Abstract

This paper proposes an innovative back-rotating flinging method for digging out oilseed beans, which is more suitable for lifting the excavated material, in response to the short service life of the existing digging device caused by the entanglement of the root system with the cutting tool. Through the analysis of the interaction and influence between the rotary tiller and the soil-root complex of the plant, a kinetic model of the soil-root complex of the kudzu rhizome being chopped and thrown was constructed, and the operating mechanism of the reverse rotary tiller for the overall overturning, digging and collision fragmentation of the soil-root complex of the plant root system was clarified. A discrete element model of the soil-enveloped root system of the hyacinth bean plant was constructed in its entirety. The structural parameters of the reverse rotary digging device were optimised using discrete element simulation and field bench tests.

Similar content being viewed by others

Introduction

Olea europaea has tufted stems, very high tillering capacity, small grains and well developed root system. Before digging in the harvest period, the oil salsa bean stem, oil salsa bean root, oil salsa bean fruit and its growing soil are tightly combined with each other in the block called oil salsa bean plant root system soil ring embrace body1,2,3,4,5. The effective digging and breaking of the root system soil ring is the key to solving the mechanised harvesting of oil salsa bean.

Sun et al. innovated the design of ultra-deep rotary ploughing tool structure in order to solve the problems of soil disturbance during the operation of the existing ultra-deep rotary ploughing tool6. Yang Xu et al. conducted a rotary ploughing performance test and a test to determine the soil fragmentation rate of the farmland after rotary ploughing in order to improve the operating effect of the rotary ploughing machine7. Zhang Mingwei et al. designed a new rotary ploughing and furrowing fertiliser planter and tested it8. Yang Daiqin et al. used EDEM discrete element method to analyse the soil cutting performance of different rotary tillage knives9. Patidar et al. optimised the rotary tillage knives of vertical shaft rotary tiller and carried out kinematic, kinetic and soil-structure interaction analyses10. Yevtushenko et al. proposed a special rotary tillage knife to prolong the service life of rotary tillage knives11. Yanshan et al. carried out a simulation and experimental study on rotary tillage knives in order to clarify the mechanism of tiller-soil interaction during strip rotary tillage12. Xiangyun et al. obtained the motion of soil particles, torque on the rotary blade and power consumption13.Gaoming et al. developed a mathematical model of operating parameters and straw motion14. Jun et al. simulated the effects of operating conditions and rotary tiller structure on the tillage characteristics of rotary tillers15. Congyang et al. developed a discrete element method model of a straw return rotary tiller16. Yuwan et al. designed a bionic rotary tiller blade based on the geometric features of the five front paws of a mole17. Kuan et al. monitored the soil motion during the operation of a furrowing rotary tiller blade18. Zhang et al. investigated the effect of rotary tiller blade parameters on the three-axis resistance19. Jian et al. proposed a model based on the Coulomb friction law combined with the DEM method to calculate the friction resistance20.

In this paper, we investigated the problem of easy congestion of the existing oil salsa bean rhizome soil ring embracing body digging device, and explored the causes of easy congestion of the positive spinning digging method on the lifting of materials after digging by comparing the field operation of the spinning digging method and the theoretical analysis of the movement process, and then innovatively proposed a more suitable counter-rotating throwing type of oil salsa bean digging method for the lifting of materials after digging. By analysing the interaction between the rotary knife and the root soil embrace, we constructed a kinetic model for the shredding and conveying of the root soil embrace, and elucidated the operation mechanism of the counter-rotary conveying type of digging device for the whole turning and digging of the root soil embrace, and collision and fragmentation. The structural parameters of the counter-rotating excavation device were optimised with the help of discrete element simulation and field test.

Materials and methods

Experiment materials

In this experiment, Yu You Sha No. 1 Cyperus esculentus was selected. After preliminary testing, its triaxial dimensions were measured to be 12 cm, 10 cm, and 8 cm, respectively. The average values of the moisture content, Poisson’s ratio, and shear modulus of Cyperus esculentus were 48.90%, 0.478 and 116.82 Mpa. The average diameter of the Cyperus esculentus stem is 2.67 mm, and the average diameter of the Cyperus esculentus root is 1.60 mm. The average moisture content of the Cyperus esculentus root and Cyperus esculentus stem is 38.2% and 22.8% respectively. The average densities of the Cyperus esculentus stems and roots were 0.025 kg/m3 and 0.082 kg/m3, respectively. The test site was selected from the Cyperus esculentus test and demonstration base in Boding Township, Minquan County, Henan Province (34°N, 115°E). 0–5 cm, 5–10 cm, 10–15 cm. The soil texture of the area is sandy soil, and the average soil firmness values are 535 kPa, 675 kPa and 856 kPa respectively. The average tensile and shear strengths of the stems of the Cyperus esculentus are 4.51 N and 3.58 N, respectively, while the average tensile and shear forces of the roots of Cyperus esculentus were 5.83 N and 4.25 N, respectively. The parameters of the root system of Cyperus esculentus, the stem and root of Cyperus esculentus, the Cyperus esculentus and the root system of the Cyperus esculentus plant were imported into EDEM to construct a discrete element unit model. The purchased Henan Haofeng general rotary tiller has the following dimensions: 1090 × 2300 × 1060 mm, a mass of 415 kg, a matching power of 60–70 horsepower, and a working width of 2000 mm. The contact parameters between particles used in the discrete element simulation analysis are shown in Table 1.

Study on the digging method of Cyperus esculentus plant root soil encirclement

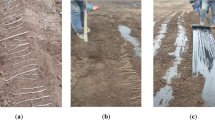

At present, the digging link in the mechanized harvesting of Cyperus esculentus in China is usually based on the rotary digging method21, or the rotary tiller is directly modified and used, and the soil embracing body of Cyperus esculentus plant root system is cut and dug by the method of positive rotary tillage, as shown in Fig. 1a. However, there are some problems in the working process, such as large resistance, easy to block soil, high fruit embedding rate and high damage rate, which lead to serious wear and tear of transmission parts and reduced life. As shown in Fig. 1b, the working efficiency is very low.

Field comparison test of positive and negative rotation of soil embracing body of Cyperus esculentus root system in field

In order to explore the hypothesis of the reverse rotary digging method of Cyperus esculentus plants, a universal rotary cultivator was purchased from Henan Haofeng Machinery Manufacturing Co., Ltd., and the rotary cultivator was modified by changing the transmission direction of the rotary cultivator gearbox and the reverse installation of the cutter shaft. The rear towing board was removed and the Dongfeng 604 tractor was configured. In December 2020, the field comparison feasibility test was carried out at the Cyperus esculentus experimental demonstration base (34° N, 115° E) in Bodang Township, Minquan County, Henan Province, as shown in Fig. *3. Through repeated assembly and replacement and field operations, it can be intuitively seen that during the forward rotation operation, as shown in Fig. 2a, the soil embracing body of Cyperus esculentus plant root system will be excavated and broken, and will accumulate at the rear of the rotary tiller. The lower and the rear throwing distance is shorter ; however, in the reverse rotation operation, as shown in Fig. 2b, the soil embracing body of Cyperus esculentus plant root system was excavated and broken obviously, and it could be thrown back a distance along the upper cover plate of the rotary tiller.

Through the field comparison test, the considerable effect of the reverse rotation throwing harvest of the soil embracing body of Cyperus esculentus rhizome was further verified. However, there is still a lack of corresponding theoretical basis for the speculation of the anti-rotation throwing method. Therefore, the dynamic analysis of the forward and reverse rotary digging process of Cyperus esculentus plant root soil encirclement was carried out, aiming to further explore the rotary cutting and digging mechanism of Cyperus esculentus plant root soil encirclement through theoretical model construction.

Analysis of rotary polishing cutter motion in reverse starting and digging mode

The reverse rotation harvesting method is that the rotation direction of the rotary blade is opposite to the rotation direction of the wheel when the tractor is advancing. The harvesting process can be divided into two stages : the cutting stage and the throwing stage. The rotary polishing knife first cuts the root soil of the Cyperus esculentus plant. In the cutting stage, the material moves cycloidally with the rotary polishing knife. When the material leaves the surface, it is the throwing stage.

The anti-polishing tool coordinate system xoy is established, as shown in Fig. 3. At this time, the motion equation of the tool tip is:

In the formula, R is the radius of rotation of the tool tip; ω is the rotation angular velocity of the cutter shaft; vm is the forward speed of the mechanism in the horizontal direction; t is the rotation time of the rotary blade.

At this time, the trajectory is a cycloid. Let Q be any point on the cycloid, and the velocity of Q point is:

After the speed synthesis, the tip speed is:

The reverse rotation absolute velocity formula (3) has a larger initial kinetic energy after the soil block of the cutting process is unearthed, and the throwing distance and height are larger.

Through experimental research and theoretical comparative analysis, the mechanism of soil backwater and the feasibility of counter-rotating digging of Cyperus esculentus were further clarified. However, the overall movement process of Cyperus esculentus root soil embracing body under the action of counter-rotating throwing knife is not clear. It is necessary to further analyze the movement process of Cyperus esculentus root soil embracing body under the action of counter-rotating digging.

Simulation analysis and single factor test of reverse-swirling digging-spinning cutter

Construction of discrete element model of Cyperus esculentus root soil encircling body.

In the discrete element simulation, in order to meet the growth state of Cyperus esculentus, the length, width and height of the soil trough are 2000 mm × 1500 mm × 800 mm in EDEM, and the initial position of the Cyperus esculentus rotary tillage throwing device is 300 mm from the bottom of the soil trough. In order to further observe the movement law of Cyperus esculentus plant root soil embracing body, the discrete element model of Cyperus esculentus plant root soil embracing body was established according to the actual growth state of Cyperus esculentus22,23,24,25,26,27. In order to achieve a higher degree of fitting, the study also divided the growing soil of Cyperus esculentus into three layers, as shown in Fig. 4a and b. Based on previous research and experiments, the physical properties of the three-layer soil structure set out in this paper are shown in Table 2, and the thickness of the three layers is 100 mm, 100 mm and 120 mm respectively.

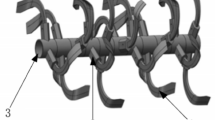

In order to further improve the accuracy of the discrete element simulation test, under the premise of ensuring the basic function of the reverse rotary throwing type Cyperus esculentus digging device, combined with the basic principle of equivalent simplification of the mechanism, a simplified model of the parametric mechanism of the reverse rotary throwing type Cyperus esculentus digging device is established. The discrete element simulation test is mainly carried out by retaining the rotary blade shaft and the cover plate, which further enhances the efficiency of the simulation test.

The simplified model of the parametric mechanism of the anti-rotary throwing type sassafras digging device is saved as STEP format and imported into EDEM software. The specific parameter settings are shown in Table 3.

Analysis of the motion law of Cyperus esculentus digging and verification of simulation fitting degree

In order to further verify the analysis of the root digging method of Cyperus esculentus plant and the motion law of Cyperus esculentus embracing body under the action of positive and negative rotary blade, this paper carried out the dynamic discrete element simulation test of Cyperus esculentus root-tuber-soil under the action of positive and negative rotary blade, and further explained the influence of different digging methods on Cyperus esculentus embracing body from the microscopic point of view. In order to ensure the accuracy and continuity of the simulation process, the simulation step is set to 3.56 × 10–6, the grid cell size is 9 mm, which is 3 times the minimum particle radius, the particle bonding radius is 5.5 mm, the particle generation time is 1 s, and the simulation time is 4 s. In addition, the soil in this paper is modeled using the Hertz Mindlin with bonding model. To ensure the reliability of the results, a minimum simulation step size of 1% of the Rayleigh time is used.

Combined with discrete element simulation test, under the action of positive and negative rotary blade, the displacement and stress curve of Cyperus esculentus root-tuber-soil tend to be consistent. During the excavation process of Cyperus esculentus root soil embracing body by rotary blade, in the cutting stage of Cyperus esculentus embracing body, Cyperus esculentus root-tuber-soil do cycloidal movement with rotary blade. When Cyperus esculentus root-tuber-soil is unearthed, do the throwing line movement, as shown in Fig. 5a–c, positive rotary excavation is carried out clockwise Cyperus esculentus harvest operation, when the rotary blade contacts Cyperus esculentus root soil embracing body, Cyperus esculentus root-tuber-soil is disturbed to varying degrees, resulting in displacement under the action of rotary blade. During 1–2 s, the change of rhizome-tuber-soil displacement of Cyperus esculentus was in a stable state. In 2–4 s, with the cutting operation of rotary polishing knife, the soil encirclement body of Cyperus esculentus plant roots moved in the tangential direction of rotary polishing knife tip, and the displacement began to change. The maximum displacement of Cyperus esculentus rhizome was 0.58 m, the maximum displacement of Cyperus esculentus tuber was 0.52 m, and the maximum displacement of soil was 0.38 m.

The crushing mechanism of reverse rotation mining is consistent with that of forward rotation mining, but the rhizome-tuber-soil of Cyperus esculentus does parabolic movement during operation. The maximum displacement of Cyperus esculentus rhizome is 0.75 m, the maximum displacement of Cyperus esculentus tuber is 0.71 m, and the maximum displacement of soil is 0.53 m. The displacement change under this operation mode is higher than that of forward rotation operation, as shown in Fig. 6a–c. Because the rotary blade is alternately operated during the harvesting process of Cyperus esculentus, the stress curve of Cyperus esculentus rhizome-tuber-soil is serrated. Therefore, the reverse rotation operation can improve the cutting efficiency of Cyperus esculentus rhizome-soil mass, reduce the external force impact of Cyperus esculentus fruit, and improve the harvesting efficiency of Cyperus esculentus. The experiment proved that the self-fragmentation and digging mechanism of the soil environmental protection body of Cyperus esculentus rhizome was enhanced under the reverse rotation operation mode, and further verified the hypothesis of the effect of the reverse rotation throwing and digging harvesting operation of Cyperus esculentus and the fitting degree of the structural parameter optimization of the reverse rotation throwing knife based on the discrete element simulation.

Optimization of single factor simulation test for structural parameters of reverse rotary polishing cutter

In order to further achieve the purpose of drag reduction and damage reduction by changing the structural parameters of the rotary polishing knife, the rotary radius of the rotary polishing knife, the oblique angle of the blade, and the bending angle of the tangent plane were selected as the test factors. The single factor simulation test was carried out in EDEM with the tool shaft torque and the damage rate of the Cyperus esculentus as the test indexes. The cutter shaft torque can be directly obtained by the statistical tool in EDEM. The damage rate of Cyperus esculentus fruit is compared with the average failure pressure of Cyperus esculentus measured in the previous period when the Cyperus esculentus fruit is struck by the rotary polishing knife under the simulation condition. According to the average failure pressure of Cyperus esculentus measured in the second chapter, it is 821.80N.Therefore, in the simulation test, the damage rate of Cyperus esculentus is determined as the ratio of the simulated particle mass of Cyperus esculentus fruit with the force greater than 821.80N to the total mass of Cyperus esculentus fruit simulated particles.

The vector diagram of discrete element simulation test in different stages is shown in Fig. 7a–d, and the crushing process of Cyperus esculentus plant is shown in Fig. 8a–d. The working width of the discrete element model of the fixed reverse rotary throwing type Cyperus esculentus digging device is 1.5 m, and the simulation test is carried out. According to the EDEM simulation data, the variation law of tool shaft torque and breakage rate with time is derived. In the simulation process, when the rotary polishing cutter does not contact the soil, the cutter shaft torque and damage rate are 0.

However, as the rotation of the cutter shaft drives the rotary polishing cutter to cut the soil, the torque and damage rate of the cutter shaft begin to increase gradually. As the rotary polishing cutter continues to advance, the cutting volume of the soil continues to increase. When the cutting depth gradually deepens, the rotary polishing cutter begins to contact the encircled body of the Cyperus esculentus plant root soil and crush the encircled body. The torque of the cutter shaft will increase. When the working depth of the rotary polishing cutter reaches the maximum value, the torque of the cutter shaft will also reach the maximum value. When the rotary blade passes through the maximum working depth, the volume of the soil cut by the rotary blade will gradually decrease, and the torque of the tool shaft will also decrease. Due to the same phase angle between the two adjacent rotary cutters, the torque of the cutter shaft changes periodically.

Five groups of simulation tests were carried out by setting the forward speed of the rotary blade 0.5 m/s, the rotation speed of the cutter shaft 200 rad/min, the rotary radius of the rotary blade 150 mm, the blade angle 30°, and the tangent bending angle α between 90° and 170°. The torque of the cutter shaft and the damage rate of Cyperus esculentus during the operation were taken as the test indexes, and the influence of the tangent bending angle on the test indexes was obtained, as shown in Fig. 9a. When the bending angle of the tangent plane is in the range of 90°–150°, the change of the bending angle of the tangent plane has a significant effect on the torque of the cutter shaft, and the torque of the cutter shaft increases gradually. When the bending angle of the tangent plane is between 150° and 170°, the change has a low effect on the torque of the cutter shaft ; when the bending angle of the tangent plane is in the range of 90°–150°, the damage rate of Cyperus esculentus increases first and then tends to be stable, and the change of the damage rate of Cyperus esculentus will increase again in the range of 150°–170°, as shown in Fig. 9b.

The forward speed of the rotary throwing cutter is set to 0.5 m/s, the rotation speed of the cutter shaft is 200 rad/min, the bending angle is 90°, the blade angle is 30°, and the rotation radius R of the rotary throwing cutter is 120, 130, 140, 150, 160 mm respectively. Five sets of simulation tests were completed, and the change of the torque of the cutter shaft with the rotation speed was obtained as shown in Fig. 10a. When the radius of gyration is in the range of 120–140 mm, the torque of the cutter shaft increases gradually, and the change of the radius of gyration R is more significant for the torque of the cutter shaft. When the radius of gyration is between 140 and 160 mm, the torque of the cutter shaft changes little. When the radius of gyration is in the range of 120–140 mm, the damage rate gradually increases. Between 140 and 160 mm, the damage rate changes more smoothly, as shown in Fig. 10b.

The forward speed of the rotary blade is set to 0.5 m/s, the rotation speed of the cutter shaft is 200 rad/min, the bending angle is 90°, the rotation radius of the rotary blade is 150 mm, and the blade angle β is 20°, 25°, 30°, 35°, 40° respectively. Five sets of simulation tests were completed. The change of the torque of the cutter shaft with the rotation speed is shown in Fig. 11a. When the blade angle is in the range of 20°–35°, the change of the blade angle has obvious influence on the torque of the cutter shaft, and the torque of the cutter shaft shows a gradual increase trend. When the blade angle β is between 35° and 40°, the change of the blade angle has little influence on the torque of the cutter shaft, and the torque of the cutter shaft changes little. When the bending angle of the tangent plane is in the range of 20°–40°, the damage rate increases first, then gradually decreases and tends to be stable. When the bending angle of the tangent plane is in the range of 20°–35°, the change of the damage rate is significant. In the range of 35°–40°, the change of the damage rate tends to be stable, as shown in Fig. 11b.

Through the simulation test, the single factor is tested and analyzed. In order to further obtain the optimal structural parameters of the rotary polishing cutter, the bending angle of the tangent plane is 110°–150°, the radius of gyration is 140–160 mm, and the oblique angle of the blade is 25°–35°. The value range of the test factors provides data support for the following multi-factor simulation test.

Multi-factor simulation test optimization of structural parameters of reverse rotary polishing cutter

Multi-factor discrete element simulation analysis of anti-rotary throwing type Cyperus esculentus digging device

According to the establishment of the previous discrete element model and the optimal parameter range of the single factor test of the rotary polishing knife, the multi-factor discrete element simulation analysis of the anti-rotary polishing oil sands digging device is carried out. The test factor code is shown in Table 4.

Taking the bending angle 'α', the radius of gyration R and the blade angle β as the test factors, the virtual simulation test of the rotary polishing cutter is carried out by using the three-factor three-level orthogonal test design.

Results and discussion

The test results of the virtual simulation experiment of the rotary polishing tool are shown in Table 5.

The regression equation of the data in Table 5 is fitted, and the quadratic multiple regression equation of the tool shaft torque and the damage rate to the coding independent variable is:

At the same time, the results of the test plan were obtained after processing by Design-Expert software, as shown in Tables 6 and 7.

From Table 6, it can be seen that the interaction bending angle AC and the quadratic term A2 have a significant effect on the working resistance, the first term A and B have a significant effect on the working resistance, and the first term C has an extremely significant effect on the working resistance. And the influence of various factors on the working resistance is from large to small rotation radius C > blade angle B > bending angle A.

It can be seen from Table 7 that the simulated rotation radii AB, AC and BC have a very significant effect on the damage rate, and the primary bending angle A, B, C and the secondary term A2 have a significant effect on the breakage rate. The influence of various factors on the torque of the tool shaft is C > B > A. The response surface analysis obtained by the interaction is shown in Fig. 12a–d.

Determination of optimal structural parameters of reverse rotary polishing cutter

Through the orthogonal test results, the constraints of each factor and each index are set as follows:

According to the Design-Expert, the constraint conditions are solved and analyzed. When the bending angle of the tangent plane is 126.01°, the blade inclination angle is 25.35°, and the radius of rotation is 142.19 mm, the optimal combination of operating parameters is obtained. The torque of the cutter shaft is 328.67 N·m, and the breakage rate is 2.37%. The optimal parameterization is zeroed as the bending angle of the tangent plane is 126°, the blade inclination angle is 25°, and the radius of rotation is 142 mm. In the EDEM virtual simulation, the test conditions are set to verify the virtual simulation test, and the torque of the cutter shaft is 341.10 N·m, and the breakage rate is 2.01%. It is basically consistent with the optimization results.

Verification of test bench for optimal structural parameters of reverse rotary polishing cutter

In order to verify the practical application of the optimized optimal parameter combination, a rotary blade with a tangent angle of 126°, a blade angle of 25°, and a radius of rotation of 140 mm was cast in reality. The test bench of the anti-selection throwing type digging device with the same structure as the virtual device in the simulation test was assembled. As shown in Figs. 13 and 14, the field test verification test was carried out at the Youshadou test demonstration base (34° N, 115° E) in Bodang Township, Minquan County, Henan Province.

The TQ101-1 K torque sensor is installed to measure the working torque of the cutter shaft. The data obtained by the sensor are collected by the data acquisition card and read on the tractor on-board computer. The damage rate of Cyperus esculentus fruit in actual operation was measured by the ratio of damaged fruit mass in soil / total fruit mass in soil after operation. Taking the average value of the three bench test results, the test results are shown in Table 8.

By comparing the experimental data in Table 6, the measured results are basically consistent with the predicted values, indicating that the field test effect of the optimal parameter combination is the best. At this time, the bending angle of the tangent plane of the rotary polishing cutter is 126°, the oblique angle of the blade is 25°, the radius of gyration is 140 mm, the torque of the working tool shaft is 337.54 N·m, and the damage rate is 1.85%. Through simulation test and bench test, it is determined that the optimal structural parameters of the rotary polishing tool are the bending angle of the tangent plane of the rotary polishing tool of 126°, the oblique angle of the blade of 25°, and the radius of rotation of 140 mm.In the subsequent optimization test, this parameter is used as the structural parameter of the rotary polishing tool.

As shown in Table 9, it can be seen from the data of the torque of the positive and negative rotation test cutter shaft in the field that the torque of the positive rotation cutter shaft is larger than that of the reverse rotation cutter shaft under the same rotary polishing cutter. When the rotary polishing cutter is installed in reverse rotation, the torque of the cutter shaft can be reduced by 33%.

Conclusion

-

1.

The problem analysis of the existing Cyperus esculentus rhizome soil encircling body digging device was carried out, and an innovative Cyperus esculentus digging method based on reverse rotary throwing was proposed. Through the dynamic analysis of the forward and reverse rotary digging device, the cutting and throwing mechanical model of Cyperus esculentus rhizome soil encircling body was constructed, and the working mechanism of the overall flipping and collision fragmentation of the reverse rotary throwing digging device was determined.

-

2.

Through the virtual simulation, the structural parameters of the reverse rotary throwing type Cyperus esculentus digging device were optimized, and the optimal combination was obtained. When the bending angle of the tangent plane was 126.011°, the blade angle was 25.355°, and the radius of rotation was 142.198 mm, the optimal combination of operating parameters was obtained. At this time, the cutter shaft torque was 328.627 N·m, and the breakage rate was 2.372%. In order to verify the actual operation of the structural parameters, the field bench test was carried out. When the tangent angle of the rotary blade was 126°, the blade angle was 25°, the radius of rotation was 140 mm, the torque of the cutter shaft was 337.3 N·m, and the damage rate was 1.86%.

Data availability

The data used to support the findings of this study are included within the manuscript.

References

He, X. et al. Design and test of resistance-reducing excavation device of Cyperus edulis based on discrete element method. Trans. Chin. Soc. Agric. Mach. 52(12), 124–133 (2021).

Huang, M., Wang, X. & Pang, Z. Research status and prospect of Cyperus esculentus L. Crop Res. 27(03), 293–295+301 (2013).

Chen, Z. et al. Research progresses on cultivation and utilization of Cyperus esculentus. Chin. J. Tro Agric. 37(12), 56–60 (2017).

Zhang, X. R & D progress report of Cyperus esculentus industry in China. Chin. Rural Sci. Tech. 04, 67–69 (2019).

Zhang, B. et al. Research progresses of mechanical seeding and harvesting technology and equipment for saline - alkali Cyperus esculentus. Shandong Agric. Sci. 51(04), 144–148 (2019).

Sun, J. et al. Simulation of ultra deep rotary tillage tool based on soil disturbance. J. Agric. Mech. Res. 46(09), 66–71 (2024).

Yang, X. et al. Research of mathematical fitting method applied to structural design of rotary cultivator. J. Agric. Mech. Res. 46(09), 240–243+248 (2024).

Zhang, M. & Liu, H. Design and research of a new type rotary tillage, trench opening fertilization and seeding machine. J. Agric. Mech. Res. 46(08), 120–124 (2024).

Yang, D. et al. Optimisation of structural parameters of rotary knives for tea garden micro-tillers based on discrete element method. Chin. Southern Agric. Mach. 55(01), 7–10+15 (2024).

Patidar, P., Soni, P., Jain, A. & Mahore, V. Modelling soil-rotor blade interaction of vertical axis rotary tiller using discrete element method (DEM). J. Terra. 112, 59–68 (2024).

Yevtushenko, T. L. et al. Analysis of rotary cutter structure. Russ. Eng. Res. 42(Suppl 1), S70–S73 (2022).

Yang, Y., Hu, Z., Gu, F. & Ding, Q. Simulation and experimental study of the tillage mechanism for the optimal design of wheat rotary strip-tiller blades. Agriculture. 13(3), 632 (2023).

Li, X., Zhu, L. & Gong, S. Soil-cutting simulation and dual-objective optimization on tillage process parameters of micro-tiller by smoothed particle Galerkin modeling and genetic algorithm. Comput. Electron. Agric. 198, 107021 (2022).

Xu, G. et al. Straw-soil-rotary blade interaction: Interactive effects of multiple operation parameters on the straw movement. Agronomy. 12(4), 847 (2022).

Du, J. et al. Investigation of the burial and mixing performance of a rotary tiller using discrete element method. Soil Till. Res. 220, 105349 (2022).

Yu, C. et al. Design and optimization and experimental verification of a segmented double-helix blade roller for straw returning cultivators. J. Chin. Inst. Eng. 44(4), 379–387 (2021).

Yang, Y. et al. Biomimetic rotary tillage blade design for reduced torque and energy requirement. Appl. Bionics Biomech. 2021, 1–16 (2021).

Qin, K., Liang, X., Cao, C. & Fang, L. Relationship between soil movement and power consumption in a furrow-opening rotary blade. INMATEH-Agric. Eng. 62(3) (2020)

Zhang, G. et al. Soil-cutting simulation and parameter optimization of rotary blade’s three-axis resistances by response surface method. Comput. Electron. Agric. 164, 104902 (2019).

Cheng, J. et al. Construction and analysis of a discrete element model for calculating friction resistance of the typical rotary blades. Comput. Electron. Agric. 214, 108303 (2023).

He, X. et al. Design and optimization tests of reverse spin-throwing Cyperus edulis starting device. Trans. Chin. Soc. Agric. Mach. 53(05), 34–43 (2022).

Yang, R. et al. Tests and analyses of mechanical properties of peanut root, stem and nut node in mechanical harvest. Trans. Chin. Soc. Agric. Eng. 25(09), 127–132 (2009).

He, J. Study on Fractional Rheological Constitutive Model of Q3 Loess (Changan Univ., 2020).

Hu, J. et al. Prediction model of double axis rotary power consumption based on discrete element method. Trans. Chin. Soc. Agric. Mach. 51(S1), 9–16 (2020).

Pan, H. Design and Parameter Optimization of Doubleaxis Rotary Tillage Stubble Extinguisherbased on Discrete Element Method (Jiangsu Univ., 2020).

Fan, Y. Research on Potato Digging Mechanism Based on Discrete Element Method and Design of Bionic Shovel (Shenyang Agric. Univ., 2020).

Li, F. Experimental Study on Nonlinear Three-Dimensional Rheological Constitutive Model of Q: Remolded-Loess and Its Implementation in FLAC3D (Changan Univ., 2016).

Author information

Authors and Affiliations

Contributions

Conceptualization, X.H., S.M. and S.S.; methodology, X.H. and S.S.; software, S.M. and D.W.; resources, X.H and S.S.; data curation, X.H. and S.M. ; validation, X.H., Z.L., D.W. and S.S.; writing—original draft preparation, X.H.; writing—review and editing, X.H. and D.W.; project administration, S.S. and X.H. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

He, X., Ma, S., Liu, Z. et al. Study on digging form of mechanized harvesting of Cyperus esculentus and optimization test of device parameters. Sci Rep 15, 16583 (2025). https://doi.org/10.1038/s41598-024-81581-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-81581-x