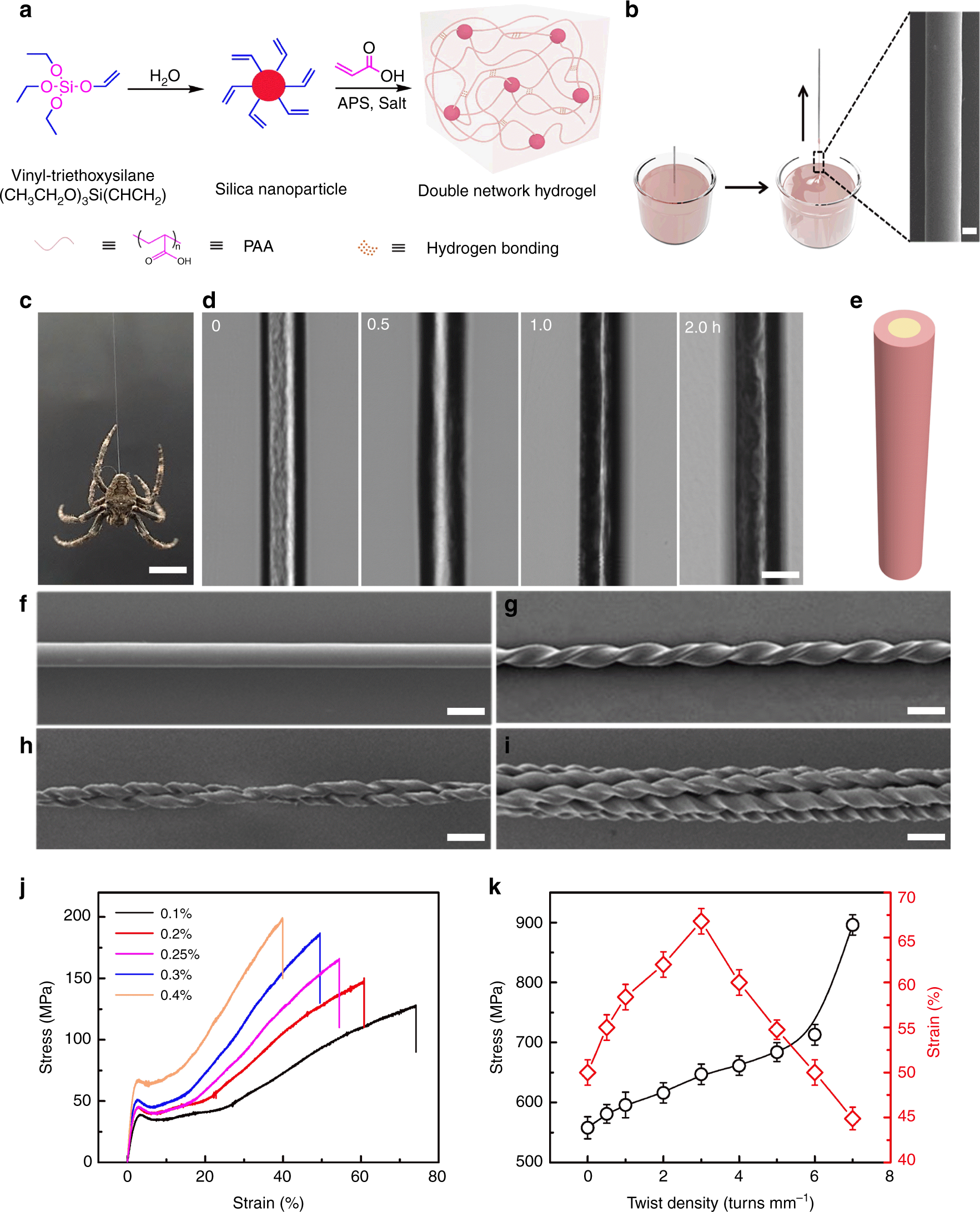

Fig. 1

From: Artificial spider silk from ion-doped and twisted core-sheath hydrogel fibres

Preparation, morphology and mechanical strength of hydrogel fibres. a Two-step synthesis of hydrogel involving VSNP formation and free-radical polymerisation. b A single fibre was drawn by dipping a steel rod into a hydrogel reservoir. The diameter of the steel rod was 0.2 mm, and the drawing speed was 4 cm s−1. Scale bar: 10 μm. The hydrogel fibre shown in the micrograph contained 0.1 wt% VSNPs, without salt or inserted twist, and had a diameter of 20 μm. It was obtained at an atmospheric relative humidity of 40%. c An Araneus diadematus spider hanging on a strand of natural spider silk; the scale bar is 2 cm. d Laser confocal microscope images of hydrogel fibres with different drying times. Scale bar: 20 μm. e Core-sheath model of the hydrogel fibre. f–i SEM images of non-twisted (f), twisted (g), self-balanced, 2-ply (h), and self-balanced, 6-ply hydrogel fibres (i). The scale bars for d–i are 20 μm. The twist density was 7 turns mm−1. j Tensile stress-strain curves of the as-drawn hydrogel fibres with different VSNP contents after shape setting. The hydrogel fibres contained 0.1–0.4 wt% VSNPs, without inserted twist or salt. The deformation rate was 1.1% s−1. k Breaking stress and breaking strain of hydrogel fibres with optimised mechanical properties as a function of twist density at a deformation rate of 27.8% s−1. In d, f–i and k, the hydrogel fibres contained 0.1 wt% VSNPs and 20 mM ZnCl2. The error bars mean the s.d. from five measurements