Abstract

The Experimental Design was applied to optimize the electrocatalytic activity of La0.8Ba0.2CoO3 perovskite oxide/Active Carbon composite material in the alkaline solution for the Oxygen Evolution Reaction. After the preparation of La0.8Ba0.2CoO3, and structural characterizations, the experimental design was utilized to determine the optimal amount of the composite material and testing conditions. The overpotential was defined as the response variable, and the mass ratio of perovskite/active carbon, Potassium hydroxide (KOH) concentration, and Poly(vinylidene fluoride) (PVDF) amount were considered effective parameters. The significance of model terms is demonstrated by P-values less than 0.0500. The proposed prediction model determined the optimal amounts of 0.665 mg of PVDF, a KOH concentration of 0.609 M, and A perovskite/Active Carbon mass ratio of 2.81 with 308.22 mV overpotential (2.27% greater than the actual overpotential). The stability test of the optimized electrode material over 24 h suggests that it could be a good candidate electrocatalyst for OER with reusability potential.

Similar content being viewed by others

Introduction

Due to the exponential growth of population, increasing energy demand, and the limitation of non-renewable energy sources, research into finding renewable and environmentally-friendly energy alternatives, such as hydrogen, has become widespread1,2,3,4. Clean energy production processes, including electrochemical water splitting5, and Reversible Fuel Cells (RFCs), which employ electrochemical processes for hydrogen production 6, as well as energy storage devices like rechargeable metal-air batteries, known for their environmentally friendly, cost-effective, and high energy density7 , are crucial for achieving a sustainable energy perspective. Nevertheless, further developing these technologies requires enhancements, because there are some electrochemical drawbacks8 that need to be addressed, particularly the slow kinetics of the Oxygen Evolution Reaction (OER)9,10. OER holds significant importance in energy production and storage systems. At standard temperature and pressure, the thermodynamic potential for water splitting is 1.23 V11. However, OER is a four- electron charge transfer process that requires a considerable additional potential (overpotential) compared to the thermodynamic potential of the reaction. This overpotential is typically attributed to inherent reaction activation barriers and resistance, and its kinetics strongly depend on the electrocatalysts used to facilitate the reaction in both acidic and alkaline solutions12. Consequently, it is highly desirable to develop efficient and cost-effective electrocatalysts to enhance the OER process.

In the field of electrocatalysts for the OER, carbon materials13,14,15 have gained widespread usage owing to their high electronic conductivity, affordability, and structural versatility16,17,18,19. Nevertheless, their application is encumbered by challenges related to corrosion susceptibility16,20, the propensity to reduce the active surface area, and the formation of COx species at elevated potentials, factors that significantly curtail their practical suitability, particularly in industrial contexts11,21.

Currently, high-surface-area and nano-sized Iridium Oxide (IrO2), achieving a maximum current density of 1300 mA/cm2 at 1.8 V at 80 °C22. Meanwhile, Ruthenium Oxide (RuO2) demonstrates a maximum current density of 180 mA/cm2 at 1.8 V in acidic media. This is confirmed by chronoamperometric measurements that show RuO2’s stability for up to 20 h23. These materials are acknowledged as benchmark OER electrocatalysts24,25. Furthermore, the IrOx:RuOy binary composite has emerged as an effective OER electrocatalyst, reaching a maximum current density of 146 mA/cm2 at 1.44 V versus NHE with a 24 h stability profile26. When placed on the volcano plot, these metal oxides exhibit a spread of data points, reflecting the interplay between OER activity and overpotential. It is evident that some metal oxides excel in OER activity, providing a high Turnover Frequency (TOF) or current density (J) at modest overpotentials. Others may display a lower overpotential but compromise on activity27. However, their non-selective nature for Chlorine-evolution reaction (CER) and OER in the water splitting process, limited resources, and their high prices have motivated researchers to seek more available, non-toxic, eco-friendly, selective, and low-cost electrocatalysts28,29. Transition metal oxides, conversely, are emerging as a highly promising class of OER electrocatalysts, driven by their cost-effectiveness, adjustable electrical conductivity, and remarkable catalytic activity for OER processes 30,31. Among them, Perovskite oxide with ABO3 structure 32, serve as attractive candidates for electrochemical applications33, especially OER in alkaline solutions 34,35,36,37,38,39,40,41,42,43,44; it is due to the unique physicochemical properties, presence of non-precious materials in the structure, being highly flexible in replacing elements in A and B sites 45,46,47, great intrinsic catalytic activity48,49,50 and chemical stability 51. The inclusion of perovskite oxides on the same volcano plot reveals intriguing insights into their OER activity. Notably, several perovskite oxides are positioned on the plot with distinct characteristics. A distinctive trend emerges, with certain perovskite oxides demonstrating remarkable OER activity at relatively low overpotentials. This suggests that these materials may possess inherent catalytic properties that hold great potential for reducing the energy barrier associated with the OER. Such behavior challenges the conventional trade-off between overpotential and activity and points toward new avenues for electrocatalyst development52,53,54. Research has indicated that Ba-based perovskites55 exhibit greater activity as OER electrocatalysts when compared to La0.2Sr0.8CoO3 56, La1−xCaxFeO357, La1−xSrxCoO358, La1−xCexNiO359, LaNi0.8Fe0.2O360 in alkaline media. However, due to the high calcination temperature of perovskites, these oxides suffer low electrical conductivity, surface area and inadequate physical stability at room temperature, which restricts their utilization as commercial electrocatalysts61,62. To address this issue, Shao-Horn and co-workers have conducted a comprehensive investigation into the trends related to the Oxygen Reduction Reaction (ORR) and OER activities of perovskite oxides. Their work has introduced fundamental design principles for perovskite-based electrocatalysts. Particularly, the significance of maximizing the surface area of perovskite catalysts and its direct influence on their activity, especially concerning OER, was emphasized by their research group 63,64. Furthermore, Wang has emphasized that a larger surface area implies an increased number of active sites 65. In addition to enhancing the perovskite structure and augmenting the surface area, addressing the mentioned limitations involves the incorporation of conductive carbon as a current-conducting component and a polymeric binder 66. Carbon-based materials, known for their role as OER electrocatalysts, can serve as a conduit between the active surface of perovskite oxides without actively participating in the OER 67,68. A substantial amount of effort has been dedicated to the production of composites consisting of perovskite and carbon materials, with physical mixing being a prominent approach. For instance, the electrochemical OER performance of physically mixed composites, such as La1−xCaxFeO3 and vulcan carbon (XC-72R)57, Ln0.5Ba0.5CoO3 (Ln: Pr, Sm, Gd and Ho) and acetylene black carbon69, LaFeO3 and Super P Li 70, LaCo0.2Fe0.8O3 and carbon black 71, as well as NdBaMn2O5.5 and vulcan XC-72 carbon71 composites has been investigated by various research groups. The synthesis of carbon nanotubes (CNTs) through Chemical Vapor Deposition (CVD) offers a promising avenue for creating composite materials with perovskite oxides for use as electrocatalysts in the OER62,72. Notably, Elumeeva and colleagues have demonstrated the potential of this technique by growing nitrogen-doped CNTs (NCNTs) on the surface of an A-site-deficient La0.58Sr0.4Fe0.2Co0.8O3 perovskite oxide. In this arrangement, the B-site metal ions in the perovskite oxide serve as effective catalysts for both the OER/ORR73. In another approach, a composite of LaNiO3 and CNTs nanohybrids has been prepared for OER electrocatalysis. To achieve this, perovskite oxides were employed as support materials, and a ferrocene-dissolved ethylenediamine solution was introduced as a precursor for the CNTs. This composite was fabricated using an injection CVD method, paving the way for improved OER electrocatalytic performance74,75. An alternative approach to enhancing the electrocatalytic activity for the OER is the synthesis of various materials using both hydrothermal and electrospinning methods. These materials include the LaNiO3-stabilized nitrogen and sulfur-codoped graphene (LaNiO3/N,S-Gr hybrid)76, LaNiO3 nanorod/reduced graphene oxide (RGO)77, and La(Co0.55Mn0.45)0.99O3 nanorod/nitrogen-doped reduced graphene oxide (NrGO)78, all produced through hydrothermal processes. Additionally, the synthesis of LaTi0.65Fe0.35O3 nanorods within nitrogen-doped carbon nanorods using electrospinning has been employed79. These methods have proven effective in enhancing the efficiency and performance of electrocatalysts in OER applications. Among these methods, the physical mixing approach is considered the most extensively researched method for preparing composite materials, mainly due to its potential for large-scale production. Historically, the incorporation of carbon through physical mixing was commonly thought to primarily function as a conductive support. Its main purpose was to increase the apparent electrical conductivity of the electrode, ultimately enhancing the overall utilization of perovskite materials80. On the other hand, adding Polyvinylidene fluoride (PVDF), with good physical stability and chemical resistance, has been recommended to prepare electrode materials81,82. Meanwhile, the relationship between the percentage of conductivity and OER activity makes it essential to find an optimal composition of electrode material83. To the best of our knowledge, notwithstanding the importance of the composition ratio on the electrochemical performance, no published articles used optimization methods to find the optimal composition and test condition at room temperature. The experimental design method is one well-known approach to study the effective parameters in different processes in which the effect of parameters can be investigated simultaneously84,85. Among these methodologies, Response Surface Methodology (RSM) plays a vital role in designing and optimizing the catalysts, which leads to improving the particular processes that contain different input variables. It is a set of mathematical and statistical techniques to explain a data set's behaviour to make statistical Predictions86,87. In our prior investigation, we synthesized a series of La1−xBaxCoO3 perovskite oxides using the sol–gel method, with surface areas ranging from 4 to 14 m2/g. However, our electrochemical analysis revealed that when x = 0.2, producing the highest surface area, it exhibited unsatisfactory performance in the OER compared to BaCoO3 perovskite materials55. In this study, our objective is to explore the influence of various parameters on the electrocatalyst's performance. These parameters include the perovskite-to-carbon material ratio, the amount of PVDF in the composite, and the concentration of the KOH (Potassium hydroxide) solution. Therefore, our work fills an important gap in the existing literature.

This study aims to find an optimal amount of composite material and electrolyte concentration as effective parameters in OER utilizing RSM and Central Composite Design (CCD). The experimental design (DOE) method investigated three critical and effective parameters in the catalyst performance; the perovskite-to-carbon material ratio, electrolyte concentration, and binder quantity at room temperature. The response variable examined in this study was the overpotential required to achieve a current of 10 mA/cm2 in the OER. Following the synthesis of the perovskite as an active electrocatalyst, various structural analyses, including XRD, SEM, EDS, XPS, TEM, FT-IR, and N2 Adsorption–Desorption analyses, were done to study the structure of the catalysts. Subsequently, all 20 experiments proposed by Experimental Design were performed to determine the optimum condition for fabricating the electrode material to reach minimum overpotential.

Materials and methods

Preparation of the electrode material

Herein La0.8Ba0.2CoO3 perovskite oxide was employed as active material. For preparation of La0.8Ba0.2CoO3, La (NO3)3·6H2O, Ba(NO3)2·3H2O, and Glycine, from Samchun Pure Chemical Company, Co(NO3)2·4H2O, from Merck Company and de-ionized water were used as starting material and the sol–gel technique was employed to synthesis the perovskite oxide88.

Activated carbon (AC) from Sigma-Aldrich and PVDF from Tetiran Company were utilized to prepare the composite. The electrode materials were prepared by varying the mass ratio of La0.8Ba0.2CoO3/AC and the quantity of binder as proposed by RSM. To achieve a homogenous suspension, the solid materials were dispersed in N-Methyl-2-Pyrrolidone (NMP) (Merk Company), and the ink sonicated for 1 h.

Structural characterization of electrocatalyst

To identify the crystalline phase of the perovskite and AC, X-ray diffraction analysis was performed in the Tongda TD-3700 (China) using Cu Kα radiation (λ = 1.5406 Å) between 20° and 75°. The morphological studies of samples were carried out using a scanning electron microscope (SEM) by Tescan instrument and Transmission Electron Microscopy (TEM) using CM120 (Netherlands). The quantitative evaluation of perovskite's composition was performed using Energy dispersive spectroscopy (EDS). The BET surface area and the textural properties of the perovskite were determined by N2 adsorption/desorption isotherms obtained using the TriStar II 3020 system. To characterize the functional groups of the surface, FT-IR spectra of the samples were obtained using a Bruker Model Tensor 27 spectrometer. The X-ray photoelectron spectroscopy (XPS) measurements were performed using a PHI 5000 VersaProbe, equipped with an Al Kα monochromatic source and a magnetic lens system. The binding energies of the acquired spectra were referenced to the C1s line at 284.9 eV.

Electrochemical measurements

The electrochemical experiments were conducted under ambient conditions using a three-electrode setup. A homemade glassy carbon electrode (GCE) with 0.215 cm2 surface area, Pt wire, and Ag/AgCl severed as the working, counter, and reference electrodes. To ensure the removal of any impurities, the GCE was polished with Alumina powder prior to the fabrication of the working electrode. The electrode material was prepared according to the procedure described in the previous section employing various mass ratios of La0.8Ba0.2CoO3/AC ranging from 1 to 4 and varying amounts of PVDF ranging from 0.25 to 1 mg. These parameters ranges were selected based on sieved tests conducted before the optimization process. Subsequently, 6 µL of the ink was dropped over the electrode, and after drying for 24 h in the air, it was used as the working electrode. Polarization curves were obtained using the Linear Sweep Voltammetry (LSV) technique in KOH solution with concentrations ranging from 0.1 to 1 M and a scan rate of 10 mV/s. The curves were corrected based on Reversible Hydrogen Electrode (RHE) (Eq. 1), and the overpotential (η) was determined using Eq. (2)89.

Experimental design

In this study, RSM based on the CCD was employed using Design Expert 12.0.3.0 software to model and optimize the experiments. The primary objective of this optimization approach was to achieve the optimal level of system variables, thereby maximizing performance90. Three factors include the mass ratio La0.8Ba0.2CoO3 /AC (A), the electrolyte material concentration (B), and the amount of PVDF (C). These factors were defined in five levels, as presented in Table 2, where 1, 0, and + 1 corresponded to low, central, and high levels, respectively. Furthermore, two levels beyond the cubic domain (Alpha) were defined to include six replicates at the central point, six at axial points, and eight at factorial points to predicate the response function. The response function assumed in this study was the required overpotential to reach 10 mA/cm2 current density during OER, denoted as (D). Design Expert software generated 20 experimental trials by varying of aforementioned variables. The validity of the model was evaluated using F-value and P-value. To establish a relationship between independent and response variables, a second-order model was employed (Eq. 3), where Dp represents the predicted response (overpotential (mV)), xi and xj denoted independent variables, xixj represents the interaction of xi and xj, βi, βii, and βij show linear, quadratic, and interaction coefficients, respectively. β0 corresponds to the intercept value, k is the number of factors considered, and ε represents modeling error91,92.

Results and discussion

Structural characterization

Figure 1 illustrates the XRD patterns of La0.8Ba0.2CoO3 and AC. Upon comparing the XRD pattern of La0.8Ba0.2CoO3 with the ICDD PDF database entries for LaCoO3, La0.5Ba0.5CoO3, and BaCoO3, it is evident that La0.8Ba0.2CoO3 exhibits a combination of these two perovskite phases88,93. Additionally, BaCO3 was formed within the perovskite structure as a side phase. It is noteworthy that the decomposition temperature of BaCO3 is above 800°C, whereas the synthesized perovskite was calcined at a lower temperature (650°C), resulting in the formation of BaCO3, which can be attributed to incomplete decomposition94.

Regarding the XRD pattern of AC, the prominent peaks observed at 2θ between 10 and 30° (the broad C (002) diffraction peak) and 40–50° (the weak and broad C (101) diffraction peak) can be attributed to the presence of graphite in the AC structure. Furthermore, noisy and disorderly diffraction signals indicate AC’s amorphous nature95.

The surface properties of the La0.8Ba0.2CoO3 catalyst were thoroughly examined through XPS analysis. The composition of the La0.8Ba0.2CoO3 sample was unequivocally confirmed using XPS, as demonstrated in Fig. 2a, which presents the survey pattern of the sample. The XPS survey scan clearly identifies the presence of La, Co, Ba, and O elements on the surface of the material.

High-resolution XPS spectra of La3d, Ba3d, Co2p, and O1s were obtained, shedding light on the formal oxidation states of these elements. Specifically, the high-resolution La3d spectrum (Fig. 2b) exhibited two strong peaks at 832.57 and 849.36 eV, corresponding to the spin–orbit splitting of 3d5/2 and 3d3/2 orbitals of La3+ ions in oxide form. Furthermore, each of these peaks exhibited additional substructure, attributed to energy loss phenomena or “shake-up” satellites. The presence of two pairs of peaks in the La 3d5/2 spectrum (832.57, and 836.26 eV) indicates the coexistence of La3+ species in distinct surface environments96,97.

Moving on to the Co2p3/2 and Ba3d5/2 spectra in the range of 770–810 eV, there is a partial overlap of the Co2p3/2 and Ba3d5/2 peaks around 778.4 eV, as well as a similar overlap between Co2p1/2 and Ba3d3/2 peaks around 793.7 eV (Fig. 2c, d). Deconvolution analysis allows for the extraction of individual peaks, with the Ba2+ peak exhibiting a slightly higher binding energy compared to the Co ions. The spin–orbit splitting of Co2p3/2 and Co2p1/2 was determined to be approximately 16.35 eV, indicative of Co being predominantly in the + 3 oxidation state. Additionally, the absence of satellite features around 787.1, and 803.2 eV rules out the presence of Co2+ on the surface98,99.

The O1s XPS peaks associated with the La0.8Ba0.2CoO3 material exhibit asymmetry (Fig. 2e). Upon employing deconvolution analysis, the observed asymmetrical peaks can be distinctly resolved into two components, each attributed to specific oxygen species. The lower-energy peak, situated at 528.87 eV and marked in green, is associated with O2− ions, signifying the presence of lattice oxygen (OL). In contrast, the second peak, located around 529.55 eV and denoted by the purple line, corresponds to highly oxidative oxygen species, including O22− or O− (Ovacancy)100,101.

The FTIR spectra of La0.8Ba0.2CoO3 and AC (Fig. 3) provide information about the functional groups of the surface. For La0.8Ba0.2CoO3, the peaks observed in the 400 cm−1 to 700 cm−1 range can be attributed to the ABO3 perovskite structure. Additionally, a broad band at 3442 cm−1 is due to the physically adsorbed H2O molecules on the perovskite surface. In contrast, two low-intensity absorption bands at 1461 cm−1 and 1388 cm−1 corresponded to these water molecules’ O–H stretching, bending, and scissoring vibrational modes. The peak at 582 cm-1 is attributed to Co3+, and the peak at 673 cm−1 to Co2+, confirms the formation of the Co3O4 spinel structure. Following the XRD results, the impurities formed as BaCO3 are evident at 1388 cm−1 and 1461 cm−1, corresponding to the C–O bond's asymmetric stretching mode102,103.

The presence of oxygen functional groups on the surface is observed in the FTIR spectra of AC. The bands at 2800–3000 cm−1 are displayed in Fig. 3 (black line), demonstrating the presence of an aliphatic-CH stretching vibration (the peaks at 2922 cm−1 and 2852 cm−1 show both methylene (–CH2–) bridges and aromatic C–H stretching vibrations). The bands at 1710 cm−1 and 1580 cm−1 indicate the presence of carbonyl/carboxyl groups and an aromatic C=C ring stretching, respectively. The broad peak at 3444 cm−1 is attributed to the stretching O–H vibration (hydroxyl group), which is present due to the water utilization during the preparation process. Finally, the band at 1630 cm−1 is associated with hybridized C–C aromatic skeletal stretching of graphite104,105.

The SEM micrographs of La0.8Ba0.2CoO3 perovskite and AC illustrate crucial insights into the microstructure of perovskite and AC, shedding light on their respective surface properties and the potential impact on their electrocatalytic performance. (a-1, 2) presents the SEM images of La0.8Ba0.2CoO3, revealing a distinctive porous microstructure. The porous nature of La0.8Ba0.2CoO3 is a fundamental feature that significantly influences its overall performance as an electrocatalyst for the OER. This porous architecture results in an impressive specific surface area of 14 m2/g to put this into context, this specific surface area outpaces that of previously reported perovskite oxides commonly used for OER including Ba0.5Sr0.5Co0.8Fe0.2O3106, LaCo1−xNixO3107, LaFeO3108, CaxLa1−xAl1−xMnxO3109, SrCo0.95P0.05O3110, BaZrxFe1−xO3111. The extensive surface area of La0.8Ba0.2CoO3 provides a larger platform for electrochemical reactions and interactions with electrolytes, enhancing its electrocatalytic performance.

Furthermore, the SEM results indicate that La0.8Ba0.2CoO3 exhibits, irregular shapes, and rough surfaces, which are distinctive characteristics of its microstructure. This morphology is pivotal in facilitating electrochemical processes, as the increased surface roughness allows for more active sites for OER, promoting better catalytic performance.

In contrast, (b-1, 2) portrays the surface morphology of AC. AC displays a distinct surface texture characterized by uneven cavities and a clear porous structure. This unique microstructure imparts a high specific surface area to AC, a well-known attribute of AC materials. The high surface area is attributed to the presence of micro and mesopores, making AC an excellent candidate for electrochemical applications. The significant surface area of AC enhances its electron conductivity and electrochemical activity. This is particularly important in electrocatalytic applications, as the high surface area allows for a greater number of active sites where electrochemical reactions can occur. Furthermore, the porous structure of AC promotes effective mass transport of reactants and products to and from the electrode surface, which is crucial for efficient electrocatalysis83.

In Fig. 4c-1,2, the TEM image of La0.8Ba0.2CoO3 nanoparticles reveals an irregular morphology characterized by distinct edges and facets. This irregular shape aligns with our observations in the SEM image. The observed roughness may be attributed to surface-related issues, such as defects, grain boundaries, or changes in chemical composition. Figure 4c-1 depicts the particle size distribution of La0.8Ba0.2CoO3 obtained through the analysis of various TEM images. The particle size has been estimated to be within the range of 1–50 nm, with approximately 54% of the particles falling within the 15–25 nm range. The average particle size is estimated to be around 25 nm112,113.

Figure 5 represents the EDS spectroscopy and elemental mapping analysis of La0.8Ba0.2CoO3 (a-1,2,3, and 4). Table a-2 (insect in Fig. 5), displays the relative atomic concentrations of La, Ba, Co, and O through semi-quantitative EDS results, which are calculated using software based on an averaged signal from thousands of particles. The obtained catalyst compositions align closely with the calculated stoichiometric amounts of material used in the preparation process.

The isotherm, pore size distribution curves, and the summarized BET report of the La0.8Ba0.2CoO3 are shown in Fig. 6 and Table 1, respectively. According to the IPUAC classification scheme, the obtained isotherm exhibits a type IV shape, accompanied by an H3-type hysteresis loop114. This type of hysteresis loop is typically observed in adsorption on mesoporous structures115. Furthermore, the pore size distribution curve displayed in the inset of Fig. 6 offers a more detailed view of the size distribution of these pores. It reveals that the majority of pores fall within a diameter range of 2.5 to 12 nm. This observation aligns seamlessly with the mesoporous structure of La0.8Ba0.2CoO3, further confirming the presence of these intermediate-sized pores. The availability of mesopores is of particular significance in electrocatalysis, as they provide an ideal environment for accommodating active sites and supporting electrochemical reactions..

RSM results

Table 2, provides a summary of the variables that RSM has assumed at each level. − Alpha, − 1, 0, + 1, and + Alpha were the five levels at which the variables were specified. The utilization of RSM at these specific levels is fundamental to the experimental design and analysis, enabling a comprehensive exploration of the variables and their potential effects on the study.

The acquired experimental conditions by RSM are listed in Table 3. Within this table, ηA represent the actual overpotential observed under experimental conditions, while ηP stands for the predicted overpotential derived from experimental design. Equation (1) was employed to determine the required overpotentials to achieve the current density of 10 mA/cm2 over composite electrode material from the polarization curves shown in Fig. 7. The figures, which are divided into two parts (a), showcasing runs 1–10 and (b), exhibiting runs 11–20, offer valuable insights into the electrocatalytic performance of the composite electrode material under various experimental conditions. The determination of the optimal overpotentials required to achieve the 10 mA/cm2 current density is enabled by this division.

The proposed model for the response (overpotential) was developed using variance analysis (ANOVA) after evaluating the data obtained from experimental design and actual overpotentials. Subsequently, a quadratic model was selected as the most suitable method to predict the observed variations in the overpotential. The final equation, expressed in terms of coded factors, establishes the relationship between the independent variables and the response function116 (Eq. (4)).

Table 4 represents the ANOVA statistics for the overpotential model, which includes the correlation coefficient (R2), adjusted coefficient of determination, prediction coefficient, F-value, P-value, and %CV.

Based on the ANOVA results as presented in Table 4, the correlation coefficient of the model is 0.9618. This indicates that the suggested empirical model in Eq. (4) is capable of predicting over 96 percent of data, demonstrating a strong correlation between the independent variables and the response variable (overpotential). The adjusted coefficient calculated at 0.9274, further accentuates the significance and reliability of the suggested model. This adjusted coefficient takes into account the number of independent variables and the sample size, emphasizing the model's practical effectiveness in explaining the observed variations in the response variable. Furthermore, the model F-value, with a value of 27.95, attests to the model's statistical significance. This indicates that the model is indeed a meaningful and reliable tool for explaining the variation in the response variable. Importantly, when the associated P-values are below 0.0500, it signifies that the model terms are statistically significant in elucidating the variations in the response variable. Overall, the ANOVA results provide strong support for the assertion that the proposed model is endowed with exceptional predictive capabilities. The robust correlation coefficient, adjusted coefficient, and significant model F-value all validate the model's effectiveness in predicting the overpotential. Figure 8 illustrates the predicted values versus the experimental values for the OER overpotential response, further confirming the high validity of the RSM.

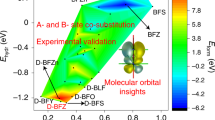

The effects of the three parameters on the response function can be visualized using response surface curves, as shown in Fig. 9. The figure shows that the increasing amount of PVDF in the composite material leads to an increase in the overpotential. This finding is consistent with the coefficient in Eq. (4) and can be attributed to the high solvent resistance and electrochemical stability of PVDF82. On the other hand, the overpotential is reduced by increasing the La0.8Ba0.2CoO3 /AC mass ratio. This parameter acts as a positive factor because it increases the active material in the composite. This finding aligns with the coefficient in Equation, indicating that a higher La0.8Ba0.2CoO3/AC ratio contributes to lower overpotentials. Additionally, the concentration of KOH positively affects the overpotential, meaning that increasing the concentration of KOH leads to lower overpotentials. This observation can be attributed to a high amount of OH- ions in the electrolyte, which enhances the electrocatalyst activity.

The perturbation plot, depicted in Fig. 10, served as a valuable tool for comparing the individual effects of the factors on the required overpotential at a specific point within the design space. This plot explains how changes in each factor influenced the overpotential response while keeping the other two factors constant. Upon close examination of the perturbation plot, it becomes evident that factors A and C have a positive effect on the overpotential. As these factors increase, the overpotential also increases, indicating a direct correlation. Conversely, factor B exhibits a negative effect on the overpotential. When factor B increases, the overpotential decreases, demonstrating an inverse relationship. Additionally, the relatively flat line for factor B in the perturbation plot suggests that its effect on the OER overpotential is less pronounced within the design space. This observation aligns well with the findings outlined in Eq. (4) and emphasizes that factor B plays a relatively minor role in influencing the overpotential in the specified experimental conditions.

Electrocatalytic results of optimized electrode material

The three variables listed in Table 5 were determined through an optimization process to minimize the OER required overpotential over the electrocatalyst. The composite material was prepared with optimized La0.8Ba0.2CoO3/AC, PVDF amount, and KOH concentration values. Based on the optimization, the predicted overpotential for the optimal condition was found to be 308.22 mV. The actual overpotential was measured to be 301.20 mV upon the experimental testing, corresponding to a 2.27% error between the experimental and predicted values. The close agreement between the overpotential values indicates that the second-order model (Eq. 4) used to optimize the variables to achieve the lowest overpotential was appropriate and reliable.

The electrochemical activity of optimized electrode material, La0.8Ba0.2CoO3/AC ratio (2.81), and PVDF Mass (0.665 mg), was evaluated by LSV measurements. These measurements were performed under the carefully chosen optimal conditions, including a KOH concentration of 0.609 M and a constant scan rate of 10 mV/s, as visually depicted in Fig. 11. Furthermore, the inset of Fig. 11 showcases the corresponding Tafel plot, derived from the LSV polarization curves.

In order to ensure the accuracy and validity of the results, the potential values obtained from the LSV tests were subjected to IR-correction and referenced to RHE. This referencing procedure is in line with established standards and conventions in the field, providing a common frame of reference for electrochemical measurements and facilitating meaningful comparisons across diverse studies.

A consistent pattern emerges when the data from the LSV curves obtained under these optimized conditions are compared with the performance of analogous anodic materials, as outlined in Table 6. A significantly lower overpotential and a markedly higher limiting current density are consistently achieved under the optimized conditions. These consistent observations collectively emphasize the clear enhancement of OER catalytic activity through the optimization of experimental parameters. This advancement represents a substantial step forward in the understanding and practical utilization of La0.8Ba0.2CoO3 electrocatalysis for the OER.

The study utilized chronopotentiometry testing to investigate the stability and reusability of the optimized electrode. In addition to its high electrocatalytic activity, the composite electrocatalyst exhibits commendable electrocatalytic stability for the OER. As illustrated in Fig. 12, the electrocatalyst maintains its electrocatalytic activity when subjected to a current density of 10 mA/cm2 for a continuous 24 h duration. Even after extended electrocatalysis, its morphology and microstructure remain unaltered, as confirmed SEM analysis (depicted in the inset of Fig. 12). Furthermore, a subsequent SEM analysis of the electrode's surface, conducted both before and after the 24-h test, unveils no discernible changes in the material. This substantial stability and resistance offer compelling evidence of the electrode material’s suitability for reuse under identical conditions. This stability can be attributed to the presence of catalytically active sites, facilitated by the inclusion of cobalt (Co), as well as the existence of oxygen vacancies. These factors collectively ensure the catalyst's resilience during the OER, thereby enhancing the material's overall stability.

Conclusion

In conclusion, the experimental design approach using Design Expert 12.0.3.0 software successfully identified the optimal composition for preparing the electrode material and electrolyte solution to minimize the overpotential in OER. The CCD method was used to investigate the three effective parameters in the catalyst performance (the ratio of perovskite (La0.8Ba0.2CoO3) to carbon material (activated carbon), electrolyte concentration (KOH), and PVDF amount). The perovskite was prepared using the sol–gel method, and various characterization techniques, including XRD, SEM, FT-IR, and N2 adsorption–desorption analyses, were performed to analyze the structure and properties of the perovskite material. The low and high ranges of the parameters were determined based on previous experience. Design Expert software generated a set of 20 experiments for the three variables. The response variable chosen was the required overpotential to achieve a current density of 10 mA/cm2. The Quartic second-order model established the relationship between independent and response variables. The ANOVA results indicated that the model was significant, with a high correlation coefficient, adjusted coefficient, F-value, and low P-value.

Furthermore, the optimized material has a 301.2 mV overpotential, slightly lower than the predicted overpotential, with a small error of 2.27%. Additionally, the stability of the composition electrode material suggests that it is a good candidate anodic material for OER. Overall, the combination of experimental design, statistical analysis, and characterization techniques allowed for identifying an optimized electrode material composition with improved OER performance and stability, providing a promising candidate for electrocatalytic applications. As a prospective direction for future research, an investigation into the activity of the La0.8Ba0.2CoO3 perovskite for the CER, utilizing an online Gas Chromatography (GC) device, is recommended. This avenue shows great promise in advancing the field of electrocatalysis for water splitting. The significance of this forthcoming research effort lies in its ability to address a critical challenge in water splitting processes—the non-selective nature of commonly used electrocatalysts for both the CER and the OER. Achieving selectivity is paramount for enhancing the efficiency and economic viability of water electrolysis, a pivotal component of clean hydrogen production.

Data availability

All data generated or analysed during this study are included in this published article.

References

Alduhaish, O. et al. Facile synthesis of mesoporous α-Fe2O3@ g-C3N4–NCs for efficient bifunctional electro-catalytic activity (OER/ORR). Sci. Rep. 9, 14139 (2019).

Khan, R. et al. Role of perovskites as a bi-functional catalyst for electrochemical water splitting: A review. Int. J. Energy Res. 44, 9714–9747 (2020).

Ahn, J. et al. 3D-printed NiFe-layered double hydroxide pyramid electrodes for enhanced electrocatalytic oxygen evolution reaction. Sci. Rep. 12, 346 (2022).

You, B. & Sun, Y. Innovative strategies for electrocatalytic water splitting. Acc. Chem. Res. 51, 1571–1580 (2018).

Malik, A. S. et al. On a high photocatalytic activity of high-noble alloys Au–Ag/TiO2 catalysts during oxygen evolution reaction of water oxidation. Sci. Rep. 12, 2604 (2022).

Dresp, S. et al. An efficient bifunctional two-component catalyst for oxygen reduction and oxygen evolution in reversible fuel cells, electrolyzers and rechargeable air electrodes. Energy Environ. Sci. 9, 2020–2024 (2016).

Lu, X. F., Chen, Y., Wang, S., Gao, S. & Lou, X. W. Interfacing manganese oxide and cobalt in porous graphitic carbon polyhedrons boosts oxygen electrocatalysis for Zn–air batteries. Adv. Mater. 31, 1902339 (2019).

Wang, S. et al. Efficient FeCoNiCuPd thin-film electrocatalyst for alkaline oxygen and hydrogen evolution reactions. Appl. Catal. B 313, 121472 (2022).

Kibsgaard, J. & Jaramillo, T. F. Molybdenum phosphosulfide: An active, acid-stable, earth-abundant catalyst for the hydrogen evolution reaction. Angew. Chem. Int. Ed. 53, 14433–14437 (2014).

Tashie-Lewis, B. C. & Nnabuife, S. G. Hydrogen production, distribution, storage and power conversion in a hydrogen economy-a technology review. Chem. Eng. J. Adv. 8, 100172 (2021).

Da, Y., Zeng, L., Wang, C., Gong, C. & Cui, L. A simple approach to tailor OER activity of SrxCo0.8Fe0.2O3 perovskite catalysts. Electrochim. Acta 300, 85–92 (2019).

Kasian, O., Grote, J., Geiger, S., Cherevko, S. & Mayrhofer, K. J. J. The common intermediates of oxygen evolution and dissolution reactions during water electrolysis on iridium. Angew. Chem. Int. Ed. 57, 2488–2491 (2018).

Yang, Y. et al. Electrocatalysis in alkaline media and alkaline membrane-based energy technologies. Chem. Rev. 122, 6117–6321 (2022).

Trogadas, P., Fuller, T. F. & Strasser, P. Carbon as catalyst and support for electrochemical energy conversion. Carbon N. Y. 75, 5–42 (2014).

Murugan, P. et al. Electrochemical detection of H2O2 using an activated glassy carbon electrode. ECS Sens. Plus 1, 034401 (2022).

Suen, N.-T. et al. Electrocatalysis for the oxygen evolution reaction: Recent development and future perspectives. Chem. Soc. Rev. 46, 337–365 (2017).

Mohamed, R. et al. Electrocatalysis of perovskites: The influence of carbon on the oxygen evolution activity. J. Electrochem. Soc. 162, F579 (2015).

Hardin, W. G. et al. Tuning the electrocatalytic activity of perovskites through active site variation and support interactions. Chem. Mater. 26, 3368–3376 (2014).

Filimonenkov, I. S. et al. Carbon materials as additives to the OER catalysts: RRDE study of carbon corrosion at high anodic potentials. Electrochim. Acta 321, 134657 (2019).

Jamesh, M.-I. & Sun, X. Recent progress on earth abundant electrocatalysts for oxygen evolution reaction (OER) in alkaline medium to achieve efficient water splitting: A review. J. Power Sources 400, 31–68 (2018).

Han, L., Dong, S. & Wang, E. Transition-metal (Co, Ni, and Fe)-based electrocatalysts for the water oxidation reaction. Adv. Mater. 28, 9266–9291 (2016).

Cruz, J. C. et al. Nanosized IrO2 electrocatalysts for oxygen evolution reaction in an SPE electrolyzer. J. Nanopart. Res. 13, 1639–1646 (2011).

Cruz, J. C. et al. Preparation and characterization of RuO2 catalysts for oxygen evolution in a solid polymer electrolyte. Int. J. Electrochem. Sci. 6, 6607–6619 (2011).

Kim, J. Y. et al. Single-crystalline, wormlike hematite photoanodes for efficient solar water splitting. Sci. Rep. 3, 2681 (2013).

Swesi, A. T. et al. Textured NiSe2 film: Bifunctional electrocatalyst for full water splitting at remarkably low overpotential with high energy efficiency. Sci. Rep. 7, 2401 (2017).

Cruz, J. C. et al. Electrochemical evaluation of a Ir–Ru binary oxide for oxygen evolution reaction. Int. J. Electrochem. Sci. 7, 7866–7876 (2012).

Wang, R. et al. Nanocarbon-based electrocatalysts for rechargeable aqueous Li/Zn-air batteries. ChemElectroChem 5, 1745–1763 (2018).

Wu, X. et al. Perovskite oxide/carbon nanotube hybrid bifunctional electrocatalysts for overall water splitting. Electrochim. Acta 286, 47–54 (2018).

Urgunde, A. B., Bahuguna, G., Dhamija, A., Kamboj, V. & Gupta, R. Scalable production of nickel cobaltite nanoplates using solution-processed inks for OER electrocatalysis. Mater. Res. Bull. 142, 111380 (2021).

Lyu, Y.-Q. & Ciucci, F. Activating the bifunctionality of a perovskite oxide toward oxygen reduction and oxygen evolution reactions. ACS Appl. Mater. Interfaces 9, 35829–35836 (2017).

Amjadi, M. S., Ashassi-Sorkhabi, H., Hosseini, M. G., Pollet, B. G. & Asghari, E. N/S-RCQD@ NiCo2S4 nanocomposite with wrinkled nanosheet-like edges as an anode for water splitting. J. Energy Storage 72, 108364 (2023).

Aso, R., Kan, D., Shimakawa, Y. & Kurata, H. Atomic level observation of octahedral distortions at the perovskite oxide heterointerface. Sci. Rep. 3, 2214 (2013).

Yu, N. et al. Dynamic equilibrium of external Fe3+ to effectively construct catalytic surface of perovskite LaNi1−xFexO3 for water oxidation. Colloids Surf. A Physicochem. Eng. Asp. 654, 130042 (2022).

Sun, Y. et al. A-site management prompts the dynamic reconstructed active phase of perovskite oxide OER catalysts. Adv. Energy Mater. 11, 2003755 (2021).

Wang, Y. et al. Tuning the surface energy density of non-stoichiometric LaCoO3 perovskite for enhanced water oxidation. J. Power Sources 478, 228748 (2020).

Wang, Y. et al. Design strategies of perovskite nanofibers electrocatalysts for water splitting: A mini review. Chem. Eng. J. 451, 138710 (2023).

Shahbazi-Derakhshi, P. et al. An ultrasensitive miRNA-based genosensor for detection of microRNA 21 in gastric cancer cells based on functional signal amplifier and synthesized perovskite-graphene oxide and AuNPs. Biosensors (Basel) 13, 172 (2023).

Ahangari, M. et al. Investigation of structural and electrochemical properties of SrFexCo1−xO3-δ perovskite oxides as a supercapacitor electrode material. J. Energy Storage 63, 107034 (2023).

Hu, M. et al. Alumina nanofiber-stabilized ruthenium nanoparticles: Highly efficient catalytic materials for hydrogen evolution from ammonia borane hydrolysis. Int. J. Hydrog. Energy 42, 24142–24149 (2017).

Zhao, J.-W., Shi, Z.-X., Li, C.-F., Ren, Q. & Li, G.-R. Regulation of perovskite surface stability on the electrocatalysis of oxygen evolution reaction. ACS Mater. Lett. 3, 721–737 (2021).

Zhu, Y. et al. A perovskite nanorod as bifunctional electrocatalyst for overall water splitting. Adv. Energy Mater. 7, 1602122 (2017).

Esmailzadeh, S., Shahrabi, T., Yaghoubinezhad, Y. & Darband, G. B. Optimization and characterization of pulse electrodeposited nickel selenide nanostructure as a bifunctional electrocatalyst by response surface methodology. Int. J. Hydrog. Energy 46, 18898–18912 (2021).

Zhao, J.-W., Shi, Z.-X., Li, C.-F., Ren, Q. & Li, G.-R. Regulation of perovskite surface stability on the electrocatalysis of oxygen evolution reaction. ACS Mater. Lett. 3, 721–737 (2021).

Dai, J. et al. Enabling high and stable electrocatalytic activity of iron-based perovskite oxides for water splitting by combined bulk doping and morphology designing. Adv. Mater. Interfaces 6, 1801317 (2019).

Suntivich, J. et al. Estimating hybridization of transition metal and oxygen states in perovskites from Ok-edge x-ray absorption spectroscopy. J. Phys. Chem. C 118, 1856–1863 (2014).

Wang, Y. et al. Tuning the surface energy density of non-stoichiometric LaCoO3 perovskite for enhanced water oxidation. J. Power Sources 478, 228748 (2020).

Grimaud, A. et al. Double perovskites as a family of highly active catalysts for oxygen evolution in alkaline solution. Nat. Commun. 4, 2439 (2013).

Wu, Y. et al. Catalytic reduction of NO by CO over B-site partially substituted LaM0.25Co0.75O3 (M = Cu, Mn, Fe) perovskite oxide catalysts: The correlation between physicochemical properties and catalytic performance. Appl. Catal. A Gen. 568, 43–53 (2018).

Li, Z. et al. An effective method for enhancing oxygen evolution kinetics of LaMO3 (M= Ni Co, Mn) perovskite catalysts and its application to a rechargeable zinc–air battery. Appl. Catal. B 262, 118291 (2020).

Grünbacher, M. et al. Promotion of La (Cu0.7Mn0.3)0.98M0.02O3−δ (M = Pd, Pt, Ru and Rh) perovskite catalysts by noble metals for the reduction of NO by CO. J. Catal. 379, 18–32 (2019).

Li, D. et al. Noble-metal-free Mo2C co-catalsyt modified perovskite oxide nanosheet photocatalysts with enhanced hydrogen evolution performance. Colloids Surf. A Physicochem. Eng. Asp. 615, 126252 (2021).

Suntivich, J., May, K. J., Gasteiger, H. A., Goodenough, J. B. & Shao-Horn, Y. A perovskite oxide optimized for oxygen evolution catalysis from molecular orbital principles. Science 1979(334), 1383–1385 (2011).

Sun, H. & Zhou, W. Progress on X-ray absorption spectroscopy for the characterization of perovskite-type oxide electrocatalysts. Energy Fuels 35, 5716–5737 (2021).

Plevova, M., Hnat, J. & Bouzek, K. Electrocatalysts for the oxygen evolution reaction in alkaline and neutral media. A comparative review. J Power Sources 507, 230072 (2021).

Mahmoudi, E. et al. LaCoO3-BaCoO3 porous composites as efficient electrocatalyst for oxygen evolution reaction. Chem. Eng. J. 473, 144829 (2023).

Boucly, A. et al. Surface segregation acts as surface engineering for the oxygen evolution reaction on perovskite oxides in alkaline media. Chem. Mater. 32, 5256–5263 (2020).

Sankannavar, R. & Sarkar, A. The electrocatalysis of oxygen evolution reaction on La1−xCaxFeO3−δ perovskites in alkaline solution. Int. J. Hydrog. Energy 43, 4682–4690 (2018).

Cheng, X. et al. Oxygen evolution reaction on La1–xSrxCoO3 perovskites: A combined experimental and theoretical study of their structural, electronic, and electrochemical properties. Chem. Mater. 27, 7662–7672 (2015).

Liu, C. et al. An A-site management and oxygen-deficient regulation strategy with a perovskite oxide electrocatalyst for the oxygen evolution reaction. J. Mater. Chem. A Mater. 10, 1336–1342 (2022).

Zhang, D. et al. Active LaNi1–xFexO3 bifunctional catalysts for air cathodes in alkaline media. J. Mater. Chem. A Mater. 3, 9421–9426 (2015).

Yan, Z. et al. Rapid low-temperature synthesis of perovskite/carbon nanocomposites as superior electrocatalysts for oxygen reduction in Zn-air batteries. Nano Res. 11, 3282–3293 (2018).

Xu, X., Wang, W., Zhou, W. & Shao, Z. Recent advances in novel nanostructuring methods of perovskite electrocatalysts for energy-related applications. Small Methods 2, 1800071 (2018).

Hong, W. T. et al. Charge-transfer-energy-dependent oxygen evolution reaction mechanisms for perovskite oxides. Energy Environ. Sci. 10, 2190–2200 (2017).

Han, B. et al. Activity and stability trends of perovskite oxides for oxygen evolution catalysis at neutral pH. Phys. Chem. Chem. Phys. 17, 22576–22580 (2015).

Wang, X. et al. High-performance platinum-perovskite composite bifunctional oxygen electrocatalyst for rechargeable Zn–air battery. Adv. Energy Mater. 10, 1903271 (2020).

Zhang, M. et al. Recent development of perovskite oxide-based electrocatalysts and their applications in low to intermediate temperature electrochemical devices. Mater. Today 49, 351–377 (2021).

Flores-Lasluisa, J. X., Huerta, F., Cazorla-Amorós, D. & Morallón, E. LaNi1−xCoxO3 perovskites for application in electrochemical reactions involving molecular oxygen. Energy 273, 127256 (2023).

Jeerh, G., Zou, P., Zhang, M. & Tao, S. Perovskite oxide LaCr0.25Fe0.25Co0.5O3−δ as an efficient non-noble cathode for direct ammonia fuel cells. Appl. Catal. B 319, 121919 (2022).

Grimaud, A. et al. Double perovskites as a family of highly active catalysts for oxygen evolution in alkaline solution. Nat. Commun. 4, 2439 (2013).

Dai, J. et al. Enabling high and stable electrocatalytic activity of iron-based perovskite oxides for water splitting by combined bulk doping and morphology designing. Adv. Mater. Interfaces 6, 1801317 (2019).

Tang, L. et al. Enhancing perovskite electrocatalysis through synergistic functionalization of B-site cation for efficient water splitting. Chem. Eng. J. 401, 126082 (2020).

Jourdain, V. & Bichara, C. Current understanding of the growth of carbon nanotubes in catalytic chemical vapour deposition. Carbon N. Y. 58, 2–39 (2013).

Elumeeva, K. et al. Perovskite-based bifunctional electrocatalysts for oxygen evolution and oxygen reduction in alkaline electrolytes. Electrochim. Acta 208, 25–32 (2016).

Chen, Z. et al. Highly active and durable core–corona structured bifunctional catalyst for rechargeable metal–air battery application. Nano Lett. 12, 1946–1952 (2012).

Lee, D. U., Park, H. W., Park, M. G., Ismayilov, V. & Chen, Z. Synergistic bifunctional catalyst design based on perovskite oxide nanoparticles and intertwined carbon nanotubes for rechargeable zinc–air battery applications. ACS Appl. Mater. Interfaces 7, 902–910 (2015).

Thanh, T. D. et al. Porous hollow-structured LaNiO3 stabilized N, S-codoped graphene as an active electrocatalyst for oxygen reduction reaction. Small 13, 1701884 (2017).

Hu, J., Liu, Q., Shi, Z., Zhang, L. & Huang, H. LaNiO3-nanorod/graphene composite as an efficient bi-functional catalyst for zinc–air batteries. RSC Adv. 6, 86386–86394 (2016).

Ge, X. et al. Efficient and durable oxygen reduction and evolution of a hydrothermally synthesized La (Co0.55Mn0.45)0.99O3−δ nanorod/graphene hybrid in alkaline media. Nanoscale 7, 9046–9054 (2015).

Prabu, M., Ramakrishnan, P., Ganesan, P., Manthiram, A. & Shanmugam, S. LaTi0.65Fe0.35O3−δ nanoparticle-decorated nitrogen-doped carbon nanorods as an advanced hierarchical air electrode for rechargeable metal-air batteries. Nano Energy 15, 92–103 (2015).

Zhu, Y., Zhou, W. & Shao, Z. Perovskite/carbon composites: Applications in oxygen electrocatalysis. Small 13, 1603793 (2017).

Su, H., Pasupathi, S., Bladergroen, B., Linkov, V. & Pollet, B. G. Performance investigation of membrane electrode assemblies for high temperature proton exchange membrane fuel cell. J. Power Energy Eng. 1, 95 (2013).

Dallaev, R. et al. Brief review of PVDF properties and applications potential. Polymers (Basel) 14, 4793 (2022).

Jeerh, G., Zou, P., Zhang, M. & Tao, S. Perovskite oxide LaCr0.25Fe0.25Co0.5O3−δ as an efficient non-noble cathode for direct ammonia fuel cells. Appl. Catal. B 319, 121919 (2022).

Tamoradi, T., Kiasat, A. R., Veisi, H., Nobakht, V. & Karmakar, B. RSM process optimization of biodiesel production from rapeseed oil and waste corn oil in the presence of green and novel catalyst. Sci. Rep. 12, 19652 (2022).

Sepehrnia, M., Maleki, H., Karimi, M. & Nabati, E. Examining rheological behavior of CeO2–GO–SA/10W40 ternary hybrid nanofluid based on experiments and COMBI/ANN/RSM modeling. Sci. Rep. 12, 22054 (2022).

Kalantari, N., Farzi, A., Çaylak Delibaş, N., Niaei, A. & Salari, D. Synthesis of multiple-template zeolites with various compositions and investigation of their catalytic properties. Res. Chem. Intermed. 47, 4957–4984 (2021).

Khoshkroodi, S. R. G., Lalinia, M., Moosavian, M. A. & Sillanpää, M. Erbium adsorption from aqueous solutions using RSM-based optimization of the phosphate functional group in modified nano titania. Colloids Surf. A Physicochem. Eng. Asp. 641, 128537 (2022).

Hosseini, S. A., Salari, D., Niaei, A. & Oskoui, S. A. Physical–chemical property and activity evaluation of LaB0.5Co0.5O3 (B = Cr, Mn, Cu) and LaMnxCo1−xO3 (x = 0.1, 0.25, 0.5) nano perovskites in VOC combustion. J. Ind. Eng. Chem. 19, 1903–1909 (2013).

Qiu, Z., Ma, Y., Niklasson, G. A. & Edvinsson, T. An electrochemical impedance study of alkaline water splitting using Fe doped NiO nanosheets. Physchem 1, 69–81 (2021).

Zhang, T. et al. Design and synthesis of α-Fe2O3/MIL-53 (Fe) composite as a photo-Fenton catalyst for efficient degradation of tetracycline hydrochloride. Colloids Surf. A Physicochem. Eng. Asp. 659, 130822 (2023).

Rana, A., Hasan, I., Koo, B. H. & Khan, R. A. Green synthesized CeO2 nanowires immobilized with alginate-ascorbic acid biopolymer for advance oxidative degradation of crystal violet. Colloids Surf. A Physicochem. Eng. Asp. 637, 128225 (2022).

Khoshkroodi, S. R. G., Lalinia, M., Moosavian, M. A. & Sillanpää, M. Erbium adsorption from aqueous solutions using RSM-based optimization of the phosphate functional group in modified nano titania. Colloids Surf. A Physicochem. Eng. Asp. 641, 128537 (2022).

Huang, X. et al. Ethylene production over A/B-site doped BaCoO3 perovskite by chemical looping oxidative dehydrogenation of ethane. Fuel 327, 125210 (2022).

Ao, R. et al. NO oxidation performance and kinetics analysis of BaMO3 (M = Mn, Co) perovskite catalysts. Environ. Sci. Pollut. Res. 28, 6929–6940 (2021).

Nagalakshmi, T. V., Emmanuel, K. A., Suresh Babu, C., Chakrapani, C. & Divakar, P. P. Preparation of mesoporous activated carbon from jackfruit PPI-1 waste and development of different surface functional groups. Int. Lett. Chem. Phys. Astron. 54, 189–200 (2015).

Zhang, W. et al. Preparation of supported perovskite catalyst to purify membrane concentrate of coal chemical wastewater in UV-catalytic wet hydrogen peroxide oxidation system. Int. J. Environ. Res. Public Health 18, 4906 (2021).

Ortiz-Quiñonez, J.-L., García-González, L., Cancino-Gordillo, F. E. & Pal, U. Particle dispersion and lattice distortion induced magnetic behavior of La1−xSrxMnO3 perovskite nanoparticles grown by salt-assisted solid-state synthesis. Mater. Chem. Phys. 246, 122834 (2020).

Rodrigues, A., Bauer, S. & Baumbach, T. Effect of post-annealing on the chemical state and crystalline structure of PLD Ba0.5Sr0.5TiO3 films analyzed by combined synchrotron X-ray diffraction and X-ray photoelectron spectroscopy. Ceram. Int. 44, 16017–16024 (2018).

Mohammadi, T., Hosseini, M. G., Ashassi-Sorkhabi, H. & Sefidi, P. Y. Investigating performance of flower-like CoCu–MOF supported on carbon felt as a binder-free anode electrode in direct ethanol fuel cell. Synth. Met. 298, 117443 (2023).

Tapia-P, J., Gallego, J. & Espinal, J. F. Calcination temperature effect in catalyst reactivity for the CO SELOX reaction using perovskite-like LaBO3 (B: Mn, Fe Co, Ni) oxides. Catal. Lett. 151, 1–14 (2021).

Wang, H. et al. Cation deficiency tuning of LaCoO3 perovskite as bifunctional oxygen electrocatalyst. ChemCatChem 12, 2768–2775 (2020).

Ansari, A. A. et al. Catalytic performance of the Ce-doped LaCoO3 perovskite nanoparticles. Sci. Rep. 10, 15012 (2020).

Mishra, A. & Prasad, R. Synthesis and performance of transition metal based perovskite catalysts for diesel soot oxidation. Bull. Chem. React. Eng. Catal. 12, 469–477 (2017).

Moyo, M., Nyamhere, G., Sebata, E. & Guyo, U. Kinetic and equilibrium modelling of lead sorption from aqueous solution by activated carbon from goat dung. Desalin. Water Treat. 57, 765–775 (2016).

Sreedhar, B., Vani, C. S., Devi, D. K., Rao, M. V. B. & Rambabu, C. Shape controlled synthesis of barium carbonate microclusters and nanocrystallites using natural polysachharide: Gum acacia. Am. J. Mater. Sci 2, 5–13 (2012).

Jin, C., Cao, X., Lu, F., Yang, Z. & Yang, R. Electrochemical study of Ba0.5Sr0.5Co0.8Fe02O3 perovskite as bifunctional catalyst in alkaline media. Int. J. Hydrog. Energy 38, 10389–10393 (2013).

Wang, H. et al. Polymer-assisted approach to LaCo1−xNixO3 network nanostructures as bifunctional oxygen electrocatalysts. Electrochim. Acta 296, 945–953 (2019).

Gosavi, P. V. & Biniwale, R. B. Pure phase LaFeO3 perovskite with improved surface area synthesized using different routes and its characterization. Mater. Chem. Phys. 119, 324–329 (2010).

Christ, J. M. et al. Synthesis of high surface area CaxLa(1–x)Al(1–x)MnxO(3−δ) perovskite oxides for oxygen reduction electrocatalysis in alkaline media. Catal. Sci. Technol. 6, 7744–7751 (2016).

Zhu, Y., Zhou, W., Sunarso, J., Zhong, Y. & Shao, Z. Phosphorus-doped perovskite oxide as highly efficient water oxidation electrocatalyst in alkaline solution. Adv. Funct. Mater. 26, 5862–5872 (2016).

Zhu, K. et al. Oxygen evolution reaction over Fe site of BaZrxFe1−xO3−δ perovskite oxides. Electrochim. Acta 241, 433–439 (2017).

Phadtare, D., Kondawar, S., Athawale, A. & Rode, C. Crystalline LaCoO3 perovskite as a novel catalyst for glycerol transesterification. Mol. Catal. 475, 110496 (2019).

Ortiz, L. G. et al. Low-temperature synthesis and gas sensitivity of perovskite-type LaCoO3 nanoparticles. J. Nanomater. 2014, 61 (2014).

Sing, K. S. W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). Pure Appl. Chem. 57, 603–619 (1985).

Nishi, Y. & Inagaki, M. Gas adsorption/desorption isotherm for pore structure characterization. In Materials Science and Engineering of Carbon 227–247 (Elsevier, 2016).

Ansaripoor-Jermafshadi, Z. & Nezamzadeh-Ejhieh, A. The experimental design and mechanism study of the rifampin photodegradation by PbS–Co3O4 coupled catalyst. Mater. Res. Bull. 155, 111972 (2022).

Li, Q. et al. Phase engineering of atomically thin perovskite oxide for highly active oxygen evolution. Adv. Funct. Mater. 31, 2102002 (2021).

Sankannavar, R. & Sarkar, A. The electrocatalysis of oxygen evolution reaction on La1−xCaxFeO3−δ perovskites in alkaline solution. Int. J. Hydrog. Energy 43, 4682–4690 (2018).

Du, Z. et al. Electrocatalytic performances of LaNi1−xMgxO3 perovskite oxides as bi-functional catalysts for lithium air batteries. J. Power Sources 265, 91–96 (2014).

Zhang, D. et al. Active LaNi1−xFexO3 bifunctional catalysts for air cathodes in alkaline media. J. Mater. Chem. A Mater. 3, 9421–9426 (2015).

Acknowledgements

The researchers extend their thanks and appreciation to the collaboration and support of the Scientific Research Projects Coordination of the University of Sakarya (BAP-ULİP-2022-16-36-36), the University of Tabriz and Turkish scholarships association.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

E.M. Conceptualization, Methodology, Writing—Original Draft, Visualization. E.A. Supervision, Data curation, Writing—Review and Editing. N.D. Supervision, Writing—Review and Editing. A.N. Supervision, Writing—Review and Editing. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mahmoudi, E., Asghari, E., Delibaş, N. et al. Application of response surface methodology for optimization of the test condition of oxygen evolution reaction over La0.8Ba0.2CoO3 perovskite-active carbon composite. Sci Rep 13, 22878 (2023). https://doi.org/10.1038/s41598-023-49836-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-023-49836-1

This article is cited by

-

Perovskite engineering for efficient oxygen evolution reaction through iron and silver doping

Scientific Reports (2025)

-

Platinum-perovskite nanocomposite-based Exosensor for specific detection of prostate cancer in clinical settings

Microchimica Acta (2024)