Abstract

The beveling process is an important process in the manufacturing of resonators, which has a significant impact on the frequency stability of resonators. Without understanding the frequency characteristics of the resonator after beveling, it is impossible to accurately design the beveled resonators. Thus, in order to investigate the vibration characteristics of AT-cut beveled resonators, we investigated the high-frequency vibration in this work by using the subregional geometric fitting method (SGFM) based on Mindlin’s plate theory. Quartz crystal plates with nonuniform thicknesses are partitioned into three regions and each region is fitted by using the polynomial functions based on the measured geometric morphology data. The governing equations are obtained based on Mindlin’s two-dimensional theory and the coupled vibrations are further solved using the partial differential equation module of COMSOL. In the numerical calculation, we compare the results obtained by the SGFM with those obtained by the global fitting method and the measured data. The accuracy and effectiveness of the SGFM are also verified. It is found that the frequencies obtained by the SGFM are slightly higher than the frequencies obtained by the global fitting method, and the results of SGFM are closer to the measured results. Meanwhile, as the beveling time increases, the frequency increases and the energy trapping effect becomes more significant. The proposed method can significantly improve the computational efficiency of thickness-shear vibration while ensuring accuracy. It is expected to provide a new geometric fitting method for the analysis of beveled crystal resonators.

Similar content being viewed by others

Introduction

Quartz crystal resonators are widely used as frequency control components for time-keeping and signal processing. They are important components in various electronic equipments. As one of the main operating modes in quartz resonators, thickness-shear vibration mode can be easily excited either by a thickness electric field1 or by a lateral electric field2,3. The resonant frequencies of thickness-shear modes are usually above megahertz and mainly determined by the plate thickness4,5 so that the frequency can be easily controlled, which is beneficial for the design of these micro-devices. A quartz resonator usually has a nonuniform thickness (beveled resonator6,7), which is thick in the central region and thin near the edges. Such geometry enhances the energy trapping behavior8,9 which is important and useful for the thickness-shear vibration mode. Energy trapping is mainly caused by the inertia effect10 which can be introduced by plating electrodes11 or additional mass layer on the partial region of the plate surfaces. It seems to be convinced that the partially bulged thickness of the beveled plate can be regarded as the additional mass on the plate to enhance the energy trapping. Additionally, when mounting and installing the quartz devices, auxiliary elements are better to locate outside the trapping region, so that these auxiliary elements have less effect on the central vibration.

To address this issue, a lot of work has been carried out including theoretical analysis, numerical simulation and experimental attempts about energy trapping12,13. After quartz blanks being beveled using the fixed abrasive method14, the thickness-shear vibration of the beveled resonators will be restricted to the center of the resonators and attenuated to the edges of resonators. The beveling process refers to mixing blank chips and sand in a drum, and gradually wearing off the sharp corners on all four sides as the drum rotates. By this way, the beveled resonators can reduce the impact of edge clamping on the resonators, and on the other hand, enhance the working mode while suppressing the spurious modes.

In the analysis of high-frequency vibration of beveled quartz crystal plates, the varying thickness causes a considerable mathematical challenge since the beveled resonator is characterized by differential equations with spatially varying coefficients. Early theoretical analyses on contoured resonators were mainly based on the two-dimensional theories for elastic or piezoelectric plates15,16,17,18,19. A general solution is hard to be achieved, and some analytical solutions can be obtained only for the cases with specific thickness variations, such as hyperbolic20, elliptical21,22, cubic23, or stepped function24,25. The existed theoretical results for resonators are mostly applicable to plates with a fixed thickness26,27. In general, we usually have to make various approximations to the model for beveled plates28.

However, different from the circular resonators, the surface of a rectangular beveled resonator in fact has different principal curvatures in two in-plane directions because of the manufacturing process of rectangular beveled resonators. Furthermore, the general way of beveling resonators is by grinding them with sand in a rolling tank. The morphologies of the resulting resonators are not exactly quadratic, so that the actual surfaces of the beveled resonators are complex. In previous studies, it was common to simplify the geometric models that may lead to significant differences between the geometric model and the practical morphology of the beveled plate. Therefore, we propose a subregional geometric fitting method (SGFM) to fit the practical morphologies of the beveled resonators with small fitting error.

Until now, most of the theoretical analyses on contoured resonators were based on a scalar differential equation derived in29,30,31 for AT-cut and SC-cut quartz resonators, and for both rectangular32,33 and circular resonators34,35,36. In this work, we also use the Mindlin’s plate theory to build the mathematical model which expands the displacements and potential into a power series of thickness coordinate. Retaining the first few terms of the series expansion, substituting these series into the field equations, and integrating along the thickness, the vibration problem of a plate is simplified from a three-dimensional problem to a two-dimensional problem, greatly reducing the difficulty of solving the equations. At meanwhile, the accuracy of the calculation can be ensured by modifying the material coefficients using shear correction factors. By changing the thickness in Mindlin’s plate theory to the polynomial morphology function, it is possible to derive the governing equations that match the geometric model well and establish a new form of mechanical model.

In this work, the beveled crystal plate is partitioned into three regions based on the thickness values from the experimentally measured morphology data. Each region is fitted by a polynomial function. Based on the Mindlin’s plate theory and considering the piezoelectric effect, the coupled vibration equations for variable thickness plates can be established and solved numerically using the partial differential equation module of COMSOL to obtain the frequencies, modes of thickness-shear vibration, and electrically forced vibration results. We separately solve for the free vibration and the forced vibration under an electric field, and compare the results obtained by using the SGFM with the results by the global fitting method to verify the accuracy and effectiveness of the SGFM. The proposed method and results of this work can provide important reference for the design and calculation of beveled crystal resonators.

Subregional geometric fitting method

To describe the contour of beveled resonator more accurately, we use the SGFM by using the experimentally measured morphology data. To obtain the morphology data, the fixed abrasive method is used for beveling the rectangular blank plates14 and the CA-11 Scanning Chip Morphometer is used measure the morphology data at different beveling time. The length of the blank crystal board is 1.659 mm, the width is 1.311 mm, and the thickness is 129 μm. Figure 1 shows the geometric morphology, region partition and fitting error at the width center of beveled plate at different beveling time. Under the condition of ensuring the continuity of the boundaries of each region, the beveled plate is partitioned into three regions according to the thickness value, as shown in Fig. 1. In the Cartesian coordinate system (x1, x2, x3), x2 is the thickness direction, and the thickness h is a function of x1 and x3. The thickness of each region is fitted by using a quadratic polynomial function with the coefficients ai for each region as given below.

For the morphologies obtained at different beveling time, shown in Fig. 1, we carried out the SGFM for three regions (A, B, C) and the obtained coefficients of polynomial functions are given in Table 1. In Fig. 1, the fitted 2D model is not exactly symmetric in both x1 and x3 directions. This is due to the errors caused during the beveling process and the contour is not exactly symmetric. The global fitting method (GFM) is also adopted for comparison, where the entire geometry is fitted by one polynomial function. To demonstrate the fitting error, we present the fitting results at the center of width as shown in the figure. We can clearly see that the thicknesses of the global fitting curves are much larger than the curves of the SGFM and the practical data at the center. With the increasing of beveling time, this error becomes smaller. However, the SGFM presents the results that are almost as same as the practical data at the center. This implies that SGFM is more accurate in predicting the geometries of the beveled resonators. Theoretically, we can divide the beveled resonator into many regions. However, according to the practical thickness data, it is enough to ensure the calculation accuracy by using three regions to fit the geometry in this work.

Mathematical model

The mathematical model is developed based on the Mindlin’s plate theory for non-uniform thickness crystal plate. The displacement fields and electric potential are given as below which are expressed in terms of the power series functions.

where \(u_{i}^{(n)}\) and \(\varphi^{\left( n \right)}\) are the nth-order displacement and electric potential, respectively.

The governing equations of the coupled vibration are given in Eq. (3). These two-dimensional higher order plate equations were established in previous works by Mindlin37.

where \(\rho\), \(T_{ij}^{(n)} (i,j = 1,2,3)\), \(D_{i}^{(n)} (i = 1,2,3)\) and \(F_{j}^{(n)}\) are the density, nth-order stress, nth-order electric displacement and nth-order face traction. And

where Tij and Di are the stress and electric displacement vector. It should be noted that h is function of x1 and x3, and its derivatives respect to both x1 and x3 have to be taken into consideration in the modeling of beveled plate.

The nth-order strain and electric field are given in Eq. (5).

where \(\delta_{i2} = 1,\;\;\;i = 2\) and \(\delta_{i2} = 0,\;\;\;i \ne 2\).

The nth-order constitutive equation of piezoelectric material can be given as below.

where \(c_{ijkl}\), \(e_{ijk}\), \(\varepsilon_{ij}\), \(S_{ij}^{(m)}\) and \(E_{k}^{(m)}\) are the elastic constant tensor, piezoelectric constant tensor, dielectric constant tensor, m-order strain tensor, and m-order electric field tensor, respectively. The integral constant Bmn is

We perform the first order truncation for the nth-order constitutive equation, and the zero and first order constitutive relationship the electric displacement expression have the following form considering the piezoelectric effect.

In this work, we consider three modes, namely the thickness-shear mode \(u_{1}^{\left( 1 \right)}\), the flexure mode \(u_{2}^{\left( 0 \right)}\) and the face-shear mode \(u_{3}^{\left( 0 \right)}\). The governing equations of the beveled crystal plate for free vibration have the following forms

For the forced vibration under an external electric field, we assume that the plate is excited by a harmonic voltage to both surfaces. With the potential expansion given in Eq. (2), the electric potential of the surface can satisfy the following form38.

where \(\varphi (h)\) and \(\varphi ( - h)\) are the driving voltages on the upper and lower faces. We can obtain \(\varphi^{(0)}\) and \(\varphi^{(1)}\) from (9) as

Through the substitution of Eq. (10) into Eq. (2), we can obtain the electric potential expansion on the faces. And then, we retain the first three terms of the power series as

For the third-order expansion, we have

Apparently, we can get the higher order electric fields related to the potential components in the above equation as

The electric potentials in the stress terms should take new forms due to the changes in the electric field. Thus, we can write out the stress and electric displacement as below.

Substituting Eq. (14) into Eq. (6), the nth-order stress components of the two-dimensional equations can be expressed by

For the first order approximation, Eq. (15) is reduced to the following equations.

To obtain the two-dimensional electric displacements, we should start from the three-dimensional charge equation for a finite volume as below.

By using the potential variation, substituting the variation in Eq. (12) into Eq. (17), it can be rewritten as

For the arbitrary variation of \(\delta \varphi^{(2)}\) and \(\delta \varphi^{(3)}\), we have the following equation for the electric displacement.

or

where the two-dimensional electric displacement components in Eq. (19) are defined with the help of Eq. (14) as below.

Substituting the first order strains and third order electric field into Eq. (20), the electric displacements become the following forms38. It should be noted that with the first order strains, it is enough to predict the fundamental thickness-shear vibration frequency accurately.

The governing equations are now rewritten as below using the first order strains and third order electric field.

Thus, substituting Eq. (16) and Eq. (21) into Eq. (22), we can obtain the governing equations for high-frequency vibration of nonuniform plate.

To obtain proper boundary conditions, we start with

where ni, tj and σ are the outward normal, prescribed traction, and prescribed charge, respectively. The variation of the two-dimensional displacements is

By substituting Eq. (12) into (24), we have the following equation for the second term of Eq. (24).

or

where

It is clear that the boundary conditions on the faces can be obtained by the variation principle. For the edges, we have

For the calculation of capacitance, we adopt the charge equation derived by Wang38. The total surface charge is defined by

where A is the area of the upper or lower surface of the beveled crystal plate and the weighting function \(f\left( {x_{2} } \right) = x_{2}^{2} - h^{2}\) which is obtained from Eq. (20).

By using Eq. (21), the charge equation is can be simplified to

The static and motional capacitances and capacitance ratio for the plate are

Thus, the capacitance ratio of a point from these equations is given as

Since the capacitance ratio solved under the above assumption is function of x1 and x3, the average value of the capacitance ratio is presented instead which is calculated by the integration over the whole region and divided by the area for the nonuniform thickness plate.

Result and discussion

Free vibration analysis

Based on the mathematical model derived earlier, we investigate the free vibration of beveled AT-cut quartz crystal plate in this section. The governing equations are solved using the differential equation module of COMSOL. The material properties of AT-cut quartz crystals are from the references7,38. In the following calculations, the free vibration results are obtained at the beveling time from 10 to 40H. For validation, the results obtained by the SGFM are compared with those obtained by the GFM.

Table 2 shows the fundamental thickness-shear vibration frequencies obtained at different beveling time for free vibration analysis. From the results, it can be found that the free vibration frequencies calculated by the SGFM are slightly higher than the results of GFM. This is due to the fact that the geometries fitted in different regions are closer to the practical model for the SGFM, and the thicknesses at the center positions of the plates are more accurate. By using the GFM, the thickness values in the center areas of the plates are higher than the practical values, so that the frequency results obtained are slightly lower than the practical values. At meanwhile, it can also be observed that as the beveling time continues to increase and the thickness of the plate gradually decreases, the frequency value gradually increases from 13.663 MHz to 15.547 MHz for the SGFM since the thickness-shear vibration frequencies are mainly determined by the thickness of plate. While for the GFM, the frequency value increases from 13.548 MHz to 15.410 MHz.

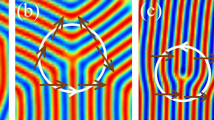

From the results of thickness-shear modes in Fig. 2, it can be observed that as the beveling time increases, the center region becomes closer and closer to a circle, indicating a more pronounced energy trapping effect. Figure 3 shows the normalized displacements of the width center obtained by the SGFM. The black line, which is the thickness-shear mode, is multiplied by the maximum thickness at different beveling time. Otherwise, the amplitude of thickness-shear mode is much larger than that of the other two modes. It can be observed that at the thickness-shear vibration frequency, the amplitude of the thickness-shear mode is much greater than the other two modes. Meanwhile, as the beveling time increases, the normalized amplitudes of the other two modes become much smaller comparing with the normalized amplitude of thickness-shear vibration mode, indicating that the energy trapping effect becomes more pronounced with the increase of beveling time.

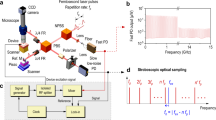

Forced vibration analysis

In this subsection, we investigate the forced vibration of beveled plate under a harmonic voltage with the magnitude of 0.01 V. We present the results obtained by both the SGFM and the GFM, and the results are compared with the experimental measurements. The frequency response of the total displacement at different beveling time are shown in Fig. 4 for a geometric middle point in the plate. At different beveling time, the amplitudes and frequencies are normalized by the corresponding maximum thickness and the frequency of the infinite plate, respectively. The amplitude is in the unit of decibel, which is defined by \(20lg({\text{abs}}(u/b))\) and u and b are the displacement of the thickness-shear mode and the corresponding maximum thickness at different beveled time, respectively. The results show that the number of peaks and their positions presented by the two methods are basically same, but the amplitude is obviously different due to different geometric models. Since the damping coefficient is not included in the calculation, the magnitudes of the peaks cannot be predicted accurately. However, it can be expected that when considering the material damping coefficient, for damped vibrations, the corresponding resonant frequencies will slightly decrease, the peak values will also decrease, and some peaks may even disappear and become invisible in the curves. As a result, the frequency results will be closer to the practical measured values. For making the comparison of the first-order thickness-shear mode, the frequencies of the GFM and SGFM are given in Table 3 as well as the experimental results. It is found that the frequency trend is same when increasing the beveling time, and the overall trend of SGFM is closer to the values of practical measurement. The frequency errors are less than 1.5% for both methods. However, it can be found that the SGFM results are larger than the global fitting results, which is consistent with the geometric morphology fitting results and the experimental results. Therefore, the present SGFM results have higher prediction accuracy for the first-order thickness-shear vibration frequency. For the results of beveling time from 10 to 30H, there is no significant difference in the peak positions of the spurious modes, that is, there is no significant change in the spurious modes for both methods. This indicates that the spurious modes (higher order modes) are not sensitive to the thickness dimension in this frequency range. When the beveling time is 40H, it is found that when the normalized frequency is greater than 1.2, the peak positions obtained by the two methods show some difference, indicating that the thickness effect begins to appear and its influence on the spurious modes increases. As the beveling time increases, some sharp peaks begin to decrease or disappear. At the same time, the heights of some sharp peaks are significantly decreased compared with the global fitting results. This reflects that the beveling process suppresses the spurious modes and the SGFM is more accurate in predicting the vibration modes by partitioning the geometry into several regions. It should be noted that the vibration magnitudes of the face-shear mode and flexure mode are much smaller than the thickness-shear mode, they are almost neglectable at this frequency range.

Finally, we also present the capacitance ratio results of the beveled plates using two different methods as shown in Fig. 5. From the results, it is found that the curves are much smoother compared with the displacement results. Similar conclusions can be achieved as discussed for the displacement results. The peak positions predicted by the both methods are generally same, except that they have significant difference at the frequency of thickness-shear mode and the peak of SGFM is located at the right of the GFM implying it has larger resonating frequency. The results of capacitance ratio can help us understand the correspondence between the thickness-shear vibration and the electrical response curves.

Conclusions

In this work, we proposed a study on high-frequency vibration of beveled quartz resonators based on the subregional geometric fitting method and compared the results with those obtained by the global fitting method. We also compared the results with the measured values under an external electric field excitation. This work is mainly based on Mindlin's two-dimensional theory and extends the theory to quartz plates with nonuniform thickness. The fundamental thickness-shear vibration frequencies obtained by SGFM proposed in this work are slightly larger than the frequency results obtained by the global fitting method as we expected. The error can be less than 1.5%, which is expected to further improve the accuracy by adjusting the geometric model. As the beveling time increases, the suppression effect on the spurious modes strengthens, and it is also expected to improve the prediction accuracy of spurious modes through subregional fitting. Due to the complexity of the morphology caused by the beveling process, using SGFM can improve the calculation accuracy of frequencies more than using an ideal simplified model in practical vibration analysis. Meanwhile, two-dimensional finite element calculation can significantly improve the computational efficiency compared with three-dimensional finite element models, which is of great significance for the design and development of beveled resonators.

Data availability

Data is provided within the manuscript.

References

Wang, W., Zhang, C., Zhang, Z., Ma, T. & Feng, G. Energy-trapping mode in lateral-field-excited acoustic wave devices. Appl. Phys. Lett. 94(19), 192901 (2009).

Ma, T., Zhang, C., Wang, W., Zhang, Z. & Feng, G. Optimal electrode shape and size of lateral-field-excited piezoelectric crystal resonators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 58(1), 263–266 (2011).

Corso, C. D., Dickherber, A. & Hunt, W. D. Lateral field excitation of thickness shear mode waves in a thin film ZnO solidly mounted resonator. J. Appl. Phys. 101(5), 054514 (2007).

Lu, F., Lee, H. P., Lu, P., Su, X. D. & Lim, S. P. Experimentally fitting the attraction strength of an interface by the response of the thickness shear-mode acoustic wave sensor. J. Phys. D: Appl. Phys. 38(10), 1599–1607 (2005).

Zhao, Z., Qian, Z., Wang, B. & Yang, J. Thickness-shear and thickness-twist modes in an AT-cut quartz acoustic wave filter. Ultrasonics 58, 1–5 (2015).

Yang, J. S. & Tiersten, H. F. Effects of free edge on the vibration characteristics of a contoured, beveled quartz resonator. Int. J. Appl. Electromagn. Mech. 46(3), 649–661 (2014).

Sinha, B. K. & Stevens, D. S. Thickness-shear vibrations of a beveled AT-cut quartz plate. J. Acoust. Soc. Am. 66(1), 192–196 (1979).

Li, N., Wang, B. & Qian, Z. Coupling vibration analysis of trapped-energy rectangular quartz resonators by variational formulation of Mindlin’s theory. Sensors 18(4), 986 (2018).

Ma, T., Wang, J., Du, J. & Yang, J. Resonances and energy trapping in AT-cut quartz resonators operating with fast shear modes driven by lateral electric fields produced by surface electrodes. Ultrasonics 59, 14–20 (2015).

Cassiède, M., Paillol, J. H., Pauly, J. & Daridon, J.-L. Electrical behaviour of AT-cut quartz crystal resonators as a function of overtone number. Sens. Actuators A: Phys. 159(2), 174–183 (2010).

He, H., Nie, G., Liu, J. & Yang, J. Energy trapping of thickness-shear and thickness-twist modes in a partially electroded AT-cut quartz resonator. Acta Mechanica Solida Sinica 25(6), 579–585 (2012).

Yang, J., Chen, Z. & Hu, Y. Trapped thickness-twist modes in an inhomogeneous piezoelectric plate. Philos. Mag. Lett. 86(11), 699–705 (2006).

Wang, J., Hu, Y. & Yang, J. Frequency spectra of AT-cut quartz plates with electrodes of unequal thickness. IEEE Trans. Ultrasonics Ferroelectr. Frequency Control 57(5), 1146–1151 (2010).

Jeong, H.-W., Aoki, T. & Hatsuzawa, T. Frequency responses of spherically contoured rectangular AT-cut quartz crystal resonators fabricated by fixed abrasive method. Int. J. Mach. Tools Manuf. 44(11), 1143–1149 (2004).

Lee, P. C. Y. & Wang, J. Piezoelectrically forced thickness-shear and flexural vibrations of contoured quartz resonators. J. Appl. Phys. 79(7), 3411–3422 (1996).

Lee, P. C. Y. & Wang, J. Thickness-shear and flexural vibrations of contoured crystal strip resonators. J. Appl. Phys. 79(7), 3403–3410 (1996).

Wang, J., Lee, P. C. Y. & Bailey, D. H. Thickness-shear and flexural vibrations of linearly contoured crystal strips with multiprecision computation. Comput. Struct. 70(4), 437–445 (1999).

Bleustein, J. L. Thickness-twist and face-shear vibrations of a contoured crystal plate. Int. J. Solids Struct. 2(3), 351–360 (1966).

Lee, P. C. Y. & Chen, S. Vibrations of contoured and partially plated, contoured, rectangular, AT-cut quartz plates. J. Acoust. Soc. Am. 46(5B), 1193–1202 (1969).

Li, P., Jin, F. & Yang, J. Thickness-shear vibration of an AT-cut quartz resonator with a hyperbolic contour. IEEE Trans. Ultrasonics Ferroelectr. Frequency Control 59(5), 1006–1012 (2012).

Wang, W., Wu, R., Wang, J., Du, J. & Yang, J. Thickness-shear modes of an elliptical, contoured at-cut quartz resonator. IEEE Trans. Ultrasonics Ferroelectr. Frequency Control 60(6), 1192–1198 (2013).

Zheng, Y., Sun, Z., Huang, B. & Guo, Y. Geometric eccentricity effect on thickness-shear vibration of an elliptical flexoelectric crystal plate. Physica Scripta 98(8), 085241 (2023).

Wang, J., & Lee, P. C. Y. The effect of cubically varying contours on the thickness-shear and flexural vibrations of quartz plates. In Proceedings of IEEE Ultrasonics Symposium, San Antonio 977–980 (1996).

He, H., Liu, J. & Yang, J. Thickness-shear and thickness-twist vibrations of an AT-cut quartz mesa resonator. IEEE Trans. Ultrasonics Ferroelectr. Frequency Control 58(10), 2050–2055 (2011).

Lu, F., Lee, H. P. & Lim, S. P. Energy-trapping analysis for the bi-stepped mesa quartz crystal microbalance using the finite element method. Smart Mater. Struct. 14(1), 272–280 (2005).

Ma, T.-F., Zhang, C., Jiang, X.-N. & Feng, G.-P. Thickness shear mode quartz crystal resonators with optimized elliptical electrodes. Chin. Phys. B 20(4), 047701 (2011).

Xu, L., Geng, Y., Hu, Y., Fan, H. & Yang, J. Thickness-shear vibration of an AT-cut quartz plate with elliptical electrodes and implications in optimal blank geometry. IEEE Trans. Ultrasonics Ferroelectr. Frequency Control 56(4), 875–879 (2009).

Li, P. & Jin, F. The investigation of trapped thickness shear modes in a contoured AT-cut quartz plate using the power series expansion technique. J. Phys. D: Appl. Phys. 51(1), 015301 (2018).

Tiersten, H. F. & Smythe, R. C. An analysis of contoured crystal resonators operating in overtones of coupled thickness shear and thickness twist. J. Acoust. Soc. Am. 65(6), 1455–1460 (1979).

Stevens, D. S. & Tiersten, H. F. An analysis of doubly rotated quartz resonators utilizing essentially thickness modes with transverse variation. J. Acoust. Soc. Am. 79(6), 1811–1826 (1986).

He, H., Yang, J. & Kosinski, J. A. Scalar differential equation for slowly-varying thickness-shear modes in AT-cut quartz resonators with surface impedance for acoustic wave sensor application. IEEE Sens. J. 13(11), 4349–4355 (2013).

Shi, J., Fan, C., Zhao, M. & Yang, J. Trapped thickness-shear modes in a contoured, partially electroded AT-cut quartz resonator. Eur. Phys. J.-Appl. Phys. 69(1), 10302 (2015).

Yuan, L., Wu, R., Du, J., Wang, J. & Yang, J. Thickness-shear and thickness-twist vibrations of rectangular quartz crystal plates with nonuniform thickness. Mech. Adv. Mater. Struct. 24(11), 937–942 (2017).

Tiersten, H. F. & Zhou, Y. S. Transversely varying thickness modes in quartz resonators with beveled cylindrical edges. J. Appl. Phys. 76(11), 7201–7208 (1994).

Slavov, S. H. & Apostolov, A. V. Frequency spectrum and modes of vibration in circular, convex AT-cut beveled-design quartz resonators: Experimental results. Appl. Phys. A 29(3), 173–175 (1982).

Yang, J. An analysis of partially electroded, contoured, quartz resonators with beveled cylindrical edges. IEEE Trans. Ultrasonics Ferroelectr. Frequency Control 54(11), 2407–2409 (2007).

Mindlin, R. D., & Yang, J. An Introduction to the Mathematical Theory of Vibrations of Elastic Plates (World Scientific, 2006).

Wang, J., Yu, J., Yong, Y.-K. & Imai, T. A new theory for electroded piezoelectric plates and its finite element application for the forced vibrations of quartz crystal resonators. Int. J. Solids Struct. 37(40), 5653–5673 (2000).

Acknowledgements

This work was supported by the Scientific Research Found of Zhejiang Provincial Education Department (Grant no. Y202351699), the Ningbo Major Research and Development Plan Project (Grant no. 2022Z210) and the research Found from the TXC (Ningbo) Corporation.

Author information

Authors and Affiliations

Contributions

Z.S. wrote the main manuscript. Z.S. and Z.W. conducted the calculation and prepared Figs. 1–5. Z.L. prepared the experimentl results. Y.G. and B.H. revised the manuscript. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sun, Z., Wang, Z., Li, Z. et al. High-frequency vibration of beveled crystal plates by using subregional geometric fitting method. Sci Rep 14, 17131 (2024). https://doi.org/10.1038/s41598-024-67846-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-67846-5