Abstract

Lithium-rich transition metal oxide (Li1+XM1−XO2) cathodes have high energy density above 900 Wh kg−1 due to hybrid anion- and cation-redox (HACR) contributions, but critical issues such as oxygen release and voltage decay during cycling have prevented their application for years. Here we show that a molten molybdate-assisted LiO extraction at 700 °C creates lattice-coherent but depth (r)-dependent Li1+X(r)M1−X(r)O2 particles with a Li-rich (X ≈ 0.2) interior, a Li-poor (X ≈ −0.05) surface and a continuous gradient in between. The gradient Li-rich single crystals eliminate the oxygen release to the electrolyte and, importantly, still allow stable oxygen redox contributions within. Both the metal valence states and the crystal structure are well maintained during cycling. The gradient HACR cathode displays a specific density of 843 Wh kg−1 after 200 cycles at 0.2C and 808 Wh kg−1 after 100 cycles at 1C, with very little oxygen release and consumption of electrolyte. This high-temperature immunization treatment can be generalized to leach other elements to avoid unexpected surface reactions in batteries.

Similar content being viewed by others

Main

As the energy density ceiling (~700 Wh kg−1) of conventional lithium transition metal oxide (LiMO2, M = Ni, Co, Mn) cathodes is approached, hybrid anion- and cation-redox (HACR) cathodes1 compete with purely anion-redox LinS and LinO (refs. 2,3) cathodes as candidates for next-generation batteries. Li-rich Li1+XM1−XO2 (LXMO) with a layered structure is one of the most promising HACR cathodes4,5. The lattice structure is a solid solution or a fine-phase mixture of Li2MnO3 and LiMnaNibCo1−a−bO2 (NMC) lattice motifs6,7, with Li-layer (LiL) and transition metal-layer (TML) cation sites. In the Li2MnO3 motif, one-third of Mn ions in the TML are replaced by Li ions (LiTML), leading to plenty of axial Li–O–Li configurations (each O is bonded to six Li/M)8. Consequently, certain O2p orbitals are less hybridized with the transition metal (M) d orbitals, and thus they have higher energies than those in 100% axial Li–O–M configurations9 (as in NMC). These oxygen anions in LXMO could be oxidized more easily when the material is charged and subsequently contribute to capacity in battery cycles.

Anion-redox capacity can be reversible or irreversible. To harness the oxygen anion-redox contribution to double the energy density, it behoves one to ponder the cause of irreversibility. It has been reported10,11 that the migration barrier of O− is only 0.9 eV, whereas that of O2− is 2.3–4.0 eV in Li2MnO3. Generally, the oxidation of O2− → Oα− (α < 2, peroxide- or superoxide-like)12 when charged to high voltages (>4.3 V versus Li+/Li) makes oxygen more mobile and easier to escape from a metal oxide particle, resulting in oxygen vacancies, transition metal co-migration and structural collapse, with a telltale fingerprint of continuous voltage decay10,13,14,15,16 and consumption of electrolyte17. Oxygen release into the liquid electrolyte must be prevented in battery cycling.

In uniformly Li-rich particles, structural collapse tends to start from the surface11,18,19. Wang et al.10 reported that once O vacancies are produced at the surface of LXMO, a massive number of new structural flaws nucleate, leading to the propagation of the crystal collapse into the whole particle. The oxygen release will persist over hundreds of cycles, with continuous M reduction and oxygen void formation10,15,16. While metal oxide coatings20,21 and other surface treatments22 were performed to improve the cycling capacity, few have addressed the problem of voltage fading and electrolyte consumption.

Inside LXMO, the heavy use of O redox triggers local oxygen mobility. But global oxygen mobility, defined by percolating oxygen transport from the particle core to the surface, should be avoided at all costs. As shown in Fig. 1a, if near the surface, we can remove all LiTML and even substitute some LiLiL with MLiL without disrupting the single crystallinity, then the M valence can be locally reduced, which would ensure less anion redox in cycling (Supplementary Fig. 1). When we make X < 0 near the surface (‘Li poor’), the initial M valence would drop below +3, which suppresses anion redox while promoting cation redox, which will lower the concentration of mobile Oα− (α < 2) near the surface.

a, Redox behaviours of transition metal cations and oxygen anions of the Li-poor surface and the Li-rich bulk. b, Schematic of the cross-section of a Li1+X(r)M1−X(r)O2 particle. The zoomed-in sector is a two-dimensional cross-section from the particle bulk to the surface. The deeper colour indicates more M and less Li. c, STEM-HAADF lattice image from the core to the surface in a lattice-coherent particle. Rectangle A is from the Li-poor surface, and rectangle B is from the Li-rich bulk. The circle with the cross inside denotes the direction travelling into the page. d, Schematic of the layered structure of the Li-gradient region in a lattice-coherent particle from the Li-rich (Li substitution in M layer) bulk to the Li-poor (M substitution in Li layer) surface. e, STEM-HAADF images from rectangle A and rectangle B in c with higher magnification, where MLiL pillars can clearly be seen in the Li layers (due to higher average atomic number, Z, of the atomic column) in rectangle A but not in B.

Herein we demonstrate a concept of full Li-gradient Li1+X(r)M1−X(r)O2 (LX(r)MO) particles, as illustrated in Fig. 1b, where X(r) is a function of position r, with X(rcore) = Xrich > 0, where rcore is the interior of the particle (Xrich = 0.2 in this work) and X(rsurface) = Xpoor ≤ 0. In other words, we make Xpoor < 0 to cut down both O anion redox and mobility near the surface without extra lattice defects23. The gradient design calls for the primary particles to be crystallographically coherent from the Li-rich bulk to the Li-poor surface (Fig. 1c–e), instead of having grain or phase boundaries in between like traditional coatings.

This continuous gradient from ‘Li richness’ to ‘Li poorness’ in the LX(r)MO single crystal achieves the following goals. First, the Li-rich core (Li1.2M0.8O2) that takes up most of the particle volume has very high capacity, due to oxygen anion-redox contribution from the ample axial Li–O2p–Li configurations9 (region B in Fig. 1c) embedded inside, akin to the Li2O–LiO–LiO2 ‘solid oxygen cathode’ concept2 but well mixed at the atomic scale. Meanwhile, the epitaxially coherent Li-poor region near the surface (region A in Fig. 1c), which mainly features Li–O–M and even M–O–M configurations, prevents oxygen ions from being oxidized and escaping into the electrolyte. The MLiL pillars would greatly stabilize the layered structure4 (Fig. 1d,e) at the surface. Essentially, the Li-poor surface can be considered ‘immunized’ against oxygen release in electrochemical cycling, due to earlier preventive ejections of LiO from the surface at a high annealing temperature of 700 °C. Then the oxygen redox in room-temperature cycling can only happen in the bulk, but oxygen cannot trespass the ‘immunized’ Li-poor surface and escape into the electrolyte. Second, in practical full cells, very little liquid electrolyte is used. Since the carbonate electrolyte can be oxidized easily in the presence of freed oxygen24,25,26, minimizing oxygen release ensures a long battery life under parsimonious electrolyte condition. In subsequent sections, we will demonstrate excellent voltage retention of our LX(r)MO material against Li4Ti5O12 anode in capacity-matched full cells with parsimonious electrolyte (2 g Ah−1) and at relatively high C-rates ≥1C (1C ≡ 250 mA g−1).

Creation of Li-gradient single crystals

Pioneering work has been done to create gradient distribution in transition metals Ni, Mn and Co27,28. However, there have been no attempts to create gradients in Li richness/poorness (LiTML/MLiL) as it appears that Li+ ions can easily diffuse throughout the particle, making it challenging to maintain a Li gradient in primary particles. But scrutiny of the Li1+X(r)M1−X(r)O2 concept indicates that a Li gradient in an uncharged state is equal and opposite to a M gradient. M would be a slow diffuser if there were no M vacancies or other lattice defects, so this ‘Li gradient’ in the discharged state could stay a permanent feature at room temperature. Constructing this M gradient requires a high-temperature process, so in this work we develop a high-temperature leaching method with molten MoO3. We start with uniform-concentration Li-rich LXMO particles, which react with a small amount of sintering aid (liquid molybdate) at 700 °C via the following reaction:

in effect extracting \(2\beta {\mathrm{LiO}} = \beta {\mathrm{Li}}_2{\mathrm{O}} + \frac{\beta }{2}{\mathrm{O}}_2( \uparrow )\)from the near-surface region of LXMO, where β is the progress variable. The sintering aid works by reacting with the ceramic host to form a liquid layer (MoO3-Li2O eutectic liquid solution at >525 °C, Supplementary Fig. 2), wetting and wrapping around the host particles. The temperature is also high enough to anneal the layered crystal, eliminating Li/O vacancies left behind to obtain a dense crystal29:

with Xpoor = (Xrich − β)/(1 − β) and some volume shrinkage.

Liquid-phase diffusion is much more rapid than solid-state diffusion, so reaction (1) is initially rate-controlled by solid-state diffusion. Thus the progress variable β in \({\mathrm{Li}}_{1 + X_{{\mathrm{rich}}} - 2\beta }{\mathrm{M}}_{1 - X_{{\mathrm{rich}}}}{\mathrm{O}}_{2 - 2\beta }\) is spatially dependent, with β(rcore) ≈ 0, while β(rsurface) > 0 or even as large as β(rsurface) > Xrich. In other words, the surface can actually become Li poor while the core still keeps the initial Li richness. As long as the MoO3 fraction, w, is small (such as 4–6 wt%), the liquid will reach thermodynamic saturation at time tsaturation for dissolving Li2O, after which no more LiO can be leached out. By adjusting w and duration t of reaction (1), we are able to throttle β(rsurface) ≥ Xrich and end up with Xpoor = (Xrich − β)/(1 − β) ≤ 0 on the surface, while still keeping an Xrich core.

Reactions (1) and (2) require only basic solid-state reaction in an air furnace and are highly scalable. Because Li2MoO4 is water soluble, a simple sonication in water can etch away the Li2MoO4 at room temperature by

With reactions (1)–(3), we created a Li-gradient region at the surface of, originally, Li1.20Mn0.48Co0.16Ni0.16O2 (labelled as G0) particles with 4 wt% MoO3 leaching (G0 → G4) and obtained the lattice-coherent LX(r)MO particles. As we can see from the X-ray diffraction (XRD) pattern and STEM high-angle annular dark field (HAADF) in Supplementary Fig. 3, G0 featured a conventional Li-rich layered structure6,7. As expected, the new phase that appeared after reactions (1) and (2) had the composition of Li2MoO4 (Supplementary Fig. 4) instead of MoO3. The scanning transmission electron microscopy energy-dispersive X-ray spectroscopy (STEM-EDS) mapping in Fig. 2a showed that the newly formed Li2MoO4 was located only at the particle surface. The XRD pattern and EDS mapping on G4 (Supplementary Fig. 5) confirmed that Li2MoO4 was completely removed after sonication in water, while no Mn, Co or Ni was lost from the particle (Supplementary Table 1). The XRD pattern also indicated that the structure of the final product (G4) after reactions (1)–(3) remained unchanged compared with G0. The inductively coupled plasma atomic emission spectroscopy (ICP-AES) analysis in Fig. 2b and Supplementary Table 2 showed that the particle-averaged Li content decreased from 1.221 ± 0.003 (G0) to 1.173 ± 0.003 (G4) (± s.d.). The well-retained layered structure and epitaxial crystallinity from the bulk up to the surface in G4 can be visualized by the STEM-HAADF image in Fig. 1c and the high-resolution transmission electron microscopy (HRTEM) image in Supplementary Fig. 3.

a, STEM-EDS mapping of the particle after reactions (1) and (2), indicating that Mo was concentrated at the particle surface, while Mn, Co and Ni were located everywhere. b, Average Li (black, left y-axis) and M (other colours, right y-axis) contents in G0 and G4 particles from ICP-AES. The data were normalized to keep the sum of Mn/Co/Ni as 0.80. The error bars were calculated from the s.d. of the data in Supplementary Table 2. c, EELS line scan across a 400 nm particle and a representative EELS spectrum near the surface marked on the particle. Raw data are shown before background subtraction and so on with Gatan software. d, X(r) profile (blue, left y-axis) and element percentages (other colours, right y-axis) from the surface to the bulk of a G4 particle, calculated on the basis of EELS data from c. e, STEM-HAADF image of the Li-gradient region from X(rsurface) = Xpoor < 0 to X(rcore) = Xrich > 0, showing a coherent lattice with d(003) = 0.473 nm in both Li-rich and Li-poor regions, with MLiL pillars (due to higher average Z of the atomic column) that disappear toward the core. The surface inclination here is different from that of Fig. 1e. f, Ratio of Mn L3/L2 peak area near the surface indicating valence change of Mn ions.

An electron energy-loss spectroscopy (EELS) line scan was used to quantify the Li-gradient profile across the G4 particle (diameter ≈ 400 nm), as shown in Fig. 2c. Since Li can barely be quantified by EELS, we sum up the molar ratio of transition metal to oxygen, σ ≡ M/O = ∑(Mn + Co + Ni)/O, which should be equal to (1 − X(r))/2 for Li1+X(r)M1−X(r)O2, to obtain the X(r) profile. As shown in Fig. 2d, the X ≈ 0.20 in the bulk agreed well with the feedstock Li1.20Mn0.48Co0.16Ni0.16O2, but near the surface, within a depletion zone thickness of ~17 nm, X(r) gradually decreased from 0.20 to about −0.05 from the bulk to the surface (the ratio of Mn, Co and Ni was kept close to 3:1:1 everywhere). Thus, the Li-poor surface had a composition of Li0.95Mn0.63Co0.21Ni0.21O2. The X(r) profile of the particles leached with 6 wt% MoO3 (G6) is shown in Supplementary Fig. 6, which indicates an ~18 nm Li-depletion region from Li1.20Mn0.48Co0.16Ni0.16O2 to ~Li0.90Mn0.66Co0.22Ni0.22O2 at the surface of an ~310 nm particle. The thickness and depletion extent of this Li-gradient layer can be adjusted based on the amount of MoO3 (Supplementary Discussion 1 and Supplementary Table 3), the leaching temperature and the time to optimize the electrochemical performance.

The composition gradient resulted in a decreased XRD intensity ratio of I(003)/I(104) (Supplementary Fig. 3) due to MLiL in G4 (Fig. 2e). It has been reported that small amounts of MLiL pillars can stabilize the layered structure in cycling4,30. The Li-gradient region also has reduced cation valence, as LiO was leached from the particle to keep charge balance from \({\mathrm{Li}}_{1.20}^ + {\mathrm{Mn}}_{0.48}^{4 + }{\mathrm{Co}}_{0.16}^{3 + }{\mathrm{Ni}}_{0.16}^{2.5 + }{\mathrm{O}}_2^{2 - }\left( {r_{{\mathrm{core}}}} \right)\) to \({\mathrm{Li}}_{0.95}^ + {\mathrm{Mn}}_{0.63}^{3.17 + }{\mathrm{Co}}_{0.21}^{3 + }{\mathrm{Ni}}_{0.21}^{2 + }{\mathrm{O}}_2^{2 - }\left( {r_{{\mathrm{surface}}}} \right)\). The increased ratio of Mn L3 peak area to L2 peak area (AL3/AL2) on the EELS curve in Fig. 2f clearly indicates that Mn3+ was generated31,32 and gradually increased in concentration from the bulk to the surface. There is electrostatic potential variation and band bending inside the particles, similar to p–n junction with gradient doping. The reduced valences of other M from the Li-rich bulk to the Li-poor surface were shown with soft X-ray absorption spectroscopy (sXAS) in Supplementary Fig. 7. Pre-positioning these reduced-valence MLiL at the surface suppresses anion redox and keeps the surface fully dense in cycling.

Therefore, we have successfully synthesized LX(r)MO single crystals with fully coherent layered lattice even when Li content varied from very rich (X = 0.2) to slightly poor (X = −0.05). All the oxygen sites in Li1+X(r)M1−X(r)O2 were fully occupied and formed an integral oxygen framework, favourable for both Li and electron conduction33, as well as stress accommodation27. This is substantially different from coatings, which have unavoidable grain or phase boundaries that are preferential locations for stress-induced spallation and oxygen mobility.

Suppressed oxygen release and enhanced cycling of LX(r)MO

Differential electrochemical mass spectrometry (DEMS) was performed on G0, G4 and G6 samples. From Fig. 3a, an O2 (gas) evolution peak of 3.4 × 10−4 μmol was detected from G0 in the first cycle, but very little O2 (gas) was detected from either G4 or G6. In the second cycle, the O2 (gas) signals for G4 and G6 were entirely absent, while there was still an obvious O2 (gas) signal for G0. Thus, the Li-gradient surface had indeed suppressed oxygen gas release in charging. Also, a notable amount of CO2 (gas) was released from G0, which was almost absent for G4 or G6. This is the key evidence for carbonate electrolyte decomposition when encountering freed oxygen24,25,26. Since liquid electrolyte is only ~40 wt% of the cathode in industrial batteries, and because the anode, cathode and separator must be wet while also being consumed on the anode side, the electrolyte is often the most limiting resource in full-cell cycling. LX(r)MO should lead to better full-cell cycle life, which we will verify later in this article.

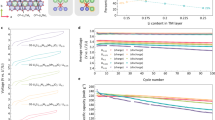

a, DEMS of G0, G4 and G6 in a CV test in a voltage range of 2.2–4.8 V with 0.1 mV s−1 scan rate. The weights of all G0, G4 and G6 active materials were from 8.0 to 9.0 mg. The mass spectra of m/z = 32 for O2 and m/z = 44 for CO2 were collected in the initial two positive scanning sweeps. b, Charge/discharge profiles of G0, G4 and G6 in the first cycle at 0.1C (1C ≡ 250 mA g−1). c, Discharge profiles of G0 and G4 for 200 cycles at 0.2C and 25 °C after five formation cycles at 40 °C and 0.1C. d, Discharge capacity, average discharge voltage and energy density of G0 and G4 at 0.2C collected from c. e,f, CV of G0 (e) and G4 (f) in the 2nd and 50th cycles.

G0, G4 and G6 were then tested in half-cells. As shown in Fig. 3b, in the first cycle under 0.1C (1C ≡ 250 mA g−1), G0 could be charged to 347.2 mAh g−1 but discharged only to 261.9 mAh g−1 with an initial Coulombic efficiency (CE) of 75.4%. G4 could be charged to 322.8 mAh g−1, but it could discharge to 293.1 mAh g−1 with a much higher initial CE of 90.8%. G6 had an even higher initial CE of 91.4%, but it could be charged only to 305.9 mAh g−1 and discharged to 279.7 mAh g−1. Thus, we should be aware that while increasing w and the amount of LiO extracted can improve the initial CE, one will also lose some capacity. So the amount of MoO3 used in leaching needs to be optimized to balance the trade-off between discharge capacity and cycle life under parsimonious electrolyte condition. It is encouraging that the gradient LX(r)MO particles improved the first-cycle CE by >15%.

The charge/discharge profiles at 0.2C are shown in Fig. 3c and Supplementary Fig. 8. G0 had seriously degraded discharge profiles after only 50 cycles. However, both the capacity and voltage were well retained for G4, which kept very similar discharge profiles even after 200 cycles. The capacity, average discharge voltage and energy density retention are summarized in Fig. 3d. G4 had not only much higher initial average discharge voltage and capacity (3.602 V, 280.7 mAh g−1) than G0 (3.533 V, 249.4mAh g−1) but also much better capacity and voltage retention. After 200 cycles at 0.2C, G4 maintained a discharge capacity of 250.4 mAh g−1 with 3.368 V average voltage, while G0 retained only 198.5 mAh g−1 with 2.944 V average voltage. In terms of energy density, G4 could reach 1,011 Wh kg−1 initially and still retained 892 Wh kg−1 after 100 cycles and 843 Wh kg−1 after 200 cycles, whereas G0 had only 589 Wh kg−1 after 200 cycles. G4 had enhanced capacity and voltage retention at other rates as well (Supplementary Figs. 8 and 9).

Voltage decay can be better understood by comparing the cyclic voltammetry (CV) between G0 and G4 in Fig. 3e,f: The oxidation peaks of G0 and G4 in the second cycle at 3.8 V and 4.2–4.6 V are dominated by Ni2+/3+/4+/Co3+/4+ cation oxidation and oxygen anion oxidation, respectively. After 50 cycles, the peak area of G0 at high voltage in charging seriously decreased due to less oxygen anion oxidation, while that due to Mn3+/4+ redox increased, inevitably down-shifting the reduction peak to a lower voltage of ~3.0 V. Thus, the average discharge voltage of G0 would continuously decay during cycling. However, for G4 (Fig. 3f), both peaks of oxygen anion redox and Mn3+/4+ redox remained almost unchanged after 50 cycles. This further confirmed that continuous oxygen loss was prevented in G4, and no additional Mn3+ was generated in room-temperature cycling. In contrast, the departure of oxygen/LiO and the reduction of cation valence also happened in G0 but, notably, during electrochemical cycling at room temperature, where severe structural disruptions and side reactions with the electrolyte occur; this was unlike in G4 where most of the structural defects were annealed out preventively under a controlled high-temperature environment. This is like the difference between the rout of an army and an ordered retreat. The average charge and discharge voltages in the cycling can be found in Supplementary Fig. 10. Galvanostatic intermittent titration technique (GITT) analysis (Supplementary Fig. 11) indicated that G4 had both well-maintained thermodynamic open-circuit voltage profiles and suppressed kinetic titration voltage drops after 150 cycles, while those of G0 both decayed severely (Supplementary Discussion 2).

Stabilized Mn valence and phase in cycling

sXAS was performed to distinguish the oxidation states of elements in the bulk and at the surface of G4 particles. The diameters of G4 particles range between 200 and 400 nm, so the fluorescence yield (FY) mode with detection depth of 100 to ~200 nm can collect the information from rcore, whereas the total electron yield (TEY) mode displays only the information at the surface within a few nanometres depth34. The O K edge starting at 528 eV comes from the excitation of O1s electrons to the hybridized M3d–O2p orbitals, which has been widely used to indicate the overall change of M–O oxidation states12,35,36,37. In Fig. 4a, by quantifying the intensity integral of the normalized sXAS O K edge peaks under FY and TEY modes at 527.5–534.2 eV, it can be confirmed that more electrons had been extracted from the Li-rich bulk (δ+ = 1.05, 329 mAh g−1) than from the Li-poor surface (δ+ = 0.81, 221 mAh g−1) in the initial charge (Supplementary Note 1).

a, Normalized (see Methods) sXAS O K edge of G4 from discharged to charged states collected from FY and TEY modes. The normalized intensity was integrated from 527.5 eV to 534.2 eV, as indicated by the light orange background. b, sXAS Mn L3 edge for discharged and charged states under FY and TEY modes. The TEY Mn L3 edge was fitted by linear combination of Mn2+, Mn3+ and Mn4+ TEY references. c, sXAS Ni L3 edge for discharged and charged states under FY and TEY modes. d, Distribution of Mn valence at the surface for discharged and charged states. e, O K edge profiles from the surface to the bulk after charge, with EELS line scan. Inset: the charged particle after FIB. The yellow circle indicates where the EELS data were collected. f–h, Sketches of Mn, Ni, Co and O valence profiles from particle surface to bulk in G4 during charging, which can also be found in Supplementary Video 1. This schematic is based on the hypothesis of 100% Co4+ and Ni4+ in the bulk when fully charged. The O anion redox can supply 204 mAh g−1 in the Li-rich bulk, while supplying no capacity at the Li-poor surface.

Meanwhile, sXAS M L3,2 edges are ideally suited to quantify the M valence in G437,38,39. Figure 4b,c shows the Mn and Ni sXAS L3 edges before and after charge. It can be clearly seen that the Mn FY L3 edge did not change (both being +4), while the TEY edge changed a lot after charge. Quantitative analysis37,38,39,40 on TEY Mn L3 edge (Fig. 4d) indicated that 5% Mn2+, 54% Mn3+ and 41% Mn4+ (average Mn valence of +3.36) was contained in the Li-poor surface of G4 particles before charge. After charging to 4.8 V, Mn4+ increased to 96%, Mn3+ decreased to 4%, and Mn2+ was totally gone (average Mn valence of +3.96). Therefore, Mn contributed no capacity in the Li-rich bulk, but 0.38e (0.63 × 0.6e) at the Li-poor surface while charging. Although quantitative valence analysis is difficult for Ni and Co ions because of the absence of standard Ni4+ and Co4+ material references, we can still see that both the Ni and Co valences increased a lot after charging, from both FY and TEY Ni sXAS L3 edges (Fig. 4c and Supplementary Fig. 12; refs. 38,40). However, in the Li1.2Mn0.48Co0.16Ni0.16O2 bulk of G4, even if all Ni and Co ions were oxidized to +4 after charging (see quantitative estimate in Supplementary Discussion 3 based on FY sXAS analysis, which reflects mainly the core, but also some surface information, thus slightly different from the illustrative Fig. 1a), M can supply at most δ+ = 0.42e (= 132 mAh g−1), and the remaining 0.63e ( =197 mAh g−1) must come from oxygen anion redox, demonstrating the genuine HACR nature1 when averaging over the LX(r)MO particle volume. In contrast, in just the Li0.95Mn0.63Ni0.21Co0.21O2 surface region, even if all the 0.81e (= 221 mAh g−1) is acquired from M redox, the Ni and Co ions were required to be oxidized to only about +3.52 after charge, which leaves room for them to reach higher valence before the oxidation of oxygen37,40,41 needs to be initiated.

We also performed an EELS line scan on a charged particle prepared by focused ion beam to obtain the depth profile of oxygen oxidation states in a G4 particle (Fig. 4e). It clearly shows that the split peak of the O K edge at 530 eV was isolated, with the peak at 532 eV at the surface, but peak A gradually grew stronger and enclosed peak B when moving to the bulk. It has been shown that peak A grows to enclose peak B only when O2p contributes to capacity12,35,36,37. The EELS result provided additional qualitative support for the claim that oxygen was highly redox active in the bulk but gradually became less oxidized and even totally unoxidized near the surface when charging. Thus Mn, Ni, Co and O oxidation state profiles throughout the G4 particle in the charge process are shown schematically in Fig. 4f–h and Supplementary Video 1 (assuming that all Ni and Co ions can be oxidized to +4 in the Li-rich bulk). They show that O in rcore contributes significant capacity, but O in rsurface does not participate in anion redox, so the altered-valence oxygen mobility (that is, local oxygen mobility) can be limited to inside the particle.

The eliminated global oxygen mobility can stabilize Mn valence in battery cycling. Figure 5a shows the FY XAS Mn L edge of G0 and G4 before cycling and after 150 cycles. It clearly shows that even though Mn3+ was pre-positioned in the Li-poor surface of G4, the amount of Mn3+ did not increase in G4 after 150 cycles, while a massive amount of new Mn3+ was introduced in G0 during cycling. Figure 5b,c shows high-resolution TEM images of G0 and G4 after 100 cycles. It can be clearly seen that for G0, as many references have also reported10,15,16, a great deal of structural damage and many phase transformations occurred, especially near the particle surface. By contrast, little phase transformation or structural collapse was found in G4 after 100 cycles. The phase difference between G0 and G4 can be seen more explicitly from the XRD analysis after 150 cycles in Supplementary Fig. 13. From the STEM-HAADF image in Fig. 5d, we can see that MLiL pillars (consistent with our density functional theory (DFT) simulation, Fig. 5d) were also well preserved after 100 cycles. Therefore, the coherent Li-gradient surface assisted by MLIL pillars had effectively supported the layered structure, preventing ‘army rout’ during prolonged cycling.

a, sXAS Mn L3,2 edges of G0 and G4 before cycling and after 150 cycles in the FY mode and those of Mn3+ and Mn4+ references. b, HRTEM image of G0 after 100 cycles; the regions on the right of the orange line and in circles indicate disordering/rock-salt phase. c, HRTEM image of G4 after 100 cycles. d, STEM-HAADF image of the G4 surface region, indicating intact layered structure with MLiL pillars in the Li layer after 100 cycles. The coloured structure is from the DFT simulation with Mn (violet), Co (grey), Ni (blue), Li (green) and O (red) atoms.

Phase stabilization can significantly enhance the kinetics in cycling. With GITT, Li diffusivity \(\left( {\hat D_{{\mathrm{Li}}^ + }} \right)\) in the 3rd cycle and the 150th cycle were compared between G0 and G4 in Fig. 6a and Supplementary Discussion 4. It can be seen that \(\hat D_{{\mathrm{Li}}^ + }\) of G0 degraded by nearly an order of magnitude after 150 cycles, while that of G4 barely changed. Electrochemical impedance spectroscopy (Supplementary Fig. 14) showed that the charge-transfer resistance of G4 was also significantly stabilized in cycling. The stabilized Li ion conductivity and interfacial impedance improved the cycling performance under higher rates. The cycling of G0 and G4 at 1C (Fig. 6b) showed that G0 had a discharge capacity of 223.3 mAh g−1 at the beginning, but it quickly decreased to 188.2 mAh g−1 after 100 cycles. G4 had a discharge capacity of 262.6 mAh g−1 at the beginning and still had discharge capacity of 238.0 mAh g−1 after 100 cycles. As shown in Fig. 6b, G4 could discharge nearly 925 Wh kg−1 in the first cycle and retained 808 Wh kg−1 after 100 cycles, whereas G0 could only discharge 793 Wh kg−1 at the beginning and faded to 571 Wh kg−1 after 100 cycles at 1C. Remarkably, for the 100th cycle under 1C, G4 had 42% higher discharge energy density than G0.

a, Average Li diffusivity in particles in the 3rd cycle and the 150th cycle of G0 and G4, measured by GITT at different states of charge. b, Discharge capacity and energy density of G0 and G4 in the initial 100 cycles in a half-cell under 1C. c,d, Charge/discharge profiles of G0 (c) and G4 (d) in a full-cell battery against an Li4Ti5O12 anode with only 2 g Ah−1 electrolyte (1 M LiPF6 in EC/DEC with a volume ratio of 1:1, and 2 wt% vinylene carbonate).

The minimized release of freed oxygen decreases side reactions and electrolyte consumption42,43,44,45,46. To simulate the operation of practical cells in industry, we used only ~2 g Ah−1 electrolyte in a capacity-matched full cell to see how many cycles the cells could survive. Li4Ti5O12 was used as the anode to avoid side reactions with the very limited electrolyte. From Fig. 6c,d it can be seen that, although both G0 and G4 could be charged to ~300 mAh g−1 in the initial cycle, G0 could only discharge to 188.1 mAh g−1 in the first cycle, and it decreased quickly to 132.3 mAh g−1 after 50 cycles at 0.2C. The consumption of liquid electrolyte due to reactions with the freed oxygen rapidly increased the impedance and dried out the full cell. In contrast, G4 could discharge to 276.9 mAh g−1 in the first cycle and could still discharge to 225.5 mAh g−1 at 0.2C after 50 cycles. This means G4 can work well in lean-electrolyte conditions prevalent in industrial batteries.

Conclusions

We developed a scalable solid-state synthesis method to produce Li-gradient Li1+X(r)M1−X(r)O2 particles through a high-temperature LiO leaching by molten MoO3. The bulk and the surface regions share a fully occupied oxygen framework without grain or phase boundaries or appreciable lattice defects. Particles with a high-energy-density core region that has excess axial Li–O–Li configurations and extra anion-redox activities are now individually wrapped by an epitaxially coherent surface region with no Li–O–Li axes and even some M–O–M axes configurations—that is, ‘atomic pillars’ that prevent structural collapse when Li is extracted—to prevent near-surface oxygen ions from participating in anion redox and gaining mobility. After that, only axial Li–O2p–Li embedded inside the interior can be activated for HACR, which is akin to the Li2O–LiO–LiO2 cathode concept2 but well mixed at the atomic scale. These oxygen ions are well trapped in the particle bulk due to the absence of percolating diffusion pathways to the surface (the concept of ‘solid oxygen’).

Our high-temperature surface treatment can be generalized to leach other elements to avoid unexpected surface reactions; for example, we may leach out Ni from Ni-rich NMC particles with other reagents that create a Ni-poor surface to reduce Li/Ni cation mixing during cycling. By further optimizing the amount of leaching agents, the temperature and the time of the reactions, one may obtain the transition metal gradient and Li-richness/poorness gradient profiles that enable the best electrochemical performance for HACR cathodes.

Methods

Synthesis of the uniformly Li-rich particles

The Li-rich Li1.20Mn0.48Ni0.16Co0.16O2 material was prepared by a wet co-precipitation method followed by a solid-state reaction process. First, MnSO4·H2O (Reagent Plus, ≥99%, Sigma-Aldrich), NiSO4·6H2O (ACS Reagent, ≥98%, Sigma-Aldrich) and CoSO4·7H2O (Reagent Plus, ≥99%, Sigma-Aldrich) were completely dissolved in deionized water with a molar ratio of 3:1:1. Then 0.5 mol l−1 NaOH solution was titrated into the solution with stirring in an 80 °C water bath until the pH reached 8–10. Stirring was maintained for 2 h, and then the solution was cooled to room temperature in air. The sediments were separated from water by centrifugation and washed with water. This process was repeated three times. Subsequently the product was dried at 80 °C in a vacuum oven to obtain a powder precursor. After that, the precursor was heated at 400 °C for 3 h to obtain a black intermediate product, and then it was mixed with LiOH·H2O (ACS Reagent, ≥98%, Sigma-Aldrich). Finally, the mixture was heated at 600 °C for 3 h and then at 900 °C for 10 h to obtain the uniformly Li-rich Li1.20Mn0.48Ni0.16Co0.16O2 material G0.

Creation of Li-gradient LX(r)MO

(NH4)6Mo7O24·4H2O (4–6 wt%) was dissolved in deionized water, and the pH was adjusted to 8–10 with NH3·H2O. Then the as-prepared Li1.20Mn0.48Ni0.16Co0.16O2 material was added to the solution and dispersed with high-power ultrasound for 1 h and then evaporated with stirring in an 80 °C water bath. The powder was milled for a while and heated at 300 °C for 2 h, then kept at 700 °C for 10 h. Then the product was milled again and dispersed in deionized water by ultrasound for 1 h, and the solid was separated by centrifugation. Finally, the solid was dried at 150 °C in a vacuum oven for 3 h to obtain the final product.

Characterizations

XRD was performed on a PANalytical X’Pert PRO X-ray diffractometer using a Cu target under 45 kV and 40 mA. The data were collected at 2° per minute and analysed with the HighScore Plus software. Scanning electron microscopy was performed on a Zeiss Merlin high-resolution scanning electron microscope. The sample for atomic resolution STEM imaging was prepared by focused ion beam lift-out using the FEI Helios 600 with a Ga ion source. A platinum layer was deposited on top of a particle to protect the cathode particle before the lift-out. The HAADF images in STEM are taken from the aberration-corrected JEOL JEM-ARM200F operated under 200 keV, equipped with a cold field emission source. The probe convergence angle on a sample is 23 mrad, with the inner and outer diameters of the HAADF detector being 68 mrad and 280 mrad, respectively. The 2 K images (2,048 × 2,048 pixels) were acquired with a dwell time of 16 μs pixel−1. EELS spectra were acquired using an FEI Talos F200X scanning/transmission electron microscope (200 kV) at the Center for Functional Nanomaterials, Brookhaven National Laboratory and using the aberration-corrected JEOL JEM-ARM200F, both with a dual EELS spectrometer. We used dual EELS to collect both the low-loss and high-loss spectra, and the low-loss spectra were utilized to correct the drift of the zero-loss peak. Based on the full-width at half-maximum of the zero-loss peak, the optimal energy resolution of EELS is about 0.7 eV. The EELS data were analyzed and processed with Gatan software. HRTEM images were taken on a JEOL 2010F at 200 kV. Local chemical analysis was performed using STEM-EDS with a HAADF detector.

sXAS measurements were carried out at the IOS (23-ID-2) beamline at the National Synchrotron Light Source II at Brookhaven National Laboratory. Spectra were acquired in total electron yield (TEY) and fluorescence yield (FY) modes. The estimated incident X-ray energy resolution was ~0.05 eV at the O K edge. The monochromator absorption features and beam instabilities were normalized by dividing the detected PFY and TEY signals by the drain current of a clean gold I0 mesh placed in the incident beam. TEY spectra were recorded from the drain current of the sample and PFY data were acquired using a Vortex-EM silicon drift detector. The sXAS spectra for the O K edge were recorded over a wide energy range, from 520 to 565 eV, covering energies well below and above sample absorptions. The normalization of the O K edge was performed12 as follows. (1) I0 normalization: the sample signal is divided by the incident intensity measured from the sample drain current from a freshly coated gold mesh inserted into the beam path before the X-rays can impinge on the sample. (2) A linear, sloping background is removed by fitting a line to the flat, low-energy region (520–524 eV) of the sXAS spectrum. (3) The spectrum is normalized by setting the flat, low-energy region to zero and the post-edge to unity (unit edge jump). The photon energy selected for the post-edge was 560 eV, beyond the region of any absorption (peaks).

Electrochemical test

R2032 coin cells were used for the electrochemical tests in this work. Half-cells were fabricated from a cathode of 80 wt% active material, 10 wt% carbon black and 10 wt% polyvinylidene fluoride (PVDF) binder, which was pasted on an Al current collector at a loading of 10 mg cm−2; an anode of Li metal sheets; a separator of Celgard 2400 polymer; and a commercial electrolyte solution of 1 M LiPF6 dissolved in a mixture of ethylene carbonate (EC) and diethyl carbonate (DEC) with a volume ratio of 1:1 and 2 wt% vinylene carbonate additive. A Land CT2001A 8-channel automatic battery test system (Wuhan Lanhe Electronics) was used for charging/discharging of the cells. An electrochemical workstation (Gamry Instruments, Reference 3000) was used for the CV scan between 2.2–4.8 V. GITT was also performed on the electrochemical workstation with constant current for 200 s followed by 1,800 s relaxation with an upper voltage of 4.8 V and a lower limit of 2.0 V. Electrochemical impedance spectroscopy was performed between 0.1 Hz and 1 MHz with a 10 mV amplitude. The electrochemical tests were all carried out at room temperature. A homemade quantitative spectrometer for DEMS was used to detect and analyse the gas during the cell testing. Two glued polyether ether ketone (PEEK) capillary tubes were used for inlet and outlet of gas. The cell was fabricated in a glove box where O2 < 0.1 ppm. Then, the output tube was connected to a commercial Thermo Scientific mass spectrometer. High-purity argon gas was used as the carrier gas with a flow rate of 3 ml min−1 during the cycling process. In the CV process, the scan rate was 0.05 mV s−1, and mass spectrometer spectra were collected every 30 s.

First-principles calculation

The calculation is performed using density functional theory (DFT) within the spin-polarized generalized gradient approximation (GGA) including the on-site Coulomb interaction correction (GGA + U), in the form of the Perdew–Burke–Ernzerhof’s exchange-correlation functional. The code is implemented in the Vienna Ab initio Simulation Package (VASP). The planewave energy cut-off is 400 eV. The U values of Mn, Co and Ni are 3.9, 3.3 and 6.2 eV, respectively.

Data availability

The data that support the plots in this paper and other findings of this study are available from the corresponding author upon reasonable request.

References

Xue, W. et al. Intercalation-conversion hybrid cathodes enabling Li–S full-cell architectures with jointly superior gravimetric and volumetric energy densities. Nat. Energy 4, 374–382 (2019).

Zhu, Z. et al. Anion-redox nanolithia cathodes for Li-ion batteries. Nat. Energy 1, 16111 (2016).

Qiao, Y., Jiang, K. Z., Deng, H. & Zhou, H. S. A high-energy-density and long-life lithium-ion battery via reversible oxide–peroxide conversion. Nat. Catal. 2, 1035–1044 (2019).

Kim, S., Cho, W., Zhang, X., Oshima, Y. & Choi, J. W. A stable lithium-rich surface structure for lithium-rich layered cathode materials. Nat. Commun. 7, 13598 (2016).

Luo, K. et al. One-pot synthesis of lithium-rich cathode material with hierarchical morphology. Nano Lett. 16, 7503–7508 (2016).

Yu, H. J. & Zhou, H. S. High-energy cathode materials (Li2MnO3–LiMO2) for lithium-ion batteries. J. Phys. Chem. Lett. 4, 1268–1280 (2013).

Yu, H. J. et al. High-energy ‘composite’ layered manganese-rich cathode materials via controlling Li2MnO3 phase activation for lithium-ion batteries. Phys. Chem. Chem. Phys. 14, 6584–6595 (2012).

Ye, D. L. et al. Understanding the origin of Li2MnO3 activation in Li-rich cathode materials for lithium-ion batteries. Adv. Fun. Mater. 25, 7488–7496 (2015).

Seo, D.-H. et al. The structural and chemical origin of the oxygen redox activity in layered and cation-disordered Li-excess cathode materials. Nat. Chem. 8, 692–697 (2016).

Yan, P. et al. Injection of oxygen vacancies in the bulk lattice of layered cathodes. Nat. Nanotechnol. 14, 602–608 (2019).

Lee, E. & Persson, K. A. Structural and chemical evolution of the layered Li-excess LixMnO3 as a function of Li content from first-principles calculations. Adv. Energy Mater. 4, 1400498 (2014).

Luo, K. et al. Charge-compensation in 3d-transition-metal-oxide intercalation cathodes through the generation of localized electron holes on oxygen. Nat. Chem. 8, 684–691 (2016).

Lee, J. Y. et al. Mitigating oxygen loss to improve the cycling performance of high capacity cation-disordered cathode materials. Nat. Commun. 8, 981 (2017).

Chen, H. R. & Islam, M. S. Lithium extraction mechanism in Li-rich Li2MnO3 involving oxygen hole formation and dimerization. Chem. Mater. 28, 6656–6663 (2016).

Singer, A. et al. Nucleation of dislocations and their dynamics in layered oxide cathode materials during battery charging. Nat. Energy 3, 641–647 (2018).

Hu, E. Y. et al. Evolution of redox couples in Li- and Mn-rich cathode materials and mitigation of voltage fade by reducing oxygen release. Nat. Energy 3, 690–698 (2018).

Hy, S., Felix, F., Rick, J., Su, W. N. & Hwang, B. J. Direct in situ observation of Li2O evolution on Li-rich high-capacity cathode material, Li[NixLi(1−2x)/3Mn(2−x)/3]O2 (0 ≤ x ≤0.5). J. Am. Chem. Soc. 136, 999–1007 (2014).

Tran, N. et al. Mechanisms associated with the “plateau” observed at high voltage for the overlithiated Li1.12(Ni0.425Mn0.425Co0.15)0.88O2 system. Chem. Mater. 20, 4815–4825 (2008).

Yan, P. F. et al. Probing the degradation mechanism of Li2MnO3 cathode for Li-ion batteries. Chem. Mater. 27, 975–982 (2015).

Guo, S. H. et al. Surface coating of lithium-manganese-rich layered oxides with delaminated MnO2 nanosheets as cathode materials for Li-ion batteries. J. Mater. Chem. A 2, 4422–4428 (2014).

Zheng, F. H. et al. Nanoscale surface modification of lithium-rich layered-oxide composite cathodes for suppressing voltage fade. Angew. Chem. Int. Ed. 54, 13058–13062 (2015).

Kang, S. H., Johnson, C. S., Vaughey, J. T., Amine, K. & Thackeray, M. M. The effects of acid treatment on the electrochemical properties of 0.5 Li2MnO3 ∙ 0.5 LiNi0.44Co0.25Mn0.31O2 electrodes in lithium cells. J. Electrochem. Soc. 153, A1186–A1192 (2006).

Qiu, B. et al. Gas–solid interfacial modification of oxygen activity in layered oxide cathodes for lithium-ion batteries. Nat. Commun. 7, 12108 (2016).

Bruce, P. G., Freunberger, S. A., Hardwick, L. J. & Tarascon, J. M. Li–O2 and Li–S batteries with high energy storage. Nat. Mater. 11, 19–29 (2012).

Freunberger, S. A. et al. Reactions in the rechargeable lithium–O2 battery with alkyl carbonate electrolytes. J. Am. Chem. Soc. 133, 8040–8047 (2011).

McCloskey, B. D., Bethune, D. S., Shelby, R. M., Girishkumar, G. & Luntz, A. C. Solvents’ critical role in nonaqueous lithium–oxygen battery electrochemistry. J. Phys. Chem. Lett. 2, 1161–1166 (2011).

Sun, Y.-K. et al. Nanostructured high-energy cathode materials for advanced lithium batteries. Nat. Mater. 11, 942–947 (2012).

Lim, B. B. et al. Advanced concentration gradient cathode material with two-slope for high-energy and safe lithium batteries. Adv. Funct. Mater. 25, 4673–4680 (2015).

Nakamura, T. et al. Defect chemical studies on oxygen release from the Li-rich cathode material Li1.2Mn0.6Ni0.2O2−δ. J. Mater. Chem. A 7, 5009–5019 (2019).

Cho, Y., Oh, P. & Cho, J. A new type of protective surface layer for high-capacity Ni-based cathode materials: nanoscaled surface pillaring layer. Nano Lett. 13, 1145–1152 (2013).

Loomer, D. B., Al, T. A., Weaver, L. & Cogswell, S. Manganese valence imaging in Mn minerals at the nanoscale using STEM-EELS. Am. Mineral. 92, 72–79 (2007).

Li, Z. P. et al. Interface and surface cation stoichiometry modified by oxygen vacancies in epitaxial manganite films. Adv. Funct. Mater. 22, 4312–4321 (2012).

Lu, J. et al. Nanoscale coating of LiMO2 (M = Ni, Co, Mn) nanobelts with Li+-conductive Li2TiO3: toward better rate capabilities for Li-ion batteries. J. Am. Chem. Soc. 135, 1649–1652 (2013).

Qiao, R. et al. Direct experimental probe of the Ni(II)/Ni(III)/Ni(IV) redox evolution in LiNi0.5Mn1.5O4 electrodes. J. Phys. Chem. C. 119, 27228–27233 (2015).

Luo, K. et al. Anion redox chemistry in the cobalt free 3d transition metal oxide intercalation electrode Li[Li0.2Ni0.2Mn0.6]O2. J. Am. Chem. Soc. 138, 11211–11218 (2016).

Oishi, M. et al. Direct observation of reversible oxygen anion redox reaction in Li-rich manganese oxide, Li2MnO3, studied by soft X-ray absorption spectroscopy. J. Mater. Chem. A 4, 9293–9302 (2016).

Dai, K. H. et al. High reversibility of lattice oxygen redox quantified by direct bulk probes of both anionic and cationic redox reactions. Joule 3, 518–541 (2019).

Qiao, R. M. et al. Direct evidence of gradient Mn(II) evolution at charged states in LiNi0.5Mn1.5O4 electrodes with capacity fading. J. Power Sources 273, 1120–1126 (2015).

Risch, M. et al. Redox processes of manganese oxide in catalyzing oxygen evolution and reduction: an in situ soft X-ray absorption spectroscopy study. J. Phys. Chem. C. 121, 17682–17692 (2017).

Li, Q. H. et al. Quantitative probe of the transition metal redox in battery electrodes through soft X-ray absorption spectroscopy. J. Phys. D. 49, 413003 (2016).

Venkatraman, S., Shin, Y. & Manthiram, A. Phase relationships and structural and chemical stabilities of charged Li1 − xCoO2 − δ and Li1 − xNi0.85Co0.15O2 − δ cathodes. Electrochem. Solid State Lett. 6, A9–A12 (2003).

Hatsukade, T., Schiele, A., Hartmann, P., Brezesinski, T. & Janek, J. Origin of carbon dioxide evolved during cycling of nickel-rich layered NCM cathodes. ACS Appl. Mater. Interfaces 10, 38892–38899 (2018).

Imhof, R. & Novak, P. Oxidative electrolyte solvent degradation in lithium-ion batteries: an in situ differential electrochemical mass spectrometry investigation. J. Electrochem. Soc. 146, 1702–1706 (1999).

Jung, R., Metzger, M., Maglia, F., Stinner, C. & Gasteiger, H. A. Oxygen release and its effect on the cycling stability of LiNixMnyCozO2 (NMC) cathode materials for Li-ion batteries. J. Electrochem. Soc. 164, A1361–A1377 (2017).

Wang, H. et al. CO2 and O2 evolution at high voltage cathode materials of Li-ion batteries: a differential electrochemical mass spectrometry study. Anal. Chem. 86, 6197–6201 (2014).

de Biasi, L. et al. Chemical, structural, and electronic aspects of formation and degradation behavior on different length scales of Ni-rich NCM and Li-rich HE-NCM cathode materials in Li-ion batteries. Adv. Mater. 31, 1900985 (2019).

Acknowledgements

We acknowledge the support from NSF ECCS-1610806 and Wuxi Weifu High-Technology Group Co., Ltd. This research used resources of the Center for Functional Nanomaterials and the 23-ID-2 (IOS) beamline of the National Synchrotron Light Source II, both of which are US Department of Energy Office of Science user facilities at Brookhaven National Laboratory, under contract DE-SC0012704. Also, this work was performed in part at the Center for Nanoscale Systems, a member of the National Nanotechnology Coordinated Infrastructure Network supported by the National Science Foundation under NSF award no. 1541959.

Author information

Authors and Affiliations

Contributions

Z.Z. and J.Li conceived and designed the experiments. Z.Z. synthesized the materials and performed the electrochemical tests. D.Y, Y.Y. and B.W. performed the HRTEM imaging, STEM-EDS mapping, EELS line scan and focused ion beam sample preparation for aberration-corrected STEM characterizations. C.S. took aberration-corrected STEM images and performed the DFT calculations. D.Y., I.W. and A.H. measured the soft X-ray absorption. Z.Z., D.Y. and X.Y. did the sXAS data analysis. Z.Z. and J.Li wrote the paper. All authors analysed the data, discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–14, Tables 1–3, Note 1, Discussion 1–4 and refs. 1–8.

Supplementary Video 1

M and O redox behaviours in the charging process.

Rights and permissions

About this article

Cite this article

Zhu, Z., Yu, D., Yang, Y. et al. Gradient Li-rich oxide cathode particles immunized against oxygen release by a molten salt treatment. Nat Energy 4, 1049–1058 (2019). https://doi.org/10.1038/s41560-019-0508-x

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41560-019-0508-x

This article is cited by

-

Advanced cathode design: ordering LiMn6 functional units in Li-rich layered oxides

Science China Materials (2026)

-

An amorphous Li–V–O–F cathode with tetrahedral coordination and O–O formal redox at low voltage

Nature Materials (2025)

-

Substantial oxygen loss and chemical expansion in lithium-rich layered oxides at moderate delithiation

Nature Materials (2025)

-

Superexchange interaction regulates Ni/Mn spin states triggering Ni-t2g/O-2p reductive coupling enabling stable lithium-rich cathode

Nature Communications (2025)

-

Comprehensive Understanding of Voltage Fade of Li & Mn Rich Cathodes

Korean Journal of Chemical Engineering (2025)