Abstract

To study the influence of cyclic disturbance stress on the mechanical behavior of coal during mining, a gas containing coal fluid-solid coupling servo seepage experimental system was used to conduct experimental research on the acoustic emission (AE) characteristics of gas containing coal under two stress paths of graded cyclic loading and unloading. The AE characteristics of coal damage and failure processes under different cyclic stress paths were analyzed. The research results indicate that: (1) The overall characteristics of AE signals for both graded cyclic loading and unloading paths are basically the same. With increasing of the amount of graded cyclic loading or unloading, the AE count reaches its maximum value when reaching failure, and the cumulative ringing calculation of AE increases exponentially. (2) The AE signals under the graded cyclic loading or unloading path exhibit obvious zoning characteristics. In the low and medium stress regions, the AE signal basically satisfies the Kaiser effect, while reaching the high stress region before failure, the AE signal exhibits a significant Felicity effect. (3) The concentration coefficient of AE and the intensity coefficient of the Kaiser effect have been newly defined. They are used to quantitatively characterize the extent of the Kaiser effect of AEs under graded cyclic stress. It was found that as the variation of graded cyclic stress increases, the concentration coefficient and Kaiser effect intensity coefficient both show a decreasing trend. (4) Combining the AF and RA values of AE, it was found that the coal failure signals of the two stress paths were basically similar, that is, the overall failure was mainly tensile failure, and the signals of cyclic unloading tensile failure were significantly more than those of cyclic loading. The AE signal characteristics studied in this article are of great significance for predicting coal power disasters.

Similar content being viewed by others

Introduction

In the process of coal mining construction, such as tunnel excavation and coal mining at working faces, there are usually dynamic mechanical problems that make it difficult to meet the actual needs of rock engineering by using coal mining rock mass construction as a quasi-static mechanical environment in the past1,2,3. Especially, the graded cyclic loading has a significant impact on the mechanical properties of coal and rock masses4,5,6. The rock grading cyclic loading and unloading test was applied to mining engineering earlier. Engineers used blasting and drilling to mine ore, and further improved the efficiency of mining ore by controlling the stress cyclic loading and unloading generated during the mining process. In the process of underground engineering construction, the external load, especially the cyclic load, will activate, expand and penetrate the micro-cracks and micro-defects in the rock. The response of these meso-structures under different stresses plays a decisive role in the macroscopic mechanical behavior of the rock7. According to the existing research, it can be seen that rock mass is often subjected to different forms of cyclic loading in rock mass engineering. It is of great engineering significance to study the damage evolution law of rock under cyclic loading for the stability determination of engineering rock mass. At present, many scholars have carried out research on the damage evolution law of rock under cyclic loading. Therefore, studying the acoustic emission (AE) characteristics of rock masses under graded cyclic loads has gradually become an important means of monitoring and distinguishing the stability of coal and rock masses.

There are a lot of original cracks or natural defects in coal and rock mass, and the change of its stress state will cause damage to varying degrees. The strain energy is released in the form of elastic waves and propagates in the rock mass, showing AE characteristics. The study of AE during rock tensile and compressive failure has achieved rich results, mainly exploring the relationship between the stress-strain characteristics of rocks and AE parameters, as well as how to predict rock stability using AE laws8,9,10. As a non-destructive monitoring technology, acoustic emission has been developed so far, especially in the study of rock stress and failure characteristics11,12. Japanese scholars first linked AF (average frequency) and RA (rise time / amplitude) two parameters to evaluate the crack failure mechanism of concrete materials. The calculation method of the parameters is: AF = acoustic emission count / duration, RA = rise time / amplitude13. Through research, it is found that the tensile AE signal is characterized by high AF and low RA distribution, while the shear AE signal is characterized by low AF and high RA distribution. Since then, a crack identification and classification method based on acoustic emission RA-RA parameters has been gradually formed14. Jing et al.15 studied investigates the crack-propagation behavior of coal and magnetite under uniaxial compression, experimental results reveal that the proportion of tensile cracks is significantly higher than shear cracks during the loading process. Carpinteri et al.16 is based on the three-point bending (TPB) test of concrete beams of different sizes and the classification of cracking modes according to AE parameters. Compression tests were also carried out to verify whether it is appropriate to use AE parameters to identify fracture modes. However, the actual engineering rock mass is in a state of graded loading or cyclic loading and unloading, which puts forward higher requirements for the study of rock mass AE in complex stress environments. The research on AE characteristics of coal and rock under cyclic loading mainly focuses on Kaiser effect and Felicity effect. For the Kaiser effect, Wang et al. and Chen et al.17,18 studied the AE characteristics and Kaiser effect of rocks during uniaxial compression; Shkuratnik et al. and Du et al.19,20 analyzed the deformation and AE characteristics of rocks through triaxial tests, and discussed the influence of different loading paths on the Kaiser effect. Some scholars have studied the influence of cyclic loading and unloading on Kaiser effect of AE processes such as coal, sandstone, marble and some sedimentary rock21,22,23,24. It can be seen that the Kaiser effect of rocks under different stress loading methods has received sufficient attention25,26. The AE activity pattern generated by fatigue failure under graded cyclic loading can be obtained by analyzing the Felicity effect, thereby studying the degree of rock damage27,28. The Felicity effect refers to the phenomenon of a significant increase in AEs during cyclic loading when the load is less than the highest stress level borne in the previous stage29. The Felicity effect is a counter evidence and supplement to the Kaiser effect, and some scholars have paid attention to the Felicity effect in rock AE. Cheng et al.30 have explored the effects of pore-water pressure and graded cyclic load on the strength characteristics and Felicity effect of limestone, and analyzed the deformation characteristics of limestone based on the change path of Felicity ratio. Chen et al.31 explored the Felicity effect of sandstone under constant amplitude cyclic loading and graded cyclic loading conditions; Li et al.32 showed that during the unloading stage, the AE signal gradually decreases, and the stress memory characteristics of rocks exhibit a significant Felicity effect. Zhang et al.27 found that when the cyclic load reaches 1/3 to 1/2 times the uniaxial compressive strength, the Felicity effect of the rock is more significant. The Felicity ratio gradually decreases in the elastic stage and increases in the plastic stage; The Felicity effect was used for the identification of crack stress threshold and damage assessment33. Many studies have also been conducted on the characteristics of AE signals under graded cyclic loading34,35,36, but the vast majority of studies have qualitatively analyzed the Kaiser effect and Felicity effect during the graded cyclic loading process. The intensity of Kaiser and Felicity effects has not been quantitatively analyzed, and the AE characteristics of different graded cycle paths have not been compared and analyzed. Therefore, the internal mechanism of the AE characteristics caused by graded cycle loads is not clear enough.

Therefore, an experimental study on the mechanical AE characteristics of gas-bearing coal and rock under two different stress paths of graded cyclic loading and graded cyclic unloading was conducted using the gas-bearing coal and rock fluid solid coupling experimental system and the PCI-2 AE system. The AE characteristics of the damage and failure process of coal and rock under two different stress paths of graded cyclic loading and unloading were analyzed. Based on the regional characteristics of the Kaiser effect and Felicity effect of AE signals under graded cyclic loading and unloading, a concentration coefficient and Kaiser effect intensity were defined to quantitatively characterize the AE signal characteristics of each stress region. Based on the AE AF and RA values, the failure mode of coal and rock under cyclic loading was determined. It was found that the internal causes of coal and rock failure induced by loading and unloading stress paths were both caused by the increase of deviatoric stress.

Materials and methods

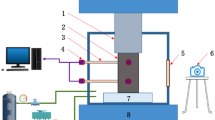

Coal samples and test equipment

The coal samples are collected from a coal mine in southwestern China. According to the experimental criterion suggested by International Society for Rock Mechanics (ISRM)32, the coal samples were processed to a cylinder with 50 mm diameter and 100 mm length. The experiment selects coal sample with similar densities drilled from the same coal block to reduce errors. The experimental study was conducted using a gas-bearing coal fluid solid coupling experimental system and a PCI-2 AE system (as shown in Fig. 1). The specific parameters and functions of the experiment can be found in reference37,38.

Multilevel cyclic loading and unloading tests

To compare the effects of different cyclic stress paths on the mechanical and AE characteristics of coal, this experiment conducted on coal failure under two cyclic stress paths: graded cyclic loading and graded cyclic unloading. The specific stress paths and loading parameters of the two cycles stress schemes were as follows:

-

(1)

Graded cyclic loading stress path

After gradually loading the axial pressure and confining pressure to 3 MPa and maintaining stability, the confining pressure remains unchanged. The axial pressure is cyclically loaded and unloaded in a 10kN gradient, with a specific path of 10→20→10→25→10→30…10 kN→peak strength→failure→immediately stopping the test, as shown in Fig. 2(a).

-

(2)

Graded cyclic unloading stress path

After gradually loading the axial pressure and confining pressure to 8 MPa and maintaining stability, continue to load the axial pressure to 40 MPa, and then perform graded cyclic unloading according to a gradient of 1 MPa. The graded cyclic unloading confining pressure path is 8→7→8 →6→8→5…8 MPa→unloading reaches the coal rock bearing limit→coal rock unloading failure →stopping the experiment, as shown in Fig. 2(b).

The link between step-by-step cyclic loading and step-by-step cyclic unloading is that in the process of material failure, the deviatoric stress (that is, the difference between the maximum principal stress σ1 and the minimum principal stress σ3) plays a crucial role. The difference between these two loading methods is that one is to load the axial pressure to keep the confining pressure unchanged, and the other is to unload the confining pressure to keep the axial pressure unchanged.

Experimental results and analysis

The failure and AE characteristics of coal rock under two stress paths of graded cyclic loading and unloading were studied, and compared and analyzed the AE signal characteristics under the two paths. Based on the regional characteristics of the Kaiser effect and Felicity effect of AE signals under cyclic loading, a concentration coefficient and Kaiser effect intensity were defined to quantitatively characterize the AE signal characteristics of each stress region. Based on the AE AF and RA values, the failure mode of coal under cyclic loading was determined. It was found that the internal causes of coal and rock failure induced by loading and unloading stress paths were both caused by the increase of deviatoric stress.

AE signal characteristics of coal under graded cyclic loading and unloading

Figure 3 shows the distribution of AE ringing counts under two different paths of graded cyclic loading axial pressure and graded cyclic unloading confining pressure. The distribution pattern of AE ringing counts under the two paths is roughly similar. As the number of graded loading or unloading cycles increases, the distribution density of AE ringing counts gradually increases and the peak value also gradually increases. Before failure, the AE ringing count sharply increases. For each cyclic loading (or unloading), the peak value of AE ringing counts basically remains near the highest (or lowest) point of cyclic loading (or unloading).

Figure 4 shows the cumulative AE ringing counts curve during the graded cyclic loading and unloading process. It can be seen that the AE ringing counts increases step by step with the gradual increase of the graded cyclic loading (or unloading), and the cumulative AE ringing count increases step by step. There are two stages for cumulative AE ringing count in each level cycle of the loading or unloading process: that is, the calm stage and the surge stage. The cumulative AE ringing count increases slowly in the low stress stage, and significantly increases in the previous stages of adjacent failure. The cumulative AE ringing counts of the two paths also exhibit similar patterns.

Zoning characteristics of AE signals in coal under graded cyclic loading

The previous section provided the overall distribution pattern of AE ringing counts and cumulative AE ringing counts. In order to further understand the pattern of AE in each cycle process, the low stress, intermediate stress, and high stress stages before failure in the graded cycle process were amplified (as shown in Figs. 5 and 6). From the enlarged image, it can be seen that different stress stages during the graded cyclic loading (or unloading) process exhibit different AE distribution patterns. In the low stress stage, both graded cyclic loading and unloading processes exhibit a significant Kaiser effect. The AE signal remains quiet until the peak (or valley) stress of the previous stage is reached during loading (or unloading). When the stress reaches the previous peak (or valley) stress, the AE ringing count increases sharply. In both medium and high stress stages, both graded cyclic loading and unloading processes exhibit significant Felicity effects. The AE signal appears throughout the entire loading and unloading process, especially when the coal sample is near failure.

AE signals have strong regional characteristics during graded cyclic loading and unloading, that is, they are not random, but mainly concentrated in specific stress regions. Therefore, studying the AE signals of different stress regions is of great significance for understanding the AE laws of coal and rock. From the enlarged image, it can also be seen that the AE signal has obvious zoning characteristics. The AE ringing counts is mainly concentrated in the area above (or below) the previous peak (or valley) stress under graded cyclic loading (or unloading). In order to quantitatively analyze the Kaiser effect and zoning characteristics of the AE signal, each stress cyclic was divided into three stress sections, namely the stress AB section, the stress BCD section, and the stress DE section. The AE ringing counts corresponding to the above stress segments are defined as N+ Pl, NPh, and N− Pl, respectively. The total number of AE ringing counts for a single stress cycle is N, as shown in Fig. 7.

According to Fig. 7, the AE ringing counts of different stress zones were accumulated to obtain a quantitative characterization of the AE ringing counts of different stress zones under different cycles, as shown in Figs. 8 and 9. The NPh values generated by the BCD stress zone are very close to N in each cycle, and the curves of N and NPh almost coincide, and are much larger than the values of N+ Pl and N− Pl. The results indicate that in each cycle, the vast majority of AE cycles are concentrated in the BCD stress zone. As the number of cycles increases, the values of NPh and N increase faster and faster, and rapidly increase near the coal failure stage. To observe N+ Pl and N− Pl more clearly on the general y-axis, parts of Figs. 8a and 9a were separated and enlarged to Figs. 8b and 9b. It is found that the AE ringing counts of the DE stress zone increase in a exponential function with the increase of the number of cycles. However, there is a certain difference in N+ Pl generated in the AB stress zone, which is mainly reflected in the smaller number of AE ringing counts N+ Pl generated in the AB stress zone during graded cyclic loading, and the larger number of AE ringing counts N+ Pl generated in the AB stress zone during graded cyclic unloading.

By comparing and analyzing the characteristics of AE ring count in different stress zones, it is found that there are great differences in AE signals. In order to quantitatively compare the difference degree and concentration degree of AE signals, and quantify the Keyser effect intensity in different stress zones, Keyser Effect Intensity Coefficient ξ+ in AB stress zone, Keyser Effect Intensity Coefficient ξ− in DE stress zone and AE Concentration Coefficient ψ in BCD stress zone are defined as:

where ξ+ shows the strength of Keyser effect in AB stress zone, ξ− shows the strength of Keyser effect in in DE stress zone, ψ shows the percentage of AE signal concentrated in BCD stress zone in each cycle. The range of three coefficients is (0,100%), 100% represents the strongest Keyser effect or the highest concentration degree of AE signal. The relationship among ξ+, ξ− and ψ is as follows

According to Eqs. 1–4, the values of ξ+, ξ− and ψ (see Fig. 10) are calculated. Overall, the value of ξ+, ξ− and ψ all decrease with the increase of the number of grading cycles. However, there are certain differences between graded cyclic loading and unloading.

-

(a)

For graded cyclic loading axial pressure: The value of ξ+ is close to the maximum value of 100% in each cycle, exhibiting a significant Keyser effect phenomenon in the loading section. The value of ξ− approaches 100% at the beginning of the cycle, and gradually moves away from 100% as the number of cycles increases. The ξ+ is always greater than ξ−, indicating that the Kaiser effect of AE during loading axial pressure is better than unloading axial pressure37. The overall trend change of ξ− is a decrease in volatility, exhibiting a significant Keyser effect phenomenon in the unloading section with low cyclic stress. As the cyclic stress increases, the Keyser effect weakens. According to Eq. 4, the change ξ+ is very small, so the changes of ψ are mainly due to the changes of ξ−. As the number of cycles increases, the change trend of ξ− and ψ are similar, which indicates that with the increase of cyclic stress, the concentration ratio of AE signals generated in the BCD stress zone decreases. Not only near the peak stress, but also during the unloading process, a large number of AE signals will be generated (see Fig. 5c).

-

(b)

For graded cyclic unloading confining pressure: the value of ξ+, ξ− and ψ all decrease with the increase of graded cyclic unloading confining pressure, and indicating that the intensity of the Keyser effect and the concentration of AE in the graded cycle unloading gradually decrease. The ξ− is always greater than ξ+, indicating that the Kaiser effect of AE signal during loading confining pressure is better than unloading confining pressure. This is exactly the opposite of the result of graded cyclic loading with axial pressure. Essentially, the Kaiser effect of both axial and radial graded loading segments is better than the Kaiser effect of unloading37. Therefore, loading exhibits a good Kaiser effect both in the axial and radial directions, while unloading is worse than the Kaiser effect during the loading process.

Analysis of internal failure morphology characteristics of coal based on AE statistics

The average frequency (AF) value is the AE count divided by the duration of the AE signal. AE signal mainly in the form of wave, so the type of micro-crack can be judged by the characteristics of wave38. The rising angle (RA) value in AE signal is used to describe the source mechanism, and the RA-AF distribution analysis is widely used to determine failure modes in various material fields39,40. The RA value is the ratio of the rise time of each AE signal to the maximum amplitude. The two parameters used to judge the crack type are RA and AF, which can be calculated by the following equation:

where RT is the rise time; A is the maximum amplitude; C is AE event number and D is the duration. The unit of RA is ms/V and the unit of AF is kHz.

Usually, the combination of low RA value and high AF value corresponds to the development of tensile cracks and energy release of fast longitudinal waves, while the combination of high RA value and low AF value is related to shear crack propagation and energy release of slower shear waves41,42. Therefore, the decrease in AF value indicates a transition from tensile crack mode to shear crack mode. Figure 11 shows the changes in AF values during the graded cyclic loading and unloading process. The AF values of two different grading cycle paths exhibit similar patterns. As the number of graded cycles increases, the distribution density and span of AF values significantly increase.

To further investigate the RA-AF distribution and crack characteristics, according to the crack identification and classification method based on acoustic emission RA-RA parameters proposed and gradually formed by researchers13,14. Figure 12 shows the distribution of RA and AF in coal rocks under different graded cycling paths. From the enlarged image, it can be seen that the distribution characteristics of RA-AF are basically the same during the loading and unloading processes of graded cycles. The main manifestation is that most of the AE signals are high AF values and low RA values, indicating that graded cycle loading and unloading cause compression and expansion of coal and rock, and tensile failure mainly occurs under the expansion force. This is because the essence of failure caused by graded cyclic loading or unloading is the same, both of which are gradually increasing deviatoric stress, which is the key to causing coal failure. The increase in graded cycles leads to an increase in deviator stress. So there are many similar patterns in AE signal between graded cyclic loading and unloading.

Conclusions

To study the influence of cyclic disturbance stress on the mechanical behavior of coal during mining, this paper uses a gas containing coal and rock fluid solid coupling servo seepage experimental system to conduct experimental research on the mechanical AE characteristics of gas containing coal under two different stress paths: graded cyclic loading and graded cyclic unloading. The AE characteristics of coal and rock damage and failure process under two different stress paths: graded cyclic loading and graded cyclic unloading are analyzed. The research results indicate that:

-

(1)

The overall characteristics of AE signals for both graded cyclic loading and unloading paths are basically the same. With increasing of the amount of graded cyclic loading or unloading, the AE count reaches its maximum value when reaching failure, and the cumulative ringing calculation of AE increases exponentially.

-

(2)

The AE signals under the graded cyclic loading or unloading path exhibit obvious zoning characteristics. In the low and medium stress regions, the AE signal basically satisfies the Kaiser effect, while reaching the high stress region before failure, the AE signal exhibits a significant Felicity effect.

-

(3)

The concentration coefficient of AE and the intensity coefficient of the Kaiser effect have been newly defined. They are used to quantitatively characterize the extent of the Kaiser effect of AEs under graded cyclic stress. It was found that as the variation of graded cyclic stress increases, the concentration coefficient and Kaiser effect intensity coefficient both show a decreasing trend.

-

(4)

Combining the AF and RA values of AE, it was found that the coal failure signals of the two stress paths were basically similar, that is, the overall failure was mainly tensile failure, and the signals of cyclic unloading tensile failure were significantly more than those of cyclic loading. The AE signal characteristics studied in this article are of great significance for predicting coal power disasters.

Data availability

All data generated or analysed during this study are included in this published article. The data that support the findings of this study are available from the corresponding author, [Minke Duan], upon reasonable reques.

References

Xiao, J., Ding, D., Jiang, F. & Xu, G. Fatigue damage variable and evolution of rock subjected to cyclic loading. Int. J. Rock. Mech. Min. 47(3), 461–468. https://doi.org/10.1016/j.ijrmms.2009.11.003 (2010).

Wang, X., Zou, Q., Wang, R., Li, Z. & zhang, T. Deformation and acoustic emission characteristics of coal with different water saturations under cyclic load. Soil. Dyn. Earthq. Eng. 162, 107468. https://doi.org/10.1016/j.soildyn.2022.107468 (2022).

Liu, J., Zhang, R., Song, D. & Wang, Z. Experimental investigation on occurrence of gassy coal extrusion in coalmine. Saf. Sci. 113, 362–371. https://doi.org/10.1016/j.ssci.2018.12.012 (2019a).

Martin, C., Kaiser, P. & Christiansson, R. Stress, instability and design of underground excavations. Int. J. Rock. Mech. Min. 40(7–8), 1027–1047. https://doi.org/10.1016/S1365-1609(03)00110-2 (2003).

Ghabezloo, S., Sulem, J., Guedon, S. & Martineau, F. Effective stress law for the permeability of a limestone. Int. J. Rock. Mech. Min. 46(2), 297–306. https://doi.org/10.1016/j.ijrmms.2008.05.006 (2009).

Vaneghi, R., Ferdosi, B., Okoth, A. & Kuek, B. Strength degradation of sandstone and granodiorite under uniaxial cyclic loading. J. Rock. Mech. Geot Eng. 10(1), 117–26. https://doi.org/10.1016/j.jrmge.2017.09.005 (2018).

Lu, Z., Ju, W., Gao, F. & Du, T. Numerical analysis on the factors affecting post-peak characteristics of coal under uniaxial compression. Int. J. Coal Sci. Technol. 11, 2. https://doi.org/10.1007/s40789-023-00626-0 (2024).

Liu, S. et al. Energy distribution and fractal characterization of acoustic emission (AE) during coal deformation and fracturing. Meas 136, 122–131. https://doi.org/10.1016/j.measurement.2018.12.049 (2019b).

Wang, H. et al. Stress-induced AE varying characteristics in distinct lithologies subjected to uniaxial compression. Eng. Fract. Mech. 13, 109266. https://doi.org/10.1016/j.engfracmech.2023.109266 (2023a).

Wang, Z., Wang, J., Yang, S., Li, L. & Li, M. Failure behaviour and acoustic emission characteristics of different rocks under uniaxial compression. J. Geophys. Eng. 17(1), 76–88. https://doi.org/10.1093/jge/gxz092 (2020).

Shang, D., Chen, Y., Zhao, Z., Shuantong, S. & Qi, X. Mechanical behavior and acoustic emission characteristics of intact granite undergoing direct shear. Eng. Fract. Mech. 245, 107581. https://doi.org/10.1016/j.engfracmech.2021.107581 (2021).

Zhang, G., Wu, S., Zhang, S. & Guo, P. P-wave velocity tomography and acoustic emission characteristics of sandstone under uniaxial compression. Rock. Soil. Mechs. 44(2), 483–496. https://doi.org/10.16285/j.rsm.2022.1106 (2023).

Wang, J. et al. Research on classification of rock tensile-shear fracture based on acoustic emission RA-AF values and kneedle algorithm. Chin. J. Rock. Mech. Eng. 43(S1), 3267–3279. https://doi.org/10.13722/j.cnki.jrme.2023.0696 (2024).

Gan, Y., Wu, S., Ren, Y. & Zhang, G. Evaluation indexes of granite splitting failure based on RA and AF of AE parameters. Rock. Soil. Mech. 41(7), 2324–2332. https://doi.org/10.16285/j.rsm.2019.1460 (2020).

Jing, G., Zhao, Y., Wang, H., Montanari, P. & Lacidogna, G. Study of coal and magnetite collapse process and precursor based on acoustic emission flicker noise spectroscopy. Rock. Mech. Rock. Eng. 57, 8545–8562. https://doi.org/10.1007/s00603-024-03989-1 (2024).

Carpinteri, A., Lacidogna, G., Corrado, M. & Di Battista, E. Cracking and crackling in concrete-like materials: a dynamic energy balance. Eng. Fract. Mech. 155, 130–144. https://doi.org/10.1016/j.engfracmech.2016.01.013 (2016).

Wang, H. et al. Stress-induced AE varying characteristics in distinct lithologies subjected to uniaxial compression. Eng. Fract. Mech. 13, 109266. https://doi.org/10.1016/j.engfracmech.2023.109266 (2023b).

Chen, C., Xu, T., Heap, M. & Baud, P. Influence of unloading and loading stress cycles on the creep behavior of darley dale dandstone. Int. J. Rock. Mech. Min. 112, 55–63. https://doi.org/10.1016/j.ijrmms.2018.09.002 (2018).

Shkuratnik, V., Filimonov, Y. & Kuchurin, S. Regularities of acoustic emission in coal samples under triaxial compression. J. Min. Sci. 41(1), 44–52. https://doi.org/10.1007/s10913-005-0062-8 (2005).

Du, F. et al. Investigation of the acoustic emission characteristics during deformation and failure of gas-bearing coal-rock combined bodies. J. Loss Prevent Proc. 55, 253–266. https://doi.org/10.1016/j.jlp.2018.06.013 (2018).

Yang, Y. et al. Experimental investigation on the permeability and damage characteristics of raw coal under tiered cyclic unloading and loading confining pressure. Powder Technol. 389, 416–429. https://doi.org/10.1016/j.powtec.2021.05.062 (2021).

Shen, R. et al. Study on the effect of the lower limit of cyclic stress on the mechanical properties and acoustic emission of sandstone under cyclic loading and unloading. Theor. Appl. Fract. Mec 108, 102661. https://doi.org/10.1016/j.tafmec.2020.102661 (2020).

Shi, K., Mei, F., Cheng, M., Yang, Z. & Luo, W. Experimental study on the effect of high stress cyclic loading on Kaiser effect in marble. Chn J. Rock. Mech. Eng. 36(12), 2906–2916. https://doi.org/10.13722/j.cnki.jrme.2017.0456 (2017).

Kharghani, M., Goshtasbi, K., Nikka, M. & Ahangari, K. Investigation of the Kaiser effect in anisotropic rocks with different angles by acoustic emission method. Appl. Acoust. 175, 107831. https://doi.org/10.1016/j.apacoust.2020.107831 (2021).

Zhang, H. et al. Directional independence of the Kaiser effect of sandstone with high diameter-thickness ratios. Meas. 196, 111291. https://doi.org/10.1016/j.measurement.2022.111291 (2022).

Lavrov, A. The Kaiser effect in rocks: principles and stress estimation techniques. Int. J. Rock. Mech. Min. 40, 151–171. https://doi.org/10.1016/S1365-1609(02)00138-7 (2003).

Zhang, Y., Chen, Y., Yu, R., Hu, L. & Irfan, M. Effect of loading rate on the felicity effect of three rock types. Rock. Mech. Rock. Eng. 50(6), 1673–1681. https://doi.org/10.1007/s00603-017-1178-2 (2017).

Li, P., Su, G., Xu, H. & He, B. Quantitative detection of damage processes in granite by sound signals. Int. J. Rock. Mech. Min. 164, 105356. https://doi.org/10.1016/j.ijrmms.2023.105356 (2023a).

Sun, B., Yang, P., Liu, S. & Zeng, S. Impact dynamic characteristics and constitutive model of granite damaged by cyclic loading. J. Mater. Res. Technol. 24, 333–345. https://doi.org/10.1016/j.jmrt.2023.03.047 (2023).

Cheng, Y. et al. Effect of pore-water pressure on felicity effect of acoustic emission in limestone under graded cyclic load. J. Bas Sci. Eng. 30(2), 361–373. https://doi.org/10.16058/j.issn.1005-0930.2022.02.010 (2022).

Chen, Y., Wei, Z. & Zhang, Q. Experimental study on felicity effect of acoustic emission in rock under cyclic loading and tiered cyclic loading. J. Chn Coal Soc. 37(2), 226–230. https://doi.org/10.13225/j.cnki.jccs.2012.02.001 (2012).

Li, N., Wang, E., Zhao, E. & Ma, Y. Experiment on acoustic emission of rock damage and fracture under cyclic loading and multi-stage loading. J. Chn Coal Soc. 35(7), 1099–1103. https://doi.org/10.13225/j.cnki.jccs.2010.07.030 (2010).

Tian, Y., Yu, R. & Zhang, Y. Application of felicity effect in crack stress identification and quantitative damage assessment of limestone. Rock. Mech. Rock. Eng. 53, 2907–2913. https://doi.org/10.1007/s00603-020-02062-x (2020).

Jiang, C. et al. Experimental study on seepage properties, AE characteristics and energy dissipation of coal under tiered cyclic loading. Eng. Geol. 221, 114–123. https://doi.org/10.1016/j.enggeo.2017.03.005 (2017).

Duan, M. et al. Experimental investigation on the permeability, acoustic emission and energy dissipation of coal under tiered cyclic unloading. J. Nat. Gas Sci. Eng. 73, 103054. https://doi.org/10.1016/j.jngse.2019.103054 (2020).

Zhao, K. et al. Damage evaluation of rock salt under multilevel cyclic loading with constant stress intervals using AE monitoring and CT scanning. J. Petrol. Sci. Eng. 208, 109517. https://doi.org/10.1016/j.petrol.2021.109517 (2022a).

Ulusay, R. The ISRM suggested methods for rock characterization, testing and monitoring: 2007–2014. Springer. 74, 1499–1500. https://doi.org/10.1007/s10064-015-0780-3 (2014).

Li, S., Lin, H., Hu, S., Cao, R. & Luo, X. Mechanical behavior of anchored rock with an infilled joint under uniaxial loading revealed by AE and DIC monitoring. Theor. Appl. Fract. Mec. 123, 103709. https://doi.org/10.1016/j.tafmec.2022.103709 (2023b).

Sagar, R. & Prasad, B. A review of recent developments in parametric based acoustic emission techniques applied to concrete structures. Nondestruct Test. Eva. 27(1), 47–68. https://doi.org/10.1080/10589759.2011.589029 (2012).

Ohno, K. & Ohtsu, M. Crack classification in concrete based on acoustic emission. Constr. Build. Mater. 24, 2339–2346. https://doi.org/10.1016/j.conbuildmat.2010.05.004 (2010).

Aggelis, D. Classification of cracking mode in concrete by acoustic emission parameters. Mech. Res. Commun. 38(3), 153–157. https://doi.org/10.1016/j.mechrescom.2011.03.007 (2011).

Zhao, K., Ma, H., Yang, C. & Daemen, J. The role of prior creep duration on the acoustic emission characteristics of rock salt under cyclic loading. Int. J. Rock. Mech. Min. 157, 105166. https://doi.org/10.1016/j.ijrmms.2022.105166 (2022b).

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (52104176, U21A20110), the Open Project Program of Anhui Engineering Research Center of Exploitation and Utilization of Closed/abandoned Mine Resources (EUCMR202201), Anhui Province Graduate Education Quality Engineering Project (2022xssfkc017, 2023dshwyx015, 2023yjsxssfkc018), Anhui University of Science and Technology Graduate Innovation Fund(2023cx2032); Funded by the Open Research Fund of the State Key Laboratory for Fine Exploration and Intelligent Development of Coal Resources, CUMT (SKLCRSM22KF014).

Author information

Authors and Affiliations

Contributions

Minke Duan:The conception and design of the study, or acquisition of data, or analysis and interpretation of data and draft the article or revising it critically for important intellectual content; Meijuan Lu:The conception and design of the study; Ruiqi Ban:acquisition of data; Ke Yang:Final approval of the version to be submitted; Xing Lyu:The analysis of data; Changbao Jiang:The interpretation of data; Xuelong Hu:The interpretation of data; Jinzhou Tang: The analysis of data.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Duan, M., Lu, M., Ban, R. et al. Study on the failure and acoustic emission characteristics of coal under graded cyclic loading and unloading stress paths. Sci Rep 14, 26863 (2024). https://doi.org/10.1038/s41598-024-76581-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-76581-w

Keywords

This article is cited by

-

The influence of cyclic loading-unloading rates on the uniaxial mechanical anisotropy of coal

Scientific Reports (2025)

-

Study on the Prediction Method for Coal and Rock Mass Fracture Process Based on Time Series Acoustic Emission Statistical Model

Rock Mechanics and Rock Engineering (2025)