Abstract

Addressing the practical challenges of difficult drilling for blasting-induced permeability enhancement in deep, soft, and high-gas coal seams, where fractures remain underdeveloped and prone to re-compaction, this study proposes blasting operations within the floor strata. This approach aims to enhance the permeability of soft coal seams, thereby extending the duration of effective gas extraction. A bidirectional loading gas–solid coupling blasting simulation system was established in the laboratory, enabling multi-faceted analysis of experimental models through macroscopic crack patterns, internal damage mechanisms, and strain data of coal and rock masses. Comparative experiments were conducted, contrasting various control hole spacings with conventional blasting techniques. The findings reveal that as the blasting stress wave traverses the control hole walls, tensile stress waves are reflected, facilitating crack propagation. The guiding effect of the control holes and the spatial compensation they provide significantly increase the extension distance of explosion-induced cracks, resulting in directional failure of the test specimens and heightened damage in the far field of the blast. After the blasting process, the arrangement of control holes can result in an increase of up to 133% in damage to the coal seam and a reduction of up to 167% in damage to the floorboard compared to the model without control holes. Notably, when the control holes are proximal to the coal-rock interface, the near-end coal body experiences the most pronounced effects, with peak damage and tensile strain in the d = 20 mm model being 1.93 and 1.79 times higher, respectively, than those in models without control holes. Conversely, for control holes located further from the interface, the distal coal body experiences the greatest influence, exhibiting 1.53 and 1.55 times higher peak damage and tensile strain, respectively, in the d = 80 mm model compared to uncontrolled counterparts. Field observations at the C13 coal seam of a mine within the Huainan mining area corroborate these findings, where the volume of gas extraction and its concentration experienced a rapid increase following blasting and penetration enhancement. Optimum permeability enhancement occurs when the blasting hole is situated 4 m from the extraction point, resulting in a 131% increase in gas extraction purity from 0.15 × 10–3 m3/min to 1.97 × 10–3 m3/min. Furthermore, gas concentration soars by 373%, from 5.86% to 21.86%. These research outcomes offer valuable insights and hold considerable reference significance for blasting-induced permeability enhancement in deep, soft, and high gas coal seams.

Similar content being viewed by others

Introduction

With shallow resources depleted, most mines in China have entered deep mining1,2. The in-situ stress in deep mines is gradually increasing, and some coal mines are transitioning from low-gas to high-outburst mines, with the proportion of mining soft, low-permeability coal seams increasing significantly3. For deep soft coal seam mining, coal seam cracks are underdeveloped, resulting in generally low gas permeability, which makes it difficult to extract large amounts of gas. Consequently, it is challenging to reduce gas pressure and original gas content to within safe limits, and gas accidents are prone to occur due to mining disturbances, increasing the complexity, danger, and difficulty of preventing gas-related dynamic disasters4. Since 2012, the death toll of coal and gas outburst accidents has decreased overall, but the proportion of coal mine disasters has not decreased, as shown in Fig. 15.

Drilling and gas extraction is one of the important measures to prevent and control underground gas disasters in coal mines6,7,8. Aiming at the mining of high gas and low permeability coal seams, many scholars have proposed enhanced anti-reflection technologies for coal seams, such as hydraulic fracturing, CO2 fracturing, and deep hole pre-cracking blasting9,10,11. Among them, deep hole pre-split blasting is widely used to improve the efficiency of gas extraction in low permeability coal seams because of its good local reflection improvement effect, quick construction, and wide range of adaptation12,13. Zhang14 employed deep hole pre-split blasting technology throughout the tunneling process of the X10901-3 rail tunnel at the Xijing Mine in Dawan, Liupanshui, Guizhou, China. Following the blast, the gas extraction rate increased from 0.18 m3/min to 0.38 m3/min, representing a 90% increase. This effectively reduced the risk during tunnel excavation and increased the efficiency of tunnel excavation. Zhao et al.15 conducted blasting to enhance permeability in Mine No. 10 of Pingdingshan Coal Mine, Henan Province, China and found that after blasting, the average gas concentration increased by 2.25 times, the average gas purity increased by 3.78 times, the permeability coefficient of the coal seam increased 21-fold, and the effective anti-reflection radius reached 7 m. Guo et al.16 conducted a blasting experiment to enhance permeability in the soft coal seam at the Ji 15–33,200 working face of Mine 10, Pingdingshan Coal Mine, Henan Province, China, and the volume fraction of gas in the extraction hole after blasting increased by more than 45%. Gao et al.17 implemented deep hole pre-cracking blasting to improve the permeability of coal seam in Pan-1 Coal Mine, Anhui, China. After blasting, the pure gas extraction volume increased from 0.07 m3/min before blasting to 1.73 m3/min, and the volume fraction increased from 10.46% to 68.50%, and maintained at a high level for a long time. Li et al.18 conducted a blasting and permeability enhancement test with set control holes in a low-permeability coal seam at the 16,071 working face of the Jiulishan Mine in Henan Province, China. The ultimate gas drainage capacity of the borehole after long hole pre-splitting blasting was found to be 3.71 times that of the ordinary borehole, in comparison to natural mining. Fu et al.19 performed shaped charge blasting to enhance permeability in a coal seam in a mine in Huainan, Anhui Province, China, and the gas extraction concentration increased by 3.65 the pure volume of gas extraction increased by 7.74 × 10-3m3/min.

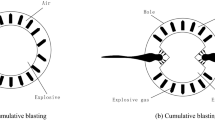

In research practice, it is observed that during deep-hole pre-splitting blasting of the soft, high-gas coal seam located in the middle of a deeply buried, rigid floor, the soft nature of the coal seam causes most of the energy to dissipate in the crushing zone, easily resulting in a large-scale crushing zone that hinders the subsequent development of remote fractures, limiting the blasting influence radius and resulting in poor blasting effects. After blasting, cracks are prone to closing rapidly under the influence of in-situ stress and other factors, leading to a rapid decay in the efficiency of high-efficiency gas extraction from the coal seam and a very short period for efficient gas extraction after blasting-induced permeability enhancement20. Additionally, drilling in soft coal is prone to hole collapse and drill burial. To address these issues, Liu21,22 proposed a method of blasting-induced permeability enhancement in the floor strata of soft, high-gas coal seams. This involves blasting in the floor of the coal seam, which generates a reflective tensile wave at the coal-rock interface, reacting to the rock mass to further expand its damage range. The weak damage planes in the rock mass then guide the explosive stress wave to act on the coal seam directionally, resulting in further expansion of coal cracks and achieving the effect of blasting-induced permeability enhancement. However, when using ordinary charge blasting, the disordered expansion of blasting cracks can result in a significant dissipation of explosion energy in the floor rock layer, preventing the effective fracturing of the protruding coal body. Additionally, the unordered expansion of blasting cracks can lead to excessive damage to the floor, posing safety risks for subsequent roadway support. Therefore, directionally controlled blasting technology is necessary to effectively control the expansion of blasting cracks23. Among the factors influencing the effectiveness of directional control, the distance between the control hole and the coal-rock interface is of particular importance.

In conclusion, focusing on the mining of deep, soft, and high-gas coal seams, investigating the effects of dynamic blasting loads on the soft coal seam floor on the damage evolution of rock mass and soft coal body, as well as the directional propagation patterns of fractures at varying control hole spacings, can provide a solid theoretical foundation and technical support for long-term gas extraction in soft and low-permeability coal seams.

Simulation experiment on enhanced permeability through floor blasting in soft and high gas coal seams

Experimental platform construction

In the laboratory, a blast simulation experimental system was built, which can simulate the gas occurrence environment and realize the bidirectional loading of in-situ stress. The system comprises a gas–solid coupling bidirectional loading test device, CO2 cylinder unit, ultrahigh dynamic strainometer, ultrasonic CT instrument, and detonation system. The experimental model can be analyzed from the macroscopic crack, internal damage, and strain data of coal rock mass after blasting. The experimental system is shown in Fig. 2.

Gas–solid coupling bidirectional loading test device

The gas–solid coupling bidirectional loading test device was made of welded Q345 channel steel, and the size of the internal cavity of the device is 300 mm × 300 mm × 300 mm. The front and rear panels of the experimental device were detachable steel plates, and the connecting parts were sealed using high-strength silicone gaskets and bolts. An air charging valve and pressure gauge were arranged at the upper side steel plate of the device, which can be inflated by a high-pressure gas cylinder and real-time pressure monitoring to simulate the gas occurrence on site. The device was equipped with support seats, strong springs, and left and right movable steel plates on the top, left, and right sides. Hydraulic jacks were mounted on the top side, while spiral mechanical jacks were installed on the left and right sides, to simulate in-situ stress loading.

CO2 cylinder unit

Considering that the adsorbability of coal for CO2 gas is much higher than that of CH4 gas, and CO2 gas is not explosive and dangerous, it can ensure the safety of the test process. During the experiment, a high-pressure CO2 cylinder was used to inflate the cavity continuously for 12 h to ensure that sufficient CO2 gas was absorbed in the coal to achieve the purpose of gas pressure in the test coal.

Ultrahigh dynamic strainometer

The LK2109A/B ultrahigh dynamic strainometer was used to collect strain data in the blasting test, and the strain brick was processed and embedded in the designated position of the test model. The size of the strain brick is 20 mm × 20 mm × 10 mm. After processing, the strain bricks were maintained for 7 days and their surfaces were smoothed with fine sandpaper to remove the oxide layer. The BX120-3CA resistance strain gauge was then bonded to the strain brick using 502 Adhesive. After bonding, a layer of 705B one-component temperature vulcanized silicone rubber was applied to the surface of the strain gauge to provide waterproof insulation.Ultrasonic CT instrument.

The "HC-U81" ultrasonic CT instrument was used to test the ultrasonic data in the blasting simulation test. In the blasting experiment, the ultrasonic wave velocity signal of the test plane was analyzed to reflect the cross-section information of the test model. When testing, it is necessary to apply Vaseline as a coupling agent on the front end of the probe to ensure the coupling between the ultrasonic detection probe and the test model.

Detonation system

The detonation system consists of a remote-controlled electric detonator and an explosive tube. The electric detonator can be triggered remotely within a range of 50 m.

Experimental scheme design

Experimental model construction

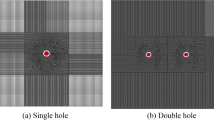

A single blast hole model and different control hole spacing models were established to investigate the influence of control hole spacing on the blast effect. The test model size is 30 cm × 30 cm × 30 cm, with a blasting hole diameter of 1.6 cm and a depth of 20 cm, arranged in the lower rock mass 2 cm away from the coal-rock interface. The control holes has a diameter of 1.6 cm and a depth of 20 cm, were arranged in the upper coal body with a horizontal spacing of 8 cm between them. To investigate the effect of blasting hole spacing on the blasting effect, the control hole spacing between the coal and rock interface was set to 20, 60, 80, and 100 mm respectively. The 1# stress measuring point was arranged in the coal seam 1 cm below the coal-rock interface, the 2# and 3# stress measuring points were arranged in the rock layer 4 and 8 cm above the coal-rock interface, and the 4# stress measuring point was arranged 4 cm to the left of the 2# measuring point. The diagram of the model and stress measuring point is shown in Fig. 3.

The similarity simulation test takes the C13-1 coal seam located in the Huainan mining area, Anhui Province, China. The main mechanical parameters of the C13-1 coal seam and its floor are shown in Table 1.

In this experiment, geometric similarity, bulk density similarity, stress similarity, and dynamic similarity were controlled accordingly according to Froude’s proportionality method24,25. The matching parameters of similar experimental materials are shown in Table 2.

In-situ stress loading scheme

Based on the measurements of in-situ stress conducted in multiple underground coal mines in the Huainan mining area, China26, the distribution characteristics and variation trends of in-situ stress were analyzed and summarized. It was calculated that when the buried depth H = 800 m, the horizontal stress σh = 18.57 MPa and the vertical stress σv = 21.40 MPa. According to the similarity simulation coefficient, σH = 0.80 MPa and σv = 0.93 MPa were loaded in this paper.

Ultrasonic wave velocity measurement point arrangement

To fully investigate the crack growth after blasting under different schemes, three test planes were selected for each group of models. The S1 test plane was located in the coal seam 8 cm above the coal-rock interface, the S2 test plane was located in the coal seam 4 cm above the coal-rock interface, and the S3 test plane was located in the rock layer 2 cm below the coal-rock interface. Each plane was equipped with 6 transmitting points and 6 receiving points, and 36 ultrasonic wave velocity measurement lines were collected. The arrangement of ultrasonic wave velocity measurement points is shown in Fig. 4.

Experimental model making

Pre-cast test models using custom steel housing. Sand, cement, pulverized coal, gypsum, and water were weighed according to the results of the similar ratio test. After mixing and stirring the materials evenly, the bottom plate and the coal seam were laid successively according to the experimental scheme. The blasting hole, control hole, and strain brick were embedded as shown in Fig. 5. The test model was removed from the box after 14 days of maintenance and reused after another 14 days of normal temperature maintenance27.

Analysis of experimental results

Macroscopic crack analysis

Figures 6 and 7 show the surface cracks and sketches of the test block subsequent to blasting. Figure 6a illustrates the blasting test conducted without the incorporation of a control hole. Following the blasting process, cracks propagated in a disorganized manner from the blasting hole to the surrounding area. The majority of these cracks were concentrated in the floor rock layer, with no discernible cracks observed in the upper coal seam. Figure 6b through e illustrate the blasting test of control holes with varying spacing. The test results demonstrate that the cracks in the model with control hole spacing of d = 20, 60, and 80 mm all develop in the direction of the control hole following blasting. This results in directional destruction of the test model, which ultimately connects with the control hole and continues to extend to the far end of the coal body. Moreover, a multitude of minor fissures were generated in the vicinity of the control hole, resulting in significant deterioration of the control hole region. Following the arrangement of the control holes, the blasting cracks at the boundary of the test model are observed to be thicker than those produced by ordinary blasting. Conversely, the crack widths in other directions are noted to be thinner and shift towards the control holes. This indicates that the configuration of control holes enhances the capacity of the explosive crack to evolve. As the distance between the control hole and the coal-rock interface increases, the degree of fissure development in the coal body around the control hole gradually decreases, and the fissure density around the control hole also decreases. In the model with a diameter of 100 mm, the crack did not extend to the control hole due to the excessive distance. It is essential to select an appropriate control hole spacing during blasting. If the hole spacing is minimal, the energy transferred by the blast is more readily distributed in the horizontal near zone between the blasting hole and the empty hole. This promotes the growth of cracks in the horizontal near zone but is ineffective in guiding the development of cracks at the far end. When the hole spacing is excessive, effective guidance of the crack development is not possible.

Strain curve analysis

Figure 8 illustrates the strain–time curve of the test model. It can be observed that the control hole serves to direct the stress wave generated by blasting in a predetermined direction. Upon reaching the hole wall, the stress wave is reflected and undergoes a transformation from a compressive stress wave to a tensile stress wave. In comparison to conventional blasting techniques, the reflection of the blast-generated stress wave by the control holes markedly increases the peak tensile strain. Given that the tensile strength of coal and rock is considerably less than their compressive strength, tensile cracks will inevitably occur, thereby enhancing the evolution ability of radial cracks after blasting. At the 1# measuring point located vertically above the blasting hole within the rock mass, the peak tensile strain of the test model is 1.26, 1.15, 1.06, and 1.01 times that of the model without the control hole, when the distance d from the control hole to the coal-rock interface is 20, 60, 80, 100 mm. At the 2# measuring point near the coal body above the vertical blasting hole, the peak tensile strain of the test model is 1.79, 1.63, 1.49, and 1.05 times that of the non-control hole model with the distance d = 20, 60, 80, 100 mm from the coal-rock interface. The influence on the strain at the near end is most significant when the control hole is situated near the coal-rock interface. In this instance, the peak tensile strain of d = 20 mm exhibits the greatest increase, reaching 1.79 times that of the model without a control hole. At the 3# measuring point located at the far end of the coal body vertically above the blasting hole, the tensile strain peak value of the test model is 1.22, 1.34, 1.55, and 1.23 times that of the model without the control hole, when the distance d from the control hole to the coal-rock interface is 20, 60, 80, 100 mm. At the 4# measuring point of the horizontal coal body above the vertical blasting hole, the tensile strain peak value of the test model is 1.28, 1.40, 1.47, and 1.12 times that of the model without the control hole when the distance d from the control hole to the coal-rock interface is 20, 60, 80 and 100 mm. When the control hole is far away from the coal-rock interface, the effect is most pronounced on the strain at the far end of the coal body, and the peak tensile strain of d = 80 mm increases the most, which is 1.55 times that of the no control hole model.

Analysis of ultrasonic CT results

Before blasting

The range of ultrasonic wave velocity for the rock layer contour map is set at 2.00 km/s to 3.00 km/s, while for the coal seam contour map, it is 1.00 km/s to 2.00 km/s. Before blasting, the ultrasonic wave velocity of the rock layer is 2.10 km/sto 2.80 km/s, with the average wave velocity is 2.56 km/s. The ultrasonic wave velocity of the coal seam without the control hole is 1.80 km/sto 2.00 km/s, with the average wave velocity is 1.90 km/s. The ultrasonic wave speed of coal seam with control holes is 1.40 km/sto 1.97 km/s, with the average wave speed is 1.76 km/s. The post-processing software was used to conduct ultrasonic CT inversion imaging of the collected data, as shown in Fig. 9. As illustrated in the figure, the wave velocity contour map of the rock section can be roughly divided into three parts from right to left. The ultrasonic wave velocity is highest on the left side, followed by the middle, and lowest on the left side. The length of the pre-embedded blasting hole is 20 cm, and the leftmost 10 cm does not have a blasting hole through it. Therefore, the wave speed on the left is the greatest. During the process of pre-embedding the blasting hole, the left edge was tamped to a lesser extent than the middle, resulting in a lower wave speed on the left than in the middle. The leftmost edge of the buried pipe exhibits the least compaction, and a distinct trough in the wave speed is evident. The background color difference of the coal seam without control holes is minimal, which is indicative of uniform cementation and robust overall integrity of the test block. The regularity of the velocity profile contour map of the coal seam with control holes is analogous to that of the rock formation, yet the velocity of the coal seam is less pronounced than that of the rock formation.

After blasting

The variable Dv, which uses ultrasonic wave velocity data to reflect the damage degree of blasting simulated test model after blasting, can be expressed as28:

where, v1 represents the ultrasonic wave velocity of the similar simulated test model before the blasting test, and v2 represents the ultrasonic wave velocity of the similar simulated test model after the blasting test. The value of the damage variable Dv ranges from 0 to 1. The larger the calculated Dv value, the more serious the damage degree of the test model at this point; the smaller the Dv value, the less severe the damage degree of the test model at this point.

The ultrasonic wave velocity curves obtained from the three groups of models were compared and analyzed, and the damage amount reflected by the ultrasonic wave velocity in the S1, S2, and S3 planes were calculated, as shown in Tables 3, 4, 5. Invert the ultrasonic velocity image of the S1, S2, and S3 planes, as shown in Fig. 10. It can be seen that the ultrasonic wave velocity collected after the control hole placement is lower than that of the test model without the control hole placement. This indicates that the setting of the control hole can improve the evolution ability of the explosion crack and enhance the damage degree and range of the test model caused by the blasting load. Compared with the Dv of ultrasonic wave velocity as a variable to characterize the damage degree, in section S1, the control hole spacing d = 20, 60, 80, and 100 mm is 1.13, 1.27, 1.47, and 2.33 times the blasting damage of the model without control hole layout. In section S2, the control hole spacing d = 20, 60, 80, and 100 mm is 1.93, 1.93, 1.53, and 1.20 times the blasting damage of the model without control hole layout. In the S3 plane, control hole spacing d = 20, 60, 80, and 100 mm is 2.67, 2.11, 1.67, and 1.44 times the blasting damage of the model without control hole layout. The layout of control holes meanwhile amplifies the impact on the coal seam and the floor rock formation. Nevertheless, the intensification of damage to the coal seam is considerably more pronounced than that to the floor rock formation. As the distance from the control hole to the coal-rock interface increases from d = 20 mm to d = 60 mm, there is no significant change in the damage to the proximal end of the coal seam. However, the damage to the distal end is reduced to a certain extent. As the distance from the control hole to the coal-rock interface increases from d = 60 mm to d = 100 mm, the damage to the proximal end of the coal seam is reduced, and the damage to the distal end is also reduced to a certain extent. By establishing an appropriate control hole, the potential for evolution in explosive cracking can be enhanced, and the extent and scope of damage caused by blasting loads to the test model can be increased. When the control hole is situated within the crack zone, its influence on cracking is most pronounced, followed by the junction between the crack zone and the stress disturbance zone. Conversely, the cracking effect is least evident in the crushing zone. When the control hole is situated in the crack zone, the blasting stress wave generates a crushing zone near the coal and rock mass, subsequently propagating in an outward direction. Upon contact with the free surface of the control hole, the blasting stress wave reflects as a tensile stress wave, forming a stress concentration zone near the control hole. This optimizes the cracking effect, enhancing its efficacy. If the control hole is situated within the crushing zone, the blasting stress wave will directly penetrate the free surface of the control hole, resulting in a constrained cracking effect. However, when the control hole is situated in the stress disturbance zone, the majority of the blast energy is directed toward the coal and rock mass, resulting in a reduction in energy at the control hole. Consequently, the free surface effect of the control hole is less pronounced.

Field test of anti-reflection by blasting of soft coal seam floor

Blasting anti-reflection scheme

The test site was located in the C13 coal seam of a mine within the Huainan mining area, the average buried depth of the C13-1 coal seam is 800 m, with a thickness of 4.5 m and a measured gas pressure of 3.8 MPa. The measured gas pressure is 3.8 MPa, the initial velocity of gas release ∆p is 4, the firmness coefficient of coal f is 0.61, the comprehensive index D is 16, and K is 6.6, classifying it as a soft and outburst-prone coal seam29. To enhance the efficacy of gas pre-extraction during drilling and increase the concentration and pure quantity of gas extraction, deep hole pre-splitting blasting was implemented in the inlet floor roadway to enhance the gas permeability of the coal seam, as shown in Fig. 11. The 2# blasting hole was located 60 m to the right of the 1# blasting hole. Based on laboratory research, the optimal permeability enhancement effect was achieved when the extraction holes were positioned within the blasting fracture zone, which generally has an area between 3~5 m. Therefore, two extraction holes were constructed at 2 m and 3 m from each side of the 1# blasting hole, which were marked as extraction holes 3# and 4#. Additionally, another two extraction holes were constructed at 4 m and 5 m from each side of the 2# blasting hole, which were marked as extraction holes 5# and 6#. The drilling holes have a length of 26.5 m and a diameter of 113 mm. According to the test conclusion, if all the blasting holes for permeability enhancement were arranged in soft coal seams, it would be prone to hole collapse and the permeability-enhancing fractures to close rapidly. Therefore, the explosives for the 1# and 2# blasting holes were designed to be embedded in the floor rock, with a charge diameter of 50 mm.

The blasting explosives utilize a custom-designed coal mine gas extraction hydrocolloid column, the loading method of which is illustrated in Fig. 12. Subsequent to the initial exploration of the borehole, the pillars are loaded with anti-skid devices and subsequently deployed into the borehole. They are then loaded into the gunhead.

Investigation of blasting effect

The evolution of gas extraction volume and concentration before and after blasting the coal seam floor are illustratedin Fig. 13. It can be seen from the figure that after blasting, the pure quantity and concentration of gas extraction increase rapidly. The pure quantity of extracted gas from holes 3#, 4#, 5#, and 6# increased from 0.10 × 10–3, 0.14 × 10–3, 0.15 × 10–3, and 0.12 × 10–3 m3/min to 1.24 × 10–3, 1.68 × 10–3, 1.97 × 10–3, and 1.14 × 10–3 m3/min. Growth rates were 124%, 120%, 131% and 95%. Gas concentration increased from 5.16%, 5.83%, 5.86%, and 5.73% to 17.09%, 20.69%, 21.86%, and 15.83%, with growth rates of 331%, 355%, 373%, and 276%. The field test results indicate that suitable hole spacing should be carefully selected between the extraction hole and the blasting hole during the process of permeability-enhancing blasting; excessive or insufficient hole spacing can diminish the effectiveness of the blasting.

The results of the field tests indicate that when the distance between the extraction hole and the blasting hole is less than 4 m, as the distance between the two holes increases, the extraction volume and the growth rate of the gas concentration increase. This suggests that the degree of development of the cracks in the coal body is high and that the effect of increasing permeability is significant. When the distance between the extraction hole and the blasting hole exceeds 4 m, an increase in the spacing between the mining hole and the blasting hole results in a reduction in the pumping volume and the growth rate of gas concentration. This indicates that if the spacing between the mining hole and the blasting hole is excessive, the cracks between the two holes will not be fully connected, and an area will be excluded from the effective range of enhanced permeability. In comparison to the placement of blasting holes in soft coal seams30, the growth rates of gas concentration and pumping volume are markedly higher, exhibiting sustained high levels over an extended period. This evidence substantiates the viability of floor blasting as a technique for achieving coal seam reinforcement in deep soft and high-gas coal seams.

Conclusion

-

During the permeability-enhancing blasting operation of the coal seam floor, the arrangement of control holes guides the extension direction of cracks, leading to directional fracture of the specimen. In addition, the role of spatial compensation provided by the control holes increases the extension distance of blast-induced cracks and enhances the damage degree in the far zone of the blast. After the blasting process, the arrangement of control holes can result in an increase of up to 133% in damage to the coal seam and a reduction of up to 167% in damage to the floorboard compared to the model without control holes.

-

When the blasting stress wave passes through the wall of the control hole, it is reflected to form a tensile stress wave, which causes the crack to develop towards the control hole and generates many tensile cracks. When the control hole is close to the coal-rock interface, the influence on the near end of the coal body is most significant. The peak value of the damage and tensile strain in the model d = 20 mm is 1.93 times and 1.79 times that in the model without the control hole. When the control hole is farfrom the coal-rock interface, the influence on the far end of the coal body is most significant. The peak value of the damage and tensile strain in the model d = 80 mm is 1.53 times and 1.55 timesthat in the model without the control hole.

-

Field test results demonstrate a rapid escalation in both the purity and concentration of gas extraction afterblasting. Excessive or inadequate spacing between the extraction and blasting holes diminishes the blasting efficacy. Optimally, when the distance is maintained at 4 m, positioning the extraction hole within the blasting-induced fracture zone, the permeability enhancement effect is maximized. Consequently, the pure gas extraction rate surges from 0.15 × 10–3 m3/min to 1.97 × 10–3 m3/min, registering a growth rate of 131%. Similarly, the gas concentration substantially increase, climbing from 5.86% to 21.86%, with a remarkable growth rate of 373%.

Data availability

Data that support the findings of this study have been deposited in Dryad Digital Repository with the URL: https://datadryad.org/stash/share/p_nFQRCkHIzgJcKcE-QQopn4XGGqhcgIFRMjobhKDQU. And the datasets used and analysed during the current study available from the corresponding author on reasonable request.

References

Yuan, L. et al. Strategic thinking of simultaneous exploitation of coal and gas in deep mining. J. China Coal Soc. 41(1), 1–6 (2016).

Xie, H. P. et al. Research framework and anticipated results of deep rock mechanics and mining theory. J. China Coal Soc. 44(5), 1283–1305 (2019).

Yang, L. et al. Risk prediction of coal and gas Outburst in deep coal mines based on the SAPSO-ELM algorithm. Int. J. Environ. Res. Public Health 19, 12382 (2022).

Li, P. et al. Technology of coupled permeability enhancement of hydraulic punching and deep-hole pre-splitting blasting in a “three-soft” coal seam. Materiali in Tehnologije 55(1), 89–96 (2021).

Cao, J. et al. Analysis of the statistical laws and dynamic effect characteristics of coal and gas outburst accidents in China in recent 10 years. Min. Saf. Environ. Protection 51(3), 1–6 (2024).

Yang, W. et al. Optimization of drilling parameters for coal seam gas extraction considering fluid-solid coupling and field application. Energy Sci. Eng. 12(3), 657–669 (2024).

Wu, F. et al. Air leakage characteristics of gas boreholes in deep coal seams and application of short-hole grouting and plugging. ACS Omega 9(20), 22074–22083 (2024).

Fan, C. J. et al. Coal seam gas extraction by integrated drillings and punchings from the floor roadway considering hydraulic-mechanical coupling effect. Geofluids. https://doi.org/10.1155/2022/5198227 (2022).

Wang, H. Y. et al. Study on the propagation laws of hydrofractures meeting a faulted structure in the coal seam. Energies 10(5), 654 (2017).

Sun, X. D. et al. Influence of supercritical CO2 fracturing mode on the fracture morphology and propagation characteristics of coal. Energy Fuels 38(5), 4325–4336 (2024).

Zhu, F. H. et al. The shaped blasting experimental study on damage and crack evolution of high stress coal seam. Journal of Loss Prevention in the Process Industries 83, 105030 (2023).

Qiao, G. D. et al. Experimental study on the control of mine pressure and gas gover-nance in thick and hard roof by pre-blasting of slotted cartridge. J. China Univ. Min. Technol. 53 (2), 334–45+76. (2024).

Zhang, X. et al. Experimental study on permeability enhancement by combined action of control hole and directional control blasting in high gas and low permeability coal seam. Chin. J. Rock Mech. Eng. 42(8), 2018–2027 (2023).

Zhang, J. W. Application and analysis of deep hole pre-splitting blasting technology in driving face. World Nonferrous Metals 21, 145–146 (2018).

Dan, Z. et al. Study on the technology of enhancing permeability by deep hole presplitting blasting in Sanyuan coal mine. Sci. Rep. https://doi.org/10.1038/s41598-021-98922-9 (2021).

Guo, D. Y. et al. Mechanism of millisecond - delay detonation on coal cracking under deep - hole cumulative blasting in soft and low permeability coal seam. J. China Coal Soc. 46(8), 2583–2592 (2021).

Gao, K. et al. Mechanism and application of cross-interface fracturing for permeability enhancement through the roof blasting of tectonic coal seams. Coal Geol. Explor. 52(4), 35–46 (2024).

Li, H. et al. Study on the technology of permeability enhancement of deep hole pre-splitting blasting in a low-permeability coal seam. Environ. Earth Sci. https://doi.org/10.1007/s12665-023-11332-0 (2024).

Fu, S. et al. Research on deep hole convergence energy blasting for increasing permeability in deep wells with high gas and low permeability coal seams. Coal Sci. Technol. (2024).

Liu, J. Z. et al. Current situation and development trend of coalbed methane development and utilization technology in coal mine area. J. China Coal Soc. 45(1), 258–267 (2020).

Zhang, J. et al. Blasting for fracturing and improving the permeability of deep, soft, outburst prone coal seams using blasthole and relief hole drilled into the underlying stratum: optimal hole distance. Geofluids. https://doi.org/10.1155/2022/7008131 (2022).

Gao, K. et al. Research of simulation experiment on permeability enhancement by blasting in soft coal seam floor and its application. Coal Sci. Technol. (2023).

Qiao, G. D. et al. Experimental study on action mechanism of control holes on cracks propagation in cross-seam blasting. J. Saf. Sci. Technol. 16(7), 68–74 (2020).

Chang, S. et al. Study on simulation experiment of anti-reflection of coal seam induced by controlled blasting in soft coal seam floor strata. Coal Technol. 42(12), 169–174 (2023).

Yang, S. et al. Experimental study on the effect of the angle of the shaped charge tube on the penetration enhancement of coal seam blasting. Coal Sci. Technol. 52(3), 129–138 (2023).

Zheng, Q. et al. Distribution characteristics and evolution process of in-situ stress field in Huainan ming area. China Min. Magaz. 32(3), 133–140+157. (2023).

Zhang, S. C. et al. Tests for control hole’s enhanced permeability mechanism under blasting load. J. Vib. Shock 36(24), 213–219+249. (2017).

Qiao, G. D. et al. Experimental study on the controlo of mine pressure and gas governance in thick and hard roof by pre-blasting of slotted cartridge. J. China Univ. Min. Technol. 53(2), 334–345+376. (2024).

Gan, L. T. et al. Coal and rock dynamic disaster analysis in Huainan Mining Area based on key stratum control principle. Saf. Coal Mines 52(7), 187–192 (2021).

Zhang, Z. Application and research of deep hole presplit blasting technology in shaft exposing coal in soft outburst coal seam. Coal Technol. 30(7), 77–79 (2011).

Author information

Authors and Affiliations

Contributions

J.Y. Zhang contributed to the conceptualization. J.Y. Zhang and Y.X. Gong contributed to the methodology. J.Y. Zhang and Y.X. Gong contributed to the software. Y.X. Gong contributed to the validation. J.Y. Zhang contributed to the formal analysis. J.Y. Zhang contributed to the investi gation. J.Y. Zhang contributed to the resources. J.Y. Zhang and Y.X. Gong contributed to the data curation. J.Y. Zhang contributed to the writing—original draft preparation. J.Y. Zhang contributed to the writing—review and editing. J.Y. Zhang contributed to the visualization. J.Y. Zhang contributed to the supervision. Y.X. Gong contributed to the project administration. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, Jy., Gong, Yx. Study on anti-reflection of deep soft and high gas coal seam floor by deep hole controlled blasting. Sci Rep 14, 25720 (2024). https://doi.org/10.1038/s41598-024-76206-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-76206-2