Abstract

For fractured gas reservoirs with strong water drive, gas phase trapping affects the gas recovery significantly. The recovery may be less than 50% for some reservoirs while it is only 12% for Beaver River gas field. The gas phase trapping mechanism has been revealed by the results of depletion experimental test. The residual pressure of the trapped gas is as high as 11.75 MPa with a 12.8 cm imbibition layer resulting in gas recovery deceased 49.5% compared with that without imbibition layer. A mathematical model is built to calculate the imbibition thickness based on capillary pressure and relative permeability of the matrix. The gas phase trapping are analyzed by two representative wells in Weiyuan gas field, the intermittent production reinforces the imbibition thickness and result in gas trapped in the matrix block with high residual pressure for the low performace gas wells, the extremely low gas recovery can be explained more rationally. That lays a foundation of improving the gas recovery for fractured reservoirs.

Similar content being viewed by others

Introduction

Gas phase trapping is a key factor affecting the gas recovery. For water drive gas reservoirs with well-developed natural fractures, the effect of gas phase trapping will be more significant. Therefore, fully understand the mechanism of gas phase trapping, and then quantitatively characterize these, helps to improve gas recovery from fractured reservoirs.

For the phase trapping phenomena, it has been analyzed mostly at micro scale. In 1994, Bennion et al. recognized the potential mechanisms behind phase trapping and postulated that the gas reservoirs with low initial water saturation tend to be susceptible to formation imparment by phase trapping1. In 1996, Bennion et al. described specific situations required for the establishment of aqueous and hydrocarbon phase traps and gave diagnostic equations to assess the potential severity of aqueous phase trap in a given reservoir condition. Besides a variety of methods that may remove the aqueous or hydrocarbon phase trapping were also presented2. In 2002, van Duijn et al. derived the effective transport equations for two phase flow with trapping on the micro scale by homogenization techniques, which was verified by numerical experiments3. In 2002, Zhou et al. observed the micro distribution relation between gas and water through visualized artificial physical models of gas–water two phase flow by laser engraving technique4. In 2003, Pang et al., conducted physical modelling of a single glass tube, which studied the critical diameter of gas trapping at different flow rate5. In 2004, Wu et al. observed that there are three phenomena of gas and water phases flowing in the fractured formation with water channeling, bypassing and plugging by laser sculpture techniques6. Xiong et al. studied aquifer behavior and water invasion performance partly trapped in heterogeneous gas reservoir by analyzing Aquifer Influenced Functions model7. In 2007, van Duijn et al. recognized that trapping effects need to be considered explicitly by deriving an upscaled equation based on the study in 20023,8. In 2010, Mirzaei et al. established a full procedure for evaluating and minimizing formation damage by aqueous phase trapping9. In 2013, Rezaee et al. concluded that the amount of trapped gas reduces as the heterogeneity of the porous media increases by using experimental models10. In 2017, the mechanism of gas–water two phase micro seepage and the formation mechanisms of trapped gas were studied through three types of visual micromodels by combining the CT scanning technology and laser etching techniques11. In 2020, Ghosh et al. studied the two-phase flow behaviors in highly heterogeneous porous media by changing porosity and permeability through an improved two-phase model12.

In spontaneous imbibition process, wetting fluid invades a porous medium and floods the non-wetting fluid under the action of capillary forces13, which will lead to water invasion and gas phase trapping in low-permeability or tight fractured reservoirs14,15,16. In the early nineteenth century, Lucas and Washburn established Lucas-Washburn imbibition model of liquid wetting and conclude that the relation between the imbibition rate and the square root of time is linear17,18. In 1960, Handy established an equation for predicting water imbibition behavior in porous media based on the postulation of piston-like manner when water displaced air19. Li et al. extended the Handy equation by considering the influence of capillary forces and gravity as well as discussing the influence of initial water saturation on imbibition rate, residual saturation and recovery20,21. In general, L–W model and handy model have been widely influential, and the theoretical study and model improvement based on these two models have continued to the present. However, the L–W model considers that the wetting phase fluid must fill all pores after the imbibition occurs. Handy model assumes that the water saturation of imbibition zone is constant, and water imbibe in a piston-like manner. In 2021, Xu et al. observed that the maximum saturation of water phase imbibition is between 45 and 76% according to the stratified NMR technique. Besides the imbibition process was a non-piston-like and there was a clear transition zone at the imbibition front and then the L–W model was optimized and modified through experimental results16.

Indeed, it is not difficult to find out that the phase trapping phenomena are not studied extensively at the field scale. The research mainly focused on the calculation of water influx, the impact degree of water invasion, and the change laws of water invasion performance in water-bearing gas reservoirs22,23,24,25. In 2012, Fan et al. described that water invasion of gas reservoir can be macroscopically classified into water invasion of rocks with low permeability, water invasion of gas reservoir and “reserve water invasion” of well shutdown, which made the gas area separated and changed the mobile gas into “dead” gas26. In 2018, Wang et al. pointed out that gas trapping in fractured sandstone gas reservoirs is difficult to simulate by existing numerical simulation techniques and its impact on gas recovery was less understood27. In 2021, Tan et al. established the material balance method considering the phenomenon of water sealed gas to characterize the non-uniformity degree of reservoir physical properties and the activity degree of peripheral water, respectively28.

To better understand the mechanism of gas phase trapping at the field scale and quantitatively characterize its forming conditions as well as explaining the extreme low recovery of fractured gas reservoir with strong heterogeneity, depletion experimental test by using core sample with spontaneous imbibition has been designed, and the gas phase trapping mechanism has been revealed by the results. A mathematical model has been established to exhibit the imbibition thickness and then the gas phase trapping is analyzed in Weiyuan gas field.

Methodology

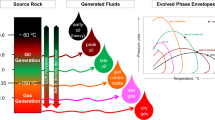

For fractured gas reservoirs with strong water drive, the aquifer is easy intrude into the reservoir with the fractures almost fully filled with invaded water owing to the pressure depletion in fractures is more quickly than that in matrix. When the well is shut in, the pressure in fractures will be built up and tend to balance with the adjacent matrix. Due to the water is wetting phase for gas reservoirs, therefore the water will spontaneous imbibe into the adjacent matrix and the imbibition thickness gets thicker and thicker over time. The imbibition of water to matrix is reverse to the direction of gas phase flow from matrix to fractures, it can be classified as counter imbibition. With high imbibition water saturation, the imbibition layer will dramatically decrease the relative permeability for gas phase and it is very difficult for the gas in matrix flow back into the fractures when the well put into production again, resulting in more gas trapped in the matrix block with very high residual pressure in its drainage area.

A physical model is established based on the above mechanism of gas phase trapping and a mathematical model is built to calculate the imbibition thickness based on capillary pressure and relative permeability of the matrix, which cuold be used in field scale study. In addition, A depletion test is designed to investigate that how the imbibition thickness affect the flow performance. Core B is 20 cm in length with different imbibition thickness established by spontaneous imbibition16, which act as the imbibition layer and put between two 100 cm core group of C and A. The effect of the imbibition thickness on gas recovery is conformed by the depletion experimental tests. The well performance in Weiyuan gas field also proved that the imbibition caused by frequent shut-in affects gas reservoir recovery dramaticly.

Mechanism of gas phase trapping

Physical model of gas phase trapping

For fractured gas reservoirs, natural gas is mainly stored in matrix, while natural fractures, with strong conductivity and small seepage resistance, often acts as the flow path for water invasion. During the process of gas reservoir depletion, the pressure in the natural fractures is preferentially decreased with very high decline rate and form a low potential energy area in fractures. When the drainage front reaches the gas–water contact (GWC), the edge/bottom water preferentially enter these fractures with low potential energy, forming a pattern of rich gas in matrix and rich water in fractures. Figure 1 is a typical dual pores model of water invasion through fractures.

Assuming that the heterogeneity of matrix block is ignored, the fractured reservoir can be equivalent to the combination of multiple matrix blocks. Taken a matrix block in the dual pores model (Fig. 1) as an example, the phase trapping process is as following: (1) With the depletion of the gas reservoir, the pressure in the natural fractures drops more rapidly than that in matrix, and the aquifer invade into the fractures when the drainage front reaches the GWC. While during the gas well shut-in, the pressure in the fractures recover and tend to equilibrium with that in the matrix. Due to the reservoir rock are mostly characterized of water wet, the water invaded in the fractures will spontaneously imbibe into the adjacent matrix (Fig. 2a) by capillary pressure. (2) An imbibition layer (Fig. 2b) is formed at the periphery of the matrix block with a certain thickness and high-water saturation. The longer the shut-in period, the greater the imbibition thickness. Due to the increase of water saturation, the seepage channel of the imbibition layer is greatly reduced, and the effective permeability of the gas phase is greatly decreased simultaneously, therefore the natural gas in the inner matrix is trapped. (3) When the gas well put into production again, it is very difficult for the trapped gas in the matrix flowing back into the fractures (Fig. 2c) due to the significant decrease of the gas phase permeability of the imbibition layer. As a result, the gas rate decreases sharply and the liquid loading capacity get lower and the gas well has to produce in an intermittent mode, furthermore the imbibition layer tends to be thicker and thicker when the well is shut-in, resulting in lower and lower the gas rate. Under the same abandoned conditions, an abnormally high residual pressure is formed in the matrix block, and the natural gas that cannot efficiently produced from the matrix become the final trapped gas.

Forming process of the trapped gas in a matrix block, (a) Water in the fractures imbibe into the matrix block; (b) Imbibition layer formed at the periphery of the matrix block over time; (c) Through the imbibition layer, gas in the matrix block flow back into the fractures with low flow rate and some gas trapped in the matrix at the end of production.

Mathematical model of gas phase trapping

It is assumed that the initial water saturation of the matrix is Swi and the imbibition is piston-like with gas saturation at imbibition front is 1-Sgr. In addition, considering that only the water and gas is exchanged in the process of imbibition while the pressure remains unchanged, the imbibition mathematical model is obtained as following.

The governing equation:

Capillary pressure of spontaneous imbibition:

Initial water saturation in matrix:

Asumming that the imbibition is piston-like and the water saturation at the imbibition front:

Equations (1)–(5) together constitute the mathematical model of spontaneous imbibition of matrix block for fractured gas reservoir with water invasion through fractures. Since the relative permeability Krg and capillary pressure Pc are nonlinear functions of saturation, the imbibition behavior is studied by numerical method.

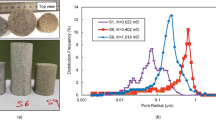

Imbibition thickness calculation. Capillary pressure (Fig. 3a) and relative permeability (Fig. 3b) could be obtained by mercury injection and core flooding test respectively. For an example, the matrix permeability is 0.1 mD with irreducible water saturation in the matrix of 35%, and the water saturation of the imbibition front of 75%.

According to the mathematical model and the known data, imbibition thickness of matrix varies with time is shown in Fig. 4. For the low permeability gas reservoir, the 30-day imbibition thickness is 0.06 m, the 180-day imbibition thickness is 0.16 m, the 360-day imbibition thickness is 0.61 m, and the 1080-day imbibition thickness is as high as 1.14 m.

Depletion experimental test considering imbibition

Three groups of cores with different imbibition thickness were connected in series to perform physical simulation experiments of depletion. The effect of imbibition later on gas recovery can be measured and the gas phase trapping by imbibition layer are verified.

Depletion experimental test. Core sample preparation: Three groups of cores with similar permeability but different imbibition thickness is used for the depletion experiment (Fig. 5). The core of group C and group A is dry samples with length of 100 cm and permeability of 0.22 mD and 0.27 mD respectively. The core length of group B is 20 cm with permeability of 0.17 mD, which is put between group C and group A act as the imbibition layer with different imbibition thickness. The imbibition layer is established by spontaneous imbibition16, and the imbibition thickness is 0 cm, 8.8 cm and 12.8 cm respectively in three depletion tests with imbibition water saturation of 75%.

The experimental process is as following: (1) Gas is injected into the three groups of cores synchronously and slowly through both the inlet and outlet until the pressure is stable at 20.5 MPa to simulate the original formation pressure of the gas reservoir. (2) The outlet is connected with a flow controller, which acted as both mass flow meter and flow controller, to control the gas flow rate according to the designed gas rate and simulate the depletion process of gas reservoir. (3) The pressures measured every 20 cm both on group A and group C, and both the inlet (left side of group C) and outlet (right side of group A), and between the core holders. The pressure profile can be built at any time of the whole test.

Analysis of experimental results of depletion. The cores of group A and C keep unchange, and the cores of group B with different imbibition thickness are successively replaced to conduct three depletion experiments. The pressure drop profile during the depletion test is shown in Fig. 6.

There is no imbibition layer in the first depletion experiment, that is, the core of group B is dry sample, and its permeability was close to that of the cores of groups A and C. The overall pressure profile decreased uniformly (Fig. 6a). At the end of experiment, the average residual pressure of the core of group C is 1.60 MPa. Assuming that the gas compression factor is constant, the estimated gas recovery of group C is 92.2%.

As for the second depletion experiment, the imbibition thickness is 8.8 cm in core of group B. Although the thickness of the imbibition layer is not so large, the lower-permeability effect is obvious (Fig. 6b). At 90 min, the average core pressure of group C is maintained at 20.13 MPa, even though the pressure drop of group B with imbibition layer is as high as 17.65 MPa and the pressure gradient is 0.88 MPa/cm. With the prolongation of time, the gas flow gradually breaks through the core of Group B, and the water saturation in the core of group B is gradually reduced, and the seepage capacity is gradually increased. At 180 min, although the pressure drop at both ends of group B is still as high as 17.79 MPa, the pressure of group C had decreased 0.85 MPa, indicating that the reserves in group C began to be recovered. At the end of the experiment (4371 min), the pressure drop at both ends of group B has decreased to 2.69 MPa, indicating that its seepage capacity has been greatly improved, but the pressure gradient at both ends of group B is still up to 0.13 MPa/cm, indicating that its seepage resistance is still very high. In contrast, the pressure gradient at both ends of group B was only 0.016 MPa/cm in the first experiment without imbibition layer. Due to the existence of imbibition layer, the average residual pressure of group C was 3.3 MPa at the end of the experiment, and the gas recovery is 83.5%, which is 8.7% lower than that in the first experiment.

The third experiment also contain imbibition layer with the imbibition thickness increased to 12.8 cm. The pressure drop at both ends of the core in group B is also obvious, and the barrier ability is stronger (Fig. 6c). At 180 min, although the pressure drop at both ends of group B is as high as 19.67 MPa with the pressure gradient of 0.98 MPa/cm, the core pressure of group C remains at the original pressure, indicating that the reserves in group C have not been recovered yet. At the end of experiment (3968 min), pressure drop at both ends of group B is still as high as 10.95 MPa with pressure gradient of 0.55 MPa/cm. The residual pressure in group C is as high as 11.75 MPa, and the gas recovery decreased to 42.7%, which is 49.5% lower than that without imbibition layer.

The comparative analysis of the three experiments shows that the imbibition layer has high water saturation and strong separation ability even the imbibition thickness is not so high. Of course, the greater the imbibition thickness, the more obvious the sealing effect, the greater the proportion of trapped gas and the lower the gas recovery.

Case study of Weiyuan gas field

Weiyuan Gas Field is located in the middle of Sichuan Basin. The Dengying gas reservoir is dolomite with low porosity, low permeability, and well developed fractures29,30,31. Matrix permeability is in range of 0.001 to 1.13 mD with an average of 0.045 mD. Natural fractures effectively improve the permeability of the gas reservoir, the permeability measured by well test is 0.01–50.27 mD with an average of 2.26 mD, which is 51 times of the matrix permeability. The gas recovery is only 37% currently, which is close to the end of development. The main reason for the low recovery is bottom water invasion through fractures. The invaded water in the fracture imbibes into adjacent matrix, which greatly reduces gas supply capacity of the matrix, resulting in the formation of a large amount of trapped gas with high residual pressure. Two representative gas wells are taken as examples to illustrate the formation of trapped gas and its impact on gas recovery.

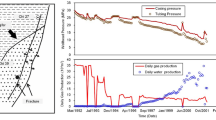

Well W2 is a high performance well with effective permeability of 1.39 mD. It was put into production in September 1965 with daily gas rate of 300–400 MCMD in the stable production period. With the increase of the number of wells put into production, the gas rate decreased quickly. The water broke through in February 1987, and daily water rate gradually rose to 30–40 CMD with the daily gas rate decreased to 15–25 MCMD. After 1991, The daily gas rate droped to 5–12 MCMD and the water rate increased to 80–120 CMD, the gas well shifts to produce intermittently with 2–15 producing days per month (Fig. 7a). The dynamic reserves of well W2 is estimated of 15.81 MMCM, while the accumulated gas production is 11.84 MMCM by the end of 2015 with the gas recovery of 74.9%.

Well W9 is a low performance well with effective permeability of 0.14 mD. It was put into production in March 1967, with a daily gas rate of 50–80 MCMD in stable production period. In May 1974, the gas rate decreased rapidly to 40 MCMD after water broke through, and the daily water rate rose to 2–6 CMD. After February 1979, the water rate increased to 5–20 CMD, and the gas well had to produce intermittently with 3–8 producing days per month (Fig. 7b). The daily gas rate is in range of 4–10 MCMD with average of 6.6 MCMD, accounting for only 23% compared with the previous period. The dynamic reserves of well W9 is 623 MMCM. By the end of 2015, the cumulative gas production is 144 MMCM, and the gas recovery is only 23.1%, 51.8% lower than that of Well W2.

Gas is mainly produced in the water-free production period and the continuous production stage after watered out. Although the intermittent production period is very long, corresponds to that the gas contribution is very low due to the imbibition layer formed in the matrix block. During the intermittent production period of well W2 from January 1992 to March 2004, the cumulative gas production is 15.69 MMCM, accounting for only 13.3% of the cumulative gas production.

For the fractured gas reservoir, the fractures filled with water after water broke through. Therefore, an imbibition layer is easy to be formed by spontaneous imbibition especially in the intermittent production period, so that the gas in the matrix is very difficult to flow through the imbibition layer and back into the fractures, resulting in gas trapped in the matrix block with very high residual pressure in its drainage area. Compare with the high performance well W2, the fractures are not well development in well W9, and relatively the large matrix block let the gas flow less efficiently from matrix flow to fractures resulting in the pressure remains very high (Fig. 8). Owing to the gas trapping is universal existence in both high and low performance wells, but the gas recovery gets lower for the low performance well.

Conclusion

-

1.

For fractured reservoirs, spontaneous imbibition plays a very important role for gas phase trapping. The invaded water in the fractures imbibes into adjacent matrix to form an imbibition layer, which greatly reduces the gas flow capacity from matrix to fractures, resulting in a large amount of trapped gas.

-

2.

The effect of phase trapping on the gas recovery has been revealed by results of depletion experimental test by using core samples with some length of spontaneous imbibition. A thin of imbibition layer could lower the effect permeability of the gas phase and trap the gas in the matrix block.

-

3.

The intermittent production reinforces the imbibition thickness and result in high residual pressure in the matrix. The low performance wells get lower gas recovery than high performance wells.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

Abbreviations

- K :

-

Permeability of matrix, mD

- K rg :

-

Gas relative permeability of matrix after imbibition, f

- P c :

-

Capillary pressure, MPa

- S w :

-

Water saturation, f

- S wi :

-

Initial water saturation of matrix, f

- S gr :

-

Residual gas saturation of matrix after imbibition, f

- t :

-

Time, d

- x :

-

Thickness of water imbibition, m

- GWC:

-

Gas–water contact

- c:

-

Capillary

- g:

-

Gas

- w:

-

Water

- I:

-

Initial

- r:

-

Residual/relative

- MCMD:

-

Thousand cubic meters of gas per day

- CMD:

-

Cubic meters of water per day

- MMCM:

-

Million cubic meters of gas

References

Bennion, D. B., Bietz, R. F., Thomas, F. B. & Cimolai, M. P. Reductions in the productivity of oil and low permeability gas reservoirs due to aqueous phase trapping. J. Can. Pet. Technol. 33(09), 45–54 (1994).

Bennion, D. B., Thomas, F. B., Bietz, R. F. & Bennion, D. W. Water and hydrocarbon phase trapping in porous media-diagnosis, prevention and treatment. J. Can. Pet. Technol. 35(10), 29–36 (1996).

van Duijn, C. J., Mikelić, A. & Pop, I. S. Effective equations for two-phase flow with trapping on the micro scale. SIAM J. Appl. Math. 62(5), 1531–1568 (2002).

Zhou, K. M. et al. Experimental research on gas-water two phase flow and confined gas formation mechanism. Nat. Gas. Ind. 22(S1), 122–125 (2002).

Pang, X. Q. et al. Critical condition for gas accumulation in the deep basin trap and physical modeling. Nat. Gas Geosci. 14(03), 207–214 (2003).

Wu, J. F., Guo, J. C. & Zhao, J. Z. Study on gas/water tow-phase percolation mechanism for fractured formations. Nat. Gas. Ind. 24(11), 85–87 (2004).

Xiong, Y., Hu, S. Q., Qu, L. & Tang, J. R. Analysis method of aquifer behavior and water invasion performance partly trapped in heterogeneous gas reservoir. Nat. Gas. Ind. 24(02), 78–81 (2004).

van Duijn, C. J., Eichel, H., Helmig, R. & Pop, I. S. Effective equations for two-phase flow in porous media: the effect of trapping on the microscale. Transp. Porous Media 69(3), 411–428 (2007).

Mirzaei Paiaman, A., Moghadasi, J. & Masihi, M. Formation damage through aqueous phase trapping in gas reservoirs. In SPE Deep Gas Conference and Exhibition, Bahrain (2010).

Rezaee, M., Rostami, B. & Pourafshary, P. Heterogeneity effect on non-wetting phase trapping in strong water drive gas reservoirs. J. Nat. Gas Sci. Eng. 14, 185–191 (2013).

Wang, L. et al. Visual experimental investigation of gas-water two phase micro seepage mechanisms in fracture-cavity carbonate reservoirs. Petrol. Sci. Bull. 2(03), 364–376 (2017).

Ghosh, T., Bringedal, C., Helmig, R. & Raja Sekhar, G. P. Upscaled equations for two-phase flow in highly heterogeneous porous media: Varying permeability and porosity. Adv. Water Resour. 145, 103716 (2020).

Ghosh, T., Deb, D. & Raja Sekhar, G. P. Non-classical flow modeling of spontaneous imbibition in spatially heterogeneous reservoirs. Comput. Geosci. 24, 1445–1461 (2020).

Hu, X. et al. The experimental study of water invasion mechanism in fracture and the influence on the development of gas reservoir. Nat. Gas Geosci. 27(05), 910–917 (2016).

Xu, X. et al. Physical simulation of water invasion and water control for the fractured water-bearing gas reservoirs. Nat. Gas Geosci. 30(10), 1508–1518 (2019).

Xu, X. et al. Microscopic imbibition characterization of sandstone reservoirs and theoretical model optimization. Sci. Rep. 11(01), 1–13 (2021).

Cai, J. C. & Yu, B. M. Advances in studies of spontaneous imbibition in porous media. Adv. Mech. 42(6), 735–754 (2012).

Washburn, E. W. The dynamics of capillary flow. Phys. Rev. 17(3), 273–283 (1921).

Handy, L. L. Determination of effective capillary pressures for porous media from imbibition data. Trans. AIME 219(01), 75–80 (1960).

Li, K. & Horne, R. N. An analytical scaling method for spontaneous imbibition in gas/water/rock systems. SPE J. 9(03), 322–329 (2004).

Li, K., Chow, K. & Horne, R. N. Influence of initial water saturation on recovery by spontaneous imbibition in gas/water/rock systems and the calculation of relative permeability. SPE Reserv. Eval. Eng. 9(4), 295–301 (2006).

Jiao, Y. et al. New material balance analysis method for abnormally high-pressured gas-hydrocarbon reservoir with water influx. Int. J. Hydrog. Energy 42(29), 18718–18727 (2017).

Li, M., Li, T., Jiang, Q., Yang, H. & Liu, S. The gas recovery of water-drive gas reservoirs. J. Hydrodyn. Ser. B 27(4), 530–541 (2015).

Li, G. Research and practice on enhancing recovery of tight sandstone gas reservoirs in Kelasu Gas Field, Tarim Basin. In Asia Pacific Unconventional Resources Technology Conference, Virtual (2021).

Liu, H. X. et al. Change laws of water invasion performance in fractured–porous water-bearing gas reservoirs and key parameter calculation methods. Nat. Gas Ind. 40(06), 90–99 (2020).

Fan, H. C. et al. Studies on water invasion mechanism of fractured-watered gas reservoir. Nat. Gas Geosci. 23(06), 1179–1184 (2012).

Wang, Z. B., Sun, X. W. & Xiao, X. J. Efficient development technologies for ultradeep, overpressured and fractured sandstone gas reservoirs: A cased study of the Kelasu Gas Field in the Tarim Basin. Nat. Gas Ind. 38(04), 87–95 (2018).

Tan, X. H. et al. Material balance method and classification of non-uniform water invasion mode for gas reservoirs with water considering the effect of water sealed gas. Nat. Gas Ind. 41(03), 97–103 (2021).

Zhu, Y., Sang, Q., Wu, C. L. & Yang, T. S. Reservoir characteristics of the Sinian Dengying formation in the Weiyuan Gasfield, Sichuan. J. Chongqing Univ. Sci. Technol. (Natural Sciences Edition) 12(05), 11–13 (2010).

Chen, Z. Q. Gas exploration in Sinian Dengying formation, Sichuan Basin,. China Petrol. Explor. 15(04), 1–14 (2010).

Wan, Y. J. & Su, Y. H. Practice and Lessons learned for the development of naturally fractured carbonate gas reservoir in Weiyuan gas field of Sichuan Basin, China. In Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE (2016).

Acknowledgements

This work was supported by PetroChina, the contribution of which is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

Y.W. and X.L. did the Study concepts, Study design and Case study; C.H. carried out the Revision and Literature research; C.J. did Numerical model and Data analysis, X.X. and Y.H., did Experimental test, Data acquisition and Data analysis, Y.L. did prove Revision.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wan, Y., He, C., Li, X. et al. Mechanism and application of gas phase trapping by spontaneous imbibition. Sci Rep 14, 17946 (2024). https://doi.org/10.1038/s41598-024-55552-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-55552-1