Abstract

This study investigates the shear strength characteristics of mudstone gravel slope following polymer grouting reinforcement through in-situ direct shear test. A corresponding numerical model was developed to analyze stress distribution. The findings indicate that shear stress initially increases and then stabilizes with horizontal displacement during the pre-grouting shear test. Post-grouting, a distinct stress peak emerges on the stress-displacement curve, signifying a substantial enhancement in overall shear strength. The peak shifts with increasing vertical stress, delaying the onset of yield strength. Moreover, a direct correlation exists between shear strength and the density of grout injected. Numerical simulations reveal an H-shaped stress distribution around the shear plane. Upon severing the grouting column, the stress distribution becomes intricate, with stress appearing to circumvent the column. The discrepancy between simulation and experimental data is minimal, with the simulated internal friction angle deviating by -0.97–1.5% from the experimental values and the simulated cohesion being marginally lower, with an error range of 3.9-5%. These results offer valuable insights for engineering applications.

Similar content being viewed by others

Introduction

Landslide occurrences are influenced by a multitude of factors. Oguz et al.1 highlighted the pivotal role of soil properties in the susceptibility of shallow landslides. In subsequent work, Alcantara-Ayala et al.2 gave an account of the field by investigating landslide reasons in the context of natural hazards such as rainfall and debris flows.To substantially mitigate landslide risks, the development of techniques for enhancing slope integrity is gaining momentum.Common reinforcement techniques include slope cutting, anti-slip columns, gravity retaining walls and the installation of anchor bolts. The slope cutting projects are often characterized by their large scale, extended duration, and high cost, with their feasibility constrained by site-specific conditions3. Kim et al.4 proposed the use of anti-slip columns for reinforcement, but limited to medium and shallow slopes. In addition, the gravity retaining walls, due to their substantial volume, necessitate an expansion of their base area with increasing slope height5. Siad6 employed grouting bolts to strengthen rock slopes, conducting stability analyses, yet this method demands stringent soil moisture content and mechanical properties7.

Additionally, the application of grouting methods for soil reinforcement to enhance overall stability has become increasingly sophisticated. Akbulut et al.8 investigated the impact of cement grouting pressure, soil particle size distribution and relative density on grouting properties. Nguyen et al.9 dissected the effects of rheological parameters during cement grouting, examining the water-binder ratio and viscosity. Considering the interplay between cement grouting solidification time and resultant strength, alongside the environmental pollution of cement grouting, the research and development of grouting materials have garnered widespread interest in the field.

Polyurethane, recognized as a polymer foam expansion material10, demonstrates significant potential in various applications including coating protection, composite material integration, and mechanical engineering11. The expansion of polyurethane polymers is achieved through the precise blending of polyether polyols, isocyanates, and catalysts, ensuring the fulfillment of pore-filling and cementation properties required in practical engineering scenarios12. Notably, polyurethane exhibits exceptional performance in addressing leakage issues13,14, road filling15,16,17, foundation reinforcement18,19, and embankment repair20,21,22.

In the realm of polymer material research, Çelik et al.23 applied polymer slurry to soil improvement, Guo et al.24 investigated the diffusion dynamics of grouting by infusing polymeric solutions into sandy soil, and the study revealed that soil porosity and particle size distribution are pivotal in influencing the grouting’s penetration and fracture propagation. Fang et al.25 and Li et al.26 both formed composite materials by mixing polymers with crushed stone soil, and found that the overall material strength was closely related to the grouting density. With the increase of grouting density, the overall strength of composite materials increased significantly. To delve deeper into the intricacies of the grouting process and the mechanics of material strength, Saeidi et al.27 employed the UDEC (Universal Distinct Element Code) to forecast grout flow and penetration within the rock mass. Liu et al.28 utilized Comsol Multiphysics to simulate the propagation dynamics of crack grouting under flowing water conditions accounting for temporal variations to achieved a close correlation with experimental outcomes by integrating numerical simulations with test data. Furthermore, Li et al.29 examined the diffusion pattern of polymer grout within sand through experimental analysis, focusing on the impact of infiltration and splitting diffusion. The study underscored that the sand’s density and the polymer grouting pressure are paramount factors that significantly influence the grout’s diffusion process.

In conclusion, these studies have contributed to the existing body of research on the mechanical properties of polymer materials and the soil consolidation process through grouting. Numerical simulations have been instrumental in examining these properties from multiple angles. It is important to highlight that the discrepancies between indoor grouting tests and actual field conditions are significant. By capitalizing on the benefits of polymer’s excellent expansibility, lightweight hardening, and corrosion resistance, this research evaluates the consolidation status of mudstone gravel after in-situ drilling grouting, and in-situ direct shear tests are conducted to determine the shear strength parameters before and after grouting. The study further integrates experimental data with numerical stress distribution analyses to assess the correlation between simulation and experimental outcomes, as well as the stability of shear reinforcement effects, so as to provide reference for the reinforcement of medium and shallow slopes with polymer in the future.

Experimental study

Project overview

The test site, a high fill slope situated in Longyan City, Fujian Province, China, was chosen for its representative characteristics. The slope is equipped with a total external height of 40 m and a steep slope rate of 1:0.75. Comprising primarily of mudstone gravel, the fill material features a particle size predominantly ranging from 200 to 500 millimeters, with a notable coarse particle content that accounts for approximately 50%. The parent rock lithology is predominantly composed of mudstone, carbonaceous siltstone, and sandstone, all of which are in a state of strong to moderate weathering.

Post the dynamic compaction operation applied to the test site, the resulting data on maximum dry density, optimal moisture content, average degree of compaction and natural density have been meticulously documented and are presented in Table 1.

Grouting materials and characteristics

The experimental grouting material employed is a polymer, synthesized through the exothermic reaction of isocyanate and polyether polyol. This polymer demonstrates a free expansion rate of 13, coupled with a swift curing time of approximately 15 s. Preceding the grouting operation, the borehole dimensions are ensured at a diameter of 80 millimeters and a depth of 2 m. The grouting volumes are determined to be 2 L and 3 L, tailored to the specific requirements of the grouting process. The post-grouting analysis reveals the intrinsic properties of the polymer matrix, as delineated in Table 2. This table succinctly encapsulates the essential characteristics of the formed body, including its primary mechanical attributes30.

To delve into the shear strength attributes of the mudstone gravel in both pre- and post-grouting contexts, a research process is imperative, and the schematic representation is articulated in Fig. 1, providing a visual route for the systematic exploration of geotechnical properties under varying conditions.

In-situ direct shear test

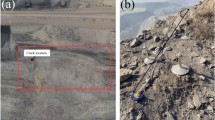

For the direct shear test, the principal apparatus comprises a 500 × 500 × 250 mm shear box, a displacement measurement assembly that integrates a transducer, a data logger, an oil pump, and three concrete blocks, one equipped with a single vertical stress of 50 kPa and two with a single vertical stress of 100 kPa. The test site is chosen at the dynamic compaction locale, where the upper strata of disturbed gravel are removed to access the underlying sample. The sample is then manually pruned to dimensions slightly exceeding the shear box’s internal dimensions, as depicted in Fig. 2(a). Utilizing an excavator, the shear box is precisely positioned to a pre-determined location, as shown in Fig. 2(b). Subsequently, a jack and a steel bearing plate are accurately placed to ensure that the operational point and the pivot point are horizontally aligned, as illustrated in Fig. 2(c). Prior to the placement of the concrete block, the sensitivity of the displacement transducer is calibrated, the acquisition instrument is zeroed, and the oil pump is activated to incrementally apply horizontal pressure, as indicated in Fig. 2(d)(e)(f). Throughout the test, the displacement transducer’s movement is closely monitored, and the corresponding curve is tracked and displayed by the acquisition instrument. Upon attaining a stable curve and reaching the maximum horizontal shear stress, the test is halted, the data are preserved, and the procedure is repeated at the subsequent test location.

The preceding overview delineates the process for conducting a direct shear test in the absence of grouting. For the subsequent direct shear tests post-borehole grouting, the operational process adheres closely to the initial steps. The test lies in carrying out in multiple layers in the same position; once the direct shear test for the uppermost layer is concluded, the testing proceeds incrementally into the substrata, a comprehensive set of analyses is depicted in Fig. 3(a), and the direct shear test of applying 200 kPa vertical stress is shown in Fig. 3(b). This approach of layering test at the same position reduces the influence on the shear test at different positions and helps to evaluate the test data reliably.

In the aspect of in-situ direct shear testing, a dataset comprising outcomes from four vertical stress levels (50 kPa, 100 kPa, 150 kPa, and 200 kPa) constitutes a valid set of experimental data. Throughout the experimental procedure, data collation is a critical step from the acquisition instrument, erroneous data or those excessively variant curves are excluded to ensure the correctness of the dataset. The resultant valid data from the ungrouted direct shear tests are marked as the test condition S-I.

For the grouted shear tests, the test conditions are bifurcated based on distinct grouting quantity, accordingly categorized as P-I and P-II. Finally, the final data collated into a comprehensive dataset encompassing three groups and a total of twelve valid data.

Experimental phenomena and results

Following the completion of the direct shear test on the grouted borehole, the shear plane exhibited a relatively regular form, as illustrated in Fig. 4(a). The excavation of the overlying mudstone gravel was initially executed with an excavator, followed by meticulous manual excavation to reveal the polymer cylinder, preserving its cylindrical integrity, as depicted in Fig. 4(b) and (c). The excavated polymer cylinder post-test maintained a consistent cylindrical form, as shown in Fig. 4(d). Upon examination of the cross-sectional area, a region of enhanced hardness within the column was identified in proximity to the grouting pipe, as observed in Fig. 4(e) and (f). The internal space within the closed hole, post-grouting, resulted in a confined expansion effect of the polymer, yielding a regular cylinder shape. This phenomenon can be attributed to the initial reaction, and expansion of the grout slurry within the pre-existing voids. As the grout fills the voids, the expansive force diminishes, culminating in an insufficient strength to achieve the desired penetration and extrusion within the gravel matrix, thereby rendering the penetration effect suboptimal.

The experimental data, categorized into three distinct groups, have been graphically represented as depicted in Fig. 5.

For the S-I condition, which reflects an ungrouted state, the analysis reveals that under varying vertical stress levels, the shear stress exhibits an initial rise followed by a plateau as the horizontal displacement continues to increase. This stabilization trend in the stress-displacement curve is indicative of a strain-hardening behavior within the mudstone gravel, culminating in shear failure.

In the cases of P-I and P-II, where the mudstone gravel has been fortified with polymer grouting, the stress-displacement curves demonstrate a pronounced peak in horizontal shear stress, which is followed by a precipitous drop and subsequent stabilization. This peak is primarily ascribed to the strength contribution from the polymer cylinder during shearing, with complete shear failure occurring post the polymer cylinder’s rupture. As observed in Fig. 5(a)(b)(c)(d), the emergence of this peak is influenced by the magnitude of the vertical stress. At lower vertical stresses, the peak manifests earlier, whereas a magnitude rise in vertical stress induces a delayed rearward shift of the peak, signifying the postponed shear failure. Additionally, the strength of polymer itself exhibits a relative insensitivity to confining pressure; at lower pressures, the polymer grouting display a heightened strengthening effect compared to the mudstone gravel itself, and during shearing, strain softening phenomena are observed, that is, the curve drops rapidly after the polymer cylinder is cut; however, under higher confining pressures, it can be seen from the curve that the softening phenomenon has decreased.

A comparative analysis of the stress-displacement curves pre and post-grouting indicates that the horizontal shear stress post-grouting surpasses that of the ungrouted condition, signifying the impact of polymer grouting on the shear properties of the reinforced mudstone gravel. Furthermore, it is discerned that the peak shear stress is contingent upon the volume of grouting applied. In the group (P-II) with an elevated amount of grouting, an increase in column density is noted, which corresponds to a higher peak shear stress compared to the group (P-I) with a lesser grouting amount. This result underscores that the quantity of polymer grouting is a significant factor in the overall shear characteristics of the mudstone gravel.

Numerical simulation

Model building

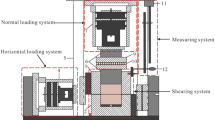

Utilizing the data garnered from in-situ direct shear tests, a computational model was crafted in ABAQUS to simulate the shear behavior of mudstone gravel. Given the quasi-static characteristics of the field direct shear process, the simulation was executed with the ABAQUS/Explicit solver. The model’s dimensions were scaled 1:1, with the upper block measuring 500 × 500 × 250 mm and the lower base measuring 1000 × 1000 × 250 mm, as illustrated in Fig. 6(a). The shear box’s internal dimensions, identical to the upper mudstone gravel block and 20 mm thick, were idealized as a rigid body.

To capture the deformation behavior of the mudstone, an isotropic linear elastic model coupled with the Mohr-Coulomb criterion was deployed. This approach, based on continuum mechanics and finite element analysis, eschews fracture effects, focusing instead on the material’s continuity to shear. The sample was meshed using8-node hexahedron linear reducing integral element (C3D8R), and common nodes were employed to articulate the interaction between the elements.

Reflecting on the in-situ test phenomenon revealed constrained penetration for post-drilling grouting, a cylindrical model was introduced to simulate this grouted column’s interaction with the surrounding gravel. To emulate the shear test conditions outlined in Table 2, which detail the yield properties of the polymer columns, an element deletion method was engaged to simulate yield initiation within the cylinders, The simulation parameters determined the damage evolution with the failure displacement of 10 mm as the revised value. The model establishment is shown in Fig. 6(b), In the model, there is frictional contact between the polymer cylinder and the mudstone gravel, and the friction coefficient is set at 0.5631.

Analysis of finite element calculation results

The simulation process is bifurcated into two analytical stages: the application of vertical stress and the imposition of displacement. Throughout the simulation, the base is constrained to remain immobile. In the simulation, the applied vertical stress is perpendicularly transmitted to the surface, upholding a right angle orientation during the shearing phase. Combined with the curve obtained from the experiment, quasi-static analysis was considered in the simulation with the horizontal displacement of 50 mm as the reference standard, and a smooth amplitude curve was used 10 mm before the displacement to reduce the influence of the simulated oscillation.

In the simulation of ungrouted mudstone gravel under direct shear, as the horizontal displacement accrues, the stress value increases gradually and its distribution extends to the other side. A vertical profile analysis elucidates that under varying vertical stress conditions, the internal stress distribution is predominantly concentrated yet non-uniform along the shearing plane, manifesting as a descending arc. This configuration is a consequence of the applied horizontal displacement conditions exertion on the shear box, as portrayed in Fig. 7. Examination of the stress distribution across the horizontal section of the shear plane, as depicted in Fig. 8, uncovers a stress concentration phenomenon along the periphery with a concomitant reduction in the central stress distribution, thereby engendering an overarching H-shaped pattern. An augmentation in the vertical stress leads to an intensification in the stress distribution, progressively encompassing broader regions of the shear plane. This detailed analysis provides critical insights into the stress behavior of mudstone gravel under different loading conditions, contributing to a deeper understanding of the shear mechanics in geotechnical applications.

In the simulation designating element deletion for the grouted column, Fig. 9 delineates the stress distribution within a column with a 2 L grouting volume across a spectrum of vertical stresses. Throughout the shearing process, stress is observed to migrate laterally, accumulating within the column and concurrently extending the distribution of soil stress in a downward trajectory towards the column. As the horizontal displacement increases, the column reaches its yield stress, leading to the deletion of the column’s cross-sectional elements and a subsequent reduction in the stress within the mudstone gravel.

At the area of yield, an asymmetrical stress distribution within the mudstone gravel becomes apparent; on the side where the horizontal displacement condition is applied, the stress is concentrated downwards and acts on the cylinder. This inclination is exacerbated as the vertical stress escalates, accentuating the asymmetry in the stress distribution pattern.

For the analysis of stress conditions in the horizontally sheared section with a 3 L grouting volume, as illustrated in Fig. 10, the attainment of yield stress and the subsequent element deletion within the column lead to a reduction in surrounding stresses. Despite this, a modest concentration of shear-induced stresses persists on the side proximal to the applied horizontal displacement condition. Integrating this observation with test data, it can be deduced that the polymer cylinder, even when truncated, continues to be influenced by vertical stress and the applied horizontal displacement condition until the displacement readings stabilize, as collected by the data acquisition system. Additionally, on the side opposite to the applied horizontal displacement condition and under a vertical pressure of 100 kPa, there is a indication of significant stress migration or dissipation around this area or along its periphery.

Figure 11 presents the displacement distribution. It is observed that the displacement within the shear zone is non-uniform under low vertical stress influence. However, as vertical stress increases, the displacement distribution along the shear plane becomes more concentrated. This can be attributed to the fact that when the column is severed, the upper portion of the shear zone continues to propel the soil beneath the shear plane, even under the imposition of vertical stress. Particularly noteworthy is the side exerting the applied horizontal displacement condition, as depicted in Fig. 11(d).

Upon comparing and analyzing the stress distribution before and after grouting, it is observed that the introduction of the polymer column complicates the stress distribution, with varying stress forces acting on either side of the column. Post column cutoff, the stress distribution within the mudstone rubble retains an approximate H-shaped pattern.

Model data extraction and experimental comparison

The model’s entire shear plane was considered as a set, and the resultant stress-displacement curve was juxtaposed with the field test data by averaging the stress and displacement values across the shear plane, as depicted in Figs. 12 and 13. Upon scrutinizing the simulation outcomes for grouted conditions, it was observed that under varying vertical stress magnitudes and in accordance with the element deletion criteria, the simulated curves exhibited a consistent degression post-peak, culminating in stabilization. As illustrated in Fig. 13, the peak magnitude of the simulated curve correlates with the magnitude of the vertical stress applied. An incremental increase in applied vertical stress leads to a rearward displacement of the peak, indicating a delayed onset of shear failure. This comparison revealed that the discrepancy between the simulated curve and the experimental data is minimal, affirming the accuracy and reliability of the simulation.

Results

The experimental and simulated stress-displacement curves were meticulously analyzed to determine the shear strength of the mudstone gravel both before and after reinforcement. The stable value derived from the ungrouted curve and the peak value from the grouted curve represent the respective shear strengths. These values are collected in Table 3.

Under varying vertical stress conditions, the relationship between vertical stress and shear strength was delineated through linear fitting, as exhibited in Fig. 14. Utilizing the Mohr-Coulomb failure criterion, the shear strength parameters, namely the internal friction angle φ and cohesion c, were extracted and are presented in Table 4. Comparative analysis reveals that the discrepancy in the internal friction angle between simulation and experimental outcomes is negligible, with an error of -0.97–1.5%. The simulated cohesion values are marginally lower than those determined experimentally, with an error margin of 3.9–5%. This minimal divergence can be attributed to the idealized representation of the grouting process in the simulation, where the grouting cylinders are modeled with perfect geometry. In actual in-situ grouting operations, the polymer grouting pipes may experience slight offset, leading to localized expansion and increased interface bond strength, thereby augmenting the cohesive interaction with the surrounding mudstone gravel.

Conclusions

Drawing from the in-situ direct shear tests, an analysis of the shear strength of mudstone gravel, both pre- and post-polymer grouting, was conducted. Numerical simulation was employed to investigate the stress distribution characteristics throughout the shearing process, with a subsequent comparative analysis of the experimental and simulated stress-displacement curves. The findings culminated in the following conclusions:

-

1.

The polymer’s expansion post-grouting is confined, resulting in a hard material that encapsulates the grouting pipe in a columnar distribution.

-

2.

The stress-displacement curves demonstrate distinct patterns before and after grouting. In ungrouted direct shear tests and simulations, these curves exhibit an initial ascent towards stabilization, indicative of the mudstone gravel’s strain-hardening behavior. A pronounced peak in the curve during direct shear testing after grouting signifies a transition to strain softening, followed by a sharp decrease in shear strength post polymer column rupture. The peak stress is correlated with the applied vertical stress, with increases in vertical stress leading to higher peak values and a delayed occurrence of shear failure.

-

3.

In ungrouted model tests, stress is predominantly concentrated near the shear plane, forming an H-shaped distribution that expands to encompass the entire shear plane with increasing vertical stress. In grouted model tests, stress migrates laterally from one side to the column’s periphery, resulting in internal stress concentration. Upon column severance, the peak stress value diminishes, and a stress flow around the column is observed. At a vertical stress of 100 kPa, this flow is gradually pronounced.

-

4.

Grouting volume significantly influences the test’s shear strength characteristics. Under a 50 kPa vertical stress, the stress incrementally rises from 78.5 kPa to 114 kPa and 133 kPa, respectively. As the vertical stress escalates to 200 kPa, the stress increases from 204.1 kPa to 235 kPa and 265 kPa, respectively. With the increase of grouting amount, the shear strength increases.

-

5.

Simulation outcomes align closely with test data, with the simulated internal friction angle and experimental error ranging from − 0.97 to 1.5%. The simulated cohesive force is marginally lower than the experimental value, with an error of 3.9-5%. This slight discrepancy can be attributed to the idealized cylindrical structure of the grouting column in numerical simulation, which contrasts with the actual grouting process where the polymer’s adhesive strength at the mudstone gravel interface enhances, thus affecting the measured cohesive force.

Data availability

All the experimental data that support the fndings of this study are available from the corresponding author upon reasonable request through email.

References

Oguz, E. A., Depina, I. & Thakur, V. Effects of soil heterogeneity on susceptibility of shallow landslides. Landslides. 19 (1), 67–83 (2022).

Alcántara-Ayala, I. & Sassa, K. Landslide risk management: from hazard to disaster risk reduction. Landslides. 20 (10), 2031–2037 (2023).

Bar, N. & Barton, N. The Q-slope method for rock slope engineering. Rock. Mech. Rock. Eng. 50, 3307–3322 (2017).

Kim, C., Kwon, J., Im, J. C. & Hwang, S. A method for analyzing the self-supported earth-retaining structure using stabilizing piles. Mar. Georesour Geotechnol. 30 (4), 313–332 (2012).

Jiang, P., Li, J., Zuo, S. & Cui, X. Z. Ecological Retaining Wall for High-Steep Slopes: A Case Study in the Ji‐Lai Expressway, Eastern China. Adv. Civ. Eng. 5106397 (2020). (2020)(1).

Siad, L. Stability analysis of jointed rock slopes reinforced by passive, fully grouted bolts. Comput. Geotech. 28 (5), 325–347 (2001).

Li, J., Chen, S., Yu, F. & Jiang, L. Reinforcement mechanism and optimisation of reinforcement approach of a high and steep slope using prestressed anchor cables. Appl. Sci. 10 (1), 266 (2019).

Akbulut, S. & Saglamer, A. Estimating the groutability of granular soils: a new approach. Tunn. Undergr. Space Technol. 17 (4), 371–380 (2002).

Nguyen, V. H., Remond, S. & Gallias, J. L. Influence of cement grouts composition on the rheological behaviour. Cem. Concr Res. 41 (3), 292–300 (2011).

Das, A. & Mahanwar, P. A brief discussion on advances in polyurethane applications. Adv. Ind. Eng. Polym. Res. 3 (3), 93–101 (2020).

Somarathna, H. M. C. C., Raman, S. N., Mohotti, D., Mutalib, A. A. & Badri, K. H. The use of polyurethane for structural and infrastructural engineering applications: a state-of-the-art review. Constr. Build. Mater. 190, 995–1014 (2018).

Wang, F. M., Shi, M. S., Li, H. J. & Zhong, Y. H. Experimental study on the anti-permeability properties of Polymer grouting materials. Adv. Mater. Res. 284, 1952–1955 (2011).

Bae, A., Jung, E., Seo, B. & Jae Lee, S. Development of Injectable Water-Stop for Grouting in Underground concrete structure Joint. J. Test. Eval. 50 (1), 300–314 (2022).

Fang, H., Li, B., Wang, F., Wang, Y. & Cui, C. The mechanical behaviour of drainage pipeline under traffic load before and after polymer grouting trenchless repairing. Tunn. Undergr. Space Technol. 74, 185–194 (2018).

Kennedy, J., Woodward, P. K., Medero, G. & Banimahd, M. Reducing railway track settlement using three-dimensional polyurethane polymer reinforcement of the ballast. Constr. Build. Mater. 44, 615–625 (2013).

Li, S., Niu, Y., Wang, B., Gao, Y. & Zhu, Y. Research on mechanical response of polymer grouting repair for longitudinal cracks in reconstructed and expanded expressway pavement. Math. Prob. Eng. 5760674 (2022). (2022)(1).

Liu, W., Zhang, S., Li, Y. & Ye, X. The expansion and mechanical property-based cavity expansion model for polyurethane grouting underneath the airport pavement. Transp. Geotech. 43, 101141 (2023).

Buzzi, O., Fityus, S. & Sloan, S. W. Use of expanding polyurethane resin to remediate expansive soil foundations. Can. Geotech. J. 47 (6), 623–634 (2010).

Saleh, S., Yunus, N. Z. M., Ahmad, K. & Ali, N. Improving the strength of weak soil using polyurethane grouts: a review. Constr. Build. Mater. 202, 738–752 (2019).

Hao, Y. et al. Application of polymer split grouting technology in earthen dam: Diffusion law and applicability. Constr. Build. Mater. 369, 130612 (2023).

Liu, H., Shi, Z., Li, Z. & Wang, Y. Experimental investigation on reinforcement application of newly permeable polymers in Dam Engineering with Fine Sand Layers. Water. 15 (21), 3761 (2023).

Adamo, N., Al-Ansari, N., Sissakian, V., Laue, J. & Knutsson, S. Dam safety: technical problems of ageing concrete dams. J. Earth Sci. Geotech. Eng. 10 (6), 241–279 (2020).

Çelik, S., Majedi, P. & Akbulut, S. Granular soil improvement by using polyester grouts. Iran. J. Sci. Technol. Trans. Civ. Eng. 43 (3), 599–606 (2019).

Guo, C., Hu, D. & Wang, F. Diffusion behavior of Polymer grouting materials in sand and gravel. Soil. Mech. Found. Eng. 57, 440–444 (2021).

Fang, H. et al. Effects of crushed stones on the compression properties of polymer grout materials. Constr. Build. Mater. 271, 121517 (2021).

Li, X., Wang, J. & Fang, H. Quantitative analysis of geometric characteristics of crushed-stone-reinforced polymer composite microstructures. Constr. Build. Mater. 325, 126829 (2022).

Saeidi, O., Stille, H. & Torabi, S. R. Numerical and analytical analyses of the effects of different joint and grout properties on the rock mass groutability. Tunn. Undergr. Space Technol. 38, 11–25 (2013).

Liu, R. et al. Numerical simulation of crack grouting process of quick setting slurry with running water and its experimental verification. Rock. Mech. Rock. Eng. 36 (S1), 3297–3306 (2017).

Li, Z., Zhu, Z., Zhao, Y., Zeng, C. & Zhang, P. Experimental investigation on the diffusion law of polymer slurry grouted in sand. Polym. 14 (17), 3635 (2022).

Shi, M. Research on Polymer grouting material properties and directional fracturing grouting mechanism for dykes and dams. Dalian Univ. Technol. (2011).

Wang, F., Fang, H., Cao, K. & Ma, S. Model tests and numerical analyses of polymer gravel piles. Chin. J. Geotech. Eng. 40 (S2), 1–5 (2018).

Acknowledgements

The authors would like to thank the project supported by the Fujian Science Foundation for Outstanding Youth (Grant No. 2023J06039), National Natural Science Foundation of China (Grant No. 41977259, No. U2005205, No. 41972268), Zhejiang Provincial Natural Science Foundation of China (Grant No. LY21E080007), and Fujian Province natural resources science and technology innovation project (Grant No. 2023J06039). Their support is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

M.S: Writing-original draf preparation; Z.Z. & C.Q.: Collecting data; Y.L. & R.Z.: Supervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shen, M., Zhang, Z., Qi, C. et al. In-situ direct shear test and numerical comparative research on mudstone gravel slope reinforced by polymer grouting. Sci Rep 14, 28510 (2024). https://doi.org/10.1038/s41598-024-79541-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-79541-6