Abstract

Scientists and engineers encounter considerable environmental and economic obstacles stemming from the depletion of crude oil or petroleum fossil fuel reservoirs. To mitigate this challenge, alternative solutions like bio-oil-modified binder derived from biomass have been innovated. This research aims to examine the feasibility of using bio-oil-modified binder obtained from cotton stalk waste as a modifier. Various mechanical and physical tests, including penetration, softening point, ductility, and dynamic shear rheometer tests, were conducted on asphalt binder incorporating 5% and 10% bio-oil-modified binder. Wheel tracker, four-point beam fatigue, and dynamic modulus tests were used to evaluate asphalt mixture performance, including rutting, fatigue, and dynamic stiffness. A rolling bottle test (RBT) and asphalt binder bond strength (BBS) were used to assess moisture susceptibility. A bio-oil-modified binder enhanced ductility and penetration characteristics while reducing the softening point. With the addition of a bio-oil-modified binder, stiffness was reduced in parameters such as complex shear modulus and phase angle. In fact, for both specimens containing 5% and 10% bio-oil-modified binder, statistically significant differences were observed among the measured samples. As a result of this reduced stiffness, the modified asphalt binder is more suitable for low-temperature applications. Additionally, 5.8% increased at 10% and 3.1% at 5% CS. Bio-oil-modified binder, compared to virgin mixtures, supports equal rut resistance. However, the RBT and BBS tests revealed that the addition of bio-oil-modified binder increased the susceptibility of conventional asphalt binder to moisture. The findings suggest that bio-oil-modified binder can enhance asphalt binder properties in low-temperature regions, but further research is needed to improve moisture resistance.

Similar content being viewed by others

Introduction

On a global scale, cotton stalk (CS) is an important agricultural crop. Cotton is grown on more than 12 million hectares of land in 80 countries across the world1. China produces 40 million metric tons of cotton stalk annually, making it the largest cotton producer in the world2. Agricultural waste, typically disposed of in landfills, poses environmental contamination risks, particularly during the rainy season when it can mix with groundwater. Proper utilization of cotton stalk waste can address these issues. Hot mix asphalt (HMA) is essential for road construction, comprising heated aggregates and asphalt binder. However, the asphalt binder industry faces challenges due to dwindling crude oil reserves, causing limited availability and rising prices. Hence, there's an urgent need for enhancing existing asphalt binder performance and exploring alternative replacements3,4,5.

Researchers are increasingly interested in bio-oil modified binders, derived from waste or biomass pyrolysis, as alternatives to traditional asphalt binders, offering a sustainable and cost-effective solution6,7,8. In literature, the existing asphalt binder is partially or completely replaced with bio-oil modified binder extracted through pyrolysis. Bio-oil modified binder from swine manure that was extracted using the pyrolysis process was added. In that study, the extricated bio-oil modified binder was combined with different proportions (i.e., 10%, 5%, and 2% by mass of virgin binder) to alter the virgin binder and consequently its performance9,10,11,12,13. The Bending Beam Rheometer (BBR) and DSR were used to characterize the response over a wide temperature range, from high to low. The viscosity behaviour of modified specimens over a high temperature range was also assessed using a rotational viscometer (RV). Another study addressed the use of bio-oil modified binder produced by the pyrolysis of swine manure. 5% swine manure bio-oil modified binder was added to the virgin PG 64-22 binder14. The performance of the modified binder was assessed in both short- and long-term ageing conditions using the RV, DSR, and BBR. Oak wood was used to produce bio-oil modified binder, which was then preheated for approximately two hours15,16. In this study, bio-oil modified binder modified with 2% and 4% polyethylene content was used. The viscosity of the produced specimens at high temperatures was determined, and the effect of temperature on viscosity was evaluated.

Bio-oil modified binder was derived from diverse sources such as maize stalks, oak wood, shredded grass, and crumb rubber. These variants were utilized to modify both virgin binder and styrene–butadiene–styrene (SBS) incorporated binder17,18. Bio-oil modified binder from cedar sawdust, representing 9%, 6%, and 3% of the total binder mass, was incorporated into the specimens. These specimens were subsequently assessed under both ageing and non-ageing conditions, as well as at high temperatures19. High-temperature viscosity, density, and distress response were studied, leading to the development of a novel technique for extracting and utilizing bio-oil modified binder for modification20,21,22. The investigation involved evaluating the impact of varying temperatures and concentrations of bio-oil modified binder on viscosity. It found viscosity decreased notably with higher concentrations of bio-oil modified binder, especially below 135 °C. The research also included physical tests on the modified binder mixture23. The study examined asphalt properties through several tests and found bio-binder to be a promising alternative in asphalt technology, showing improved performance in various aspects. Increasing bio-oil modified binder content led to reduced penetration and enhanced ductile response, supporting its potential as a replacement for conventional asphalt technology24.

This study evaluates waste vegetable oil (WVO) and waste engine oil (WEO) as rejuvenating agents for asphalt binders with reclaimed asphalt pavement (RAP). Results show improved low-temperature properties and flexibility in RAP-containing asphalt mixes, indicating potential for enhanced performance in recycled asphalt applications25. The study investigates the impact of rejuvenation on RAP binders and mixes, exploring both short-term and long-term aging effects. Its objective is to evaluate the sustainability of pavement construction methods26. Laboratory experiments assessed Mahua oil's effectiveness in rejuvenating aged binder, exploring its potential as an asphalt binder rejuvenator to improve pavement performance and sustainability27.

Cotton stalk (CS) is defined as the waste derived from agricultural and industrial activities. The methods of open dumping and landfilling lead to the production of a significant amount of waste, which can lead to negative effects on the environment, including the contamination of subsurface water sources and a problem with land scarcity. This mass production of CS waste provides opportunity for recycling and its use for paving, which has never been tried in the form of bio-oil modified binder, to the best of the author’s knowledge. Therefore, this research’s aim is to characterize the pavement response of virgin binder and mixtures modified using bio-oil modified binder from CS.

Objectives of the study

The primary objectives of this research are: (1) to evaluate the chemical, morphological, and rheological properties of base binder blended with bio-oil derived from agricultural waste; (2) to quantify the optimum dose of different bio-oils with the best performance; and (3) to produce an efficient, cost-effective, and environmentally friendly partially modified binder.

Materials and methods

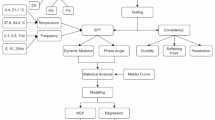

Figure 1 illustrates a schematic representation of the materials and methodology employed in this study to investigate the feasibility of using bio-oils as a partial substitute for virgin binder in asphalt mixtures. This study employed the fast pyrolysis method to extract bio-oil from CS, integrating it into conventional binder at concentrations of 5% and 10%. The experimental approach encompassed a thorough characterization of the CS bio-oil modified binders alongside the conventional binder, incorporating penetration, softening point, and ductility tests. Subsequently, the dynamic mechanical response of binder samples was analyzed using a dynamic shear rheometer (DSR). Following this, the modified binder was combined with aggregates to produce modified asphalt mixtures, which underwent rigorous testing for moisture sensitivity via the rolling bottle test (RBT) and the bitumen bond strength (BBS) test. Additionally, the performance of asphalt mixtures against rutting and fatigue cracking was evaluated using the dynamic modulus test, wheel tracker test (WTT), and four-point beam fatigue test (FPBFT). Comprehensive details regarding the materials, preparation process, and experimental program are shown below:

Materials and preparation

Conventional asphalt binder

For this study, asphalt binder with a 60/70 penetration grade was sourced from Pak-Arab Refinery Limited (PARCO) in Pakistan. Table 1 outlines the specific characteristics of the PARCO asphalt binder.

Cotton stalk

The cotton stalks (CS) utilized for the preparation of bio-oil modified binder were sourced from Faisalabad, Punjab, Pakistan. Bio-oil modified binder was procured from reputable suppliers using established methods to ensure both quality and quantity for experimental evaluation. Table 2 outlines the physical characteristics of CS28.

Bio-oil

In this study, bio-oil was derived from fast pyrolysis of CS feedstock. Initially, the CS material underwent mechanical grinding to attain a particle size of approximately 0.5 mm. Preheating was then conducted to reduce moisture content before subjecting the CS to rapid heating, in the absence of air, at temperatures ranging from 450 to 600 °C29. The initial moisture content fell within the range of 10–20% by weight. During each run, a 30 g test sample underwent processing in the pyrolysis reactor for approximately 20 s, with temperatures varying from 450 to 600 °C. The variation in pyrolysis temperature was aimed at optimizing yield, resulting in an optimal yield of 53.3% achieved at 550 °C.

Rapid pyrolysis, involving the heating of CS and subsequent condensation of resulting vapors into a liquid state, was employed in this study to extract bio-oil. The residual biomass ash constitutes the remaining material at the bottom of the pile. To reduce the moisture in the CS, it is critical to sun-dry it first. Moisture content in control CS bio-oil was found to be between 6 and 8% by weight in the initial research. Table 3 shows the physical parameters of bio-oil derived from CS.

Aggregates and gradation

The Margalla region provided the source for the aggregates utilized in this investigation. Limestone makes up the aggregates found in Margalla, Pakistan30. Table 4 shows the physical properties of aggregate. This study utilized the class B aggregate gradation specified by the National Highway Authority (NHA), as illustrated in Fig. 2. Aggregates were cleaned and dried before the test.

Process of preparing modified binder

The CS bio-oil modified binder was added to the base binder in the recommended proportions of 5% and 10% by weight. The selection of the proportions of CS bio-oil modified binder is based on a careful assessment and consideration of various factors, including prior research studies, preliminary experiments, and the desired objectives of the study. This study aims to determine the optimal dosage of CS bio-oil modified binder that would exhibit significant improvements in the performance characteristics of the base binder without compromising the overall quality and integrity of the asphalt mixture. To ensure uniform mixing of CS bio-oil modified binder at the specified percentages, a shear mixer was utilized in previous studies. The CS bio-oil modified binder and virgin binder were both heated to initial temperatures of about 120 and 60 °C, respectively. The materials underwent mixing at a temperature of 120 °C and a shear rate of 3000 rpm for a duration of one hour. Following these parameters consistently, three types of binder (two for CS bio-oil modified binders and one conventional binder) were used throughout this study.

Process of preparing modified asphalt mixture

The batched aggregate and asphalt binder were thoroughly mixed to prepare the asphalt mixture samples at the optimum binder content (OBC). The OBC of the control mixture sample, was determined to be 4.33% using the Job Mix Formula (JMF) method specified in ASTM D155932. The specimens were then compacted by applying 75 blows for each face of sample, which was dropped from a height of 18 inches. All mixture samples were prepared with the same OBC to ensure consistency and facilitate better comparability of the test results33.

Experimental program

Basic binder properties test

The assessment of the asphalt binder's consistency is conducted through a penetration test. Both bio-oil modified binder and control (unmodified) samples were tested under defined conditions based on AASHTO T4934. The softening point of the produced specimens was determined using the ring and ball apparatus in accordance with ASTM D36 standard35. A ductility test was performed based on ASTM D11336 on every produced sample with the use of a ductilometer.

whereas, PI is the penetration index, Pent at T represents the penetration value of the asphalt binder at a specific temperature T and SP is the softening point of the asphalt binder.

Rheological properties tests

Performance grading (PG) and frequency sweep tests

Frequency sweep and PG grade tests were carried out to evaluate viscoelastic response in the linear range using DSR based on AASHTO T-31537. The frequency sweep under the strain-controlled approach was chosen for the wide range of temperatures (22, 34, 46, 58, 70, and 82 °C)38. Additionally, frequencies between 0.1 and 10 Hz were used for each temperature. In agreement with the literature, the strain levels exerted were 2% and 10% for virgin and CS-oil binder, respectively38. The 8 mm and 25 mm plate geometries were chosen for higher (> 46 °C) and lower (46 °C) temperatures, respectively, with a gap of 2 mm and 1mm39. In addition, a PG-grade test was conducted using a 25 mm plate geometry and a frequency of 10 Hz. The point where G*/sinδ came below 1 kPa corresponded to failure temperatures38. In Eq. 3, the sigmoidal equation is stated.

where, A is the complex modulus, δ is the phase angle, fr is the reduced frequency, α is the difference between the minimum and maximum G*, γ and β are the shape factors40.

Multi stress creep recovery test

Both the conventional and bio-oil modified binder modified asphalt binder were subjected to a multiple stress creep recovery (MSCR) test using DSR in accordance with AASHTO T31537. The viscoelastic nature of Asphalt binder is a widely acknowledged phenomenon. At moderate temperatures, the behavior of asphalt binder is viscoelastic, with the dominant behavior being viscous at high temperatures and elastic at low temperatures. When constant stress (creep) is applied to Asphalt binder, strain is produced in the asphalt binder, and after the stress is relieved, the Asphalt binder tends to return to its original form, but some residual strain (permeant strain) will remain in the Asphalt binder, whereas an elastic strain is recovered after the load is removed. To assess the permanent deformation resistance of asphalt binder under varying stress levels ranging from 0.25 to 3.2 kPa and temperature ranges between 58 and 76 °C, a creep compliance test was conducted. This test aimed to cover all the PG ranges of samples and to evaluate the elastic response of asphalt binder. Non-recoverable creep compliance (Jnr) was measured to determine the asphalt binder's permanent deformation resistance to repeated creep loads. After applying a one-second creep load, a recovery period of nine seconds was given to the sample. The residual strain in the specimen in terms of Jnr after the creep and recovery times was calculated using Eq. (4).

where;Jnr = permanent strain in a binder after creep implementation in kPa−141, \(\gamma \mu\) = permanent strain after 9-s interval, \(\tau\) = shear stress applied for 1-s interval.

Through this test, the stress sensitivity of modified and unmodified samples under different loading conditions was determined. Anton Paar DSR was used in this study to evaluate the rheological properties of asphalt binder. For high temperature 25 mm diameter plates were used while for low temperature the 8 mm diameter geometry were used. Gap between two parallel pates were 1 mm and 2 mm for 25 mm and 8 mm respectively.

Asphalt binder bond strength test

The asphalt binder bond strength (BBS) test was conducted to measure the tensile force required to detach the stub from the base plate, in the presence of binders as shown in Fig. 3. The test was conducted following the controlled conditions outlined in ASTM D454142. Initially, a 15" × 6" × 1.5" base plate was prepared by trimming a Margalla limestone slab. The base plate was cleaned for one hour at 60 °C using an ultrasonic cleaner. Prior to the test, the base plate was preheated in an oven at 150 °C for 60 min and then reheated for 30 min at 75 °C. The stubs were also heated for 30 min at 65 °C. A pressure of 120 psi was applied to the cylinder, and 0.4 g of either virgin or modified binder was applied to the stubs and pressed onto the base plate of aggregates. Excess asphalt binder was carefully removed from all samples using a cutter. Specimens were conditioned as either unconditioned (dry) or moist conditioning specimens after 24 h. The F4 piston and circular spacer were carefully set, and the pressure was gradually applied to the stubs during the test. The pull-off test strength (POTS) values were recorded for each specimen. Equation 5 was used to estimate POTS43.

whereas, BP = Burst Pressure, C = Piston Constant (C = 0.286 in2), Ag = Contact Area of Gasket (Ag = 4.06 in2), Aps = Pull-out Stub Area (Aps = 0.193 in2).

Rolling bottle test

The moisture damage to each material was evaluated using the rolling bottle test (RBT) (EN 12697-11A)44. After being coated with virgin or modified binder, the coated aggregates were mechanically abraded by water as shown in Fig. 4. After being completely coated with virgin or modified binder (weight: 8 gm), aggregates (weight: 170 gm) were put in bottles (500 ml) of deionized water with a stirrer. Then, the bottles were rotated at 60 RPM for interaction. The results in the form of the remaining coating percentage were noted at diverse time intervals (6 h, 24 h, 48 h, and 72 h). In this hypothetical scenario, the key indicators might include the ability of the asphalt mix to resist deformation and maintain structural integrity under simulated rolling conditions. Observations would focus on signs of rutting or other distresses, providing insights into the mix's performance and stability under the stresses encountered in a rolling environment, such as those experienced by vehicles on a roadway.

Assessment on the asphalt mixture performance

Wheel tracking test

The resistance of the produced mixes (virgin or modified) against permanent deformation was evaluated referring to BS EN 12697-2545. The test was run using a 700-N wheel that could complete 53 passes in 60 s. The selected protocols were 12.5 mm and 50 °C (rut-depth criteria). These methods were chosen to assess the mixtures' resistance to permanent deformation in Pakistan's predominately hot climate46. The slabs with the specified dimensions (300 mm × 300 mm × 50 mm) were first prepared by compaction using the roller compactor to conduct the stated experiment. The produced slabs were then put into the frame of the apparatus for testing while being passed by wheels frequently. The device was programmed to automatically stop at 10,000-wheel passes when the test was completed. The use of a software program on the PC linked with the apparatus allowed the rut depth to be automatically registered for each produced sample.

Dynamic modulus test

After adding CS bio-oil modified binder to the produced mixes, the stiffness effect was assessed using the Dynamic Modulus Test, AASHTO TP6247. Cylindrical specimens with dimensions of 150 mm diameter and 170 mm height, along with an air-void content of 5.5 ± 0.5%, were prepared using the Superpave gyratory compactor. Afterwards, these samples were subjected to coring and cutting into new dimensions (101.6 mm dia. and 150 mm height). At 4.4, 21.1, 37.5, and 54.4 °C and 25, 10, 5, 1, and 0.5 Hz, all the produced samples were evaluated48. The output from the examination includes values of dynamic modulus at formerly stated conditions. The sinusoidal loads of about 53 kPa, 195 kPa, 525 kPa, and 1050 kPa were applied to the produced samples within the equipment frame.

Four-point beam fatigue test

The fatigue resistance of the produced mixes, both virgin and modified, was evaluated using the four-point beam fatigue test, AASHTO T32149. The stress-control mode was used to conduct the test. Firstly, the stress-controlled mode allows for a more accurate and controlled application of stress levels throughout the test. This helps in simulating the actual stress conditions that the material would experience in real-world applications, such as the repeated loading of a structural component. Secondly, stress-controlled testing is particularly relevant when the material being tested exhibits significant strain hardening or strain softening behaviour. In such cases, controlling the stress levels allows for a more consistent and controlled response from the material, ensuring that the test results are representative of its true fatigue behaviour. The selected protocols for this test were 10 Hz (frequency level) and 20 °C (set temperature). The beams produced were 380 mm 50 mm 63 mm in size. The produced beams passed repeated loading tests. The test was programmed to automatically end after the initial stiffness of the produced mixes had decreased by 50%.

Statistical analysis

Statistical analysis was conducted using the SPSS software to further evaluate the test results. This analysis can be useful in determining the extent to which CS bio-oil modified binder affects the asphalt binder and mixes. The asphalt binder and mixture were shown to be significantly impacted by CS bio-oil modified binder. The recorded laboratory data was further analyse using variance analysis (ANOVA) for this analysis with a 95% confidence level, the general linear model was selected. The dependent variable for each test was chosen as the result of the corresponding test (with 3 replicates). However, the independent variables varied with each test type (as presented in Table 5). The P-values from the statistical analysis were then compared with α = 0.05 (also known as reliability) to determine whether an effect was significant. According to the specified criteria, the null hypothesis should be accepted if P < 0.05. The independent variable does not significantly affect the dependent variable, according to the null hypothesis. The null hypothesis in this instance also stated that "One independent variable does not have an interaction effect on the other independent variable, and vice versa." This evaluation was done for RBT and BBS”.

Results and discussion

Basic properties of asphalt binders and thermal susceptibility

This section presents an analysis of the consistency test results in terms of penetration, ductility, softening point, and penetration index. The increasing penetration trend is commonly accompanied by an increase in the quantity of CS bio-oil modified binder, which denotes the start of the softening-gain mechanism, as shown in Fig. 5.

In comparison to the virgin binder, a percentage rise of approximately 27.1% and 19.5% is observed for penetration values of 10% and 5% CS bio-oil modified binder, respectively in Fig. 5, the rising trend for penetration is typically seen with increasing CS bio-oil modified binder content, which indicates the initiation of the softening-gain mechanism. In comparison to the virgin binder, a percentage rise of approximately 27.1% and 19.5% is observed for penetration values at 10% and 5% CS bio-oil modified binder, respectively. This trend is confirmed by the softening point trend (Fig. 6), which also shows the production of soft binder by increasing the amount of CS bio-oil modified binder. Compared to the virgin binder, the lowest softening point was observed at a concentration of 10% CS bio-oil modified binder. However, the lower softening point values with increasing CS bio-oil modified binder content suggest a rise in thermal susceptibility50, which will be further evaluated through the PI values at the end of this section.

Table 6 presents the findings of the ductility test conducted on the virgin and modified binders. Additionally, Table 6 indicates that the rise in ductile response was mainly due to the higher CS bio-oil modified binder content in the virgin binder, which is linked to the softness-gain mechanism. The highest ductile response was observed when 10% of CS bio-oil modified binder was combined with the virgin binder, resulting in the greatest increase in ductility compared to the virgin binder. The impact of CS bio-oil modified binder on the ductility of binder blends was statistically significant. Moreover, maximum ductility is an indication of better flexibility as well as resistance to fracture. The incorporation of CS bio-oil modified binder at 10% and 5% weight percentages resulted in a change in the penetration grade of the virgin binder, to Pen-grade 80/100 and Pen-grade 70/80, respectively. The incorporation of CS bio-oil modified binder resulted in the production of softer binders. Furthermore, the ductility, penetration, and softening point values of CS bio-oil modified binder fall within the typical paving grade specifications used in Pakistan (refer to Table 6)51. Moreover, the production of softer binders indicates the potential of CS bio-oil modified binder to soften hard binders, highlighting its applicability for recycling materials52.

The Penetration Index (PI) measurement offers quantitative insights into the thermal susceptibility of materials53. The Penetration Index (PI) values typically fall within the range of − 3 to + 7, indicating the high or low thermal susceptibilities of asphalt binders. Equations (2) and (3) were employed to calculate the PI values and thermal susceptibility (A), following the methodology outlined in the literature54. Figure 7 shows the results of asphalt binder sample penetration index. The analysis of the results shows that increasing the CS bio-oil modified binder content resulted in a decrease in PI values. The 10% CS bio-oil modified binder content in virgin binder was used to determine the bottom PI value. The decreasing PI values and increasing trend of susceptibility (A) values demonstrate that the addition of CS bio-oil modified binder increased the susceptibility of the binders treated with it. However, the PI values remain within the permissible limits defined by the earlier studies33 as an allowable limit for paving binder (− 2 to + 2). The CS bio-oil modified binder binders are therefore inferred to be suitable for use in paving applications, as previously expected. Yet, the primary problem with predicting thermal susceptibility from PI estimation is that, when calculating A values, only two temperatures are used (i.e., 20 °C and 25 °C for softening point and penetration respectively). Because of this, there is a need to study the rheology of virgin and modified binders at wide temperatures and frequency levels, for which testing through DSR is the best option.

Rheological behaviour

The rheological assessment of the asphalt binders and mixtures was performed to understand their flow and deformation behaviour. The results indicated that the addition of bio-oil modified binder in the binder led to notable changes in its rheological properties as shown in Fig. 8. The rheological assessment demonstrated that adding bio-oil modified binder reduced the viscosity of the binder, enhancing its resistance to flow at low temperatures. While this may increase susceptibility to rutting, it also improves flexibility by decreasing stiffness, reducing the risk of cracking due to thermal changes. These findings offer critical insights into the impact of bio-oil modified binder on asphalt mixtures, guiding the development of more durable and sustainable road construction materials.

Performance grading (PG) of bio-oil modified binder-modified asphalt binder

Figure 9 shows the results of the PG-grade test, indicating failure temperatures. Overall, adding CS bio-oil modified binder reduced the failure temperatures compared to using base binder. When compared to virgin binder, which has a failure temperature of 63.9 °C, the most significant decrease in failure temperature is seen at 10% content of CS bio-oil modified binder. Additionally, any binder specimen can be selected for PG-grade using the failure temperatures. Startlingly, the PG-58 was similar for every binder specimen. Thus, as far as its practical implications are concerned, the binders modified with CS bio-oil modified binder can be used as surrogates for a virgin binder, which is additionally confirmed by the rheological behaviour studied previously, as there was equal rut resistance and improved fatigue resistance.

The black diagram, independent of frequency and temperature, provides a comprehensive overview of the data in a single graph. It may be noted from the Fig. 10 that the viscoelastic properties of bitumen are very sensitive to CS bio-oil content as there is a significant change in path of the unmodified binder and binder modified with different dosages of CS bio-oil. Moreover, an increase in temperature correlated with a rise in the phase angle of bitumen and a decrease in G* value. Notably, beyond a certain threshold depicted in Fig. 10, the phase angle of 5% and 10% CS bio-oil demonstrates a reduction at high temperatures and low frequencies compared to the base binder, indicating heightened elastic behavior of bitumen for these proportions. Consequently, the addition of CS bio-oil enhances resistance against deformation in bitumen.

The section represents a rheological assessment as well as the statistical examination of the results acquired through DSR (frequency sweep and PG-grade tests) to study the impact of adding CS bio-oil modified binder in virgin or modified binder at various temperatures and frequencies. The rheological assessment comprises (a) the complex modulus (G*), (b) fatigue factor (G*.sinδ), (c) rut factor (G*.sinδ), and (d) PG-grading. The master curves in Fig. 9 are comprised of reduced frequency (fr) values along the x-axis and complex modulus (G*) values along the y-axis. They were produced using a sigmoidal function at a reference temperature of 58 °C. Referring to master curves for both the virgin binders and CS bio-oil modified binder, it was observed that the complex modulus values in the high-temperature range reduced as the proportion of CS bio-oil modified binder increased, with the most substantial reduction noted at a 10% CS bio-oil modified binder concentration. This indicates that CS bio-oil modified binder has a greater potential to enhance the fatigue resistance of virgin binder due to the softening-gain mechanism at low temperatures. Moreover, the complex modulus values for each CS bio-oil modified binder specimen just slightly change, demonstrating nearly similar high-temperature performance for both virgin and modified binders. This shows that the CS bio-oil modified binder specimen can reduce stresses and withstand increased external loading just like a virgin binder. Additionally, these results are consistent with other studies on bio-oil modified binder40. A statistical analysis of the data in Table 7 was done to corroborate these trends. The null hypothesis is supported by enough evidence when the P-value is greater than α = 0.05. Thus, it can be confirmed that there was nearly equal performance between CS bio-oil modified binder binders and virgin binders. Additionally, it confirms earlier findings that the addition of any amount of CS bio-oil modified binder had no effect on virgin binder performance at high temperatures.

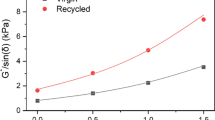

For a more effective view of rheological behaviour, the Superpave factors (fatigue and rut factors) were also estimated. By considering these factors, it is possible to better understand how virgin and modified binders behave rheologically in terms of fatigue and rutting resistance55. For each temperature (82 °C, 70 °C, 58 °C, and 46 °C), G*/sin (δ) (rut factor) was calculated at a frequency of 10 rad/s, in accordance with recommendations from the prior study56. The fatigue factor, G*.sin (δ), was determined in a similar way to this at two distinct temperatures, 34 and 22 °C. Figure 11 shows temperatures along the x-axis and values for G*/sin (δ) along the y-axis. The G*/sin (δ) is slightly affected by the addition of CS bio-oil modified binder contents, as expected, showing that both virgin and modified specimens have equal rut resistance in the high-temperature range. These results confirm the previous assessment of rheological behaviour studied through master curves of complex modulus.

Asphalt binder's sensitivity to stress variations

Using a loading mode that approximated real pavement loading, the MSCR test data were analysed to simulate real pavement force and deformation. This represents how the materials behave in hot environments. For an asphalt binder to meet the requirements of high quality, it is crucial that it demonstrates sufficient elasticity and recovery capabilities over a broad range of high temperatures, while also being able to resist continuous deformation under elevated temperature conditions. The non-recoverable creep compliance (Jnr) was measured at 64 °C, with stress as the independent variable and percent recovery as the dependent variable, as depicted in Fig. 12.

While the recovery rate decreases as stress increases, the value of Jnr increases along with it, with the amount varying according to the type of binder. The previous study indicates that stiffer binder Jnr values are lower than softer binder Jnr values. Figure 12 illustrates how a stiffer grade binder can be converted into a softer one by adding bio-oil modified binder, with the Jnr values increasing as a result. Figure 12 demonstrates how the addition of bio-oil modified binder affects the rheological properties of asphalt binders. It shows the relationship between the stiffness of the binder, represented by the Jnr values, and the addition of bio-oil modified binder. In the figure, as move from left to right along the x-axis, increasing the amount of bio-oil modified binder added to the original asphalt binder. As a result, the stiffness of the binder decreases, which is reflected in the increasing Jnr values along the y-axis. This trend indicates that the addition of bio-oil modified binder softens the original asphalt binder, making it less stiff. This is important because it demonstrates how the properties of asphalt binders can be modified by incorporating additives like bio-oil to achieve desired performance characteristics, such as improved flexibility or reduced susceptibility to cracking.

Moisture susceptibility

Moisture can be a significant factor in causing premature failure of asphalt pavements, as it can decrease both the strength and stiffness of the material, leading to various types of distress, such as ravelling and hydraulic damage. This section investigates into the effects of incorporating CS bio-oil modified binder into both base and modified binders, particularly regarding their susceptibility to moisture. The results of the BBS and RBT tests are analysed to evaluate the response of the mixtures to damage caused by moisture. The BBS and RBT test results are analysed to evaluate the mixtures' susceptibility to moisture damage and their ability to withstand such effects.

Bitumen-aggregate adhesion (BBS results)

In this section, the pull-out tensile strength (POTS) values obtained from the BBS results were analysed to evaluate the adhesive strength between unmodified or modified binders and aggregates.

The results presented in Fig. 13 exhibit a notable enhancement in the bond strength between the binder and aggregates with the increasing concentration of CS bio-oil modified binder in dry conditions. The highest POTS value recorded at 10% CS Bio-oil modified binder content signifies a substantial improvement in the bond strength between the aggregates and binder in the absence of moisture. The wettability concept, which is defined as the covering of aggregates with binder, can be used to describe the philosophy behind these results. Usually, soft binders possess wettability when compared to hard binders. More CS bio-oil modified binder was added, and as a result of the softness-gain mechanism, this promoted improved wettability, which in turn increased POTS values in dry conditions57,58. It is a well-known fact that binders with high wettability are more susceptible to the negative effects of stripping and emulsification in the presence of water. This is primarily attributed to the increased number of vulnerable sites on the aggregate surface that result from high wettability, which leads to enhanced water permeability57,58. This is supported by a decrease in POTS under moist conditions when more CS bio-oil modified binder content is added to virgin binder, demonstrating the severe action of water as a result of the softness-gain mechanism59. The highest reduction, which is seen for 10% of the CS bio-oil modified binder concentration, indicates a weaker binding between the binder and aggregate. Table 8 presents the statistical analysis results in more detail to determine the significance of the CS bio-oil modified binder percentage and test condition. The fact that the null hypothesis was rejected shows that the condition type and CS bio-oil modified binder, respectively, have a considerable impact on the bond strength of asphalt binder and aggregates. Additionally, the percentage of CS bio-oil modified binder and the condition type (either moist or dry) interact significantly (null hypothesis is rejected, P 0.05). This demonstrates the interaction of the effects of condition type and CS% level on the bond strength between asphalt binder and aggregate.

Remaining coating around aggregates in moist condition (RBT results)

Generally, the coating of binder around a single aggregate was reduced at various time intervals that resulted in a maximum decrease at 10% CS bio-oil modified binder concentration (Fig. 14). The study findings indicate that the bond strength between binder and aggregates is highly influenced by the addition of CS bio-oil modified binder, and this effect is further enhanced in the presence of water due to the increased content of bio-oil modified binder. These observations support the hypothesis that increased wettability of the binder leads to a higher probability of binder emulsification and stripping. The statistical analysis of the RBT results presented in Table 9 supports these conclusions, showing a significant impact of both the time interval and % of CS bio-oil modified binder on the bond strength between the binder and aggregates. The P-values for both variables were less than α = 0.05, leading to the rejection of the null hypothesis. There is no interactive influence between the percentage of CS bio-oil modified binder and the other variable, time interval, as shown by the P-value for the case "CS bio-oil modified binder x time interval" being greater than α = 0.05. This shows the independent influences of time and the amount of CS bio-oil modified binder on the moisture sensitivity of materials. Further supporting the damaging effect of moisture on the strength of the binding between binder and aggregate are BBS data that demonstrate the addition of CS bio-oil modified binder improves the CS bio-oil modified binder binder's moisture sensitivity. The damage caused by moisture is controlled using various modifiers, which include hydrated lime, Portland cement, and polymers (in liquid form). Further research is warranted to explore methods for improving the moisture resistance of CS bio-oil modified binder binders. The statistical analysis presented in Table 9 reveals that both the percentage of CS bio-oil modified binder and the time interval have a statistically significant impact on the bond between aggregates and asphalt binder. The impacts of both parameters on moisture resistance are interrelated, as evidenced by a comparable interactive effect between time interval and CS bio-oil modified binder content. The modified binder's reduced capacity to withstand moisture is caused by the addition of CS bio-oil modified binder, and this result is consistent with prior BBS test results.

Asphalt mixture testing results

The durability of a pavement, which is closely tied to its performance, is a key factor in estimating its structural capacity60. The use of additives to improve the performance of asphalt mixtures can result in longer pavement service life and reduced maintenance costs, as well as improved resource conservation, particularly in terms of aggregates and binder. The resistance of pavement against moisture damage, rutting, and wear plays a key role in determining its durability. This section presents a comparison of the performance of asphalt mixtures containing CS bio-oil modified binder additives and virgin mixtures.

Wheel tracker test

This results of the Wheel Tracker Test (WTT) in Fig. 15. The test is specifically designed for precisely evaluating resistance to rutting in the form of rut depth, to further support the analysis performed in the preceding section. The outcomes acquired through the WTT test are graphically shown in Fig. 15 (rut depths at consecutive and cumulative passes till 10,000 for virgin and modified mixtures). Generally, cumulative passes with more CS bio-oil modified binder content show a decrease in rut depth. In addition, the rut depths at initial wheel passes for each base or modified mixture have a sharp inclination (sharp increase), which later changes to a slow and gradual rise. The actual causes behind this outcome are material densification and aggregate locking under the repeated wheel loads. The rut depth consequently abruptly increases at the beginning of the WTT61. After 10,000-wheel passes, the rut depths of both the virgin and CS bio-oil modified binder modified mixtures were measured and compared. The analysis revealed that the rutting resistance of the mixtures did not improve significantly with an increase in CS bio-oil modified binder content. In comparison to the virgin mixture, there is a percentage increase of 5.8% and 3.1% for the contents of 10% and 5% CS bio-oil modified binder, respectively. This supports the previous claims of equal rut resistance in virgin and modified mixtures. The statistical analysis in Table 10 was conducted to determine whether the observed improvement in rutting resistance with increasing CS bio-oil modified binder content is statistically significant. After comparing the final rut depths following 10,000-wheel passes, the results showed no statistically significant increase in the pavement's ability to resist rutting with the addition of CS bio-oil modified binder (P-value > 0.05).

Dynamic modulus test

This section compares the results of the virgin mixtures with those of the CS bio-oil modified binder modified mixtures, with a focus on the dynamic modulus, which is an essential design parameter for flexible pavements. The impact of dynamic modulus on pavement performance, specifically in terms of fatigue and rutting resistance, is also analysed. The dynamic modulus master curves for both the virgin and modified mixes are illustrated in Fig. 16. In agreement with the previous finding, the softening-gain process causes an obvious decrease in E* values for higher concentrations of the CS bio-oil modified binder mixture at low temperatures. The maximum decrease is noted at 10% content of CS bio-oil modified binder, which shows better resistance of the material against fatigue when compared to a virgin mixture62. The statistical analysis described above further confirms these results. Furthermore, as expected, a negligible increase in E* values are observed at low frequencies, indicating that CS bio-oil modified binder mixtures have the same response to distress (rutting) as virgin mixtures.

Table 11 presents the results of statistical analysis of dynamic modulus in the high-frequency range, which confirms that adding CS bio-oil modified binder can enhance the mixture's resistance to fatigue cracking (the null hypothesis is rejected as the p-value is less than 0.05).

Four-point beam fatigue test

The progressive weakening of materials due to repetitive loads caused by fatigue cracking leads to the development of cracks and eventual pavement failure63. This section presents a discussion on the results of the Four-Point Beam Fatigue Test (FPBFT) in terms of failure cycles, considering the impact of material failure on the formation of fatigue cracks. Figure 17 shows the results that were obtained in stress control mode. In general, the failure cycles increase with the addition of CS bio-oil modified binder to the virgin mixture due to the softening-gain mechanism. When compared to the virgin mixture, the maximum increase is noted for 10% CS bio-oil modified binder concentration in the mixture. The percentage increase of 4.47% and 1.53% is noted at 10% and 5% contents of CS bio-oil modified binder in the virgin mixture, respectively. This rise in fatigue cycles is the function of decreased flexural stiffness as well as initial dissipated energy22. The statistical analysis (Table 12) conducted on the loading cycles has shown a significant enhancement in the fatigue resistance of the asphalt binder upon the incorporation of CS bio-oil modified binder (P-value < 0.05, null hypothesis rejected).

Conclusions

This research examines the impact of various asphalt binder modifications on fatigue, rutting, and moisture damage. The research delves into detailed analyses across different sections, offering thorough interpretation and discussion of the results. The conclusions drawn from these analyses are summarized as follows:

-

a)

Asphalt binders modified with CS bio-oil showed significant softening effects, as evidenced by increased penetration values, and decreased softening points. Furthermore, these modified binders were more ductile than virgin binders.

-

b)

The DSR test result indicated that the 10% CS bio-oil modified binder performed well against rutting without compromising rutting resistance.

-

c)

The CS Bio-oil modified binder binders maintained equivalent PG ratings compared to virgin binder binders, indicating enhanced resilience against fatigue cracking.

-

d)

The inclusion of CS bio-oil modified binder weakened moisture resistance, resulting in deterioration of the bond between aggregates and binder, as measured using the BBS and RBT.

-

e)

Evaluation of fatigue performance using Dynamic Modulus showed that CS bio-oil modified binder improved fatigue performance similarly to DSR. This enhancement occurred without negatively impacting rutting resistance.

-

f)

The WTT and FPBFT tests further supported the conclusions drawn from the analysis of dynamic modulus (i.e., negligible change in rutting resistance and greater improvement in fatigue performance, respectively).

Data availability

All data used in this research appear in the submitted article.

Change history

04 October 2024

A Correction to this paper has been published: https://doi.org/10.1038/s41598-024-74547-6

References

McIntosh, S., Vancov, T., Palmer, J., & Morris, S. J. B. t. Ethanol production from cotton gin trash using optimised dilute acid pretreatment and whole slurry fermentation processes. 173, 42–51 (2014).

Du, S.-k., Zhu, X., Wang, H., Zhou, D., Yang, W., & Xu, H. J. B. t. High pressure assist-alkali pretreatment of cotton stalk and physiochemical characterization of biomass. 148, 494–500 (2013).

Bostancioğlu, M. & Oruç, Ş. Effect of furfural-derived thermoset furan resin on the high-temperature performance of Asphalt binder. Road Mater. Pavement Des. 16(1), 227–237 (2015).

Cavaca, L. A. & Afonso, C. A. Oleuropein: A valuable bio-renewable synthetic building block. Eur. J. Org. Chem. 2018(5), 581–589 (2018).

Pereira, P. & Pais, J. Main flexible pavement and mix design methods in Europe and challenges for the development of an European method. J. Traffic Transp. Eng. (Engl. Ed.) 4(4), 316–346 (2017).

Cuadri, A., García-Morales, M., Navarro, F. & Partal, P. Processing of Asphalt binders modified by a Bio-oil modified binder-derived polyurethane. Fuel 118, 83–90 (2014).

Mohammad, L. N., Elseifi, M. A., Cooper, S. B. III., Challa, H. & Naidoo, P. Laboratory evaluation of asphalt mixtures that contain biobinder technologies. Transp. Res. Rec. 2371(1), 58–65 (2013).

Yang, X., You, Z., & Dai, Q. Performance evaluation of asphalt binder modified by bio-oil modified binder generated from waste wood resources. Int. J. Pavement Res. Technol. 6(4) (2013).

Fini, E. H., Al-Qadi, I. L., You, Z., Zada, B. & Mills-Beale, J. Partial replacement of asphalt binder with bio-binder: Characterisation and modification. Int. J. Pavement Eng. 13(6), 515–522 (2012).

Fini, E. H., Hosseinnezhad, S., Oldham, D. J., Chailleux, E. & Gaudefroy, V. Source dependency of rheological and surface characteristics of bio-modified asphalts. Road Mater. Pavement Des. 18(2), 408–424 (2017).

Fini, E. H. et al. Chemical characterization of biobinder from swine manure: Sustainable modifier for asphalt binder. J. Mater. Civ. Eng. 23(11), 1506–1513 (2011).

Fini, E. H., Oldham, D. J. & Abu-Lebdeh, T. Synthesis and characterization of biomodified rubber asphalt: Sustainable waste management solution for scrap tire and swine manure. J. Environ. Eng. 139(12), 1454–1461. https://doi.org/10.1061/(ASCE)EE.1943-7870.0000765 (2013).

Fini, E. H., Yang, S.-H., & Xiu, S. Characterization and application of manure-based bio-binder in asphalt industry (2010)

Mills-Beale, J. et al. Ageing influence on rheology properties of petroleum-based asphalt modified with biobinder. J. Mater. Civ. Eng. 26(2), 358–366 (2014).

Raouf, M. A., & Williams, R. C. Determination of pre-treatment procedure required for developing bio-binders from Bio-oil modified binders. Proc., Proc., 2009 Mid-Continent Transportation Research Symposium.

Raouf, M. A. & Williams, R. C. Temperature and shear susceptibility of a nonpetroleum binder as a pavement material. Transp. Res. Rec. 2180(1), 9–18 (2010).

Tang, S., & Williams, R. C. Antioxidant effect of Bio-oil modified binder additive ESP on asphalt binder. Proc., Proceedings of the 2009 Mid-Continent Transportation Research Symposium, Ames, IA, USA, 20–21.

Khan, D. et al. Effects of crumb rubber and styrene-butadiene rubber additives on the properties of asphalt binder and the Marshall performance properties of asphalt mixtures. Budownictwo i Architektura 22(4), 147–161 (2023).

Yang, S.-H. & Suciptan, T. Rheological behavior of Japanese cedar-based biobinder as partial replacement for bituminous binder. Constr. Build. Mater. 114, 127–133 (2016).

Gao, J., Wang, H., You, Z. & Yang, X. Gray relational entropy analysis of high temperature performance of bio-asphalt binder and its mixture. Int. J. Pavement Res. Technol. 11, 698–708 (2018).

Wang, H., Gao, J., Zhao, X., You, Z. & Tian, Y. Rheological properties on bio-binder based on DSR and RV. J. Hu Nan Univ. Nat. Sci. 42, 26–33 (2015).

Wang, H. & Junfeng, Z. Y. Advances in bio-binder application on road pavement. J. Wuhan Univ. Technol. 36(7), 4 (2014).

He, M., Cao, D.-W., Zhang, H.-Y., Song, Z.-R. & Wu, X.-W. Research on conventional performance of modified bio-asphalt. J. Highw. Transp. Res. Dev. (Engl. Ed.) 9(2), 1–6 (2015).

Gaudenzi, E., Canestrari, F., Xiaohu, L. & Cardone, F. Performance assessment of asphalt mixture produced with a bio-based binder. Materials 14(4), 918. https://doi.org/10.3390/ma14040918 (2021).

Ali, B. et al. Investigation into the effect of waste engine oil and vegetable oil recycling agents on the performance of laboratory-aged bitumen. Budownictwo i Architektura 23(1), 033–054 (2024).

Pradhan, S. K. Short-term and long-term aging effect of the rejuvenation on RAP binder and mixes for sustainable pavement construction. Int. J. Transp. Sci. Technol. 12(4), 937–954. https://doi.org/10.1016/j.ijtst.2022.09.005 (2023).

Pradhan, S. K. & Sahoo, U. C. Use of Mahua oil for rejuvenation of the aged binder through laboratory investigations. Int. J. Transp. Sci. Technol. 11(1), 32–45. https://doi.org/10.1016/j.ijtst.2020.11.002 (2022).

Zheng, J.-l., Yi, W.-m., Wang, N.-n. J. E. C., & Management. Bio-oil modified binder production from cotton stalk. 49(6), 1724–1730 (2008).

Yang, X., You, Z., Dai, Q. & Mills-Beale, J. Mechanical performance of asphalt mixtures modified by Bio-oil modified binders derived from waste wood resources. Constr. Build. Mater. 51, 424–431 (2014).

Tufail, M., Ahmad, N., Mirza, S. M., Mirza, N. M., & Khan, H. J. S. o. t. t. e. Natural radioactivity from the building materials used in Islamabad and Rawalpindi, Pakistan. 121, 283–291 (1992).

Hussan, S., Kamal, M. A., Hafeez, I., Farooq, D., Ahmad, N., & Khanzada, S. J. I. J. o. P. E. Statistical evaluation of factors affecting the laboratory rutting susceptibility of asphalt mixtures. 20(4), 402–416 (2019).

ASTM International. Standard Test Method for Resistance to Plastic Flow of Bituminous Mixtures Using Marshall Apparatus (ASTM D1559) (1998).

Enieb, M. & Diab, A. Characteristics of asphalt binder and mixture containing nanosilica. Int. J. Pavement Res. Technol. 10(2), 148–157 (2017).

AASHTO. Standard method of test for penetration of bituminous materials (AASHTO T49) (1997).

ASTM. ASTM D36 standard test method for softening point of bitumen (ring-and-ball apparatus) (2006).

ASTM. ASTM D113 standard test method for ductility of bituminous materials (1999).

AASHTO. AASHTO T-315 standard method of test for determining the rheological properties of asphalt binder using a dynamic shear rheometer (DSR) (2012).

Jamal, Hafeez, I., Yaseen, G., & Aziz, A. J. I. J. o. P. E. Influence of Cereclor on the performance of aged asphalt binder. 21(11), 1309–1320 (2020).

Ahmad, N., Nasir, M. A., Hafeez, M., Rafi, J., Zaidi, S. B. A., & Haroon, W. J. A. S. Carbon nanotubes (CNTs) in asphalt binder: Homogeneous dispersion and performance enhancement. 8(12), 2651 (2018).

Gao, J. et al. Rheological behavior and sensitivity of wood-derived Bio-oil modified binder modified asphalt binders. Appl. Sci. 8(6), 919 (2018).

Elliott, R., & Thompson, M. R. Mechanistic design concepts for conventional flexible pavements. Interim Report Illinois Univ., Urbana-Champaign. Dept. of Civil Engineering (1985).

ASTM. ASTM D4541: Standard test method for pull-off strength of coatings using portable adhesion testers (2017).

Moraes, R., Velasquez, R. & Bahia, H. U. Measuring the effect of moisture on asphalt–aggregate bond with the Asphalt binder bond strength test. Transp. Res. Rec. 2209(1), 70–81 (2011).

EN 12697-11:2012. Bituminous mixtures—Test methods for hot mix asphalt—Part 11: Determination of the affinity between aggregate and bitumen. Brussels: European Committee for Standardization (2012).

BSI. BS EN 12697–25:2005 Bituminous mixtures—Test methods for hot mix asphalt - Part 25: Cyclic compression test. British Standards Institution (2005).

Jamal, Hafeez, I., Yaseen, G., & Aziz, A. Influence of Cereclor on the performance of aged asphalt binder. Int. J. Pavement Eng. 1–12 (2018).

AASHTO. AASHTO TP62: Standard Method of Test for Determining the Dynamic Modulus and Flow Number for Asphalt Mixtures Using the Asphalt Mixture Performance Tester (AMPT). American Association of State Highway and Transportation Officials (2003).

Khan, D., Khan, R., Khan, T. & Alam, M. Performance of hot mix asphalt using polymers modified bitumen and marble dust as a filler. J. Traffic Transp. Eng. (Engl. Ed.) 10(3), 385–398. https://doi.org/10.1016/j.jtte.2022.12.002 (2023).

AASHTO. AASHTO T321: Standard Method of Test for Determining the Fatigue Life of Compacted Hot Mix Asphalt (HMA) Subjected to Repeated Flexural Bending. American Association of State Highway and Transportation Officials (2017).

Jahromi, S. G. & Khodaii, A. Effects of nanoclay on rheological properties of Asphalt binder binder. Constr. Build. Mater. 23(8), 2894–2904 (2009).

Lu, G., Liu, P., Wang, Y., Faßbender, S., Wang, D., & Oeser, M. J. J. o. C. P. Development of a sustainable pervious pavement material using recycled ceramic aggregate and bio-based polyurethane binder. 220, 1052–1060 (2019).

Girimath, S. & Singh, D. Effects of Bio-oil modified binder on performance characteristics of base and recycled asphalt pavement binders. Constr. Build. Mater. 227, 116684 (2019).

Zapién-Castillo, S., Rivera-Armenta, J. L., Chávez-Cinco, M. Y., Salazar-Cruz, B. A. & Mendoza-Martínez, A. M. Physical and rheological properties of asphalt modified with SEBS/montmorillonite nanocomposite. Constr. Build. Mater. 106, 349–356 (2016).

Ehinola, O. A., Falode, O. A. & Jonathan, G. Softening point and Penetration Index of Asphalt binder from parts of Southwestern Nigeria. Nafta 63(9–10), 319–323 (2012).

Kennedy, T. W., Huber, G. A., Harrigan, E. T., Cominsky, R. J., Hughes, C. S., Von Quintus, H., & Moulthrop, J. S. Superior performing asphalt pavements (Superpave): The product of the SHRP asphalt research program (1994).

Ingrassia, L. P., Lu, X., Ferrotti, G., & Canestrari, F. Chemical, morphological and rheological characterization of Asphalt binder partially replaced with wood Bio-oil modified binder: Towards more sustainable materials in road pavements. J. Traffic Transp. Eng. (Engl. Ed.) (2019).

Ahmad, N. Asphalt Mixture Moisture Sensitivity Evaluation Using Surface Energy Parameters (University of Nottingham, 2011).

Grenfell, J., Apeagyei, A. & Airey, G. Moisture damage assessment using surface energy, Asphalt binder stripping and the SATS moisture conditioning procedure. Int. J. Pavement Eng. 16(5), 411–431 (2015).

Zhang, R. et al. Thermal storage stability of Bio-oil modified binder modified asphalt. J. Mater. Civ. Eng. 30(4), 04018054 (2018).

Van Dam, T. J. et al. Towards Sustainable Pavement Systems: A Reference Document (Federal Highway Administration, United States, 2015).

Cordeiro, G. C. & Kurtis, K. E. Effect of mechanical processing on sugar cane bagasse ash pozzolanicity. Cem. Concr. Res. 97, 41–49 (2017).

Fernandes, S., Peralta, J., Oliveira, J. R., Williams, R. C. & Silva, H. M. Improving asphalt mixture performance by partially replacing Asphalt binder with waste motor oil and elastomer modifiers. Appl. Sci. 7(8), 794 (2017).

Fallon, E., McNally, C. & Gibney, A. Evaluation of fatigue resistance in asphalt surface layers containing reclaimed asphalt. Constr. Build. Mater. 128, 77–87 (2016).

Acknowledgements

This publication is supported under the excellence initiative—research university program under the grant no. 32/014/SDU/10-27-09, Silesian University of Technology, Gliwice, Poland and TRC research project BFP/RGP/EI/23/073 University of Nizwa, Oman.

Funding

The Article Processing Charges (APC) of this project is funded by TRC research project BFP/RGP/EI/23/073 University of Nizwa, Oman.

Author information

Authors and Affiliations

Contributions

All of the authors contributed in literature search, figures, study design, data collection, data analysis, data interpretation, and writing etc. Such as, Sahib Ullah and Diyar Khan carried out the experimental work. Sahib Ullah and Diyar Khan analyzed the data and interpreted the results. Sahib Ullah ,Diyar Khan and Ayyaz Fareed drafted the manuscript. Sahib Ullah & Syed Bilal Ahmed Zaidi, Diyar Khan: Conceptualization, Methodology, Software, Data curation, Writing- Original draft preparation. Sahib Ullah & Syed Bilal Ahmed Zaidi: Software, Validation, Supervision Diyar Khan, Ayyaz Fareed, Mohd Rosli Mohd Hasan, Abdalrhman Milad and Basit Ali: Funding aqusition, Writing- Reviewing and Editing. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this Article was revised: The original version of this Article contained an error in the Acknowledgements section. Full information regarding the correction made can be found in the correction for this article.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ullah, S., Zaidi, S.B.A., Khan, D. et al. Bio-oil modified binder derived from cotton stalks as an eco-friendly alternative binder for flexible pavements. Sci Rep 14, 13519 (2024). https://doi.org/10.1038/s41598-024-62652-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-62652-5

Keywords

This article is cited by

-

Evaluation of the performance of bio-oil modified asphalt mixtures through response surface methodology and optimization techniques

Scientific Reports (2025)

-

Eco-Modified asphalt binders: enhancing pavement longevity with Delonix seed extract and optimized crumb rubber granulometry

Journal of Material Cycles and Waste Management (2025)