Abstract

This paper aims to address the issue of environmental pollution resulting from marine oil spills by evaluating the oil adsorption performance of commonly used fence materials. Conventional oil adsorption materials exhibit limited rates and capacities for oil adsorption. Existing methods have proven insufficient in meeting the requirements for efficient and rapid oil–water separation. A new oil-absorbing barrier was developed by utilizing high oil adsorption resin as the primary material and hydroxypropyl methyl cellulose (HPMC) as the binder, leveraging the exceptional oil adsorption and hydrophobic properties of P(BMA-SMA-St)/MIL-101(Fe) resin. The oil-absorbing fence was characterized using scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FTIR) and thermogravimetric analysis (TGA). The oil adsorption rates of carbon tetrachloride, toluene, diesel and gasoline by the oil adsorption fence with 25 g/L resin content were 101.26 g/m2, 68.12 g/m2, 35.19 g/m2, and 46.69 g/m2, respectively. After 120 h of UV irradiation, the coating’s oil absorption capacity remained nearly unchanged, and it demonstrated outstanding mechanical, chemical, and wear resistance. As a result, the oil adsorption fence possesses the capability to rapidly absorb oil from the water’s surface during the process of containing oil pollution, leading to positive social and economic impacts.

Similar content being viewed by others

Introduction

Oil spills frequently occur during the process of offshore oil exploration and transportation, driven by the increasing global demand for oil. The 2011 Penglai 19-3 oil field oil spill resulted in serious pollution of approximately 5500 km2 of sea area, leading to a marine ecological loss valued at 683 million yuan. Additionally, the collision between two foreign cargo ships in the Qingdao sea area in 2021 caused the leakage of about 9400 tons of cargo oil into the sea, resulting in extremely serious harm to the marine environment. Oil spill accidents not only cause significant damage to the marine environment but also pose risks to marine organisms and human health. Therefore, there is an urgent need for researchers both domestically and internationally to develop environmentally friendly, cost-effective, and efficient adsorption materials for removing marine oil spills1,2.

A new kind of polymer functional material for oil adsorption is oil-absorbing resin3,4. High oil-absorbing resins, in contrast to conventional oil-absorbing materials, primarily adsorb oil to the resin fiber cavity by the interaction of their own lipophilic groups with oil molecules5,6,7. The oil adsorption ratio and oil retention rate of the oil-absorbing resin are significantly higher than those of conventional oil-absorbing materials because of the lipophilic hydrophobicity and high adsorption of the resin. Its low density and diversity make it ideal for cleaning and recovering floating water surfaces as well as for the cleaning, separation, and repurification of oily wastes8,9,10.

Based on the classification of polymer monomers, high oil-absorbing resins can be broadly classified as polyolefin high oil-absorbing resins, polyurethane high oil-absorbing resins, and polymethacrylate oil-absorbing resins. The polymerization process of the acrylate high oil adsorption resin is reasonably mature, and the monomer has a wide variety of sources; nevertheless, the oil adsorption rate of the produced resin is slow. The resin is typically changed to further increase the oil adsorption rate and adsorption performance of the resin in order to make up for the aforementioned deficiencies11,12,13,14. Bu et al.15 prepared FHMS/acrylic resin composites by suspension polymerization. The adsorption capacity of G-OAR aerogels for low-density organic solvents such as acetone, anhydrous ethanol, cyclohexane, toluene, ethyl acetate, and diesel can reach 40–50 g/g. Cui et al.16 prepared highly interconnected porous (butyl acrylate-octadecyl methacrylate-styrene-divinylbenzene) monolithic columns and microbeads by polymerization of high internal phase emulsions (HIPEs) and double emulsions. The results showed that the optimum mass adsorption capacity of the resin for kerosene and carbon tetrachloride was 8.52 times and 20.82 times of its own weight, respectively, which was higher than that of the corresponding poly HIPE monomer. At the same time, the resin has good thermal stability and can be collected and recovered by filtration and washing.

From the previously mentioned methods, the synergistic oil adsorption effect between the components allows the oil-absorbing resin compounded with each material to have high oil adsorption performance and good reusability. MOFs and their composites are a potential class of adsorbents that can be used to remove a variety of contaminants from wastewater. Compared to conventional adsorption materials, the adsorption efficiency and capacity are higher17,18,19,20. Materials from the MIL-101 series are well suited for the adsorption treatment of contaminants in water due to their high specific surface area and strong hydrothermal stability21,22. Mohamed et al.23 showed that MIL-101(Fe) has high selectivity for anionic dyes at all temperatures. The adsorbent can be reused without affecting the removal efficiency after 5 adsorption–desorption cycles. Liu et al.24 prepared graphene oxide (GO)/MIL101(Fe) composites by one-pot reaction method. The results showed that the maximum adsorption capacities of MIL-101(Fe) and 10% GO/MIL-101(Fe) for methyl orange were 117.74 mg g−1 and 186.20 mg g−1, respectively. GO/MIL-101(Fe) could be reused at least three times. Thus, MIL-101(Fe) can be considered a very promising adsorbent for the elimination of organic hazardous pollutants from water due to its unique synergistic adsorption capability, chemical stability, and regeneration performance.

Using butyl methacrylate (BMA), stearyl methacrylate (SMA), and styrene (St) as oil-absorbing monomers, our team effectively created an oil-absorbing resin P(BMA-SMA-St)/MIL-101(Fe) with high oil adsorption, oil retention, and regeneration in the early stages. The results of the oil adsorption performance test indicated that the P(B-S–S)/MIL-101(Fe) resin had an oil adsorption capacity of 37.35 g/g, 32.67 g/g, and 16.82 g/g for carbon tetrachloride, toluene, and diesel, respectively. After 10 cycles of adsorption and desorption, the resin still exhibited good adsorption capability. However, research on using the greater potential of resins as a convenient and practical oil-absorbing material resource is still limited.

In the actual remediation of water pollution, the oil-absorbing resin should be able to float on the water’s surface, which necessitates a lower density. In this paper, a new type of oil adsorption fence was prepared by using P(BMA-SMA-St)/MIL-101(Fe) resin as raw material and hydroxypropyl methyl cellulose (HPMC) as adhesive. By curing the oil-absorbing resin on the PVC oil boom, the PVC oil boom can quickly absorb the oil slick on the water surface while maintain the original function of collecting oil on the water surface. The combination of oil adsorption resin material and oil fence may effectively solve oil pollution in real life, which is critical to improving the human living environment.

Experiment

Materials

Tetrafluorofuran was purchased from Shanghai McLean Biochemical Technology Co., Ltd. Hydroxypropyl methyl cellulose (HPMC) was purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., and sea crystal was purchased from Jiangxi Haiding Technology Co., Ltd. All chemicals used in the process were analytical grade. 1 kg of sea crystal was mixed with 30 L of tap water to configure artificial seawater with a salinity of 3.5%. The sodium, magnesium, potassium, calcium, sulfate, and chloride ions are the primary constituents of sea crystal. The preparation of diesel emulsion involves adding 5 mL of deionized water to a sample bottle, followed by the addition of 1 mL of diesel to the water solution. The mixture is then left to settle, resulting in a clear separation of water and oil, which is then stored for further use.

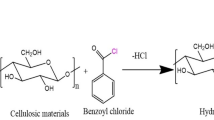

Preparation of oil suction fence

Preparation of HPMC binder

Three flasks containing 100 mL of deionized water were heated to 75 °C. Then 1 g HPMC was weighed. HPMC was added to the flask frequently and in small amounts while using a magnetic stirrer set to 7000 rpm to prevent HPMC agglomeration. The stirring solution is a viscous transparent solution uniformly mixed and placed for later use.

Preparation of oil suction fence

P(B-S–S)/MIL-101(Fe) resins of varying masses were weighed, added, and agitated for 6 h at 55 °C and 900 rpm in a 15 mL tetrafluorofuran solution. Then, using magnetic stirring at 900 r/min, 30 mL of HPMC was dropped to create the oil-absorbing coating. The PVC oil boom was cut into rectangular pieces of 3 cm × 4.5 cm and 70 cm × 15 cm, and then the surface of the oil boom was cleaned with ethanol and acetone, and the oil boom was dried for later use. After that, a pipette gun was used to apply the resin coating to the PVC substrate, and the PVC was allowed to cure for 24 h at 80 °C in an oven. Finally, PVC with oil adsorption performance was obtained. Figure 1 depicts the experiment’s preparation procedure.

Sample characterization

The morphology of the resin was observed by scanning electron microscopy (Quanta 650 FEG). The test resin was treated by the coating of the gold spray instrument, and then the resin was observed by scanning electron microscope, and the scanning electron microscope images at different multiples were obtained. The infrared spectrum of the resin was analyzed by Fourier transform spectrometer (Spotlight 200i). KBr tablet method was used for infrared spectrum testing. The scanning times of Fourier transform spectrometer were set to 32 times, and the scanning wavelength was set to 400–4000 cm−1. The thermal stability of the resin was analyzed by TGA/DSC1 thermogravimetric analyzer. After vacuum drying of a certain mass of resin, thermogravimetric tests were carried out at the flow rate of nitrogen protection gas (20 mL/min), reaction gas (50 mL/min) and heating rate (10 °C/min). The test temperature range was 50–700 °C. The wettability of the samples was analyzed by contact angle measuring instrument. The contact Angle of the resin was measured by the method of seat drop, and the test liquid was deionized water.

Sample performance test

Oil adsorption performance test of coating

Weighing was used to measure the coating’s ability to absorb oil. Initially, an electronic balance is used to weigh and record the oil-absorbing PVC quality, which is represented as m0. Next, the entire side of the PVC covered in oil-absorbing substance is submerged in the oil to be examined. Following complete adsorption of the oil adsorption coating, the PVC corner is clamped using tweezers, and the cutting piece is positioned using the hanging foot method on the iron frame platform to cause the oil droplets on the PVC surface to completely drop. The PVC quality is then weighed and noted as mt. The saturated oil adsorption rate (qmax) of the coating can be computed using the following formula:

In the formula: qmax is the saturated oil adsorption rate of the oil adsorption coating, g/m2; mt is the mass of PVC cut piece under the saturated state of oil adsorption, g; m0 is the initial weight of PVC sheet, g; s is the area of coated with oil adsorption coating of PVC sheet, m2.

Wear resistance test

The wear resistance of the coating was examined in order to look at its capacity to withstand mechanical friction. The 360-mesh sandpaper is first set up on a horizontal desktop. Next, the coated side of the PVC is fastened to the sandpaper’s sanding surface, and a 500 g weight is set on top of the PVC. After that, a pulling force was used to drag the PVC across the sandpaper at an average speed of 20 cm in one direction. Reciprocal drag in PVC is thought of as a wear cycle. Following 10, 20, 30, and 40 cycles of dragging, the coating’s wear was noted, and its oil adsorption was quantified. The coating was applied on a 2.5 cm × 8 cm glass plate for a wear test in order to better observe the coating’s resistance to wear.

Adhesion test

According to GB/T 1720–1979, the adhesion performance of the coating was tested by the Baige knife adhesion test method. First, 11 parallel notches with a 2 mm spacing were cut on the oil-absorbing PVC. Next, vertical notches with the same number and spacing were made. Next, use a soft brush to carefully brush off the shedding object along the two diagonal directions of the grid. Ultimately, the 3M600 tape was adhered to the grid and ripped off at the least angle. The adhesive area of the coated surface and the adhesion test standard were used to determine the coating’s adhesion.

Oil adsorption capacity of resin

The oil adsorption performance of resin was tested by weighing method. Weigh the resin with mass M0 in the filter bag, place the filter bag in the oil to be tested and soak it for 24 h to ensure that the adsorption capacity of the resin reaches saturation. At this time, the resin mass is recorded as Mt, and the calculation formula of resin saturation oil adsorption rate Qmax is as follows:

In the formula: Qmax is the saturated oil adsorption capacity, g/g; Mt is the resin mass under saturated oil adsorption, g; M0 is the initial weight of the resin, g.

Influence of pH on adsorption properties of coating

In order to explore whether the coating can maintain stable oil absorption performance in acidic or alkaline working environment, diesel emulsions of different pH were configured to test the oil absorption performance of the coating. First, the coating was soaked in 18% hydrochloric acid solution, 48% sodium hydroxide solution and artificial seawater for 72 h, dried to constant weight in an oven at 60 °C and weighed. The acid–alkali resistance of the coating was roughly analyzed according to the coating mass loss. Then, according to the analysis results, the coating was placed in diesel emulsion of different pH, and the saturation oil absorption performance of the coating was tested, and the influence of different pH on the oil absorption performance of the coating was analyzed.

Influence of ultraviolet light on adsorption properties of coating

In order to investigate whether ultraviolet irradiation would destroy the coating structure, the coating was placed in the ultraviolet analyzer and removed every 24 h. Diesel oil was used as the test oil to test the saturation oil absorption rate of the coating, and the wettability of the coating surface was tested to analyze the influence of ultraviolet irradiation on the coating.

Analysis of resin adsorption kinetics

The adsorption kinetic analysis of resin is a method to study the adsorption rate and mechanism of substances on the surface of resin during the adsorption process of resin, which is helpful to further understand the kinetic characteristics of resin adsorption process and provide theoretical and experimental basis for the design, optimization and application of resin25. The pseudo-first-order kinetic model and pseudo-second-order kinetic model were used to fit the adsorption kinetics of the resin26.

Pseudo-first orderkinetic model:

where dQ/dt represents the adsorption rate at time t, g/min; k1 is the quasi-first-order adsorption rate constant, min−1; Qt is the adsorption amount at time t, g; Qe is the adsorption amount at the adsorption equilibrium, g.

Pseudo-second orderkinetic model:

where dQ/dt represents the adsorption rate at time t, g/min; k2 is the quasi-first-order adsorption rate constant, min−1; Qt is the adsorption amount at time t, g; Qe is the adsorption amount at the adsorption equilibrium, g.

In order to ensure the accuracy of the experiment, all the above experiments were repeated three times.

Results and discussion

Infrared spectrum analysis

The structure of the sample was characterized by Fourier transform spectrometer, and the results are shown in Fig. 2. It can be observed from the oil-absorbing coating spectrum that the methyl and methylene C–H stretching vibration adsorption peaks of P(B-S-S)/MIL-101(Fe) resin exist at 2920.1 cm−1 and 2849.1 cm−1, and the characteristic adsorption peak of C–O–C exists at 1193.7 cm−1. The primary distinctive peaks of BMA and SMA are listed above. Peaks indicative of HPMC were seen at 3347 cm−1, 2878 cm−1, and 1024 cm−1. The benzene ring has a C–H bending vibration peak between 850.6 and 613.3 cm−1. Furthermore, distinct peaks of MIL-101(Fe) were observed at 567.8 cm−1, 751.3 cm−1, 1395.3 cm−1, and 1626.7 cm−1. The vibration adsorption peak of Fe–O is located at 567.8 cm−1, while the C–H vibration adsorption peak of the benzene ring is located at 751.3 cm−1. The symmetric and asymmetric stretching vibration peaks of terephthalic acid –COO– are located at 1395.3 cm−1 and 1626.7 cm−1, respectively. The successful preparation of the oil-absorbing coating was clearly demonstrated by the results of infrared spectroscopy.

Morphology analysis of oil-absorbing PVC

The morphology of the samples was characterized by scanning electron microscopy. Figure 3a–c is the surface topography of PVC substrate, P(B-S-S)/MIL-101(Fe) resin and resin coating, respectively. It can be clearly observed from the figure that the P(B-S-S)/MIL-101(Fe) resin was successfully solidified on the surface of the PVC sheet, and the resin particles were unevenly distributed and the surface was rough. In contrast to P(B-S-S)/MIL-101(Fe) resin, the coating’s resin retains its clear, and sharp edges as its particle size reduces. The particle size of resin particles in coatings with different resin content was determined by particle size analyzer. The average resin particle size is around 44.5 μm when the coating’s resin concentration is less than 25 g/L, as indicated by the particle size distribution (Fig. 3d). When the resin content was 35 g/L, the average particle size of the resin was 72.6 μm. Compared with the resin content of 25 g/L, the particle size of the resin increased sharply.

Morphology analysis of oil-absorbing PVC. (a) SEM of PVC substrate, (b) SEM of P(B-S-S)/MIL-101(Fe) resin, (c) SEM of resin content of 25 g/L coating, (d) resin content of 5 g/L, 15 g/L, 25 g/L, 35 g/L particle size, (e) XPS of resin content of 25 g/L coating, (f) Morphology of oil-absorbing PVC with different resin content.

The element valence and chemical composition of oil-absorbing PVC were studied by XPS. As demonstrated in Fig. 3e, the Fe element in the resin is visible in the energy scattering spectrum of the oil-absorbing PVC in addition to Na, O, C, Cl, Si, and other PVC elements. The two characteristic peaks of C1s are located at 284.83 eV and 286.26 eV, corresponding to C–C/C–H and C–O, respectively. The two characteristic peaks of O1s are located at 531.17 eV and 532.95 eV, corresponding to –OH and C–O, respectively. In the Fe2p spectrum, the two main peaks near 710.59 and 723.99 eV belong to the Fe2p3/2 and Fe2p1/2 spin–orbit peaks. At the same time, the peaks at 712.59 and 726.28 eV are consistent with the Fe3+ ions of the Fe–O bond. These spectroscopic and crystallographic results support the loading of PVC by oil-absorbing coatings.

Using an optical microscope, coatings with various resin concentrations were examined (Fig. 3f). The coating has more resin particles and a more even resin distribution over PVC as the resin content rises. The PVC substrate’s surface is essentially covered with resin particles, has the highest level of surface flatness when the resin content is 25 g/L. In cases where the resin concentration surpasses 25 g/L, there is a noticeable rise in the resin crystal particle size and coating particle feel. This is mostly caused by tetrahydrofuran’s inability to dissolve the resin enough when an excessive amount of resin is introduced, which causes the resin’s particle size to increase. Consequently, the optimal coating shape is achieved when the produced resin oil-absorbing coating has a resin concentration of 25 g/L.

Thermogravimetric analysis

The resin coating with a 25 g/L resin content underwent a thermal weight loss investigation. Figure 4 illustrates the resin coating’s minor mass loss before to 100 °C, which is mostly due to the coating’s water evaporating. In the temperature range of 100–200 °C, the coating is relatively stable, and the intramolecular structure is almost not destroyed. Around 200 °C to 440 °C, the coating displayed a significant mass loss. The early mass loss takes place between 220 and 300 °C, and the primary cause of the thermal weight loss during this phase is the fiber’s biocracking. The coating’s mass loss mostly happens between 300 and 440 °C, and it’s mostly caused by the resin’s polymers and MIL-101(Fe) coordination organic ligands breaking down. Furthermore, the early-stage fiber macromolecule residues slowly break down into ash and carbon. Owing to the presence of MIL-101(Fe), it exhibited a minor decrease in weight at 600–800 °C. The coating’s overall weight loss rate was 97.3%. The oil-absorbing coating exhibits good thermal stability overall.

Wettability analysis

In order to determine the surface wettability of different MIL-101(Fe) content composite resins, the static water contact angle of P(BMA-SMA-St)/MIL-101(Fe) composite resin was measured by a water contact angle measuring instrument. The results are shown in Fig. 5. As the amount of coating resin rises, the contact angle of the coating first increases and subsequently lowers, as shown in Fig. 5. The PVC surface’s hydrophobicity progressively rose. The alteration in surface hydrophobicity will reduce the duration of contact between the corrosive medium and the surface, hence mitigating the medium’s impact on the coating. Given that the P(B-S-S)/MIL-101(Fe) resin generated at an early stage exhibits more satisfactory hydrophobicity and lipophilicity, we believe that the concentration of the coating resin is the main factor affecting the change of the contact angle of the coating. When combined with the Fig. 3d optical microscope observation, the resin with a moderate addition amount was equally dispersed and totally dissolved in the coating, and the corresponding PVC had the best hydrophobicity. Excessive resin addition will lead to incomplete resin decomposition, larger resin particles, lower resin concentration bonded to the surface of PVC, and slightly lower hydrophobicity of the coating. The coating exhibits optimal hydrophobicity at a concentration of 25 g/L, with a contact angle of 103°. PVC has more satisfactory hydrophobic and lipophilic qualities.

Adhesion test

The scratch test was used to evaluate the bonding strength of the coatings with varying resin contents, and Fig. 6 displays the experimental findings. After the resin coating was scratched by the knife and pasted with the tape, there was a more obvious coating peeling at the intersection of the scratches. Further observation by 2 times magnifying glass showed that when the resin concentration was lower than 25 g/L, in addition to a small amount of peeling at the cutting edge, a small amount of flakes also fell off. With the increase of resin concentration, the shedding of thin slices gradually increased, but the overall shedding area was controlled between 5 and 15%. The ASTM grade of the coating was determined to be 2B according to the adhesion test standard. There is a strong bond between the coating and PVC. The coating’s adhesion performance is greatly decreased and the ASTM grade is 4B at 35 g/L of resin concentration.

Wear resistance test

The wear resistance of the coating is one of the key factors for the stable use of the coating. Figure 7 shows the morphology, wettability and oil absorption of coatings with resin concentrations of 15 g/L, 25 g/L and 35 g/L at different wear cycles (0, 5, 10, 15, 20). Before wear, the surface roughness Ra of 15 g/L, 25 g/L and 35 g/L coatings is 19.56 μm, 25.32 μm and 46.36 μm, respectively. After grinding in different cycles, the surface of the coating with three resin concentrations all showed different degrees of wear, and the resin in the coating lost part of the convex structure. Among them, the coating with a resin content of 15 g/L showed the most serious wear. As shown in Fig. 7(a1)–(a5), obvious scratches appeared on the surface of the coating after 10 times of wear. After 20 times of sandpaper grinding, the surface roughness of the coating was reduced to Ra7.03. After the coatings with resin content of 25 g/L and 35 g/L were worn by sandpaper, the surface layer of resin in the coating was partially shed, but the overall coating morphology remained intact. After 20 cycles of sandpaper grinding, the surface roughness of 25 g/L and 35 g/L coatings is Ra18.03 μm and 40.42 μm, respectively. Compared with the wear conditions of the three coatings at different periods, the higher the resin content in the coatings, the higher the wear resistance of the coatings. This is mainly due to the elastic deformation of the resin in the coating during the entire reciprocating friction process, thus reducing the damage to the coating, in addition to the rigid benzene ring structure in the resin structure also improves the wear resistance of the coating.

In order to explore the properties of the three coatings after different degrees of wear, the contact Angle and adsorption properties of the coatings at different wear periods (0, 5, 10, 15, 20) were tested. It can be seen from Fig. 7(a6),(b6),(c6) that the hydrophobicity of the three coatings decreases to different degrees after wear. Under the same wear period, the hydrophobic properties of the coatings with low resin content decreased more. The hydrophobicity of the coating with a resin content of 25 g/L decreased slightly after 20 cycles of sandpaper polishing, while the hydrophobicity of the coating with a resin content of 35 g/L barely changed after sandpaper polishing, which was due to the different conditions of resin shedding after polishing. The higher the resin content, the less likely the coating to fall off, and the better the overall morphology of the coating could be maintained after wear. Taking diesel oil as the experimental product, the oil absorption performance of resin at different grinding cycles was tested. As can be seen from the figure, the adsorption capacity of the coating gradually decreases with the increase of wear times of the coating resin. After 40 cycles of sandpaper grinding, the adsorption capacity of the 25 g/L coating decreases from 46.69 to 37.84 g/m2, indicating that the resin coating still has good oil absorption performance. Although the wettability of 35 g/L coating does not change much, the oil absorption performance is also reduced to a certain extent due to the shedding of some resins. By observing the wear morphology of the coating and testing the properties of the coating, different degrees of wear will cause a certain degree of performance damage to the coating, but in comparison, the higher the resin content of the coating is better wear resistance.

Oil adsorption performance test of oil-absorbing PVC

Figure 8a reflects the saturated oil adsorption rate of different organic solvents and oils by coatings with different resin concentrations (5 g/L, 10 g/L, 15 g/L, 20 g/L, 25 g/L, 30 g/L, 35 g/L). The adsorption capacity of the coating to various organic solvents and oil coatings is different, which is mainly related to the diffusion ability of the absorbed oil molecules. For organic solvents such as carbon tetrachloride, chloroform, toluene, etc. Compared with the oil with high viscosity and poor fluidity, the adsorption capacity of resin organic solvent is significantly higher than that of the three kinds of oil. Among the three oils, because the number of carbon atoms in diesel is closest to the number of carbon atoms in the reaction monomer octadecyl methacrylate, the adsorption capacity of PVC for diesel is greater than that of the other two oils according to the principle of similar miscibility. When the resin content is 25 g/L, the oil adsorption capacity of carbon tetrachloride, toluene, chloroform, kerosene diesel and gasoline is 101.26 g/m2, 68.12 g/m2, 76.12 g/m2, 38.13 g/m2, 46.98 g/m2, 32.84 g/m2, respectively. Figure 8e is the adsorption diagram of carbon tetrachloride, diesel oil and toluene on PVC with different resin contents.

(a) The adsorption capacity of PVC with different resin content for different oils. (b) The mass loss of PVC with resin content of 15 g/L, 25 g/L and 35 g g/L in acidic, alkaline solution and artificial seawater. (c) The adsorption properties of PVC with resin content of 15 g/L, 25 g/L and 35 g g/L at different pH. (d) The adsorption properties of PVC with resin content of 15 g/L, 25 g/L and 35 g g/L after 120 h and ultraviolet irradiation. (e) The adsorption effect of PVC with different resin content on carbon tetrachloride, diesel and toluene.

Different pH emulsions were prepared to test the oil adsorption performance of the coating to explore whether the oil-absorbing PVC can maintain stable oil adsorption performance in an acidic or alkaline working environment. Firstly, PVC with resin content of 15 g/L, 25 g/L and 35 g/L was immersed in 18% hydrochloric acid solution, 48% sodium hydroxide solution and artificial seawater. The acid and alkali resistance of the coating was roughly analyzed. The test results were shown in Fig. 8b. It can be seen from the figure that the weight loss rates of the three PVCs are all within 5%, indicating that the oil-absorbing PVC can maintain stability in a complex chemical environment.

Therefore, we used diesel emulsion as the test oil to further study the effect of pH on the adsorption performance of oil-absorbing PVC, as shown in Fig. 8c. With the increase of pH, the oil adsorption performance of the coating increased first and then decreased. The PVC coating had the best oil adsorption at pH 6. The saturated oil adsorption rates of 15 g/L, 25 g/L and 35 g/L coatings were 23.65 g/m2, 38.68 g/m2 and 45.05 g/m2, respectively. It demonstrates that the oil adsorption coating has better performance in neutral and acidic environment. In a strong acid and alkali environment, the coating was damaged, resulting in a decrease in its oil adsorption performance. On the other hand, under acidic and neutral conditions, the MIL-101(Fe) surface in the resin carries a positive charge, while the oil droplet surface carries a negative charge. The electrostatic attraction between the two makes the oil droplet molecules more easily adsorbed by the resin. When the pH is greater than 9, the coating surface carries a negative charge, which is electrostatically mutually exclusive with the negative charge carried on the surface of the oil droplet, reducing the adsorption capacity of the coating, resulting in a decrease in adsorption capacity. Therefore, the appropriate initial pH of the coating is 4–9.

Since PVC materials are typically used outdoors, the coating’s ability to withstand UV light must be taken into account. In this research, the samples were placed in an ultraviolet analyzer for 120 h to test whether the oil adsorption performance of oil-absorbing PVC would be destroyed after long-term irradiation of ultraviolet light. During this period, the adsorption performance of the coating was tested, and the test results are shown in Fig. 8d. It can be clearly observed from the figure that the oil adsorption performance of oil-absorbing PVC has almost no obvious change after continuous ultraviolet irradiation for 120 h, and it can still maintain more than 95% of the original adsorption capacity. The coating continues to work well at absorbing oil. With the extension of UV irradiation time, a small amount of hydrophobic long chains in the resin broke under oxidation, resulting in a decrease in the hydrophobicity of the resin. The above results show that the oil-absorbing PVC can maintain stable oil adsorption under long-term ultraviolet light irradiation, which proves that the coating has excellent ultraviolet light resistance.

Mechanochemical stability analysis

The morphology of the coating failure process in 3.5% artificial seawater solution was recorded to study the failure behavior of oil-absorbing PVC. It can be seen from Fig. 9a–c that the coating surface is smooth and complete at the beginning of immersion. After 5 days of immersion, the surface of the coating was uniform and smooth, and no defects such as blistering and shrinkage were observed. After soaking for 10 days, the coating appeared tiny blisters. With the extension of soaking time, the bubbling phenomenon of the coating was more obvious and slight damage occurred at 15 days. After 20 days of immersion, a large bubbling area appeared on the surface of the coating, a large area of peeling occurred on the edge coating, and the internal damage of the coating was more serious. Comparing the failure of PVC with different resin content at the same time, it was found that the higher the resin concentration, the more serious the resin bubbling and damage. This is due to the uneven size of the resin inside the high concentration resin coating, resulting in oil adsorption and swelling of the larger particle size resin particles. The separation of the coating from the surrounding resin or substrate produces voids, which aggravates the internal shedding of the coating. Consequently, it’s necessary to control the concentration of oil adsorption resin in the coating.

Resin oil adsorption capacity analysis

The composite resin was immersed in the oil to be measured, the resin quality was measured at an interval of 5 min, the oil adsorption of the resin was calculated according to the quality difference formula, and the oil adsorption rate of the resin was plotted according to the change of the quality of the composite resin over time27.

It can be seen from FIG. 10 that the adsorption saturation could be achieved within 30 min. The saturated oil adsorption ratios of resin to carbon tetrachloride, toluene, diesel oil and gasoline were 39.01 g/g, 35.69 g/g, 14.82 g/g and 17.81 g/g, respectively. According to the calculation results of the oil adsorption ratio, the adsorption kinetics was analyzed.

According to the experimental data, the adsorption kinetic constants k and correlation coefficients R were determined by the pseudo-first-order kinetic model and pseudo-second-order kinetic model. Among them, the correlation coefficient R is an indicator to measure the degree of fitting of the adsorption kinetics equation. The value range is usually between 0 and 1, and the closer to 1, the better the fitting.

The adsorption kinetics curves fitted by the pseudo-first-order kinetic model and the pseudo-second-order kinetic model of the composite resin are shown in Fig. 11, and the parameters of the corresponding kinetic model are shown in Table 1. Table 1 shows that P(BMA-SMA-St)/MIL-101(Fe) resin has (R1)2 < (R2)2 and (R2)2 is closer to 1 for the six tested oils, indicating that the resin adsorption process is combined with a pseudo-second-order kinetic model. That is, the adsorption rate of P(BMA-SMA-St)/MIL-101(Fe) resin on oil is mainly controlled by chemisorption.

Resin oil adsorption process analysis

The oil adsorption process of PVC is presented in Fig. 12. The oil adsorption process of oil-absorbing PVC is actually the oil adsorption swelling of the resin in the coating. On the one hand, in the oil–water system, the oil molecules diffuse into the resin through the resin gap, and then produce solvation with the lipophilic groups of the polymer chain. Due to the moderate crosslinking of the resin structure, the resin particles swell and do not dissolve in the oil, resulting in oil molecules stored in the three-dimensional network structure of the resin. On the other hand, MIL-101(Fe) in the resin has a larger specific surface area and a specific pore volume, which is conducive to the diffusion of oil molecules from the solution to the resin. In a neutral or acidic environment, the surface of MIL-101(Fe) carries a large amount of positive charge, which attracts negatively charged oil droplets through electrostatic interaction, further improving the adsorption capacity of PVC. In the process of surrounding the oil pollution on the water surface, the oil adsorption PVC can also achieve the adsorption of the oil floating on the surface due to the resin’s high oil adsorption ability.

Comparison with other methods

The adsorption capacity of the P (BMA-SMA-St)/MIL-101 (Fe) material against the reported material shows in Table 2, the P (BMA-SMA-St)/MIL-101 (Fe) material is competitive for both organic solvents and oils.

Conclusion

In this paper, P(BMA-SMA-St)/MIL-101(Fe) resin with excellent oil adsorption performance was dissolved in polar organic solvent tetrahydrofuran, and a series of resin coatings were prepared under the bonding action of hydroxypropyl methyl cellulose (HPMC). The paint is coated on the PVC oil fence to give the PVC oil fence oil adsorption performance. Through the indoor simulation of sea oil overflow experiment, the coated PVC oil containment boom can not only contain the performance of oil and dirt on the water surface, but also adsorb the oil slick on the water surface. When the concentration of resin in the coating is 25 g/L, the comprehensive performance of the coating is the best. The saturated oil adsorption rates of the coating for carbon tetrachloride, toluene, chloroform, kerosene, diesel and gasoline were 101.26 g/m2, 68.12 g/m2, 76.12 g/m2, 38.13 g/m2, 35.19 g/m2, 30.08 g/m2. The resin coating has good adhesion, stability and wear resistance. ASTM class of the coating is determined to be 4B; After 20 cycles of sandpaper wear, the coating still maintains good hydrophobic and oil absorbing properties. After soaking the resin coating in 3.5% artificial seawater solution for 15 days, the coating surface was uniform and smooth, and no defects such as foaming and shrinkage were found. This opens up new possibilities for the creation and use of oil-absorbing coatings.

Data availability

Data is provided within the manuscript or Supplementary Information files.

References

Anselain, T., Heggy, E., Dobbelaere, T. & Hanert, E. Qatar Peninsula’s vulnerability to oil spills and its implications for the global gas supply. Nat. Sustain. 6, 273–283 (2023).

Liu, Z. et al. Risk assessment of marine oil spills using dynamic Bayesian network analyses. Environ. Pollut. 317, 120716 (2023).

Ma, L. et al. In-depth investigation on the factors affecting the performance of high oil-absorption resin by response surface method. Chin. J. Chem. Eng. 33, 286–296 (2021).

Liu, X. et al. Recycling waste epoxy resin as hydrophobic coating of melamine foam for high-efficiency oil absorption. Appl. Surf. Sci. 1, 147151 (2020).

Chun Tong, Y., Yun Wang, Q., Feng, M., Ling He, Q. & Liu, Y. Preparing an ATP/P (n-BuMA-St)/Fe3O4 oil-absorbing resin composite via a double pickering emulsion template method and elucidation of its properties. ChemPlusChem 7, e202200100 (2022).

Zhou, Y. et al. An oil-absorbing resin with a simple polymerization system with benzyl methacrylate as a functional monomer. R. Soc. Open Sci. 10, 230343 (2023).

Bu, X. et al. Fabrication of porous carbon nitride foams/acrylic resin composites for efficient oil and organic solvents capture. Chem. Eng. J. 355, 299–308 (2019).

Han, Y. et al. Modified SiO2 microspheres/polyacrylate resin composites for the enhancement of oil-absorbing performance. Colloid Surf. A 671, 131642 (2023).

Kang, L. et al. Melamine resin-coated lignocellulose fibers with robust superhydrophobicity for highly effective oil/water separation. Sep. Purif. 279, 119737 (2021).

Li, C., Ren, X., Han, S., Li, Y. & Chen, F. The preparation and performance of bamboo waste bio-oil phenolic resin adhesives for bamboo scrimber. Forests 1, 79 (2023).

Ozkur, S., Sezgin, H., Akay, E. & Yalcin-Enis, I. Hybrid bio-based composites from blends of epoxy and soybean oil resins reinforced with jute woven fabrics. Mater. Res. Express. 1, 015335 (2020).

Wu, X., Li, J., Wang, J. & Cao, L. Poly(butyl acrylate) gel prepared in supercritical CO2: An efficient recyclable oil-absorbent. Int. J. Ind. Chem. 11, 91–99 (2020).

Yu, Z. et al. Waterborne acrylic resin co-modified by itaconic acid and γ-methacryloxypropyl triisopropoxidesilane for improved mechanical properties, thermal stability, and corrosion resistance. Prog. Org. Coat. 168, 106875 (2022).

Chen, G. et al. Self-sealing polyurethane coatings containing high oil-absorption resin for storage facility and fuel pipelines. Prog. Org. Coat. 166, 106789 (2022).

Bu, X. et al. Flower-like hollow MoS2 microspheres/acrylic resin composites for enhanced oil contaminants removal from water. Sep. Sci. Technol. 55, 1227–1238 (2020).

Cui, X. et al. Preparation of highly interconnected porous polymer microbeads via suspension polymerization of high internal phase emulsions for fast removal of oil spillage from aqueous environments. RSC Adv. 44, 25730–25738 (2019).

Li, Y. et al. Efficient C2Hn hydrocarbons and VOC adsorption and separation in an MOF with Lewis basic and acidic decorated active sites. ACS Appl. Mater. Interfaces 37, 41785–41793 (2020).

Liu, Y. et al. Synthesis of a magnetic Co@C material via the design of a MOF precursor for efficient and selective adsorption of water pollutants. J. Inorg. Organomet. Proc. 32, 700–712 (2022).

Han, L. J., Ge, F. Y., Sun, G. H., Gao, X. J. & Zheng, H. G. Effective adsorption of Congo red by a MOF-based magnetic material. Dalton Trans. 14, 4650–4656 (2019).

Qi, H., Niu, X., Wu, H. & Liu, X. Adsorption of Chromium (VI) by Cu(I)-MOF in water: Optimization, kinetics, and thermodynamics. Chin. J. Chem. 4, 1–9 (2021).

Fattahi, M. et al. Boosting the adsorptive and photocatalytic performance of MIL-101 (Fe) against methylene blue dye through a thermal post-synthesis modification. Sci. Rep. 1, 14502 (2023).

Hamza, I. et al. Removal of 4-chloro-2-methylphenoxyacetic acid from water by MIL-101(Cr) metal-organic framework: Kinetics, isotherms and statistical models. R. Soc. Open Sci. 8, 201553 (2021).

Shakly, M., Saad, L., Seliem, M. K., Petriciolet, A. & Shehata, N. New insights into the selective adsorption mechanism of cationic and anionic dyes using MIL-101(Fe) metal–organic framework: Modeling and interpretation of physicochemical parameters. J. Contam. Hydrol. 247, 103977 (2022).

Liu, Z., He, W., Zhang, Q., Shapour, H. & Bakhtari, M. Preparation of a GO/MIL-101(Fe) composite for the removal of methyl orange from aqueous solution. ACS Omega 7, 4597–4608 (2021).

Kaveh, R. et al. Ternary nanohybrid of biochar/NiFe2O4/Ag3PO4 for simultaneous adsorption of Hg (II) and photodegradation of methylene blue; modeling, kinetic and isotherm studies. J. Solid State Chem. 331, 124503 (2024).

Kaveh, R., Alijani, H. & Beyki, M. H. Oxine-mediated magnetic MnFe2O4-starch-based surface imprinted polymer toward highly selective Pb (II) targeting from aqueous environment. Microchem. J. 198, 110192 (2024).

Santos, O. D. S. H., da Silva, M. C., Silva, V. R., Mussel, W. N. & Yoshida, M. I. Polyurethane foam impregnated with lignin as a filler for the removal of crude oil from contaminated water. J. Hazard. Mater. 324, 406–413 (2017).

He, Z. et al. Facile preparation of robust superhydrophobic/superoleophilic TiO2-decorated polyvinyl alcohol sponge for efficient oil/water separation. ACS Omega 7(8), 7084–7095 (2022).

Ravi, Y., Prasanthi, I., Behera, S. & Datta, K. K. R. MIL-101 (Fe) networks supported on fluorinated graphene nanosheets as coatings for oil sorption. ACS Appl. Nano Mater. 5(4), 5857–5867 (2022).

Wang, H. et al. Superhydrophobic nanodiamond-functionalized melamine sponge for oil/water separation. Langmuir 38(37), 11304–11313 (2022).

Acknowledgements

This work was supported by the Natural Science Foundation of Heilongjiang (Grant No. LH2022E025).

Author information

Authors and Affiliations

Contributions

C.L and X. J: Conceptualization and Methodology and Editing. Y. W: Software, Supervision and Reviewing. Y.L and Y. G: Paper Writing and Editing. L. W: Software, Supervision and Reviewing. L. X: Funding acquisition, Supervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liu, C., Jia, X., Wang, Y. et al. Synthesis of a new oil-absorbing PVC oil boom and its application to maritime oil spills. Sci Rep 14, 20356 (2024). https://doi.org/10.1038/s41598-024-71437-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-71437-9