Abstract

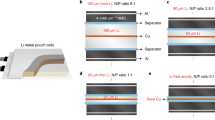

Stabilizing lithium (Li) metal anodes has long been hindered by the challenge of forming a stable solid–electrolyte interphase, stemming from the inherently high reactivity of Li metal with liquid electrolytes. Here we developed a progressive dual-passivation polymer coating strategy to stabilize Li-metal anodes, achieving exceptional cycle life of Li-metal batteries in carbonate electrolyte. Unlike current approaches, the synthesized copolymer coating passivates the Li-metal anode while also tailoring the Li-ion solvation structure by facilitating selective anion decoordination in a binary salt carbonate electrolyte. This process leads to the formation of an integrated solid–electrolyte interphase, featuring a chemical passivation outer layer predominant in LiF generated by the polymer coating and an anion-derived Li2O-prevalent inner layer from the electrolyte decomposition. Consequently, this coating strategy remarkably enhances the stability of Li-metal anodes, enabling double-layer Li||NMC811 pouch cells to maintain 80% of their initial capacity up to 611 cycles under a low electrolyte/capacity (E/C) ratio of 2.0 g Ah−1.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data supporting the conclusions of this study are provided within the main article and its Supplementary Information files.

References

Xu, W. et al. Lithium metal anodes for rechargeable batteries. Energy Environ. Sci. 7, 513–537 (2014).

Lin, D., Liu, Y. & Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotechnol. 12, 194–206 (2017).

Liu, B., Zhang, J.-G. & Xu, W. Advancing lithium metal batteries. Joule 2, 833–845 (2018).

Albertus, P., Babinec, S., Litzelman, S. & Newman, A. Status and challenges in enabling the lithium metal electrode for high-energy and low-cost rechargeable batteries. Nat. Energy 3, 16–21 (2018).

Hobold, G. M. et al. Moving beyond 99.9% Coulombic efficiency for lithium anodes in liquid electrolytes. Nat. Energy 6, 951–960 (2021).

Xu, K. Electrolytes and interphases in Li-ion batteries and beyond. Chem. Rev. 114, 11503–11618 (2014).

Cheng, X.-B. et al. A review of solid electrolyte interphases on lithium metal anode. Adv. Sci. 3, 1500213 (2016).

Peled, E. & Menkin, S. Review—SEI: past, present and future. J. Electrochem. Soc. 164, A1703–A1719 (2017).

Wu, H., Jia, H., Wang, C., Zhang, J.-G. & Xu, W. Recent progress in understanding solid electrolyte interphase on lithium metal anodes. Adv. Energy Mater. 11, 2003092 (2021).

Jiao, S. et al. Stable cycling of high-voltage lithium metal batteries in ether electrolytes. Nat. Energy 3, 739–746 (2018).

Ren, X. et al. Role of inner solvation sheath within salt–solvent complexes in tailoring electrode/electrolyte interphases for lithium metal batteries. Proc. Natl Acad. Sci. USA 117, 28603–28613 (2020).

Aurbach, D. et al. Design of electrolyte solutions for Li and Li-ion batteries: a review. Electrochim. Acta 50, 247–254 (2004).

Piao, Z., Gao, R., Liu, Y., Zhou, G. & Cheng, H.-M. A review on regulating Li+ solvation structures in carbonate electrolytes for lithium metal batteries. Adv. Mater. 35, 2206009 (2023).

Xu, R. et al. Artificial interphases for highly stable lithium metal anode. Matter 1, 317–344 (2019).

Zhou, H., Yu, S., Liu, H. & Liu, P. Protective coatings for lithium metal anodes: recent progress and future perspectives. J. Power Sources 450, 227632 (2020).

Li, J. et al. Polymers in lithium-ion and lithium metal batteries. Adv. Energy Mater. 11, 2003239 (2021).

Zhang, J.-G., Xu, W., Xiao, J., Cao, X. & Liu, J. Lithium metal anodes with nonaqueous electrolytes. Chem. Rev. 120, 13312–13348 (2020).

Cao, X., Jia, H., Xu, W. & Zhang, J.-G. Review—localized high-concentration electrolytes for lithium batteries. J. Electrochem. Soc. 168, 010522 (2021).

Li, G. et al. Stable metal battery anodes enabled by polyethylenimine sponge hosts by way of electrokinetic effects. Nat. Energy 3, 1076–1083 (2018).

Gao, Y. et al. Polymer–inorganic solid–electrolyte interphase for stable lithium metal batteries under lean electrolyte conditions. Nat. Mater. 18, 384–389 (2019).

Yu, Z. et al. A dynamic, electrolyte-blocking, and single-ion-conductive network for stable lithium-metal anodes. Joule 3, 2761–2776 (2019).

Huang, Z., Choudhury, S., Gong, H., Cui, Y. & Bao, Z. A cation-tethered flowable polymeric interface for enabling stable deposition of metallic lithium. J. Am. Chem. Soc. 142, 21393–21403 (2020).

Li, S. et al. A robust all-organic protective layer towards ultrahigh-rate and large-capacity Li metal anodes. Nat. Nanotechnol. 17, 613–621 (2022).

Huang, Z. et al. A salt-philic, solvent-phobic interfacial coating design for lithium metal electrodes. Nat. Energy 8, 577–585 (2023).

Li, G. –X. et al. Interfacial solvation-structure regulation for stable Li metal anode by a desolvation coating technique. Proc. Natl Acad. Sci. USA 121, e2311732121 (2024).

Li, G. –X. et al. Enhancing lithium-metal battery longevity through minimized coordinating diluent. Nat. Energy 9, 817–827 (2024).

Lorger, S., Usiskin, R. & Maier, J. Transport and charge carrier chemistry in lithium oxide. J. Electrochem. Soc. 166, A2215–A2220 (2019).

Zeng, H. et al. Beyond LiF: tailoring Li2O‑dominated solid electrolyte interphase for stable lithium metal batteries. ACS Nano 18, 1969–1981 (2024).

Hobold, G., Wang, C., Steinberg, K., Li, Y. & Gallant, B. M. High lithium oxide prevalence in the lithium solid–electrolyte interphase for high Coulombic efficiency. Nat. Energy 9, 580–591 (2024).

Lu, Y., Tu, Z. & Archer, L. A. Stable lithium electrodeposition in liquid and nanoporous solid electrolytes. Nat. Mater. 13, 961–969 (2014).

Suo, L. et al. Fluorine-donating electrolytes enable highly reversible 5-V-class Li metal batteries. Proc. Natl Acad. Sci. USA 115, 1156–1161 (2018).

Von Aspern, N., Roschenthaler, G.-V., Winter, M. & Cekic-Laskovic, I. Fluorine and lithium: ideal partners for high-performance rechargeable battery electrolytes. Angew. Chem. Int. Ed. 58, 15978–16000 (2019).

Tan, J., Matz, J., Dong, P., Shen, J. & Ye, M. A growing appreciation for the role of LiF in the solid electrolyte interphase. Adv. Energy Mater. 11, 2100046 (2021).

Sina, M. et al. Investigation of SEI layer formation in conversion iron fluoride cathodes by combined STEM/EELS and XPS. J. Phys. Chem. C. 119, 9762–9773 (2015).

Cao, X. et al. Stability of solid electrolyte interphases and calendar life of lithium metal batteries. Energy Environ. Sci. 16, 1548–1559 (2023).

Adams, B. D., Zheng, J., Ren, X., Xu, W. & Zhang, J. −G. Accurate determination of Coulombic efficiency for lithium metal anodes and lithium metal batteries. Adv. Energy Mater. 8, 1702097 (2018).

Green, C. P. & Sader, J. E. Torsional frequency response of cantilever beams immersed in viscous fluids with applications to the atomic force microscope. J. Appl. Phys. 92, 6262–6274 (2002).

Johnson, K. L., Kendall, K. & Roberts, A. D. Surface energy and the contact of elastic solids. Proc. R. Soc. Lond. A. 324, 301–313 (1971).

Acknowledgements

This work was supported by the Assistant Secretary for Energy Efficiency and Renewable Energy, Office of Vehicle Technologies of the US Department of Energy, through the Advanced Battery Materials Research Program (Battery500 Consortium) and Battelle-Pacific Northwest National Laboratory Subcontract Award (614551, 790825, D.W.). Y.-S.L., J.L. and S.H.K. acknowledge support from the National Science Foundation (grant number CMMI-2038494, S.H.K.).

Author information

Authors and Affiliations

Contributions

G.-X.L. and D.W. developed and designed the concept for this study. G.-X.L. and R.K. performed the electrochemical evaluation, 1H and 19F NMR analysis. A.N. performed and analysed the XPS characterization. K.W. performed and analysed the cryo-TEM characterization. Under the supervision of S.H.K., Y.-S.L. and J.L. performed the AFM characterization and wrote the corresponding experimental section. G.-X.L. and D.W. wrote and revised the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks Jong-Won Lee and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–41, Table 1 and Discussion.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, GX., Kou, R., Nguyen, A. et al. Long-cycling lithium-metal batteries via an integrated solid–electrolyte interphase promoted by a progressive dual-passivation coating. Nat Energy 10, 941–950 (2025). https://doi.org/10.1038/s41560-025-01803-y

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41560-025-01803-y

This article is cited by

-

Passivation by design

Nature Energy (2025)

-

Regulating anion chemistry in electrolytes from molecular principles to interphases engineering for high energy batteries

Science China Chemistry (2025)