Abstract

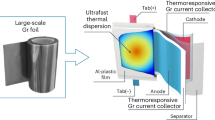

Effective thermal safety management relies on the thermal conductivity of interlayer materials, yet current designs lack the needed responsiveness for both performance and safety. Here we design a thermal-switching material with high switching ratio from thermal conduction to thermal insulation state to address this predicament. The designed thermal-switching material exhibits a wide temperature range for heat conduction (1.33 W m−1 K−1 at room temperature) and can transform to an adiabatic state within 30 s (0.1 W m−1 K−1 at around 100 °C) when heated. When applied as cell-to-cell interlayers for a module with four 50 Ah nickel–cobalt–manganese lithium-ion cells, the material not only ensures a uniform temperature distribution under normal working conditions, but more importantly prevents 80% of the heat transmission from thermal runaway, effectively avoiding catastrophic battery explosion. We believe that this thermally responsive material design will ensure safety and high performance throughout the lifespan of high-energy-density battery modules.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data supporting the findings of this study are available within the paper, Supplementary Information and Source data. Source data are provided with this paper.

References

Zeng, Y. Q., Chalise, D., Lubner, S. D., Kaur, S. & Prasher, R. S. A review of thermal physics and management inside lithium-ion batteries for high energy density and fast charging. Energy Storage Mater. 41, 264–288 (2021).

Guo, C. et al. Bifunctional liquid metals allow electrical insulating phase change materials to dual-mode thermal manage the Li-ion batteries. Nano-Micro Lett. 14, 202 (2022).

Akinlabi, A. H. & Solyali, D. Configuration, design, and optimization of air-cooled battery thermal management system for electric vehicles: a review. Renew. Sustain. Energy Rev. 125, 109815 (2020).

Feng, X. N. et al. Thermal runaway mechanism of lithium ion battery for electric vehicles: a review. Energy Storage Mater. 10, 246–267 (2018).

Jin, C. Y. et al. Model and experiments to investigate thermal runaway characterization of lithium-ion batteries induced by external heating method. J. Power Sources 504, 230065 (2021).

Liu, F. et al. Experimental study on the alleviation of thermal runaway propagation from an overcharged lithium-ion battery module using different thermal insulation layers. Energy 257, 124768 (2022).

Hao, M. L., Li, J., Park, S., Moura, S. & Dames, C. Efficient thermal management of Li-ion batteries with a passive interfacial thermal regulator based on a shape memory alloy. Nat. Energy 3, 899–906 (2018).

Wang, Q., Jiang, B., Li, B. & Yan, Y. Y. A critical review of thermal management models and solutions of lithium-ion batteries for the development of pure electric vehicles. Renew. Sustain. Energy Rev. 64, 106–128 (2016).

Lin, J. Y., Liu, X. H., Li, S., Zhang, C. & Yang, S. C. A review on recent progress, challenges and perspective of battery thermal management system. Int. J. Heat Mass Transf. 167, 120834 (2021).

Lin, Y. et al. Spider web-inspired graphene skeleton-based high thermal conductivity phase change nanocomposites for battery thermal management. Nano-Micro Lett. 13, 180 (2021).

Wu, W. X. et al. A critical review of battery thermal performance and liquid based battery thermal management. Energy Convers. Manag. 182, 262–281 (2019).

Cai, T. et al. Detection of Li-ion battery failure and venting with carbon dioxide sensors. eTransportation 7, 100100 (2021).

Rui, X. Y. et al. Synergistic effect of insulation and liquid cooling on mitigating the thermal runaway propagation in lithium-ion battery module. Appl. Therm. Eng. 199, 100100 (2021).

Yang, X. L. et al. An experimental study on preventing thermal runaway propagation in lithium-ion battery module using aerogel and liquid cooling plate together. Fire Technol. 56, 2579–2602 (2020).

Li, L. et al. Thermal-switchable, trifunctional ceramic–hydrogel nanocomposites enable full-lifecycle security in practical battery systems. ACS Nano 16, 10729–10741 (2022).

Wang, H. B. et al. A comparative analysis on thermal runaway behavior of Li(NixCoyMnz)O2 battery with different nickel contents at cell and module level. J. Hazard. Mater. 393, 122361 (2020).

Zhang, J. et al. Ice-templated large-scale preparation of two-dimensional sheets of conjugated polymers: thickness-independent flexible supercapacitance. ACS Nano 15, 8870–8882 (2021).

Guo, F. M. et al. Highly thermally conductive dielectric nanocomposites with synergistic alignments of graphene and boron nitride nanosheets. Adv. Funct. Mater. 30, 1910826 (2020).

Yao, T., Chen, K., Niu, T. T. & Yang, Y. Effects of frequency and thermal conductivity on dielectric breakdown characteristics of epoxy/cellulose/BN composites fabricated by ice-templated method. Compos. Sci. Technol. 213, 108945 (2021).

Chen, J., Huang, X. Y., Sun, B. & Jiang, P. K. Highly thermally conductive yet electrically insulating polymer/boron nitride nanosheets nanocomposite films for improved thermal management capability. ACS Nano 13, 337–345 (2019).

Yao, T. et al. Nano-BN encapsulated micro-AlN as fillers for epoxy composites with high thermal conductivity and sufficient dielectric breakdown strength. IEEE Trans. Dielectr. Electr. Insul. 27, 528–534 (2020).

Wu, W. X. et al. An experimental study of thermal management system using copper mesh-enhanced composite phase change materials for power battery pack. Energy 113, 909–916 (2016).

Li, Y. M., Hu, S. L. & Wang, D. Y. Polymer-based ceramifiable composites for flame retardant applications: a review. Compos. Commun. 21, 100405 (2020).

Ihlefeld, J. F. et al. Room-temperature voltage tunable phonon thermal conductivity via reconfigurable interfaces in ferroelectric thin films. Nano Lett. 15, 1791–1795 (2015).

Marinelli, M., Mercuri, F., Zammit, U. & Scudieri, F. Thermal conductivity and thermal diffusivity of the cyanobiphenyl (nCB) homologous series. Phys. Rev. E 58, 5860–5866 (1998).

Shin, J. et al. Thermally functional liquid crystal networks by magnetic field driven molecular orientation. ACS Macro Lett. 5, 955–960 (2016).

Meng, T. et al. Solid-state thermal memory of temperature-responsive polymer induced by hydrogen bonds. Nano Lett. 21, 3843–3848 (2021).

Chen, R. J. et al. Controllable thermal rectification realized in binary phase change composites. Sci. Rep. 5, 8884 (2015).

Dhara, S. et al. Tunable thermal conductivity in defect engineered nanowires at low temperatures. Phys. Rev. B 84, 121307 (2011).

Zheng, R. T., Gao, J. W., Wang, J. J. & Chen, G. Reversible temperature regulation of electrical and thermal conductivity using liquid–solid phase transitions. Nat. Commun. 2, 289 (2011).

Shin, J. et al. Light-triggered thermal conductivity switching in azobenzene polymers. Proc. Natl Acad. Sci. USA 116, 5973–5978 (2019).

Tomko, J. A. et al. Tunable thermal transport and reversible thermal conductivity switching in topologically networked bio-inspired materials. Nat. Nanotechnol. 13, 959–964 (2018).

Lyeo, H. K. et al. Thermal conductivity of phase-change material Ge2Sb2Te5. Appl. Phys. Lett. 89, 151904 (2006).

Lee, J. et al. Phonon and electron transport through Ge2Sb2Te5 films and interfaces bounded by metals. Appl. Phys. Lett. 102, 191911 (2013).

Acknowledgements

This work was supported by the Zhejiang Provincial Natural Science Foundation of China (LD21E070001), National Key R&D Program of China (2023YFB2408202, 2021YFB2401800), National Natural Science Foundation of China (52077113), Beijing Natural Science Foundation (3232046), National Natural Science Foundation for Excellent Young Scholars (51722703) and State Grid Corporation of China (5500-201999527A-0-0-00).

Author information

Authors and Affiliations

Contributions

Y. Yang and J.L. conceptualized the research and contributed to supervision of research, paper preparation and revision. J. Wang contributed to the experimental design, material preparation, characterization analysis and original draft preparation. X.F. contributed to the experimental design and original draft preparation. Y. Yu contributed to data collection, data analysis and paper revisions. M.Z. contributed to writing of the original draft, paper review and editing. H.H., Y.X. and J. Wu contributed to the paper review and editing.

Corresponding authors

Ethics declarations

Competing interests

Y. Yang and J. Wang filed a patent related to the fabrication of TSM submitted by Tsinghua University (Y. Yang and J. Wang are inventors, CN202211333875.4, granted patent application). The other authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks Zhenan Bao and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–3, Figs. 1–20, Table 1 and References.

Supplementary Video 1

TR propagation test for 1 Ah cell.

Supplementary Video 2

TR propagation test for 50 Ah cell.

Source data

Source Data Fig. 3

Source data for Fig. 3a,b,d,f.

Source Data Fig. 4

Source data for Fig. 4a,b,d,g.

Source Data Fig. 5

Source data for Fig. 5b,c.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Feng, X., Yu, Y. et al. Rapid temperature-responsive thermal regulator for safety management of battery modules. Nat Energy 9, 939–946 (2024). https://doi.org/10.1038/s41560-024-01535-5

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41560-024-01535-5

This article is cited by

-

Dynamic thermal management under variable operating conditions through magnetic field control

Nature Communications (2026)

-

Energy storage management in electric vehicles

Nature Reviews Clean Technology (2025)

-

Solidifying safety on cue

Nature Energy (2025)

-

Thermal responsive Rh1-Pd single-atom catalyst for controlling activity in direct formic acid fuel cells

Nature Communications (2025)

-

Special Issue on Battery Fires

Fire Technology (2025)