Abstract

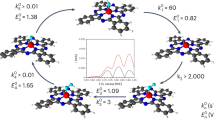

The lack of mechanistic understanding and catalyst design principles for alkaline electrolytes, especially for the sluggish oxygen reduction reaction, has impeded the advancement of alkaline fuel cells. Here we propose a modified volcano plot and apply this rationale to strategically design Pt nanosheets with PdHx nanosheets substrates. This catalyst exhibited high stability with a specific activity of 1.71 mA cm−2 at 0.95 V versus the reversible hydrogen electrode, surpassing the benchmark of Pt/C by 49-fold. Spectroscopic, electrochemical and electron microscopic characterizations revealed that such performance enhancement originated from tensile-strained Pt{111} facets, improving oxidative stability and suppressing carbon corrosion. In fuel cell testing, the catalyst enabled a peak power density of 1.67 W cm−2 with a loading of 10 µgPGM Cathode cm−2. Further optimization delivered a peak power density of 21.7 W mg−1PGM Cathode+Anode with a total specific catalyst cost US$1.27 kW−1, surpassing the US Department of Energy’s Pt group metal loading and cost targets. This study provides valuable insights into catalyst design for the alkaline oxygen reduction reaction.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data supporting the findings of this study are available in the Article and its Supplementary Information. Additional data are available from the corresponding authors on request. Source data are provided with this paper.

References

Britton, B. et al. Perspective—the next decade of AEMFCs: near-term targets to accelerate applied R&D. J. Electrochem. Soc. 167, 084514 (2020).

Luo, M. & Koper, M. T. M. A kinetic descriptor for the electrolyte effect on the oxygen reduction kinetics on Pt(111). Nat. Catal. 5, 615–623 (2022).

She, Z. W. et al. Combining theory and experiment in electrocatalysis: insights into materials design. Science 355, eaad4998 (2017).

Ooka, H., Huang, J. & Exner, K. S. The Sabatier principle in electrocatalysis: basics, limitations, and extensions. Front. Energy Res. 9, 654460 (2021).

Sabatier, P. How I have been led to the direct hydrogenation method by metallic catalysts. Ind. Eng. Chem. 18, 1005–1008 (1926).

Kulkarni, A., Siahrostami, S., Patel, A. & Nørskov, J. K. Understanding catalytic activity trends in the oxygen reduction reaction. Chem. Rev. 118, 2302–2312 (2018).

Nørskov, J. K. et al. Origin of the overpotential for oxygen reduction at a fuel-cell cathode. J. Phys. Chem. B 108, 17886–17892 (2004).

Wang, Y. J. et al. Carbon-supported Pt-based alloy electrocatalysts for the oxygen reduction reaction in polymer electrolyte membrane fuel cells: particle size, shape, and composition manipulation and their impact to activity. Chem. Rev. 115, 3433–3467 (2015).

Lim, C., Fairhurst, A. R., Ransom, B. J., Haering, D. & Stamenkovic, V. R. Role of transition metals in Pt alloy catalysts for the oxygen reduction reaction. ACS Catal. 13, 14874–14893 (2023).

Stamenkovic, V. R., Strmcnik, D., Lopes, P. P. & Markovic, N. M. Energy and fuels from electrochemical interfaces. Nat. Mater. 16, 57–69 (2016).

Li, H. et al. Oxidative stability matters: a case study of pallidum hydride nanosheets for alkaline fuel cells. J. Am. Chem. Soc. 144, 8106–8114 (2022).

Zhou, M. et al. Improvement of oxygen reduction performance in alkaline media by tuning phase structure of Pd-Bi nanocatalysts. J. Am. Chem. Soc. 143, 15891–15897 (2021).

Wang, L. et al. Tunable intrinsic strain in two-dimensional transition metal electrocatalysts. Science 363, 870–874 (2019).

Luo, M. et al. PdMo bimetallene for oxygen reduction catalysis. Nature 574, 81–85 (2019).

Gómez-Marín, A. M., Rizo, R. & Feliu, J. M. Oxygen reduction reaction at Pt single crystals: a critical overview. Catal. Sci. Technol. 4, 1685–1698 (2014).

Li, M. F., Liao, L. W., Yuan, D. F., Mei, D. & Chen, Y. X. pH effect on oxygen reduction reaction at Pt(111) electrode. Electrochim. Acta 110, 780–789 (2013).

Jensen, K. D. et al. Elucidation of the oxygen reduction volcano in alkaline media using a copper–platinum(111) alloy. Angew. Chem. Int. Ed. 57, 2800–2805 (2018).

Suntivich, J. et al. Design principles for oxygen-reduction activity on perovskite oxide catalysts for fuel cells and metal–air batteries. Nat. Chem. 3, 546–550 (2011).

Friebel, D. et al. In situ X-ray probing reveals fingerprints of surface platinum oxide. Phys. Chem. Chem. Phys. 13, 262–266 (2010).

McCaulley, J. A. In-situ X-ray absorption spectroscopy studies of hydride and carbide formation in supported palladium catalysts. J. Phys. Chem. 97, 10372–10379 (1993).

Liu, G. et al. Hydrogen-intercalation-induced lattice expansion of Pd@Pt core-shell nanoparticles for highly efficient electrocatalytic alcohol oxidation. J. Am. Chem. Soc. 143, 11262–11270 (2021).

Sasaki, K., Marinkovic, N., Isaacs, H. S. & Adzic, R. R. Synchrotron-based in situ characterization of carbon-supported platinum and platinum monolayer electrocatalysts. ACS Catal. 6, 69–76 (2016).

Takimoto, D. et al. Platinum nanosheets synthesized via topotactic reduction of single-layer platinum oxide nanosheets for electrocatalysis. Nat. Commun. 14, 19 (2023).

Stamenkovic, V. R. et al. Improved oxygen reduction activity on Pt3Ni(111) via increased surface site availability. Science 315, 493–497 (2007).

Liang, Y., McLaughlin, D., Csoklich, C., Schneider, O. & Bandarenka, A. S. The nature of active centers catalyzing oxygen electro-reduction at platinum surfaces in alkaline media. Energy Environ. Sci. 12, 351–357 (2019).

Govindarajan, N., Xu, A. & Chan, K. How pH affects electrochemical processes. Science 375, 379–380 (2022).

Kelly, S. R., Kirk, C., Chan, K. & Nørskov, J. K. Electric field effects in oxygen reduction kinetics: rationalizing pH dependence at the Pt(111), Au(111), and Au(100) electrodes. J. Phys. Chem. C 124, 14581–14591 (2020).

Briega-Martos, V., Herrero, E. & Feliu, J. M. Effect of pH and water structure on the oxygen reduction reaction on platinum electrodes. Electrochim. Acta 241, 497–509 (2017).

Li, H. et al. Analysis of the limitations in the oxygen reduction activity of transition metal oxide surfaces. Nat. Catal. 4, 463–468 (2021).

Tian, X. et al. Engineering bunched Pt-Ni alloy nanocages for efficient oxygen reduction in practical fuel cells. Science 366, 850–856 (2019).

Wang, Q. et al. Unveiling the pitfalls of comparing oxygen reduction reaction kinetic data for Pd-based electrocatalysts without the experimental conditions of the current−potential curves. ACS Energy Lett. 7, 952–957 (2022).

He, T. et al. Mastering the surface strain of platinum catalysts for efficient electrocatalysis. Nature 598, 76–81 (2021).

Bugaev, A. L. et al. Palladium carbide and hydride formation in the bulk and at the surface of palladium nanoparticles. J. Phys. Chem. C 122, 12029–12037 (2018).

Kabiraz, M. K. et al. Ligand effect of shape-controlled β-palladium hydride nanocrystals on liquid-fuel oxidation reactions. Chem. Mater. 31, 5663–5673 (2019).

Zhang, J. et al. Controlling the catalytic activity of platinum-monolayer electrocatalysts for oxygen reduction with different substrates. Angew. Chem. Int. Ed. 44, 2132–2135 (2005).

Xu, Y., Ruban, A. V. & Mavrikakis, M. Adsorption and dissociation of O2 on Pt-Co and Pt-Fe alloys. J. Am. Chem. Soc. 126, 4717–4725 (2004).

Rizo, R., Sitta, E., Herrero, E., Climent, V. & Feliu, J. M. Towards the understanding of the interfacial pH scale at Pt(111) electrodes. Electrochim. Acta 162, 138–145 (2015).

Kuo, D. Y., Lu, X., Hu, B., Abruña, H. D. & Suntivich, J. Rate and mechanism of electrochemical formation of surface-bound hydrogen on Pt(111) single crystals. J. Phys. Chem. Lett. 13, 6383–6390 (2022).

Editor, G. et al. Stripping voltammetry of carbon monoxide oxidation on stepped platinum single-crystal electrodes in alkaline solution. Phys. Chem. Chem. Phys. 10, 3802–3811 (2008).

Jia, Q. et al. Activity descriptor identification for oxygen reduction on platinum-based bimetallic nanoparticles: in situ observation of the linear composition–strain–activity relationship. ACS Nano 9, 387–400 (2015).

Roth, C. et al. Determination of O[H] and CO coverage and adsorption sites on PtRu electrodes in an operating PEM fuel cell. J. Am. Chem. Soc. 127, 14607–14615 (2005).

Teliska, M., O’Grady, W. E. & Ramaker, D. E. Determination of O and OH adsorption sites and coverage in situ on Pt electrodes from Pt L23 X-ray absorption spectroscopy. J. Phys. Chem. B 109, 8076–8084 (2005).

Meier, J. C. et al. Design criteria for stable Pt/C fuel cell catalysts. Beilstein J. Nanotechnol. 5, 44–67 (2014).

Zeng, R. et al. Methanol oxidation using ternary ordered intermetallic electrocatalysts: a DEMS study. ACS Catal. 10, 770–776 (2020).

Cherstiouk, O. V. et al. Microstructure effects on the electrochemical corrosion of carbon materials and carbon-supported Pt catalysts. Electrochim. Acta 55, 8453–8460 (2010).

Wang, X. X., Swihart, M. T. & Wu, G. Achievements, challenges and perspectives on cathode catalysts in proton exchange membrane fuel cells for transportation. Nat. Catal. 2, 578–589 (2019).

Hydrogen and Fuel Cell Technologies Office DOE Technical Targets for Polymer Electrolyte Membrane Fuel Cell Components (US DOE, 2022); https://www.energy.gov/eere/fuelcells/doe-technical-targets-polymer-electrolyte-membrane-fuel-cell-components

Setzler, B. P., Zhuang, Z., Wittkopf, J. A. & Yan, Y. Activity targets for nanostructured platinum-group-metal-free catalysts in hydroxide exchange membrane fuel cells. Nat. Nanotechnol. 11, 1020–1025 (2016).

Douglin, J. C. et al. High-performance ionomerless cathode anion-exchange membrane fuel cells with ultra-low-loading Ag–Pd alloy electrocatalysts. Nat. Energy 8, 1262–1272 (2023).

Kim, D., Resasco, J., Yu, Y., Asiri, A. M. & Yang, P. Synergistic geometric and electronic effects for electrochemical reduction of carbon dioxide using gold–copper bimetallic nanoparticles. Nat. Commun. 5, 4948 (2014).

Lima, F. H. B. et al. Catalytic activity–d-band center correlation for the O2 reduction reaction on platinum in alkaline solutions. J. Phys. Chem. C 111, 404–410 (2007).

Mustain, W. E., Chatenet, M., Page, M. & Kim, Y. S. Durability challenges of anion exchange membrane fuel cells. Energy Environ. Sci. 13, 2805–2838 (2020).

Wang, H. & Abruña, H. D. IrPdRu/C as H2 oxidation catalysts for alkaline fuel cells. J. Am. Chem. Soc. 139, 6807–6810 (2017).

Leshchev, D. et al. The Inner Shell Spectroscopy beamline at NSLS-II: a facility for in situ and operando X-ray absorption spectroscopy for materials research. J. Synchrotron Radiat. 29, 1095–1106 (2022).

Yang, Y. et al. In situ X-ray absorption spectroscopy of a synergistic Co-Mn oxide catalyst for the oxygen reduction reaction. J. Am. Chem. Soc. 141, 1463–1466 (2019).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 12, 537–541 (2005).

Yang, Y. et al. High-loading composition-tolerant Co-Mn spinel oxides with performance beyond 1 W/cm2 in alkaline polymer electrolyte fuel cells. ACS Energy Lett. 4, 1251–1257 (2019).

Acknowledgements

This work was supported by the Center for Alkaline Based Energy Solutions (CABES), part of the Energy Frontier Research Center (EFRC) program supported by the US DOE, Office of Science, Office of Basic Energy Sciences, under grant number DE-SC-0019445 (H.L., R.Z., Z.S., H.W., M.M.T-C., W.X., M.K., A.M.V., Q.L., D.M. and H.D.A). This work made use of the TEM facilities at the Cornell Center for Materials Research (CCMR), which are supported through the National Science Foundation Materials Research Science and Engineering Center (NSF MRSEC) program (DMR1719875; Z.S. and D.M.). This research used the ISS (8-ID) beamline of the National Synchrotron Light Source II, a US DOE, Office of Science User Facility, operated for the US DOE, Office of Science, by Brookhaven National Laboratory under contract number DE-SC0012704 (D.L. and E.S.). H.L. gratefully acknowledges support from the Scientific Foundation for Youth Scholars of Shenzhen University (868-000001033351; H.L.).

Author information

Authors and Affiliations

Contributions

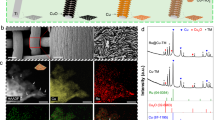

H.L., R.Z. and H.D.A. conceived the research and wrote the paper. H.L., R.Z. and H.W. performed the catalyst synthesis, electrochemical measurements and general characterization. Z.S. conducted the STEM/EDX characterization and analysis, supervised by D.A.M. H.L., R.Z., D.L. and E.S. performed the operando XAS characterization. H.L. and R.Z. handled the XAS data analysis and operando XAS electrochemical cell design with the help of M.M.T.-C., W.X. and A.M.V. H.L. performed the MEA testing with the assistance of Q.L., A.M.V. and M.-J.K. H.D.A. supervised the research. All authors contributed to the discussions and revisions of the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Min-Rui Gao, Hirohito Ogasawara and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Comparison of ORR activities on Polycrystalline Pt (Poly_Pt) and Polycrystalline Pd (Poly_Pd) in acidic and alkaline electrolytes.

a, O2-saturated 0.1 M HClO4. b, O2-saturated 0.01 M HClO4. c, O2-saturated 0.01 M KOH. d, O2-saturated 0.1 M KOH. e, O2-saturated 1.0 M KOH. Scan rate: 5 mV s−1; rotation rate: 1,600 rpm. f, Specific activity measured at 0.85 V vs. RHE. The comparison showed that the ORR performance of polycrystalline Pd could rival, and even surpass, that of polycrystalline Pt at higher pH values, despite polycrystalline Pd being significantly less active than Pt at lower pHs.

Extended Data Fig. 2 CO stripping and ORR performance of Pt/C, Pd/C and a series of PdHx@Pt NS catalysts prepared with different Pt precursor molar ratios (5%, 10%, 15%, 25% and 50%).

a, CO stripping voltammograms of different catalysts in Ar-saturated 1.0 M KOH solution. Since Pt was deposited onto the surface of PdHx NS, the surface coverage increased with higher Pt precursor ratios. Accordingly, the CO stripping peak of PdHx NS initially exhibited a much more positive peak potential than Pt/C, but progressively shifted negatively as the Pt ratio increased. Notably, PdHx@Pt NS showed a peak position matching that of Pt/C, indicating that its surface was nearly fully covered with Pt. b, c, ORR polarization profiles of catalysts during anodic (b) and cathodic (c) scans in O2-saturated 1.0 M KOH solution. Even though PdHx@Pt NS did not significantly enhance the ORR activity (ΔE1/2 = 5 mV compared to PdHx NS) during the anodic scans, an activity improvement of 43 mV was achieved in the cathodic scans, pointing to the superior oxidative stability of PdHx@Pt NS.

Extended Data Fig. 3 Operando XANES spectra at the Pt L3-edge.

a, b, Spectra of PdHx@Pt NS (a) and Pt/C (b) measured under steady-state conditions. c, d, Comparisons of XANES spectra collected at 0.3 V for PdHx@Pt NS (c) and Pt/C (d) during different scan directions. The 0.3 V during anodic scan indicates the initial potential when the potential was ramped from 0.3 V to 1.1 V. The 0.3 V during cathodic scan means the applied potential when it decreased from 1.1 V to 0.3 V.

Extended Data Fig. 4 XANES and EXAFS analyses of catalyst stability after 10,000 ADT cycles.

a, b, XANES spectra of PdHx@Pt NS (a) and Pt/C (b) before and after 10,000 ADT cycles. PdHx@Pt NS displayed no change before and after ADT cycles while Pt/C exhibited a clear diminution in intensity at the white line. c, d, Pd K-edge XANES (c) and Fourier transforms of k3-weighted EXAFS spectra (d) of PdHx@Pt NS after 10,000 cycles. PdHx@Pt NS displayed no substantial changes before and after ADT cycles.

Supplementary information

Supplementary Information

Supplementary Figs. 1–18, Tables 1–4 and Notes 1–3.

Source data

Source Data Fig. 1

ORR polarization data for the catalysts plotted in Fig. 1a–e, data of the half-wave potentials versus oxygen binding energy plotted in Fig. 1f and white-line or i1/i2 intensity data from the XANES spectra plotted in Fig. 1g,h.

Source Data Fig. 2

XANES and EXAFS spectral data at the Pd K edge plotted in Fig. 2d,e, XANES and EXAFS spectral data at the Pt L3 edge plotted in Fig. 2f,g, XRD data plotted in Fig. 2h and XPS data plotted in Fig. 2i.

Source Data Fig. 3

CV and ORR polarization data in alkaline media plotted in Fig. 3a,b, CV and ORR polarization data in acidic media plotted in Fig. 3d,e and the corresponding mass and specific activity data plotted in Fig. 3c,f.

Source Data Fig. 4

Operando XANES and Δµ(E) spectral data plotted in Fig. 4a–e, and white-line or i1/i2 intensity data from the XANES spectra plotted in Fig. 4g–i.

Source Data Fig. 5

ORR polarization data before and after the ADT cycles plotted in Fig. 5a, EXAFS spectral data plotted in Fig. 5c,d, DEMS data plotted in Fig. 5e and temperature-dependent ORR data plotted in Fig. 5f.

Source Data Fig. 6

AEMFC polarization and power density data plotted in Fig. 6a,b,d, stability test data plotted in Fig. 6c and data of cost versus PGM loading analysis plotted in Fig. 6e.

Source Data Extended Data Fig./Table 1

ORR polarization data for polycrystalline Pd and Pt electrodes plotted in Extended Data Fig. 1a–e and specific activity data plotted in Extended Data Fig. 1f.

Source Data Extended Data Fig./Table 2

CO stripping voltammogram data plotted in Extended Data Fig. 2a and ORR polarization data during anodic and cathodic scans plotted in Extended Data Fig. 2b,c.

Source Data Extended Data Fig./Table 3

Operando XANES spectral data at the Pt L3 edge plotted in Extended Data Fig. 3a,d.

Source Data Extended Data Fig./Table 4

XANES and EXAFS spectral data for catalysts before and after the ADT cycles plotted in Extended Data Fig. 4a–d.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, H., Zeng, R., Shi, Z. et al. Rational design of high-performance low-loading oxygen reduction catalysts for alkaline fuel cells. Nat. Mater. (2026). https://doi.org/10.1038/s41563-025-02422-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41563-025-02422-4