Abstract

Spraying Bentonite NanoClay as an innovative idea satisfied an urgent need for conservation of historical brick constructions. This research explores the application of Nanotechnology as a Nano-Geotechnics (NaG) and Nano Ground Improvement (NGI) techniques for fortifying the mortar between bricks in historical buildings against some environmental erosive factors. Bentonite Nanoparticles were selected because of their compatibility with mortar. They were applied via Nano Spray to mitigate holes and cracks caused by erosion. Various percentages of bentonite NanoClay (2–10%) Spray and the number of times to spray on the mortar were evaluated. Validation through field emission scanning electron microscopy imaging (FESEM/SEM), X-Ray differaction and Fluorescence analyses (XRD/XRF), Inductively coupled plasma optical emission spectroscopy (ICP-OES), Brunauer–Emmett–Teller (BET), porosity tests, water absorption time measurement, and weathering tests confirmed the efficacy and long-term stability of this method. The result indicated that double spraying of a 2% NanoClay solution proved most effective in reducing porosity, declining water absorption, and enhancing resistance to freezing and rain.

Similar content being viewed by others

Introduction

After the cave, humans experienced life in earth structures as the first shelter and gradually found how to build more enduring buildings. Although various behaviors of soil in different conditions have caused problems, nowadays, decent houses can be constructed through the climate identification and the help of soil mechanics1. In addition, Nanotechnology, with capability to change materials, presents boundless opportunities to reshape the built environment2. Brick, as one of the popular materials throughout history has formed many historical buildings. Its versatility has facilitated the creation of various structural elements like domes, arches and vaults3. Brick walls serve multiple purposes, including forming exterior and interior walls, parapets, freestanding walls, retaining walls4. Investigations indicate that the conservation of historical brick structures is vital due to their features such as high surface porosity, low strength, and vulnerability in severe climate conditions. Among these, the mortar joints, which serve as crucial binding elements, are particularly vulnerable to deterioration over time5,6,7,8,9,10,11,12,13. In general, it can be said that the resilience of the mortar is intricately tied to a myriad of factors such as climate patterns, geographical location, environment, and the type of building14. Historical mortars are generally made from a mixture of binders, aggregates, and water. Over the centuries, artisans have experimented with different additives in attempts to enhance the mortar quality and durability. For instance, in mixed mortar, quick or dead-lime, volcanic ash, sand, baked clay, rock salts, bricks, and chromite salts have been used. The binder of the mortar is usually limestone-based15,16. In the following, the applications of some mortars are defined. 1- Mud mortar: For mixing with clay and layered material. The adhesive material for mud mortar is clay. Using mud mortar is not recommended because of its low resistance to tension caused by seismic forces. 2- Lime mortar: for buildings that are built with stone and brick in the humid climate. 3- Gypsum mortars: mainly utilized in arching for materials such as brick and stone17,18.

Interest in the systematic study of ancient mortars is relatively new. In 1981, for the first time, ICCROM pioneered the creation of an ancient mortar research strategy as well as mortar repair. In order to plan appropriate protection measures for mortars, it is important to know the structure and mixture used in mortars so that we can use effective methods for these measures of protection and apply restoration to destructive factors in each case19.

The purpose of investigating Nanoscale materials is to achieve a new class of materials that can be introduced with high functionality and efficiency20. Nano soil improvement, an emerging concept in geotechnical engineering, capitalizes on nanomaterials to enhance soil properties21. Nanoparticles, with their remarkable surface-to-volume ratio, enable the creation of organic coatings with unprecedented capabilities22. Commercial nanoclays, derived from meticulously processed clay powders, exhibit enhanced UV resistance, strength, and thermal stability23,24,25. Bentonite, an omnipresent natural clay, finds widespread utility in diverse industries, notably construction and public works. It serves as a versatile additive in concrete manufacturing, soil stabilization, foundation waterproofing, agriculture, and nuclear waste containment. Noteworthy advantages of bentonite include its abundance, cost-effectiveness, water retention capacity, and ability to enhance the physical and chemical attributes of materials26,27. Commercial variants typically contain over 60–70% montmorillonite, along with other minerals like quartz, feldspar, and kaolinite, depending on their origin. Montmorillonite is the basic and active component of bentonite, and in fact, its economic importance is also determined by the amount of montmorillonite present in it28.

Bentonite's composition comprises primarily montmorillonite clay, with variations in exchange cations determining classifications such as sodium or calcium bentonite. Sometimes the words expanding and non-expanding clay are considered synonymous with this group29. Despite extensive research on Nano-additives like nanoclays for soil stabilization, their application as a spray for reinforcing and protecting historical brick mortar remains largely unexplored. also due to the lack of in-depth studies, the conservation of the mortar of historical brickworks is too limited.

In this regard, due to the presence of a large number of historical works made of bricks, it seems that research in this field should be done locally according to different climates. This research investigates the possibility of using the coating effect of Bentonite Nanoclay spray on mortar samples by examining the case study of Kashaneh Bastam Tower (Semnan, Iran). Moreover, the application of such coating in protecting brick buildings against many destructive environmental effects, such as rain and snow. The sample has been under the influence of the cold, dry, and semi-dry climate and has suffered erosion and cracks, which leads to a reduction in the strength of the mortar. It should be noted that the main materials of the Kashaneh Bastam Tower include: brick, mortar, plaster, lime, and clay in the walls of the building.

Materials and methods

The tested samples are decorative mortars between the bricks with dimensions of 4 × 4 × 6 cm, which were used in the external surface of the historical monument of Kashana Bastam Tower in Semnan province of Iran. After sampling, they were cut to the minimum required dimensions, then cleaned with a soft brush and 96% neutral ethyl alcohol and sorted for testing. Bentonite NanoClay with a density of 0.8 (gr/cm3) and a particle size of 1–2 nm is a product of Sigma Aldrich, an American company, by the commercial name of Nano clay Hydrophilic Bentonite. The chemical characteristics of Bentonite NanoClay by XRF analysis are displayed in table S4 (Supplementary materials).

Preparation of samples

To achieve the optimal proportion of Bentonite Nanoclay for spraying, the percentage of Bentonite Nanoclay used was determined in the range of 2, 4, 6, and 10 percent by weight of Nanoclay per Ethanol solvent in a volume of 100 ml. Then, all the obtained solutions were placed in an ultrasonic bath for 30 min.

Applying the spray to the samples and comparing the data were done in two steps:

The first step

In order to achieve the most effective percentage of used Bentonite Nanoclay, the area of that surface was calculated. By this technique, the required amount of solution to spray on each surface was obtained and sprayed with different percentages of Bentonite Nanoclay (for every 100 ml of solution, an area of approximately 175 square centimeters was covered). The reason for choosing the presented values is based on the comparison of the penetration of Nanoclay particles and the amount of filling per surface area of utilized samples. Furthermore, in the selection of the solvent, low surface absorption and no surface washing are considered.

The second step

After reaching the optimal percentage of nano clay based on the results of the FE-SEM test, the frequency of spraying with the optimal percentage was done with two methods to achieve the best result: in the first method; The solution with the optimal percentage was sprayed in one phase, and in the second method; The solution was sprayed with the optimal percentage in two phases. After that, the effects of both types of Nanoclay in improving the condition of the mortar were compared. Following the process, the essential samples in the required dimensions and numbers were sprayed again with the final solutions. Hence, the samples in two groups A and B were tested with five types (control sample without spray, NB2 = 2% Nanoclay, NB4 = 4% Nanoclay, NB6 = 6% Nanoclay, NB10 = 10% Nanoclay.

Nanotechnological methods

Determining the optimal percentage of Nanoclay was done based on the comparison of the hole-filling rate in all samples using the electron microscope test (FESEM/SEM) of the MIRA3 device. In this test, samples with dimensions less than 1 square centimeter were prepared. The porosity test was also done by the BET method with the mini II device. This device works without destroying the samples and using Nitrogen gas. For this test, samples were prepared with maximum dimensions of 0.4 × 0.4 × 0.3 cm. To perform the BET porosity test, all the surfaces of the samples were sprayed to obtain a more realistic amount of data. Mortar samples were tested before and after spraying with the desired percentages. For XRD, XRF, and ICP-OES tests, the tested sample was used in powder form and the amount of several grams. Ultima iv device model was used for the XRD test to check and qualitatively identify the minerals in Nanoclay. The XRF test of the X-Pert-Pro-MPD device model was used to detect the elements and oxides in Bentonite Nanoclay and determine their weight percentage, according to the ASTM E 1621–13 standard. In the ICP-OES test, the ARCOS FHS12 device was used as a replacement for traceable XRF with the Series reference standard of NIST SRM 31. The largest size of the samples related to the rain simulator test and the freezing test were prepared with dimensions of 1 × 2 × 2 cm. To evaluate the durability of the mortar samples against precipitation, the erosion test was done through the use of a rain simulator. In this test, a non-pressure drop generator was used for a specified period on the control sample and the optimal samples. The average rainfall height was 55 cm, the average diameter of the raindrops produced by the rainmaker was 4.8 mm, and the number of drops per minute at a constant speed and with a slight slope was 11%. At first, all the dimensions of the samples were accurately measured. Then, all of them were dried for 4 h in an oven at a temperature of 50 degrees Celsius, and after leaving the oven and cooling down, the exact weight of the samples was recorded before the test. According to the type of mortar (plaster mortar), the samples were prepared under artificial rain in the speed interval, 30 drops per minute in one period of rain and in two-time intervals, 30 min. They were placed in the laboratory for 16 h to reduce the humidity of their surface. Following this, they were placed at 60 degrees Celsius temperature for 4 h to dry completely. After cooling down, the weight of each one was recorded until the amount of solid material loss of the samples due to erosion under artificial rainfall was compared to their initial total dry weight. At the next step, the samples were ready for FE-SEM testing for further investigation. In this analysis, sprayed samples with optimal percentages, and initial mortar samples were tested.

Degradation testing

Since the Kashaneh Tower is located in a dry and semi-arid cold region and based on the number of frost days in this area and according to the purpose of the research about the control of snow and rain erosion, the test of frost resistance with the destruction mechanism caused by frost on the control samples and the optimal sample has been taken into consideration. To perform this test, taking into account the conditions of the mentioned region, first, all the samples were dried for 4 h in an oven at a temperature of 50 degrees Celsius, and after leaving the oven and cooling down, the samples were prepared for a Freezing/melting cycle. After that, they were subjected to artificial rain for 30 min. Then, the samples were immediately placed in a freezer at − 10 degrees Celsius for 4 h to reach freezing conditions and they were placed in the laboratory for 4 h to reduce the surface moisture of the samples. Following that, they were placed at a temperature of 60 degrees Celsius for 4 h to dry completely. Evaluation and examination of the samples were done after the end of a freezing cycle. Then, the samples were prepared for FE-SEM testing for further investigation. In this test, sprayed samples with optimal percentages and initial mortar samples were analyzed to check the resistance of the formed coating against corrosion effects and to understand the behavior of the clay nanoparticles in the long term and with the assurance of maintaining its capabilities over time and detecting the difference in its long-term properties, without nanoparticles and with the addition of nanoparticles, the aging test was done on the samples. The examined historical monument is located in a dry and semi-arid cold region and has climatic changes in different seasons of the year. Moreover, the purpose of the research is erosion control. Therefore, in this test degradation mechanism caused by changes in temperature and humidity was considered on the control samples and the optimal sample. An aging cycle was created for the samples before and after spraying as follows: according to Table S5 (Supplementary materials) in four intervals of temperature and humidity (their intensity and duration) in the fixed duration of the rapid aging cycle (12 h), the length of each stage in the heating cycle is done. The above experiment was repeated for 40 alternating periods, corresponding to 480 h of accelerated aging. The coated parts and the control sample were placed in each step so that the coated side of the samples was exposed to water vapor and humidity.

Discussion

X-Ray diffraction analysis (XRD) is employed to examine the the crystal structure of a substances23. Figure 1, A illustrates the XRD pattern of the mortar sample. According to the XRD pattern, quartz (Quartz Low SiO2) and gypsum (Gypsum H4Ca1O6S1) are observed in the sample. The results of the identified phases indicate that the gypsum phase is the largest component of this mortar. As seen by XRD analysis, the mortar has Calcium Sulfate and Silica in it, and the highest amount of Oxygen, Sulfur, and Calcium is for Calcium Sulfate, and Silicon and Oxygen are for Silica. In Fig. 1, B displays the Nitrogen absorption and desorption curve (BET), and C shows the pore size distribution (BJH) of the historical mortar sample. The results demonstrate that the surface area is equal to 18.56 square meters per gram, the volume of the holes is 0.064 cubic centimeters per gram, and the average size of the holes is equal to 14.00 nm. Based on the hole size distribution curve, most of the holes are less than 1.85 nm. Scanning electron microscopy (SEM) is a powerful imaging technique utilized to investigate the micro and nano scale structure and composition of materials23. In Fig. 1, SEM shows the mortar, according to which the surface erosion of the mortar can be seen in the form of pores and cracks. The magnification of images D and E are 1 and 20 µm respectively. Covering the historical mortar with Nanoclay spray In this research, various tests were conducted on the durability of the coated mortar compared to the raw mortar (control mortar). We will review them below:

Recognition of historical mortar. X-ray diffraction pattern of historical mortar (A), The nitrogen absorption and desorption curve (BET), and the pore size distribution (BJH) of the historical mortar sample (B and C), Scanning Electron Microscopy (SEM) displays the cracks and pores of the mortar with the magnification of 1 and 20 µm (D and E).

Optimal number and percentage of Nanoclay spraying

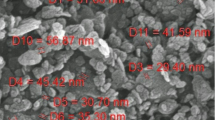

At first, to determine the optimal percentage of Nanoclay based on the filling rate of the holes, SEM was taken from the sprayed mortar samples. Figure 2A displays the images of control and sprayed mortar samples with 2, 4, 6, and 10% Nanoclay, and Fig. 2B–K shows the SEM images of the samples. Figure 2A shows the creation of a layer of Nanoclay coating on the mortar surface intuitively. The comparison of the pictures shows that in picture a, the control sample of the mortar surface has corrosion and small cracks in different parts. In picture b, for instance, with a 2% spray of Nanoclay, small cracks can still be seen in some places on the surface of the mortar. In picture c, the sample is covered with 4% Nanoclay spray in one step, the cracks are very hard to detect. In picture d, the sample is covered with 4% Nanoclay spray in two steps, it has a uniform surface without any cracks. In picture e, the sample is covered with 6% Nanoclay spray. It becomes difficult to detect cracks and the surface appears to be integrated and free of cracks but a cumulative coating of Nanoclay can be seen on the surface in some places. In picture f, with 10% Nanoclay spray on the surface of the mortar, the formation of new and hairy cracks can be seen, because the surface of the sample is covered with Nanoclay spray too much. consequently, it was avoided to spray the surface of the samples with a higher percentage.

A images of control and sprayed mortar samples. control and sprayed mortar samples with 2, 4, 6, and 10% nanoclay (A), The control sample of the mortar surface (a), covered with a 2% solution of nanoclay (b), a sample solution with 4% nanoclay in one spraying step (c), the sample sprayed with 4% nanoclay solution in two spraying stages (d), B–K SEM images of the sprayed samples, Covered with the 2% solution of Nanoclay NB2 (B, C). Covered with a 4% Nanoclay solution of one spray step NB4-1 (D–E). With a 4% solution of two-step Nanoclay spray NB4-2 (F–G). Covered with a 6% solution of Nanoclay NB6 (H–I). with a solution of 10% Nanoclay NB10 (J–K). images with 200 nm magnification were prepared from the one-stage and two-stage spray samples (L–M).

From the comparison of the SEM images of the sprayed samples (Fig. 2B–K) with the control sample (Fig. 1D–E), it can be seen that in the microscopic images (B-C), although the surface of the Nanoclay coating is uniform in the sample, the cracks are not filled and still exist. Therefore, the 2% solution of Nanoclay (NB2) was rejected for further experiments. In the microscopic images (H-I) with an increase of 6% of Nanoclay (NB6), although it becomes difficult to detect cracks and the surface appears to be integrated and free of cracks, a cumulative coating of Nanoclay can be seen on.

the surface in some places. In this sense, this amount of Nanoclay is not a suitable percentage to solve the problem of cracks and holes in the primary mortar. In the microscopic images (J-K) with an increase of 10% Nanoclay (NB10), the formation of new and excess cracks on the surface of the mortar was observed compared to other samples. therefore, this amount of Nanoclay is not considered a suitable percentage. But the microscopic images (D-E) with a 4% Nanoclay solution of one spray step (NB4-1) show a better coverage of Nanoclay particles on the surface and the cracks are very hard to detect.

In the microscopic images (F–G) with a 4% solution of two-step Nanoclay spray (NB4-2), it can be seen that there is a single layer of Nanoclay coating and no cracks. At this stage, to obtain a more accurate result from these two samples NB4-1 and NB4-2, as seen in Fig. 2, microscopic images L and M with 200 nm magnification were prepared from the one-stage and two-stage spray samples. According to these images, the use of 4% Nanoclay spray in two steps compared to the sample of 4% Nanoclay spray in one step, due to the lower thickness of the sprayed layer, the penetration of Nanoclay particles is better and it fills more holes and cracks in the mortar sample. So, it has a more complete and effective cover. Based on this, double spraying with 4% Bentonite Nanoclay was selected as the optimal percentage (opt).

Effects of Nanoclay spray on surface water absorption

Table S1 (Supplementary materials) shows the surface water absorption time in the control sample by reducing the water surface absorption time in the sprayed samples with both types of spray methods; It shows 4% Nanoclay in one step spraying (NB4-1) and 4% Nanoclay in two spray steps (NB4-2). According to the results, the correctness of choosing the optimal percentage by spraying the samples in two stages was assured and this sample showed a better performance in this test.

Porosity percentage

Considering Fig. 3, BET curve displays that the surface area of the sample covered with NB4-2 Nanoclay (double spray of 4% Nano-Bentonite solution) is equal to 18.67 square meters per gram, the volume of the holes is 0.064 cubic centimeters per gram, and the average size of the holes is equal to 13.91 nm. BJH curve also shows that most of the holes are less than 1.85 nm. While, Fig. 1 illustrates that the surface area of the control sample is equal to 18.56 square meters per gram, the volume of the holes is 0.064 cubic centimeters per gram, and the average size of the holes is equal to 14.00 nm. BJH curve also shows that the most holes are less than 1.85 nm. By examining and comparing the BJH and BET curves of the mortar samples in Fig. 1 with the NB4-2 sprayed sample, in Fig. 3, considering the number of filled holes and the surface porosity of the samples before and after spraying, conclude that the sample sprayed with Bentonite Nanoclay may have performed better in this test than the control sample. The reason for this increase in porosity can be considered to be very fine holes covered with Nanoclay.

Effects of precipitation on Nanoclay spray

Before and after the test (Table S2 (supplementary materials)), the control mortar sample and NB4-2 sample were weighed, then SEM images were prepared from them. By examining the samples according to Table S2, it was observed that the sample sprayed with Nanoclay had a lower erosion rate than the control sample. Also, from a comparison of Fig. 4A and B of the control mortar sample after performing the rain simulator test with the sample before performing this test, it is concluded that the size of the cracks has decreased. The sample sprayed with Bentonite Nanoclay still has more suitable conditions than the control sample, and according to the objectives of this research, it is more effective.

Effects of freezing on Nanoclay spray

By weighing the samples before and after this test, the following results were obtained. According to Table S3 (Supplementary materials) the sample sprayed with NB4-2 has a lower erosion rate than the control sample. Then, they were compared with the control sample through the preparation of microscopic images, examination of the structure of the particles, and the amount of Bentonite Nanoclay spray coverage with the optimal percentage and its effects on the cracks and voids resulting from erosion on the surface of the samples before and after the frost resistance test. In Fig. 5A, FE-SEM obtained from the control sample with a magnification of 20 µm shows the presence of holes and a porous surface in it and after performing the resistance test against frost, the texture and size of the cracks compared to the control sample before performing this test (Fig. 2F–G) has been changed and the crack distance is less than 20.20 µm.

In the Fig. 5B samples of mortar sprayed with the optimal percentage of NB4-2 spray after performing the frost resistance test with a magnification of 20 µm can be seen that it still maintains its uniform surface after performing the frost resistance test. However, the size of the cracks has changed and the distance between them has reached less than 5.43 µm, the cover of the surface is still uniform.

By comparing these samples after performing the frost resistance test, with the conditions before performing this test, it can be concluded that: Although there is an incremental change in the size of the cracks and the distance between the pores of both samples of the mortars, the samples sprayed with Bentonite Nanoclay have more suitable conditions than the control sample and they have more effective performance.

The effect of nano spray on samples

In the accelerated aging test, the control and optimal samples of NB4-2 were examined after 40 alternating periods of repetition during the cold-heat cycle for 480 h. Then, microscopic images with a magnification of 20 µm were prepared for the control mortar samples and the NB4-2 sample after performing the accelerated aging test, which can be seen in Fig. 6. According to Fig. 6B, the mortar sample sprayed with the optimal percentage.

of NB4-2 spray still has a uniform surface of the Nanoclay coating after the aging test. In this experiment, better and more effective performance and cohesion of the optimal sample of NB4-2 can be observed in advancing the goals of this research.

Result

In this research, we have delved into the impact of Bentonite Nanoclay spray on strengthening and protecting the mortar between bricks of the historic buildings, utilizing a range of tests including FE-SEM, SEM, BET porosity measurement, contact angle measur ement, rain simulator, and frost resistance tests. Our findings shed light on the effectiveness of this innovative approach in preserving historical structures. Through detailed analysis of FE-SEM and BET test results, we have observed that the Bentonite Nanoclay spray effectively infiltrates the mortar, filling voids and forming a uniform surface layer. This infiltration not only enhances the mortar's structural integrity but also reduces water absorption, crucial for protecting against moisture-related damage. Our investigation into the resistance of Bentinite nanoclay-sprayed mortars against moisture and water absorption further confirms the efficacy of this approach. Particularly, the NB-2 sample demonstrates superior performance compared to NB-1, showcasing its potential as an optimal choice for building preservation. By comparing images from FE-SEM and BET tests, we have documented the significant improvements brought about by the Bentonite Nanoclay Spray, including reduced voids and increased mortar strength. Notably, the application of double spray of 4% solution effectively fills empty spaces and reinforces the mortar between the bricks. Nanospray technology emerges as a swift and eco-friendly alternative to traditional reinforcement methods, aligning with the principles of cultural heritage conservation. Our research underscores the Bentonite Clay Nanoparticle Spray as an effective solution for fortifying historical mortar. Ultimately, prolonging the lifespan of cherished historical buildings.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Change history

10 December 2025

A Correction to this paper has been published: https://doi.org/10.1038/s41598-025-30693-z

References

Wolfskill, L. A., Dunlap, W. A. & Gallaway, B. M. Handbook For Building Homes of Earth, Translated by tabesh (H. Institute of University Publication, 1987).

Niroumand, H., Zain, M. F. M. & Jamil, M. The role of nanotechnology in architecture and built environment. Soc. Behav. Sci. 89, 10–15 (2013).

Niroumand, H., Zain, M. F. M. & Jamil, M. Various types of earth buildings. Soc. Behav. Sci. 89, 226–230 (2013).

Almssad, A., Almusaed, A. & Homod, R. Z. Masonry in the context of sustainable buildings: A review of the brick role in architecture. Sustainability 14, 14734 (2022).

Silveira, D., Varum, H., Costa, A. & Neto, C. Survey of the facade walls of existing adobe buildings. Int. J. Architect. Herit. 10(7), 867–886 (2016).

Zabihi, Sh. Pathology of Brick-Made Decoration of Chahar Bagh School of Isfahan, MSc Thesis, Art University of Isfahan, Iran (1997).

Amin-Shirazi Nejad, Sh. Investigation of Paraloid as Adhesive and Consolidant Material at Climatic Conditions of Iran, MSc Thesis, Art University of Isfahan, Iran (1998).

khakban, M. The Examination of Renovation Materials for Application in Historic Work Conservation in Guilan Region, MSc Thesis, Art University of Isfahan, Iran (1997).

Bater, M., Abed Esfehani, A. & Paidar, H. Structural studies of haft Tappeh’s cuneiform tablets. Iran. J. Cryst. Mineral. 13, 155–166 (2005).

Vahidzadeh, R. The Examination of Glaze Decorative Production Process Related to Architectural Middle Elam and Analysis of its Damages, MSc Thesis, Art University of Isfahan, Iran (2005)

Sadat-Shojai, M. & Ershad-langroudi, A. Polymeric coatings for protection of historic monuments: Opportunities & challenges. J. Appl. Polym. Sci. 112, 2535–2551 (2009).

Honeyborne, D.B. Weathering and Decay of Masonry, Conservation of Building and Decorative Stone, v.1, Edited by J. Ashurst and F.G. Dimes, Butterworth-Heinemann Series in Conservation and Museology, London (1990)

Amoroso, G. G. & Fassina, V. Stone Decay and Conservation (Elsevier, Amsterdam, 1983).

Mokhtarian, A. Pathology and Restoration of Historical Buildings (Parsia, Iran, 2017).

Bayraktar, A. Analysis of Historical Monuments and Seismic Retrofitting Methods, Translated by Nezhatzadeh (S. Publications of the Research Institute of Cultural Heritage, 2013).

de Oliveira, L. M. et al. Investigation of the mortars and clay bricks of a luso-brazilian historic structure from XVIII century: The Nosso Senhor do Bonfim Church. J. Build. Eng. 1(45), 103592 (2022).

Ali khan, M. Earthquake-Resistant Structures, London, (2013)

Bozorgmehri, Z. Mortar, plaster of Clay and Straw, Ornaments, Cultural heritage Organization, Iran (2009)

Palomo, A., Blanco-Varela, M.T., Martinez-Ramirez, S., Puertas, F. and Fortes, C. Historic mortars: characterization and durability. New tendencies for research. In Advanced Research Centre for cultural heritage interdisciplinary projects, Fifth Framework Programme Workshop (2002)

Zahedi, M., Sharifipour, M., Jahanbakhshi, F. & Bayai, R. Nanoclay performance on resistance of clay under freezing cycles. J. Appl. Sci. Environ. Manag. 18(3), 427–34 (2014).

Niroumand, H., Balachowski, L. & Parviz, R. Nano soil improvement technique using cement. Sci Rep 13, 10724 (2023).

HuaWu, Z., Shen, Sh. Jian“Chemical Reviews “. vol 109 “pp. 3893–3957 (2008)

Ghasabkolaei, N., Choobbasti, A. J., Roshan, N. & Ghasemi, S. E. Geotechnical properties of the soils modified with nanomaterials: A comprehensive review. Arch. Civil Mech. Eng. 17(3), 639–50 (2017).

Ouhadi, V. R. & Amiri, M. Geo-environmental behaviour of nanoclays in interaction with heavy metals contaminant. Amirkabir J, Civil 42(3), 29–36 (2011).

Melo, J. V. S. & Trichês, G. Effects of organophilic nanoclay on the rheological behavior and performance leading to permanent deformation of asphalt mixtures. J. Mater. Civ. Eng. 28(11), 04016142 (2016).

Cheraghalikhani, M., Niroumand, H. & Balachowski, L. Micro- and nano- bentonite to improve the strength of clayey sand as a nano soil-improvement technique. Sci Rep 13, 10913 (2023).

Grim, R.E., Güven, N. Developments in Sedimentology, Elsevier, Chapter 5 Properties and Uses of Bentonite, Volume 24, Pages 217–248, (1978)

Inglethorpe S.D.J., Morgan D.J., Highley D.E., and Bloodworth A.J. Thchinal reportWG/93/20. Mineralogy and Petrology Series. British Geological Survey. 1–115 (1993)

Adamis Z. and Williams R.B. Bentonite, kaolin, and selected clay minerals. Environmental Health Criteria. World Health Organization Library, Vol. 231. Cataloguing-in-Publication Data, Geneve. (2005)

Author information

Authors and Affiliations

Contributions

S. J., H.N. and M.A. wrote the main manuscript text and S.R. and L.B. prepared figures and tables. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this Article was revised: The original version of this Article contained an error in the graph and its associated numerical values, as the result, the corrections were made in the Discussion section and Figure 3. Full information regarding the corrections made can be found in the correction for this Article.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jalalifar, S., Niroumand, H., Afsharpour, M. et al. Impact of spraying commercial Bentonite Nanoclay on fortification of the mortar as Nano Sprying Technique (NST) in heritages and historical buildings. Sci Rep 14, 21300 (2024). https://doi.org/10.1038/s41598-024-72414-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-72414-y