Abstract

A simple technique was utilized to fabricate pure hexagonal La2O3 nanorods by utilizing lanthanum(III) nitrate hexahydrate (La(NO3)3·6H2O) and ammonia (NH4OH). The La2O3 nanoparticles were analyzed using XRD, TGA, Raman, SEM, FTIR, TEM, PL spectroscopy, and Mott–Schottky techniques. The XRD analysis confirmed the production of La(OH)3 nanorods under appropriate conditions, which were then successfully converted into La2O2CO3 and finally into La2O3 nanorods through annealing. The TGA analysis showed that the total weight loss was due to water evaporation and the dissolution of minimal moisture present in the environment. The FTIR analysis confirmed the presence of functional groups. The SEM analysis revealed changes in morphology. The TEM analysis to determine the particle size. The PL findings showed three emission peaks at 390, 520, and 698 nm due to interband transitions and defects in the samples. The Mott–Schottky analysis demonstrated that the flatband potential and acceptor density varied with annealing temperature, ranging from 1 to 1.2 V and 2 × 1018 to 1.4 × 1019 cm−3, respectively. Annealing at 1000 °C resulted in the lowest resistance to charge transfer (Rct).

Similar content being viewed by others

Introduction

There are various rare earth metal oxides including La2O3, Y2O3, CeO2, Sm2O3, Nd2O3, Eu2O3, Lu2O3, and Gd2O31. La2O3 is a p-type semiconductor and has a hexagonal phase structure2. It appears as a white solid that is insoluble in water. However, it can dissolve in acidic solutions and convert into lanthanum hydroxide upon absorbing moisture from the air3. La2O3 is considered one of the most desirable oxide semiconductors due to its unique chemical and physical properties. It has a wide band gap of 5.5 eV, is thermally stable and non-toxic, and has a significant relative dielectric constant (K > 20)4. Because of these properties, La2O3 is used in potential applications like biosensors5, catalysts6, dielectric layers7, fuel cells8, gas sensors9, rechargeable batteries10, photoelectric conversion, and optical devices for measuring various body temperatures, and biomedical11,12. Various nanostructures, such as nanoneedles, nanobundles, nanorods, nanowires, nanosheets, and nanopowders of La2O3, have been obtained using different methods, including the hydrothermal method13, chemical precipitation method14, microwave method15, sol–gel method16, sonochemical method17, solvothermal method18, reverse micelles method2, arc discharge method19, thermal decomposition6, and laser deposition method20. Among these techniques, the hydrothermal method is the most effective one to fabricate La2O3 nanoparticles due to its low cost, environmentally friendly nature, good homogeneity, and simple methodology21. S Karthikeyan et al. Discovered that the ammonia source had significantly superior thermal, structural, and optical properties where La2O3 nanoparticles were synthesized using ammonia triethanolamine (TEA) and polyethylene glycol (PEG). In summary, the produced La2O3 nanoparticles could find usage in gas sensors to identify CO and CO2 as well as dielectric applications2. S. Karthikeyan et al. Used the reflux approach, lanthanum nitrate and urea were able to react to produce lanthanum oxide nanoparticles. These nanoparticles were calcined for one hour at 500 °C in their prepared state. Morphological investigations showed that the as-prepared La2O3 micro-plates had a thickness of 50 nm and that the plate-like structure broke into smaller La2O3 nanoparticles during the calcination process. For MOSFET applications, the pre-pare La2O3 structure may be utilized22. L. Wang et.al. prepared the La2O3 NPs catalyst using the precipitation method, and then calcined it at 600 °C. La2O3 NPs demonstrated increased catalytic activity in the reaction that transformed glycerol into glycerol carbonate and urea23. Qiuying Mu et al. In order to create lanthanum oxide carbonate (La2O2CO3) nanorods, lanthanum hydroxide (La(OH)3) nanorods were synthesized at 60 °C. Then, the nanorods were calcinated to 400 °C for two hours in a furnace. After calcining the La(OH)3 nanorods for two hours at 800 °C, pure La2O3 nanorods could be formed effectively24. Jun-Gill Kang et al. The hexagonal phase La(OH)3 nanowires and La2O3 microboards were effectively manufactured using a hydrothermal technique at 900 °C. On the other hand, hexagonal La2O3 is unstable in surrounding conditions. Due to the hygroscopic nature of La2O3, it progressively re-transforms into a hexagonal phase La(OH)3 via rehydroxylation25. Xing Wang et al. fabricated La2O3 films at different annealing temperatures of 400, 600, and 800 °C, for 60 s through atomic layer deposition. It was found that after 400 °C annealing temperatures, amorphous disordered structures of the film can be obtained. After being annealed at 600 and 800 °C, only weak crystalline planes such as hexagonal (101) appear, indicating the possibility of converting the 10 nm La2O3 film into complete crystallized. After being crystallized, the refractive index increases dramatically while the bandgap is slightly decreased26. The annealing temperature can improve the lattice structure and NPs characteristics in our work. In biological applications, the temperature-dependent crystal size is significant. In this work, La2O3 nanoparticles were synthesized via hydrothermal method at different annealing temperatures ranging from 500 and 1000 °C. The synthesized nanoparticles are intended to be used for biological applications. To investigate the effect of annealing temperature on the microstructures, morphology, optical and photoelectrochemical characteristics of La2O3 nanoparticles, various characterization techniques were employed.

Experimental methods

La2O3 nanoparticles were synthesized using a hydrothermal technique. The chemical solutions used in the process included lanthanum (III) nitrate hexahydrate (La(NO3)3·6H2O; 99%; BDH) and ammonia (NH4OH; 32%; PIOCHEM, EGYPT). To begin, 0.1 M lanthanum nitrate was dissolved in 100 mL of distilled water (Milli-Q, 18MΩ cm) at 60 °C. The mixture was vigorously stirred until it became clear. Then, liquid ammonia was added slowly, drop by drop, to adjust its pH to 10. The solution was then left undisturbed to allow the precipitation to occur. The precipitate obtained was gathered and rinsed with water and ethanol to ensure no unreacted substances remained. The washed powder was then dried in an 80 °C hot air oven for an entire night. Afterward, the dry powder samples were collected and crushed using a mortar before analysis. The experiment was conducted at different annealing temperatures ranging from 500 to 1000 °C. The following analysis techniques were used: X-ray diffraction (Shimadzu), Thermo Gravimetric analysis (TGA- Setaram Themys one +) to determine the total weight loss, Raman spectra using a WITec alpha300 R system, and Fourier transform infrared FTIR with single beam (Nicolet.iS10-U.S.A.) to identify the functional groups present in the synthesized samples. Scanning electron microscopy (SEM) (JSM-651OLV) was employed to analyze the morphological properties. Transmission electron microscopy (TEM) images were taken by (JEOL 2010–200 kV). The optical characteristics of La2O3 nanoparticles were examined by PL with a Kimmon He-Cd laser of 325 nm (3.82 eV). The CHI660E electrochemical workstation with the help of 0.5 M Na2SO4 was utilized to make Mott–Schottky and EIS.

Results and discussion

Structural studies

Figure 1 shows XRD patterns for La2O3 NPs samples via annealing of La(OH)3. Samples fabricated at 60 °C, can be perfectly indexed to a pure hexagonal phase of La(OH)3 (JCPDS Card No. 13–1481) with lattice constant a = 6.528 Å, c = 3.858 Å and diffraction angles located at 2θ = 27°, 27.7°, 39.4°, 48.5° and 55° correlate with the (110), (101), (201), (211) and (112) planes27. La2O2CO3 and La2O3 can be produced via annealing of La(OH)3 at 500 °C and 600 °C for 3 h, respectively28. Therefore, samples annealed at 500 °C and 600 °C contain a mixture of La(OH)3, La2O2CO3 (JCPDS Card No. 37–0804) and La2O3 (JCPDS Card No. 73–2141) phase due to the partial transformation of La(OH)3. The diffraction peaks centered at 2θ = 23°, 32° and 44°, corresponding to (011), (110) and (200) planes, can be assigned to a hexagonal phase of La2O2CO324,29,30. With the increase in annealing temperature until 1000 Co, La2O2CO3 is decomposed into La2O3 with hexagonal phase and lattice constants a = 3.973 Å, c = 6.129 Å. Diffraction angles related to La2O3 are located at 2θ = 26°, 28.6°, 29.9°, 39°, 46°, 52° and 55.3° and correspond with the (100), (101), (102), (201), (110), (103), and (112) planes, respectively31. Debye-Scherer’s relation was employed to estimate the average crystal size (D) by the following formula32.

where D corresponded the crystal size, β is the FWHM indicated in radians, λ is X-ray wavelength and θ is the diffraction angle33.

It was observed that the crystallite size increased from 12 to 33.26 nm as the annealing temperature was raised. This could be attributed to two possible reasons; Firstly, higher temperatures may have facilitated ion diffusion in the samples. Secondly, the reduction of defects in the samples could have lowered the barriers between the particles, leading to the production of larger particles34,35,36,37,38. In order to determine microstrain (ε), the following equation is utilized39:

The density of dislocation (δ) is represented by the following Eq. 40:

The values for microstructural properties are summarized in Table 1. Figure 2 displays that annealing at a higher temperature leads to fewer surface defects compared to non-annealed samples41.

TGA analysis

To evaluate the La2O3 NPs' thermal stability, a Thermo Gravimetric analysis was performed in a nitrogen environment between room temperature and 1000 °C at a heating rate of 10 °C /min42. The TGA curve for the La2O3 NPs produced under nitrogen environment up to 1000 °C is shown in Fig. 3.

At a temperature of 100 °C, weight loss occurred in the low-temperature region due to the reduction of water molecules43. There was also a sharp weight loss observed at around 400 °C, indicating an endothermic process. The weight loss observed is related to the loss of carbon dioxide, and it amounts to approximately 6.77%2,44. At the high-temperature area, the breakdown of lanthanum carbonate and weight loss is approximately 1.5%. Finally, at temperatures above 700 °C, lanthanum oxy-carbonate dissolves and produces pure La2O3 nanoparticles45. It has been observed that the total weight loss of La2O3 NPs is caused by the evaporation of water and the dissolution of minimal moisture present in the particles. From the TGA curve, it has been estimated that only 12.77% of the total weight loss occurs. These findings clearly demonstrate that ammonia, which is used as a reducing agent in the fabrication process of La2O3 NPs, is highly stable. The ammonia is entirely removed by the washing process of water and ethanol, and annealing at 500 °C is sufficient to remove any unprocessed ammonia and additional impurities2. The decomposition pathway of La (OH)3 is proposed as follows24:

Raman analysis

Raman spectra are used to confirm the results obtained from X-ray powder diffraction46. A laser Raman analysis was conducted to identify the phases, which ranged from 100 to 1300 cm−1, as shown in Fig. 4. At 60 °C, three vibrational modes were observed, which are related to only La(OH)3 phase47. These vibrational modes are A1g, E2g, and E1g at 280, 340, and 450 cm−1, respectively. A1g is a non-degenerate total-symmetric vibration, that means it is symmetric under all symmetry operations (rotation, mirror plane, inversion center). E1g, E2g is a double-degenerate vibration that is symmetric under inversion48. By annealing at 500 °C and 600 °C, it was observed that four vibrational modes appeared around 340, 405, 450 and 1057 cm−1, which contained a mix of La (OH)3, La2O2CO3, and La2O3 phases48. With an increase in annealing temperature up to 1000 °C, vibrational modes were observed, which were related to only La2O3 phase49. It was found that the sharpness of Raman peaks increased with an increase in annealing temperature, which might be related to the increase in particle size50. These results are consistent with the XRD measurements.

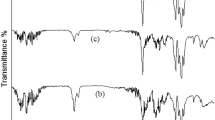

Fourier transform infrared spectroscopy analysis

Figure 5 shows the FTIR spectrum of La2O3 NPs samples at different annealing temperatures, ranging from 4000 to 400 cm−1. The aim was to identify the functional groups present in the prepared samples51. The wide peak observed at 3609 cm−1 indicates the presence of O–H stretching vibration due to absorbed moisture on the nanoparticle surfaces3,52. The bands at 1620 cm−1 and 1366 cm−1 are caused by the O–H vibration in absorbed water on the sample surface24,53. The intensity of the peaks at 1620 cm−1 and 1366 cm−1 decreased with increasing annealing temperature. Two small peaks at 852 cm−1, observed at 500 °C and 600 °C, were related to C–O bending vibrations2,16. The broad absorption band measured at 660 cm−1 is thought to occur due to the La–O stretching vibration24,54. These bands demonstrated the existence of the La2O3 phase in the synthesized nanoparticles.

Surface morphology evaluation

The SEM technique was used to analyze the morphology of the La2O3 that was synthesized. Figure 6 The samples exhibit rod-shaped nanostructures with nanoparticle aggregation, which become more spherical at high temperatures, hindering size identification24,55. This aggregation could be influenced by annealing temperature that increases the mobility of atoms52. As the annealing temperature is increased, the nanoparticles' grain size also increases. The merging process is enhanced by the oxygen or lanthanum defects at the grain boundaries through the annealing of additional grains at high temperatures. It is proposed that grains with lower surface energy will expand more at higher temperatures. Moreover, higher temperatures provide more energy for the atoms to move and occupy their correct positions in the crystal lattice35. When the annealing temperature rises, this aggregation increases and produces large particles, as confirmed by XRD results.

TEM pattern

Figure 7a,b, display TEM images of two samples, La2O2 CO3 and La2O3, that were fabricated and annealed at 500 °C and 1000 °C, respectively. The sample annealed at 500 °C showed aggregation and had nanorods with an average size of 11 ± 2 nm. As the annealing temperature increased to 1000 °C, the aggregation of particles increased which become more spherical at high temperatures with an average particle size of 31 ± 2 nm56. These findings agree with XRD results57.

PL analysis

The PL emission is caused by the recombination of free carriers. This makes PL spectra useful for analyzing the efficiency of trapped charges58. In Fig. 8, you can see the PL spectrum of all samples taken at room temperature with an excitation wavelength of 320 nm. The measurements were taken between 300 and 800 nm. The PL spectrum has three peaks: the first is around 390 nm, the second is located at 520 nm, and the third peak is found at 698 nm. The first peak is correlated with inter-band transitions in La2O3. The second peak is the result of cation vacancy defects in La2O359,60. The third peak results from radiative relaxational transitions phenomena of La3+ ions61. It was observed that the peaks’ intensity increase with annealing temperature, showing that lanthanum vacancies may be enhanced by increasing of annealing temperature61.

Electrochemical impedance spectroscopy (EIS)

The behavior of charge transfer at the interface between semiconductor and electrolyte was studied by examining the electrical responses of La2O3 nanoparticles using the electrochemical impedance spectra technique over a wide frequency range of 104 HZ62,63. Figure 9 shows the Nyquist diagram of La2O3 nanoparticles, which were fabricated at various annealing temperatures ranging from 500 to 1000 °C. The Nyquist curves (Z" vs. Z') were fitted using ZSimpwing software )https://www.ameteksi.com/products/software/zsimpwin (and an electrical circuit model with the corresponding components of solution-resistance (Rs), charge-transfer resistance (RRCT), and double-layer capacitance (Cdl)64. The plots are composed of semicircles, and their diameters decrease as the annealing temperature increases41. This suggests that there is a higher rate of charge transfer and a lower rate of charge recombination65,66. The reason for this is that when the annealing temperature increases, the electrons present in the valence band acquire enough energy to move into the conduction band. Because the number of electrons in the conduction band rose, conductivity is improved and resistivity declines67.

Mott–Schottky measurements

Mott–Schottky technique was used to determine the type of conductivity and compute the density of donors or acceptors in the fabricated samples68. The Mott–Schottky plot (1/C2 vs. V) is obtained from the electrochemical impedance data using the following relation69:

where f is 10 kHz and Xc represents the imaginary part (Z”). Figure 10 shows Mott–Schottky plots for the prepared La2O3 nanoparticles at various annealing temperatures. According to the Mott–Schottky formula, the acceptor density (NA), the semiconductor capacitance (C), and the built-in voltage (Vfb) are related by the following formula68:

where ε, ε0, e, kB, A, T represents dielectric constant (ε for La2O3 = 27), vacuum permittivity, charge of electron, Boltzmann constant, active surface area of the photoelectrode and temperature, respectively70.

Vfb could be obtained experimentally by interception of the linear part of the Mott–Schottky plot on the x-axis and it was observed to increase from 1 to 1.21 V with the raise in annealing temperature. The more the built-in voltage, the more the charge separation at the interface between the semiconductor and electrolyte, the acceptors density was estimated by the following formula71.

where S represents the slope of the Mott–Schottky graph70. M-S plots exhibited a negative slope, showing that all samples were p-type semiconductors. The acceptors density improved from 1.3 × 1017 to 3.2 × 1017 cm-3 with the raise in annealing temperature, signifying a higher density of the lanthanum vacancies in La2O3 after it’s annealed at 1000 °C. Table 2 shows the calculated acceptors density and flat band potentials for La2O3 nanoparticles at different annealing temperatures.

Conclusions

In this study, La2O3 nanoparticles were synthesized via hydrothermal method and characterized for microstructure, morphology, thermal, optical, and electrical properties. The XRD findings revealed that La(OH)3 nanorods were produced at 60 °C under appropriate conditions and could be converted into La2O2CO3 by annealing at temperatures of 500 °C and 600 °C for 3 h. Finally, the annealing temperature was raised until 1000 °C to obtain La2O3. According to TGA analysis, the weight loss observed in the manufactured La2O3 NPs was due to water evaporation and the dissolution of a minimal amount of moisture present in the environment. FTIR analysis confirmed the presence of functional groups related to La(OH)3, La2O2CO3, and La2O3. SEM results showed that the nanoparticles' aggregation increased with higher annealing temperatures. that the nanostructures were rod-shaped and became more spherical at high temperatures as the particle size increased. PL analysis revealed three peaks: the first peak was associated with inter-band transitions in La2O3, the second peak resulted from cation vacancy defects in La2O3, and the third peak resulted from radiative relaxational transitions phenomena of La3+ ions. The Mott–Schottky test results show that the flatband potential and acceptor density change depending on the annealing temperature. Specifically, the flatband potential ranges from 1 to 1.2 V, while the acceptor density ranges from 2 × 1018 to 1.4 × 1019 cm−3. Moreover, the annealing temperature of 1000 °C resulted in the lowest resistance to charge transfer (Rct).

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Dudnik, O. et al. Composite ceramics for thermal-barrier coatings produced from zirconia doped with rare earth oxides. Powder Metall. Met. Ceram. 61(7–8), 441–450 (2022).

Karthikeyan, S. et al. Synthesis and characterization of lanthanum oxide nanoparticles: A study on the effects of surfactants. Mater. Today: Proc. 47, 901–906 (2021).

Yu, L. et al. Controllable synthesis and luminescence properties of one-dimensional La2O3 and La2O3: Ln3+ (Ln= Er, Eu, Tb) nanorods with different aspect ratios. J. Lumin. 229, 117663 (2021).

Bilel, C. et al. Synthesis and physical characterization of Ni-doped La 2 O 3 for photocatytic application under sunlight. J. Mater. Sci.: Mater. Electron. 32, 5415–5426 (2021).

Jadhav, S. et al. Vertically aligned nanosheets of an electrodeposited lanthanum oxide electrode for non-enzymatic glucose sensing application. J. Electron. Mater. 50, 675–685 (2021).

Ebrahimi, P., Kumar, A. & Khraisheh, M. Combustion synthesis of lanthanum oxide supported Cu, Ni, and CuNi nanoparticles for CO2 conversion reaction. Int. J. Hydrogen Energy 48(64), 24580–24593 (2023).

Su, J. et al. Electrical characteristics of normally off hydrogen-terminated diamond field effect transistors with lanthanum oxide gate dielectric. Appl. Phys. Lett. 121, 16 (2022).

Luo, Z. et al. Improving sealing properties of CaO-SrO-Al2O3-SiO2 glass and glass-ceramics for solid oxide fuel cells: Effect of La2O3 addition. Ceram. Int. 46(11), 17698–17706 (2020).

Eswaran, A. et al. Highly selective CO 2 sensing response of lanthanum oxide nanoparticle electrodes at ambient temperature. Nanoscale Adv. 5(14), 3761–3770 (2023).

Wang, M., et al., Lanthanum modified Fe3N/carbon foam as highly efficient electrode for zinc-air batteries. J. Alloys Comp. 169713 (2023).

Muthulakshmi, V., Kumar, C. D. & Sundrarajan, M. Biological applications of green synthesized lanthanum oxide nanoparticles via Couroupita guianensis abul leaves extract. Anal. Biochem. 638, 114482 (2022).

Brabu, B. et al. Biocompatibility studies on lanthanum oxide nanoparticles. Toxicol. Res. 4(4), 1037–1044 (2015).

Madani, R. F. et al. Synthesis methods and green synthesis of lanthanum oxide nanoparticles: A review. Arab. J. Chem. Environ. Res. 8(2), 287–314 (2021).

Chaudhary, N. et al. Designing and characterization of a highly sensitive and selective biosensing platform for ciprofloxacin detection utilizing lanthanum oxide nanoparticles. J. Environ. Chem. Eng. 9(6), 106771 (2021).

Chien, A. C. & Zheng, M. S. Catalytic activity of methane oxidation on nickel-doped lanthanum strontium titanate perovskite from three synthesis methods. J. Taiwan Inst. Chem. Eng. 105120 (2023).

Khalaf, W. M. & Al-Mashhadani, M. H. Synthesis and characterization of lanthanum oxide La2O3 net-like nanoparticles by new combustion method. Biointerface Res. Appl. Chem. 12, 3066–3075 (2022).

Karthikeyan, S. et al. Sonochemical synthesis of Sn-doped La2O3 nanoparticles and its application for the photocatalytic degradation of hazardous pollutants. J. Mater. Sci. Mater. Electron. 34(14), 1157 (2023).

Muñoz, H. J., Korili, S. A. & Gil, A. Progress and recent strategies in the synthesis and catalytic applications of perovskites based on lanthanum and aluminum. Materials 15(9), 3288 (2022).

Khoja, A. H., Tahir, M. & Saidina Amin, N. A. Evaluating the performance of a Ni catalyst supported on La2O3-MgAl2O4 for dry reforming of methane in a packed bed dielectric barrier discharge plasma reactor. Energy Fuels 33(11), 11630–11647 (2019).

Sethulakshmi, N. et al. Ferroelectric-ferromagnetic heterostructures based on sodium substituted lanthanum manganite thin films deposited on pmn-pt substrate by pulsed laser deposition. J. Magn. Magn. Mater. 541, 168484 (2022).

Nivetha, A., Mangala Devi, S. & Prabha, I. Fascinating physic-chemical properties and resourceful applications of selected cadmium nanomaterials. J. Inorgan. Organometall. Polym. Mater. 29, 1423–1438 (2019).

Karthikeyan, S. et al. A role of annealing temperature on the properties of lanthanum oxide (La2O3) microplates by reflux routes. Mater. Today: Proc. 26, 3576–3578 (2020).

Bhautik, M. P. N., Ugwekara, R. P. & Singhb, M. K. Review on synthesis of Lanthanum oxide (La2O3) and characterization techniques.

Mu, Q. & Wang, Y. Synthesis, characterization, shape-preserved transformation, and optical properties of La (OH) 3, La2O2CO3, and La2O3 nanorods. J. Alloys Comp. 509(2), 396–401 (2011).

Kang, J.-G. et al. Synthesis and physicochemical properties of La (OH) 3 and La2O3 nanostructures. Mater. Sci. Semicond. Process. 40, 737–743 (2015).

Wang, X. et al. Structural properties characterized by the film thickness and annealing temperature for La 2 O 3 films grown by atomic layer deposition. Nanoscale Res. Lett. 12, 1–7 (2017).

Singh, A. et al. Green synthesis of 1, 4-benzodiazepines over La 2 O 3 and La (OH) 3 catalysts: Possibility of Langmuir-Hinshelwood adsorption. RSC Adv. 6(105), 103455–103462 (2016).

Wu, Q. et al. Interaction-induced self-assembly of Au@ La2O3 core–shell nanoparticles on La2O2CO3 nanorods with enhanced catalytic activity and stability for soot oxidation. ACS Catal. 9(4), 3700–3715 (2019).

Bakiz, B., et al., Carbonatation and decarbonatation kinetics in the La2O3-La2O2CO3 system under CO 2 gas flows. Adv. Mater. Sci. Eng. (2010).

Yu, H. et al. Hexagonal and monoclinic phases of La2O2CO3 nanoparticles and their phase-related CO2 behavior. Nanomaterials 10(10), 2061 (2020).

Cheraghali, R. & Aghazadeh, M. A simple and facile electrochemical route to synthesis of metal hydroxides and oxides ultrafine nanoparticles (M= La, Gd, Ni and Co) (2016).

Ali, A., Chiang, Y. W. & Santos, R. M. X-ray diffraction techniques for mineral characterization: A review for engineers of the fundamentals, applications, and research directions. Minerals 12(2), 205 (2022).

Abdelfatah, M. et al. Improvement of physical and electrochemical properties of Cu2O thin films with Fe ions doping towards optoelectronic applications. Opt. Mater. 130, 112583 (2022).

Zaid, M. H. M. et al. Effect of heat treatment temperature to the crystal growth and optical performance of Mn3O4 doped α-Zn2SiO4 based glass-ceramics. Results Phys. 15, 102569 (2019).

Mathew, J. P., Varghese, G. & Mathew, J. Effect of post-thermal annealing on the structural and optical properties of ZnO thin films prepared from a polymer precursor. Chin. Phys. B 21(7), 078104 (2012).

Omri, K. et al. Effects of temperature on the optical and electrical properties of ZnO nanoparticles synthesized by sol–gel method. Microelectron. Eng. 128, 53–58 (2014).

Goswami, M., Adhikary, N. C. & Bhattacharjee, S. Effect of annealing temperatures on the structural and optical properties of zinc oxide nanoparticles prepared by chemical precipitation method. Optik 158, 1006–1015 (2018).

Rajkumar, C. Effect of annealing temperature on response time of ZnO photoconductor fabricated using thermal evaporation technique. Physica Scripta 97(11), 115806 (2022).

Das, N. et al. Effect of substrate temperature on the properties of RF sputtered CdS thin films for solar cell applications. Results Phys. 17, 103132 (2020).

Oh, Y. et al. Effect of rare earth oxide addition on microstructure and mechanical properties of Ni-based alloy. J. Alloys Comp. 853, 156980 (2021).

Ismail, W. et al. Advancement of physical and photoelectrochemical properties of nanostructured CdS thin films toward optoelectronic applications. Nanomaterials 13(11), 1764 (2023).

Li, X. et al. Dry reforming of methane over Ni/La2O3 nanorod catalysts with stabilized Ni nanoparticles. Appl. Catal. B: Environ. 202, 683–694 (2017).

Karthikeyan, S. et al. Morphology and vibrational modes of lanthanum oxide (La2O3) nanoparticles prepared with reflux routes at different reaction times. Chem. Africa 5(5), 1427–1432 (2022).

Kabir, H. et al. Polyethylene glycol assisted facile sol-gel synthesis of lanthanum oxide nanoparticles: Structural characterizations and photoluminescence studies. Ceram. Int. 45(1), 424–431 (2019).

Suresh, K. et al. Green synthesis of SnO 2 nanoparticles using Delonix elata leaf extract: Evaluation of its structural, optical, morphological and photocatalytic properties. SN Appl. Sci. 2, 1–13 (2020).

Lu, X. et al. CdS nanoparticles decorated 1D CeO2 nanorods for enhanced photocatalytic desulfurization performance. Catalysts 12(11), 1478 (2022).

Sanivarapu, S. R., Lawrence, J. B. & Sreedhar, G. Role of surface oxygen vacancies and lanthanide contraction phenomenon of Ln (OH) 3 (Ln= La, Pr, and Nd) in sulfide-mediated photoelectrochemical water splitting. ACS Omega 3(6), 6267–6278 (2018).

Orera, A., Larraz, G. & Sanjuán, M. Spectroscopic study of the competition between dehydration and carbonation effects in La2O3-based materials. J. Eur. Ceram. Soc. 33(11), 2103–2110 (2013).

Ansari, A. A. et al. Synthesis, optical properties and toxic potentiality of photoluminescent lanthanum oxide nanospheres. Colloids Surf. A Physicochem. Eng. Aspects 607, 125511 (2020).

Sahoo, D. et al. Optimization of linear and nonlinear optical parameters of As40Se50Te10 thin films by thermal annealing. Optics & Laser Technology 140, 107036 (2021).

Salah, H. et al. Improvement of the structural, morphological, optical, and photoelectrochemical properties of Al-doped ZnO nanorods for use in biosensors and solar cells. Eur. Phys. J. Plus 137(12), 1319 (2022).

Chen, K. et al. Facile preparation and characterization of lanthanum oxide powders by the calcination of lanthanum carbonate hydrate in microwave field. Ceram. Int. 46(1), 165–170 (2020).

Nehra, P. et al. Synthesis and characterization of rare earth metal doped tungsten trioxide photocatalyst for degradation of Rhodamine B dye. J. Rare Earths 41(9), 1302–1310 (2023).

Sulaiman, N., Yulizar, Y. & Apriandanu. D. Eco-friendly method for synthesis of La2O3 nanoparticles using Physalis angulata leaf extract. In AIP Conference Proceedings. 2018. AIP Publishing.

Lingamdinne, L. P. et al. Facile synthesis, characterization, and adsorption insights of lanthanum oxide nanorods. Metals 10(8), 1001 (2020).

Maheshwaran, G. et al. Green synthesis of lanthanum oxide nanoparticles using Moringa oleifera leaves extract and its biological activities. Adv. Powder Technol. 32(6), 1963–1971 (2021).

Moothedan, M. & Sherly, K. Synthesis, characterization and sorption studies of nano lanthanum oxide. J. Water Process Eng. 9, 29–37 (2016).

Porkalai, V., et al., Study on the synthesis, structural, optical and electrical properties of ZnO and lanthanum doped ZnO nano particles by sol-gel method. Mech. Mater. Sci. Eng. J. 9 (2017).

Jbeli, R. et al. Structural and optical investigations on sprayed Co doped La2O3 thin films along with photocatalytic and anti-bacterial applications. Optik 242, 166837 (2021).

Ajmal, M. et al. Structural and optical properties of La2O3: Ho3+ and La (OH) 3: Ho3+ crystalline particles. Mater. Today: Proc. 4(3), 4900–4905 (2017).

Ramjeyanthi, N., Alagar, M. & Muthuraman, D. Synthesis, structural and optical characterization of uncalcined lanthanum oxide nanoparticles by Co-precipitation method. Int. J. Interdiscip. Res. Innov. 6(3), 389–395 (2018).

Bilel, C. et al. Physical investigations on annealed structure Cu/La2O3 for photocatalytic application under sunlight. J. Mater. Sci. Mater. Electron. 31, 7398–7410 (2020).

Abdelfatah, M. et al. Enhancement of structural, optical and photoelectrochemical properties of n−Cu2O thin films with k ions doping toward biosensor and solar cell applications. Nanomaterials 13(7), 1272 (2023).

Suni, I. I. Impedance methods for electrochemical sensors using nanomaterials. TrAC Trends Anal. Chem. 27(7), 604–611 (2008).

Koiki, B. A. et al. Cu2O on anodised TiO2 nanotube arrays: A heterojunction photoanode for visible light assisted electrochemical degradation of pharmaceuticals in water. Electrochimica Acta 340, 135944 (2020).

Siddiqui, H. et al. Performance evaluation of optimized leaf-shaped two-dimension (2D) potassium doped CuO nanostructures with enhanced structural, optical and electronic properties. Ceram. Int. 46(12), 20404–20414 (2020).

Ma, H. et al. Strategies for enhancing thermal conductivity of polymer-based thermal interface materials: A review. J. Mater. Sci. 56, 1064–1086 (2021).

Han, J. et al. Mechanistic investigation on tuning the conductivity type of cuprous oxide (Cu2O) thin films via deposition potential. Int. J. Hydrogen Energy 43(30), 13764–13777 (2018).

Ali, G. A. et al. High performance MnO2 nanoflower supercapacitor electrode by electrochemical recycling of spent batteries. Ceram. Int. 43(11), 8440–8448 (2017).

Abdelfatah, M. et al. Inverting electrodeposited nanostructured Cu2O thin films from n-type to p-type semiconductors and variation of their physical and photoelectrochemical properties for optoelectronic applications. Ceram. Int. 49(18), 30732–30743 (2023).

Kalubowila, K. et al. Effect of bath pH on electronic and morphological properties of electrodeposited Cu2O thin films. J. Electrochem. Soc. 166(4), D113 (2019).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

Conceptualization, W.I., A.E-S., A.B., and W.A.; methodology, W.I., A.B., A.E-S.; validation, W.I. and A.E-S.; for-mal analysis, W.I. and A.E-S.; investigation, A.B., W.A. and W.I.; resources, A.B. and W.I.; data curation, W.I.; writing—original draft preparation, W.I., A.E-S., and A.B., and W.I.; writing—review and editing W.A., A.E-S. and W.I.; visualization, W.I., W.A.; supervision, W.I., and A.E-S.; project administration A.E-S..; funding acquisition, W.I. authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ismail, W., Belal, A., Abdo, W. et al. Investigating the physical and electrical properties of La2O3 via annealing of La(OH)3. Sci Rep 14, 7716 (2024). https://doi.org/10.1038/s41598-024-57848-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-57848-8

Keywords

This article is cited by

-

Enhanced photocatalytic degradation of anionic azo dyes using copper-doped lanthanum oxide nanoparticles

Journal of Materials Science: Materials in Electronics (2026)

-

Fabrication of an inorganic-organic hybrid based on lanthanum and trigonella grandiflora extract as an innovative corrosion inhibitor

Scientific Reports (2025)

-

Deferential nephrotoxicity effect of lanthanum oxide nanoparticle responses to concentration and time in vivo

Scientific Reports (2025)

-

In situ generation of highly active sites by chemical vapor deposition of C2H4 over the LaMn0.7Co0.3O3 perovskite for the oxygen reduction reaction

Journal of Materials Science (2025)

-

Synthesis, Characterization, Optical and Gamma Shielding Properties of La2O3 Doped Recycled PS-PVC/PCL Ternary Blend Composites

Journal of Polymers and the Environment (2025)