Abstract

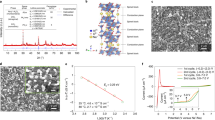

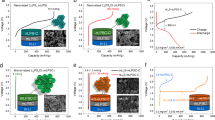

The need for higher energy-density rechargeable batteries has generated interest in alkali metal electrodes paired with solid electrolytes. However, metal penetration and electrolyte fracture at low current densities have emerged as fundamental barriers. Here we show that for pure metals in the Li–Na–K system, the critical current densities scale inversely to mechanical deformation resistance. Furthermore, we demonstrate two electrode architectures in which the presence of a liquid phase enables high current densities while it preserves the shape retention and packaging advantages of solid electrodes. First, biphasic Na–K alloys show K+ critical current densities (with the K-β″-Al2O3 electrolyte) that exceed 15 mA cm‒2. Second, introducing a wetting interfacial film of Na–K liquid between Li metal and Li6.75La3Zr1.75Ta0.25O12 solid electrolyte doubles the critical current density and permits cycling at areal capacities that exceed 3.5 mAh cm‒2. These design approaches hold promise for overcoming electrochemomechanical stability issues that have heretofore limited the performance of solid-state metal batteries.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All the relevant data are included in the paper and its Supplementary Information. Source data are provided with this paper.

Change history

31 March 2021

A Correction to this paper has been published: https://doi.org/10.1038/s41560-021-00819-4

References

Howell, D., Cunningham, B. Duong, T. & Faguy, P. Overview of DOE Vehicle Technologies Office Advanced Battery R&D Program (Vehicle Technologies Office, 2016).

Harlow, J. E. et al. A wide range of testing results on an excellent lithium-ion cell chemistry to be used as benchmarks for new battery technologies. J. Electrochem. Soc. 166, A3031–A3044 (2019).

Bills, A., Sripad, S., Fredericks, W. L., Singh, M. & Viswanathan, V. Performance metrics required of next-generation batteries to electrify commercial aircraft. ACS Energy Lett. 5, 663–668 (2020).

Albertus, P., Babinec, S., Litzelman, S. & Newman, A. Status and challenges in enabling the lithium metal electrode for high-energy and low-cost rechargeable batteries. Nat. Energy 3, 16–21 (2018).

Aurbach, D., Zinigrad, E., Cohen, Y. & Teller, H. A short review of failure mechanisms of lithium metal and lithiated graphite anodes in liquid electrolyte solutions. Solid State Ion. 148, 405–416 (2002).

Liu, Z. et al. Interfacial study on solid electrolyte interphase at Li metal anode: implication for Li dendrite growth. J. Electrochem. Soc. 163, A592–A598 (2016).

Manthiram, A., Yu, X. & Wang, S. Lithium battery chemistries enabled by solid-state electrolytes. Nat. Rev. Mater. 2, 16103 (2017).

Kerman, K., Luntz, A., Viswanathan, V., Chiang, Y.-M. & Chen, Z. Practical challenges hindering the development of solid state Li ion batteries. J. Electrochem. Soc. 164, A1731–A1744 (2017).

Janek, J. & Zeier, W. G. A solid future for battery development. Nat. Energy 1, 16141 (2016).

Thangadurai, V., Narayanan, S. & Pinzaru, D. Garnet-type solid-state fast Li ion conductors for Li batteries: critical review. Chem. Soc. Rev. 43, 4714–4727 (2014).

Liu, D. et al. Recent progress in sulfide-based solid electrolytes for Li-ion batteries. Mater. Sci. Eng. B 213, 169–176 (2016).

McGrogan, F. et al. Compliant yet brittle mechanical behavior of Li2S–P2S5 lithium-ion-conducting solid electrolyte. Adv. Energy Mater. 7, 1602011 (2017).

Wolfenstine, J. et al. A preliminary investigation of fracture toughness of Li7La3Zr2O12 and its comparison to other solid Li-ion conductors. Mater. Lett. 96, 117–120 (2013).

Monroe, C. & Newman, J. The impact of elastic deformation on deposition kinetics at lithium/polymer interfaces. J. Electrochem. Soc. 152, A396–A404 (2005).

Porz, L. et al. Mechanism of lithium metal penetration through inorganic solid electrolytes. Adv. Energy Mater. 7, 1701003 (2017).

Swamy, T. et al. Lithium metal penetration induced by electrodeposition through solid electrolytes: example in single-crystal Li6La3ZrTaO12 garnet. J. Electrochem. Soc. 165, A3648–A3655 (2018).

Aguesse, F. et al. Investigating the dendritic growth during full cell cycling of garnet electrolyte in direct contact with Li metal. ACS Appl. Mater. Interfaces 9, 3808–3816 (2017).

Sharafi, A., Meyer, H. M., Nanda, J., Wolfenstine, J. & Sakamoto, J. Characterizing the Li–Li7La3Zr2O12 interface stability and kinetics as a function of temperature and current density. J. Power Sources 302, 135–139 (2016).

Ren, Y. Y., Shen, Y., Lin, Y. H. & Nan, C. W. Direct observation of lithium dendrites inside garnet-type lithium-ion solid electrolyte. Electrochem. Commun. 57, 27–30 (2015).

Nagao, M. et al. In situ SEM study of a lithium deposition and dissolution mechanism in a bulk-type solid-state cell with a Li2S–P2S5 solid electrolyte. Phys. Chem. Chem. Phys. 15, 18600–18606 (2013).

Taylor, N. J. et al. Demonstration of high current densities and extended cycling in the garnet Li7La3Zr2O12 solid electrolyte. J. Power Sources 396, 314–318 (2018).

Jolly, D. S. et al. Sodium/Na β″ alumina interface: effect of pressure on voids. ACS Appl. Mater. Interfaces 12, 678–685 (2020).

Bay, M.-C. et al. Sodium plating from Na-β″-alumina ceramics at room temperature, paving the way for fast-charging all-solid-state batteries. Adv. Energy Mater. 10, 1902899 (2019).

Kasemchainan, J. et al. Critical stripping current leads to dendrite formation on plating in lithium anode solid electrolyte cells. Nat. Mater. 18, 1105–1111 (2019).

Griffith, A. A. The phenomena of rupture and flow in solids. Phil. Trans. Roy. Soc. 221A, 163–198 (1920).

Inglis, C. E. Stresses in a plate due to the presence of cracks and sharp notches. Trans. Roy. Inst. Nav. Archit. 55, 219–241 (1913).

Orowan, E. Fracture and strength of solids. Rep. Prog. Phys. 12, 185–232 (1949).

Virkar, A. V. & Viswanathan, L. Sodium penetration in rapid ion conductors. J. Am. Ceram. Soc. 62, 528–529 (1979).

Virkar, A. V. On some aspects of breakdown of β″-alumina solid electrolyte. J. Mater. Sci. 16, 1142–1150 (1981).

Fincher, C. D., Ojeda, D., Zhang, Y., Pharr, G. M. & Pharr, M. Mechanical properties of metallic lithium: from nano to bulk scales. Acta Mater. 186, 215–222 (2019).

LePage, W. S. et al. Lithium mechanics: roles of strain rate and temperature and implications for lithium metal batteries. J. Electrochem. Soc. 166, A89–A97 (2019).

Xu, C., Ahmad, Z., Aryanfar, A., Viswanathan, V. & Greer, J. R. Enhanced strength and temperature dependence of mechanical properties of Li at small scales and its implications for Li metal anodes. Proc. Natl Acad. Sci. USA 114, 57–61 (2017).

Vaks, V. G., Kravchuk, S. P., Zarochentsev, E. V. & Safronov, V. P. Temperature dependence of the elastic constants in alkali metals. J. Phys. F 8, 725–742 (1978).

Hull, D. & Rosenberg, H. M. The deformation of lithium, sodium and potassium at low temperatures: tensile and resistivity experiments. Philos. Mag. 4, 303–315 (1959).

Andrade, E. Nd-C. & Dobbs, E. R. The viscosities of liquid lithium, rubidium and caesium. Proc. R. Soc. Lond. A 211, 12–30 (1952).

Grosse, A. V. Viscosities of liquid sodium and potassium, from their melting points to their critical points. Science 147, 1438–1411 (1965).

Fincher, C. D., Zhang, Y., Pharr, G. M. & Pharr, M. Elastic and plastic characteristics of sodium metal. ACS Appl. Energy Mater. 3, 1759–1767 (2020).

Tabor, D. The Hardness of Metals (Oxford Univ. Press, 2000).

Bates, J. B., Dudney, N. J., Neudecker, B., Ueda, A. & Evans, C. D. Thin-film lithium and lithium-ion batteries. Solid State Ion. 135, 33–45 (2000).

Baclig, A. C. et al. High-voltage, room-temperature liquid metal flow battery enabled by Na–K|K–β″-alumina stability. Joule 2, 1287–1296 (2018).

Liu, C., Shamie, J. S., Shaw, L. L. & Sprenkle, V. L. An ambient temperature molten sodium–vanadium battery with aqueous flowing catholyte. ACS Appl. Mater. Interfaces 8, 1545–1552 (2015).

Guo, X. et al. A self‐healing room‐temperature liquid‐metal anode for alkali‐ion batteries. Adv. Funct. Mater. 28, 1804649 (2018).

Sharafi, A. et al. Surface chemistry mechanism of ultra-low interfacial resistance in the solid-state electrolyte Li7La3Zr2O12. Chem. Mater. 29, 7961–7968 (2017).

Anstis, G. R., Chantikul, P., Lawn, B. R. & Marshall, D. B. A critical evaluation of indentation techniques for measuring fracture toughness: I, direct crack measurements. J. Am. Ceram. Soc. 64, 533–538 (1981).

Evans, A. G. & Charles, E. A. Fracture toughness determinations by indentation. J. Am. Ceram. Soc. 59, 371–372 (1976).

Kaufman, L. The lattice stability of metals—I. Titanium and zirconium. Acta Metall. 7, 575–587 (1959).

Dinsdale, A. T. SGTE data for pure elements. Calphad 15, 317–425 (1991).

Redlich, O. & Kister, S. T. Algebraic representation of thermodynamic properties and the classification of solutions. Ind. Eng. Chem. 20, 345–348 (1948).

Lukas, H., Fries, S. G. & Sundman. B. Computational Thermodynamics: the CALPHAD Method (Cambridge Univ. Press, 2007).

Zhang, S. J. Thermodynamic Investigation of the Effect of Alkali Metal Impurities on the Processing of Al and Mg Alloys PhD thesis (Pennsylvania State Univ., 2006).

Balluffi, R., Allen, S. M. & Carter, W. C. Kinetics of Materials (Wiley, 2005).

Acknowledgements

We acknowledge support from the US Department of Energy, Office of Basic Energy Science, through award no. DE-SC0002633 (J. Vetrano, Program Manager). This work made use of the MRL MRSEC Shared Experimental Facilities at MIT, supported by the National Science Foundation under award no. DMR-1419807. We also acknowledge use of the MIT Nanomechanical Technology Laboratory (A. Schwartzman, Manager). We thank T. Swamy for helpful discussions, and N. Katorova and P. Morozova for assistance with alkali metal handling procedures. We acknowledge financial support from the MIT-Skoltech Next Generation Program, award no. 2016-1, for the portion of the work related to K metal. C.D.F. acknowledges the support of the National Science Foundation Graduate Research Fellowship under grant no. 1746932. M.P. acknowledges the support of the National Science Foundation under award no. DMR-1944674.

Author information

Authors and Affiliations

Contributions

Y.-M.C. and R.J.-Y.P. designed the study. R.J.-Y.P. prepared, measured and analysed the results from the electrochemical cells. C.M.E. measured the alkali metal wetting angles. C.D.F. measured the alkali metal mechanical properties. A.F.B. performed the image analysis of disassembled cells. P.G. calculated the Li–Na–K ternary phase diagram. All the authors contributed to writing the manuscript.

Corresponding author

Ethics declarations

Competing interests

Massachusetts Institute of Technology has filed for patents on the subject matter related to this article in which R.J.-Y.P., Y.-M.C., P.G. and V.V. are listed inventors.

Additional information

Peer review information Nature Energy thanks Qiang Zhang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Tables 1–3, Figs. 1–12, discussion, methods and references.

Source data

Source Data Fig. 6

Microhardness data for Li, Na and K (10 independent measurements per metal).

Rights and permissions

About this article

Cite this article

Park, R.JY., Eschler, C.M., Fincher, C.D. et al. Semi-solid alkali metal electrodes enabling high critical current densities in solid electrolyte batteries. Nat Energy 6, 314–322 (2021). https://doi.org/10.1038/s41560-021-00786-w

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41560-021-00786-w

This article is cited by

-

High plating currents without dendrites at the interface between a lithium anode and solid electrolyte

Nature Energy (2025)

-

Constructing an anion-capturing interface to achieve Li+ cross-phase transport in composite solid electrolytes

Nature Communications (2025)

-

Revitalizing interphase in all-solid-state Li metal batteries by electrophile reduction

Nature Materials (2025)

-

Magnetic microscopy for operando imaging of battery dynamics

Nature Communications (2025)

-

Synthesis of monocrystalline lithium for high-critical-current-density solid-state batteries

Nature Synthesis (2025)