Abstract

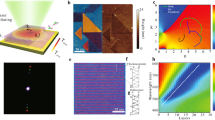

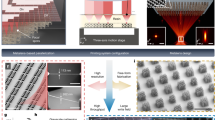

Nanoscale three-dimensional (3D) printing of metals and alloys has faced challenges in speed, miniaturization and deficiency in material properties. Traditional nanomanufacturing relies on lithographic methods with material constraints, limited resolution and slow layer-by-layer processing. This work introduces polymer-free techniques using two-photon decomposition and optical force trapping for free-space direct 3D printing of metals, metal oxides and multimetallic alloys with resolutions beyond optical limits. This method involves the two-photon decomposition of metal atoms from precursors, rapid assembly into nanoclusters via optical forces and ultrafast laser sintering, yielding dense, smooth nanostructures. Enhanced near-field optical forces from laser-induced localized surface plasmon resonance facilitate nanocluster aggregation. Our approach eliminates the need for organic materials, layer-by-layer printing and complex post-processing. Printed Mo nanowires show an excellent mechanical performance, closely resembling the behaviour of single crystals, while Mo–Co–W alloy nanowires outperform Mo nanowires. This innovation promises the customizable 3D nanoprinting of high-quality metals and metal oxides, impacting nanoelectronics, nanorobotics and advanced chip manufacturing.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are present in the paper and/or in the Supplementary Information. Additional data related to the paper are available from the corresponding author upon request.

References

Zheng, X. Y. et al. Multiscale metallic metamaterials. Nat. Mater. 15, 1100–1106 (2016).

Blasco, E. et al. Fabrication of conductive 3D gold-containing microstructures via direct laser writing. Adv. Mater. 28, 3592–3595 (2016).

Ren, Y. et al. Synthesis of orthogonally assembled 3D cross-stacked metal oxide semiconducting nanowires. Nat. Mater. 19, 203–211 (2020).

Kalinin, S. V. & Spaldin, N. A. Functional ion defects in transition metal oxides. Science 341, 858–859 (2013).

Rothschild, M. Projection optical lithography. Mater. Today 8, 18–24 (2005).

Kim, F. et al. Direct ink writing of three-dimensional thermoelectric microarchitectures. Nat. Electron. 4, 579–587 (2021).

Park, Y. G., An, H. S., Kim, J. Y. & Park, J. U. High-resolution, reconfigurable printing of liquid metals with three-dimensional structures. Sci. Adv. 5, aaw2844 (2019).

Visser, C. W. et al. Toward 3D printing of pure metals by laser-induced forward transfer. Adv. Mater. 27, 4087–4092 (2015).

Seol, S. K. et al. Electrodeposition-based 3D printing of metallic microarchitectures with controlled internal structures. Small 11, 3896–3902 (2015).

Madden, J. D. & Hunter, I. W. Three-dimensional microfabrication by localized electrochemical deposition. J. Microelectromec. Syst. 5, 24–32 (1996).

Xu, J. K., Ren, W. F., Lian, Z. X., Yu, P. & Yu, H. D. A review: development of the maskless localized electrochemical deposition technology. Int. J. Adv. Manuf. Technol. 110, 1731–1757 (2020).

El-Giar, E. M., Said, R. A., Bridges, G. E. & Thomson, D. J. Localized electrochemical deposition of copper microstructures. J. Electrochem. Soc. 147, 586 (2000).

Ren, W. F. et al. Localized electrodeposition micro additive manufacturing of pure copper microstructures. Int. J. Extrem. Manuf. 4, 015101 (2022).

Reiser, A. et al. Multi-metal electrohydrodynamic redox 3D printing at the submicron scale. Nat. Commun. 10, 1853 (2019).

Menetrey, M. et al. Targeted additive micromodulation of grain size in nanocrystalline copper nanostructures by electrohydrodynamic redox 3D printing. Small 18, 2205302 (2022).

Wang, S., Zhou, Z., Li, B., Wang, C. & Liu, Q. Progresses on new generation laser direct writing technique. Mater. Today Nano 16, 100142 (2021).

Liu, X. et al. Capillary-force-driven self-assembly of 4D-printed microstructures. Adv. Mater. 33, e2100332 (2021).

Ma, Z. C. et al. Femtosecond laser programmed artificial musculoskeletal systems. Nat. Commun. 11, 4536 (2020).

Meza, L. R., Das, S. & Greer, J. R. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science 345, 1322–1326 (2014).

Kotz, F. et al. Two-photon polymerization of nanocomposites for the fabrication of transparent fused silica glass microstructures. Adv. Mater. 33, e2006341 (2021).

Wen, X. et al. 3D-printed silica with nanoscale resolution. Nat. Mater. 20, 1506–1511 (2021).

Cao, Y. Y., Takeyasu, N., Tanaka, T., Duan, X. M. & Kawata, S. 3D metallic nanostructure fabrication by surfactant-assisted multiphoton-induced reduction. Small 5, 1144–1148 (2009).

Xu, B. B. et al. Flexible nanowiring of metal on nonplanar substrates by femtosecond-laser-induced electroless plating. Small 6, 1762–1766 (2010).

Liu, S.-F. et al. 3D nanoprinting of semiconductor quantum dots by photoexcitation-induced chemical bonding. Science 377, 1112–1116 (2022).

Anisimov, S. I., Kapeliovich, B. L. & Perel'man, T. L. Electron emission from metal surfaces exposed to ultrashort laser pulses. Sov. Phys. J. Exp. Theor. Phys. 39, 375–377 (1974).

Buffat, P. & Borel, J. P. Size effect on the melting temperature of gold particles. Phys. Rev. A 13, 2287–2298 (1976).

Lai, S. L., Guo, J. Y., Petrova, V., Ramanath, G. & Allen, L. H. Size-dependent melting properties of small tin particles: nanocalorimetric measurements. Phys. Rev. Lett. 77, 99–102 (1996).

Zhang, M. et al. Size-dependent melting point depression of nanostructures: nanocalorimetric measurements. Phys. Rev. B 62, 10548–10557 (2000).

Belonoshko, A. B. et al. Molybdenum at high pressure and temperature: melting from another solid phase. Phys. Rev. Lett. 100, 135701 (2008).

Das, R., Deo, M., Mukherjee, J. & Rao, M. S. R. Strain induced FCC to BCC structural change in sputtered molybdenum thin films. Surf. Coat. Technol. 353, 292–299 (2018).

Bosnell, J. R. & Voisey, U. C. The effect of deposition parameters on the structure and resistivity of molybdenum films. Thin Solid Films 6, 107–111 (1970).

Denbigh, P. N. & Marcus, R. B. Structure of very thin tantalum and molybdenum films. J. Appl. Phys. 37, 4325–4330 (2004).

Wang, S. J. et al. Deformation-induced structural transition in body-centred cubic molybdenum. Nat. Commun. 5, 3433 (2014).

Kitakami, O., Sato, H., Shimada, Y., Sato, F. & Tanaka, M. Size effect on the crystal phase of cobalt fine particles. Phys. Rev. B 56, 13849–13854 (1997).

Shin, D. et al. Comparison of different tungsten precursors for preparation of tungsten nanopowder by RF induction thermal plasma. Int. J. Refract. Met. Hard Mat. 86, 104995 (2020).

Redel, E., Thomann, R. & Janiak, C. Use of ionic liquids (ILs) for the IL-anion size-dependent formation of Cr, Mo and W nanoparticles from metal carbonyl M(CO)6 precursors. Chem. Commun. 2008, 1789–1791 (2008).

Reiser, A. et al. Metals by micro-scale additive manufacturing: comparison of microstructure and mechanical properties. Adv. Funct. Mater. 30, 1910491 (2020).

Kim, J. Y. & Greer, J. R. Size-dependent mechanical properties of molybdenum nanopillars. Appl. Phys. Lett. 93, 101916 (2008).

Schneider, A. S., Clark, B. G., Frick, C. P., Gruber, P. A. & Arzt, E. Effect of orientation and loading rate on compression behavior of small-scale Mo pillars. Mater. Sci. Eng. A 508, 241–246 (2009).

Huang, L. et al. A new regime for mechanical annealing and strong sample-size strengthening in body centred cubic molybdenum. Nat. Commun. 2, 547 (2011).

Lowry, M. B. et al. Achieving the ideal strength in annealed molybdenum nanopillars. Acta Mater. 58, 5160–5167 (2010).

Oehlerking, F., Stawovy, M. T., Ohm, S. & Imandoust, A. Microstructural characterization and mechanical properties of additively manufactured molybdenum and molybdenum alloys. Int. J. Refract. Met. Hard Mater. 109, 105971 (2022).

Kim, J.-Y., Jang, D. & Greer, J. R. Crystallographic orientation and size dependence of tension–compression asymmetry in molybdenum nano-pillars. Int. J. Plast. 28, 46–52 (2012).

Kim, J.-Y., Jang, D. & Greer, J. R. Tensile and compressive behavior of tungsten, molybdenum, tantalum and niobium at the nanoscale. Acta Mater. 58, 2355–2363 (2010).

Kim, J.-Y. & Greer, J. R. Tensile and compressive behavior of gold and molybdenum single crystals at the nano-scale. Acta Mater. 57, 5245–5253 (2009).

Chaudhari, P. & Turnbull, D. Structure and properties of metallic glasses. Science 199, 11–21 (1978).

Wang, W. H. The elastic properties, elastic models and elastic perspectives of metallic glasses. Prog. Mater. Sci. 57, 487–656 (2012).

Chen, N. et al. Formation and properties of Au-based nanograined metallic glasses. Acta Mater. 59, 6433–6440 (2011).

Acknowledgements

We thank L. Li from the Core Facility of Wuhan University for his assistance with TEM analysis; Y. Zhang from the Core Facility of Wuhan University for her assistance with focused ion beam testing; and engineer X. Ji for the support with the nanomechanical testing at the microscopic in situ mechanics laboratory at the Institute of Water Engineering Sciences at Wuhan University.

Author information

Authors and Affiliations

Contributions

Y.W. and G.J.C. conceived this study. Y.W. carried out the experimental treatments, material characterization and data analysis. C.Y. carried out data analysis. W.T. carried out the in situ mechanical test. F.L. provided resources. Y.W. and G.J.C. wrote the draught of the paper. G.J.C. supervised the project. All authors discussed the results and commented on the paper. Y.W., C.Y. and W.T. contributed equally to this work.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Jianchao Ye and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–18 and Discussion.

Supplementary Video 1

Printing video of the spiral array.

Supplementary Video 2

Printing video of the diamond crystal structure.

Supplementary Video 3

Printing video of the triangular truss structure.

Supplementary Video 4

Printing video of the buckyball structure.

Supplementary Video 5

Printing video of the 3D flower structure.

Supplementary Video 6

Real-time video of the compression test on the 3D lattice structure.

Supplementary Video 7

Real-time video of the in situ compression of a Mo nanowire.

Supplementary Video 8

Real-time video of in situ tension of a Mo nanowire.

Supplementary Video 9

Real-time video of in situ tension of an alloy nanowire.

Supplementary Video 10

Printing videos with different irradiation times at single points.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Yi, C., Tian, W. et al. Free-space direct nanoscale 3D printing of metals and alloys enabled by two-photon decomposition and ultrafast optical trapping. Nat. Mater. 23, 1645–1653 (2024). https://doi.org/10.1038/s41563-024-01984-z

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41563-024-01984-z

This article is cited by

-

Enhanced optical trapping by concentrated local fields in metallic semi-continuous films

Discover Nano (2025)

-

Static mechanical cloaking and camouflage from disorder

Nature Communications (2025)

-

Ligand-exchange-assisted printing of colloidal nanocrystals to enable all-printed sub-micron optoelectronics

Nature Communications (2025)

-

Inkjet printing of adamantane-type organotin sulfide clusters featuring extreme nonlinear optical properties

Communications Materials (2025)

-

Rapid 3D printing of hierarchical nanoporous copper structures with self-disintegration capability

Nature Communications (2025)