the Y-direction. Furthermore, the MTJ connected by beams and columns suffers from a high tensile stress level. Maintenance must include particular attention paid to the MTJ connected by beams and columns since they can withstand more significant pressures but cannot withstand greater tensile loads.

Under three-dimensional ground motion, the inter-story shear forces of the D-axis timber frame and the A-axis timber frame of the Hanging Temple are shown in Fig. 17. Due to the restraint of the cantilever beam, the stiffness of the D-axis timber frame is greater than that of the A-axis timber frame, resulting in an increased inter-story shear force in the D-axis timber frame than in the A-axis timber frame. The maximum inter-story shear force occurs on the second floor. It is mainly concentrated in the second-floor girders. The cantilever beams are fixed at the end and have a large stiffness, which bears most of the horizontal force, resulting in the largest stiffness on the second floor, and the other floors are relatively small. The inter-story shear force from the first floor to the roof floors shows a trend of increasing first and then decreasing. The selection sequence of key members for monitoring is columns, second-floor beams, and roof rafters. The location of plastic hinges is selected from the top of columns and column footings, the ends of beams, and the middle of beams with large spans.

Structural damage to the Hanging Temple

The structural damage of the Hanging Temple under rare earthquakes is investigated by dynamic elastic–plastic analysis of the structure under 3D ground motion excitation. The plastic hinges of SAP2000 are used to consider the nonlinear behavior of the members. Plastic hinges were selected based on the key members above, selecting all columns, floor beams, cantilever beams, and roof rafters. Plastic hinges are set at the tops of columns with column footings, the ends of beams, and the middle of beams with large spans. The force–displacement curves of plastic hinges are shown in Fig. 18, where A–E are the individual control points, IO, LS, and CP are the building performance indexes developed by FEMA27335, and different colors are used to denote the individual indexes. AB, BC, CD, and DE denote the elastic section, the reinforcement section, the unloading section, and the destructive section, respectively, where point B is the yield point of the hinge. The hinge loses its load-bearing capacity at point C, and there is a sudden loss of strength. FEMA 273 identifies stages B-IO as immediate use, IO-LS as life safety, and LS-CP as collapse prevention.

The PUSHOVER analysis of the Hanging Temple is carried out using SAP2000, and the Y-direction vibration mode is applied to analyze the distribution of plastic hinges of the structure under a rare earthquake to determine the yielding sequence of the members and to predict the seismic response of the structure. Figure 19 depicts the development of plastic hinges of the Hanging Temple in the PUSHOVER analysis (Corresponding to the last phase of Fig. 20).

An analysis of one of the plane frames was conducted to more intuitively observe and understand the development and distribution of plastic hinges in the Hanging Temple. Based on the PUSHOVER analysis, the distribution of plastic hinges is depicted in Fig. 20. With the increase of horizontal load in PUSHOVER, the ‘yield limit’ plastic hinges appear at the beam ends and MTJs of the side columns, followed by the ‘direct use’ plastic hinges, and the plastic hinges extend from the ends to the center and from the first floor to the top floor. The beam ends, and MTJs of the center columns also appear one after another. Then, the plastic hinges continue to develop and increase, gradually appearing as ‘life safety’ and ‘strength limit’ plastic hinges, finally reaching ‘collapse prevention’ and ‘strength limit’ plastic hinges. From the above, it can be seen that the presence of cantilever beams resulted in vertical asymmetry and uneven stiffness distribution, especially at the top of the columns connecting the DG parts. As a result, the MTJs at the beam ends of the side columns on the first floor of the cantilevered temple are prone to be damaged first under seismic action and require special attention in routine maintenance.

Conclusions

In this paper, a simplified simulation method based on the DG of shear plastic hinge-modified MTJ and compressive constitutive model of the wood tensile and compressive constitutive model of a Hanging Temple in northern China is adopted as an example. On this basis, a finite element model of the Hanging Temple was established based on field research and mapping results. In this study, the Hanging Temple structure’s dynamic response to a rare earthquake has been thoroughly examined, and its seismic performance has been evaluated. Based on the analysis results, the conclusions of this study about the Hanging Temple are summarized as follows:

(1) From the results of the modal analysis, it can be seen that the modal vibration pattern in the Y direction plays a dominant role in the dynamic response of the structure. In contrast, the X direction and the torsional RZ direction contribute negligibly to the dynamic response of the structure, i.e., the most prone to deformations of the Hanging Temple is the north–south vibration (Y-direction), followed by east–west (X-direction) vibration and torsional (RZ-direction) vibration since the cantilever beams are connected to the rock slopes, which provide longitudinal constraints so that the stiffness of the Hanging Temple structure is unevenly distributed in both directions (Y-direction stiffness is much smaller than X-direction stiffness). The cantilever beams control the displacement of the structure in the X-direction and limit the structure’s torsion.

(2) When the seismic time-course analysis was carried out in the north–south direction (i.e., Y direction), where the stiffness of the Hanging Temple was small, it was found that the lateral deformation of the roof and its beams was larger in the side-span position and eaves. Due to the presence of cantilever beams, the stiffness of the second floor of the Hanging Temple is the largest, and the other floors are relatively smaller, resulting in a decreasing and then increasing trend of the inter-story displacement angle from the bottom to the top floor. The structural deformation was mainly concentrated on the unequal foundation’s embedded end, i.e., the column end of the first floor and the cantilever beams of each floor. In contrast, the roof and its beams had large deformations at side span locations.

(3) The Hanging Temple’s force situation differs from general wooden structures. The existence of cantilever beams leads to vertical asymmetry of the structure, which in turn causes uneven distribution of stiffness, and the middle column becomes the main point of stiffness distribution due to the connection of several horizontal beams and the DG, which is subjected to larger eccentric loads and tensile stresses, especially in the connection of DG at the top of the columns and bears more internal forces in transferring and dispersing seismic forces. Earthquake damage to the corner and edge columns is effectively reduced through vibration isolation and energy dissipation by the middle column’s DGs. Meanwhile, the tensile stresses near the MTJ joints where the beams and columns are connected are higher. Under three-dimensional ground motion, the structural inter-story shear force increases and decreases from the first to the top floor. The maximum shear force occurs on the second floor, mainly concentrated on the second-floor beams. Due to the restraint of the cantilever beam, the stiffness of the D-axis timber frame is greater than that of the A-axis timber frame, resulting in a greater inter-story shear force in the D-axis timber frame than in the A-axis timber frame.

(4) Under the earthquake, the ‘yield limit’ plastic hinges appear at the beam ends and MTJs of the side columns, followed by the ‘direct use’ plastic hinges, and the plastic hinges extend from the ends to the center and from the first floor to the top floor. The beam ends, and MTJs of the center columns also emerge one after another. Then, the plastic hinges continue to develop and increase, gradually appearing as ‘life safety’ and ‘strength limit’ plastic hinges and finally reaching ‘collapse prevention’ and ‘strength limit.’ As a result, the MTJs at the beam ends of the side columns on the first floor of the cantilevered temple are prone to being damaged first under seismic action and require special attention in routine maintenance.

Data availability

No datasets were generated or analysed during the current study.

References

Deng, Y., Li, Y. & Li, A. Seismic safety assessments of historical timber buildings using updated finite element models: case study of Yingxian wooden pagoda, China. J. Build. Eng. 63, 105454 (2023).

Genç, A. F. et al. Dynamic analyses of experimentally-updated FE model of historical masonry clock towers using site-specific seismic characteristics and scaling parameters according to the 2018 Turkey building earthquake code. Eng. Fail. Anal. 105, 402–426 (2019).

Liu, K., Yan, R.-J. & Guedes Soares, C. An improved model updating technique based on modal data. Ocean Eng. 154, 277–287 (2018).

Wang, X. et al. Model updating strategy for structures with localised nonlinearities using frequency response measurements. Mech. Syst. Signal Process. 100, 940–961 (2018).

Wang, J., Cui, Z., Yang, Q. & Yang, N. A study on horizontal resistance mechanism of palace-style wooden frame in tang dynasty. Eng. Mech. 36, 104–114 (2019).

Jiang, S., Wu, M., Tang, W. & Liu, X. Multi-scale modeling method and seismic behavior analysis for ancient timber structures. J. Build. Struct. 37, 44–53 (2016).

Han, Y., Chun, Q., & Jin, H. Wind-induced vibration performance of early Chinese hall-style timber buildings. J. Wood Sci. https://doi.org/10.1186/s10086-020-01939-3 (2021).

Wang, J., He, J., Yang, N., & Yang, Q. Study on aseismic characteristics of Tibetan ancient timber structure. Adv. Mater. Sci. Eng. https://doi.org/10.1155/2017/8186768 (2017).

Wu, C., Xue, J., Zhou, S. & Zhang, F. Seismic performance evaluation for a traditional Chinese timber-frame structure. Int. J. Archit. Herit. 15, 1842–1856 (2021).

Yue, Z. Traditional Chinese wood structure joints with an experiment considering regional differences. Int. J. Archit. Herit. 8, 224–246 (2014).

Li, X., Zhao, J., Ma, G. & Chen, W. Experimental study on the seismic performance of a double-span traditional timber frame. Eng. Struct. 98, 141–150 (2015).

Li, Y., Deng, Y. & Li, A. Simplified simulation method for hysteretic behavior of wood brackets. J. Perform. Constr. Facil. 35, 4021085 (2021).

Gharib, M., Hassanieh, A., Valipour, H. & Bradford, M. A. Three-dimensional constitutive modelling of arbitrarily orientated timber based on continuum damage mechanics. Finite Elem. Anal. Des. 135, 79–90 (2017).

Sirumbal-Zapata, L. F., Málaga-Chuquitaype, C. & Elghazouli, A. Y. A three-dimensional plasticity-damage constitutive model for timber under cyclic loads. Comput. Struct. 195, 47–63 (2018).

Wang, M., Song, X. & Gu, X. Three-dimensional combined elastic-plastic and damage model for nonlinear analysis of wood. J. Struct. Eng. 144, 04018103 (2018).

Chen, C., Qiu, H. & Lu, Y. Flexural behavior of timber dovetail mortise-tenon joints. Constr. Build. Mater. 112, 366–377 (2016).

Cowled, C. J., Crews, K. & Gover, D. Influence of loading protocol on the structural performance of timber-framed shear walls. Constr. Build. Mater. 288, 123103 (2021).

Zhang, Z., Liu, M., Liu, X., Wang, X. & Zhang, Y. Model identification of durability degradation process of concrete material and structure based on Wiener process. Int. J. Damage Mech. 30, 537–558 (2021).

Zhao, H. T., Zhang, H. Y., Xue, J. Y., Sui, Y. & Wu, L. The stiffiness analysis on the characteristic of mortise-tenon joint in historical timber buildings. Xi’an University of Architecture and Technology (Natural Science Edition). 2009;41:04. (2017).

Chu, C. H., Liao, C. J. & Lin, S. C. Comparing augmented reality-assisted assembly functions—a case study on Dougong structure. Appl. Sci. 10, 3383 (2020).

Hao, S. Using virtual reality to produce 3-D graphical simulation of the construction and use of Dougong in Chinese architecture emphasizing the Song and Qing Dynasties (Doctoral Dissertation, The Ohio State University). http://rave.ohiolink.edu/etdc/view?acc_num=osu1523616323665237 (2018).

Zhang, Y. & Wang, X. Exploring the inspiration of structural beauty on craftsmanship in the book of examination and works—taking the Hanging Temple of Hengshan as an Example. Research on Art Education (20), 76–77 (in Chinese) (2019).

Zhao, Q. Engineering and Technical Support and Restrict the Mountain Scenic Area Landscape Architectural Design and Research (Master’s Degree Thesis). Xi’an University of Architecture and Technology. (in Chinese) (2013).

Wang, B. Q. & Wang, P. Hengshan Mountain and Hanging Temple. China Architecture & Building Press. (in Chinese) (2015).

Zhang, X., Wu, C., Xue, J. & Ma, H. Fast nonlinear analysis of traditional Chinese timber-frame building with Dou-Gon. Int. J. Archit. Herit. 14, 1252–1268 (2020).

Xie, Q., Wang, L., Zhang, L., Xiang, W. & Hu, W. Rotational behaviors of fork-column dou-gong: experimental tests and hysteresis model. J. Perform. Constr. Facil. 34, 4020032 (2020).

Chun, Q., Yue, Z. & Pan, J. Experimental study on seismic characteristics of typical mortise-tenon joints of Chinese southern traditional timber frame buildings. Sci. China Technol. Sci. 54, 2404–2411 (2011).

Zhang, X., Xue, J., Zhao, H. & Sui, Y. Experimental study on Chinese ancient timber-frame building by shaking table test. Struct. Eng. Mech. 40, 453–469 (2011).

Lu, P. Analysis of the effect of aging on mechanical behavior of ancient timber structural members. (Master’s Degree Thesis). (Xi’an University of Architecture and Technology, 2017).

GB 50009-2001 Load code for the design of building structures [S]. (China Architecture and Building Press, Beijing, 2001) (in Chinese).

GB 50165-92 Technical code for maintenance and strengthening of ancient timber building [S]. (China Architecture and Building Press, Beijing, 1992) (in Chinese).

Code for design of wood structures (GB50005-2003) [S]. (China Planning Publishing House, Beijing, 2004) (in Chinese).

Technical code for maintenance and strengthening of ancient timber building (GB50165-92) [S]. (China Machine Press, Beijing, 1993) (in Chinese).

GB 50011-2010 Code for Seismic Design of Buildings [S]. (China Architecture & Building Press, 2010) (in Chinese).

FEMA-273, Guidelines and Commentary for the Seismic Rehabilitation of Buildings[S], Washington D.C. NEHRP. (1997).

Acknowledgements

The writers gratefully acknowledge the financial support of the High-level Talent Support Project of Yunnan Province, China (2020).

Author information

Authors and Affiliations

Contributions

Zhuoxin Yang mainly wrote the paper, Dewen Liu proposed revisions to the article, and others helped to check the article.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yang, Z., Liu, D., Shen, L. et al. Seismic vulnerability assessment of historical timber temples: a case study of the Hanging Temple in China. npj Herit. Sci. 13, 4 (2025). https://doi.org/10.1038/s40494-025-01608-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s40494-025-01608-y

This article is cited by

-

Experimental and numerical research on the lateral hysteretic behavior and simplified model of typical Dou-Gong in Ming-Qing dynasties

npj Heritage Science (2026)

-

Construction of integrated, contiguous conservation and utilization system for cultural relics protection unit in Qiandongnan based on quantitative analysis

npj Heritage Science (2025)

-

Individual segmentation method of ancient architectural components based on point cloud and construction techniques

npj Heritage Science (2025)