Abstract

We developed a computational-based model for simulating adsorption capacity of a novel layered double hydroxide (LDH) and metal organic framework (MOF) nanocomposite in separation of ions including Pb(II) and Cd(II) from aqueous solutions. The simulated adsorbent was a composite of UiO-66-(Zr)-(COOH)2 MOF grown onto the surface of functionalized Ni50-Co50-LDH sheets. This novel adsorbent showed high surface area for adsorption capacity, and was chosen to develop the model for study of ions removal using this adsorbent. A number of measured data was collected and used in the simulations via the artificial intelligence technique. Artificial neural network (ANN) technique was used for simulation of the data in which ion type and initial concentration of the ions in the feed was selected as the input variables to the neural network. The neural network was trained using the input data for simulation of the adsorption capacity. Two hidden layers with activation functions in form of linear and non-linear were designed for the construction of artificial neural network. The model’s training and validation revealed high accuracy with statistical parameters of R2 equal to 0.99 for the fitting data. The trained ANN modeling showed that increasing the initial content of Pb(II) and Cd(II) ions led to a significant increment in the adsorption capacity (Qe) and Cd(II) had higher adsorption due to its strong interaction with the adsorbent surface. The neural model indicated superior predictive capability in simulation of the obtained data for removal of Pb(II) and Cd(II) from an aqueous solution.

Similar content being viewed by others

Introduction

Artificial intelligence (AI) has recently attracted much attention for simulating physical, biochemical, and chemical processes to provide a simulation tool for process understanding, optimization, and improvement. Basically, mathematical models and simulations are performed to understand the process, and minimize the operational costs, while maximizing the process efficiency1,2,3,4,5,6,7. Simulation and optimization of processes have been used in many different areas in the recent years8,9,10,11. The models developed using artificial intelligence techniques require measured data for training the algorithm. Also, selection of artificial intelligence algorithm depends on the process, and the degree of complexity12,13. Artificial intelligence-based simulation methodology and models can be employed for the systems that are too complex to be formulated via mechanistic models. Therefore, the artificial intelligence models can help simulate complex processes for optimization and process improvement11,14,15.

Recently, artificial intelligence models have been combined with computational fluid dynamics techniques to improve the simulations and reduce the computational costs. In this hybrid modeling approach, the CFD simulation results are used as the input for artificial intelligence model to predict fluid flow, heat transfer, mass transfer, chemical reactions, and multiphase flow systems16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31. The artificial intelligence models have shown to be more accurate and faster than the mechanistic models in terms of computation which make them attractive for implementation in prediction of physical and chemical processes. The main disadvantage of these modes is that they need measured data for training the process, and these models are not of pure predictive nature13.

These artificial intelligence models can be applied for simulation of ion adsorption to the surface of nanoporous materials with high accuracy. Adsorption has indicated to be an efficient technique for wastewater treatment with low content of impurities32,33,34. Due to the complexity of nanoporous materials, mechanistic models are difficult to be developed and artificial intelligence-based models are preferred in this case. Adsorption using nanoporous materials and nanocomposite materials have been recently simulated via semi-empirical and empirical correlations35,36,37,38,39,40. Good agreement has been obtained for implementing empirical models for simulation of adsorption process, however these models show poor applicability in considering the effect of various parameters on adsorption capacity of the used adsorbent in the process. These models have been developed for mesoporous silica and nanocomposite materials in removal of organic materials and heavy metals from water11,41,42,43,44,45,46,47,48,49,50,51,52.

Development of artificial intelligence models for simulation of ion adsorption onto the surface of nanomaterials would be attractive for design of materials and optimization of the process53. For example, Ayaz and Khan54 performed a survey on the application of AI techniques on the modeling of heavy metal contaminants removal from wastewater using Levenberg–Marquardt (LM) and scale conjugate Gradient (SCG). Yaqub et al.55 used ANN and adaptive neuro-fuzzy inference system (ANFIS) to investigate the prediction of Cr(VI) adsorption on polymer inclusion membranes. The modeling results confirmed the high accuracy of these models, but the ANN results were more reliable than the outcomes obtained from ANFIS model. Usually, if the model is validated through comparing with experimental results, then the model can be used to map the adsorption process and find the optimum conditions56,57.

In order to propose and implement a high-performance model for prediction of adsorption process using hybrid materials with nanostructure, herein we demonstrate for the first time simulation of a novel Ni50Co50-LDH-COOH/UiO-66(Zr)-(COOH)2 nanocomposite (LDH/MOF) in separation of Pb(II) and Cd(II) solutes from water considering various conditions by development of an artificial intelligence-based model58. Different adsorbents had been used as effective adsorbents for pollutant removal from aqueous media such as MOFs, natural materials, and mesoporous silica59,60,61,62. In the recent years, metal organic framework (MOF) adsorbents have attracted so many attentions for this application due to their fantastic properties63,64. These models outperformed the traditional empirical correlations in fitting adsorption data such as the well-known Langmuir adsorption model13. The work is conducted by development of artificial neural network model considering ion type as well as initial ion concentrations as the inputs, while the adsorption capacity of the nanocomposite was considered as the only simulated output by the neural model. Training and cross-validation are performed to evaluate the accuracy of the neural model in description of the ion removal via the novel Ni50Co50-LDH-COOH/ UiO-66(Zr)-(COOH)2 nanocomposite.

Materials and methods

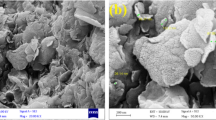

The model is developed for simulation of ions removal using a novel nanocomposite made of functionalized Ni50Co50-LDH-COOH/UiO-66(Zr)-(COOH)2. Two ions are considered in this study including Pb(II) and Cd(II) for removal from water at different conditions by changing the ions concentration. The ions were considered at different initial concentrations between 0.5 and 250 mg/L. The data are collected from literature58, and this work is focused on the simulation of adsorption using an artificial intelligence model. We have also provided a little description about the measurements. According to this research58 as the needed materials for production of adsorbent were in analytical grade and used as received. Zirconium (IV) chloride (ZrCl4), Nickel(II) nitrate hexahydrate, Pyromellitic acid, Cobalt(II) nitrate hexahydrate, (3-Aminopropyl)triethoxysilane, and Cadmium nitrate tetrahydrate were obtained from Sigma-Aldrich. Also, ethanol, ethylene glycol, sodium hydroxide, acetone, and hydrochloric acid were obtained from Merck, as reported in Ref.58.

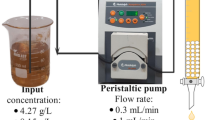

The nanocomposite of LDH/MOF which is considered in this study has indicated that this novel adsorbent can be utilized for the separation and capture of ions owing to its adsorption surface area in the interconnected nanoporous network. Therefore, the separation performance of the nanocomposite for the separation of Cd(II) and Pb(II) ions were evaluated. As reported in literature58, the adsorption experiments were carried out in conventional batch mode at temperature of \(T\) = 25 ℃, by variations of initial ions concentration in the feed solution. The adsorption capacity of the adsorbent which is used as the only simulated output is estimated using53,58:

where \({Q}_{\mathrm{e}}\) and \({C}_{\mathrm{e}}\) denote the equilibrium capacity of the adsorbent (mg g–1) and the ion concentration (mg g–1) at the equilibrium58.

Modeling and simulation

Simulation of the adsorption data is here carried out using artificial neural network (ANN) method. In this technique, training the data is carried out to obtain the weight and bias parameters for the neural network65,66,67. The structure of the ANN model is represented in Fig. 1 in which the model has been developed by designing two hidden layers in which 2 non-linear (TanH), 1 linear, and 1 Gaussian function are used in the hidden layers’ nodes. The functions and nodes are utilized to estimate the output parameter which is adsorption capacity (Qe). The artificial neural network calculations were performed using JMP software which utilizes multi-layer perceptron neural network for simulation of the target value. The software is a powerful tool for prediction of output and making a relation between the input and output variables68,69. The simulations were performed using KFold as the validation technique in which K was set at 3 implying that the data points are split into three groups, and the best group with the minimum deviation is selected as the validation column. In this method of simulation using neural network, the designed hidden nodes are nonlinear functions of the original input variables.

Results and discussion

Simulation results

The simulation results obtained by artificial neural network model are listed in Table 1 for the training and validation. Also, the predicted Qe values versus the experimental values are collected and compared in Fig. 2, while the residual of fittings are represented in Fig. 3. The results of simulated Qe using the neural network model confirmed that the great agreement has been achieved with high accuracy, and the R2 equal to 0.99 has been calculated for training and validation of the network in this work. Also other statistical parameters including SSE and RMSE indicated great values implying that the model has been properly trained70 and the model can simulate the process for removal of Pb(II) and Cd(II) from water by the nanocomposite adsorbent of functionalized LDH/MOF.

The fitted and trained model was further used to interpret the obtained adsorption data71. The results of simulations as 3D and 2D plots of Qe are illustrated in Figs. 4 and 5. Also, the scatterplots of predicted Qe using the developed ANN are illustrated in Figs. 6 and 7. In Fig. 4, the 3D plot of simulated Qe versus ion type and initial concentration of ions (C0) is indicated. It is observed that initial concentration can have effect on the adsorption capacity. The initial concentration can change the driving force for mass transfer of the solute from the bulk of feed solution towards the nanocomposite adsorbent. Indeed, increasing the initial content of the ions in the solution will increase the adsorption capacity (Qe) significantly as predicted by the developed neural network model. Moreover, the results presented in Fig. 5 indicate that Cd has higher adsorption on the surface of nanocomposite adsorbent which is due to its favorable interaction with the functional groups on the surface of adsorbent53,58,70. A review on different reported results for ML modeling methods and specially ANN method, for adsorption of Cd and Pb heavy metal ions from aquatic solution is reported in Table 272.

Conclusions

Removal of Pb(II) and Cd(II) ions from water using a nanocomposite of MOF/LDH was studied in this work. Computational studies were carried out in order to simulate the process to understand the effect of parameters affecting the adsorption process. The model was developed based on artificial neural network considering a combination of linear and non-linear transfer functions which were designed inside the hidden layers. The optimum designed neural network indicated high accuracy in terms of fitting the data with R2 more than 0.99 which is a great agreement. The model was further assessed in prediction of adsorption capacity of the process and revealed that the initial solute concentration has major influence on the adsorption removal rate due to changing the mass transfer rate and driving force of the separation process. The modeling results showed that increasing the initial content of both heavy metal ions in the solution will increase the adsorption capacity (Qe) significantly. Moreover, it was confirmed that Cd had higher adsorption on the surface of MOF/LDH nanocomposite adsorbent which is due the strong interaction between the solute and the adsorbent surface. The ANN model strategy indicated to be rigorous and robust in simulation of adsorption data for the studied ions and can be further developed for other ions and organic materials.

References

Rezakazemi, M., Mosavi, A. & Shirazian, S. ANFIS pattern for molecular membranes separation optimization. J. Mol. Liq. 274, 470–476. https://doi.org/10.1016/j.molliq.2018.11.017 (2019).

Shirazian, S., Kuhs, M., Darwish, S., Croker, D. & Walker, G. M. Artificial neural network modelling of continuous wet granulation using a twin-screw extruder. Int. J. Pharmaceut. 521, 102–109. https://doi.org/10.1016/j.ijpharm.2017.02.009 (2017).

Ranjbar, M., Shirazian, S., Parto, S. G. & Ahmadi, M. Computational fluid dynamics simulation of mass transfer in the separation of fermentation products using nanoporous membranes. Chem. Eng. Technol. 36, 728–732. https://doi.org/10.1002/ceat.201300008 (2013).

Ghadiri, M., Darehnaei, M. G., Sabbaghian, S. & Shirazian, S. Computational simulation for transport of priority organic pollutants through nanoporous membranes. Chem. Eng. Technol. 36, 507–512. https://doi.org/10.1002/ceat.201200513 (2013).

Farajnezhad, A., Afshar, O. A., Khansary, M. A., Shirazian, S. & Ghadiri, M. Correlation of interaction parameters in Wilson, NRTL and UNIQUAC models using theoretical methods. Fluid Phase Equilib. 417, 181–186. https://doi.org/10.1016/j.fluid.2016.02.041 (2016).

Ismail, H. Y. et al. Developing ANN-Kriging hybrid model based on process parameters for prediction of mean residence time distribution in twin-screw wet granulation. Powder Technol. 343, 568–577. https://doi.org/10.1016/j.powtec.2018.11.060 (2019).

Rezakazemi, M., Marjani, A. & Shirazian, S. Development of a group contribution method based on UNIFAC groups for the estimation of vapor pressures of pure hydrocarbon compounds. Chem. Eng. Technol. 36, 483–491. https://doi.org/10.1002/ceat.201200422 (2013).

Shokoohi, R., Salari, M., Safari, R., Zolghadr Nasab, H. & Shanehsaz, S. Modelling and optimisation of catalytic ozonation process assisted by ZrO2-pumice/H2O2 in the degradation of Rhodamine B dye from aqueous environment. Int. J. Environ. Anal. Chem. 101, 2629–2653. https://doi.org/10.1080/03067319.2019.1704748 (2021).

Dehghani, M. H., Salari, M., Karri, R. R., Hamidi, F. & Bahadori, R. Process modeling of municipal solid waste compost ash for reactive red 198 dye adsorption from wastewater using data driven approaches. Sci. Rep. 11, 11613. https://doi.org/10.1038/s41598-021-90914-z (2021).

Heidari, Z. et al. Degradation of furosemide using photocatalytic ozonation in the presence of ZnO/ICLT nanocomposite particles: Experimental, modeling, optimization and mechanism evaluation. J. Mol. Liq. 319, 114193. https://doi.org/10.1016/j.molliq.2020.114193 (2020).

Ding, Y., Jin, Y., Yao, B. & Khan, A. Artificial intelligence based simulation of Cd(II) adsorption separation from aqueous media using a nanocomposite structure. J. Mol. Liq. 344, 117772. https://doi.org/10.1016/j.molliq.2021.117772 (2021).

Hashemi, S. Y., Azari, A., Raeesi, M. & Yaghmaeian, K. Application of response surface methodology (RSM) in optimisation of fluoride removal by magnetic chitosan/graphene oxide composite: Kinetics and isotherm study. Int. J. Environ. Anal. Chem. https://doi.org/10.1080/03067319.2021.1938021 (2021).

Bhagat, S. K., Tung, T. M. & Yaseen, Z. M. Development of artificial intelligence for modeling wastewater heavy metal removal: State of the art, application assessment and possible future research. J. Clean. Prod. 250, 119473. https://doi.org/10.1016/j.jclepro.2019.119473 (2020).

Rezakazemi, M., Azarafza, A., Dashti, A. & Shirazian, S. Development of hybrid models for prediction of gas permeation through FS/POSS/PDMS nanocomposite membranes. Int. J. Hydrogen Energy 43, 17283–17294. https://doi.org/10.1016/j.ijhydene.2018.07.124 (2018).

Dashti, A., Harami, H. R., Rezakazemi, M. & Shirazian, S. Estimating CH4 and CO2 solubilities in ionic liquids using computational intelligence approaches. J. Mol. Liq. 271, 661–669. https://doi.org/10.1016/j.molliq.2018.08.150 (2018).

Pishnamazi, M. et al. ANFIS grid partition framework with difference between two sigmoidal membership functions structure for validation of nanofluid flow. Sci. Rep. 10, 1–11 (2020).

Marjani, A., Babanezhad, M. & Shirazian, S. Application of adaptive network-based fuzzy inference system (ANFIS) in the numerical investigation of Cu/water nanofluid convective flow. Case Stud. Therm. Eng. https://doi.org/10.1016/j.csite.2020.100793 (2020).

Babanezhad, M., Behroyan, I., Marjani, A. & Shirazian, S. Artificial intelligence simulation of suspended sediment load with different membership functions of ANFIS. Neural Comput. Appl. https://doi.org/10.1007/s00521-020-05458-6 (2020).

Babanezhad, M., Pishnamazi, M., Marjani, A. & Shirazian, S. Bubbly flow prediction with randomized neural cells artificial learning and fuzzy systems based on k–ε turbulence and Eulerian model data set. Sci. Rep. 10, 1–12 (2020).

Babanezhad, M., Nakhjiri, A. T. & Shirazian, S. Changes in the number of membership functions for predicting the gas volume fraction in two-phase flow using grid partition clustering of the ANFIS method. ACS Omega 5, 16284–16291. https://doi.org/10.1021/acsomega.0c02117 (2020).

Babanezhad, M., Behroyan, I., Nakhjiri, A. T., Marjani, A. & Shirazian, S. Computational modeling of transport in porous media using an adaptive network-based fuzzy inference system. ACS Omega 5, 30826–30835. https://doi.org/10.1021/acsomega.0c04497 (2020).

Babanezhad, M., Taghvaie Nakhjiri, A., Rezakazemi, M. & Shirazian, S. Developing intelligent algorithm as a machine learning overview over the big data generated by Euler-Euler method to simulate bubble column reactor hydrodynamics. ACS Omega 5, 20558–20566. https://doi.org/10.1021/acsomega.0c02784 (2020).

Babanezhad, M., Nakhjiri, A. T., Rezakazemi, M., Marjani, A. & Shirazian, S. Functional input and membership characteristics in the accuracy of machine learning approach for estimation of multiphase flow. Sci. Rep. 10, 1–15 (2020).

Babanezhad, M., Nakhjiri, A. T., Marjani, A. & Shirazian, S. Gbell learning function along with fuzzy mechanism in prediction of two-phase flow. ACS Omega 5, 25882–25890. https://doi.org/10.1021/acsomega.0c03225 (2020).

Babanezhad, M. et al. High-performance hybrid modeling chemical reactors using differential evolution based fuzzy inference system. Sci. Rep. https://doi.org/10.1038/s41598-020-78277-3 (2020).

Babanezhad, M., Masoumian, A., Nakhjiri, A. T., Marjani, A. & Shirazian, S. Influence of number of membership functions on prediction of membrane systems using adaptive network based fuzzy inference system (ANFIS). Sci. Rep. https://doi.org/10.1038/s41598-020-73175-0 (2020).

Babanezhad, M., Rezakazemi, M., Hajilary, N. & Shirazian, S. Liquid-phase chemical reactors: Development of 3D hybrid model based on CFD-adaptive network-based fuzzy inference system. Can. J. Chem. Eng. 97, 1676–1684. https://doi.org/10.1002/cjce.23378 (2019).

Babanezhad, M., Rezakazemi, M., Marjani, A. & Shirazian, S. Predicting air superficial velocity of two-phase reactors using ANFIS and CFD. ACS Omega 6, 239–252. https://doi.org/10.1021/acsomega.0c04386 (2021).

Cao, Y., Babanezhad, M., Rezakazemi, M. & Shirazian, S. Prediction of fluid pattern in a shear flow on intelligent neural nodes using ANFIS and LBM. Neural Comput. Appl. 32, 13313–13321 (2019).

Babanezhad, M. et al. Prediction of nanofluid characteristics and flow pattern on artificial differential evolution learning nodes and fuzzy framework. ACS Omega 5, 22091 (2020).

Soltani, H., Pelalak, R., Heidari, Z., Ghadiri, M. & Shirazian, S. CFD simulation of transport phenomena in wastewater treatment via vacuum membrane distillation. J. Porous Media 19, 515 (2016).

Basheer, A. A. Chemical chiral pollution: Impact on the society and science and need of the regulations in the 21st century. Chirality 30, 402–406. https://doi.org/10.1002/chir.22808 (2018).

Basheer, A. A. & Ali, I. Stereoselective uptake and degradation of (±)-o, p-DDD pesticide stereomers in water-sediment system. Chirality 30, 1088–1095. https://doi.org/10.1002/chir.22989 (2018).

Basheer, A. A. New generation nano-adsorbents for the removal of emerging contaminants in water. J. Mol. Liq. 261, 583–593. https://doi.org/10.1016/j.molliq.2018.04.021 (2018).

Pelalak, R. et al. Synthesis, molecular dynamics simulation and adsorption study of different pollutants on functionalized mesosilica. Sci. Rep. 11, 1967. https://doi.org/10.1038/s41598-020-80566-w (2021).

Badi, M. Y. et al. Degradation of dimethyl phthalate using persulfate activated by UV and ferrous ions: Optimizing operational parameters mechanism and pathway. J. Environ. Health Sci. Eng. 17, 685–700. https://doi.org/10.1007/s40201-019-00384-9 (2019).

Azari, A. et al. Nitrate removal from aqueous solution by carbon nanotubes magnetized with nano zero-valent iron. J. Mazandaran Univ. Med. Sci. 23, 15–27 (2014).

Ahmadi, E. et al. The performance of mesoporous magnetite zeolite nanocomposite in removing dimethyl phthalate from aquatic environments. Desalin. Water Treat. 57, 27768–27782. https://doi.org/10.1080/19443994.2016.1178174 (2016).

Azari, A. et al. Rapid and efficient ultrasonic assisted adsorption of diethyl phthalate onto FeIIFe2IIIO4@GO: ANN-GA and RSM-DF modeling, isotherm, kinetic and mechanism study. Microchem. J. 150, 104144. https://doi.org/10.1016/j.microc.2019.104144 (2019).

Azari, A., Yeganeh, M., Gholami, M. & Salari, M. The superior adsorption capacity of 2,4-dinitrophenol under ultrasound-assisted magnetic adsorption system: Modeling and process optimization by central composite design. J. Hazard. Mater. 418, 126348. https://doi.org/10.1016/j.jhazmat.2021.126348 (2021).

Pishnamazi, M. et al. Adsorption of dyes on multifunctionalized nano-silica KCC-1. J. Mol. Liq. 338, 116573. https://doi.org/10.1016/j.molliq.2021.116573 (2021).

Soltani, F. et al. Direct leaching of low-grade zinc oxide ore containing high amounts of iron and manganese. Trans. Indian Inst. Met. https://doi.org/10.1007/s12666-019-01635-x (2019).

Soltani, R., Shahvar, A., Dinari, M. & Saraji, M. Environmentally-friendly and ultrasonic-assisted preparation of two-dimensional ultrathin Ni/Co-NO3 layered double hydroxide nanosheet for micro solid-phase extraction of phenolic acids from fruit juices. Ultrason. Sonochem. 40, 395–401. https://doi.org/10.1016/j.ultsonch.2017.07.031 (2018).

Marjani, A., Soltani, R., Pishnamazi, M., Rezakazemi, M. & Shirazian, S. Functionalized pollen-like mesoporous silica. Microporous Mesoporous Mater. 310, 110531. https://doi.org/10.1016/j.micromeso.2020.110531 (2021).

Soltani, R., Marjani, A. & Shirazian, S. A hierarchical LDH/MOF nanocomposite: Single, simultaneous and consecutive adsorption of a reactive dye and Cr(vi). Dalton Trans. 49, 5323–5335. https://doi.org/10.1039/D0DT00680G (2020).

Soltani, R., Marjani, A., Hosseini, M. & Shirazian, S. Meso-architectured siliceous hollow quasi-capsule. J. Colloid Interface Sci. 570, 390–401 (2020).

Roozbeh, S., Marjani, A., Hosseini, M. & Shirazian, S. Mesostructured hollow siliceous spheres for adsorption of dyes. Chem. Eng. Technol. 43, 392–402 (2019).

Soltani, R. et al. Novel bimodal micro-mesoporous Ni50Co50-LDH/UiO-66-NH2 nanocomposite for Tl(I) adsorption. Arab. J. Chem. 14, 103058. https://doi.org/10.1016/j.arabjc.2021.103058 (2021).

Soltani, R., Marjani, A. & Shirazian, S. Novel mesoporous crumpled paper-like silica balls. Mater. Lett. 281, 128230. https://doi.org/10.1016/j.matlet.2020.128230 (2020).

Soltani, R. et al. Preparation of COOH-KCC-1/polyamide 6 composite by in situ ring-opening polymerization: Synthesis, characterization, and Cd(II) adsorption study. J. Environ. Chem. Eng. https://doi.org/10.1016/j.jece.2020.104683 (2020).

Soltani, R., Dinari, M. & Mohammadnezhad, G. Ultrasonic-assisted synthesis of novel nanocomposite of poly (vinyl alcohol) and amino-modified MCM-41: A green adsorbent for Cd (II) removal. Ultrason. Sonochem. 40, 533–542 (2018).

Soltani, R., Pelalak, R., Pishnamazi, M., Marjani, A. & Shirazian, S. A water-stable functionalized NiCo-LDH/MOF nanocomposite: Green synthesis, characterization, and its environmental application for heavy metals adsorption. Arab. J. Chem. 14, 103052. https://doi.org/10.1016/j.arabjc.2021.103052 (2021).

Wei, Y., Yu, J., Du, Y., Li, H. & Su, C.-H. Artificial intelligence simulation of Pb(II) and Cd(II) adsorption using a novel metal organic framework-based nanocomposite adsorbent. J. Mol. Liq. 343, 117681. https://doi.org/10.1016/j.molliq.2021.117681 (2021).

Ayaz, M. & Khan, N.-U. Forecasting of heavy metal contamination in coastal sea surface waters of the Karachi harbour area by neural network approach. Nat. Environ. Pollut. Technol. 18, 719–733 (2019).

Yaqub, M., Eren, B. & Eyupoglu, V. Soft computing techniques in prediction Cr(VI) removal efficiency of polymer inclusion membranes. Environ. Eng. Res. 25, 418–425. https://doi.org/10.4491/eer.2019.085 (2020).

Yang, J., Du, Q., Ma, R. & Khan, A. Artificial intelligence simulation of water treatment using a novel bimodal micromesoporous nanocomposite. J. Mol. Liq. 340, 117296. https://doi.org/10.1016/j.molliq.2021.117296 (2021).

Zeng, K. et al. Molecular dynamic simulation and artificial intelligence of lead ions removal from aqueous solution using magnetic-ash-graphene oxide nanocomposite. J. Mol. Liq. 347, 118290. https://doi.org/10.1016/j.molliq.2021.118290 (2022).

Soltani, R. et al. A novel and facile green synthesis method to prepare LDH/MOF nanocomposite for removal of Cd(II) and Pb(II). Sci. Rep. https://doi.org/10.1038/s41598-021-81095-w (2021).

Pelalak, R. et al. Molecular dynamics simulation of novel diamino-functionalized hollow mesosilica spheres for adsorption of dyes from synthetic wastewater. J. Mol. Liq. 322, 114812. https://doi.org/10.1016/j.molliq.2020.114812 (2021).

Cao, Y. et al. Molecular dynamic simulations and quantum chemical calculations of adsorption process using amino-functionalized silica. J. Mol. Liq. 330, 115544. https://doi.org/10.1016/j.molliq.2021.115544 (2021).

Heidari, Z. et al. Molecular modeling investigation on mechanism of cationic dyes removal from aqueous solutions by mesoporous materials. J. Mol. Liq. 329, 115485. https://doi.org/10.1016/j.molliq.2021.115485 (2021).

Khan, M. S., Khalid, M. & Shahid, M. Engineered Fe3 triangle for the rapid and selective removal of aromatic cationic pollutants: Complexity is not a necessity. RSC Adv. 11, 2630–2642. https://doi.org/10.1039/D0RA09586A (2021).

Babapour, M. et al. Adsorption of Cr(VI) from aqueous solution using mesoporous metal-organic framework-5 functionalized with the amino acids: Characterization, optimization, linear and nonlinear kinetic models. J. Mol. Liq. 345, 117835. https://doi.org/10.1016/j.molliq.2021.117835 (2022).

Khan, M. S. & Shahid, M. Metal−Organic Frameworks for Environmental Remediation Vol. 1395. ACS Symposium Series 171–191 (American Chemical Society, 2021).

Dehghani, M. H. et al. Process optimization and enhancement of pesticide adsorption by porous adsorbents by regression analysis and parametric modelling. Sci. Rep. 11, 11719. https://doi.org/10.1038/s41598-021-91178-3 (2021).

Heidari, Z. et al. A new insight into catalytic ozonation of sulfasalazine antibiotic by plasma-treated limonite nanostructures: Experimental, modeling and mechanism. Chem. Eng. J. 428, 131230. https://doi.org/10.1016/j.cej.2021.131230 (2022).

Asgari, G., Shabanloo, A., Salari, M. & Eslami, F. Sonophotocatalytic treatment of AB113 dye and real textile wastewater using ZnO/persulfate: Modeling by response surface methodology and artificial neural network. Environ. Res. 184, 109367. https://doi.org/10.1016/j.envres.2020.109367 (2020).

Pelalak, R., Alizadeh, R., Ghareshabani, E. & Heidari, Z. Degradation of sulfonamide antibiotics using ozone-based advanced oxidation process: Experimental, modeling, transformation mechanism and DFT study. Sci. Total Environ. 734, 139446. https://doi.org/10.1016/j.scitotenv.2020.139446 (2020).

Asgari, G. et al. Diuron degradation using three-dimensional electro-peroxone (3D/E-peroxone) process in the presence of TiO2/GAC: Application for real wastewater and optimization using RSM-CCD and ANN-GA approaches. Chemosphere 266, 129179. https://doi.org/10.1016/j.chemosphere.2020.129179 (2021).

Pelalak, R. et al. Oak wood ash/GO/Fe3O4 adsorption efficiencies for cadmium and lead removal from aqueous solution: Kinetics, equilibrium and thermodynamic evaluation. Arab. J. Chem. 14, 102991. https://doi.org/10.1016/j.arabjc.2021.102991 (2021).

Pelalak, R. et al. Efficient oxidation/mineralization of pharmaceutical pollutants using a novel Iron (III) oxyhydroxide nanostructure prepared via plasma technology: Experimental, modeling and DFT studies. J. Hazard. Mater. 411, 125074. https://doi.org/10.1016/j.jhazmat.2021.125074 (2021).

Alam, G., Ihsanullah, I., Naushad, M. & Sillanpää, M. Applications of artificial intelligence in water treatment for optimization and automation of adsorption processes: Recent advances and prospects. Chem. Eng. J. 427, 130011. https://doi.org/10.1016/j.cej.2021.130011 (2022).

Ahmad, M. & Haydar, S. Evaluation of a newly developed biosorbent using packed bed column for possible application in the treatment of industrial effluents for removal of cadmium ions. J. Taiwan Inst. Chem. Eng. 62, 122–131 (2016).

Dashti, A., Amirkhani, F., Jokar, M., Mohammadi, A. & Chau, K.-W. Insights into the estimation of heavy metals ions sorption from aqueous environment onto natural zeolite. Int. J. Environ. Sci. Technol. 18, 1773–1784. https://doi.org/10.1007/s13762-020-02912-9 (2021).

Dil, E. A., Ghaedi, M. & Asfaram, A. The performance of nanorods material as adsorbent for removal of azo dyes and heavy metal ions: Application of ultrasound wave, optimization and modeling. Ultrason. Sonochem. 34, 792–802. https://doi.org/10.1016/j.ultsonch.2016.07.015 (2017).

Khandanlou, R. et al. Enhancement of heavy metals sorption via nanocomposites of rice straw and Fe3O4 nanoparticles using artificial neural network (ANN). Ecol. Eng. 91, 249–256. https://doi.org/10.1016/j.ecoleng.2016.03.012 (2016).

Nasr, M., Mahmoud, A. E. D., Fawzy, M. & Radwan, A. Artificial intelligence modeling of cadmium (II) biosorption using rice straw. Appl. Water Sci. 7, 823–831 (2017).

Popoola, L. T. Nano-magnetic walnut shell-rice husk for Cd(II) sorption: Design and optimization using artificial intelligence and design expert. Heliyon 5, e02381. https://doi.org/10.1016/j.heliyon.2019.e02381 (2019).

Ashrafi, M., Borzuie, H., Bagherian, G., Chamjangali, M. & Nikoofard, H. Artificial neural network and multiple linear regression for modeling sorption of Pb 2+ ions from aqueous solutions onto modified walnut shell. Sep. Sci. Technol. 55, 1–12. https://doi.org/10.1080/01496395.2019.1577437 (2019).

Nag, S., Mondal, A., Roy, D. N., Bar, N. & Das, S. K. Sustainable bioremediation of Cd(II) from aqueous solution using natural waste materials: Kinetics, equilibrium, thermodynamics, toxicity studies and GA-ANN hybrid modelling. Environ. Technol. Innov. 11, 83–104 (2018).

Varshney, S., Jain, P., Arora, J. & Srivastava, S. Process development for the removal of toxic metals by functionalized wood pulp: Kinetic, thermodynamic, and computational modeling approach. Clean Technol. Environ. Policy. https://doi.org/10.1007/s10098-016-1175-2 (2016).

Author information

Authors and Affiliations

Contributions

M.P.: Conceptualization, Writing-original draft, Validation. E.R.: Resources, Software, Revision, Formal analysis. F.P.: Validation, Formal analysis, Writing-review & editing. A.S.E.-S.: Writing-review & editing, Resources, Funding acquisition, Formal analysis. C.-H.S.: Supervision, Revision, Funding acquisition, Validation. H.C.N.: Formal analysis, Validation. M.A.: Supervision, Funding acquisition. S.G.: Conceptualization, Modeling, Writing-review & editing, Formal analysis. M.A.: Supervision, Revision, Writing-review & editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Parsaei, M., Roudbari, E., Piri, F. et al. Neural-based modeling adsorption capacity of metal organic framework materials with application in wastewater treatment. Sci Rep 12, 4125 (2022). https://doi.org/10.1038/s41598-022-08171-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-022-08171-7

This article is cited by

-

Artificial intelligence integration in conventional wastewater treatment techniques: techno-economic evaluation, recent progress and its future direction

International Journal of Environmental Science and Technology (2025)

-

Water and wastewater quality prediction: current trends and challenges in the implementation of artificial neural network

Environmental Monitoring and Assessment (2023)