Abstract

The study is based on a section of the Zhengzhou Metro Line 8 quasi-rectangular shield tunnel. Field excavation trials were conducted to analyze the surface settlement patterns caused by the construction of a large-section quasi-rectangular shield tunnel in the rich water sand layer in Zhengzhou. Based on the characteristics of the rich water sand layer, ground settlement control measures were proposed. The research findings show that the surface settlement caused by the construction of the large-section quasi-rectangular shield tunnel in the rich water sand layer exhibits a temporal curve pattern of slow settlement (Stage I: pre-arrival of the shield), rapid settlement (Stage II: shield passage, Stage III: shield tail exiting 14.4 ~ 18 m), and stable settlement (Stage IV: late settlement). In Stage I, controlling the excavation rate to maintain balance between the cutter face pressure and soil pressure is effective. In Stage II, injecting lubricating mud between the shell and the sand layer to reduce soil friction and shear slip is recommended. In Stage III, increasing the synchronous grouting volume at the shield tail and adjusting grouting pressure, as well as timely filling the shield tail construction gap, are effective methods to reduce surface settlement. The Peck formula was used to fit the transverse settlement trough on the surface, with a linear correlation coefficient R²=0.983, validating the use of the Peck formula to predict surface settlement troughs for quasi-rectangular shield tunneling in the rich water sand layer. These research findings can provide data support and reference for similar projects.

Similar content being viewed by others

Introduction

The technology of large-section quasi-rectangular shield tunnels in urban metro tunnel projects, which enables the formation of dual-line tunnels in one go, effectively increases section utilization, saves urban underground space resources, and minimizes impacts on the surrounding environment, is gradually being widely applied. However, the large dimensions of rectangular tunnel sections often result in sizable building voids, and the low early strength of the synchronous grouting slurry makes it difficult to control ground deformation, leading to significant surface settlement and posing serious challenges to the safety and stability of the surrounding environment.

Currently, there have been numerous studies in China focusing on surface settlement caused by the excavation of rectangular shield tunnels. In terms of field measurements, based on monitoring data from the Ningbo Metro Line 3 construction site, Si et al.1 analyzed the vertical deformation characteristics of the strata caused by the construction of rectangular shield tunnels in soft soil layers. Building upon this analysis, Ji et al.2 constructed a model of surrounding strata deformation induced by rectangular tunnel construction. Cheng et al.3 utilized monitoring data from the Hangzhou Metro to study the impact of rectangular tunnel construction on the surrounding environment in cases where there is no superposition or superposition with existing metro tunnels.

In theoretical calculations, Wei et al.4 studied the vertical displacement of soil caused by rectangular shield tunnel construction based on Mindlin displacement solutions and stochastic medium theory. Chen et al.5 employed elastic mechanics Mindlin solutions to analyze additional stress in soil induced by rectangular shield tunnel construction. Zhang et al.6, based on Mindlin displacement solutions, used numerical integration and superposition principles to analyze surface deformation caused by construction. Zhang et al.7 proposed a method for calculating soil deformation induced by rectangular shield tunnel construction based on the mirror method and the Winkler foundation model. Wei et al.8, based on stochastic medium theory and cumulative probability curves, calculated vertical soil displacement. Xiao et al.9, based on Verruijt solutions and integral methods, derived analytical solutions for soil response.

Regarding model experiments, Wei et al.10,11 investigated longitudinal deformation of surface and deep soil through indoor reduced-scale model tests. Zhang et al.12 established an excavation model test system to analyze the distribution and development of free-field soil displacement induced by rectangular tunnel construction.

In numerical analysis, Ma et al.13 used three-dimensional numerical simulation technology to explore the influence of advance pressure on surface settlement ahead of the excavation face. Chen et al.14, using finite element software, analyzed the influence of construction factors on strata deformation. Deng et al.15 conducted numerical simulations and sensitivity analyses on various construction factors. Tang et al.16 simulated the entire construction process of rectangular shield tunnels and analyzed the effects of advance pressure and grouting materials on strata deformation and surface settlement.

Influenced by the shield construction process, the shield tunnel construction will inevitably cause the loss of the ground layer, which will lead to uneven ground settlement. Scholars in various countries have conducted predictive studies on the ground settlement caused by circular shield tunnel boring construction, and the main methods are as follows: ① empirical method17,18; ② theoretical analysis method19,20; ③ random medium theory21,22; ④ the boundary element method23,24; ⑤ the finite element analysis method25,26; ⑥ model test method27,28. In summary, there are fewer studies on the effect of quasi-rectangular shield tunnel excavation on surface settlement. It is the first time in China to carry out excavation construction in the typical high permeability sand layer in Zhengzhou. Influenced by the characteristics of high permeability, abundant water, and high water pressure in the highly permeable sand layers, phenomena such as water and sand influx may occur during the excavation process, leading to significant strata settlement and subsequent ground collapse, damaging surface structures. Therefore, based on a section of the Zhengzhou Metro Line 8 as the project foundation, this study conducted onsite excavation experiments for quasi-rectangular shield tunnel construction in highly permeable sand layers in Zhengzhou. It analyzed the surface settlement patterns induced by quasi-rectangular shield tunnel construction and proposed corresponding control measures for surface settlement. The research findings can provide construction technical references and data support for similar projects.

Engineering background and geological conditions

Project overview

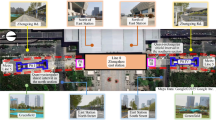

The actual engineering of a large cross-section rectangular shield tunnel for Zhengzhou Metro Line 8 is shown in Fig. 1. The project is located within the scope of Zhengzhou East Railway Station, with sensitive and complex geological conditions and surrounding environments. The cross-section rectangular shield tunnel segment needs to pass under North Street and South Street of East Station and traverse existing operational subway Line 5 tunnel and other important infrastructure. The construction process of the cross-section rectangular shield tunnel requires a high level of precision control.

Geological conditions

The segment of the quasi-rectangular shield tunnel is constructed using one 11.83 m × 7.27 m rectangular earth pressure balance shield tunneling machine. The tunnel section is 87.473 m long, with a maximum longitudinal gradient of -26‰, and the top cover soil is buried at a depth of 17.26 m to 18.17 m. The main geological formations traversed in the section are: layer ②41, consisting of fine sand, and layer ②51, consisting of silty sand. Groundwater mainly exists in the layers of fine sand and silt. Groundwater recharge mainly comes from precipitation infiltration, surface water infiltration, and lateral groundwater flow. There is no surface water within the segment of the rectangular shield tunnel. The stable groundwater level depth ranges from 8.9 m to 12.1 m (absolute elevation 76.59 m to 77.55 m). The segment’s plan axis starts with a gentle curve and ends with a straight line, while the longitudinal axis is a variable gradient segment (-26‰ to 2‰). The longitudinal cross-section of the geological formations in the rectangular shield tunnel section is shown in Fig. 2. The physical and mechanical parameters of each soil layer are listed in Table 1.

Monitoring results and analysis

Monitoring plan

To explore the ground settlement pattern induced by the construction of a large-section quasi-rectangular shield tunnel in the Fushui sand layer in Zhengzhou, multiple ground settlement monitoring sections are arranged along the excavation direction of the shield tunnel. The monitoring points are distributed approximately 30 m on each side of the tunnel centerline.

The study selects three ground settlement monitoring sections above the excavation positions of the 40th, 45th, and 50th rings from the North Departure Shaft (I Foundation Pit) to the North Receiving Shaft as research objects, denoted as DBC40, DBC45, and DBC50 respectively. The layout of the monitoring sections is illustrated in Fig. 3. DBC40 and DBC45 are small monitoring sections, each with five measurement points positioned above and 3 m, 6 m to the left and right sides of the tunnel centerline. They are numbered from left to right as 1 to 5. The large monitoring section has 15 measurement points, positioned above and 3 m, 6 m, 11 m, 16.6 m, 19.7 m, 22.8 m, and 27.8 m to the left and right sides of the tunnel centerline, numbered from left to right as 1 to 15. The profile layout of the DBC50 monitoring section is shown in Fig. 4.

Surface settlement

According to the law of the time-history curve of measured data, the spatial relationship between the shield machine and the monitoring section is divided into four stages (as shown in Fig. 5; Table 2), namely Stage I: Before the shield machine arrives (as shown in Fig. 5a), Stage II: Shield passing (as shown in Fig. 5b), Stage III: Shield tail exits 14.4 ~ 18 m (as shown in Fig. 5c), and Stage IV: Later settlement (as shown in Fig. 5d). In the text, the notation of “+” for settlement values indicates uplift, and “- ” indicates settlement.

Figures 6 and 7, and 8 respectively depict the time-history curves of surface settlement for monitoring sections DBC40, DBC45, and DBC50. From the figures, it can be observed that the overall trend of surface settlement is similar, showing a pattern of gradual settlement, rapid settlement, and stable settlement. The maximum cumulative settlement of the surface is located at monitoring points DBC40-3, DBC45-3, and DBC50-8, which are above the tunnel centerline. The maximum settlement values are − 41.58 mm, -39.55 mm, and − 44.84 mm respectively.

As shown in Figs. 6 and 7, and 8, during Stage I: Before the shield machine arrives, this stage is characterized by a period of gradual settlement, indicating initial settlement of the surface. The analysis of its cause reveals that the excavation of the shield machine leads to changes in pore water pressure ahead, resulting in consolidation settlement of the soil. The phenomenon of increased surface settlement 6 ~ 7.2 m ahead of the excavation face is caused by disturbance of the soil ahead due to the cutterhead excavation while the face is in a slightly under-pressure state. The variations in surface settlement at monitoring points DBC40-3, DBC45-3, and DBC50-8 during this stage are 4.61 mm, 3.67 mm, and 3.99 mm respectively, accounting for 11.09%, 9.28%, and 8.90% of the final cumulative surface settlement.

Stage II: When the shield passes through, the ground enters a rapid settlement period. This is because there is a hinge gap between the front shield and the middle shield, the diameter of the cutter head is larger than the outer diameter of the shield, resulting in over-excavation clearance, and factors such as shear and compression of the surrounding soil under the friction of the shield cause rapid increase in ground settlement. At this stage, the ground settlement changes at monitoring points DBC40-3, DBC45-3, and DBC50-8 are 19.25 mm, 12.05 mm, and 20.69 mm respectively, accounting for 43.30%, 30.47%, and 46.14% of the final cumulative settlement.

Stage III: When the shield tail exits at 14.4 to 18 m, the ground also enters a rapid settlement period. This is because the diameter of the shield machine is larger than the outer diameter of the lining pipe, causing the construction gap to not be filled with grout in a timely manner, and the low early strength of the grout causes collapse of the surrounding soil around the shield. At this stage, the ground settlement changes at monitoring points DBC40-3, DBC45-3, and DBC50-8 are 11.75 mm, 17.64 mm, and 14.48 mm respectively, accounting for 28.25%, 44.60%, and 32.29% of the final cumulative settlement.

Stage IV: In the later settlement stage, the ground enters a stable settlement period. This is because the disturbance of the shield advancement on the surrounding soil dissipates the pore water pressure generated, causing consolidation settlement and creep settlement of the soil layer, and the ground settlement gradually tends to be stable. At this stage, the ground settlement changes at monitoring points DBC40-3, DBC45-3, and DBC50-8 are 5.97 mm, 6.19 mm, and 5.68 mm respectively, accounting for 14.36%, 15.65%, and 12.67% of the final cumulative settlement.

Lateral ground settlement trough

Figure 9 shows the cumulative surface deformation at various stages of the DBC50 monitoring section, with the shaded area representing the surface range corresponding to the shield outline. Before the shield reached the monitoring section, initial settlement occurred within 6 m, with minimal differences in settlement at each measurement point. As the shield advanced, the depth of the surface settlement trough increased while its width remained relatively constant. The influence range of surface settlement caused by shield excavation was within 20 m on either side of the tunnel centerline (approximately twice the tunnel width). The settlement values on the right side of the tunnel centerline were slightly smaller than those on the left side, with noticeable bulging of the soil above on the right side, preliminarily attributed to the deviation of the shield posture.

Figure 10a–c respectively fit the final settlement data of monitoring sections DBC40, DBC45, and DBC50 using the Peck formula. The linear correlation coefficients ( R2 ) for the fitted curve of monitoring section DBC50 are 0.983, with a settlement trough width parameter (K = 0.383) and a ground loss rate (Vl = 1.366%). This indicates that using the Peck formula to predict surface settlements caused by large-section quasi-rectangular shield tunnel construction in the Zhengzhou Fushui sand layer is feasible.

Settlement control measures

According to the surface settlement law during the construction of large-section rectangular shield tunnels crossing through rich water and sand layers as described above, the following surface settlement control measures are proposed:

During over-excavation in the rich water and sand layers, due to the small cohesive force of the soil, the front soil may undergo compression and shear failure, which may lead to pipe jacking and cause greater surface settlement, especially under high water pressure. During under-excavation, there may be an increase in surface settlement within 6 to 7.2 m ahead of the excavation face, as mentioned earlier. Therefore, to control the surface settlement in front of the cutterhead, it is necessary to maintain the balance of soil pressure by controlling the excavation rate reasonably.

To reduce the surface settlement during the passage of the shield tunnel, low-friction slurry can be injected into the surrounding soil layers to reduce the effect of frictional resistance, thereby reducing the shear slip effect on the surrounding soil.

To reduce the surface settlement after the shield tail breakout, the synchronous grouting volume can be appropriately increased to fill the shield tail construction gap adequately, and the grouting pressure can be adjusted appropriately to balance the relationship between filling gaps and grouting-induced shear disturbances, and to match the early strength of the synchronous slurry with the excavation speed.

When the shield machine rotates around the longitudinal axis, it will produce obvious squeezing effect on one side of the soil, causing bulging of the soil on that side. This creates voids in the strata above the shell on the other side, thereby increasing the settlement of the soil on that side. Therefore, to reduce surface settlement, attention should be paid to controlling the attitude of the shield machine.

Conclusions

This paper takes a section of the Zhengzhou Rail Transit Line 8 as the engineering background and conducts on-site excavation tests of a certain type of quasi-rectangular shield tunnel. It investigates the surface settlement law during the construction of large-section quasi-rectangular shield tunnels in rich water and sand layers. The following main conclusions are drawn:

(1) Considering the spatial positioning of shield and monitoring sections, the construction of large-section quasi-rectangular shield tunnels in Zhengzhou’s rich water and sand layers shows distinct settlement stages: slow settlement (Stage I before shield arrival), rapid settlement (Stage II during shield passage, Stage III at shield tail breakout between 14.4 and 18 m), and stable settlement (Stage IV post-settlement). To manage these conditions effectively, it is recommended to balance cutterhead frontal pressure with soil pressure by adjusting excavation rates. Implementing low-friction slurry between the shield shell and sand layer can mitigate soil friction and shear slip. Enhancing synchronous grouting at the shield tail and promptly filling construction gaps, while matching grouting slurry strength with construction speed, and controlling shield machine attitude, are crucial for controlling surface settlement.

(2) The Peck formula was used to fit the lateral surface settlement trough data of the DBC50 monitoring section, resulting in a linear correlation coefficient (R2) of 0.983. The width parameter of the settlement trough (K) was calculated as 0.383, and the stratum loss rate (Vl) was determined to be 1.366%. This indicates that using the Peck formula to predict surface settlement troughs caused by the construction of large-section quasi-rectangular shield tunnels in the rich water and sand layers of Zhengzhou is feasible.

Data availability

Some or all data, models, or code that support the findings of this study are available fromthe corresponding author upon reasonable request. These items include detailed output for all analyzed scenarios.

References

Si, J. B., Zhu, Y. H., Ji, C. & Zhou, S. H. Measurement and analysis of vertical deformation of stratum induced by quasi-rectangular shield tunneling in soft ground. Chin. J. Rock Mechan. Eng. 36(06), 1551–1559 (2017).

Ji, C., Zhu, S. H., Zhu, Y. H., Wang, L. S. & Si, J. B. Surrounding strata deformation pattern under the interaction between shell of quasi-rectangular shield and soft soil. Chin. J. Rock Mechan. Eng. 36(S1), 3644–3655 (2017).

Cheng, G. M., Gui, Y. P., Ding, Z., Liu, S. X. & Jinag, Y. J. Measurement and analysis of quasi-rectangular shield over-crossing an existing tunnel in water-rich sand strata. Low Temp. Archit. Technol. 44(06), 141–145 (2022).

Wei, G., Zhang, X. H. & Xu, Y. F. Deriving vertical displacement of ground due to quasi-rectangular shield tunneling considering multiple factors. Chin. J. Rock Mechan. Eng. 37(01), 199–208 (2018).

Chen, A., Zhang, X. H., Bai, Y., Huang, D. Z. & Huang, Y. Analysis of the superimposed stress of soil layer induced by quasi rectangle EPB shield tunneling. Chin. J. Rock Mechan. Eng. 36(07), 1813–1819 (2017).

Zhang, X. H., Chen, J. X., Bai, Y., Chen, A. & Huang, D. Z. Ground surface deformation induced by quasi-rectangle EPB shield tunneling. J. Zhejiang Univ. (Engineering Science). 52(02), 317–324 (2018).

Zhang, Z. G., Shi, M. Z., Zhang, C. P., Wei, G. & Wang, Z. W. Research on deformation of adjacent underground pipelines caused by excavation of quasi-rectangular shields. Chin. J. Rock Mechan. Eng. 38(04), 852–864 (2019).

Wei, G., Zhao, D. Q. L. & Qi, Y. J. Determination of vertical displacement of an existing tunnel caused by underpass of quasi-rectangular shield tunnel. Tunn. Constr. 42(06), 960–966 (2022).

Xiao, F. Q., Zhu, C. B., Gan, X. L., Yu, J. L. & Gong, X. N. Analytical solution for soil settlements due to quasi-rectangular shield tunneling. Railway Standard Des. 68(03), 172–176 (2024).

Wei, G., Wang, Z., Cai, S. G., Xu, X. & Hong, Z. H. Model tests on influences of quasi-rectangular shield construction on underground pipelines. Chin. J. Geotech. Eng. 41(08), 1489–1495 (2019).

Wei, G. & Zhao, D. Q. L. Model tests on soil settlement caused by quasi-rectangular shield passing through adjacent existing tunnels. J. Railway Sci. Eng. 20(01), 222–232 (2023).

Zhang, Z. G. et al. Model test study on ground settlement caused by excavation of quasi-rectangular tunnels in soft soils. Mod. Tunn. Technol. 57(S1), 762–771 (2020).

Ma, X. F., Huang, D. Z. & Li, G. 3D Numerical Simulation of the Ground Settlement affected by the Quasi-rectangular Shield Construction. Mod. Tunn. Technol. 53(S1), 265–268 (2016).

Chen, J. M., Ji, C., Zhou, S. H., Si, J. B. & Wang, L. S. Settlement law of stratum in soft ground area during construction period of quasi-rectangular EPB shields. Mod. Tunn. Technol. 53(S1), 257–264 (2016).

Deng, S. J., Xiao, G. L., Hu, X. D., Bai, Y. & Chen, A. Numerical simulation and analysis of construction factors affecting quasi-rectangular shield tunnelling. Mod. Tunn. Technol. 53(S1), 232–239 (2016).

Tang, J. X., Wang, L. S., Ji, C. & Kou, X. Y. Three-dimensional numerical analysis of ground deformation induced by quasi-rectangle EPB shield tunneling. J. China Jiaotong Univ. 33(01), 9–15 (2016).

Peck, R. B. Deep excavations and tunneling in soft ground. In Proceedings of the 7th International Conference on Soil Mechanics and Foundation Engineering. Mexico City, 7, 225–290 (1969).

Wang, J., Zhou, P., Song, Z., Li, S. & Zhang, Q. A new calculation method for tunneling-caused stratum settlement. KSCE J. Civ. Eng. 26(6), 2624–2640 (2022).

Sagaseta, C. Discussion: analysis of undrained soil deformation due to ground loss. Geotechnique. 38, 647–649 (1988).

Yu, L. et al. Semi-analytical solutions of three-dimensional ground movements due to shallow tunnelling. Tunn. Undergr. Space Technol. 136, 105074 (2023).

Han, X. & Li, N. Comparative analysis of strata prediction models for ground movement induced by tunnel construction. Chin. J. Rock Mechan. Eng. 26(3), 594–597 (2007).

Yang, J. S., Liu, B. C. & Wang, M. C. Modeling of tunnelinginduced ground surface movements using stochastic medium theory. Tunn. Undergr. Space Technol. 19, 113–123 (2004).

Liao, S. M., Yu, Y., Bai, Y. H. & Gao, L. Q. Distribution of ground displacement field owing to two overlapped shield tunneling interaction. Chin. J. Geotech. Eng. 28(4), 485–490 (2006).

Shiuly, A. & Roy, S. Study on settlement behaviour of Annular Raft Foundation using Finite element-boundary element Method. Iran. J. Sci. Technol. Trans. Civil Eng. 45, 1705–1721 (2021).

Sang, B., Yan, C., Wang, C. & Qu, X. Study on dynamic response and long-term settlement of silty soil around Shanghai Metro tunnel. Sci. Rep. 14(1), 9172 (2024).

Zhou, P. Y., Wang, J. B., Song, Z. P., Cao, Z. L. & Pei, Z. M. Construction Method optimization for transfer section between Cross passage and main tunnel of Metro Station. Front. Earth Sci. 10, 770888 (2022).

He, C., Feng, K., Fang, Y. & Jiang, Y. C. Surface settlement caused by twin-parallel shield tunnelling in sandy cobble strata. J. Zhejiang University-SCIENCE A. 13(11), 858–869 (2012).

Ahmed, M. & Iskander, M. Evaluation of tunnel face stability by transparent soil models. Tunn. Undergr. Space Technol. 27(1), 101–110 (2012).

Acknowledgements

The research described in this paper was financially supported by A new round of construction project of key academic discipline in Henan Province (Teaching and Research [2023] No.414 issued by Education Department of Henan Province), Key Research Projects of Higher Education Institutions in Henan Province (No. 24A560023) and Zhengzhou University of Technology High-level Talent Research Project (No. 24GC02).

Author information

Authors and Affiliations

Contributions

Yong-gang Ding, Cheng Huang, Shi-ju Ma and Kai-rong Hong, Qi-keng Xu, Miao-jun Yan wrote the main manuscript text and E.F. prepared Figs. 1, 2, 3, 4, 5, 6, 7, 8, 9 and 10. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ding, Yg., Huang, C., Ma, Sj. et al. Measurement and analysis of surface settlement caused by construction of quasi-rectangular shield tunnel in rich water-sand stratum. Sci Rep 14, 24497 (2024). https://doi.org/10.1038/s41598-024-74164-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-74164-3

Keywords

This article is cited by

-

Ground deformation prediction based on SBAS-InSAR and RBF neural network: a case study of Zhengzhou Metro Line 10

Natural Hazards (2026)

-

Study on the Influence of Underground Excavation on Adjacent Structures in Liao-Tian Section of Beijing Subway in China

Indian Geotechnical Journal (2026)

-

Hydropower Station diversion tunnel layered excavation deformation mechanism under high crustal stress

Scientific Reports (2025)

-

Measurement analysis of strata deformation caused by construction of quasi-rectangular shield

Scientific Reports (2025)

-

Analysis of parameters for large cross-section quasi-rectangular EPBM in water-rich sandy strata

Scientific Reports (2025)