Abstract

The development of electric vehicles (EVs) has been incremental because EVs satisfy a significant demand for energy sources. Electronic control unit (ECU) is an important component that processes the electric signals received from various sensors for generating the control signals for the actuators. Automotive control systems were initially operated manually throughout the automotive revolution based on the responses of input signals received from ECUs and drivers. Most of the functions in EV are controlled by the ECU and every ECU consumes power at all times even if it is not in use. The larger power consumption of passive ECUs like adaptive lighting systems (ALS), automatic wiper systems (AWS) brake light systems (BLS), etc., affect the life of ECUs and the range of EVs. This article is primarily concerned with limiting power consumption by switching the power supply to the passive ECUs based on their requirements. Hence, to achieve the objective, the intelligent zone (i-zone) based master ECU is triggered to activate the slave ECUs. Designing suites including Proteus and KiCAD were used for designing the circuits including master as well as slave ECU. This prototype is built using three secondary ECUs such as ALS & AWS and BLS which are controlled using i-zone-based master ECU. The performance of this implemented design is evaluated, and it is discovered that almost 40% of the battery consumption is reduced. This i-zone-based master ECU and all its slave ECUs manage power while ensuring the safety and reliability of EVs.

Similar content being viewed by others

Introduction

In recent years, the growth of electric vehicles (EVs) has been rapid. As the domestic usage of EVs among people is becoming more familiar, it may become that transportation in the future is entirely electric. EVs are cost-effective due to their significant efficiency during operation. The reason for the increase in EV usage is that the cost of fuel is drastically rising. The main challenge is to improve EV performance by controlling the power consumption of electronic components1,2,3,4,5. The electronic control unit (ECU)6 is a device that regulates the electrical and electronic systems in vehicles. More than 70–100 ECUs are installed in a mid-level vehicle. Each ECU serves a specific purpose, such as the body control ECU and the tire pressure monitoring system (TPMS) ECU7. These ECUs consume an average current ranging from 150 to 200 mA. In general, ECUs are classified into two categories: primary ECUs and secondary ECUs. The primary ECUs are used to perform basic mobility and safety functions. Secondary ECUs are used for additional applications such as automatic wiper systems, automatic adaptive lighting systems, and other automobile infotainment systems8.

Conventional systems have several limitations, primary and secondary ECUs power consumption is increased which affects the range of EVs and lifespan of ECUs because an average of 150 ECUs were present in the EV9. A battery management system (BMS) ensures an efficient operation of these ECUs. To overcome these issues there is a necessity to turn the secondary ECUs ON only when it is needed. However, in the case of primary ECUs, no modifications will be made as they involve safety-related tasks. Hence, in this proposed work, intelligent zone based master ECU (i-zone based master ECU) has been introduced9,10,11,12. i-Zone-based master ECU monitors and controls the power usage of secondary ECUs which in turn reduces the overall power consumption of subsystems. i-Zone-based master ECU manages the power by switching to ON and OFF states autonomously only when required by collecting various sensory inputs from the EV. The scientific contribution claimed in the work is to design and develop of cost-effective i-zone-based system by satisfying requirements including minimum power consumption, and improvising the range of EV and ECU’s lifespan13,14,15.

The three ECUs namely adaptive lighting system (ALS) and automatic wiper system (AWS) and brake light system (BLS) are considered as secondary ECUs in this analysis16. The ALS is a controller that switches the lights ON or OFF automatically following the ambiance. AWS is a similar controller that turns the wiper ON/OFF when it is raining on the windshield. The BLS turns the brake lights on upon the activation of the brake limit switch. The organization of the paper is as follows. In “Literature survey” section presents the literature review of various techniques that are used for improving the performance of EVs in terms of power consumption of ECU. In “Methodology of the proposed work” section describes the proposed system model and analysis involved in reducing the power consumption in EVs. In “Results and discussion” section discusses the results obtained from the analysis of i-zone-based ECU. In “Conclusion” section concludes the results of this work with future directions.

Literature survey

In17, the authors proposed zone-based architecture using electronic components assignment and cable routing with the help of Dijkstra’s and k-means clustering algorithms. The Zone control unit will be the hub for the in-vehicle data and transporting formation to zonal architectures. The reason for considering the position and number of electronic components presented for analyzing the effect of the wiring harness. Simulation results show that it reduces wiring harness length as well as weight and brings functional benefits18. However, the number of zones must be chosen with care, as there may also be functional limitations. In19, the authors proposed a fuzzy logic controller that improves the initial current amplitude and saves power using MATLAB software. The performance of the fuzzy logic controller is compared with the integral derivative controller. The simulation results achieved good results in time-domain response and rapid rejection of system-affected disturbance20.

The reduction in core losses produced by the induction motor is also achieved, which will improve the system's efficiency. The authors focused on reducing the component size by aiming to improve the battery power and energy. It is achieved by designing the power of an extended-range electric vehicle. Finally, optimization for control parameters was implemented21. In22, the authors provided solutions for practical EVs that integrate solar technology, MEDs, and hardware which will improve the range of EVs. The most feasible one of them is to improve the current generation of EVs using improved hardware. This can be done with ease and won’t be costly. It is strongly recommended that researchers and car manufacturers implement these technologies with each iteration of vehicles that come out in the market23. EVs are the future as they are efficient, cheap, and eco-friendly as they emit nearly zero compared to ICE’s24.

In25, the authors developed an assisting system to suggest the correct driving style depending on the area. The reason for creating the assistance system is that the charge level will be different depending on the patterns. The system also intimated the battery state and the weather conditions for suggesting the driving patterns. The driving styles included after performing tests like accelerations, decelerations, and impact of battery state and vehicle range. In26, the authors proposed the in-vehicle network for minimizing the wiring harness which is important for communication as well as for power minimization. It is achieved by separating the ECUs based on their functions as domains using OMNeT++ simulator. From the findings, the authors concluded that the architecture helps to reduce 24.6% of the wiring harnesses in both lengths and weights where transmission delay is also reduced. In27, the authors proposed an optical-based vehicle network architecture for replacing Ethernet using two slot scheduling algorithms such as dynamic slot scheduling algorithm and periodic slot scheduling. In the dynamic slot scheduling algorithm, packet delay decreased when compared to fixed periodic slot scheduling, particularly in the network architecture.

The performance evaluation has been evaluated with the help of measuring the total delays which includes traffic shaping and processing delays28. Further, the occurrence of extra delays in slot scheduling is low and neglected but not in the traffic shaping delay. In29, the authors designed a zonal-based vehicle architecture named UNICARagil to reduce the power supply. It is achieved by clustering the positions of the electric load to identify the right position for the zone control unit as well as routing done for wire harness reduction using the Dijkstra algorithm. From the evaluation, the authors achieved better experience in the testing phase and wire harness complexity. In30, the study focused on the parallel roadmap for the development of E/E architecture. Domain-oriented and zone-oriented schemes were evaluated. The networking mechanism, modeling, and tools used for verifying the networking condition were discussed additionally. In31, the miles-per-charge internal combustion engine vehicles are high compared to EVS. It is improved by proposing a Range Extension Autonomous Driving (READ) system which minimizes the energy usage which is achieved by velocity profile optimization. This READ system is applied both straight and curved with the help of vehicle rotation motion and the cornering resistance models. In32 the authors have presented a power coordinated control approach (PCCA) for stable driving. This PCCA comprises a control model and Lyapunov–Razumikhin stability theorem for finding the communication delay. From the integration of PCCA, decrease in engine speed error and DC-bus voltage error to 39.87%, 43.85%, 44.67%, and 79.94%. In33 The authors discussed types of EVs, various charging methods, and different artificial intelligence and machine learning-based optimization techniques for improving the efficiency of the EV.

From the literature, it is found that the complexity is the large number of ECUs and their power consumption34. This impacts the range of EVs and the assembly process of cable packaging which in turn increases the production time and labor. The raging count of ECUs in the EVs is increasing the complexity of the system and power consumption. Industrial research and developments including Aptiv35 & NXP36, and Texas Instruments37 & Keysight38 are focusing on the zone-based architecture approach for optimizing the power consumption. Hence, in this proposed research work, a novel system involving intelligent zone (zone) based architecture is taken into consideration.

Methodology of the proposed work

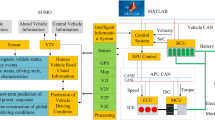

The proposed system is developed to check the power drain through secondary ECUs when it is in standby mode, particularly for zone architecture-based EVs. Zone architecture is a generalized approach that classifies ECUs depending on their physical location in the EV which also provides the central gateway for communication which is shown in Fig. 1. This approach focuses on reducing the power consumption of the secondary ECUs and the overall power consumption of the system. To enhance efficiency in terms of power consumption, an iZone-based master ECU is introduced in this work39. This iZone-based strategy is an evolving technique to enable better electrification in fully battery-operated EVs and hybrid EVs.

iZone-based master ECU is the main hub placed in an EV that serves as a node for all of the power distribution and data communication40 via CAN protocol as per the requirements of secondary ECUs namely ALS, AWS, and BLS ECU, etc. In conventional systems, the zone-based master ECU keeps the safety components and less prioritized secondary ECUs in standby mode which will affect the range of EVs. But in this proposed work, iZone-based master ECU keeps the secondary ECUs in an OFF state when not in use, ensuring the safety and security of the EV system. In this way, an iZone-based master ECU reduces the power consumption and increases the range of the EV.

Layout of iZone-based master ECU

To implement the iZone-based Master ECU, ALS, AWS, and BLS, ATMEGA32 Microcontroller (MCU) and MCP2515 CAN module are used. The ALS is a secondary ECU, which operates the actuators with the input signal from the light dependent resistor (LDR). AWS ECU operates the wiper motor with the help of the rain sensor. BLS ECU receives a signal from a Limit switch and activates the brake light41. The proposed iZone-based master ECU is implemented for two significant processes based on the sensory input signals. The first one is to enable and disable the power supply of secondary ECUs via MOSFET. The Next is the communication between the based master ECU and the corresponding secondary ECU through CAN protocol which is preceded by enabling the actuators. The block diagram of the zone-based master ECU along with secondary ECUs is illustrated in Fig. 2. From Fig. 2, it is noted that the LDR transmits the signal to the iZone-based master ECU for performing the logic functions to activate the power signal and data command for the ALS ECU42. Similarly, the Rain sensor sends the signal to provide the power supply and data command for the AWS ECU. Similarly, the limit switch fitted with a brake lever sends the signal to the master ECU which enables the power supply and sends the data command to the BLS ECU.

Hardware and software for iZone communication

The circuit design and its simulations were performed using four major components: one master ECU and three secondary ECUs to experience their performance in Proteus software. The Proteus IDE is used to simulate the circuit. The proteus tool has both hardware design and software design for this system43. The 8-bit microcontroller ATmega328 which is a reduced instruction set computer (RISC) based microcontroller operated between 1.8 and 5.5 V is used. For communication purposes, a serial programmable universal synchronous/asynchronous receiver and transmitter, a 2-wire serial interface, and a serial peripheral interface were used. CAN communication is used to transfer and receive the data between iZone-based ECUs & secondary ECUs. MCP2515 CAN Module with TJA1050 Transceiver is used. The power supply for secondary ECUs is controlled by MOSFET IRF13044. The software simulations and Hardware tests were conducted, and the outcomes are discussed below.

Results and discussion

This section discusses the results obtained from the simulation and prototype of the iZone-based master ECU.

Circuit design

Firstly, the circuit design of ALS is laid out using Proteus software45 as shown in Fig. 3. The figure illustrates that the CAN Serial input is given to the ATMEGA’s 27th pin (PC4) for transferring the signals. Then, the CAN Serial output is connected to the ATMEGA’s 28th pin (PC5). ATMEGA’s 9th and 10th output pins are connected with transistor drivers Q3 & Q5 to trigger light 1 (L2) and light 2 (L4) respectively for enabling the powering purpose. Similar to ALS models, simulations were performed for AWS ECU and BLS ECU46.

The proteus simulation model of iZone-based master ECU is shown in Fig. 4. ALS (LDR Sensor), AWS (Rain sensor), and BLS (Limit switch) are connected with three input pins namely the 9th pin, 20th pin, and 11th pin of the iZone-based master ECUs microcontroller47. The outputs are taken from the 32nd, 1st pin, and 10th pin which are powered by the constant + 5 V power supply continuously, to produce activation signals to all secondary ECUs. This master ECU acts as a switch to power the considered Secondary ECUs. To control the power source of secondary ECUs, MOSFET IRF130 is used. The MOSFET IRF130 is an electronic switch that controls the power source of secondary ECUs48. After designing, an appropriate Embedded C program is written for this application to activate the ECUs in proteus software49.

Hardware

After the completion of the simulation, circuit design was performed. There are various commercially available products including Eagle, KiCad, Proteus, and Altium for PCB design. In this system, KiCad software is used to create the PCB layout. Initially, ALS ECU is developed according to the proteus design. After completing the circuit design, the components were assembled in their space on the PCB and further tests were performed.

A similar procedure is followed for AWS ECU and BLS ECU. The PCB layout and 3D modes of ALS ECU are shown in Fig. 5.

The 3D view of the assembled iZone-based master ECU is shown in Fig. 6. This will be very helpful to modify the design in an economical way before moving into electronic components assembly50. Based on the Proteus and KiCAD design, the fabricated hardware of ALS & iZone-based master ECU is shown in Fig. 7a and b. Similarly, AWS and BLS are perfectly implemented using their respective components51,52.

Initially, the power consumption of the ALS, AWS, BLS, and iZone-based Mased ECUs are noted accurately53. All three ECUs are allowed to run for 900 s, to calculate the energy consumed by the individual ECUs as shown in Table 1. Table 1 displays the power and energy acquired data for each of the four ECUs over a 900-s run via the before-mentioned experimental setup. This is the stringent time limit process that will be upheld for all upcoming experiments54. Figure 8 represents the power consumption of all the considered individual ECUs.

The iZone-based master ECU, ALS, AWS, and BLS ECUs utilize 0.035 A, 0.065 A, 0.036 A, and 0.030 A of current, respectively. For the iZone-based master ECU, ALS ECU, AWS ECU, and BLS ECU, the measured power is 0.420 W, 0.780 W, 0.432 W, and 0.360 W, respectively55,56. In a similar vein, the ECUs use 378 J, 702 J, 389 J, and 324 J of energy each. The findings are ALS ECU consumes more power than other ECUs because of the design constraint of ALS ECU.

Experimental setup of iZone-based master ECU prototype

The four ECUs connected for the implementation of the proposed system are shown in Figs. 9 and 10. After the connections are made, the current flow through the combined system is noted and the power consumption is calculated. Then, the final energy consumption is calculated based on the power consumed for the run time of 900 s in the ON and OFF states.

Figure 10 displays the experimental setup of the iZone-based master and slave ECU system. The wiper motor and brake light are directly connected to the AWS ECU and BLS ECU respectively. The high-beam and low-beam lamps are connected to the ALS ECU. Then all the considered ECUs are connected with the master ECU or iZone-based ECU to monitor the function of secondary ECUs. The communication among these ECUs is established using the CAN protocol.

From this analysis, it is noted that the wiper motor which is connected to the AWS ECU is activated in response to the rain sensor output while sending the i-zone master ECU sending an enable signal to the AWS ECU. Figure 11 shows a visual representation of the signal interaction. Interestingly, 125 ns are measured as the time response between the triggered signal and the enabled signal. The system's operation is ensured by this little time delay, highlighting the effectiveness of communication between the i-zone master ECU and the AWS ECU in enabling prompt responses to environmental circumstances.

From Table 2, the prototype is tested with eight different combinations and their readings were recorded and compared. This experiment was performed for all eight possible combinations in the proposed iZone-based architecture. The 1st condition is executed when all three systems are not engaged; the ALS, AWS, and BLS are in an OFF state. The 2nd condition is executed when the braking condition satisfies the ALS OFF, AWS OFF, and BLS ON. The 3rd function is executed when the raining condition satisfies the ALS-OFF, AWS-ON, and BLS-OFF. The 4th condition is executed when both the raining and braking condition satisfies the ALS OFF, AWS ON, and BLS ON. The 5th function is executed when the ambiance satisfies the ALS-ON, AWS OFF, and BLS OFF. The 6th condition is executed when both the lighting and Braking condition satisfies the ALS ON, AWS OFF, and BLS ON. The 7th condition is executed when both the lighting and raining conditions satisfy the ALS & AWS ON and BLS OFF. The 8th condition is executed when all three are satisfied with ALS ON, AWS ON, and BLS ON.

From Table 3, it is evident that the average power consumption without iZone is 1.572 whereas while implementing izone, the power consumption is varied from 0.42 to 1.992 concerning the switch condition of slave nodes. Since conditions 1–8 are mentioned in Table 1 the slave node swings randomly. The overall power consumption decreases in the izone configuration when compared to without izone configuration.

From Fig. 12, the consumption of current by the considered ECUs was 0.166 A when all the ECUs were working and the current consumption was 0.035 A when no ECUs were in use or the first Condition. Thereby, 78.9% of the current consumption is majorly saved while using this iZone-based system when compared to all the conditions. When a single ECU such as ALS, AWS, or BLS is working in the iZone-based system, the consumed currents are 0.065 A, 0.036 A, and 0.030 A respectively which results in 60.8%, 57.1%, and 39.7% in current saving. When two ECUSs such as BLS & ALS, AWS & ALS, and BLS & AWS are working (Fourth, sixth, and seventh conditions), the consumed currents are 0.141 A, 0.147 A, 0.118 A respectively and the differences in consumption concerning all the ECUs working are 0.042 A, 0.036 A, 0.065 A which results in a lower current saving compared with the usage of individual ECU. The current saving percentages for the two ECUs involved stages are 21.6%, 21%, and 18% respectively. However, the current usage is less when compared with the use of three ECUs. From the observations, it is evident that the saved current range is from 18 to 78% using the iZone-based system. From the current consumption analysis, it is identified that the consumption of current is varied depending on the usage of the number of ECUs.

Figure 13, indicates the consumption of power for the considered conditions while using the iZone-based system. The high value is attained when all the ECUs are working, it is 2.196 W. The very low value is noted when no ECUs are in use i.e. in the first Condition, it is 0.48 W. 17% of the power is majorly saved when compared to all the conditions. A single ECU such as BLS, ALS, and AWS are working in the iZone-based system, the consumed power values are 0.912 W, 0.984 W, and 1.26 W respectively which results in 12.8%, 12.12%, and 9.36% in power saving. When two ECUSs such as BLS & ALS, AWS & ALS, and BLS & AWS are working (Fourth, sixth, and seventh conditions), the consumed powers noted are 1.692 W, 1.764 W, and 1.416 W respectively and the consumption differences are 0.504 W, 0.036 W, 0.065 W which results in a lower power because of the number of ECU. The power-saving percentages for the two ECUs involved are 5.04%, 0.432%, and 0.65% respectively. However, the power usage is less when compared with the use of three ECUs. From the observations, it is evident that the saved current range is from 0.432 to 12.8% using the iZone based system. The consumption of power also varies like current depending on the usage of the number of ECUs.

From Fig. 14, the consumption of energy by the considered ECUs was 1792.8 J when all the ECUs were working and the energy consumption was 378 J when no ECUs were in use i.e. in the first Condition. 73% of the consumption is majorly saved while using the iZone-based system when compared to all the conditions. When a single ECU such as BLS, ALS, or AWS is working in the iZone-based system, the consumed currents are 702 J, 766.8 J, and 1080 J respectively which results in 50.4%, 45.6%, and 23% respectively in energy saving. When two ECUSs such as BLS & ALS, AWS & ALS, and BLS & AWS are working (Fourth, sixth, and seventh conditions), the consumed currents are 1090.8 J, 1404 J, and 1468.8 J respectively and the differences in saving the energy consumption are 325 J and 11 J which results in a lower power saving compared with the usage of individual ECU whereas ALS and AWS are monitored by our iZone system is little high compared to conventional system. From Fig. 15, the observed range of power saving statuses spanning from 0.76 to 73.2%, underscores the dynamic nature of energy conservation within the system. This variance highlights the intricate complex between diverse configurations of iZone master ECU, ALS ECU, AWS ECU, and BLS ECU. These fluctuations in power saving efficacy not only illuminate the sensitivity of energy consumption to specific operational setups.

Conclusion

Growing concern about power consumption is becoming apparent as the area of ECU development in the automotive industry expands. Implementation of a master ECU that serves as a controller of the secondary ECUs with the help of defined sensory input signals improves the range of the EV. The iZone-based master ECU is an independent ECU structure that reduces power consumption directly. This i-zone-based master is relatively cost-effective and more reliable because an average of 36.20% of power saving is achieved and the highest range of 73% power saving is reached while all the secondary ECUs are in the OFF state. Finally, it is concluded that the implementation of this iZone-based master ECU is used to improve the range of EVs and seamlessly increase the lifespan of EVs. Many ECUs can be considered to reduce the current consumption of ECUs in the future to improve the efficiency and life span of EVs. Inclusion of the optimization approaches and control for improving the performance of EVs as well as the impact of software updates on ECUs are future works.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

Kaiser, M. Electronic control unit (ECU). In Gasoline Engine Management: Systems and Components (ed. Reif, K.) 254–259 (Springer Fachmedien Wiesbaden, 2014).

Egaji, O. A., Chakhar, S. & Brown, D. An innovative decision rule approach to tyre pressure monitoring. Expert Syst. Appl. 124, 252–270 (2019).

Mruzek, M., Gajdáč, I., Kučera, Ľ & Barta, D. Analysis of parameters influencing electric vehicle range. Proc. Eng. 134, 165–174 (2016).

Lu, Y. et al. Adaptive disturbance observer-based improved super-twisting sliding mode control for electromagnetic direct-drive pump. Smart Mater. Struct. 32(1), 017001 (2022).

Senthilkumar, S., Haidari, M., Devi, G., Britto, A. S. F., Gorthi, R., Hemavathi & Sivaramkrishnan, M. Wireless bidirectional power transfer for E-vehicle charging system. In 2022 International Conference on Edge Computing and Applications (ICECAA), Tamilnadu, India, 13–15. https://doi.org/10.1109/ICECAA55415.2022.9936175 (IEEE, 2022).

Maier, J. & Reuss, H.-C. Design of zonal E/E architectures in vehicles using a coupled approach of k-means clustering and Dijkstra’s algorithm. Energies 16(19), 6884 (2023).

Kassem, R., Sayed, K., Kassem, A. & Mostafa, R. Power optimisation scheme of induction motor using FLC for electric vehicle. IET Electr. Syst. Transp. 10(3), 301–309 (2020).

Tingting, D., et al. Design method and control optimization of an extended range electric vehicle. In 2011 IEEE Vehicle Power and Propulsion Conference (IEEE, 2011).

Kadav, P. & Asher, Z. D. Improving the range of electric vehicles. In 2019 Electric Vehicles International Conference (EV), 1–5 (IEEE, 2019).

Mruzek, M., Gajdáč, I., Kučera, Ľ & Gajdošík, T. The possibilities of increasing the electric vehicle range. Proc. Eng. 192, 621–625 (2017).

Xu, Bo. & Guo, Yu. A novel DVL calibration method based on robust invariant extended Kalman filter. IEEE Trans. Veh. Technol. 71(9), 9422–9434 (2022).

Park, C. & Park, S. Performance evaluation of zone-based in-vehicle network architecture for autonomous vehicles. Sensors 23(2), 669 (2023).

Xu, B. et al. A novel adaptive filtering for cooperative localization under compass failure and non-Gaussian noise. IEEE Trans. Veh. Technol. 71(4), 3737–3749 (2022).

Alparslan, O., Arakawa, S. & Murata, M. A zone-based optical intra-vehicle backbone network architecture with dynamic slot scheduling. Opt. Switch. Netw. 50, 100753 (2023).

Maier, J. & Reuss, H.-C. Handling system complexity in zonal E/E architectures. Transp. Eng. 13, 100195 (2023).

Wang, W. et al. Review of electrical and electronic architectures for autonomous vehicles: Topologies, networking and simulators. Autom. Innov. 7(1), 82–101 (2024).

Zhang, X. et al. Robust tube-based model predictive control with Koopman operators. Automatica 137, 110114 (2022).

Ikezawa, Y. et al. Range extension autonomous driving for electric vehicle based on optimal vehicle velocity profile in consideration of cornering. Electr. Eng. Jpn. 207(1), 43–54 (2019).

Yang, L. et al. Time-delay-aware power coordinated control approach for series hybrid electric vehicles. Energy 294, 130934 (2024).

Shahed, M. T. & Harun-ur Rashid, A. B. M. Battery charging technologies and standards for electric vehicles: A state-of-the-art review, challenges, and future research prospects. Energy Rep. 11, 5978–5998 (2024).

Hussaian Basha, C. H. & Rani, C. Performance analysis of MPPT techniques for dynamic irradiation condition of solar PV. Int. J. Fuzzy Syst. 22(8), 2577–2598 (2020).

Song, X. et al. Predefined-time sliding mode attitude control for liquid-filled spacecraft with large amplitude sloshing. Eur. J. Control 77, 100970 (2024).

Zhang, J. et al. A novel multiple-medium-AC-port power electronic transformer. IEEE Trans. Ind. Electron. 71, 6568–6578 (2023).

Zone Controllers Build Bridge to Tomorrow’s Technology [white paper]. https://www.aptiv.com/en/insights/article/zone-controllers-build-bridge-to-tomorrow-s-technology (2021).

Automotive Zone Controller [white paper]. https://www.nxp.com/applications/automotive/vehicle-networking/automotive-zone-controller:AUTOMOTIVE-ZONE-CONTROLLER (2021).

Processing the advantages of zone architecture in automotive [white paper]. https://e2e.ti.com/blogs_/b/behind_the_wheel/posts/processing-the-advantages-of-zone-architecture-in-automotive (2021).

Meng, Q. et al. Revolutionizing photovoltaic consumption and electric vehicle charging: A novel approach for residential distribution systems. IET Gener. Transm. Distrib. https://doi.org/10.1049/gtd2.13232 (2024).

Ashwini Kumari, P. et al. Adaptive RAO ensembled dichotomy technique for the accurate parameters extraction of solar PV system. Sci. Rep. 14(1), 12920 (2024).

Hussaian Basha, C. H. et al. A novel on intelligent energy control strategy for micro grids with renewables and EVs. Energy Strategy Rev. 52, 101306 (2024).

Schmutzler, C., Lakhtel, A., Simons, M. & Becker, J. Increasing energy efficiency of automotive E/E-architectures with intelligent communication controllers for FlexRay. In 2011 International Symposium on System on Chip (SoC), 92–95 (IEEE, 2011).

Hussaian Basha, C. et al. A novel on design and implementation of hybrid MPPT controllers for solar PV systems under various partial shading conditions. Sci. Rep. 14(1), 1609 (2024).

Liang, J. et al. A direct yaw moment control framework through robust TS fuzzy approach considering vehicle stability margin. IEEE/ASME Trans. Mechatron. 29(1), 166–178 (2023).

Automotive ECU Designer Reduces Power Consumption by 10% [Case Study]. https://www.keysight.com/us/en/assets/7120-1018/case-studies/Automotive-ECU-Designer-Reduces-Power-Consumption-by-10-percent.pdf (2020).

Prabhakaran, A., Annamalai, V., Dineshvikram, B. & Julash, T. Design of ECU for automatic headlight beam control during city driving. Int. J. Veh. Struct. Syst. 13(1), 32–36 (2021).

Chen, J. et al. Hybrid modeling for vehicle lateral dynamics via AGRU with a dual-attention mechanism under limited data. Control Eng. Pract. 151, 106015 (2024).

Hussaian Basha, C. H. & Rani, C. Different conventional and soft computing MPPT techniques for solar PV systems with high step-up boost converters: A comprehensive analysis. Energies 13(2), 371 (2020).

Asparuhova, K., Shehova, D. & Lyubomirov, S. Using proteus to support engineering student learning: Microcontroller-driven sensors case study. In 2018 IEEE XXVII International Scientific Conference Electronics-ET, 1–4 (IEEE, 2018).

Zhu, C. Y. Intelligent robot path planning and navigation based on reinforcement learning and adaptive control. J. Logist. Inform. Serv. Sci. 10(3), 235–248 (2023).

Hussaian Basha, C. H. et al. Development of cuckoo search MPPT algorithm for partially shaded solar PV SEPIC converter. In Soft Computing for Problem Solving: SocProS 2018, vol. 1 (Springer Singapore, 2020).

Zhang, J. et al. A novel multiport transformer-less unified power flow controller. IEEE Trans. Power Electron. 39, 4278–4290 (2023).

Hussaian Basha, C. H., Rani, C. & Odofin, S. A review on non-isolated inductor coupled DC–DC converter for photovoltaic grid-connected applications. Int. J. Renew. Energy Res. IJRER 7(4), 1570–1585 (2017).

Hu, F. et al. Innovative association network of new energy vehicle charging stations in China: Structural evolution and policy implications. Heliyon 10(2), e24764 (2024).

Ju, Y. et al. Distributed three-phase power flow for AC/DC hybrid networked microgrids considering converter limiting constraints. IEEE Trans. Smart Grid 13(3), 1691–1708 (2022).

Kumari, P. A. et al. Application of DSO algorithm for estimating the parameters of triple diode model-based solar PV system. Sci. Rep. 14(1), 3867 (2024).

Wang, R. et al. FI-NPI: Exploring optimal control in parallel platform systems. Electronics 13(7), 1168 (2024).

Hussaian Basha, C. & Murali, M. A new design of transformerless, non-isolated, high step-up DC–DC converter with hybrid fuzzy logic MPPT controller. Int. J. Circuit Theory Appl. 50(1), 272–297 (2022).

Feng, J. et al. Electric vehicle charging stations’ installing strategies: Considering government subsidies. Appl. Energy 370, 123552 (2024).

Govinda Chowdary, V. et al. Hybrid fuzzy logic-based MPPT for wind energy conversion system. In Soft Computing for Problem Solving: SocProS 2018, vol. 2 (Springer Singapore, 2020).

Nadimuthu, L. P. R. et al. Energy conservation approach for continuous power quality improvement: A case study. IEEE Access 9, 146959–146969 (2021).

Murali, M. et al. Design and analysis of neural network-based MPPT technique for solar power-based electric vehicle application. In Proceedings of Fourth International Conference on Inventive Material Science Applications: ICIMA 2021 (Springer Singapore, 2022).

Song, F. et al. Motion control of wafer scanners in lithography systems: From setpoint generation to multi-stage coordination. IEEE Trans. Instrum. Meas. https://doi.org/10.1109/TIM.2024.3413202 (2024).

Udhay Sankar, V. et al. Application of WDO for decision-making in combined economic and emission dispatch problem. In Soft Computing for Problem Solving: SocProS 2018, vol. 1 (Springer Singapore, 2020).

Reddy, K. R. et al. A novel on energy management strategy with maximum exploitation of renewables and EV storage in distribution networks. Int. Trans. Electr. Energy Syst. 2023(1), 1365608 (2023).

Murali, M. et al. Design of high step-up interleaved boost converter-fed fuel cell-based electric vehicle system with neural network controller. In Pattern Recognition and Data Analysis with Applications, 789–801 (Springer Nature Singapore, 2022).

Puppala, R. et al. Framework for smart grid to implement a price elasticity-based peak time rebate demand response program. Front. Energy Res. 10, 1079695 (2023).

Velpula, S. et al. Impact of DFIM controller parameters on SSR characteristics of wind energy conversion system with series capacitor compensation. In International Conference on Computer Vision and Robotics (Springer Nature Singapore, 2023).

Author information

Authors and Affiliations

Contributions

All the authors contributed to this research work in terms of concept creation, conduct of the research work, and manuscript preparation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Prabhakaran, A., Thirumoorthi, P. & Sri Dhivya Krishnan, K. Design and development of an intelligent zone based master electronic control unit for power optimization in electric vehicles. Sci Rep 14, 20142 (2024). https://doi.org/10.1038/s41598-024-70580-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-70580-7