Abstract

Bamboo is an ideal green building material with excellent mechanical properties. Phosphogypsum (PG) is a kind of solid waste residue which is in urgent need of resource utilization and has been used as construction material. In this paper, a kind of round bamboo-fiber reinforced phosphogypsum composite short column was proposed. Axial compression tests of pure bamboo columns, bamboo columns filled with phosphogypsum inside, bamboo columns with phosphogypsum outside and bamboo columns with phosphogypsum inside and outside were carried out to explore the failure mode and mechanical properties of the short columns. The effects of the parameters include bamboo node, hose hoops, size of the bamboo tube and the strength of phosphogypsum on the mechanical properties of the short columns were analyzed, and the theoretical calculation method of the bearing capacity of the short columns was put forward. The results show that the bamboo nodes and hose hoops can improve the bearing capacity, initial stiffness and ductility of the column. The larger the size of the bamboo tube, the better the mechanical properties of the short column. The bearing capacity of round bamboo—phosphogypsum composite short column is higher than that of pure bamboo column. The ductility of bamboo columns with phosphogypsum outside is obviously higher than that of pure bamboo columns. The finite element analysis results are in good agreement with the test results. The theoretical calculation method of the bearing capacity of columns considering the strength reduction coefficient, the bamboo node effect coefficient and the constraint effect in this paper has high accuracy.

Similar content being viewed by others

Introduction

Bamboo is a green and renewable building material with advantages of high strength-to-weight ratio, good toughness and fast growth1,2,3,4,5,6,7,8,9,10. Bamboo is widely distributed in the world, among which China is the center of the distribution of bamboo resources in the world, with rich varieties and huge planting area. With the development of economy and society, environmental pollution has been paid more and more attention by various countries. Traditional building materials consume a lot of resources and produce huge pollution in the process of production and construction11,12,13,14,15. The civil engineering industry is one of the major sources of global pollution. The Chinese government has put forward a strategic goal of reaching a carbon peak by 2030 and achieving carbon neutrality by 2060. If new green building materials can be used in buildings, it may provide new ideas for energy conservation and emission reduction16,17,18.

Columns are important load-bearing components. In order to explore the mechanical properties of bamboo columns, experts and scholars have carried out a series of studies19,20,21,22,23. Nie et al.19 studied the influence of slenderness ratio and diameter to thickness ratio on the axial compression performance of bamboo columns, and the research results show that the larger the slenderness ratio, the lower the bearing capacity of the columns. Under the same slenderness ratio, the larger diameter to thickness ratio, the higher the bearing capacity of the column. Li et al.20 conducted the axial compression tests on laminated bamboo lumber short columns confined with CFRP, and the results show that carbon fiber cloth has a good limiting effect on the deformation of laminated bamboo columns. Gan et al.21 studied the influence of bamboo tube wall thickness, bamboo tube diameter and steel tube wall thickness to diameter ratio on the axial compression performance of circular concrete-filled steel tubular stub columns with an inner bamboo culm. The results show that the short columns with small diameter and large wall thickness have better ductility. He et al.22 studied the buckling performance of Julong Bamboo and proposed the anti-buckling design method. Cheng et al.23 conducted experiments and theoretical research on bamboo sheet twining tube-confifined concrete columns, and the results show that the increase of outer bamboo composite tube thickness can effectively reduce the expansion of the specimen. Li et al.24 explored the destruction mode and mechanical performance of laminated bamboo columns, and the research results show that the influence of initial defects on the bearing capacity of the columns increases with the increase of slenderness ratio. Li et al.25 carried out tests on the axial compression performance of round bamboo filled with concrete and cement mortar, and found that bamboo tubes with filling materials had higher carrying capacity and initial stiffness than original bamboo tubes.

Phosphogypsum is a kind of solid industrial waste residue. At present, there are a large number of phosphogypsum accumulated in the world, but the degree of resource utilization is very low. If the phosphogypsum can be rationally used, it will be beneficial to environmental protection. Phosphogypsum has been used as a building material in some projects26,27,28. Although bamboo has good mechanical properties, it is prone to corrosion and mildew. Phosphogypsum has poor ductility. This paper presents a kind of round bamboo-fiber reinforced phosphogypsum composite short column. The bamboos are wrapped by phosphogypsum, and the bamboos can also be filled with phosphogypsum. In order to improve the cracking resistance of phosphogypsum, fibers are added to the phosphogypsum. This short column can realize the complementary advantages of bamboo and phosphogypsum, which can not only realize the protection of bamboo but also realize the resource utilization of phosphogypsum.

In order to explore the performance of round bamboo-fiber reinforced phosphogypsum composite short columns, this paper mainly carried out the following works: (1) Axial compression tests were carried out on the short column specimens of pure bamboo, bamboo filled with phosphogypsum inside, bamboo with phosphogypsum outside and bamboo with phosphogypsum inside and outside to explore the failure mode of the short columns. (2) The effects of the parameters such as bamboo node, hose hoops and bamboo tube size on the mechanical properties of the short columns were analyzed. (3) The finite element analysis was carried out and the theoretical calculation method of short columns was put forward.

Materials and methods

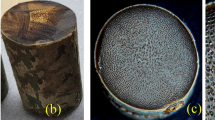

Bamboo

The Moso bamboo used in the test was licensed and purchased from Zhejiang Province, China. The bamboo age was about 4 years. The compression and moisture content tests of bamboo parallel to the fibers were carried out in reference to ISO 22157-1:200429 and JG/T 199-200730. The moisture content of bamboo was about 11%, the compressive strength parallel to the fibers was 68.24 MPa, and the elastic modulus parallel to the fibers was 10.8GPa.

Phosphogypsum

The phosphogypsum was produced in Henan Province, China, and the proportion of fibers in phosphogypsum was 1%. The fibers were mainly used to enhance the cracking resistance of the phosphogypsum. The mechanical properties of phosphogypsum were tested according to GB/T 50081-201931 and JGJT70-200932. The compressive strength of phosphogypsum was 1.5 MPa, and the elastic modulus was 1.25GPa.

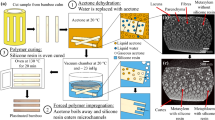

Specimens

A total of 20 specimens were tested for axial compression, and the details are shown in Table 1. The specimens can be divided into four groups: bamboo group (BC1-5), inner phosphogypsum group (BI1-5), outer phosphogypsum group (BIO1-5) and inner and outer phosphogypsum group (BA1-5). The dimensions of the BC1-5 specimens were D × 200 mm, and the dimensions of the other specimens were 120 mm × 120 mm × 200 mm (L × B × H). Each group included 5 specimens, including internode bamboo specimen, node bamboo specimen, specimen with hose hoops, node bamboo specimen with hose hoops, and node bamboo specimen with large diameter. The schematic diagram of the specimens is shown in Fig. 1.

Instrumentation and loading

The schematic diagram of instrument arrangement and loading in the test are shown in Fig. 2. A vertical strain gauge and a transverse strain gauge were arranged in the middle of the bamboo on both sides to measure the vertical and transverse strain of bamboo, respectively. Vertical and transverse strain gauges were also arranged at the corresponding positions of phosphogypsum to measure the vertical and transverse strain of phosphogypsum. Specimens BC1-5 only had strain gauges on bamboo. The 500-kN mechanical testing machine was used for loading. Loading was carried out according to ISO 2215729, and the loading rate was 0.5 mm/min.

Test results and discussion

Failure processes and patterns

For the pure bamboo group (BC1-5), the failure process and mode of the specimens are similar. The failure process of the internode specimen (BC1) is as follows: At the initial stage of loading, the specimen was in the elastic stage, and no obvious deformation occurred. With the increase of load, the specimen gradually buckled and deformed. When the bulging deformation of the specimen reached a certain degree, cracks occurred on the specimen. The cracks gradually increased and widened, eventually formed a penetrating fracture (Fig. 3a). The failure process and failure mode of the node specimen (BC2) were consistent with that of the internode specimen (BC1), and eventually it was also destroyed by splitting (Fig. 3b). The failure mode of the specimen with hose hoops (BC3) was slightly different from that of the specimens BC1-2. As can be seen from Fig. 3c, when specimen BC3 was damaged, it only split in the area between the two hose hoops, and there was no crack in the area between the hose hoops and the end. This indicates that the end of the bamboo tube was protected by the hose hoop, which avoided cracking and thus improved the bearing capacity of the specimen. When the specimen filled with phosphogypsum inside the bamboo tube (BI1-5) was destroyed, the destruction morphology of the bamboo tube was similar to that of the specimens BC1-5. In the case of specimen BI1 (Fig. 3d), the bamboo tube was split at destruction state and the phosphogypsum inside was crushed, indicating that the strength of both materials was fully utilized. For the specimens with phosphogypsum outside the bamboo tube (BO1-5), when the elastic limit was reached, the phosphogypsum at the end of the specimens was crushed, and then the specimens reached the plastic stage. With the increase of load, the cracks of phosphogypsum gradually increased and widened. At the limit state, the bamboo was crushed. The failure mode of specimen BO1 is shown in Fig. 3e. For the specimen with phosphogypsum inside and outside the bamboo tube (BA1-5), both phosphogypsum and bamboo were crushed when destroyed (Fig. 3f).

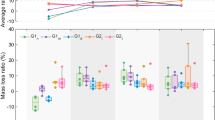

Load–displacement curves

The load–displacement curves of the test are shown in Fig. 4. It can be seen from Fig. 4 that the trend of load–displacement curve of each specimen is similar. The displacement increases with the increase of load. When the load reaches a certain degree, the slope of the load–displacement curve decreases. When the same displacement is increased, the increase of the displacement of the specimen increases. The specimen experienced a long plateau stage, which shows that the ductility of the specimen is good. The mechanical properties of short columns are different under different parameters. The bearing capacity is shown in Fig. 5. For the pure bamboo group, the bearing capacity of the node specimen (BC2) is higher than that of the internode specimen (BC1). The bearing capacity of the specimen increases by 5.87% with the existence of bamboo node. The bearing capacity of the specimen can also be improved by the existence of hose hoops. The bearing capacity of specimen BC3 is 4.98% higher than that of specimen BC1. The bearing capacity of specimen BC2 and specimen BC3 are similar. The bearing capacity of specimen BC4 is higher than that of specimen BC2 and specimen BC3. The bearing capacity of specimen BC5 is higher than that of specimens BC1-4, indicating that the larger the diameter and wall thickness, the higher the bearing capacity of bamboo. The bearing capacity of the specimen with node (BI2) and with hose hoops (BI3) filled with phosphogypsum is 5.13% and 5.37% higher than that of the internode specimen (BI1), respectively. The bearing capacity of the specimen with node and hose hoops (BI4) filled with phosphogypsum is 3.28% and 3.05% higher than that of specimen BI2 and specimen BI3, respectively. Since the diameter and wall thickness of specimen BI5 are larger than those of specimen BI1-4, its bearing capacity is the highest in this group. The bearing capacity of specimens BO1-5 are similar to that of the above two groups. The bearing capacity of specimen BO1 is the lowest and that of specimen BO5 is the highest. The bearing capacity of specimens BO2-3 are higher than that of BO1. The bearing capacity of specimen BO4 is higher than that of BO2 and BO3. The bearing capacity difference between specimen BO2 and BO3 is very small. For the specimens with both inner filling and outer phosphogypsum (BA1-5), the bearing capacity increases from BA1 to BA5. The bearing capacity of specimen BA1 is 101.31kN. The bearing capacity of specimen BA2, BA3 and BA4 is 3.34%, 9.74% and 20.14% higher than that of specimen BA1, respectively. The bearing capacity of specimen BA5 is 29.37% higher than that of BA2. Figure 6a shows that the average bearing capacity of BI1-5, BO1-5 and BA1-5 is 11.68%, 0.84% and 23.66% higher than that of BC1-5, respectively. The variation of initial stiffness is consistent with the bearing capacity. Figure 6b shows that the average stiffness of BI1-5, BO1-5 and BA1-5 is 39.17%, 98.10% and 140.59% higher than that of BC1-5, respectively.

The ductility coefficient is defined as follows:

where, μis the ductility coefficient, Δyis the displacement at yield point, Δuis the ultimate displacement, that is, the displacement at 0.85 times the ultimate load.

The calculation results of ductility coefficient are shown in Table 1 and Fig. 6. The test shows that the ductility coefficient of phosphogypsum is about 0.84. Figure 6c shows that the ductility of bamboo is significantly better than that of phosphogypsum, and the ductility coefficient of specimen BC1 is 146.43% higher than that of phosphogypsum. The ductility of the node specimen (BC2) and the specimen with hose hoops (BC3) is better than that of the internode specimen (BC1). The existence of bamboo node and hose hoops can improve the ductility of bamboo. The ductility coefficient of BC2-4 is 7.25%, 24.15% and 30.92% higher than that of BC1, respectively. As shown in Fig. 6c, the average ductility coefficients of specimens BI1-5, BO1-5 and BA1-5 are -3.82%, 158.41% and 187.62% higher than those of BC1-5, respectively. For the bamboo-phosphogypsum composite short columns with phosphogypsum outside, their ductility coefficients are obviously higher than that of pure bamboo and pure phosphogypsum specimens, indicating that the restriction of phosphogypsum is helpful to improve the ductility of specimens (Table 2).

Finite element analysis

ABAQUS software was used for finite element analysis. Both bamboo tubes and phosphogypsum used C3D8R eight-node solid units. The contact relationship between bamboo tube and phosphogypsum was simulated by binding constraint method. The elastic–plastic model was used for the compression of bamboo parallel to the fibers, and the Poisson’s ratio was 0.3 considering the strength reduction factor. The deformation process and stress state of phosphogypsum were simulated by CDP concrete plastic damage model with Poisson’s ratio of 0.3. The displacement control method was used for loading. Considering the bamboo tubes diameter, bamboo tubes wall thickness and strength of phosphogypsum, the 9 models with phosphogypsum inside and outside as shown in Table 3 were modeled and analyzed. Figure 7 shows the results of finite element analysis of model BAFE1, and Fig. 8 shows the load–displacement curves of test and finite element analysis of model BA1. As can be seen from Fig. 8, the load–displacement curve obtained by finite element simulation is close to the load–displacement curve of the test, indicating that the finite element analysis method has high accuracy. Figure 9 shows the load–displacement curves of each model obtained by finite element analysis. Table 4 shows the results of finite element analysis. According to Fig. 9 and Table 4, the bearing capacity and initial stiffness of the model increase with the increase of bamboo tube diameter, wall thickness and phosphogypsum strength.

Theoretical calculation method

Calculation formulas of bearing capacity

In the process of calculating the bearing capacity of composite short columns, the constraint effect of bamboo tube on phosphogypsum can not be ignored. In the limit state, due to the constraint effect of bamboo tube, the internal phosphogypsum is in the state of triaxial compression, so the internal phosphogypsum can not be considered in the state of uniaxial compression. Because of the different properties of bamboo and phosphogypsum, the reduction of strength should be taken into account in the calculation. The results of this test show that the bamboo nodes have an enhancing effect on the bearing capacity of the specimens. Considering the above factors, the following calculation formulas are proposed in this paper.

where, Ncu is theoretical bearing capacity (kN); μ is the strength reduction coefficient, 0.9 for pure bamboo columns and 0.8 for composite columns33. α is the effect coefficient of bamboo nodes; f’cb is the compressive stress of bamboo (MPa), Ab is the stressed area of bamboo (mm2), f’cp is the compressive strength of phosphogypsum in the core area (MPa), A’p is the stressed area of phosphogypsum in the core area (mm2), fcp is the compressive strength of external phosphogypsum (MPa), Ap is the stressed area of external phosphogypsum (mm2). D is the outer diameter of the bamboo tube (mm), t is the wall thickness of the bamboo tube (mm), L is the width of the composite short column (mm).

Determination of the parameters

Determination of α

Bamboo node is a special part of bamboo. The existence of bamboo node enhances the compressive resistance of bamboo. According to the test results, the strengthening effect of the hose hoops on the bearing capacity of the specimen is similar to that of the bamboo node. Therefore, the enhancement effect coefficient of hose hoops is equivalent to the bamboo node effect coefficient. The following formula for calculating α is proposed.

Determination of fʹcb and fʹcp

The force diagram of the short column filled with phosphogypsum in the bamboo tube is shown in Fig. 10. Johnston’s Failure Criterion explains the constraint effect, as shown in Fig. 1134. In Fig. 10 and Fig. 11, fr is the lateral confining pressure, fhb is the horizontal force of the bamboo tube. According to the stress state of the short column, the following calculation formulas can be obtained.

where, k is the constraint effect coefficient, which can be calculated through Formula (9).

Formula (10) can be obtained from Von Mises yield criterion.

where, fy is yield strength.

fr can be calculated by Formula (11)34.

where,εb is the transverse strain of the bamboo tube, Ecb is the elastic modulus of the bamboo, D is the outer diameter of the bamboo, and t is the wall thickness of the bamboo tube. A is the force area, ∆P is the difference between the upper and lower loads, ∆l is the difference between the deformation value of the specimen under the upper and lower loads.

Comparison of theoretical and experimental results

In order to verify the consistency of the theoretical calculation method proposed in this paper with the experimental and finite element results, the theoretical results are compared with the actual results. See Tables 2, 4 and Fig. 12 for details. For pure bamboo columns, the phosphogypsum part of the formula is not calculated. For specimens with only inner or outer phosphogypsum, only the part of the formula with phosphogypsum is considered. According to the results in Tables 2, 4 and Fig. 12, the theoretical calculation formulas proposed in this paper has high accuracy. The mean error is 0.05, and the standard deviation is 0.04. In addition, it is worth mentioning that the experimental data of this paper is limited, and the theoretical method of this paper still needs to be improved.

Conclusion

In this paper, the axial compression performance tests of 20 bamboo short columns were carried out, the finite element analysis of composite short columns was carried out, and the theoretical calculation method of short columns was proposed. The main conclusions are as follows:

-

1.

The internode and node specimens were split when damaged. Only the area between the two hose hoops was split when the specimens with hose hoops failed. When the composite short columns were destroyed, the bamboo tubes were split and the phosphogypsum was crushed, so the strength of the two materials was fully utilized.

-

2.

The bearing capacity of the specimen can be improved by the existence of bamboo node and hose hoops. The larger the diameter and wall thickness of the bamboo tube, the higher the bearing capacity of the short columns. The average bearing capacity of the three groups of specimens filled with phosphogypsum inside, with phosphogypsum outside and with phosphogypsum inside and outside were 11.68%, 0.84% and 23.66% higher than that of the pure bamboo column group, respectively. The average initial stiffness of the three groups of specimens filled with phosphogypsum inside, with phosphogypsum outside and with phosphogypsum inside and outside was 39.17%, 98.10% and 140.59% higher than that of the pure bamboo column group, respectively. The ductility of bamboo is significantly better than that of phosphogypsum, and the ductility of the node specimens and the specimens with hose hoops is better than that of the internode specimens. The ductility of short columns with phosphogypsum outside is obviously better than that of pure bamboo columns. The composite effect between bamboo and phosphogypsum is remarkable.

-

3.

The finite element analysis results are in good agreement with the test results. The bearing capacity of the composite short column increases with the increase of phosphogypsum strength. The theoretical calculation method of the bearing capacity of short columns is put forward, and the parameters include the effect coefficient of bamboo node, the strength reduction coefficient and the constraint effect are determined. The theoretical calculation method has high accuracy.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request. Please contact Dr Zhili Cui at ahwhdxwy@126.com.

References

Wang, Y. et al. High-performance bamboo steel derived from natural bamboo. ACS Appl. Mater. Interfaces. 13(1), 1431–1440 (2020).

Huang, Z., Künzel, H., Krus, M. & Zhang, W. Three-dimensional tests on hygric properties of laminated bamboo and bamboo scrimber. J. Build. Eng. 56, 104712 (2022).

Nkeuwa, W. et al. Bamboo-based composites: A review on fundamentals and processes of bamboo bonding. Compos. B Eng. 235, 109776 (2022).

Wang, Z. et al. Preparation and performance of fluorescent transparent bamboo. Ind. Crops Prod. 186, 115222 (2022).

Zheng, L. et al. Effect of the proportion of bamboo scraps on the properties of bamboo scraps/magnesium oxychloride composites. J. Renew. Mater. 9(10), 1729–1739 (2021).

Si, S., Zheng, X. & Li, X. Effect of carbonization treatment on the physicochemical properties of bamboo particleboard. Constr. Build. Mater. 344, 128204 (2022).

Harries, K., Trujillo, D., Kaminski, S. & Lopez, L. Development of load tables for design of full-culm bamboo. Eur. J. Wood Wood Prod. 80(3), 621–634 (2022).

Guan, X., Yin, H., Lin, C. & Zhan, W. Effect of layups on the mechanical properties of overlaid laminated bamboo lumber made of radial bamboo slices. J. Wood Sci. https://doi.org/10.1186/s10086-022-02047-0 (2022).

Guan, M. & Huang, Z. Direct strain distribution and finite-element-analysis simulation of the bonding interface of bamboo laminated lumber with ultrasound-treated bamboo strips. BioResources 17(1), 890–907 (2021).

Yuan, T. et al. Bamboo flattening technology ebables efficient and value-added utilization of bamboo in the manufacture of furniture and engineered composites. Compos. B Eng. 242, 110097 (2022).

Zhou, Y., Elchalakani, M., Du, P. & Sun, C. Cleaning up oil pollution in the ocean with photocatalytic concrete marine structures. J. Clean. Prod. 329, 129636 (2021).

Purdy, K., Reynolds, J. & Wright, I. Potential water pollution from recycled concrete aggregate material. Mar. Freshw. Res. 72(1), 58 (2021).

Hussain, R., Al-Negheimish, A., Alhozaimy, A. & Singh, D. Corrosion characteristics of vanadium micro-alloyed steel reinforcement bars exposed in concrete environments and industrially polluted atmosphere. Cement Concrete Compos. 113, 103728 (2020).

Wang, Y., Zhu, R., Bo, X., Dan, M. & Shu, M. Volatile organic compounds constituents of a typical integrated iron and steel plant and influence on O3 pollution. Int. J. Environ. Sci. Technol. 20, 3323–3334 (2022).

Wang, S. et al. Trends in air pollutant emissions from the sintering process of the iron and steel industry in the Fenwei Plain and surrounding regions in China, 2014–2017. Chemosphere 291, 132917 (2022).

Dong, X. et al. Low-value wood for sustainable high-performance structural materials. Nat. Sustain. 5(7), 628–635 (2022).

Wang, L., Chen, S., Tsang, D., Poon, C. & Dai, J. CO2 curing and fibre reinforcement for green recycling of contaminated wood into high-performance cement-bonded particleboards. J. CO2 Util. 18, 107–116 (2017).

Shu, B. et al. Review on the application of bamboo-based materials in construction engineering. J. Renew. Mater. 8(10), 1215–1242 (2020).

Nie, Y., Wei, Y., Huang, L., Liu, Y. & Dong, F. Influence of slenderness ratio and sectional geometry on the axial compression behavior of original bamboo columns. J. Wood Sci. https://doi.org/10.1186/s10086-021-01968-6 (2022).

Li, H. et al. Experimental investigation on axial compression behavior of laminated bamboo lumber short columns confined with CFRP. Compos. Part A Appl. Sci. Manuf. 150, 106605 (2021).

Gan, D., Li, Z., Zhang, T., Zhou, X. & Chung, K. Axial compressive behaviour of circular concrete-filled steel tubular stub columns with an inner bamboo culm. Structures 26, 156–168 (2020).

He, M., Li, Z., Sun, Y. & Ma, R. Experimental investigations on mechanical properties and column buckling behavior of structural bamboo. Struct. Des. Tall Special Build. 24(7), 491–503 (2014).

Cheng, X., Wei, Y., Nie, Y., Wang, G. & Li, G. Compressive behavior of bamboo sheet twining tube-confined concrete columns. Polymers 13(23), 4124 (2021).

Li, H., Su, J., Zhang, Q., Deeks, A. & Hui, D. Mechanical performance of laminated bamboo column under axial compression. Compos. Part B Eng. 79, 374–382 (2015).

Li, W., Long, Y., Huang, J. & Lin, Y. Axial load behavior of structural bamboo filled with concrete and cement mortar. Construct. Build. Mater. 148, 273–287 (2017).

Rashad, A. Phosphogypsum as a construction material. J. Clean. Prod. 166, 732–743 (2017).

Garbaya, H., Jraba, A., Khadimallah, M. & Elaloui, E. The development of a new phosphogypsum-based construction material: a study of the physicochemical. Mech. Therm. Charact. Mater. 14(23), 7369 (2021).

Mymrin, V. et al. Material cycle realization by hazardous phosphogypsum waste, ferrous slag, and lime production waste application to produce sustainable construction materials. J. Mater. Cycles Waste Manag. 23(2), 591–603 (2021).

International Standards, Bamboo—Determination of Physical and Mechanical Properties—Part I: Requirements ISO 22157–1:2019 (E) (International Organization for Standardization, 2019) https://www.iso.org/standard/65950.html (Accessed 1 Jan. 2019).

Chinese Standards Agency (CSA). Testing Methods for Physical and Mechanical Properties of Bamboo Used in Building. JG/T199-2007. (2007) https://www.chinesestandard.net/PDF/English.aspx/JGT199-2007 (Accessed 1 Oct 2007) (in Chinese).

GB/T 50081 Standard for test methods of concrete physical and mechanical properties, (Ministry of Housing and Urban-Rural Construction of the People’s Republic of China, 2019) (in Chinese).

JGJT70 Standard for test method of performance on building mortar. (Ministry of Housing and Urban-Rural Construction of the People’s Republic of China, 2009) (in Chinese).

Tian, L., Kou, Y. & Hao, J. Axial compressive behaviour of sprayed composite mortar–original bamboo composite columns. Construct. Build. Mater. 215, 726–736 (2019).

Nguyen, D., Thai, D., Tran, N., Ngo, T. & Le, H. Confined compressive behaviors of high-performance fiber-reinforced concrete and conventional concrete with size effect. Construct. Build. Mater. 336, 127382 (2022).

Acknowledgements

The work described in this paper is supported by grants from the National Natural Science Foundation of China (Grant No. 52204083).

Author information

Authors and Affiliations

Contributions

Conceptualization, Z.C. and Z.J.; methodology, Z.C.; software, Z.C.; validation, Z.C., W.T. and P.L.; formal analysis, Z.C.; investigation, Z.C.; resources, Z.C.; data curation, Z.C.; writing—original draft preparation, Z.C.; writing—review and editing, Z.C.; visualization, Z.C.; supervision, Z.C.; project administration, Z.C.; funding acquisition, Z.C. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Statement

A permission was obtained to collect the experimental bamboo species—Moso bamboo from Zhejiang Province, China.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Cui, Z., Jiao, Z., Tong, W. et al. Axial compressive properties of round bamboo-fiber reinforced phosphogypsum composite short columns. Sci Rep 14, 24818 (2024). https://doi.org/10.1038/s41598-024-75061-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-75061-5