Abstract

To enhance the volumetric energy density and initial coulombic efficiency (ICE) of titanium oxide (TiO2) as anode electrode material for lithium-ion batteries (LIB), this study employed a surface-confined in-situ inter-growth mechanism to prepare a TiO2 embedded carbon microsphere composite. The results revealed that the composite exhibited a highly integrated structure of TiO2 with oxygen vacancies and carbon, along with an exceptionally small specific surface area of 11.52 m2/g. Due to its unique microstructure, the composite demonstrated remarkable lithium storage properties, including a high ICE of 75%, a notable capacity of 426.8 mAh/g after 200 cycles at 0.2 A/g, superior rate performance of 210.1 mAh/g at 5 A/g, and an outstanding cycle life, with a capacity decay rate of only 0.003% per cycle over 2000 cycles. Furthermore, electrochemical kinetic studies further validated the advantages of this microstructure.

Similar content being viewed by others

Introduction

In the context of the rapid development of the global economy, the energy crisis and environmental pollution remain two significant challenges that humanity must address. The advent of rechargeable lithium-ion batteries (LIBs) appears to offer an effective solution to these issues, given their numerous advantages, including high energy density, environmental sustainability, and portability1,2,3,4,5,6. Currently, the anode of LIBs is predominantly composed of commercial graphite due to its low lithium insertion potential, abundant availability, and cost-effectiveness. However, the low lithium embedding potential of graphite can lead to the formation of lithium dendrites, which pose safety risks7,8,9. Consequently, it is essential to identify a safer anode material to replace graphite.

Among the various anode materials for LIB, TiO2 exhibits a high lithium embedding potential, which effectively mitigates the formation of lithium dendrites, thereby significantly enhancing the safety of LIBs10,11,12. Furthermore, it is favored by researchers due to its environmental friendliness, abundant availability, minimal volume expansion, and excellent cycling stability13,14. However, TiO2 also presents certain limitations, including low specific capacity, poor electrical conductivity, and slow lithium insertion kinetics, which are inherent to its characteristics15,16,17. In recent years, researchers have proposed numerous strategies to address these shortcomings, including the use of nanostructures18,19,20, the incorporation of carbon21,22,23, and the development of specialized morphologies24,25 or porous structures26. While these measures can significantly enhance the lithium storage capacity of TiO2, they also introduce certain drawbacks, such as reduced volumetric energy density and initial coulombic efficiency (ICE), which are crucial factors for the commercial viability of TiO2. The primary contributors to these negative effects include the large specific surface area (SSA) of TiO2, which diminishes its volumetric mass and exacerbates electrolyte side reactions. Previous research has demonstrated that reducing the SSA of the active material can improve its bulk mass and decrease the occurrence of electrolyte side reactions, thereby enhancing its ICE27. However, a low SSA in the active material can impair lithium storage performance, particularly the rate performance, due to suboptimal electrochemical kinetics. Consequently, achieving a balance between these two opposing factors to attain optimal overall performance remains a significant challenge.

In this study, we employed a surface-confined in-situ inter-growth mechanism to produce TiO2 embedded in a carbon microsphere (denoted as TiO2@C), which exhibits a highly complex structure comprising both TiO2 and carbon, alongside an extremely small specific surface area (SSA) of only 11.52 m2/g. This intricate structure effectively promotes the transfer of electric charge, while the presence of oxygen vacancies enhances lithium storage sites. Additionally, the small SSA significantly mitigates the occurrence of electrolyte side effects. As a result, TiO2@C demonstrates an impressive initial coulombic efficiency (ICE) of 75%, a stable capacity of 426.8 mAh/g after 200 cycles at a current density of 0.2 A/g, a remarkable rate capability of 210.1 mAh/g at 5 A/g, and an outstanding cycle life, with a capacity decay rate of only 0.003% per cycle over 2000 cycles.

Experimental

Synthesis of materials

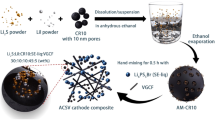

The preparation of TiO2@C microspheres is achieved through a surface-confined in-situ inter-growth mechanism. The process begins with the injection of 280 µL of methanal (Macklin, 37 wt% in H2O, containing 10–15% methanol stabilizer), 200 mg of 3-aminophenol (aladdin, ≥ 98%), and 1 mL of NH3·H2O (aladdin, AR, 25–28%) into 80 mL of ethyl alcohol (aladdin, AR, water ≤ 0.3%), followed by stirring for 0.5 h. Subsequently, 3.4 mL of titanium tetrabutoxide (TBOT, aladdin, ≥ 99.0%) is swiftly added to the solution and stirred for 2 h. After stirring, the resulting yellowish precursor is collected through repeated vacuum filtration and washed with ethanol, then dried at 80 °C for 12 h. Finally, the precursor undergoes heat treatment in a tube furnace under an argon atmosphere, where it is heated to 500 °C and held for 2 h to form the TiO2@C composite. For comparison, the preparation method for pure TiO2 follows a similar procedure, with the only difference being the use of air instead of argon, while all other experimental conditions remain constant.

Material characterization

The crystal structure of the sample was determined through the use of the X-ray diffraction (XRD) technique with a Rigaku D/Max−2500 instrument. A scanning electron microscope with energy-dispersive X-ray spectroscopy (SEM, HITACHI SU8010) was employed to observe the morphology and composition of the samples, while transmission electron microscopy (TEM, JEM−2100 F) was utilized to characterize the internal structure. The nanoscale structure of the sample underwent further investigation via a high-resolution transmission electron microscope (HRTEM, JEM−2100 F). Accurate calculations of the specific surface area and pore structure of the sample were performed using the Brunauer-Emmett-Teller (BET) method with a Micrometrics ASAP2460. X-ray photoelectron spectroscopy (XPS, Thermo ESCALAB 250XI) was applied to analyze the chemical states of the elements C, Ti and O on the sample’s surface. The composite’s carbon content was assessed through thermal analysis (PE STA−8000). Moreover, Raman spectroscopy (DXR3 Flex) was employed to characterize the structural properties of the samples. Electron paramagnetic resonance (EPR, BRUKE A300) was conducted to detect the oxygen vacancy signals in the samples. A UV-visible spectrophotometer (LAMBDA 35) was utilized to analyze the diffuse absorption spectrum of the samples, using BaSO4 as the reflection standard during the measurements.

Calculation methods

The crystallite size of the samples was calculated using the Scherrer equation: L = 0.89 λ/βcosθ, in which λ, β and θ are X-ray wavelength, intrinsic peak width, and diffraction angle, respectively. All density functional theory (DFT) calculations were performed using the Vienna Ab initio Simulation Package (VASP). The exchange-correlation potential was described by the Perdew-Burke-Ernzerhof (PBE) generalized gradient approximation (GGA). Electron-ion interactions were accounted for using the projector augmented wave (PAW) method. Each DFT calculation utilized a cut-off energy of 400 eV, and a 5 × 5 × 2 Gamma-centered Monkhorst-Pack grid of k-points was selected for sampling the Brillouin zone integration. The energy and force convergence criteria for the self-consistent iterations were set to 10− 5 eV and 0.02 eV Å−1, respectively. The DFT-D3 method was employed to describe van der Waals (vdW) interactions.

Electrochemical measurements

The assembly of the CR2025 battery was conducted inside a glove box filled with argon gas. To prepare the working electrode slurry, a mixture was formed by blending 80 wt% active material, 10 wt% acetylene black, and 10 wt% carboxymethyl cellulose (CMC) in deionized water, which was stirred at room temperature for 12 h. This resulting slurry was then spread onto copper foil and left to dry overnight in a vacuum oven set to 80 °C. In assembling the CR2025 coin cells, lithium foil was utilized as the anode, while celgard polypropylene was employed as the separator. The selected electrolyte consisted of a 1 M solution of LiPF6, dissolved in a 1:1 volume ratio of ethylene carbonate (EC) and dimethyl carbonate (DMC). Charge-discharge cycling using a galvanostatic method and the galvanostatic intermittent titration technique (GITT) were performed within a voltage range of 0.01–3 V. Cyclic voltammetry (CV) analyses were implemented with a CHI 660d electrochemical workstation, at a scan rate of 0.1 mV/s across a voltage range of 0.01 to 3 V. Additionally, electrochemical impedance spectroscopy (EIS) was conducted using the same CHI 660d workstation, spanning a frequency range from 0.01 to 100,000 Hz.

Results and discussion

The XRD spectra of the samples are presented in Fig. 1a, where all spectral peaks of both samples align perfectly with those of standard anatase TiO2. Due to the low carbon ratio in TiO2@C, or its presence in an amorphous form, the characteristic peaks of carbon were not detected in the TiO2@C sample. In comparison to pure TiO2, TiO2@C exhibited lower crystallinity and broader diffraction peaks. According to Scherrer’s formula, the average crystallite sizes of the TiO2 phase in the pure TiO2 and TiO2@C samples are 12.9 and 9.3 nm, respectively. This result indicates that the presence of carbon effectively suppresses TiO2 grain growth, leading to a smaller grain size. Furthermore, the structural characteristics of the samples were analyzed using raman spectroscopy, as shown in Fig. 1b. In both samples, five distinct peaks were observed near 145, 203, 395, 521, and 635 cm − 1, corresponding to the typical raman vibration modes of TiO228. Additionally, two faint Raman peaks at 1599 and 1348 cm − 1 in the TiO2@C composite material were identified as the G and D peaks of carbon29. The ID/IG value is approximately 0.91, indicating that the existing carbon primarily exists in a graphitized form, which will enhance the conductivity of the carbon. Figure S1 presents the TG-DSC curve of TiO2@C. The TG curve demonstrates a weight loss up to 300 °C, which is primarily attributed to the vaporization of surface-adsorbed water. Following this, a rapid decrease in weight is observed between 300 and 500 °C, accompanied by a significant exothermic peak at 375 °C, which is attributed to the combustion and elimination of carbon. The carbon content, as determined from the TG-DSC curve, is calculated to be approximately 7.9%.

The morphology of samples prepared through different processes was analyzed using SEM. Figure S2 illustrates the precursor, which displays an irregular shape characterized by several interconnected nanospheres (Fig. S2a). Upon closer inspection, the precursor appears as a slightly rough spheroid with an approximate size of 500 nm (Fig. S2b). Following heat treatment in various atmospheres, the overall morphology of the TiO2@C and TiO2 samples remains largely unchanged compared to the precursor (Fig. 2a,c). However, a subtle distinction in surface morphology is observed, with TiO2 exhibiting a relatively rougher surface due to the combustion of carbon during the precursor’s heat treatment in an air atmosphere (Fig. 2b,d). This combustion effectively promotes the further growth of TiO2 grains, providing visual evidence for the inhibitory role of carbon in TiO2 grain growth. TEM was employed to investigate the internal structure of the TiO2@C composite material. As shown in Fig. 2e, the TiO2@C nanospheres possess a compact solid internal structure, indicating that the TiO2@C composite has a low specific surface area (SSA). Figure 2f presents HRTEM image of the TiO2@C, revealing clear lattice fringes corresponding to the anatase TiO2 (101) crystal plane. Notably, amorphous carbon (shown as a white curved region) closely envelops the TiO2 without discernible boundaries, suggesting a potential co-existence process during the formation of the TiO2@C precursor. This co-existence process facilitates the persistent polymerization of 3-aminophenol and methanal around TiO2, with the resulting polymer effectively preventing the aggregation of primary TiO2 grains. The electron diffraction pattern depicted in Fig. 2g indicates that TiO2 within the TiO2@C sample exists in a polycrystalline state. Additionally, Fig. 2h displays the elemental distribution mapping for TiO2@C, revealing a uniform distribution of C, Ti and O elements within the composite.

Figure 3 illustrates the SSA and pore size of both samples. As shown in Fig. 3a, there is no discernible hysteresis loop in the nitrogen adsorption/desorption curves for either sample at relative pressures (P/P0) of 0.5 and 1.0, indicating that the SSA of TiO2@C and TiO2 is quite small. The SSA values for TiO2@C and TiO2 were determined to be 10.41 and 9.84 m2 g−1, respectively. Furthermore, Fig. 3b indicates that the pore sizes of TiO2@C and TiO2 are predominantly concentrated at 4.8 and 4.3 nm, respectively. The observed difference in pore sizes can be attributed to the inhibition of TiO2 grain growth by carbon during the heat treatment of the TiO2@C composite in an argon atmosphere. Such small SSA not only contribute to an increase in the tap density of the anode electrode material, thereby enhancing its volumetric energy density, but also significantly reduce the contact area between the active material and electrolyte. This reduction leads to a decrease in side reactions and an improvement in the ICE of the TiO2@C electrode.

Figure 4a presents the XPS full spectrum of both samples, indicating the presence of C, Ti and O elements on the surface of TiO2@C. Figure 4b illustrates the high-resolution XPS (HR-XPS) spectra of the Ti 2p for both TiO2@C and TiO2. The Ti 2p HR-XPS spectra of the TiO2 sample reveal a pair of peaks located at 463.9 and 458.2 eV, corresponding to the binding energies of 2p1/2 and 2p3/2 of Ti4+30. In contrast, the Ti 2p HR-XPS spectra of the TiO2@C sample exhibit two pairs of peaks: a prominent pair at 464.8 and 458.9 eV, which correspond to 2p1/2 and 2p3/2 of Ti4+, and another pair at 463.8 and 458.2 eV, attributed to 2p1/2 and 2p3/2 of Ti3+31. Notably, the binding energy of Ti4 + in the TiO2@C sample is higher, which can be ascribed to the presence of Ti3+. Figure 4c displays the O 1s HR-XPS spectrum of the TiO2@C sample, where three peaks can be fitted at 531.9, 530.2 and 529.9 eV, corresponding to the oxygen vacancy (Vo), O-C, and O-Ti4 + bonds, respectively32. The formation of Vo in the TiO2@C may result from insufficient oxygen during heat treatment in an argon atmosphere. The proportion of Vo can be calculated to be 16.2% by the ratio of the XPS peak area of Vo to the total XPS peak area of Ti and O elements. Previous studies have confirmed that the presence of Vo not only enhances the intrinsic conductivity of TiO2 but also increases the active sites for lithium storage in TiO2@C composite materials33. Figure 4d illustrates the HR-XPS of C 1s in TiO2@C, where the two fitted peaks at 284.8 and 283.4 eV correspond to the binding energies of C-C/C = C and C-O bonds, respectively34.

Figure 5a presents the EPR spectra of TiO2 and TiO2@C samples. The TiO2@C sample exhibits a pronounced EPR signal with a g-value of 2.0035, suggesting the presence of significant Vo35. In contrast, the TiO2 sample does not display any EPR response. This finding aligns with the O 1s HR-XPS spectrum (Fig. 4c). To further investigate the influence of Vo on the energy band structure of TiO2, density functional theory (DFT) was employed to simulate and calculate the energy band structures of both pristine TiO2 and TiO2 with introduced Vo. The results are presented in Fig. 6. As illustrated in Fig. 6c,d, the band gaps of pristine TiO2 and TiO2 containing Vo are 2.93 and 2.42 eV, respectively. This indicates that the presence of Vo reduces the band gap of TiO2, which may enhance electronic conductivity and carrier transport. As predicted by DFT calculations, the presence of Vo has a direct impact on the band structure and band gap of TiO2, a phenomenon that can be verified through changes in light absorption. As illustrated in Fig. 5b, TiO2 primarily absorbs light below 450 nm, predominantly in the ultraviolet range, whereas TiO2@C exhibits a broader absorption spectrum and increased absorption intensity.

Through the analysis of the aforementioned test results, this paper proposes a surface-confined in-situ inter-growth mechanism for the formation of TiO2@C, as illustrated in Fig. 7. The experimental synthesis process described herein involves only three reactants: TBOT, methanal, and 3-aminophenol. Initially (Step I), due to the high concentration of NH3·H2O, TBOT rapidly hydrolyzes to form primary TiO2 grains, while NH4 + accumulate on its surface. Concurrently, methanal and 3-aminophenol undergo rapid polymerization to generate 3-aminophenol-methanal (3-APM) oligomers in the presence of NH4+, which subsequently accumulate around the primary TiO2 grains, resulting in the formation of high-density TiO2@3-APM microspheres. Subsequently (Step II), following thermal treatment under an argon atmosphere, TiO2@3-APM is transformed into TiO2@C with oxygen vacancies due to the absence of an oxygen source.

In the preparation of nano-TiO2, NH3·H2O solution is typically excluded because of its propensity to induce rapid hydrolysis of the titanium source, leading to significant particle aggregation of TiO2. In contrast, the synthesis method presented in this paper strategically leverages the rapid hydrolysis properties of the titanium source, facilitating the formation of a micro-environment on the TiO2 surface that triggers the polymerization of 3-aminophenol with methanal. The advantages of this approach are as follows: The technical route is straightforward, time-efficient, and does not require precise control, thereby enhancing its feasibility for commercial preparation; The micro-environment created around the primary TiO2 promotes a close association between TiO2 and 3-APM oligomers, which is essential for the subsequent thermal treatment aimed at achieving a highly integrated carbon and TiO2 structure.

The electrochemical behavior of TiO2@C electrode was investigated using CV, with the result presented in in Fig. 8a. During the initial discharge process, the CV curve reveals a broad reduction peak between 1.75 and 1 V, indicative of the initial Li + insertion into TiO2@C and the formation of the solid electrolyte interphase (SEI)36. Subsequently, during the charging process, the Li + extraction potential is observed to be approximately 2.2 V. In the subsequent cycles, the CV curves demonstrate a notable overlap, with the Li + insertion potential shifting towards a higher value. This observation suggests that the TiO2@C electrode has undergone a degree of activation, exhibiting excellent electrochemical reversibility and structural stability. The discharge/charge curves for both electrodes during the first three cycles at a current density of 0.2 A/g are presented in Fig. 8b and Fig. S3. The initial discharge specific capacities of the TiO2@C and TiO2 electrodes are 584.4 and 368.2 mAh/g, respectively. Correspondingly, the initial charge specific capacities are 438.3 mAh/g for TiO2@C and 272.4 mAh/g for TiO2. The ICE for TiO2@C and TiO2 electrodes are 75% and 74%, respectively, surpassing those reported in previous studies (Fig. 8c)18,22,25,37,38,39. These results demonstrate that the experimental approach employed in this study effectively enhances the ICE of the electrode by minimizing their SSA. The discharge/charge curves of both the TiO2@C and TiO2 electrodes over the subsequent two cycles exhibit a significant degree of overlap, indicating the high reversibility of these electrode materials during the Li + insertion and extraction processes. Furthermore, the reversible specific capacity of the TiO2@C electrode is approximately 1.6 times greater than that of the TiO2 electrode. This enhancement can be attributed to the intimate connection between TiO2 and carbon within the TiO2@C composite, which facilitates the full participation of the TiO2 active material. Additionally, the presence of oxygen vacancies provides extra Li + storage active sites. Figure 8d,e illustrate the cyclic and rate performance of both electrodes. As depicted in Fig. 8d, both electrodes demonstrate remarkable cyclic stability, with only a slight decrease in reversible specific capacity during the initial cycles. The reversible specific capacities recorded during the second cycle for the TiO2@C and TiO2 electrodes are 466.4 and 287.5 mAh/g, respectively. After 200 cycles, the reversible specific capacities are maintained at 426.8 and 275.9 mAh/g, respectively. The capacity retention rates for the TiO2@C and TiO2 electrodes, relative to their second cycle capacities, are 91.5% and 95.6%, respectively. Notably, the TiO2 electrode exhibits a superior capacity retention rate compared to the TiO2@C electrode, which may be attributed to the TiO2 electrode undergoing stronger activation during repeated charge and discharge cycles, thereby enabling more TiO2 active sites to participate in Li+. As the current density increases, the reversible specific capacities of both the TiO2@C and TiO2 electrodes exhibit a gradual decline, as illustrated in Fig. 8e. The average reversible specific capacities of the TiO2@C electrode at current densities of 0.1, 0.2, 0.5, 1.0, 2.0, and 5.0 A/g are 512.9, 468.2, 417.4, 350.9, 299.1, and 210.1 mAh/g, respectively, which surpass those reported in previous studies (Fig. 8f)22,40,41,42,43,44,45. Upon returning the current density to 0.1 A/g, the average reversible specific capacity is recorded at 511.8 mAh/g, indicating remarkable cycling reversibility. In contrast, the reversible capacity of TiO2 is only 124.3 mAh/g at a current density of 5.0 A/g, which is significantly lower than that of TiO2@C. This disparity suggests that the incorporation of carbon and the presence of oxygen vacancies considerably enhance the electrochemical kinetics of TiO2@C. The long-term cycling stability of the TiO2@C electrode, as demonstrated in Fig. 8g, confirms that it possesses an extended cycling life and stable coulombic efficiency. After 2000 cycles, the reversible specific capacity decreases from an initial value of 216.8 mAh/g to 203.8 mAh/g, resulting in an impressive capacity retention rate of 94%. This translates to a capacity decay rate of only 0.003% per cycle, indicating that the TiO2@C composite maintains exceptional structural integrity. EIS was conducted to better understand the changes in the electrochemical kinetics of TiO2@C before and after 2000 cycles, with the results presented in Fig. S4, in which the charge transfer resistance (Rct) of the TiO2@C electrode is significantly reduced after 2,000 cycles. This reduction indicates a substantial improvement in the kinetics of the TiO2@C electrode following repeated Li + de/insertion reactions.

(a) CV curves of the TiO2@C electrode at a scan rate of 0.1 mV s− 1. (b) Discharge/charge curves of the TiO2@C electrode at 0.2 A/g, (c) The initial coulombic efficiency comparison between the TiO2@C in this paper and other TiO2-based electrode (the current densities of the first cycle test for Ref. 18, 22, 25, 37, 38 and 39 are 0.1 A/g, 0.2 A/g, 0.2 A/g, 3 C, 0.25 C and 0.2 C, 1 C = 170 mA/g) (d) Cycling performance of TiO2@C and TiO2 electrodes at 0.2 A/g, (e) rate performance of TiO2@C and TiO2 electrodes at different current densities, (f) comparison of rate performance of TiO2@C in this paper with recently reported works on TiO2-based electrode for LIBs, (g) the long-term cycling performance of the TiO2@C electrode increased to a current density of 5 A/g after 10 cycles at a current density of 0.1 A/g.

The electrochemical kinetics of TiO2@C and TiO2 electrodes were investigated using EIS and GITT, with the results presented in Figure 9. The EIS data indicate that the TiO2@C electrode exhibits reduced Rct, as shown in Fig. 9a. Fig. 9b illustrates the GITT curves for both electrodes. The diffusion rates of Li + during the charge and discharge processes were calculated using the following equation:

where the ΔEs,ΔEt,m, t, M, Vm, and A represent the voltage changes caused by pulses, voltage changes of galvanostatic current charging/discharging, active material loading, pulse duration (s), molar mass (79.9 g/mol), molar volume (20.5 cm3/mol) and surface area of electrode, respectively32. The diffusion rates of Li+, depicted in Fig. 9c,d, indicate that the TiO2@C electrode achieves a diffusion rate ranging from approximately 10 − 9 to 10 − 10 cm2 s − 1, which is significantly higher than that of the TiO2 electrode. By integrating the findings from the EIS and GITT tests, it can be concluded that the optimal composite structure of TiO2 with carbon, coupled with the presence of oxygen vacancies, collectively enhances the electrochemical kinetics of the TiO2@C electrode, thereby resulting in superior electrochemical performance.

Conclusions

Nonporous TiO2@C microspheres with a highly integrated structure were synthesized using a surface-confined in-situ inter-growth strategy. When employed as an anode electrode for LIB, these microspheres exhibit a high volumetric energy density and improved ICE. The enhanced ICE is attributed to the extremely small SSA of the TiO2@C microspheres, which minimizes contact between the active material and the electrolyte, thereby reducing the occurrence of side reactions. Results from electrochemical kinetics studies strongly indicate that the synergistic interaction between the highly integrated structure and oxygen vacancies contributes to effective Li + storage. Furthermore, our synthesis method is not only efficient but also presents a novel approach for the development of other electrode materials.

Data availability

Data is provided within the manuscript or supplementary information files.

References

Wang, C., Yang, C. & Zheng, Z. Toward practical high-energy and high‐power lithium battery anodes: present and future. Adv. Sci. 9, 2105213 (2022).

Li, J. et al. Revolutionizing lithium storage capabilities in TiO2 by expanding the redox range. ACS Nano. 17, 21604–21613 (2023).

Zhang, Y. et al. Polydopamine sacrificial layer mediated SiOx/C@ C yolk@ shell structure for durable lithium storage. Mater. Chem. Front. 4, 1656–1663 (2020).

Lee, J. et al. Everlasting living and breathing gyroid 3D network in Si@ SiOx/C nanoarchitecture for lithium ion battery. ACS Nano. 13, 9607–9619 (2019).

Zhao, C. et al. Recent progress on Electrolyte boosting initial Coulombic Efficiency in Lithium-Ion Batteries. Adv. Funct. Mater. 34, 2303457 (2024).

Zhang, Y., Nie, Z., Du, C., Zhang, J. & Zhang, J. Ultrahigh lithiation dynamics of Li4Ti5O12 as an anode material with open diffusion channels induced by chemical presodiation. Rare Met. 42, 471–483 (2023).

Adams, R. A., Varma, A. & Pol, V. G. Carbon anodes for nonaqueous alkali metal-ion batteries and their thermal safety aspects. Adv. Energy Mater. 9, 1900550 (2019).

Feng, X. et al. Thermal runaway mechanism of lithium ion battery for electric vehicles: a review. Energy Storage Mater. 10, 246–267 (2018).

Wang, H. et al. Underpotential lithium plating on graphite anodes caused by temperature heterogeneity. Proc. Natl. Acad. Sci. 117, 29453–29461 (2020).

Paul, S. et al. TiO2 as an Anode of high-performance lithium-ion batteries: a comprehensive review towards practical application. Nanomaterials 12, 2034 (2022).

Ryu, J. et al. Dual buffering inverse design of three-dimensional graphene‐supported Sn‐TiO2 anodes for durable lithium‐ion batteries. Small 16, 2004861 (2020).

Shi, H. et al. Titanium dioxide-based anode materials for lithium-ion batteries: structure and synthesis. RSC Adv. 12, 33641–33652 (2022).

Lee, D. H. et al. Engineering titanium dioxide nanostructures for enhanced lithium-ion storage. J. Am. Chem. Soc. 140, 16676–16684 (2018).

Xie, X. et al. Complementary two-phase anode improving stability and conductivity for lithium storage performance. Rare Met. 42, 85–99 (2023).

Wang, W. et al. Porous TiO2/C nanocomposite shells as a high-performance anode material for lithium-ion batteries. ACS Appl. Mater. Interfaces. 5, 6478–6483 (2013).

Liao, J. Y. et al. Dual phase Li4Ti5O12–TiO2 nanowire arrays as integrated anodes for high-rate lithium-ion batteries. Nano Energy. 9, 383–391 (2014).

Yan, X. et al. Enhanced electrochemical properties of TiO2 (B) nanoribbons using the styrene butadiene rubber and sodium carboxyl methyl cellulose water binder. J. Power Sources. 246, 95–102 (2014).

Xu, J. et al. Nanowires-assembled TiO2 nanorods anchored on multilayer graphene for high-performance anodes of lithium-ion batteries. Nanomaterials 12, 3697 (2022).

Bi, X. et al. Cluster-derived TiO2 nanocrystals with multiple carbon coupling for interfacial pseudo-capacitive lithium storage. Dalton Trans. 51, 17858–17868 (2022).

Yu, W. et al. Unprecedented and highly stable lithium storage capacity of (001) faceted nanosheet-constructed hierarchically porous TiO2/rGO hybrid architecture for high-performance Li-ion batteries. Natl. Sci. Rev. 7, 1046–1058 (2020).

Liang, Y. et al. Ultrathin 2D mesoporous TiO2/rGO heterostructure for high-performance lithium storage. Small 16, 2000030 (2020).

Yin, J. et al. TiO2 quantum dots confined in 3D carbon framework for outstanding surface lithium storage with improved kinetics. J. Colloid Interface Sci. 582, 874–882 (2021).

Huang, H. et al. Hierarchical TiO2/C nanocomposite monoliths with a robust scaffolding architecture, mesopore-macropore network and TiO2-C heterostructure for high-performance lithium ion batteries. Nanoscale 8, 10928–10937 (2016).

Liu, S. et al. Nanosheet-constructed porous TiO2-B for advanced lithium ion batteries. Adv. Mater. 24, 3201–3204 (2012).

Yin, J. et al. Self-templated hierarchical TiO2@ C microrods with synergic battery/capacitor hybrid energy storage: toward ultra-long cycling life and outstanding rate performance. J. Alloys Compd. 808, 151728 (2019).

Cai, Y. et al. Walnut-like porous core/shell TiO2 with hybridized phases enabling fast and stable lithium storage. ACS Appl. Mater. Interfaces. 9, 10652–10663 (2017).

Zhao, B. et al. Interface-induced pseudocapacitance in nonporous heterogeneous particles for high volumetric sodium storage. Adv. Funct. Mater. 30, 2002019 (2020).

Shoaib, A. et al. Ultrathin single-crystalline TiO2 nanosheets anchored on graphene to be hybrid network for high-rate and long cycle-life sodium battery electrode application. J. Power Sources. 342, 405–413 (2017).

Yang, F. et al. TiO2/carbon hollow spheres as anode materials for advanced sodium ion batteries. Electrochim. Acta. 178, 871–876 (2015).

Chen, L., Ho, Y., Guo, W., Huang, C. & Pan, T. Enhanced visible light-induced photoelectrocatalytic degradation of phenol by carbon nanotube-doped TiO2 electrodes. Electrochim. Acta. 54, 3884–3891 (2009).

Zhang, Y. et al. Oxygen vacancies evoked blue TiO2 (B) nanobelts with efficiency enhancement in sodium storage behaviors. Adv. Funct. Mater. 27, 1700856 (2017).

Ni, Q. et al. Superior sodium-storage behavior of flexible anatase TiO2 promoted by oxygen vacancies. Energy Storage Mater. 25, 903–911 (2020).

Yin, J. et al. Highly compacted TiO2/C micospheres via in-situ surface-confined intergrowth with ultra-long life for reversible Na-ion storage. J. Colloid Interface Sci. 582, 526–534 (2021).

Cheng, Y., Chen, Z., Wu, H., Zhu, M. & Lu, Y. Ionic liquid-assisted synthesis of TiO2-carbon hybrid nanostructures for lithium‐ion batteries. Adv. Funct. Mater. 26, 1338–1346 (2016).

Wang, Z. et al. A high performance TiO2 anode modified by germanium and oxygen vacancies for lithium-ion batteries. J. Alloy Compd. 968, 172217 (2023).

Chen, Y., Ma, X., Cui, X. & Jiang, Z. In situ synthesis of carbon incorporated TiO2 with long-term performance as anode for lithium-ion batteries. J. Power Sources. 302, 233–239 (2016).

Cai, L. et al. Improved Lithium Storage performance of a TiO2 Anode Material Doped by Co. Materials 16, 1325 (2023).

Hao, Z. et al. Oxygen-deficient blue TiO2 for ultrastable and fast lithium storage. Adv. Energy Mater. 10, 1903107 (2020).

Ko, W. Y., Wu, T. C., He, S. Y. & Lin, K. J. Phosphorus-doped TiO2 mesoporous nanocrystals for anodes in high-current-rate lithium ion batteries. Nanotechnology 35, 175403 (2024).

Li, S., Song, Y., Wan, Y., Zhang, J. & Liu, X. Hierarchical TiO2 nanoflowers percolated with carbon nanotubes for long-life lithium storage. J. Electroanal. Chem. 934, 117305 (2023).

Liang, C. et al. Synthesis of porous hollow spheres Co@TiO2 – x-Carbon composites for highly efficient lithium-ion batteries. Nanoscale Res. Lett. 17, 86 (2022).

Ran, K. et al. Ultra-thin graphene cube framework@TiO2 heterojunction as high-performance anode materials for lithium ion batteries. J. Colloid Interface Sci. 625, 100–108 (2022).

Li, L. et al. Hierarchical Ti3C2@TiO2 MXene hybrids with tunable interlayer distance for highly durable lithium-ion batteries. Nanoscale 12, 10369–10379 (2020).

Fan, M., Yang, Z., Lin, Z. & Xiong, X. Facile synthesis of uniform N-doped carbon-coated TiO2 hollow spheres with enhanced lithium storage performance. Nanoscale 13, 2368–2372 (2021).

Ren, Y. et al. Flower-like TiO2 hollow microspheres with mixed-phases for high-pseudocapacitive lithium storage. J. Alloys Compd. 902, 163730 (2022).

Acknowledgements

This research is financially supported by the China Postdoctoral Science Foundation (Grant No. 2023M732858), the Shandong Provincial Natural Science Foundation (Grant No. ZR2022QE290) and The Development Plan for Weifang City (Grant No. 2023GX061).

Author information

Authors and Affiliations

Contributions

Jinpeng Yin: Conceptualization, Methodology, Data analysis and Writing-Original Draft.Guanqin Wang: Data Curation and Data CurationDongqing Kong: Funding acquisition and ValidationChuang Li: Visualization Qiang Zhang: VisualizationDongbai Xie: Original DraftYangyang Yan: Funding acquisition Ning Li: Funding acquisitionQiang Li: Project administration, Project administration, and Writing - Review & Editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yin, J., Wang, G., Kong, D. et al. Nonporous TiO2@C microsphere with a highly integrated structure for high volumetric lithium storage and enhance initial coulombic efficiency. Sci Rep 14, 31029 (2024). https://doi.org/10.1038/s41598-024-82179-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-82179-z