Abstract

Coagulation is a simple and cost-effective water treatment method that does not work well in removing multiple cationic and anionic heavy metals simultaneously from drinking water. Titanium potassium oxalate (K2TiO(C2O4)2), a fur tanning reagent, was found to be able to efficiently remove arsenite (As(III)), arsenate (As(V)), and Cd simultaneously. A dose of 120 µmol/L K2TiO(C2O4)2 could remove more than 90% of As and Cd to meet the drinking water standards when their initial concentrations were 10 times their maximum concentration limits, whereas traditional coagulants, such as Fe2(SO4)3 and Al2(SO4)3, failed to meet the drinking water standards. Additionally, K2TiO(C2O4)2 coagulation consumes natural water hardness (Ca2+/Mg2+) to produce softer water and releases healthy K+ as a by-product. The mechanism study indicated that K2TiO(C2O4)2 reacted with natural calcium ions in drinking water to form calcium oxalate, while residual titanium was hydrolyzed with water to form hydrous titanium oxide. Arsenic was removed primarily via complexation with hydrous titanium oxide, while Cd was removed via the combined effect of adsorption by hydrous titanium oxide and mixed-crystal formation by calcium oxalate. This study provides an efficient coagulant for removing multiple heavy metals simultaneously, which can be applied in water treatment to provide safe and healthy drinking water.

Similar content being viewed by others

Introduction

Heavy metals are non-degradable, highly toxic, and can accumulate inside organisms throughout the food chain. They threaten drinking water safety owing to increasing anthropogenic industrial discharge into the environment and have attracted tremendous social and scientific concerns1. Arsenic (As) and cadmium (Cd) are common toxic heavy metals that primarily exist as inorganic anionic and cationic ions in natural environments, respectively2,3. They can be frequently found together in acid mine drainage, the smelting industry, fuel combustion, and other sources4,5,6. As and Cd co-contamination poses a severe threat to drinking water supply systems7,8,9. The World Health Organization, the Environmental Protection Agency of the United States, and many other countries have set strict standards for drinking water supply, e.g., the maximum contaminant levels (MCL) for As and Cd are 10 and 5 μg/L, respectively, according to the drinking water quality standard of China (GB 5749–2006); however, millions of people, mostly in the developing world, still suffer from excess heavy metal uptake through contaminated water being used for drinking, cooking, and other domestic purposes10,11,12. As such, there is a need to develop a simple method that is effective for removing As and Cd from drinking water.

Many advanced technologies have been developed for efficient heavy metal sequestration from drinking water, including adsorption13, ion exchange14, and membrane separation15. For example, Fe-modified mesoporous carbon has been developed for the efficient removal of As (V) from water16. Microporous stannosilicate AV-6 has been reported as an efficient ion-exchange material for Cd removal17. The Ti3C2TX-ethylenediamine nanofiltration membrane showed comprehensive rejection rates higher than 93% for multiple heavy metals, including Cd2+, Mn2+, Zn2+, Cu2+, Ni2+, and Pb2+18. Although these technologies are efficient for heavy metal sequestration, they rely on expensive materials and professional operations, such as the regeneration and disposal of used sorbents and ion exchange resins, control of biofouling, and replacement of membrane assemblies19. Traditional coagulation is still the most widely applied water treatment process in removing heavy metals from drinking water because it is simple and cost-effective20,21. Fe and Al reagents are the most frequently used coagulants in drinking water treatment22. By adding aluminum polychloride, zeolite, powdered activated carbon, and sodium hypochlorite to As(V)-contaminated tap water, the combined coagulation/adsorption process removed low concentrations of As(V) in the range of 25–100 μg/L with a removal efficiency of up to 85.9%23. Ferrous sulfate was successfully used for the simultaneous removal of As(V) and chromate (Cr(VI)) from ground and surface waters; residual As(V) and Cr(VI) concentrations were both below 10 μg/L, from initial concentrations of 50 μg/L24. Organic coagulants, mainly polyacrylamide, were also used in heavy metal removal. But their applications were somehow restrained within industrial wastewater treatment due to the potential toxicity of residue monomer or oligomer25. Biopolymers were developed to substitute polyacrylamide, but their costs are still too high for massive applications26. Other metal reagents have been explored as potential coagulants. For example, titanium sulfate was used as an effective coagulant for As(III) removal, in which more than 99% of As(III) could be removed at an initial concentration of 200 μg/L using ultraviolet photocatalysis27. Although coagulation is effective in removing anionic As(V), it is less effective in removing cationic Cd2+ because of electrostatic repulsion from positively charged Fe or Al hydroxides. Ti reagent has the potential for simultaneous coagulation removal of As and Cd; as its coagulum, hydrous TiO2, is effective in the adsorption of anionic As(III)/As(V), Cd2+, and other cationic heavy metal ions28,29. For example, efficient simultaneous removal of Cd and As in aqueous solutions was realized by using titanium-modified biochar, with maximum sorption capacities of 72.62 mg/g for Cd and 118.06 mg/g for As, respectively30. As(III) and Cd in raw water at 2590 ± 295 and 12 ± 2 mg/L, respectively, could be reduced to 0.16 ± 0.11 and 0.0133 ± 0.0134 mg/L when using three granular TiO2 adsorption columns in series31. Although the adsorption capabilities of TiO2 have been shown, reports on the simultaneous coagulation removal of As and Cd using Ti reagents are still rare.

Most Ti reagents are easily hydrolyzed in water32. Titanium tri-/tetra-chloride33, titanium sulfate (Ti(SO4)2)27, and polytitanium chloride/sulfate34,35 have been developed as coagulants for water treatment36. Titanium tetrachloride hydrolyzes with water vapor immediately, even when exposed to air37. Ti(SO4)2 can only be dissolved in strong acids such as 1 mol/L sulfuric acid38. Unlike other Ti reagents, titanium potassium oxalate (K2TiO(C2O4)2), which is currently used as an environment-friendly tanning reagent in the leather industry, is soluble in water, and its addition to water only leads to weak pH variation owing to the weak acidity of oxalate acid. K2TiO(C2O4)2 hydrolyzes to hydrous TiO2 and calcium oxalate (CaC2O4) after its addition to tap or natural water. Hydrous TiO2 is an efficient sorbent for As removal39, while CaC2O4 has been reported to be active in the adsorption removal of Pb2+ and Cd2+40. In this study, K2TiO(C2O4)2 was explored as an efficient coagulant for the simultaneous removal of As(III)/As(V) and Cd from drinking water using response surface methodology (RSM). The coagulation mechanism was studied by characterizing coagulum using X-ray diffraction, scanning electron microscopy, and X-ray photoelectron energy spectroscopy.

Results and discussion

The influence of reaction time on As(III)/As(V) and Cd removal by K2TiO(C2O4)2 and CaCl2

The initial As and Cd concentrations were both set at 10 times the MCL of As and Cd in drinking water, according to drinking water quality standards (GB 5749–2006, China). As shown in Fig. 1, the removal of both As and Cd occurred primarily during the first 5 min. Specifically, As(III) and As(V) concentrations dropped rapidly from 100 μg/L to approximately 5 μg/L in 5 min, which was much lower than the MCL (10 μg/L). Furthermore, there were no significant differences in the As(III) and As(V) removal by K2TiO(C2O4)2 and CaCl2. Similarly, Cd concentrations, whether with As(III) or As(V), dropped rapidly from 50 μg/L to MCL (5 μg/L) in drinking water in five min. The rapid hydrolysis of Ti(IV) in aqueous solutions and the fast reaction rate of chemical coagulation and precipitation could be the reasons for these results. Overall, K2TiO(C2O4)2 combined with CaCl2 showed excellent potential for simultaneous As and Cd removal from drinking water. With no significant change in residual As concentrations and only a slight drop in residual Cd concentrations (from approximately 5 µg/L to 3 µg/L) between reaction times of 5 and 120 min, 30 min was chosen as the reaction time for the following experiments considering operational convenience. In addition, the formed coagulant settled down to the bottom very quickly within 30 min (Supplementary Figure 1). It is convenient to realize efficient slurry separation via traditional gravity settling.

The influence of reaction temperature on As(III)/As(V) and Cd removal by K2TiO(C2O4)2 and CaCl2

To investigate the influence of the reaction temperature on As and Cd removal by K2TiO(C2O4)2 and CaCl2, a series of experiments were conducted at various temperatures ranging from 20 to 80 °C, as shown in Supplementary Figure 2. The results indicate that temperature had little effect on Cd removal but had a significant negative effect on As removal. Specifically, when mixed with As(III) or As(V), the Cd removal efficiency was maintained at approximately 97%, with only approximately 3% change as the temperature increased from 20 to 80 °C. However, for both As(III) and As(V), the removal efficiency decreased by approximately 21% as the temperature increased from 20 to 80 °C. Interestingly, there were obvious linear correlations between temperature and the As(III) or As(V) removal efficiencies, and their correlation coefficients (R2) were 0.999. Similar temperature effect was reported on arsenic removal from mining effluent using iron nanoparticles, in which the As removal efficiency dropped from 90% to 73% when the temperature increased from 20 to 70 °C41. Therefore, removal operations should avoid high temperatures. A temperature of 20 °C was chosen for the following experiments considering the economy, efficiency, and ease of operation.

Response surface analysis

There was no significant difference on As(III) or As(V) removal from drinking water using K2TiO(C2O4)2 and CaCl2, but As(III) has much higher toxicity and mobility than As(V)42; therefore, As(III) was selected as the As existing species in the simulated As and Cd co-contaminated drinking water in the following RSM analysis, which was conducted using BBD via Design Expert 12.0.

According to the ANOVA results provided in Table 1, firstly, for both As(III) and Cd, the quadratic model (Supplementary Equation 1) was suggested due to the high significance (p < 0.0001 for both As(III) and Cd) of the model and high correlation (R2 = 0.9591 for As(III) and R2 = 0.9411 for Cd) between observed and predicted values. Secondly, for each model terms, on removal of As(III), X1 (p < 0.0001), X3 (p < 0.0001), X5 (p < 0.0001), X3X5 (p = 0.0004), X1² (p = 0.0003), X3² (p = 0.0003), and X5² (p < 0.0001) were significant. That is the initial As(III) concentration, K2TiO(C2O4)2 dose, and pH values had significant effects on As(III) removal from drinking water, and there was an interaction between the K2TiO(C2O4)2 dose and pH value. For the removal of Cd, X3 (p < 0.0001), X5 (p < 0.0001), X3² (p = 0.0046), and X5² (p = 0.0001) were significant model terms, indicating only K2TiO(C2O4)2 dose and pH had significant effects on Cd removal from drinking water and there was no interaction between any two variables. A detailed discussion of the effect of each operating variable on As(III) and Cd removal efficiencies is provided in the following.

The effects and interactions of pH and K2TiO(C2O4)2 dose on As(III) and Cd removal efficiencies are illustrated in Fig. 2 at a constant initial As(III) concentration of 500 μg/L, Cd concentration of 500 μg/L, and CaCl2 dose of 30 mg/L. The pH and K2TiO(C2O4)2 dose both showed positive effects on As(III) removal efficiency, which was minor at low pH and K2TiO(C2O4)2 dose and increased to maximum 85.6% at pH of 9 and K2TiO(C2O4)2 dose of 40 mg/L, as depicted in Fig. 2(a). Similar results were reported for As(III) removal by Ti(SO4)2, in which As(III) removal was enhanced as pH increased from 5 to 9 and Ti(IV) dose increased from 0 to 25.0 mg/L38. When the pH was increased from 5 to 9, more H3AsO3 dissociated (pK1 = 9.2), which is favorable for As(III) removal43. A higher pH is conducive to K2TiO(C2O4)2 hydrolysis to produce more binding sites, that is, high-affinity surface hydroxyl groups44. Moreover, there was a significant interaction between K2TiO(C2O4)2 dose and pH on As(III) removal (Fig. 2(b)). The As(III) removal efficiency increased by less than 10% at pH 5 but by approximately 80% at pH 9 as the K2TiO(C2O4)2 dose increased from 4 to 40 mg/L. The underlying mechanism could be the dual effects of pH, that is, higher pH promoted H3AsO3 dissociation and K2TiO(C2O4)2 hydrolysis according to the above analysis. In terms of Cd, as shown in Fig. 2(c), high pH value and K2TiO(C2O4)2 dose were also favorable for Cd removal because of the increased number of available binding sites. Low pH values resulted in low Cd removal due to competition between hydrogen ions and Cd for binding sites45. Thus, increasing the pH to produce more activated coagulants could be the main reason for the enhanced Cd removal from water by precipitation and coagulation techniques, which have been observed in previous reports, such as removing Cd from water by carbonate46, hydroxyapatite47, and sulfide48. However, unlike As(III) removal, the curves of Cd removal efficiency with K2TiO(C2O4)2 dose were almost parallel at pH 5 and 9, suggesting K2TiO(C2O4)2 dose and pH had no significant interaction on Cd removal (Fig. 2(d)). This could be explained by the different effects of pH on As(III) and Cd states; that is, at pH levels below 7, As(III) exists as a neutral species (H3AsO3) and Cd exists as positively charged ions (Cd2+), but when the pH increased to 9, approximately half of H3AsO3 dissociated to anionic species (H2AsO3−), while Cd still existed as positively charged ions (Cd(OH)+)39,45. An alternative explanation is that there are independent mechanisms of As (III) and Cd removal by K2TiO(C2O4)2. In this study, Cd precipitation via multiple pathways resulted in a minor interaction between the K2TiO(C2O4)2 dose and pH on Cd removal.

(a) Response surface of As(III) removal efficiency, (b) interaction on As(III) removal efficiency, (c) response surface of Cd removal efficiency, and (d) interaction on Cd removal efficiency. Other conditions were initial As(III) concentration of 500 μg/L, Cd concentration of 500 μg/L, and CaCl2 dose of 30 mg/L. The dash lines in (b) and (d) are 95% confidence interval (CI) bands.

The response surface and contour plots revealing the influence of the initial As(III) and Cd concentrations on the As(III) and Cd removal efficiencies at a constant K2TiO(C2O4)2 dose of 20 mg/L, CaCl2 dose of 30 mg/L, and pH of 7 are shown in Supplementary Figure 3. The initial As(III) concentration had no significant effect on Cd removal and vice versa, indicating no competitive adsorption between As(III) and Cd because of the distinct charges between anions and cations. Moreover, the initial As(III) concentration negatively affected the As(III) removal efficiency due to limited binding sites available at constant K2TiO(C2O4)2 dose. However, initial Cd concentration showed little influence on Cd removal efficiency. Theoretically, different from As(III), Cd was mainly removed via occlusion. In the occlusion coprecipitation process, the absolute removal amount is usually positively correlated with the initial concentration, but the removal efficiency has little connection with it.

According to the hypothesis, the CaCl2 dose would have a positive effect on Cd removal; however, for both pollutants, CaCl2 dose showed no significant influence on the removal efficiency, as presented in Fig. 3, which is consistent with the results shown in Table 1. The P values of the CaCl2 dose (X4) (for A(III), p = 0.7413; for Cd, p = 0.7461) were much larger than 0.05. A possible reason is that the number of calcium ions (Ca2+) in tap water was sufficient to precipitate all oxalates (C2O42−) from K2TiO(C2O4)2 hydrolysis. Over the examined range, 4 − 40 mg/L of K2TiO(C2O4)2 provided 0.025 − 0.25 mmol/L of C2O42−. The total hardness of the tap water used for the experiments was 143 mg CaCO3/L (Supplementary Table 1), which is much lower than the 450-mg CaCO3/L limit given by the national standards for drinking water quality (GB 5749 − 2006). Regular water hardness of 143 mg CaCO3/L is equal to 1.43 mmol/L of Ca2+, which is enough to precipitate 0.25 mmol/L of C2O42−, so the additional supply of Ca2+ showed no effect on Cd removal efficiency. Therefore, no CaCl2 was added in the following experiments. Moreover, most water utilities provide water with hardness levels between 50 and 150 mg CaCO3/L49, which is enough to precipitate all C2O42− released from K2TiO(C2O4)2 at given levels according to this study. Thus, adding a single K2TiO(C2O4)2 not only coprecipitates As and Cd but also softens water to reduce cardiovascular disease risks due to drinking hard water50.

Across all experimental data, the As(III) removal efficiency values ranged from 0 to 97.69%, and Cd removal efficiency values ranged from 0 to 100% (no Cd was detected by AFS). Based on the observed removal efficiencies, the calculated coefficients of the response function (Supplementary Equation 1) for As(III), and the Cd removal efficiencies are presented in Supplementary Table 2. The response function with the obtained coefficients can be used to predict the removal efficiencies at given levels of each factor. A comparison between the actual and predicted values is shown in Fig. 4. The experimental and predicted value R2 results were 0.9591 for As(III) removal and 0.9411 for Cd removal, indicating a good agreement between the observed and predicted values.

To test the reliability of using response functions for predictions, four groups were established, that is, As(III) with Cd, As(V) with Cd, As(III) and As(V) with Cd, and natural-As-contaminated water, and three experiments were conducted per group. The levels of each operating variable are listed in Supplementary Table 3 and are different from the BBD points that have been conducted (shown in Supplementary Table 4). The characteristics of the natural As-contaminated water used for the experiments are listed in Supplementary Table 5. The images of the sampling sites are shown in Supplementary Figure 4. The experimental and predicted values, calculated from the quadratic response surface functions, are compared in Supplementary Figure 5. There were no significant differences between these observed and predicted values for both As and Cd removal in all four groups, suggesting good agreement between response function predictions and experimental results. Therefore, the obtained response functions were effective and reliable for predicting and determining the optimum operating conditions.

Comparison with regular coagulants

Whether K2TiO(C2O4)2 has advantages over common coagulants in the coprecipitation of As and Cd from drinking water is an important consideration when using K2TiO(C2O4)2 as an alternative coagulant for water treatment. In a comparative study of treating simulated water containing 50 µg/L As(III), 50 µg/L As(V), and 50 µg/L Cd, K2TiO(C2O4)2 exhibited much better performance for As(V) removal than Al2(SO4)3 (Supplementary Figure 6) which is frequently used in drinking water coagulation to remove turbidity. Fe2(SO4)3 performed slightly better than K2TiO(C2O4)2 for As(V) removal, which is efficient for As(V) removal from water51. However, it is not widely used in drinking water treatment because of the unfavorable color of the residual ion hydroxide in treated water. Regarding As(III) removal, K2TiO(C2O4)2 performed much better than Al2(SO4)3 and slightly better than Fe2(SO4)3. This observation is consistent with existing reports that hydrous titanium oxide possesses superior adsorption capacity for As(III)38. Many coagulants, including ferric coagulants, show low removal efficiency for As(III)52, whereas Ti can compensate for this drawback owing to its excellent performance in As(III) removal39,53. In the case of Cd removal, neither Al2(SO4)3 nor Fe2(SO4)3 could remove Cd efficiently to meet the drinking water standard (GB 5749–2006, China), but K2TiO(C2O4)2 could. Specifically, at the same molar dose of 120 µmol/L, Al2(SO4)3 showed only slight removal capability with Cd concentration decreasing from 50.0 µg/L to 38.2 µg/L. Fe2(SO4)3 performed better than Al2(SO4)3, but the residual Cd concentration remained as high as 20.7 µg/L. K2TiO(C2O4)2 exhibited excellent performance on Cd removal and lowered Cd concentration to 4.7 µg/L to meet the safe level. Moreover, compared to other Cd removal technologies, coagulation generates only a small amount of hazardous solid waste and could serve as a useful pretreatment to alleviate the load of existing methods54,55,56.

Although Al salts are frequently used in drinking water coagulation treatment, mostly for turbidity removal, Al2(SO4)3 has poor performance for either As(III)/As(V) or Cd removal. Fe2(SO4)3 could remove As (V) efficiently but did not effectively remove As(III) and even failed to remove Cd to meet drinking water standards. Furthermore, the use of Fe2(SO4)3 in drinking water treatment is limited owing to the unfavorable color of iron hydroxide. K2TiO(C2O4)2 exhibited not only good As(III)/As(V) removal capability but also, more importantly, superior Cd removal capability. It is more suitable for treating water containing multiple heavy metals, such as As(III)/As(V) and Cd, which are more frequently encountered in drinking water supplies than single heavy metal contamination.

Characteristics of floc formed during the coagulation removal of As(III) and Cd

The XRD pattern indicated the presence of crystalline CaC2O4 (JCPDF card No. 00-003-0090) and a small amount of CaC2O4 hydrate (JCPDF card No. 00-002-0140) in the floc, as shown in Fig. 5. No crystalline characteristics can be seen for anatase TiO2, indicating that Ti exists as amorphous hydrous TiO2. This result is consistent with existing reports on coagulation by Ti(SO4)238. No apparent diffraction peaks were found for As or Cd minerals, indicating that As and Cd possibly exist as adsorbed ions57. Soft modeling using Visual Minteq 3.1 also indicate that CaC2O4 and hydrous TiO2 are the only two stable solid phase at current conditions.

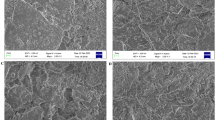

Rod-like crystals can be seen in the scanning electron microscope (SEM) images of the flocs, as shown in Fig. 6 a. CaC2O4 is highly insoluble in water at neutral pH conditions with a solubility product (ksp) of 2.3 × 10–9.; therefore, CaC2O4 crystals were formed during the hydrolysis reaction of K2TiO(C2O4)2 with natural calcium ions in tap water (usually with a concentration higher than 1 mmol/L). The crystal surface of CaC2O4 had small amorphous nanoparticles, indicating possible TiO(OH)2 deposition formed by K2TiO(C2O4)2 hydrolysis (Supplementary Figure 7). The elemental mapping results in Fig. 6 b and c further proved that most of the crystalline CaC2O4 (dashed line) and amorphous TiO(OH)2 (dot line) formed a mixture. Interestingly, it should be noted than As is more abundant in Ti-rich area and relatively less abundant in Ca-rich area, indicating As is mainly adsorbed by amorphous TiO(OH)2 (dot line in Fig. 6 c and d). Differently, Cd distributes homogeneously in both Ti-rich and Ca-rich area, indicating that CaC2O4 and TiO(OH)2 both contributes to the removal of Cd (Fig. 6 b, c and e). In a previous report, Cd2+ was found coprecipitated together with Ca2+ by forming (Ca,Cd)C2O4 mixed crystal58. Therefore, the removal of As and Cd may possibly follow different mechanisms. As is removed mainly by surface adsorption of TiO(OH)2 while Cd is removed by surface adsorption of TiO(OH)2 and encapsulation of CaC2O4.

XPS was used to analyze the elemental composition and chemical valence of the flocs (Fig. 7). The flocs mainly consisted of Ca, C, Ti, and O. As and Cd can also be observed in refined spectra57,59. Ti exists as Ti(IV)60, whereas As exists as As(III), indicating that there is no redox reaction during the coagulation process61,62. The floc formed by treating As(V) and Cd contaminated tap water with K2TiO(C2O4)2 was also analyzed using XPS. The refined elemental As energy spectrum indicated that As exists mainly as As(V), no apparent As(III) peak can be observed, indicating no significant reduction of As(V) into As(III) (Supplementary Figure 8).

Proposed mechanism of the coagulation As and Cd removal process using K2TiO(C2O4)2

To elucidate the possible mechanism, a geochemical modelling software, Visual Minteq 3.1, was used to identify the arsenic and cadmium species in water and solid species in the precipitation. (i) At pH ranges from 5 to 9, As(III) exists mainly as neutral molecule H3AsO3 (higher than 99.48%), while As(V) exists mainly as HAsO42- (from 97.27% to 99.06%). As(III) and As(V) can’t form stable speciation directly with Cd2+ and Ca2+ due to their rather low concentrations. (ii) Most of C2O42- (97.76% to 97.90%) and Ti (99.98%) precipitate completely as solid CaC2O4 and Ti(OH)4, respectively. (iii) Cd exists mainly as Cd2+ (from 90.75% to 85.87%) and other soluble species binding with OH-, Cl-, NO3-, CO32-, C2O42-, and SO42-. Only 0%, 5.7% and 6.3% Cd2+ can form the only stable precipitation as Cd4(OH)6SO4 at pH 5, 7 and 9, respectively. Additional experimental results indicate that no precipitate was formed between As and Cd at the present conditions (Supplementary Figure 9). In a comparing experiment, preformed CaC2O4 solid, K2C2O4 solution, and K2TiO(C2O4)2 solution were added to tap water spiked with 50 μg/L Cd, respectively. As shown in Supplementary Figure 10, there was no significant difference in Cd concentration between control and CaC2O4 treatment, indicating preformed CaC2O4 can’t effectively adsorb Cd2+. Importantly, in situ formed CaC2O4 (K2C2O4 treatment) precipitated 40% of Cd2+, and K2TiO(C2O4)2 precipitated 98% of Cd2+, suggesting occlusion with in situ formed CaC2O4 and electrostatic adsorption by negatively charged Ti(OH)4 maybe the two main pathways of Cd2+ removal by K2TiO(C2O4)2.

Based on these results, a possible mechanism was proposed. After addition of K2TiO(C2O4)2 to drinking water, it hydrolyzes and reacts with the natural Ca2+ in water to form hydrous TiO2 (or TiO(OH)2) and crystalline CaC2O4 (Eqs. 1 and 2). As(III) and As(V) are adsorbed on the TiO(OH)2 particle surface and removed from water (Eqs. 3 and 4). Because of the negative surface charges of TiO(OH)2, some Cd2+ is also adsorbed on the TiO(OH)2 particle surface (Eq. 5). Because of the similar chemical valences and ionic radii of Cd and Ca, most of the Cd was encapsulated inside the lattice of CaC2O4, forming Cd-doped Ca(Cd)C2O4 mixed crystal (Eq. 6). Overall, adding K2TiO(C2O4)2 enabled the comprehensive utilization of Ti and C2O42− while the only byproduct was K+ (no Ti and C2O42− were detected in the effluent), which is a healthy element for humans (Fig. 8). A bonus advantage is decreased water hardness and improved taste due to the C2O42− precipitation of natural Ca2+/Mg2+.

Overall, K2TiO(C2O4)2 was found to be an efficient coagulant for the removal of both anionic As(III)/ As(V) and cationic Cd. Its ability to remove As and Cd surpasses that of Al salts, which are currently used in drinking water treatment. Importantly, K2TiO(C2O4)2 could remove Cd much more efficiently than Al2(SO4)3 or Fe2(SO4)3. Coagulation using K2TiO(C2O4)2 consumes a part of the natural water hardness and releases healthy K+ as a byproduct. Thus, softened and healthy drinking water could be obtained. Heavy metal removal efficiency can be successfully predicted using a responsive surface function, which has potential applications in automatic or intelligent water treatment. In short, this study provides a candidate functional coagulant for the removal of multiple heavy metals from drinking water, which cannot be realized using existing Al or Fe salt coagulants. K2TiO(C2O4)2 may have potential applications in water treatment, alone or in combination with existing coagulants, to provide safer and healthier drinking water.

Materials and Methods

Chemicals

K2TiO(C2O4)2, Fe2(SO4)3, Al2(SO4)3, and CaCl2 are analytical grade and was used as acquired unless stated otherwise. Standard solutions of As(III) (1000 mg As/L), As(V) (1000 mg As/L), and Cd(NO3)2 (Cd(II), 1000 mg Cd/L) were purchased from Inorganic Ventures (USA). The As(III)/As(V) and Cd(II) stock solutions were added to tap water to simulate contaminated drinking water. The tap water characteristics used in the experiments are listed in Supplementary Table 1. Concentrated sulfuric acid and NaOH were used to adjust pH.

Preparation of coagulant solution

A K2TiO(C2O4)2 stock solution (80 g/L) was prepared by dissolving K2TiO(C2O4)2 in deionized water at 45 °C, a CaCl2 stock solution was prepared by dissolving CaCl2 in deionized water at a concentration of 55.5 g/L, and the Fe2(SO4)3 and Al2(SO4)3 stock solutions were prepared by dissolving the corresponding salts in a 1 mol/L sulfuric acid solution to prevent hydrolysis and precipitation.

Coagulation experiments

All coagulation experiments were conducted in a 500 mL glass beaker with 300 mL of sample water. First, the pH of the water sample was adjusted by adding 5.0 mol/L NaOH or concentrated sulfuric acid. Then, K2TiO(C2O4)2 and CaCl2 stock solutions were added dropwise to each 500-mL glass reactor with 1 min of rapid mixing at approximately 300 rpm, followed by slow mixing at approximately 100 rpm until the end of the experiments, with each experiment performed in triplicate. At desired time intervals, 4 mL samples were collected and filtered through a 0.45 μm membrane filter. The concentrations of residual As and Cd were analyzed using atomic fluorescence spectrophotometry (AFS). All experiments were conducted at 20 ± 1 °C, except for the reaction temperature experiment, which was conducted at temperatures ranging from 20 to 80 °C.

As(III) and Cd removal using response surface methodology

To determine the effects of major operating variables, optimize their combination, and predict As and Cd removal efficiency, the Box-Behnken design (BBD), a common RSM, was used. Referring to existing reports51,63, five important operating parameters, namely, initial As(III) and Cd concentrations, K2TiO(C2O4)2 and CaCl2 doses, and pH, were chosen as the independent variables and designated as X1, X2, X3, X4, and X5, respectively. The levels and symbols for each variable are listed in Table 2. Forty-six experimental points, including six center points to estimate the errors, are listed in Supplementary Table 4. The randomly arranged experimental runs in Supplementary Table 4 were generated using Design Expert 12.0 (Stat-Ease Inc., Minneapolis, USA), which was also used for analysis of variance (ANOVA) and determination of the response surface function (Supplementary Equation 1).

Comparison with general coagulants

To comprehensively evaluate the application potential of K2TiO(C2O4)2 in the simultaneous As and Cd removal from drinking water, common Al and Fe coagulant salts, such as Al2(SO4)3 and Fe2(SO4)352, were chosen for As and Cd removal from drinking water under the same conditions as K2TiO(C2O4)2. Briefly, Fe from the Fe2(SO4)3 solution, Al from the Al2(SO4)3 solution, and Ti from the K2TiO(C2O4)2 solution were added dropwise to As(III)-, As(V)-, and Cd-contaminated tap water with final concentrations of 0, 10, 20, 30, 40, 80, and 120 µmol/L, respectively. The initial As(III), As(V), and Cd(II) concentrations were all 50 μg/L and the initial pH was 7. It is worth mentioning that no CaCl2 was added. After 30 min of slow mixing, followed by 30 min of settling, 4 mL of the sample was collected from the middle part of the solution, and As(III), As(V), and Cd(II) were detected through AFS without filtration. The other experimental procedures were the same as those described in Section 3.3.

Geochemical modelling

To test whether anionic forms of As(III) and As(V) can form speciations with Cd, Ca, and Ti, a geochemical modelling, Visual Minteq 3.1, was used to show what As speciations can form in the pH range (5 − 9) analysed and at the concentrations of other elements found (Cl- 5.3×10–4 mol/L, NO3–2.8×10–4 mol/L, Ca2+ 1.4×10–3 mol/L). As(III), As(V), Cd, Ti, and C2O42- were tested at their highest concentrations in the experimental ranges. Specifically, As(III) 1.3×10–5 mol/L (1000 µg/L), As(V) 1.3×10–5 mol/L (1000 µg/L), Cd 4.4×10–6 mol/L (500 µg/L), Ti 1.3×10–4 mol/L and C2O42–2.5×10–4 mol/L (equivalent to 40 mg/L of K2TiO(C2O4)2).

Analytical methods and characterization

The concentrations of As(III)/As(V) and Cd in the water were analyzed using AFS (JC-YG-200, Qingdao Tongchuang Environment Protection, China). The Ti, K, and Ca concentrations were analyzed by inductively coupled plasma mass spectrometer (ICP-MS, 7700 series, Agilent Technologies, USA). Oxalates (C2O42−) was determined though ion chromatography system (ICS-2000, Dionex, Themo scientific, USA). Quality control was conducted by running standard solution with every 10 samples. The recovery rates were controlled within 95% − 105%, otherwise standard curve was rebuilt.

To explore the underlying mechanism, the precipitates were collected via centrifugation after coagulation, washed with distilled water, and dried at 80 °C. The coagulation conditions were 40 mg/L K2TiO(C2O4)2 added to 200 μg/L As(III) and 200 μg/L Cd co-contaminated tap water at initial pH was 7.8. No CaCl2 was added. The reaction took place at 20 ± 1 °C and lasted for 30 min.

The X-ray diffraction (XRD) patterns of the coagulum were obtained using a D2 PHASER diffractometer (AXS, Germany) with Cu Kα radiation (λ = 1.5418 Å). The morphology of the coagulum was observed using a field-emission SEM with an electron-accelerating voltage of 3 kV (S-4800, Hitachi, Japan). The Ca and Ti elemental mapping images were acquired using energy-dispersive X-ray spectroscopy (EDS) module coupled with the SEM under an electron-accelerating voltage of 20 kV. The elemental valence and abundance analysis was conducted by using an X-ray photoelectron Spectrometry (XPS).

Reporting summary

Further information on research design is available in the Nature Research Reporting Summary linked to this article.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Hussain, S. et al. Health Risk Assessment of Different Heavy Metals Dissolved in Drinking Water. Int J. Environ. Res. Public Health 16, 1737 (2019).

Rathi, B. S. & Kumar, P. S. A review on sources, identification and treatment strategies for the removal of toxic Arsenic from water system. J. Hazard. Mater. 418, 126299 (2021).

Farkhondeh, T., Naseri, K., Esform, A., Aramjoo, H. & Naghizadeh, A. Drinking water heavy metal toxicity and chronic kidney diseases: a systematic review. Rev. Environ. Health 36, 359–366 (2021).

Arancibia-Miranda, N. et al. Mechanistic insights into simultaneous removal of copper, cadmium and arsenic from water by iron oxide-functionalized magnetic imogolite nanocomposites. J. Hazard. Mater. 398, 122940 (2020).

N.A.A. Qasem, R.H. Mohammed, D.U. Lawal, Removal of heavy metal ions from wastewater: a comprehensive and critical review, npj Clean Water https://doi.org/10.1038/s41545-021-00127-0 (2021)

A.S. Krishna Kumar et al. Heavy metal and organic dye removal via a hybrid porous hexagonal boron nitride-based magnetic aerogel, npj Clean Water https://doi.org/10.1038/s41545-022-00175-0 (2022).

Gao, J., Liu, Q., Song, L. & Shi, B. Risk assessment of heavy metals in pipe scales and loose deposits formed in drinking water distribution systems. Sci. Total Environ. 652, 1387–1395 (2019).

Sierra-Sanchez, A. G., Castillo-Suarez, L. A., Martinez-Miranda, V., Linares-Hernandez, I. & Teutli-Sequeira, E. A. As and F- cooccurrence in drinking water: critical review of the international scenario, physicochemical behavior, removal technologies, health effects, and future trends. Environ. Sci. Pollut. R. 29, 38768–38796 (2022).

Oseghe, E. O., Idris, A. O., Feleni, U., Mamba, B. B. & Msagati, T. A. M. A review on water treatment technologies for the management of oxoanions: prospects and challenges. Environ. Sci. Pollut. R. 28, 61979–61997 (2021).

Jiang, J. Q. Removing arsenic from groundwater for the developing world–a review. Water Sci. Technol. 44, 89–98 (2001).

Chakrabarty, S. & Sarma, H. P. Heavy metal contamination of drinking water in Kamrup district, Assam, India. Environ. Monit. Assess. 179, 479–486 (2011).

Cipriani-Avila, I. et al. Heavy metal assessment in drinking waters of Ecuador: Quito, Ibarra and Guayaquil. J. Water Health 18, 1050–1064 (2020).

Zhu, F., Zheng, Y. M., Zhang, B. G. & Dai, Y. R. A critical review on the electrospun nanofibrous membranes for the adsorption of heavy metals in water treatment. J. Hazard. Mater. 401, 123608 (2021).

Bashir, A. et al. Removal of heavy metal ions from aqueous system by ion-exchange and biosorption methods. Environ. Chem. Lett. 17, 729–754 (2019).

Vasseghian, Y., Dragoi, E. N., Almomani, F., Le, V. T. & Berkani, M. Graphene-based membrane techniques for heavy metal removal: A critical review. Environ. Technol. Inno 24, 101863 (2021).

Wang, Z. Y. et al. Arsenate adsorption on iron-impregnated ordered mesoporous carbon: Fast kinetics and mass transfer evaluation. Chem. Eng. J. 357, 463–472 (2019).

Cardoso, S. P. et al. Experimental measurement and modeling of ion exchange equilibrium and kinetics of cadmium(II) solutions over microporous stannosilicate AV-6. Chem. Eng. J. 295, 139–151 (2016).

Jang, J. et al. Ti3C2TX-Ethylenediamine nanofiltration membrane for high rejection of heavy metals. Chem. Eng. J. 437, 135297 (2022).

Kerdi, S., Qamar, A., Alpatova, A., Vrouwenvelder, J. S. & Ghaffour, N. Membrane filtration performance enhancement and biofouling mitigation using symmetric spacers with helical filaments. Desalination 484, 114454 (2020).

Tang, X. M. et al. Chemical coagulation process for the removal of heavy metals from water: a review. Desalin Water Treat. 57, 1733–1748 (2016).

Ge, J. et al. Challenges of arsenic removal from municipal wastewater by coagulation with ferric chloride and alum. Sci. Total Environ. 725, 138351 (2020).

Matsui, Y. et al. Characteristics and components of poly-aluminum chloride coagulants that enhance arsenate removal by coagulation: Detailed analysis of aluminum species. Water Res. 118, 177–186 (2017).

Pio, I. et al. Efficient removal of low-arsenic concentrations from drinking water by combined coagulation and adsorption processes. Sep Purif. Technol. 147, 284–291 (2015).

Laskaridis, A., Sarakatsianos, I., Tzollas, N. & Katsoyiannis, I. A. Simultaneous Removal of Arsenate and Chromate from Ground- and Surface- Waters by Iron-Based Redox Assisted Coagulation. Sustainability-Basel 12, 5394 (2020).

M.S.S. Abujazar, S.U. Karaagac, S.S. Abu Amr, M.Y.D. Alazaiza, M.J.K. Bashir, Recent advancement in the application of hybrid coagulants in coagulation-flocculation of wastewater: A review. J. Clean Prod. 345, 131133 (2022).

P. Pal, A. Pal, K. Nakashima, B.K. Yadav, Applications of chitosan in environmental remediation: A review. Chemosphere 266, 128934 (2021).

Wang, Y. X., Duan, J. M., Li, W., Beecham, S. & Mulcahy, D. Aqueous arsenite removal by simultaneous ultraviolet photocatalytic oxidation-coagulation of titanium sulfate. J. Hazard. Mater. 303, 162–170 (2016).

Xu, Z. H. & Meng, X. G. Size effects of nanocrystalline TiO2 on As(V) and As(III) adsorption and As(III) photooxidation. J. Hazard. Mater. 168, 747–752 (2009).

Xie, X. F. & Gao, L. Effect of crystal structure on adsorption behaviors of nanosized TiO2 for heavy-metal cations. Curr. Appl. Phys. 9, S185–S188 (2009).

Lun, M. K. et al. Efficient simultaneous removal of cadmium and arsenic in aqueous solution by titanium-modified ultrasonic biochar. Bioresour. Technol. 284, 333–339 (2019).

Yan, L., Huang, Y. Y., Cui, J. L. & Jing, C. Y. Simultaneous As(III) and Cd removal from copper smelting wastewater using granular TiO2 columns. Water Res. 68, 572–579 (2015).

Wang, X. M. et al. Preparation and Evaluation of Titanium-Based Xerogel as a Promising Coagulant for Water/Wastewater Treatment. Environ. Sci. Technol. 50, 9619–9626 (2016).

Zhou, X. & Liu, J. Simultaneous reduction and coagulation removal of perrhenate with titanium (III) trichloride: Performance and mechanism. J. Water Process Eng. 46, 102601 (2022).

Eslami, H. et al. Simultaneous presence of poly titanium chloride and Fe2O3-Mn2O3 nanocomposite in the enhanced coagulation for high rate As(V) removal from contaminated water. J. Water Process Eng. 36, 101342 (2020).

Zhao, Y. X., Phuntsho, S., Gao, B. Y. & Shon, H. Polytitanium sulfate (PTS): Coagulation application and Ti species detection. J. Environ. Sci. 52, 250–258 (2017).

Gan, Y. H., Zhang, L. & Zhang, S. J. The suitability of titanium salts in coagulation removal of micropollutants and in alleviation of membrane fouling. Water Res. 205, 117692 (2021).

Wang, X. M. et al. Advantages of titanium xerogel over titanium tetrachloride and polytitanium tetrachloride in coagulation: A mechanism analysis. Water Res. 132, 350–360 (2018).

Sun, Y. K. et al. Enhanced arsenite removal from water by Ti(SO4)2 coagulation. Water Res. 47, 4340–4348 (2013).

Guan, X. et al. Application of titanium dioxide in arsenic removal from water: A review. J. Hazard. Mater. 215-216, 1–16 (2012).

Le, Q. T. N., Vivas, E. L. & Cho, K. Calcium oxalate/calcium silicate hydrate (Ca-Ox/C-S-H) from blast furnace slag for the highly efficient removal of Pb2+ and Cd2+ from water. J. Environ. Chem. Eng. 9, 106287 (2021).

P. Karimi, S. Javanshir, M.H. Sayadi, H. Arabyarmohammadi, Arsenic Removal from Mining Effluents Using Plant-Mediated, Green-Synthesized Iron Nanoparticles. Processes https://doi.org/10.3390/pr7100759 (2019).

Hao, L. L., Liu, M. Z., Wang, N. N. & Li, G. J. A critical review on arsenic removal from water using iron-based adsorbents. Rsc Adv. 8, 39545–39560 (2018).

Burton, E. D. et al. Sorption of arsenic(V) and arsenic(III) to schwertmannite. Environ. Sci. Technol. 43, 9202–9207 (2009).

Xu, Z. C., Li, Q., Gao, S. A. & Shang, J. K. As(III) removal by hydrous titanium dioxide prepared from one-step hydrolysis of aqueous TiCl4 solution. Water Res. 44, 5713–5721 (2010).

Pfeifer, A. & Škerget, M. A review: a comparison of different adsorbents for removal of Cr (VI), Cd (II) and Ni (II).Turkish J Chem. 44, 44–883 (2020).

Patterson, J., Allen, H. & Scala, J. Carbonate precipitation for heavy metals pollutants. J. Water Pollut. Control Fed. 49, 2397–2410, https://www.jstor.org/stable/25039473 (1977).

O.K. Ince, M. Ince, N.M. Karaaslan, V. Yonten, Optimization of cadmium removal from water by hydroxyapatite using experimental design methodology. Anal. Lett. 2513–2524, https://doi.org/10.1080/00032719.2016.1151022 (2016).

Bhattacharya, D., Jumawan, K. & Grieves, R. Separation of toxic metals by sulfide precipitation. Specul. Sci. Technol. 14, 441–452 (1979).

Ahn, M. K., Chilakala, R., Han, C. & Thenepalli, T. Removal of hardness from water samples by a carbonation process with a closed pressure reactor. Water 10, 1–10 (2018).

Monarca, S., Donato, F., Zerbini, I., Calderon, R. L. & Craun, G. F. Review of epidemiological studies on drinking water hardness and cardiovascular diseases. Eur. J. Cardiovasc Prev. Rehabil. 13, 495–506 (2006).

Baskan, M. B. & Pala, A. Determination of arsenic removal efficiency by ferric ions using response surface methodology. J. Hazard Mater. 166, 796–801 (2009).

Sarkar, A. & Paul, B. The global menace of arsenic and its conventional remediation - A critical review. Chemosphere 158, 37–49 (2016).

Ashraf, S., Siddiqa, A., Shahida, S. & Qaisar, S. Titanium-based nanocomposite materials for arsenic removal from water: A review. Heliyon 5, e01577 (2019).

Liu, T. et al. Adsorption of cadmium and lead from aqueous solution using modified biochar: A review. J. Environ. Chem. Eng. 10, 106502 (2022).

Pyrzynska, K. Removal of cadmium from wastewaters with low-cost adsorbents. Remov. cadmium wastewaters low.-cost. adsorbents 7, 102795 (2019).

Purkayastha, D., Mishra, U. & Biswas, S. A comprehensive review on Cd(II) removal from aqueous solution. J. Water Process Eng. 2, 105–128 (2014).

Liu, K., Li, F. B., Cui, J. H., Yang, S. Y. & Fang, L. P. Simultaneous removal of Cd(II) and As(III) by graphene-like biochar-supported zero-valent iron from irrigation waters under aerobic conditions: Synergistic effects and mechanisms. J. Hazard. Mater. 395, 122623 (2020).

McBride, M. B., Frenchmeyer, M., Kelch, S. E. & Aristilde, L. Solubility, structure, and morphology in the co-precipitation of cadmium and zinc with calcium-oxalate. J. Colloid Inter. Sci. 486, 309–315 (2017).

Liu, J. Q. et al. Synergistic deep removal of As(III) and Cd(II) by a calcined multifunctional MgZnFe-CO3 layered double hydroxide: Photooxidation, precipitation and adsorption. Chemosphere 225, 115–125 (2019).

Ehsan, M. A. et al. Fabrication of photoactive CaTiO3-TiO2 composite thin film electrodes via facile single step aerosol assisted chemical vapor deposition route. J. Mater. Sci.-Mater. El 30, 1411–1424 (2019).

Yang, Y. et al. Efficient arsanilic acid removal from water via reversible phase transition in a cyclic adsorption process based on reactivated MgO. J. Hazard. Mater. Lett. 1, 100006 (2020).

Han,X. et al. As(III) removal and speciation of Fe (Oxyhydr)oxides during simultaneous oxidation of As(III) and Fe(II). Chemosphere. 147, 337–344(2016).

Li, B. B., Gan, L., Owens, G. & Chen, Z. L. New nano-biomaterials for the removal of malachite green from aqueous solution via a response surface methodology. Water Res. 146, 55–66 (2018).

Acknowledgements

This work was co-funded by the National Key Research and Development Program of China (2020YFC1807805) and National Natural Science Foundation of China (41877334).

Author information

Authors and Affiliations

Contributions

J.Z.: Conceptualization, data curation, formal analysis, and writing the original draft. Y.L.: Data curation. B.L.: Formal analysis. H.L.: Formal analysis. G.C.: Funding acquisition, investigation, supervision, writing - review, and editing. R.Q.: supervision, writing-review, and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this study.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhou, J., Liu, Y., Li, B. et al. Coagulation of trace arsenic and cadmium from drinking water using titanium potassium oxalate. npj Clean Water 6, 9 (2023). https://doi.org/10.1038/s41545-023-00227-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41545-023-00227-z

This article is cited by

-

Efficient and fast arsenate removal from water by in-situ formed magnesium hydroxide

Scientific Reports (2024)

-

Efficiency of magnetic zeolitic imidazolate framework-8 (ZIF-8) modified graphene oxide for lead adsorption

Environmental Science and Pollution Research (2024)