Abstract

In order to solve the problems of serious deformation and difficult support of roadway surrounding rock in the process of gob-side entry driving, taking 230,708 working face of Huopu Mine as the engineering background, the migration characteristics of overburden rock and the stress distribution of surrounding rock before and after roof cutting in the process of gob-side entry driving were studied by means of theoretical analysis, similar simulation test and field measurement. The results show that: ① the establishment of lateral suspension mechanical model analysis found that, with the increase of coal seam dip angle, the reduction of the coal pillar bearing capacity before and after cutting the top gradually decreases, the dip angle of coal seam is 30°, Compared with the reduction of coal pillar bearing capacity before roof cutting is 2164 KN; with the increase of the overburden rock caving angle, the reduction of the coal pillar bearing capacity before and after cutting the top increases continuously, the caving angle of overburden rock is 63°, Compared with the reduction of coal pillar bearing capacity before roof cutting is 2218 KN. ② After the implementation of roof cutting and cutting off the overhanging roof structure, the stress of the surrounding rock of the coal pillar gang in the roadway has significantly decreased by 18.87%, and the stress of surrounding rock of roadway solid coal gang, roof and floor is reduced by 8.48%,5.79% and 4.81% respectively, which relieved the concentration in the surrounding rock stress of the roadway and improves the stress condition of the roadway. The study concludes that roof cutting can not only change the stress environment of the surrounding rock in the roadway, but also increase the filling degree of the goaf, realizing that the coal pillar and the gangue in the goaf jointly bear the overburden rock pressure, ensuring the stability of the roadway.

Similar content being viewed by others

Introduction

At present, in our country, the gob-side entry type is mainly divided into complete gob-side entry and leave small coal pillars gob-side entry1, completely gob-side entry refers to the upper section after mining, close to the upper section of the abandoned back to the edge of the gateway to re-excavate a roadway, leave small coal pillar gob-side entry refers to leave a certain size of small coal pillars at the edge of the upper section of the gateway and excavate the next section of the gateway. Due to the side of the complete gob-side entry is the goaf, the goaf water accumulation, broken gangue and residual gas in the goaf are easy to enter the gateway and have an impact, therefore, at present, the main commonly used in high-gas mines is to leave small coal pillar gob-side entry. Leaving small coal pillar excavating is not only conducive to the full exploitation of coal resources, but also can avoid the direct connection between the roadway and the goaf in the high gas coal seams, play a role in blocking gangue, waterproofing, and preventing air leakage, and is very beneficial to ensure the safe production of coal. However, after the upper working face has been mined back, the overburdened rock structure near the working face’s goaf and the leaved coal pillar bends, rotates, and sinks, ultimately forming a support structure that supports the overburdened rock. This structure will increase the stress on the coal pillar, causing uneven stress and asymmetric deformation of the roadway2,3. Especially in the Guizhou area, it is mainly (gently) inclined thin and medium-thick coal seams. Compared with the horizontal/near-horizontal coal seam gob-side entry, due to the asymmetry and heterogeneity of the surrounding rock structure of the roadway, the roadway gang is more affected by shear slip dislocation, the sidewall is serious, and the roadway deformation is large. To solve the problem of large deformation and serious sidewall in gob-side entry, the roof cutting technology is applied to gob-side entry. The connection between the roof of the goaf and the roof above the coal pillar is cut off artificially, and the stress transfer path of the two is changed. While improving the stress state of the surrounding rock, the upper roof can fully collapse. The caving gangue can effectively fill the goaf, and can also support the overburdened roof of the goaf and relieve the bending subsidence of the roof. Improve the ability of the roadway to resist deformation and reduce the deformation of roadway surrounding rock4.

In recent years, scholars at home and abroad have done a lot of research on the surrounding rock control technology of roof cutting and pressure relief roadway in gob-side entry through theoretical analysis, numerical simulation, similar simulation test, and on-site measurements. Based on the energy design criterion, a method of roof cutting pressure relief and energy absorption is proposed. The directional roof cutting technology is used to cut off the stress transfer path of the overburden roof so that the roadway is in a low-stress state. The comparative model test of the dynamic pressure roadway collaborative pressure relief control method and the traditional method is carried out, and the evolution law of the displacement and stress of the surrounding rock of the stope and the roadway and the characteristics of the overburden rock movement are compared and analyzed. The results show that the cooperative pressure relief method reduces the degree of mine pressure behavior of dynamic pressure roadways and effectively controls the deformation of roadway surrounding rock5,6,7,8. The influence of roof cutting parameters on the roadway is studied by numerical simulation, and the optimized parameters are applied to similar material simulation experiments. The numerical simulation results show that with the increase of roof cutting angle and roof cutting height, the vertical stress and horizontal displacement of the coal wall increase first and then decrease, which is the same as the vertical stress and displacement of roadway support. It is found that the roof cutting and pressure relief technology can cut off the cantilever beam structure of the main roof, isolate the stress transfer between rock masses, and reduce the deformation of the roadway9,10,11,12,13,14. Ma et al.15 according to the theory of statics and energy theory, the stress state and roof deformation mechanism of hydraulic support in the gateway are analyzed. According to the geological conditions of 12,201 working face, the design scheme of roof cutting and pressure relief in mining roadway is determined, and the effect of roof cutting is analyzed by numerical simulation. The field test was carried out on the 12,201 working face to verify the pressure relief effect of roof cutting and pressure relief. The results show that the deformation of the roadway is reduced, that is, the effect of roof cutting and pressure relief is obvious. The stress distribution and deformation characteristics of different types of roof cutting are studied by means of theoretical analysis, numerical simulation and field measurement. The results show that the advance pre-splitting effectively blocks the stress transfer of the high-rise roof strata, the roadway is in the stress unloading area, the stress environment of the roadway surrounding rock is obviously optimized, and the deformation of the roadway surrounding rock is obviously reduced16,17,18,19,20,21. Aiming at the problems that the overburden movement and stress distribution of steeply inclined coal seam are more complex than that of the horizontal coal seam, and the control is more difficult, based on the actual project, the roof caving filling, stress evolution characteristics, and overburden movement law are studied. The results show that the roof is asymmetrically damaged, and the stress concentration occurs at both ends of the working face. With the continuous filling of the caving roof, the stress concentration of the lower inclined roof will occur again, and finally stabilize22,23,24,25. Based on the research background of mining coal seams with large dip angles and static distance, the overburden strata movement and roof failure characteristics of stope in large dip angle and close distance coal seams are studied by various research methods. The results show that the position relationship of different positions of two working faces in close distance coal seam will lead to different mechanical structures of the roof in the lower coal seam working face, and different deformation, failure, and displacement will occur, which will affect the mine pressure appearance26,27,28,29.

In summary, this paper takes the 230,708 mining face of Huopu Mine as the engineering background, and uses comprehensive research methods such as theoretical analysis, similar simulation test, and field measurement to analyze the failure characteristics of roadway surrounding rock and the migration law of roof strata, and reveals the effect of roof cutting on improving the stress of roadway surrounding rock.

Engineering background

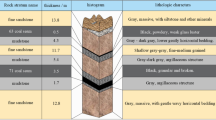

The underground elevation of the 230,708 mining working face is + 1356.2 m ~ + 1255.4 m, and the project is about 2500 m from the industrial square to the north.230708 mining working face is located in the south wing of 23 mining area; the 2179 mining face in the upper section of the coal seam has been completed; the overburden 3# and 5# coal seams are not mined; there is no project in the underlying 9# and 12# coal seams. The dip angle of the coal seam is 30, the immediate roof of the coal seam is siltstone, and the thickness is 2 m; the main roof is argillaceous siltstone with a thickness of 6.6 m. The direct bottom is mudstone with a thickness of 0.3 m. The basic bottom is argillaceous siltstone with a thickness of 0.7 m. The comprehensive histogram of rock strata and the plane layout of working face are shown in Fig. 1.

Study on roof breaking structure gob-side entry roadway

"Masonry beam structure" after roof breaking

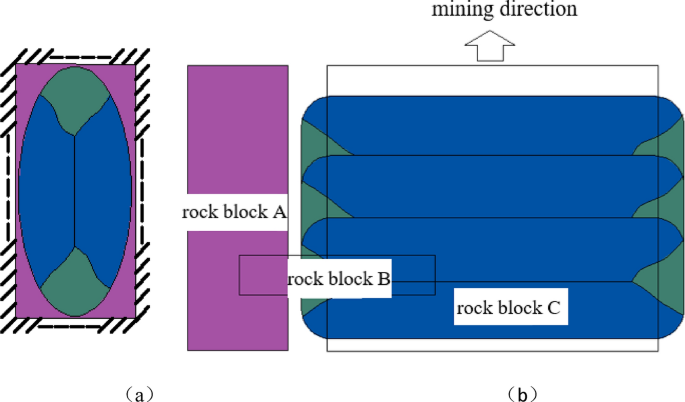

With the continuous advancement of the working face, the overburden rock in the goaf will lose the original supporting conditions. At this time, the roof of the goaf is pressure-bearing for a long time under the continuous loading of the overburden rock. In the process of advancing the working face, only the false roof will collapse, and other roofs are still in a suspended state. The suspended roof can be regarded as a four-sided fixed plate. When the uncollapsed roof reaches the limit span, it first breaks in the middle of the long side of the roof, and then cracks are formed in the middle of the short side. After all the cracks penetrate, the "O" -shaped damage is formed, resulting in the initial fracture of the "X" shape. With the mining advance of the working face, the "K"-shaped periodic collapse will be formed after multiple collapses, and the roof state changes to three sides fixed and one side simply supported plate. According to the horizontal force of mutual extrusion of broken rock, friction is generated between rock blocks. The working face can be divided into three areas: upper, middle, and lower. The upper and lower areas of the working face form an arc-shaped failure under the action of friction. The rock blocks belong to a three-dimensional occlusion relationship. In the middle area, a beam-like appearance is formed, which is essentially an arched fractured beam structure, called a “masonry beam”, as shown in Fig. 230,31.

According to the “masonry beam” structure model of the overburden rock, the key strata of the overburden rock are divided into rock block A, rock block B and rock block C, as shown in Fig. 2b. The deformation and failure of the roadway is determined by the degree of rotation and subsidence of the main roof rock block A and the key block B. The coal pillar, the roadway roof and the solid coal side are the rock block A and B support bodies, and the fracture position of the two has an important influence on the force effect of the lower support body.

Mechanical analysis of suspended roof gob-side entry roadway

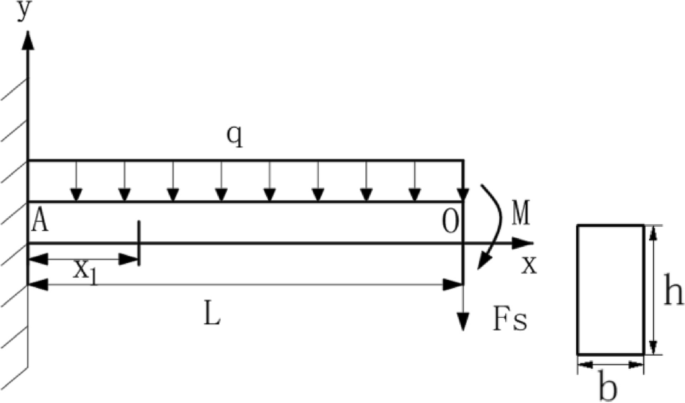

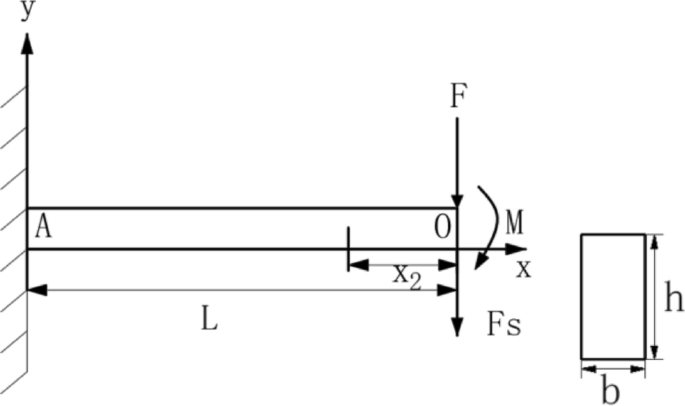

After the mining of the working face, the O-X collapse of the roof of the goaf occurs, and the arc triangular block structure on both sides of the working face is not broken. There is still a certain suspended roof structure, which continues to bear the weight of the overburdened rock and continues to act on the coal pillar and the roadway of the adjacent working face. In order to facilitate the analysis of its beam structure, it can be simply regarded as a cantilever beam. The deep roof cantilever beam structure is mainly affected by two parts of the load. The first part is the rock mass load perpendicular to the top of the hanging roof range, and the other part is the partial hanging roof structure load that falls backward along the direction of the caving angle, as shown in Fig. 3.

As shown in Fig. 4, assuming that the average bulk density of the rock mass above each rock layer is γ and the dip angle of the coal seam is α, then the uniform load q is:

where:α is the dip angle of coal seam,°; n is the number of rock strata from top to bottom; q is the uniform load of the rock layer above the hanging roof of the triangular block, N/m; Hi is the height of the i layer above the roof, m; the average bulk density of γ-rock, N/m3.

Under the uniform load q, the bending moment of the cantilever beam at this time is:

where:M is cantilever beam bending moment, KN m; x1 is the distance from any point on L to the fixed end A, m.

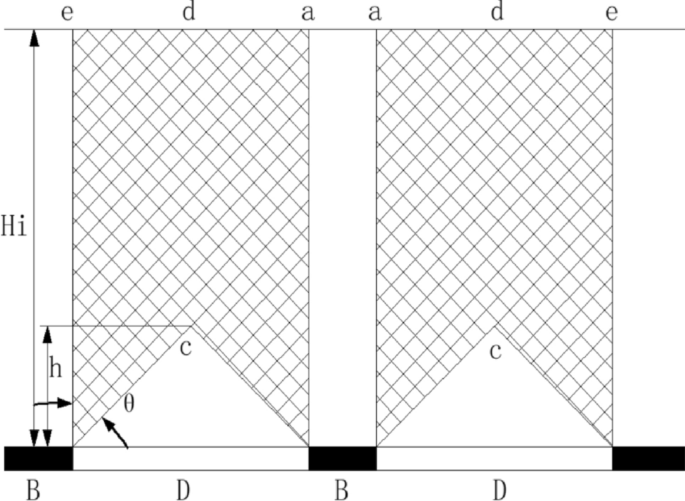

The load on the coal pillar of the roadway is caused by the weight of the overburden rock on the coal pillar and the weight of the suspended strata on one or both sides of the coal pillar transferred to the coal pillar, which is closely related to the caving angle of the rock stratum. The caving angle of the rock stratum is the fracture of the roof of the goaf after reaching a certain hanging roof span. The fracture surface of each rock stratum is roughly located on the same straight line and its angle with the vertical direction. The caving angle mainly depends on the strength of the coal body. The coal body has high strength, good integrity, and a small caving angle, on the contrary, the caving angle is large. Therefore, we can calculate the weight of part of the overburden rock carried by the coal pillar after the collapse of the rock stratum. As shown in Fig. 5, the total load P on the coal pillar of one unit length is:

where:B is the width of coal pillar, m; D is the width of goaf, m; H is the buried depth of roadway, m; θ is the caving angle of overburden rock in goaf; h is the single layer thickness of the main roof strata, m; γ is the average volume force of overburden rock, kN/m3.

As shown in Fig. 6, according to the Saint–Venant principle, the load imposed by the overburden rock within this range can be equivalent to applying a concentrated force F at the end of the cantilever beam:

where:θ-rock collapse angle.

The bending moment equation is:

where:M is cantilever beam bending moment; x2 is the distance from any point on L to the fixed end A.

According to the superposition of the effect of the mechanical force of the material, the result of the combined action of multiple forces is equivalent to the sum of the results of each force acting alone. Based on this, it can be concluded that the maximum bending moment of the hanging roof vertical overburden rock load and the overburden rock load in the caving zone to the triangular block hanging roof is:

From the analysis of the mechanical structure of the cantilever beam, the upper edge is subjected to tensile stress and the lower edge is subjected to compressive stress. Combined with rock mechanics, the compressive strength of the rock is far greater than the tensile strength, so according to the maximum tensile strength of the suspended roof, the ultimate caving step of the roof can be calculated.

where: σtmax is the maximum tensile stress of the section, N/m2; y is the distance from the point to the neutral axis of the beam, taking half of the thickness of the immediate roof, m; JZ is the moment of inertia, and the rectangular section takes JZ = bh3/12; h is the thickness of immediate roof, m4.

The limit caving step distance of the triangular block of the lateral suspended roof is solved as follows:

At this time, the overburden load under the condition of the maximum span of the lateral suspension roof reaches the maximum:

The stress of the coal pillar after gob-side entry driving is mainly composed of the rock mass above the lower section roadway, the rock mass above the vertical coal pillar, the suspended roof of the goaf, and some of the rock mass above. Now, the load of these rock masses is analyzed:

The load of rock mass above the lower section roadway is borne by the coal pillar and the solid coal of the lower section mining face. Therefore, the central axis of the roadway is taken as the dividing point, and the load of rock mass above it is borne by two parts. The part borne by the coal pillar is inclined due to the coal seam. The dip angle is α, and then half of the width of the divided central axis roadway is used to calculate the weight of the bearing rock mass:

Similarly, the load on the coal pillar by the overburden rock mass is:

The limit span of the hanging roof structure near the goaf side of the coal pillar has been calculated before. The weight of the rock mass above the limit span can be calculated according to the formula:

In the middle of the roof of the goaf, it first breaks and collapses. The cantilever beam structure still bears the weight of the uncollapsed part of the rock mass. The weight is evenly distributed to the support bodies on both sides. The weight of this part of the rock mass can be calculated from the collapse angle θ at this time:

Through the roof cutting technology, the fracture line position of the basic roof is artificially controlled, and the overburden structure is improved to make the upper part of the roadway and the basic roof rock block of the goaf disconnect without forming a structure. The suspended roof structure collapses along the cutting line to reduce the lateral pressure effect of the lateral suspended roof on the roadway and coal pillar. If the collapse angle is θ1 at this time, it can be seen from the weight analysis of the overburden rock mass that the weight of the suspended roof after the roof cutting is:

The bearing capacity of coal pillar after roof cutting is:

The reduction relative to the pre-cut top is:

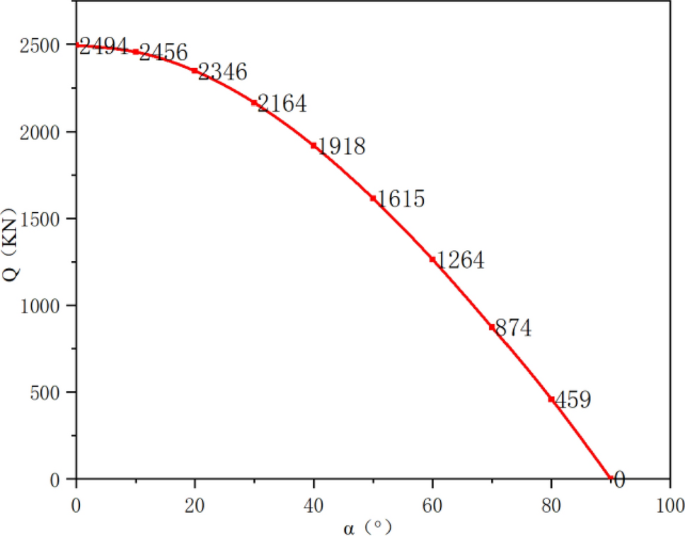

In order to obtain the influence of coal seam dip angle on the reduction of coal pillar bearing capacity before and after roof cutting, the reduction of coal pillar bearing capacity corresponding to different coal seam dip angles is calculated according to Formula (16). The calculation parameters are selected according to the mechanical parameters of the rock strata given in the geological data of the 230,708 working face of Huopu Mine. The γ is 14.21 kN/m3, the thickness of the immediate roof is 2.2 m, the thickness of the main roof is 6.6 m, and the unit body b is 1. According to the literature32,33, θ is 63°. The calculation results are shown in Fig. 7. With the increase of the dip angle of the coal seam, the reduction of the bearing capacity of the coal pillar before the comparative roof cutting is gradually reduced to zero.

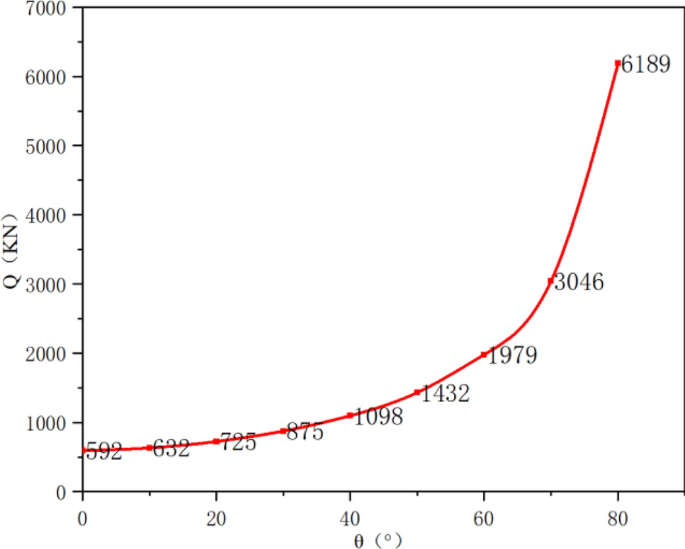

In order to obtain the influence of the caving angle of the overburden rock on the reduction of the bearing capacity of the coal pillar before and after the roof cutting, the reduction of the bearing capacity of the coal pillar corresponding to the different caving angles of the overburden rock is calculated according to the formula (16). The calculation parameters are selected according to the mechanical parameters of the rock strata given in the geological data of the 230,708 working face of Huopu Mine. The γ is 14.21 kN/m3, the thickness of the immediate roof is 2.2 m, the thickness of the main roof is 6.6 m, the α is 30°, and the unit body b is 1. The calculation results are shown in Fig. 8. With the increase of the caving angle of the overburden rock, the reduction of the bearing capacity of the coal pillars before the comparative roof cutting continues to increase.

Similar simulation test of roadway excavation

Based on the actual engineering and geological conditions, the similar simulation test is based on the similarity criterion and similarity principle, and the physical model is built with the appropriate similar material ratio to reproduce the excavation, disturbance and other engineering behaviors in the actual project. The deformation motion characteristics and stress evolution law are monitored by various means. In this similar simulation test, fine river sand was selected as aggregate, gypsum and calcium carbonate as cementing materials, and mica powder as layered material of each rock layer.

Similarity theory and ratio materials

-

(1)

Similarity theory.

The similarity simulation test requires that there is a certain inherent law between the model and the prototype. According to the basic criteria of the similarity theory, the following conditions should be satisfied between the two:

-

➀

Geometric similarity:Combined with the field engineering practice and laboratory model conditions, the geometric similarity ratio c1 = 1:50 is determined.

-

➁

Bulk density similarity:According to the relevant data of similar material ratio test, the average bulk density of similar materials is 17 kN/m3, the average bulk density of actual rock mass is 25 kN/m3, and the similarity ratio of similar simulated bulk density is cv = 1:1.4.

-

➂

Stress similarity:From the known geometric similarity ratio c1 and bulk density similarity ratio cv, the stress similarity ratio cσ = 1:70 can be calculated.

-

➀

-

(2)

The results of similar material ratio test and mechanical parameters are shown in Table 1.

Table 1 Ratio table of similar simulation test.

Similar test model design

The size of the test model is 1400 mm long, 30 mm wide, and 1200 mm high. Firstly, according to the dip angle and thickness of similar rock strata set by the actual engineering geological conditions, the corresponding identification is made on the back plate of the model to facilitate the accurate laying of similar materials. According to the conclusion of the similar ratio test, the fine river sand, calcium carbonate, gypsum, and water were weighed and stirred according to the ratio to prepare similar materials. According to the thickness of different rock strata, the prefabricated roadway was buried from bottom to top, as shown in Fig. 9. After the model was built, the model was dried naturally for 25 days and then the model was monitored.

In the process of similar simulation test, the high-speed camera is used to record the migration and change of rock strata under the action of excavation and continuous stress loading. The equipment can capture all aspects of the whole process of the test at all times. The displacement monitoring equipment is shown in Fig. 10.

The BW type pressure box and JM3813 multifunctional static strain gauge were used for stress monitoring. The connection method is as follows: the pressure box is connected according to the red, yellow, blue, and black corresponding strain gauge A, B, C, and D ports, and the green line is grounded.

The monitoring points are arranged as shown in Fig. 11. A total of 9 monitoring points are arranged around the roadway. 1#, 2#, and 3# are arranged on the left side of the roadway to monitor the stress changes of the solid coal side, left shoulder angle, and left side angle of the roadway. 5#, 6#, 7#, and 8# are arranged in the coal pillar of the right side of the roadway to monitor the stress changes of the right side, the right shoulder angle, the right side angle, and the coal pillar of the roadway. 4# is arranged directly below the floor of the roadway to monitor the change of floor stress during the excavation of the roadway. 9# is arranged directly above the roadway roof and the stress change trend of the roof during the separation process after the excavation of the roadway is monitored.

Failure characteristics of roadway surrounding rock and migration law of roof strata

After the natural air drying of the test model, the fracture evolution of the surrounding rock and the migration characteristics of the overburden rock under pressure were monitored. The different loading stress was used as the segmentation interval, and the Thousand Eye Wolf high-speed camera was used to monitor the migration of the overburden rock before and after the roof cutting. Observe and analyze the caving of overburden rock in goaf, the deformation of coal pillar and roadway surrounding rock, and the development of fissures in different sub-intervals.

After the monitoring work is ready, the goaf is excavated. With the stress loading, the roof above the coal seam is separated and broken, and horizontal and vertical cracks are developed.

As shown in Fig. 12, when the roof is not cut, (a) there are many different degrees of separation in the roof of the goaf. The roof above the goaf can be roughly regarded as forming an "E"-shaped stepped cantilever structure with a long upper end and a short lower end. Under the influence of the weight of the overburden rock mass, the interior of the coal pillar roof is affected by the tensile stress. The coal pillar is broken on the side of the goaf, and there are developed cracks on the side of the goaf above the roadway. The roof fracture line is located above the coal pillar and extends to the side of the roadway in the lower section. The key stratum is divided into rock block A, key block B and bending sinking part C along the fracture line. The three parts are hinged together to form an unstable structure. The existence of suspended roof structure makes the control of goaf with great uncertainty, which is easy to cause roof accidents. Although the separation layer also appears above the goaf of (b) after roof cutting, the degree and quantity of separation layer are weaker than those without roof cutting. At this time, the fracture line is located on the side of the goaf. The "E" -shaped suspended roof structure above the goaf collapses and fills the compacted goaf along the cutting seam line. The implementation of roof cutting improves the stress environment and eliminates the stress influence of the suspended roof structure on the coal pillar and the roadway in the lower section. As shown in Fig. 11, when the roof is not cut, (a) there are many different degrees of separation in the roof of the goaf. The roof above the goaf can be roughly regarded as forming an "E" -shaped stepped cantilever structure with a long upper end and a short lower end. Under the influence of the weight of the overburden rock mass, the interior of the coal pillar roof is affected by the tensile stress. The coal pillar is broken on the Comparing (a) and (b) roof caving and roadway surrounding rock fracture development, under the same stress loading, the method of roof cutting control surrounding rock can effectively alleviate the influence of coal pillar and lower section roadway after working face mining, reduce the pressure of coal pillar by lateral suspension roof, and improve the bearing capacity of coal pillar.

As shown in Fig. 13, when the loading stress continues to increase, the strength of the immediate roof strata above the goaf is low and the compressive capacity is weak. Under the action of the overburden load, the rock cracks are connected, the roof subsidence increases, and the separation between the rock strata occurs. In the middle of the goaf, the roof loses the original support body, resulting in the most serious subsidence. When the roof is not cut in the figure (c), the high-level rock strata are broken, the separation degree of the low-level rock strata is intensified, and the masonry beam structure is formed. The immediate roof touches the bottom, and the deformation degree of the coal seam roof is large. At this time, the coal pillar still has a certain bearing capacity on the side of the coal pillar, and the roof is not broken, bearing part of the suspended roof and its bearing overburden load. When the roof is cut (d), the beam connection structure between the goaf and the roof of the coal pillar is cut off, and the "E"-shaped stepped upper long and lower short cantilever wall is changed into a full short cantilever. The roof strata of the goaf have a strong integrity and the fracture is not obvious. With the seam line falling to the bottom, the coal pillar is complete near the goaf side, and there is no crushing. It is proved that the implementation of roof cutting can not only change the stress environment of the coal pillar, but also increase the filling degree of the goaf, realize the coal pillar and the caving roof rock mass of the goaf to share the overburden pressure, and ensure the stability of the coal pillar and the lower section roadway.

As shown in Fig. 14, in the process of increasing stress, when the roof is not cut, the cracks above the (e) roadway are more developed, the three-zone cracks in the overburden strata of the goaf are connected, and the transverse cracks continue to expand inside the roof strata, which further aggravates the degree of rock layer separation. The longitudinal cracks expand upward, the scope of the fracture zone is increased, the integrity of the rock layer is destroyed, the direct roof collapse in the middle of the goaf is full of the goaf, and the roadway is deformed and broken by the side of the coal pillar. The lower section of the "E"-shaped stepped suspended roof structure is bent and sunk, and the coal pillar is broken. The cracks extend to the upper part of the roadway through the coal pillar, and the development is obvious, indicating that under the continuous loading of the overburden rock load. The hanging roof of the lateral arc triangular block existing on the side of the coal pillar in the goaf diffracts the weight of the overburden rock mass it bears to the coal pillar and the upper part of the roadway. After the implementation of roof cutting, the (f) cutting line completely cuts the roof of the upper section, so that it collapses along the cutting line to fill the goaf. The cutting line cuts off the stress transfer path between the caving roof of the goaf and the original suspended roof structure and the roof above the coal pillar and the roadway, which reduces the stress influence of the cantilever beam structure on the coal pillar. The integrity of the coal pillar is good, and there are no obvious cracks and crushing, which protects the stability of the coal pillar and the roadway.

Stress distribution and evolution of surrounding rock of roadway

According to the change of pressure box data buried around the roadway before and after roof cutting, it can be seen that roof cutting plays an extremely important role in maintaining of coal pillar and the stability roadway. The surrounding rock stress of the roadway without roof cutting is generally greater than that after roof cutting, which proves that roof cutting changes the surrounding rock stress environment of the roadway and relieves the pressure of coal pillar and roadway surrounding rock.

As shown in Fig. 15, in the three test points on the side of the solid coal side of the roadway, they all increased first and then stabilized for a period of time and then changed to varying degrees. This is due to the change of stress at different positions caused by the excavation of the roadway. The stress value before and after the 1# point at the left shoulder angle did not change much, and the value increased first and then decreased slowly, which proved that the lower strata of the measuring point had cracks after the excavation of the roadway, and the stress at the bottom changed, and then the value continued to rise steadily after compaction. The change of 3# point of the bottom corner is the second. The influence of roof cutting on these three monitoring points can be obtained by the difference of their respective changes, 2# > 3# > 1#. Among them, the stress of surrounding rock at 2# point before and after roof cutting changed the most at 45 min of excavation, and the stress of surrounding rock decreased by 8.48%.

At point 4#, when the stress peak is loaded to 0.307 MPa, it stabilizes for a period of time and begins to decline. This is because the overburden pressure on the floor after the excavation of the roadway begins to relieve pressure, and the roadway is continuously excavated, resulting in a stepped decline. When the roadway is completely excavated, the surrounding rock layer will squeeze the floor to make it finally stable. Among them, the stress of surrounding rock at 4# point before and after roof cutting changed the most at 23 min of excavation, and the stress of surrounding rock decreased by 4.81%.

The 5#, 6#, 7# and 8# measuring points on the coal pillar are all first increased and then decreased and then maintained a slow upward trend. The pressure on the 5# measuring point at the bottom of the right side is the smallest. The pressure value of the 7# measuring point in the coal pillar is the largest, which is due to its strength is softer than the upper and lower strata, and the stress change is more obvious. The 8# measuring point is most affected by whether the roof cutting conditions, because there is a lateral suspension structure when the roof is not cut. The position of the 8# point can be regarded as the part of the suspension structure in a fulcrum area on the coal pillar. After the roof is cut, the original suspension roof is removed so that it is no longer affected by the lateral pressure of the lateral suspension roof. Therefore, the stress improvement is the most obvious. The stress of the surrounding rock at 8# point before and after the excavation of 7 min is the largest, and the stress of the surrounding rock is reduced by 18.87%. The influence of roof cutting on the right side of the roadway on the measuring point is 8# > 7# > 6# > 5#, and the stress of the measuring point is 7# > 8# > 6# > 5#.

The 9# measuring point of the roof is the same as the floor measuring point, which has been declining after the excavation of the roadway. After the excavation of the roadway, the roof rock layer of the roadway is separated, resulting in the lower part of the pressure box not being stressed. Under the continuous action of the overburden pressure, the degree of rock layer separation is aggravated, resulting in a decrease in the pressure value. The stress of the surrounding rock at the 9# point before and after the roof cutting is the largest, and the stress of the surrounding rock is reduced by 5.79%. From the stress value in the diagram, it can be seen that the stress on the coal pillar is about twice the stress on the solid coal. The stress of the coal body at the 7# measuring point of the coal pillar is large and will be squeezed to the inside of the roadway due to the effect of the inclination angle. In the actual project, it is necessary to pay attention to the support of the coal pillar side of the roadway, especially the upper side of the roadway in the inclined coal seam. It is necessary to take corresponding strengthening support measures to maintain the stability of the roadway.

In summary, the roof cutting has a significant effect on improving the stress conditions of the surrounding rock of the roadway. When the lateral suspended roof is not cut off, the load of the high-level rock stratum is transmitted to the coal pillar and the surrounding rock of the roadway through the suspended roof structure, so that it can bear more pressure on the original basis, which is prone to the separation and fracture of the rock stratum, resulting in large deformation of the roadway and roof fall and other accidents. After the implementation of roof cutting, the suspended roof structure is cut off, which eliminates this influence, and has the greatest pressure relief effect on the surrounding rock in the middle of the roadway, reduces the stress concentration on the coal pillar, and improves the bearing capacity of the coal pillar.

Engineering practice

Directional roof cutting pressure relief scheme design

In this experiment, the two-way energy-gathering blasting method is mainly used to cut the roof in the mining roadway of 230,708 working face. The blasting adopts the energy-gathering pipe with a length of 1.5 m, an outer diameter of φ42 mm and an inner diameter of φ36.5 mm as the energy-gathering device. The coal mine allowable three-stage emulsion water-containing explosive with a diameter of φ32 mm and a length of 300 mm was used as the pre-splitting cutting explosive.

Combined with the site conditions, the design and construction process of roof cutting and pressure relief scheme are as follows:

-

(1)

Blasthole construction: according to the geological conditions of the working face, in order to ensure that the borehole can penetrate the basic roof above the roadway and make it completely collapse when the roof is cut, the design depth of the borehole is 10 m. The blast hole is perpendicular to the roof of the roadway, and the outer diameter of the energy-gathering pipe is φ42 mm, so the diameter of the designed borehole is φ50 mm. In the field, pre-splitting blasting tests were carried out on different hole spacings, and pre-splitting blasting was carried out by using interval charge. Finally, the hole spacing was determined to be 800 mm. The roadway of the test section is 100 m, and 125 blasting holes are arranged by the roof cutting drilling machine. The construction position of the first blast hole is 100 m away from the open-off cut of 230,708 working face.

-

(2)

Charging mode: as shown in Fig. 16, the connection mode of detonator foot line in shaped charge tube is in series, and forward blasting is adopted. Five energy-gathering tubes are used in each hole, the length of sealing mud is 2.5 m, and the charge structure is 43,321. Explosives and stemming are alternately loaded into the hole, and the energy-gathering tubes are connected in turn. When the energy-gathering tubes are sent into the hole, it is necessary to ensure the level of the energy-gathering holes on both sides of the tube, and finally seal the hole with yellow mud.

-

(3)

Sounding gun and post-processing: Before detonation, all personnel need to be evacuated to check the safety of the environment around the detonation hole; after the detonation, the security inspector monitored the gas concentration and blasting situation of the roadway, after meeting the reasonable requirements, it can enter the roof cutting blasting section for the next construction.

Observation and evaluation of roof cutting effect

Taking the roof cutting position at a distance of 100 m from the open-off cut as the reference point, the stress measurement station is arranged at a distance of 50 m from the open-off cut, and the borehole stress meter depth of each stress measurement station is arranged at a distance of 2.5 m from the surface of the roadway. The surrounding rock borehole stress monitoring system can observe the stress variation law after roof cutting and evaluate the effect of roof cutting on roadway maintenance. The data collection is shown in Fig. 17.

As shown in Fig. 18, the stress evolution law of the surrounding rock of the roadway at different installation times is shown. After the installation of monitoring equipment, the stress rises steadily and slowly, but the rising rate is small. At this stage, it is less affected by the mining face, and the stress changes obviously after the 10th day, indicating that the surrounding rock of the roadway is affected by the mining face. After the 19th day, the stress value of the surrounding rock of the roadway in the uncut section still kept rising rapidly, and the rising rate of the stress value of the surrounding rock in the cut section became slower and more stable, indicating that the implementation of roof cutting in the field can effectively improve the stress environment of the surrounding rock of the roadway and enhance the stability of the roadway.

Conclusion

-

1.

In this paper, the roof-breaking characteristics of gob-side entry along goaf are studied, and the mechanical model of lateral hanging roofs is established. The bearing load of the hanging roof and the limit caving step are calculated, and the bearing load of the coal pillar is calculated. Compared with the load variation before and after roof cutting, it can be seen that the weight of the upper rock mass carried by the coal pillar after the implementation of the roof-cutting technology reduces the weight of all the rock mass in the limit span range and the weight of the other part of the rock mass that needs to be calculated by the caving angle. It shows that roof cutting can effectively reduce the bearing load of coal pillar, and reveals the internal mechanism of roof cutting to maintain the coal pillar and stability of the roadway.

-

2.

A similar simulation test platform was built, and a similar simulation study of roof cutting and pressure relief roadway excavation was carried out on the test platform. Through different working conditions under the condition of roof cutting and non-roof cutting, the stress of roadway surrounding rock under two conditions is studied. The research shows that the stress of the surrounding rock of the coal pillar side of the roadway is greatly reduced by 18.87%, and the stress of the surrounding rock of the solid coal side, roof, and floor of the roadway is reduced by 8.48%, 5.79%, and 4.81% respectively. The stress concentration of the surrounding rock of the roadway is alleviated, the stress conditions of the roadway are improved, and the mechanism of the roof cutting and pressure relief on the surrounding rock structure of the roadway is revealed.

-

3.

Through the analysis of the stress value data of the surrounding rock in the engineering practice, it can be seen that the stress value of the surrounding rock of the roadway rises slowly in the initial stage, which is less affected by the mining face at this stage, and the stress changes significantly after the 10th day, indicating that the influence degree of roadway surrounding rock by mining face increases at this time. After the 19th day, the stress value of the roadway surrounding rock in the uncut section still kept rising rapidly, and the rising rate of the surrounding rock stress value in the cut section became slower and more stable. It can be seen that the implementation of roof cutting in the field can effectively improve the stress environment of the roadway surrounding rock, enhance the stability of the roadway, and provide technical support for the control of such roadway surrounding rock.

Data availability

The data used and analyzed in the research process of this paper can be obtained from the corresponding author under reasonable requirements.

References

Kang, H. P. et al. Control technology and application of perimeter rock in pillarless mining. J. Coal Sci. 47(01), 16–44 (2022).

Liu, Y. X. et al. Study on the stability of peripheral rock in the tunnel of inclined extra-thick coal seam. J. China Univ. Min. Technol. 50(06), 1051–1059 (2021).

Li, M.P. Research on the Mechanism and Parameter of Top-Cutting Pressure Relief of Thick Hard Top Plate (China University of Mining and Technology, 2022).

He, M. C. et al. The theory of longwall mining roof-cutting short-wall beam and its 110 workings-the third mining science and technology change. Coal Sci. Technol. (01), 1–9+13. https://doi.org/10.19896/j.cnki.mtkj.2017.01.002 (2017).

Xue, H. J. et al. Study on the method of pressure relief by roof cutting and absorbing energy in deep coal mines. Bull. Eng. Geol. Environ. 82, 298 (2023).

Guo, Z. B. et al. Research on the transmission of stresses by roof cutting near gob rocks. Energies 14(5), 1237. https://doi.org/10.3390/en14051237 (2021).

Li, Z. H. et al. Longwall mining method with roof-cutting unloading and numerical investigation of ground pressure and roof stability. Arab. J. Geosci. 11(22), 1–13. https://doi.org/10.1007/s12517-018-3962-z (2018).

Jiang, Z. H. et al. Model test research and application on control method of cooperative pressurerelief by directional roof cutting for roadways with strong dynamic pressure. Environ. Earth Sci. 82, 434 (2023).

Hu, C. W. et al. Key parameters of gob-side entry retaining by roof cutting in close-distance seam group. Geomech. Geophys. Geo-Energy Geo-Resour. 10(1), 1–16. https://doi.org/10.1007/s40948-024-00772-y (2024).

Huang, X. H., Zhang, C. & Ren, Z. P. Parameter determination and effect evaluation of gob-side entry retaining by directional roof cutting and pressure releasing. Eng. Fail. Anal. 156, 1–15. https://doi.org/10.1016/j.engfailanal.2023.107847 (2024).

Wang, W. et al. Novel application of the roof-cutting-type gob-side entry retaining in coal mine. Math. Probl. Eng. 2021, 1–16 (2021).

Fan, D. Y. et al. Roof cutting parameters design for gob-side entry in deep coal mine: A case study. Energies 12(10), 1–25. https://doi.org/10.3390/en12102032 (2019).

Zhu, Q. W. et al. An exploration of improving the stability of mining roadways constructed in soft rock by roof cutting and stress transfer: A case study. Eng. Fail. Anal. 156, 1–24. https://doi.org/10.1016/j.engfailanal.2023.107898 (2024).

Liu, J. Z. et al. Overburden stress arch elevation effect induced by roof cutting and destress technique in coal mine longwall panel and its control mechanism to entry surrounding rock. Min. Metall. Explor. 40, 1237–1252 (2023).

Ma, X. G. et al. Study and application of roof cutting pressure releasing technology in retracement channel roof of Halagou 12201 working face. Math. Probl. Eng. 2018, 1–15 (2018).

Yu, B. et al. The sustainable development of coal mines by new cutting roof technology. R. Soc. Open Sci. 7 (2020).

Tian, C. et al. Stability control of a roadway surrounding rock during the cutting and pressure relief of a coal-bearing roof at a shallow mining depth. Geofluids 2022, 1–16 (2022).

Hao, Y. X. et al. Study on the stress distribution and stability control of surrounding rock of reserved roadway with hard roof. Sustainability 15(19), 1–21. https://doi.org/10.3390/su151914111 (2023).

Yang, X. J. et al. Research on the deformation mechanism and directional blasting roof cutting control measures of a deep buried high-stress roadway. Shock Vib. 2020, 1–14 (2020).

Zhang, K. et al. Research on roof cutting pressure relief of the gob-side entry retaining with roadside backfilling. Front. Earth Sci. 10, 1–14. https://doi.org/10.3389/feart.2022.835497 (2022).

Zhang, Z. et al. Coal pillar stress weakening technology and application by gob-side entry driving and hydraulic roof cutting in deep shafts mines. Processes 10(5), 827–827 (2022).

Yang, T. et al. Research on stress release for the gob-side roadway using the roof-cutting technology with a chainsaw arm. R. Soc. Open Sci. 7(3), 1–16. https://doi.org/10.1098/rsos.191663 (2020).

Chen, X. J. et al. Evolution and application of airflow permeability characteristics of gob in roof cutting and pressure releasing mining method. Energy Sci. Eng. 8, 2073–2085 (2020).

Wang, D. F. et al. Study on the transportation law of overburden rock in pseudo-slope mining of sharply inclined medium-thick coal seam. Coal Eng. 55(01), 76–80 (2023).

Su, C. et al. Research on the mechanism of cutting top and unloading pressure in deep shafts with high stress. J. Min. Saf. Eng. 37(06), 1104–1113. https://doi.org/10.13545/j.cnki.jmse.2020.06.004 (2020).

Zhu, D. Y. et al. Model test and numerical study on surrounding rock deformation and overburden strata movement law of gob-side entry retaining via roof cutting. Minerals 10(5), 458. https://doi.org/10.3390/min10050458 (2020).

Xu, L. et al. Parameters and surrounding rock control of gob-side driving under double key stratum after roof cutting. Sci. Rep. 14, 76–80. https://doi.org/10.1038/s41598-024-55679-1 (2024).

Yang, Y. G. & Zhang, Y. Research on the technology of small coal pillars of gob-side entry retained in deep mines based on the roof cutting for pressure unloading in the lower key stratum. Geofluids 2022, 1–18 (2022).

Wu, Y. P. et al. Characteristics of overburden transportation and roof damage in large inclination near coal seam mining. J. Xi’an Univ. Sci. Technol. 40(01), 1–10 (2020).

Wang, J. C. et al. Research progress on rock strata movement and control in coal mine stope-in commemoration of 40 years of Qian Minggao academician " masonry beam " theory. Coal Sci. Technol. 51(01), 80–94 (2023).

Guo, J. W. Study on Roof Breaking Movement law and Water Control Mining Technology of Inclined Working Face Under Aquifer (China University of Mining & Technology 2023).

Shi, Z. S. et al. Influence of horizontal stress on spanning fall angle of roof slab and its application. Exp. Mech. 32(04), 543–550 (2017).

Chen, L. et al. Research on the influence of roof collapse height and collapse angle on supporting pressure of quarry. Coal Sci. Technol. 44(S2), 62–66 (2016).

Funding

Fund number Qiankehe results-LH〔2024〕major 024.

Author information

Authors and Affiliations

Contributions

Y.S. wrote the main manuscript text and data collection work, Z.M. guided the paper and objectively reviewed the article, X.F. completed the research design and data analysis, and all the authors contributed to the further revision of this paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shuai, Y., Ma, Z. & Feng, X. Study on transportation and stress distribution of the overburden rock of gob side entry with cutting top and unloading pressure. Sci Rep 15, 2631 (2025). https://doi.org/10.1038/s41598-024-79218-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-79218-0

Keywords

This article is cited by

-

Study on the stress migration law and theoretical model of the stope roof under roof-cutting conditions

Geomechanics and Geophysics for Geo-Energy and Geo-Resources (2026)

-

Mechanism and control of floor heave in two entry retained roadways using dense boreholes

Scientific Reports (2025)

-

Excavation methods and stability control strategies for gob-side roadways based on spatiotemporal evolution

Scientific Reports (2025)