Abstract

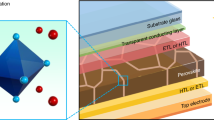

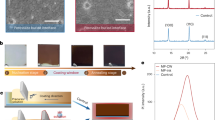

As a vital step towards the industrialization of perovskite solar cells, outdoor field tests of large-scale perovskite modules and panels represent a mandatory step to be accomplished. Here we demonstrate the manufacturing of large-area (0.5 m2) perovskite solar panels, each containing 40 modules whose interfaces are engineered with two-dimensional materials (GRAphene-PErovskite (GRAPE) panels). We further integrate nine GRAPE panels for a total panel area of 4.5 m2 in a stand-alone solar farm infrastructure with peak power exceeding 250 W, proving the scalability of this technology. We provide insights on the system operation by analysing the panel characteristics as a function of temperature and light intensity. The analysis, carried out over a months-long timescale, highlights the key role of the lamination process of the panels on the entire system degradation. A life-cycle assessment based on primary data indicates the high commercial potential of the GRAPE panel technology in terms of energy and environmental performances.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Data generated or analysed during this study are included in the published article and its Supplementary Information and Source Data files. All experimental data collected outdoors in the solar farm have been gathered in an open data repository at HMU and are available at https://solarfarmhmu.gr/. The website includes the weather data of the installation area and the electrical characteristics of GRAPE panels. The online monitoring system of the solar farm presented on the website was built using an in-house developed IV-MPP tracker and commercial IV tracers. Source data are provided with this paper.

References

Best research-cell efficiencies. NREL https://www.nrel.gov/pv/assets/images/efficiency-chart.png (2022).

Zafoschnig, L. A., Nold, S. & Goldschmidt, J. C. The race for lowest costs of electricity production: techno-economic analysis of silicon, perovskite and tandem solar cells. IEEE J. Photovolt. 10, 1632–1641 (2020).

Tian, X., Stranks, S. D. & You, F. Life cycle energy use and environmental implications of high-performance perovskite tandem solar cells. Sci. Adv. 6, eabb0055 (2020).

Li, Z. et al. Cost analysis of perovskite tandem photovoltaics. Joule 2, 1559–1572 (2018).

Champion photovoltaic module efficiency chart. NREL https://www.nrel.gov/pv/module-efficiency.html (2022).

Park, N. G. & Zhu, K. Scalable fabrication and coating methods for perovskite solar cells and solar modules. Nat. Rev. Mater. 5, 333–350 (2020).

Petridis, C., Kakavelakis, G. & Kymakis, E. Renaissance of graphene-related materials in photovoltaics due to the emergence of metal halide perovskite solar cells. Energy Environ. Sci. 11, 1030–1061 (2018).

Agresti, A. et al. Two-dimensional (2D) material interface engineering for efficient perovskite large-area modules. ACS Energy Lett. 4, 1862–1871 (2019).

Taheri, B. et al. Graphene-engineered automated sprayed mesoscopic structure for perovskite device scaling-up. 2D Mater. 5, 045034 (2018).

Razza, S., Pescetelli, S., Agresti, A. & Di Carlo, A. Laser processing optimization for large-area perovskite solar modules. Energies 14, 1069 (2021).

Pescetelli, S. et al. Synergic use of two-dimensional materials to tailor interfaces in large area perovskite modules. Nano Energy 95, 107019 (2022).

Agresti, A. et al. Graphene-perovkite solar cells exceed 18% efficiency: a stability study. ChemSusChem 9, 2609–2619 (2016).

Biccari, F. et al. Graphene-based electron transport layers in perovskite solar cells: a step-up for an efficient carrier collection. Adv. Energy Mater. 7, 1701349 (2017).

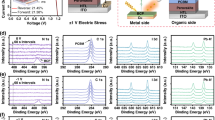

Agresti, A. et al. Titanium-carbide MXenes for work function and interface engineering in perovskite solar cells. Nat. Mater. 18, 1228–1234 (2019).

Arora, N. et al. Perovskite solar cells with CuSCN hole extraction layers yield stabilized efficiencies greater than 20%. Science 358, 768–771 (2017).

Busby, Y. et al. Aging effects in interface-engineered perovskite solar cells with 2D nanomaterials: a depth profile analysis. Mater. Today Energy 9, 1–10 (2018).

Jung, E. H. et al. Efficient, stable and scalable perovskite solar cells using poly(3-hexylthiophene). Nature 567, 511–515 (2019).

Thrithamarassery Gangadharan, D. & Ma, D. Searching for stability at lower dimensions: current trends and future prospects of layered perovskite solar cells. Energy Environ. Sci. 12, 2860–2889 (2019).

Agresti, A. et al. Graphene interface engineering for perovskite solar modules: 12.6% power conversion efficiency over 50 cm2 active area. ACS Energy Lett. 2, 279–287 (2017).

Del Rio Castillo, A. E. et al. High-yield production of 2D crystals by wet-jet milling. Mater. Horiz. 5, 890–904 (2018).

Najafi, L. et al. MoS2 quantum dot/graphene hybrids for advanced interface engineering of a CH3NH3PbI3 perovskite solar cell with an efficiency of over 20%. ACS Nano 12, 10736–10754 (2018).

O’Keeffe, P. et al. Graphene-induced improvements of perovskite solar cell stability: effects on hot carriers. Nano Lett. 19, 684–691 (2019).

Agresti, A. et al. Graphene and related 2D materials for high efficient and stable perovskite solar cells. In 2017 IEEE 17th International Conference on Nanotechnology, NANO 2017 145–150 (IEEE, 2017).

Agresti, A. et al. Titanium-carbide MXenes for work function and interface engineering in perovskite solar cells. Nat. Mater. 18, 1228–1234 (2019).

Khenkin, M. V. et al. Consensus statement for stability assessment and reporting for perovskite photovoltaics based on ISOS procedures. Nat. Energy 5, 35–49 (2020).

Palma, A. L. et al. Laser-patterning engineering for perovskite solar modules with 95% aperture ratio. IEEE J. Photovolt. 7, 1674–1680 (2017).

Corsini, F. & Griffini, G. Recent progress in encapsulation strategies to enhance the stability of organometal halide perovskite solar cells. JPhys Energy 2, 031002 (2020).

Kempe, M. D. et al. Acetic acid production and glass transition concerns with ethylene-vinyl acetate used in photovoltaic devices. Sol. Energy Mater. Sol. Cells 91, 315–329 (2007).

Spena, A., Cornaro, C., Intreccialagli, G. & Chianese, D. Data validation and uncertainty evaluation of the ESTER outdoor facility for testing of photovoltaic modules. In 24th European Photovoltaic Solar Energy Conference and Exhibition 3586–3589 (EU PVSEC, 2009).

Gouda, L. et al. Open circuit potential build-up in perovskite solar cells from dark conditions to 1 sun. J. Phys. Chem. Lett. 6, 4640–4645 (2015).

Stoichkov, V. et al. Outdoor performance monitoring of perovskite solar cell mini-modules: diurnal performance, observance of reversible degradation and variation with climatic performance. Sol. Energy 170, 549–556 (2018).

Dupré, O., Vaillon, R. & Green, M. A. Physics of the temperature coefficients of solar cells. Sol. Energy Mater. Sol. Cells 140, 92–100 (2015).

Gulkowski, S., Zdyb, A. & Dragan, P. Experimental efficiency analysis of a photovoltaic system with different module technologies under temperate climate conditions. Appl. Sci. 9, 141 (2019).

Makrides, G., Zinsser, B., Phinikarides, A., Schubert, M. & Georghiou, G. E. Temperature and thermal annealing effects on different photovoltaic technologies. Renew. Energy 43, 407–417 (2012).

Jošt, M. Perovskite solar cells go outdoors: field testing and temperature effects on energy yield. Adv. Energy Mater. 10, 2000454 (2020).

Fu, F. et al. High-efficiency inverted semi-transparent planar perovskite solar cells in substrate configuration. Nat. Energy 2, 16190 (2017).

Wang, D., Wright, M., Elumalai, N. K. & Uddin, A. Stability of perovskite solar cells. Sol. Energy Mater. Sol. Cells 147, 255–275 (2016).

Ruf, F. et al. Temperature-dependent studies of exciton binding energy and phase-transition suppression in (Cs,FA,MA)Pb(I,Br)3 perovskites. APL Mater. 7, 031113 (2019).

Kymakis, E., Kalykakis, S. & Papazoglou, T. M. Performance analysis of a grid connected photovoltaic park on the island of Crete. Energy Convers. Manag. 50, 433–438 (2009).

Reynaa, Y. et al. Performance and stability of mixed FAPbI3(0.85)MAPbBr3(0.15) halide perovskite solar cells under outdoor conditions and the effect of low light irradiation. Nano Energy 30, 570–579 (2016).

Stoichkov, V. et al. Outdoor performance monitoring of perovskite solar cell mini-modules: diurnal performance, observance of reversible degradation and variation with climatic performance. Sol. Energy 170, 549–556 (2018).

Bowring, A. R., Bertoluzzi, L., O'Regan, B. C. & McGehee, M. D. Reverse bias behavior of halide perovskite solar cells. Adv. Energy Mater. 8, 1702365 (2018).

Song, W. & Aernouts, T. Novel test scenarios needed to validate outdoor stability of perovskite solar cells. J. Phys. Energy 2, 021003 (2020).

Environmental Management—Life Cycle Assessment—Principles and guidelines. ISO 14040:2006 (2006).

Environmental Management—Life Cycle Assessment—Requirements and guidelines. ISO 14044:2006 (2006).

Maranghi, S., Parisi, M. L., Basosi, R. & Sinicropi, A. Environmental profile of the manufacturing process of perovskite photovoltaics: harmonization of life cycle assessment studies. Energies 12, 3746 (2019).

Fazio, S. et al. Supporting Information to the Characterisation Factors of Recommended EF Life Cycle Impact Assessment Methods: New Methods and Differences with ILCD (Publications Office of the European Union, 2018).

Leccisi, E. & Fthenakis, V. Life cycle energy demand and carbon emissions of scalable single-junction and tandem perovskite PV. Prog. Photovolt. Res. Appl. 29, 1078–1092 (2021).

Mariani, P. et al. Low-temperature graphene-based paste for large-area carbon perovskite solar cells. ACS Appl. Mater. Interfaces 13, 22368–22380 (2021).

Wang, J. T. et al. Low-temperature processed electron collection layers of graphene/TiO2 nanocomposites in thin film perovskite solar cells. Nano Lett. 14, 724–730 (2014).

Lamanna, E. et al. Mechanically stacked, two-terminal graphene-based perovskite/silicon tandem solar cell with efficiency over 26%. Joule 4, 865–881 (2020).

Del Rio Castillo, A. E., Ansaldo, A., Pellegrini, V. & Bonaccorso, V. Exfoliation of layered materials by wet-jet milling techniques. World patent 2017089987A1 (2017).

Backes, C. et al. Production and processing of graphene and related materials. 2D Mater. 7, 0222001 (2020).

Najafi, L. et al. Solution-processed hybrid graphene flake/2H–MoS2 quantum dot heterostructures for efficient electrochemical hydrogen evolution. Chem. Mater. 29, 5782–5786 (2017).

Rakocevic, L. et al. Loss analysis in perovskite photovoltaic modules. Sol. RRL 3, 1900338 (2019).

Shi, L. et al. Gas chromatography–mass spectrometry analyses of encapsulated stable perovskite solar cells. Science 368, 6497 (2020).

Cornaro, C., Renzi, L., Pierro, M., Di Carlo, A. & Guglielmotti, A. Thermal and electrical characterization of a semi-transparent dye-sensitized photovoltaic module under real operating conditions. Energies 11, 155 (2018).

Acknowledgements

The work has been supported by European Union’s Horizon 2020 research and innovation programme under grant agreement numbers 785219—GrapheneCore2 (A.D.C., E.K., L.S. and F.B.) and 881603—GrapheneCore3 (A.D.C., E.K., L.S. and F.B.).

Author information

Authors and Affiliations

Contributions

A.D.C., E.K. and F.B. conceived the work. S.P. and A.A. designed, realized and optimized 2D material-based perovskite solar cells and modules by performing the electrical characterizations. S.P. and A.A., developed the module encapsulation procedure. S.R. performed laser scribe ablation for module realization. G.V., K.R., I.K. and E.S. designed and built the solar farm infrastructure and performed in situ electrical panel characterizations. E.L. and L.S. laminated the GRAPE panels. M. Pierro and C.C. performed panel measurements on the ESTER station. S.B., L.N., B.M.-G., A.E.D.R.C., R.O.-N. and M. Prato produced and characterized 2D materials. P.M., S.M., M.L.P., A.S. and R.B. performed LCA. A.D.C., E.K. and F.B. supervised the work. All authors contributed to the discussion of the results and to the writing of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

F.B. is a co-founder and CSO, and S.B. is a senior scientist at BeDimensional S.p.A., a company that is commercializing 2D materials. L.S. and E.L. are employees of Greatcell Solar Italia, part of the Greatcell Energy Group focused on the commercialization of Perovskite solar technology.

Peer review

Peer review information

Nature Energy thanks Ilke Celik, Nam-Gyu Park, Trystan Watson and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–40, Discussion, Tables 1–15, Methods and References 1–49.

Supplementary Data 1

a, Statistical analysis of weather variables (temperature) from June 2020 until June 2021 at the installation field (0.5 m2 for each panel). b, Statistical analysis of weather variables (relative humidity) from June 2020 until June 2021 at the installation field (0.5 m2 for each panel). c, Statistical analysis of weather variables (panel temperature) from June 2020 until June 2021 at the installation field (0.5 m2 for each panel). d, Statistical analysis of weather variables (wind speed) from June 2020 until June 2021 at the installation field (0.5 m2 for each panel).

Source data

Source Data Fig. 1

Statistical distribution of the PCE data recorded for the PSMs.

Rights and permissions

About this article

Cite this article

Pescetelli, S., Agresti, A., Viskadouros, G. et al. Integration of two-dimensional materials-based perovskite solar panels into a stand-alone solar farm. Nat Energy 7, 597–607 (2022). https://doi.org/10.1038/s41560-022-01035-4

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41560-022-01035-4

This article is cited by

-

Translating insights from progress in photovoltaics to accelerate industrial-scale CO2 electroreduction

Nature Energy (2026)

-

Emerging Role of 2D Materials in Photovoltaics: Efficiency Enhancement and Future Perspectives

Nano-Micro Letters (2026)

-

Solution-processed halide perovskite solar cells: from coating to modules

Journal of Materials Science: Materials in Energy (2026)

-

A review on advances towards achieving net-zero carbon footprint through sustainable agrivoltaic technology

Bulletin of the National Research Centre (2025)

-

Sustainability pathways for perovskite photovoltaics

Nature Materials (2025)