Abstract

This research study is performed on the self-compacting geopolymer concrete (SCGC) combining coal bottom ash (CBA) and metakaolin (MK) as a substitution for GGBFS alone and combined for analysing the fresh properties (slump flow, V-Funnel, and T50 flow), mechanical characteristics (compressive, splitting tensile and flexural strengths) and durability tests (permeability and sulfate attack test). Though, total 195 SCGC samples were made and tested for 28 days. It has been revealed that the consumption of CBA and MK as a substitution for GGBFS alone and combine in the production of SCGC is decreased the workability of SCGC while mechanical characteristics of SCGC are enhanced by utilizing CBA and MK as a substitution for GGBFS alone and combine up to 10%. In addition, the compressive, splitting tensile and flexural strengths were calculated by 59.40 MPa, 5.68 MPa, and 6.12 MPa while using the 5CBA5MK as a substitution for GGBFS in the production of SCGC after 28 days correspondingly. Furthermore, the permeability is decreased by growing the quantity of CBA and MK by the weight of GGBFS alone and jointly in the production of SCGC after 28 days. Besides, the minimum change in length of the SCGC specimen is recorded by 0.062 mm at 7.5MK7.5CBA while the maximum change in length is calculated by 0.11 mm at 10CBA10MK as a substitution for GGBFS at 180 days correspondingly. In addition, the embodied carbon is recorded reduce as the addition of CBA while it is getting higher when the accumulation of MK alone or combined with CBA in SCGC. Besides, response models for prediction were constructed and confirmed using ANOVA at an accuracy rate of 95%. The models' R2 fluctuated from 88 to 99%. It has been observed that the utilization of CBA and MK alone and together up to 10% as substitution for GGBFS in geopolymer concrete provides the best results therefore it is suggested for structural applications.

Similar content being viewed by others

Introduction

Concrete is frequently employed in construction applications throughout the globe1. Portland cement (PC) is an imperative component of concrete, and it is not universally sustainable. Sustainability issues associated with Portland cement production are well-known. Portland cement production discharges large quantities of carbon dioxide (CO2) and additional dangerous gases into the environment due to the mechanism of decarbonation of limestone and the burning of energy sources such as fossil fuels. 1 tonne of PC needs approximately 1.6 tonnes of raw materials and 6.5 million British thermal units of energy, resulting in the release of 1 tonne of CO2 into the natural environment2,3,4.

Globally, the PC industry releases about 1.65 billion tonnes of global warming annually, contributing to about 7% of global CO2 emissions5,6,7,8. The CO2 production from the manufacture of PC is projected to increase by approximately 50% from existing levels by 20509,10. To protect the environmental issues from the impacts of PC production, new options for producing a more economical and environmentally friendly concrete material to substitute standard PC concrete must be identified and evaluated11. To resolve global warming concerns, enormous initiatives have been made to minimize the usage of PC on a global scale. Among these are the recycling of waste by-products and the production of PC replacements12.

Geopolymer concrete (GC) is a significant advancement in unique product development, resulting in an economical, environmentally acceptable constituent that can be used in place of PC12,13,14,15. It is an alumino-silicate-based synthetic polymer concrete that can be produced in a strong alkaline solvent using silicon and aluminum-rich geological elements or by-product constituents16. The GC is invented by substituting the PC entirely17,18,19,20,21. Apart from PC, the manufacturing of natural components for geopolymers are not necessarily involve a lot of energy consumption. The binder used in geopolymer has been proven to discharge between a 5th to 6th of the Carbon dioxide generated by Portland cement22. As a result, geopolymer concrete not only minimizes CO2 production associated with the PC sector, and waste materials residues of alumino—silicate concentration are also used to make high-performance constituents for construction23,24.

Moreover, GGBFS is obtained through the collection of waste components from a particular industry, namely metallurgical. The slag is produced in the form of molten iron, which is formed when a mixture of components such as coke, iron ore, and limestone is heated to between 15,000 and 16,000 degrees Celsius. The resulting slag has a chemical structure alike to PC, with approximately 45% CaO and 35–45% silicon dioxide. Additionally, glassy particles are formed when silicon-aluminum slag is rapidly immersed in liquid form after molten iron is removed25,26,27,28. Dewatering and converting such glassy particles to the desired size29,30. This crushed slag is referred to as GGBFS, and because it is an environmentally friendly building material, which can be utilized in place of PC in concrete, thereby reducing carbon dioxide production and PC use in the construction industry31. GGBFS can enhance durability assets, resistance to corrosion, and sulfate resistance. By considering these properties, it is feasible to prolong the infrastructure life and reduces maintenance budgets. Due to the high concentration of GGBFS in the eco-friendly circumstances utilized to substitute cement, concrete not only recycles waste but also conserves natural assets and reduces energy utilization32,33. As a consequence, GGBFS was preferred as the starting material for geopolymer synthesis in this investigation to maximize the utilization of this industrial waste and to produce geopolymer concrete based on GGBFS.

The enhancement of concrete construction throughout the last 2 decades has increased focus on improving efficiency and striving to improve the effective atmosphere. Self-compacting concrete (SCC) is a comparatively novel improvement in the field of concrete production which is gaining traction. Distinct from conventional concrete, SCC has the capability to flow through and around obstacles by itself, completely covering the formwork and self-compacting without segregation or blocking34. It has a variety of technical, economic, and ecologic benefits over existing concrete, like enhanced concrete quality, decreased duration of construction, relatively easy installation in clogged reinforcement, and consolidation completion, enhanced bond strength, reduced overall costs, and a quieter working environment due to the absence of vibration35,36,37. This results in a reduction in the presence of guidance from a professional, along with a decreased tolerance for pictorial errors, excessive noise, and workplace injury. The essential components in the production of SCC are the same to plane concrete, with the exception that SCC is composed of a variety of different percentages and supplementary mineral admixtures blends. SCC mixtures typically contain a larger quantity of ultra-fine constituents. SCC has superior flowability owing to its lesser concentration of coarse aggregates, lesser water/binder ratio, and utilization of superplasticizers and viscosity-modifying agents38,39. The cement substitution ingredients are extensively utilized to decrease costs and increase the performance of fresh and hardened concrete40,41. The usage of SCMs like groundnut shell ash (GSA), GGBFS, fly ash (FA), coconut shell ash (CSA), millet husk ash (MHA), and silica fume (SF) is well recognized for improving concrete properties and for environmental and economic reasons34.

Metakaolin (MK) is created by burning kaolin clay at temperatures fluctuating from 650 to 800 °C. It has possessed the pozzolanic property, therefore, MK can be used as a SCM in concrete, and when it is mixed in concrete as cementitious material that improves the ITZ of concrete compared to other ingredients which results in improving the strength42. For decades, MK has been utilized commercially in construction sector43. The majority of studies used concrete containing MK as supplementary cementitious material (SCM), showing a notable enhancement in the mechanical characteristics. Poon et al.44 performed research work on MK as SCM in concrete which enhanced the mixture’s mechanical properties while decreasing its porosity. It has been realized that by using MK dosages enhanced in concrete, pore spaces are minimized. Jin and Li45 explained an associated tendency. Ahmed et al.,46 stated that the consumption of MK up to 15% in matrix increases crushing and flexural strength. The majority of prior investigation has focused on using MK in geopolymers mixture47,48. MK is a crucial strategy for reducing the carbon footprint of concrete47,48.

Moreover, the CBA is produced when coal is burned in thermal power plants which is the primary waste product of fly ash (FA). Owing to the existence of SiO2, Fe2O3, and Al2O3 in the CBA, it possesses pozzolanic properties. The calcium hydroxide reacts with calcium aluminate hydrate (CAH) throughout cement hydration to form supplementary CAH and calcium silicate hydrate (CSH)49. According to prior research49, suitable crushing can enhance the CBA pozzolanic activity, and six hrs of crushing CBA can result in a 27% growth in strength. As a result, it is partially substituted in concrete by FA and PC50. CBA usage in building sector is one of the most effective ways to mitigate environmental issues due to a lack of discharge sources and augmented CBA production. India generates almost 105 million metric tons of CBA every year for many thermal power plants, which provide 68% of the nation’s energy production. The inclusion of CBA in the current and future building industries is being advocated for owing to its comparable particle size distribution and supplementary pozzolanic characteristics to NFA49.

Furthermore, based on the literature study, there are no experimental investigations performed on SCGC mix inclusion with MK and CBA as a substitution for GGBFS individually and combine. Therefore, this study examined the fresh properties, mechanical properties, durability properties and embodied carbon of GGBFS-based SCGC inclusion with MK and CBA as a substitution for GGBFS. The outcomes demonstrate a noteworthy enhancement in the strength properties of GGBFS-based SCGC blended with MK and CBA separate and combined and these materials can be advantageously utilized in the production of SCGC mixture by applying response surface methodology (RSM) tool for modelling and optimization.

Concept of the geopolymerization mechanism

The concept of the geopolymerization mechanism is fundamental to understanding the formation and performance of SCGC with MK and CBA as substitutions for GGBFS. Geopolymerization is a complicated chemical process that starts with aluminosilicate materials dissolving in an alkaline solution51. The ions that are dissolved then condense into a stable network of three-dimensional tetrahedral structures52,53. The reaction of the alumina and silica available in the constituents (like MK and CBA) with the alkaline activator (in this case, sodium carbonate) drives this process. The resulting geopolymer matrix is composed of interconnected Si–O–Al bonds, forming a rigid, stable structure that contributes to the material’s mechanical strength and durability54,55,56,57.

The inclusion of MK and CBA in the SCGC affects the geopolymerization process and the final microstructure. Metakaolin, because of its high reactivity and small particle size, easily dissolves in alkaline conditions, delivering a plentiful supply of reactive alumina and silica. This promotes the creation of aluminosilicate gels, which are essential for the construction of the tetrahedral network58. While CBA has lower reactivity than MK, it plays a role in the overall matrix by occupying empty spaces and decreasing porosity, potentially enhancing the strength and longevity of the geopolymer concrete. The synergistic impact of MK and CBA results in a more condensed and tightly packed microstructure, characterised by a well-established tetrahedral network that exhibits high resistance to environmental factors such as water and sulfates58.

The geopolymerization mechanism clarifies the several steps involved in the geopolymerization process, starting with the initial dissolution of aluminosilicate minerals and culminating in the production and expansion of the tetrahedral network59,60. Additionally, it might elucidate how the distinctive attributes of MK and CBA contribute to this procedure and how the fine-tuning of their proportions impacts the overall efficacy of the SCGC. This feature would enhance readers' comprehension of the development of the material’s microstructure and its correlation with the observed mechanical characteristics and durability by offering a clear and comprehensive explanation of the underlying processes. Gaining a more profound comprehension of this subject matter will not only enhance the present investigation but also provide direction for future investigations and actual implementations in the realm of sustainable construction.

Experimental program

Materials

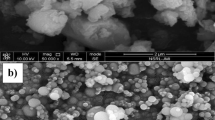

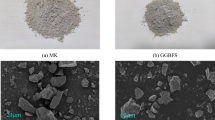

The GGBFS was obtained with permission from the steel mill and thereafter dried for 24 h in the open environment. After sieving the dried GGBFS from a 75 µm mesh to disregard any undesired particles, it is applied as a binding constituent in SCGC. However, in this investigational study, metakaolin (MK) served as a substitution for GGBFS in the production of SCGC. It was obtained and then dried for 24 h under the environment before being sieved from a 75 µm mesh to disregard unwanted constituents and then it was utilized in SCGC as a substitute for GGBFS material. Additionally, coal bottom ash (CBA) was stored with permission from the Coal Power Plant. After collecting the CBA, it was dried for 24 h at 105 °C and then allowed to pass from a 75 µm mesh to disregard bulky particles. Sieved ash was then utilized in place of GGBFS in the production of SCGC. Table 1 summarises the chemical configurations of GGBFS, MK, and CBA. Furthermore, both the manufacturing of geopolymers is needed to absorb alumina, and silica, and the polymerization catalyst procedure, which is required for an alkaline solution61. This research was using an alkaline liquid composed of sodium silicate (SS) and sodium hydroxide (SH). For this experimental investigation, SH and SS solutions were used. To prepare an SH solution, dissolve SH particles in enough drinkable water to reach the desired concentrations and left the solution for 24 h to cool down. Besides, to develop an alkaline solution by combining the two aqueous mixtures. Additionally, the superplasticizer (SP) is added for increasing the fresh property which is to the level needed for SCGC mixture compliance with the EFNARC36 code procedure. Additionally, in this investigational study, drinking water was provided to create the alkaline solution. In addition, the coarse aggregates (CA) with a 12 mm particle size and fine aggregates (FA) with possess 4.75 mm in size were applied for this study.

Mix proportions

This experimental procedure was adopted to thirteen SCGC mixes, one of which was composed entirely of GGBFS as a binding material, four of which contained 5–20% GGBFS replaced with MK, four of which contained 5–20% CBA as a substitution for GGBFS, and four of which contained a combination of MK and CBA as a replacement for GGBFS. All SCGC mixes are examined in this investigational study, as seen in Table 2. Though, to generate a homogeneous mixture, dry materials such as GGBFS, MK, CBA, and aggregates are mixed in a concrete mixer for approximately 2.50 min in the dry state, monitored by the accumulation of a well-shaken premixed solution combination comprising an alkaline solution, SP, and additional water for three minutes. The SCGC mixture was characterized after the homogeneous SCGC mixture was examined for key tests on workability such as slump flow, V-Funnel, and T50 flow. After checking the SCGC mixture’s workability, it was placed without compaction into steel moulds (cubes, cylinders, and prisms), entirely occupying all gaps in the moulds with self-weight of mixtures. In addition, cubical samples were cast to analyse the compressive strength, cylinders to determine the indirect tensile strength, and beam samples were prepared to perform the flexural strength. Furthermore, concrete samples were cast to determine the permeability and sulfate attack test of SCGC.

Testing methods

Workability of SCGC

It was accomplished in terms of slump flow, V-Funnel, and T50 flow blended with several extents of MK and CBA as a substitution for GGBFS separately and in combination were determined utilizing EFNARC’s European self-compacting concrete guidelines36.

Mechanical properties of SCGC

The cubical samples made of SCGC inclusion of MK and CBA as a substitution for GGBFS were cast for compressive strength while the cylindrical samples of SCGC addition with MK and CBA as a substitution for GGBFS were tested for splitting tensile strength by obeying the BS EN 12390-367 and BS EN 12390-668 code procedure at 28 days consistently. In the same way, the prism specimens made of SCGC mixture introduction of MK and CBA as a substitution for GGBFS were prepared for analysing the flexural strength by obeying the BS EN 12390-569 code standard.

Durability of SCGC mixture

The permeability was performed on the concrete samples made of SCGC inclusion with MK and CBA as a substitution for GGBFS by using BS EN-12390-870 code procedure while the sulfate attack test was executed on the prism samples made of SCGC incorporating CBA and MK as a substitution for GGBFS and length change of samples was evaluated by using the ASTM C 1012-0471 code procedure at 180 days.

Results and discussions

Fresh properties

Slump flow

It is employed for assessing the workability of SCGC production accumulation with CBA and MK as a substitution for GGBFS alone and combined as shown in Fig. 1. According to the EFNARC36, the slump flow is lying between 650 and 850 mm for all fresh mixes of SCGC. However, the highest slump flow is measured by 752 mm in the SCGC mixture which is made of GGBFS only while the lowest value is measured by 582 mm at 20% of GGBFS replaced with MK in the production of SCGC. It has been noted that as the amount of MK as a substitution for GGBFS grows in SCGC is decreased the slump flow. This finding is related to Arun et al.,72 where the workability of mix decreases but MK increases. Bheel et al.,2 reported that the usage of FA replaced with MK rises in the production of SCGC reducing the slump flow. A similar kind of study was done by Guneyisi and Gesoglu73. In the same way, the maximum slump flow is predicted to be 695 mm at 5% CBA, while the lowest value is projected to be 550 mm with 20% of CBA substituted with GGBFS in the production of SCGC. The addition of CBA to SCGC decreases the slump flow. This trend has been executed by Bheel et al.,3 that the slump flow is declined as content of WSA as a substitution for MK rises in SCGC. Furthermore, the CM has the highest slump flow of 752 mm, while the smallest value is noted by 578 mm at 10MK10CBA as a replacement for GGBFS in the production of SCGC. The combined amount of MK and CBA used to replace GGBFS rises in SCGC declined the slump flow. The greater specific surface area of MK and CBA which absorbs more water, leading to a drop in slump flow, and resulting in a stiffer mix. In real-world construction scenarios, a significant amount of MK may require the incorporation of superplasticizers to ensure the material remains flowable, as it tends to have a reduced slump flow. On the other hand, a higher amount of CBA can result in decreased workability, making it more difficult to place the material in complicated formwork or heavily reinforced portions. Although MK improves the material’s mechanical characteristics and durability by virtue of its pozzolanic reactivity, CBA may also make a significant contribution to the material’s strength and durability at an early stage. Local availability, affordability, and sustainability factors may also impact the selection between MK, CBA, and GGBFS. CBA, being an industrial by-product, is often more affordable and easily accessible, hence aiding waste management efforts as well as decreasing the carbon footprint associated with concrete manufacturing. Conversely, because MK is a manufactured material, it has a higher level of embodied energy. Thus, in order to meet the demands of structural purposes that require exceptional strength and durability, it may be more advantageous to use a mixture with a higher percentage of GGBFS and MK, even if it results in lower workability. On the other hand, for non-structural purposes where workability is of utmost importance, it is essential to carefully control the quantities of CBA. Ensuring a proper balance of these elements is crucial for optimising the mix design of SCGC to meet particular building requirements. This assertion is connected to Guneyisi and Gesoglu73, who discovered that slump flow reduces while MK rises in the SCC. Bheel et al.,3 conveyed that the accumulation of WSA and Millet husk ash (MHA) as a substitution for MK increases in the production of SCGC is reduced the slump flow. A similar kind of trend was perceived by Memon et al.,74, and Bheel et al.,2.

V-funnel test

It was executed to measure the workability of SCGC addition with MK and CBA as a substitute for GGBFS alone and combined in the production of SCGC as revealed in Fig. 2. The flow time of the fresh mix is documented during the experiments. Based on the experimental outcome, the V-funnel flow time is lying in ranges from 8.40 to 13.10 s when various amounts of MK and CBA are used to substitute GGBFS separately and combined in the SCGC combination. Except for MK15, MK20, CBA20, 7.5CBA7.5MK, and 10CBA10MK, the V-funnel flow time of the remaining nine SCGC combinations accomplishes the requirement for a desirable V-funnel flow time. The minimal V-funnel flow duration is 8.40 s for SCGC without the accumulation of CBA and MK as substitutes for GGBFS alone and jointly. As shown in Fig. 2, the V-funnel flow time is improved as the content of MK and CBA as a substitute for GGBFS separate and together rises, which cause the decrease in the flow of SCGC. This decrease in V-funnel flow time is owing to the extremely small particle size of MK and CBA, which increases their specific surface area relative to GGBFS. The presence of varying amounts of MK and CBA in the V-Funnel test for SCGC has a notable impact on the flow time. This suggests that the viscosity of the mixture and the possibility of segregation are altered. Greater concentrations of MK, as a consequence of its elevated reactivity and small particle size, often lead to longer flow times, suggesting heightened viscosity and a more viscous mixture. The heightened viscosity contributes to a decrease in the likelihood of segregation, guaranteeing a more consistent and stable mixture. Conversely, adding more CBA often leads to longer flow times. This is because the irregular shape and larger size of CBA particles increase internal friction, as well as the viscosity of the mixture. Nevertheless, an overabundance of CBA may also result in workability problems and possible segregation if it is not well balanced with other constituents. In general, adding both MK and CBA in the right quantities may improve SCGC’s stability by increasing viscosity and decreasing segregation. However, it is important to carefully analyse the amounts of these additives to ensure that the ideal flow features and workability of the concrete mix are maintained. Bheel et al.,3 presented that the V-funnel flow time of fresh mixture is decreased as the quantity of WSA and MHA as a substitution for MK separate and together rises in the production of SCGC. A comparable investigation was conducted by Memon et al.75, Dhiyaneshwaran et al.76, and Bheel et al.2.

T50 flow

Figure 3 illustrates the T50 flow assessment, which is executed to check the flow of mixture of SCGC production qualities, comprising the use of MK and CBA as a substitute for GGBFS. For this test, the slump flow time should be attained to 50 cm in diameter when performing the fresh mix of SCGC. It has been observed from the experimental outcome that the slump flow time of fresh mixture is lying in the ranges from 2.8 to 6.15 s when MK and CBA are used in varying quantities to replace GGBFS separately and combined in SCGC mixture. According to EFNARC36, the slump flow time is noted within the acceptable range (2–5 s) for all SCGC combinations except MK15, MK20, CBA15, CBA20, and 10CBA10MK. The minimum slump flow time of 2.80 s is observed at the SCGC mixture without the accumulation of CBA and MK as substitutes for GGBFS separately and in combination. As illustrated in Fig. 3, the slump flow time of SCGC improves as the proportion of MK and CBA used to replace GGBFS alone and jointly increases in the production of SCGC. This increase in the T50 flow time is attributable to the increased paste volume achieved by using MK and CBA in place of GGBFS alone and together in SCGC. Moreover, the T50 time characteristic provides information about the concrete mixture’s viscosity and flow properties. A shorter T50 time implies lower viscosity and improved flowability, while a longer T50 time predicts greater viscosity and decreased workability. Using MK and CBA separately as GGBFS substitutes tends to increase the T50 flow time. MK, owing to its pronounced reactivity and the presence of small particles, substantially elevates the viscosity and diminishes the flowability. Likewise, CBA, because of its irregular and bigger particles, causes a rise in internal friction, resulting in increased viscosity and longer T50 times. The combined influence of MK and CBA on the T50 flow time is cumulative, leading to a mixture with increased viscosity and extended T50 durations. Using this combined substitution may improve the stability of the concrete mix while reducing the danger of segregation. However, it is important to carefully balance the proportions to ensure that the workability of the mix remains sufficient. Therefore, whereas each material alone enhances the T50 flow time, their combined use necessitates optimisation to maximise their advantages while balancing the compromise in flowability. Bheel et al.,2 itemized that the T50 flow time is amplified by inclusion the content of Groundnut shell ash and MK by the weight of FA alone and together rises in the production of SCGC. The analogous trend was perceived in Memon et al.75, Bheel et al.,3, Keerio et al.,65, and Dhiyaneshwaran et al.76.

Mechanical properties

Compressive strength (CS)

The CS of SCGC containing CBA and MK as substitutes for GGBFS is measured in Fig. 4. Nevertheless, the compressive strength is 57.40 MPa, 59.86 MPa, and 57.10 MPa at 5%, 10%, and 15% of GGBFS substituted with MK, respectively, which is more than CM, and thus the strength of SCGC mixture is reached. After 28 days, 52.50 MPa at 20% MK as a substitution for GGBFS is less than SCGC prepared with GGBFS as the only binding agent in the mixture. It has been detected that the accumulation of 5–15% of MK as a substitution for GGBFS in the production of SCGC is increased the CS, however, increasing the amount of MK as a GGBFS substitution ingredient in SCGC decreases the strength. Additionally, the CS is optimized at 56.80 MPa, 58.76 MPa, and 56.40 MPa when 5%, 10%, and 15% of GGBFS are substituted with CBA, correspondingly, while the minimum strength is seen at 51.25 MPa when 20% of GGBFS is substituted with CBA after 28 days. The outcomes indicate that using CBA as a substitute for GGBFS augmented the CS of the SCGC combination up to a point where it begins to drop. This aspect is correlated to Memon et al.,75, who demonstrated an increase in the crushing strength of SCGC by substituting SF for FA up to 15% in the combination at 28 days. Furthermore, the highest CS is 57.25 MPa, 59.40 MPa, and 56.98 MPa at 2.5CBA2.5MK, 5CBA5MK, and 7.5CBA7.5MK, consecutively, while the minimum CS is 52.20 MPa at 10CBA10MK as a substitution for GGBFS in the production of SCGC after 28 days. It has been perceived that the use of CBA and MK up to 15% as a substitution for GGBFS combined in the production of SCGC is increased the CS. This enhancement in strength is related to the extremely small size of CBA and MK particles in comparison to GGBFS, which makes the pores smaller and the particles more densely packed, producing the concrete denser and more stable. Bheel et al.,3 described that the 10% of MK substituted with WSA and MHA combined in SCGC augmented the CS. A similar observation was done by Keerio et al.65 and Bheel et al.,2.

Splitting tensile strength (STS)

It was achieved on SCGC specimens’ addition with MK and CBA as a substitution for GGBFS alone and jointly after 28 days as directed in Fig. 5. The highest STS is noted by 5.75 MPa and 5.63 MPa when using 10% of MK and CBA as a substitution for GGBFS, while the least strength is measured by 5.18 MPa and 5.0 MPa at 20% of CBA and CBA as a substitution for GGBFS in the production of SCGC after 28 days consistently. The experimental result has shown that the STS is enhanced when the usage of CBA and MK up to 15% as a substitution for GGBFS alone and further addition of CBA and MK in the SCGC, the STS gets declined. Bheel et al.,2 assured that the accumulation of 10% FA substituted with MK in the production of SCGC boosted the STS at 28 days. Memon et al.,75 notified that the usage of 10% of FA replaced with SF in the production of SCGC augmented the STS after 28 days. Moreover, the greatest STS is estimated by 5.68 MPa at 5CBA5MK and the lowest strength is 5.12 MPa at 10CBA10MK as a substitution for GGBFS in the production of SCGC on 28 days correspondingly. From Fig. 5, it has been shown that the consumption of MK and CBA combined up to 15% as a substitution for GGBFS boosted the STS of SCGC. This enhancement in strength is associated with the MK and CBA possessing a higher specific surface area as compared to GGBFS in the production of SCGC. A analogous study was performed by Bheel et al.2, where the STS of SCGC is augmented when the consumption of MK and GSA combined up to 10% as a substitution for FA after 28 days. Similar kinds of findings were observed in3,65,72,76.

Flexural strength (FS)

It was performed on the prism samples made of SCGC introduction of MK and CBA as a substitution for GGBFS alone and together for 28 days as exhibited in Fig. 6. The optimal flexural strength is measured by 6.20 MPa at 10% of MK while the least flexural strength is recorded by 5.50 MPa at 20% of MK as a substitution for GGBFS in the production of SCGC on 28 days, consistently. The result has shown that the FS is enhanced when the usage of MK as a substitution for GGBFS alone up to 15% and more accumulation of MK in the SCGC, the strength starts declined. In the same way, the optimum flexural strength is computed by 6.0 MPa when the consumption of 10% CBA as a substitution for GGBFS and the minimum value is seen by 5.35 MPa at 20% GGBFS replacement with CBA after 28 days consistently. The assessment results demonstrated that the using of CBA as a substitution for GGBFS to 15% in the production of SCGC increased the flexural strength, and after 15% of CBA, it begins to deteriorate. The finding of the experimental was provided by Bheel et al.2, wherever the usage of 10% FA as substituted with MK in the production of SCGC augmented the flexural strength for 28 days. Bheel et al.3 declared that the accumulation of 10% WSA as a substitution for MK in the production of SCGC enhanced flexural strength at 28 days. A comparable finding was done by Memon et al.,75. Furthermore, the greatest flexural strength is estimated by 6.12 MPa at 5CBA5MK while the minimum strength is acquired by 5.42 MPa at 10CBA10MK as a substitution for GGBFS in SCGC on 28 days consistently. The outcome has been discovered that using CBA and MK as combination material substituted with GGBFS up to 15% in the production of SCGC improved the FS. The increased FS is related with the very fineness of CBA and MK particles, which plugs the voids produced by water in the production of the SCGC matrix. The usage of MK and CBA as the finer particles decrease the microcracks in SCGC and generate a significantly denser SCGC that results in improving the strength of the concrete77. Bheel et al.2 described that the combined consumption of 10% FA substituted with GSA and MK augmented the FS of SCGC at 28 days. The comparable findings were carried out by3,65,72,73,78.

Durability of SCGC

Permeability of SCGC

It was executed on the SCGC samples incorporating CBA and MK as a substitution for GGBFS alone and jointly at 28 days as indicated in Fig. 7. The permeability of SCGC was assessed by 20 mm, 17 mm, 14 mm, and 10 mm at 5%, 10%, 15%, and 20% of GGBFS substituted with MK at 28 days, correspondingly. The permeability is decreased when the amount of MK as a substitution for GGBFS grows in the production of SCGC. According to Keerio et al.,64, the permeability is lowered by up to 15% when MK is used as a substitution for cement for 28 days. The comparable findings were provided by Bheel et al.79. Furthermore, the permeability of SCGC is calculated by 22 mm, 19 mm, 16 mm, and 12 mm at 5%, 10%, 15%, and 20% of GGBFS substituted by CBA at 28 days, correspondingly. As the extent of CBA as a substitution for GGBFS in SCGC rises, the permeability of the SCGC decreases. Guneyisi et al.80 carried out a similar study in which the permeability decreased as the MK extent of concrete increases. Furthermore, the permeability of the SCGC is calculated by 21 mm, 18 mm, 15 mm, and 11 mm at 2.5CBA2.5MK, 5CBA5MK, 7.5CBA7.5MK, and 10CBA10MK as a substitute for GGBFS after 28 days is smaller as compared to SCGC without the presence of CBA and MK. According to Fig. 7, the permeability is decreased, while the content of CBA and MK combined as a substitution for GGBFS rises in the production of SCGC. The water penetration depth in SCGC specimens with MK and CBA substitutes for GGBFS, as determined by BS EN 12390-8, offers important information on the long-term durability and permeability of the concrete. A lower water penetration depth usually suggests a more compact and less porous concrete structure, which is directly linked to improved durability. The replacement of GGBFS with MK and CBA might have an impact on the microstructural properties of the concrete. Because of its small particle size and strong reactivity, MK may fill empty spaces and aid in the creation of more gel-like substances, thereby decreasing the concrete’s porosity and permeability. When appropriately treated, CBA may also function as a filler substance, resulting in a further reduction in pore volume and enhancing the overall density of the matrix. These changes in the microstructure result in a concrete that is more resistant to water penetration, which is critical for ensuring its long-term durability. Decreased water infiltration results in a lower vulnerability to phenomena such as freeze–thaw cycles, chloride ion intrusion, and other types of chemical attack. These processes may gradually weaken the structural integrity of the concrete. Hence, the water penetration test’s depth, as specified in BS EN 12390-870, acts as a vital indicator of the concrete’s performance in hostile surroundings. The correlation between total permeability and the ability of the SCGC with MK and CBA substitutes to survive environmental stressors and preserve its structural integrity over a long period of time is evident. Existing research supports this association, highlighting the significance of low permeability in the construction of long-lasting concrete buildings. Bheel et al.79 did related work in which the permeability is reduced when the doses of combined GGBFS and MK by the mass of cement rise in concrete. A related finding was agreed by Bheel et al.2 where the usage of FA substituted with GSA and MK increases alone and jointly in the production of SCGC is reduced the permeability at 28 days.

Sulfate attack test

Sulfate attack is one of the main aspects of durability that can be modified by the independent and combined substitution of GGBFS with MK and CBA as shown in Fig. 8. Sulfates are typically found in water, especially when the soil contains a high amount of clay. The abundance of sulfates in rainwater is likely owing to air pollution and the presence of sulfates in seawater. This sulfate attack test was conducted on prism samples of SCGC combined with MK and CBA as a substitution for GGBFS, and the difference between the beginning and final values is shown in Fig. 8. However, the change in length of SCGC samples with 5%, 10%, 15%, and 20% substitution of GGBFS with MK and CBA separate and combine owing to sulfate attack is within the acceptable limit (i.e., 0.1% maximum length change) as defined by ASTM for pozzolanic material. Nevertheless, a 15% substitution of GGBFS with MK resulted in the smallest change in length. Sample break-down was not observed in this investigation, which could be attributed to the dense matrix of SCGC, which has a low water-to-binder ratio and a lower specific surface area of metakaolin. Khatib and Wild81 informed that the integration of MK in composite reduced sulfate attack growth. The concrete comprising 10% or additional MK displayed no expansion, whereas the concrete comprising 0% or 5% MK did not start growing until the age of 180 days81. Similarly, at 180 days, a 15% replacement of GGBFS with CBA resulted in the smallest change in length. Specimen breakdown was not observed in this investigation, which could be attributed to the dense matrix of SCGC with a low water-to-binder ratio. According to Sajjad Ali Mangi et al.82. The efficacy of concrete including CBA versus concrete with no CBA under 5% sodium sulfate (Na2SO4) exposure is similar up to 90 days. For short-term exposure, there is no discernible effect of Na2SO4 solution on concrete with and without CBA82. Furthermore, at 180 days, the MK7.5CBA7.5 combined replacement of GGBFS with MK and CBA resulted in the smallest decrease in length. Courard et al.83 conducted a similar type of study on the sulfate resistance of MK in matrix by using ASTM C 1012. Within a short period of time, the PC mortar prisms exhibit expansion, and the accumulation of 10% MK leads to a 3.7% decrease in expansion compared to CM83. According to Kasemchaisiri and Tangtermsirikul84, the highest expansion of CM was SCC, followed by SCC-BA 10%, SCC-BA 20%, and SCC-BA 30%, correspondingly. The dense matrix greatly reduced SO42- ion migration into the concrete, indicating that increasing bottom ash concentration results in greater sodium sulfate resistance. The pozzolanic reaction of bottom ash reduces this expansion in concrete85. Despite their higher porosity, the expansion of SCC with bottom ash (BA) reduces as the BA concentration rises. This suggests that sodium sulfate resistance can be attained by the pozzolanic reaction of BA, which takes precedence over porosity rise. Sulfate resistance improvement is helpful for SCC in sulfate-exposing structures such as underground structures, drilled piles, and undersea structures, among others85. Different research81,82,83,84,85 discovered nearly the same trend of sulfate resistance. The ratios of MK and CBA used as GGBFS replacements directly correlate with the extent of length change in SCGC specimens subjected to sulfate attack. Metakaolin, due to its high reactivity and small particle size, aids in the production of a compact and stable geopolymer structure. This structure effectively prevents the penetration of sulphate ions and minimises the development of expansive substances such as ettringite and gypsum. Consequently, an increase in the fraction of MK often results in a decrease in length changes, indicating enhanced resistance to sulfate attack. Moreover, CBA may serve as a substance that fills in gaps, enhancing the structure of the pores and reducing the capacity of sulfate to pass through. The efficacy of CBA depends on its proportions and particle dimensions. It is essential to achieve an appropriate balance between MK and CBA, since an excessive quantity of either might result in negative consequences, such as decreased workability or inadequate geopolymerization. The relationship between material selection and better durability is shown by emphasising the significance of proportioning MK and CBA to produce a geopolymer matrix that is both dense and impermeable. By carefully adjusting the mix’s ingredients, adding the right amount of MK to make sure it has enough pozzolanic activity, and using CBA to increase the toughness, the resulting SCGC may show small changes in length when exposed to sulfate attack. This optimisation guarantees that the concrete retains its structural integrity and durability in situations with high levels of sulphates. Therefore, understanding the relationship between MK and CBA amounts and their impact on the duration change due to sulphate attack is crucial for the creation of long-lasting SCGC combinations.

Sustainability assessment

Embodied carbon (EC)

In order to determine the embodied carbon dioxide emissions associated with GGBFS-based SCGC, an environmental impact assessment is conducted for all aspects pertaining to the combination of different GGBFS replacements with MK and CBA in the combination. Table 3 displays the EC levels for all GGBFS-based SCGC components, sourced from prior research. Equation (1)86 is used to determine the EC for all SCGC based on GGBFS. Equation (1) represents the unit volume weight (kg/m3) and total EC for any GGBFS-based SCGC, denoted by the symbols Ee, CO2e, Wi, and i. Moreover, the symbols Ei and CO2i are used to denote the EC content of the physical constituents, as shown in Table 3.

The study assessed the environmental impact of utilizing GGBFS98,99,100 based SCGC mixed with MK and CBA as substitutes for GGBFS by evaluating the EC of each mix. Figure 9 presents the results and compares them to the reference mix. The Fig. 9 illustrates the significant carbon footprint of sodium silicate compared to MK, CBA, GGBFS, CA, FA, SP, SH, and water. Additionally, the embodied carbon of SCGC blended with various GGBFS substitutes, both separate and combined, is shown in Fig. 9. Furthermore, the figure indicates that sodium silicate emits the high quantity carbon, followed by SH, coarse and fine materials. However, the graph does not show the impact of CBA, SP, and water in the SCGC, suggesting that their contribution to carbon intensity is minimal. Besides, the EC of MK is greater than GGBFS and CBA. Equation (1) was useful to find out the total of carbon of all SCGC built on the information revealed in Fig. 9. Figure 9 reveals that the EC of SCGC is recorded by 2.93%, 5.86%, 8.78%, and 11.71% at MK5, MK10, MK15, and MK20 which is greater than that of reference mixture of GGBFS based SCGC at 28 days separately. It has been perceived that the embodied carbon of SCGC is getting higher with accumulation of MK as substitution for GGBFS in SCGC. This enhancement in EC is associated to the EC factor of MK is more than that of GGBFS. Moreover, the EC of SCGC combined with CBA5, CBA10, CBA15, and CBA20 as substitution for GGBFS is calculated by 0.59%, 1.18%, 1.78%, and 2.37% which is lesser than CM of GGBFS based SCGC at 28 days respectively. This reduction in EC of GGBFS based SCGC is owing to the EC factor of CBA is lesser as associated to the GGBFS. Furthermore, the EC of GGBFS based SCGC is noted by 1.17%, 2.34%, 3.50%, and 4.67% at 2.5MK2.5CBA, 5MK5CBA, 7.5MK7.7CBA, and 10MK10CBA which is higher than that of reference mix of GGBFS based SCGC at 28 days consistently. From the findings, it is noted that the EC of GGBFS based SCGC is reducing with addition of CBA alone and the addition of MK is increased the EC of SCGC alone and together with CBA.

RSM modelling and optimization

The development of response surface models and ANOVA

RSM is employed for the construction and development of response surface models, which are then evaluated applying ANOVA. For RSM modelling and optimization, the fresh, mechanical, and durability features of SCGC were considered with the inclusion of 0 to 20% MK and CBA alone or together as a GGBFS substitute. In addition, quadratic models were deemed more appropriate for the slump flow test, V-funnel flow test, and T50 flow test, CS, STS, FS, permeability, and sulfate attack test. Moreover, each of these responses is contained in Eqs. (2)–(9). Equations described in relationships of coded constituents may be utilized to predict the impact of changing parameter values. By default, the greatest levels of the constituents are represented as + 1 and the lowest values as − 1. Using the coefficients of the factors, the coded equations may be used to assess the variables' relative significance98,99,100. A and B are variables of input (MK and CBA). The ANOVA findings are shown in Table 4.

In ANOVA, the significance level was established at 95%, meaning that any prototype component with a possibility lesser than 5% is measured statistically important. All of the produced approaches are statistically significant because their probabilities are below 0.05. The slump flow test model’s model terms A, B, AB, A2, and B2 have statistical significance. A, B, AB, A2, and B2 are also key model terms for the V-funnel flow test, T50 flow test, CS, STS, FS, permeability, and sulfate attack test. The coefficient of determination, often referred to as R2, is a crucial performance metric. It quantifies the model’s goodness of fit to the observed data and can range between 0 and 1, or be presented as a percentage from 0 to 100. A higher R2 value indicates a better fit of the model to the empirical data, while a lower value suggests a weaker fit. Table 5 presents the R2 value along with other evaluation factors for the models. R2 values are observed by 99.53%, 99.85%, 99.25%, 97.65%, 93.20%, 97.85%, 99.83%, and 88.82% for slump flow test, V-funnel flow test, T50 flow test, CS, STS, FS, permeability, and sulfate attack test. Furthermore, "Adeq. Precision" computes the signal-to-noise ratio. A ratio greater than four is preferred. Precision values for the slump flow test, V-funnel flow test, T50 flow test, CS, STS, FS, permeability and sulfate attack test is 60.19, 112.03, 47.28, 22.78, 14.82, 25.69, 98.78, and 12.18, respectively, according to Table 5. These results show that the models are capable of precisely anticipating responses.

Here, SFT, VFT, TFT, CS, STS, FS, WPD, and SAT are Slump Flow Test, V-Funnel Flow Test, T50 Flow Test, Compressive Strength, Splitting Tensile Strength, Flexural Strength, Water Penetration Depth, and Sulphate Attack Test respectively.

The “Residual against Normal” diagram and the “Predicted against Actual” diagram, as shown in Figs. 10, 11, 12, 13, 14, 15, 16 and 17 for the eight parameters, are utilized as effective approach for more rapidly analyzing the condition and applicability of generated response models (SFT, VFT, TFT, CS, STS, FS, WPD, and SAT). All charts display the linearity of the data sets along the fit line to illustrate the accuracy of the created approaches. The arrangement of data facts on residual normal plots suggests that the error components have a normal distribution, which is desired. If 95% of the points lie between − 2 and + 2, which is true for all approaches101,102, residuals are often dispersed.

The effect of the relationships between the output responses and input factors is shown using 2D diagram and 3 D graphs. Figures 18, 19, 20, 21, 22, 23, 24 and 25 depict response surface plots for the SFT model, VFT model, TFT model, CS model, STS model, FS model, WPD model, and SAT model. In this case, both 2 D plots and 3 D graphs show how the MK and CBA interact. The graphs' color coding illustrates the size of the response as well as the various input feature values under consideration. Figure 18a and b show the 2D and 3D plots for the slump flow test. The data showed that the control combination has a high intensity of slump at up to 15.33% MK and 4.71% CBA as GGBFS replacement material. Moreover, the slump flow of geopolymer GGBFS-based concrete diminishes when more MK and CBA alone and merge in matrix. The surface responses for permeability, and sulfate attack test are all similar. The V-funnel flow test of geopolymer GGBFS-based concrete rises when the proportions of MK and CBA in matrix. The T50 flow test produced similar surface reactions. Furthermore, Fig. 20a and b show the 2D diagram and 3D graphs for CS, respectively. According to the graphs, a high concentration of CS has been stated as a GGBFS replacement material, up to 15.33% of MK and 4.71% of CBA. Furthermore, by including up to 15.33% MK and 4.71% CBA in the concrete, the strength value is substantially increased. This is owing to the void-filling and densification properties of MK and CBA as a pozzolanic material combination. The similar behaviour of response surface plots was observed for STS, and FS respectively.

Optimization

It is employed to analyse the ideal values of the independent variables that result in the highest possible output level. This is performed by creating quality objectives (input and output characteristics) with varied conditions and degrees of priority to achieve the intended purpose. The optimization is assessed via the desirability (0 ≤ dj ≤ 1). The desirability rate is near to one which indicates the superior results103,104.

Table 6 illustrates the objectives and prerequisites for optimizing this scenario. However, the usage of MK and CBA as a substitute for GGBFS has been restricted to a range of 0 to 20% separate and combined, so that the system can select the appropriate amount required to fulfil the stated purpose. According to the optimization findings, the highest values for SFT, VFT, TFT, CS, STS, FS, WPD, and SAT could be obtained by 639.15 mm, 12.38 s, 5.23 s, 57.08 MPa, 5.50 MPa, 5.93 MPa, 13.31 mm, and 0.081%, respectively. Given the nature of the considerable response value variability, the optimization’s desirability is assessed to be 69.10%. Figures 26 illustrate 3D diagram for desirability.

Conclusions

This study examined the fresh, mechanical properties and durability of SCGC integrating the CBA and MK as a substitution for GGBFS alone and jointly. The following key points are drawn from this investigation:

-

The slump flow is decreased as the amount of GGBFS is replaced with MK and CBA alone and jointly rises in the production of SCGC grows. This drop-in slump flow is associated with the very fineness of CBA and MK particles and the specific surface area of GGBFS is lower as compared to MK and CBA.

-

The V-funnel flow time is boosted when the consumption of CBA and MK as a substitution for GGBFS alone and together rises in the production of SCGC that result in dropping the fluidity of SCGC.

-

The slump flow time is enhanced as the consumption of CBA and MK as a substitution for GGBFS alone and combined increases in the production of SCGC. This increase in the T50 flow time is attributable to the increased paste volume achieved by using MK and CBA in place of GGBFS alone and together in the production of SCGC.

-

The peak CS is recorded by 59.86 MPa, 58.76 MPa, and 59.40 MPa at 10% of MK, 10% of CBA, and 5CBA5MK, and the lowest CS is noted by 52.50 MPa, 51.25 MPa and 52.20 MPa at 20% of MK, 20% of CBA and 10CBA10MK as a substitution for GGBFS in SCGC after 28 days, consistently. It has been perceived that the use of CBA and MK up to 15% as a substitution for GGBFS combined in SCGC is augmented the CS.

-

The maximum STS is recorded by 5.75 MPa, 5.63 MPa, and 5.68 MPa at 10% of MK, 10% of CBA, and 5CBA5MK, and the lowest strength is found by 5.18 MPa, 5.0 MPa, and 5.12 MPa at 20% of MK, 20% of CBA and 10CBA10MK as a substitution for GGBFS in SCGC after 28 days, consistently. Moreover, the use of CBA and MK up to 15% as a substitution for GGBFS combined in SCGC is increased the STS.

-

The maximum FS is recorded by 6.20 MPa, 6.0 MPa, and 6.12 MPa at 10% of MK, 10% of CBA, and 5CBA5MK, and the lowest FS is noted by 5.50 MPa, 5.35 MPa and 5.42 MPa at 20% of MK, 20% of CBA and 10CBA10MK as a substitution for GGBFS in the production of SCGC on 28 days, consistently. It has been perceived that the use of CBA and MK up to 15% as a substitution for GGBFS combined in the production of SCGC increased flexural strength.

-

The permeability plummeted as the consumption of MK and CBA alone and jointly as a substitution for GGBFS in the production of SCGC after 28 days.

-

The minimum change in length is recorded by 0.075 mm, 0.059 mm, and 0.062 mm at 15% of MK, 15% of CBA, and 7.5MK7.5CBA as a replacement for GGBFS while the maximum change in length is calculated by 0.096 mm, 0.10 mm and 0.11 mm at 20% of MK, 20% of CBA and 10CBA10MK as a substitution for GGBFS in SCGC at 180 days correspondingly.

-

The embodied carbon of GGBFS based SCGC is getting decrease when the concentration of CBA rises while the EC of GGBFS based SCGC is getting higher with addition of MK as substitution for GGBFS alone or combine with CBA in SCGC.

-

Response surface models predict GGBFS-based self-compacting geopolymer concrete’s fresh, mechanical, and durability characteristics using ANOVA. Models have R2 values ranging from 88 to 99%. Using MK and CBA, desirability factor is 69.10%.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

Fang, B. et al. Evaluation of early crack resistance performance of concrete mixed with ternary minerals using temperature stress testing machine (TSTM). J. Clean. Prod. 465, 142780. https://doi.org/10.1016/j.jclepro.2024.142780 (2024).

Bheel, N., Awoyera, P., Tafsirojjaman, T., Hamah Sor, N. & Sohu, S. Synergic effect of metakaolin and groundnut shell ash on the behavior of fly ash-based self-compacting geopolymer concrete. Constr. Build. Mater. 311, 125327. https://doi.org/10.1016/j.conbuildmat.2021.125327 (2021).

Bheel, N. et al. Synergic effect of millet husk ash and wheat straw ash on the fresh and hardened properties of Metakaolin-based self-compacting geopolymer concrete. Case Stud. Constr. Mater. 15, e00729. https://doi.org/10.1016/j.cscm.2021.e00729 (2021).

Dai, T. et al. Waste glass powder as a high temperature stabilizer in blended oil well cement pastes: Hydration, microstructure and mechanical properties. Constr. Build. Mater. 439, 137359. https://doi.org/10.1016/j.conbuildmat.2024.137359 (2024).

Shan, H. et al. Effect of carbon dots with different sizes on chloride binding of cement. Constr. Build. Mater. 425, 136103. https://doi.org/10.1016/j.conbuildmat.2024.136103 (2024).

Ke, G., Li, Z. & Jiang, H. Study on long-term solidification of all-solid waste cementitious materials based on circulating fluidized bed fly ash, red mud, carbide slag, and fly ash. Constr. Build. Mater. 427, 136284. https://doi.org/10.1016/j.conbuildmat.2024.136284 (2024).

Malhotra, V. Sustainable development and concrete technology. Concr Int. 24, 22 (2002).

McCaffery, R. Climate change and the cement industry. Global cement and lime magazine, Environ. Spec. Issue. (2002) 15–19.

Naik, T.R. Sustainability of cement and concrete industries. In Proc. Int. Conf. Achiev. Sustain. Constr. 141–150 (2005). https://doi.org/10.1680/asic.34044.0017.

Salloum, T., Concordia, U., & Nokken, M.N.M. Effect of fly ash replacement on alkali and sulphate resistance of mortars. Doctoral dissertation, (2007).

Kong, D. L. Y. & Sanjayan, J. G. Damage behavior of geopolymer composites exposed to elevated temperatures. Cem. Concr. Compos. 30, 986–991. https://doi.org/10.1016/j.cemconcomp.2008.08.001 (2008).

Rangan, B.V. Fly ash-based geopolymer concrete, Research Report GC 4, Faculty of Engineering, Curtin University of Technology, Perth, Australia, (2008).

Duxson, P., Provis, J. L., Lukey, G. C. & Van Deventer, J. S. The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr. Res. 37(12), 1590–1597 (2007).

Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. 37, 1633–1656 (1991).

Temuujin, J., Van Riessen, A. & MacKenzie, K. J. D. Preparation and characterisation of fly ash based geopolymer mortars. Constr. Build. Mater. 24, 1906–1910. https://doi.org/10.1016/j.conbuildmat.2010.04.012 (2010).

Davidovits, J. Chemistry of geopolymeric systems. In Terminol. Proc. 2nd Int. Conf. Geopolymer’99, Saint Qunentin. 9–39 (1999).

Verma, M. & Dev, N. Effect of liquid to binder ratio and curing temperature on the engineering properties of the geopolymer concrete. Silicon. 14, 1743–1757. https://doi.org/10.1007/s12633-021-00985-w (2022).

Verma, M. & Dev, N. Sodium hydroxide effect on the mechanical properties of flyash-slag based geopolymer concrete. Struct. Concr. 22, E368–E379. https://doi.org/10.1002/suco.202000068 (2021).

Kumar, R., Verma, M. & Dev, N. Investigation on the effect of seawater condition, sulphate attack, acid attack, freeze–thaw condition, and wetting–drying on the geopolymer concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 46, 2823–2853. https://doi.org/10.1007/s40996-021-00767-9 (2022).

Verma, M. et al. Geopolymer concrete: a material for sustainable development in Indian construction industries. Crystals. 12, 514. https://doi.org/10.3390/cryst12040514 (2022).

Verma, M. Prediction of compressive strength of geopolymer concrete by using ANN and GPR. Asian J. Civ. Eng. 24, 2815–2823. https://doi.org/10.1007/s42107-023-00676-4 (2023).

Davidovits, J. Geopolymer chemistry and sustainable development. The Poly(sialate) terminology: A very useful and simple model for the promotion and understanding of green-chemistry. In Geopolymer Conference, vol 02100, 9–16 (2005).

Malhotra, V.M. Making concrete greener with fly ash. In Concrete International 61–66 (1999). https://trid.trb.org/view/504169.

Davidovits, J., Comrie, D. C., Paterson, J. H. & Ritcey, D. J. Geopolymeric concretes for environmental protection. Concr. Int. 12, 30–39 (1990).

Arivalagan, S. Sustainable studies on concrete with GGBS as a replacement material in cement. Jordan J. Civ. Eng. 8, 263–270 (2014).

Elchalakani, M., Aly, T. & Abu-Aisheh, E. Sustainable concrete with high volume GGBFS to build Masdar City in the UAE, Case Stud. Constr. Mater. 1, 10–24. https://doi.org/10.1016/j.cscm.2013.11.001 (2014).

Wang, H. Y. The effects of elevated temperature on cement paste containing GGBFS. Cem. Concr. Compos. 30, 992–999. https://doi.org/10.1016/j.cemconcomp.2007.12.003 (2008).

Ten Kuo, W., Wang, H. Y. & Shu, C. Y. Engineering properties of cementless concrete produced from GGBFS and recycled desulfurization slag. Constr. Build. Mater. 63, 189–196. https://doi.org/10.1016/j.conbuildmat.2014.04.017 (2014).

Suresh, D. & Nagaraju, K. Ground Granulated Blast Slag (GGBS) in concrete—A review. IOSR J. Mech. Civ. Eng. 12, 76–82 (2015).

Shoubi, M. V., Barough, A. S. & Amirsoleimani, O. Assessment of the roles of various cement replacements in achieving the sustainable and high performance concrete. Int. J. Adv. Eng. Technol. 6, 68–77 (2013).

Siddique, R. & Kaur, D. Properties of concrete containing ground granulated blast furnace slag (GGBFS) at elevated temperatures. J. Adv. Res. 3, 45–51. https://doi.org/10.1016/j.jare.2011.03.004 (2012).

Leung, P.W.C., & Wong, H.D. Final Report on Durability and Strength Development of Ground Granulated Blastfurnace Slag Concrete, vol. 76 (2011).

Wang, L., Tian, P., & Yao, Y. Application of ground granulated blast furnace slag in high-performance concrete in China. In Proceedings of the International Workshop on Sustainable Development and Concrete Technology 309–317 (2004).

Boukendakdji, O., Kenai, S., Kadri, E. H. & Rouis, F. Effect of slag on the rheology of fresh self-compacted concrete. Constr. Build. Mater. 23, 2593–2598. https://doi.org/10.1016/j.conbuildmat.2009.02.029 (2009).

Aharon-Shalom, E. & Heller, A. Tensile strength and bonding characteristics of self-compacting concrete. J. Electrochem. Soc. 129, 2865 (1982).

EFNARC (European Federation of Specialist Construction Chemicals and Concrete Systems). The European guidelines for selfcompacting concrete: Specification, production and use 2005 U.K., (2005) 2020.

Liu, M. Self-compacting concrete with different levels of pulverized fuel ash. Constr. Build. Mater. 24, 1245–1252. https://doi.org/10.1016/j.conbuildmat.2009.12.012 (2010).

Gaimster, R., & Dixon, N. Self-compacting concrete. In Advanced Concrete Technology 1–23 (2003). https://doi.org/10.1016/B978-075065686-3/50295-0.

Nanthagopalan, P. & Santhanam, M. A new empirical test method for the optimisation of viscosity modifying agent dosage in self-compacting concrete. Mater. Struct. Constr. 43, 203–212. https://doi.org/10.1617/s11527-009-9481-3 (2010).

Koehler, E.P., & Fowler, D.W. Aggregates in Self-Consolidating Concrete, 2007.

Dehwah, H. A. F. Mechanical properties of self-compacting concrete incorporating quarry dust powder, silica fume or fly ash. Constr. Build. Mater. 26, 547–551. https://doi.org/10.1016/j.conbuildmat.2011.06.056 (2012).

Duan, P., Shui, Z., Chen, W. & Shen, C. Effects of metakaolin, silica fume and slag on pore structure, interfacial transition zone and compressive strength of concrete. Constr. Build. Mater. 44, 1–6. https://doi.org/10.1016/j.conbuildmat.2013.02.075 (2013).

Brooks, J. J., Megat Johari, M. A. & Mazloom, M. Effect of admixtures on the setting times of high-strength concrete. Cem. Concr. Compos. 22, 293–301. https://doi.org/10.1016/S0958-9465(00)00025-1 (2000).

Poon, C. S., Kou, S. C. & Lam, L. Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constr. Build. Mater. 20, 858–865. https://doi.org/10.1016/j.conbuildmat.2005.07.001 (2006).

Jin, X. & Li, Z. Effects of mineral admixture on properties of young concrete. J. Mater. Civ. Eng. 15, 435–442. https://doi.org/10.1061/(asce)0899-1561(2003)15:5(435) (2003).

Si-Ahmed, M., Belakrouf, A. & Kenai, S. Influence of metakaolin on the performance of mortars and concretes. Int. J. Civil Environ. Struct. Archit. Eng. 6, 1354–1357 (2012).

Rovnaník, P. Effect of curing temperature on the development of hard structure of metakaolin-based geopolymer. Constr. Build. Mater. 24, 1176–1183. https://doi.org/10.1016/j.conbuildmat.2009.12.023 (2010).

Cassagnabère, F., Mouret, M., Escadeillas, G., Broilliard, P. & Bertrand, A. Metakaolin, a solution for the precast industry to limit the clinker content in concrete: Mechanical aspects. Constr. Build. Mater. 24, 1109–1118. https://doi.org/10.1016/j.conbuildmat.2009.12.032 (2010).

Cheriaf, M., Rocha, J. C. & Péra, J. Pozzolanic properties of pulverized coal combustion bottom ash. Cem. Concr. Res. 29, 1387–1391. https://doi.org/10.1016/S0008-8846(99)00098-8 (1999).

Dwikojuliardi, R. Malaysia and construction industry present. Res. Gate. 53, 1689–1699 (2016).

Dişçi, E. & Polat, R. The influence of nano-CaO and nano-Al2O3 and curing conditions on perlite based geopolymer concrete produced by the one-part mixing method. Constr. Build. Mater. 346, 128484. https://doi.org/10.1016/j.conbuildmat.2022.128484 (2022).

Shilar, F. A., Ganachari, S. V., Patil, V. B., Neelakanta Reddy, I. & Shim, J. Preparation and validation of sustainable metakaolin based geopolymer concrete for structural application. Constr. Build. Mater. 371, 130688. https://doi.org/10.1016/j.conbuildmat.2023.130688 (2023).

Shilar, F. A. et al. Review on the relationship between nano modifications of geopolymer concrete and their structural characteristics. Polymers (Basel). 14, 1421. https://doi.org/10.3390/polym14071421 (2022).

Shilar, F. A., Ganachari, S. V. & Patil, V. B. Advancement of nano-based construction materials-A review. Constr. Build. Mater. 359, 129535. https://doi.org/10.1016/j.conbuildmat.2022.129535 (2022).

Shilar, F. A., Ganachari, S. V., Patil, V. B., Khan, T. M. Y. & Dawood Abdul Khadar, S. Molarity activity effect on mechanical and microstructure properties of geopolymer concrete: A review. Case Stud. Constr. Mater. 16, e01014. https://doi.org/10.1016/j.cscm.2022.e01014 (2022).

Jumaa, N. H., Ali, I. M., Nasr, M. S. & Falah, M. W. Strength and microstructural properties of binary and ternary blends in fly ash-based geopolymer concrete. Case Stud. Constr. Mater. 17, e01317. https://doi.org/10.1016/j.cscm.2022.e01317 (2022).

Shilar, F. A. et al. Optimization of alkaline activator on the strength properties of geopolymer concrete. Polymers (Basel). 14, 2434. https://doi.org/10.3390/polym14122434 (2022).

Li, L., Xie, J., Zhang, B., Feng, Y. & Yang, J. A state-of-the-art review on the setting behaviours of ground granulated blast furnace slag- and metakaolin-based alkali-activated materials. Constr. Build. Mater. 368, 130389. https://doi.org/10.1016/j.conbuildmat.2023.130389 (2023).

Istuque, D. B. et al. Impedance spectroscopy as a methodology to evaluate the reactivity of metakaolin based geopolymers. Materials (Basel). 15, 8387. https://doi.org/10.3390/ma15238387 (2022).

Madirisha, M. M., Dada, O. R. & Ikotun, B. D. Chemical fundamentals of geopolymers in sustainable construction. Mater. Today Sustain. 27, 100842. https://doi.org/10.1016/j.mtsust.2024.100842 (2024).

Khale, D. & Chaudhary, R. Mechanism of geopolymerization and factors influencing its development: A review. J. Mater. Sci. 42, 728–736 (2007).

Bheel, N. et al. Utilization of corn cob ash as fine aggregate and ground granulated blast furnace slag as cementitious material in concrete. Buildings. 11, 422. https://doi.org/10.3390/buildings11090422 (2021).

Bheel, N. et al. An investigation on fresh and hardened properties of concrete blended with rice husk ash as cementitious ingredient and coal bottom ash as sand replacement material. Silicon. 14, 677–688. https://doi.org/10.1007/s12633-020-00906-3 (2022).

Keerio, M. A. et al. The effect of local metakaolin developed from natural material Soorh on selected properties of concrete/mortar. Silicon. 14, 1807–1816. https://doi.org/10.1007/s12633-021-00993-w (2022).

Keerio, M. A., Saand, A., Kumar, A., Bheel, N. & Ali, K. Effect of local metakaolin developed from natural material Soorh and coal bottom ash on fresh, hardened properties and embodied carbon of self-compacting concrete. Environ. Sci. Pollut. Res. 28, 60000–60018. https://doi.org/10.1007/s11356-021-14960-w (2021).

Saand, A., Ali, K., Kumar, A., Bheel, N. & Keerio, M. A. Effect of metakaolin developed from natural material Soorh on fresh and hardened properties of self-compacting concrete. Innov. Infrastruct. Solut. 6, 1. https://doi.org/10.1007/s41062-021-00534-9 (2021).

BS EN 12390-3. Testing harden concrete. Compressive strength of test specimens. BSI; 2009., (n.d.).

BS EN 12390-6. Testing hardened concrete. Tensile splitting strength of test specimens. BSI; 2009., (n.d.).

BS EN 12390-5. Testing hardened concrete. Flexural strength of test specimens. BSI; 2009., (n.d.).

British Standard Institution, BS EN 12390-8. Testing Hardened Concrete: Part 8: Depth of Penetration of Water under Pressure, BSI, London, UK, 2009, (n.d.).

ASTM, 2004. Standard Test Method for Length Change of Hydraulic-Cement Mortars Exposed to a Sulfate Solution ASTM C 1012-04., (n.d.).

Arun, B. R., Nagaraja, P. S. & Srishaila, J. M. An effect of NaOH molarity on fly ash—Metakaolin-based self-compacting geopolymer concrete. Lect. Notes Civ. Eng. 25, 233–244. https://doi.org/10.1007/978-981-13-3317-0_21 (2019).

Güneyisi, E. & Gesoğlu, M. Properties of self-compacting mortars with binary and ternary cementitious blends of fly ash and metakaolin. Mater. Struct. Constr. 41, 1519–1531. https://doi.org/10.1617/s11527-007-9345-7 (2008).

Fareed Ahmed, M., Fadhil Nuruddin, M. & Shafiq, N. Compressive strength and workability characteristics of low-calcium fly ash-based self-compacting geopolymer concrete. World Acad. Sci. Eng. Technol. 74, 8–14 (2011).

Memon, F. A., Nuruddin, M. F. & Shafiq, N. Effect of silica fume on the fresh and hardened properties of fly ash-based self-compacting geopolymer concrete. Int. J. Miner. Metall. Mater. 20, 205–213. https://doi.org/10.1007/s12613-013-0714-7 (2013).

Dhiyaneshwaran, S., Ramanathan, P., Baskar, I. & Venkatasubramani, R. Study on durability characteristics of self-compacting concrete with fly ash, Jordan. J. Civ. Eng. 7, 342–353 (2013).

Newman, J., & Choo, B.S. Advanced concrete technology. In Advanced Concrete Technology 1–1433 (2003). https://doi.org/10.1016/B978-0-7506-5686-3.X5246-X.

Guo, L. et al. Sulfate resistance of hybrid fiber reinforced metakaolin geopolymer composites. Compos. Part B Eng. 183, 107689. https://doi.org/10.1016/j.compositesb.2019.107689 (2020).

Bheel, N. et al. Fresh and hardened properties of concrete incorporating binary blend of metakaolin and ground granulated blast furnace slag as supplementary cementitious material. Adv. Civ. Eng. https://doi.org/10.1155/2020/8851030 (2020).

Güneyisi, E., Gesoglu, M. & Özbay, E. Evaluating and forecasting the initial and final setting times of self-compacting concretes containing mineral admixtures by neural network. Mater. Struct. Constr. 42, 469–484. https://doi.org/10.1617/s11527-008-9395-5 (2009).

Khatib, J. M. & Hibbert, J. J. Selected engineering properties of concrete incorporating slag and metakaolin. Constr. Build. Mater. 19, 460–472. https://doi.org/10.1016/j.conbuildmat.2004.07.017 (2005).

Mangi, S. A., Wan Ibrahim, M. H., Jamaluddin, N., Arshad, M. F. & Putra Jaya, R. Short-term effects of sulphate and chloride on the concrete containing coal bottom ash as supplementary cementitious material. Eng. Sci. Technol. Int. J. 22, 515–522. https://doi.org/10.1016/j.jestch.2018.09.001 (2019).

Courard, L. et al. Durability of mortars modified with metakaolin. Cem. Concr. Res. 33, 1473–1479. https://doi.org/10.1016/S0008-8846(03)00090-5 (2003).

Kasemchaisiri, R. & Tangtermsirikul, S. Properties of self-compacting concrete incorporating bottom ash as a partial replacement of fine aggregate. ScienceAsia. 34, 87–95. https://doi.org/10.2306/scienceasia1513-1874.2008.34.087 (2008).

Khatri, R. P., Sirivivatnanon, V. & Yang, J. L. Role of permeability in sulphate attack. Cem. Concr. Res. 27, 1179–1189. https://doi.org/10.1016/S0008-8846(97)00119-1 (1997).

Bheel, N. et al. Effect of wheat straw ash as cementitious material on the mechanical characteristics and embodied carbon of concrete reinforced with coir fiber. Heliyon. 10, e24313. https://doi.org/10.1016/j.heliyon.2024.e24313 (2024).

Jones, R., Mccarthy, M., & Newlands, M. Fly Ash route to low embodied CO2 and implications for concrete construction. In WOCA Proc. Pap. (2011) 1–14. http://www.flyash.info/2011/018-Jones-2011.pdf.

Bheel, N. et al. A comprehensive study on the impact of nano-silica and ground granulated blast furnace slag on high strength concrete characteristics: RSM modeling and optimization. Structures. 62, 106160. https://doi.org/10.1016/j.istruc.2024.106160 (2024).

Turner, L. K. & Collins, F. G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 43, 125–130. https://doi.org/10.1016/j.conbuildmat.2013.01.023 (2013).

Yahya, Z. et al. Optimizing and Characterizing geopolymers from ternary blend of Philippine coal fly ash, coal bottom ash and rice hull ash. Materials (Basel). 9, 1485–1495 (2016).

Adesina, A. Recent advances in the concrete industry to reduce its carbon dioxide emissions. Environ. Chall. 1, 100004. https://doi.org/10.1016/j.envc.2020.100004 (2020).

Bheel, N. et al. Synergistic effect of recycling waste coconut shell ash, metakaolin, and calcined clay as supplementary cementitious material on hardened properties and embodied carbon of high strength concrete. Case Stud. Constr. Mater. 20, e02980. https://doi.org/10.1016/j.cscm.2024.e02980 (2024).

Letchumi, T., Sumiani, Y. & Zin Zawawi, N. Life cycle assessment of sodium hydroxide. Aust. J. Basic Appl. Sci. 7, 421–431 (2013).

Heath, A., Paine, K. & McManus, M. Minimising the global warming potential of clay based geopolymers. J. Clean. Prod. 78, 75–83. https://doi.org/10.1016/j.jclepro.2014.04.046 (2014).

Flower, D. J. M. & Sanjayan, J. G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 12, 282–288. https://doi.org/10.1007/s11367-007-0327-3 (2007).

Neupane, K. Evaluation of environmental sustainability of one-part geopolymer binder concrete. Clean. Mater. 6, 100138. https://doi.org/10.1016/j.clema.2022.100138 (2022).

Yang, K.-H., Song, J.-K. & Song, K.-I. Assessment of CO2 reduction of alkali-activated concrete. J. Clean. Prod. 39, 265–272 (2013).

Bheel, N., Mohammed, B. S., Mohamad, H., Sutanto, M. H. & Tafsirojjaman, T. Synergetic effect of multiwalled carbon nanotubes on mechanical and deformation properties of engineered cementitious composites: RSM modelling and optimization. Diam. Relat. Mater. 147, 111299. https://doi.org/10.1016/j.diamond.2024.111299 (2024).

Bheel, N. et al. A comprehensive study on the impact of human hair fiber and millet husk ash on concrete properties: response surface modeling and optimization. Sci. Rep. 14, 13569. https://doi.org/10.1038/s41598-024-63050-7 (2024).

Bheel, N. & Mohammed, B. S. Modelling and optimization of long-term modulus of elasticity and Poisson’s ratio of graphene oxide based engineered cementitious composites by using response surface methodology. Diam. Relat. Mater. 143, 110949. https://doi.org/10.1016/j.diamond.2024.110949 (2024).

Abdullah, G. M. S. et al. Effect of titanium dioxide as nanomaterials on mechanical and durability properties of rubberised concrete by applying RSM modelling and optimizations. Front. Mater. https://doi.org/10.3389/fmats.2024.1357094 (2024).

Bheel, N., Mohammed, B. S., Ali, M. O. A., Shafiq, N. & Radu, D. Effect of graphene oxide as a nanomaterial on the bond behaviour of engineered cementitious composites by applying RSM modelling and optimization. J. Mater. Res. Technol. 26, 1484–1507. https://doi.org/10.1016/j.jmrt.2023.07.278 (2023).

Chohan, I. M. et al. Effect of seawater salinity, pH, and temperature on external corrosion behavior and microhardness of offshore oil and gas pipeline: RSM modelling and optimization. Sci. Rep. https://doi.org/10.1038/s41598-024-67463-2 (2024).

Bheel, N., Chohan, I. M., Alwetaishi, M., Waheeb, S. A. & Alkhattabi, L. Sustainability assessment and mechanical characteristics of high strength concrete blended with marble dust powder and wheat straw ash as cementitious materials by using RSM modelling. Sustain. Chem. Pharm. 39, 101606. https://doi.org/10.1016/j.scp.2024.101606 (2024).

Acknowledgements

The authors extend their appreciation to Taif University, Saudi Arabia, for supporting this work through project number (TU-DSPP-2024-32).

Funding

The authors extend their appreciation to Taif University, Saudi Arabia, for supporting this work through project number (TU-DSPP-2024-32).

Author information

Authors and Affiliations

Contributions

Naraindas Bheel: Conceptualization; Data analysis; Investigation; methodology; Writing - Original Draft; Writing - Review & Editing. Mamdooh Alwetaishi: Formal analysis; Funding Acquisition; visualization; Writing - Review & Editing. Idris Ahmed Jae: Formal Analysis; methodology; Writing - Review & Editing. Agusril Syamsir: Conceptualization; Formal analysis; methodology; Writing - Review & Editing. Ahmed Saleh Alraeeini: Formal analysis; Data analysis; visualization; Writing - Review & Editing. Sahl Abdullah Waheeb: Conceptualization; Formal analysis; visualization; Writing - Review & Editing. Loai Alkhattabi: Formal analysis; data curing; visualization; Writing - Review & Editing. Omrane Benjeddou: Conceptualization; Formal Analysis; and Writing - Review & Editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Bheel, N., Alwetaishi, M., Jae, I.A. et al. Enhancing performance and sustainability of GGBFS-based self-compacting geopolymer concrete blended with coal bottom ash and metakaolin by using RSM modelling. Sci Rep 14, 19754 (2024). https://doi.org/10.1038/s41598-024-70800-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-70800-0

Keywords

This article is cited by

-

Effect of seawater salinity and temperature on material performance and marine ecotoxicity of offshore pipeline using RSM modelling

International Journal of Environmental Science and Technology (2026)

-

Investigations on mechanical and stress strain characteristics of geopolymer concrete reinforced with glass fibers

Scientific Reports (2025)

-

Performance Evaluation and Statistical Modelling of Glass Waste Powder-Geopolymer Concrete Subjected to Dual Curing Regimes: Strength, Durability, and Predictive Analysis

Iranian Journal of Science and Technology, Transactions of Civil Engineering (2025)

-