Abstract

In order to meet the requirements of hole tray seedling transplanting operation for tomato, pepper and other irregular-shaped vegetable seeds, and to solve the problems of poor seeding performance of irregular-shaped vegetable seeder, this study designed an Air-suction Drum-type Precision Seeder. The basic structure and working principle of the seeder were elaborated, the key components were designed, and the distribution of the airflow field in the flow paths of the suction nozzles of three different hole types was simulated and analyzed by Fluent software; the relationship between the main influencing factors of the seeder’s operational performance (suction air pressure, clearing air pressure, and vibration frequency of the seed cassette) and the sowing indexes (replanting rate, cavity rate, and qualification rate) was investigated and the relationship between the factors and the sowing indexes (reseeding rate, cavity rate, and qualification rate) was analyzed by the quadratic orthogonal combination experiment method. The relationship between the main factors (suction air pressure, clearing air pressure and vibration frequency of seed supply box) and the seeding indexes (reseeding rate, empty hole rate and pass rate) was studied, and the effects of the factors and their interactions on the indexes were analyzed and the parameters were optimized by multi-objective optimization method. The results show that: the factors affecting the seeding qualification rate in the order of suction air pressure, clearing air pressure and vibration frequency, the optimal parameter combination of suction air pressure 16.0 kPa, clearing air pressure 3.4 kPa, vibration frequency of 50 Hz, in the optimal parameter combination of the sowing test, to get the replanting rate, the rate of empty holes, the qualification rate of the time were 1.4%, 1.7% and 96.9%, respectively.It shows that the performance of this seeder is better adapted, accurate and efficient, and can meet the requirements of irregular-shaped vegetable seeding operation. The results of the study can provide a reference for the research and development of the irregular-shaped vegetable seedling seeding machine.

Similar content being viewed by others

Introduction

There are two main types of vegetable planting methods: seedling transplanting and direct seeding1. Seedling transplanting is a kind of agricultural production work that separates vegetable field production from seedling production. This method has the advantages of high seed survival rate, saving seeds and reducing production cost compared with field direct seeding2,3,4,5. The seeding performance is poor, labor costs, investment costs, time costs and other aspects of the cost is huge and low seeding efficiency, when vegetable seeding machine in the sowing of irregular-shaped seeds6,7,8. At present, the comprehensive mechanization level of vegetables is only about 20%, much lower than food crops, in the face of the expanding scale of vegetable cultivation, the realization of vegetable seeding mechanization is imperative9.

Due to the advantages of air-suction seeder such as less stringent requirements on seed size, hard to injure the seed, and high sowing accuracy10,11,12, it has been vigorously developed and widely used in domestic and foreign seeding machines13,14. Air-suction seeder sucks seeds through negative pressure, the pressure plate isolates the negative pressure, and then relies on the seed’s own gravity for seed casting, which is mainly applied to large-size and medium-size seeds15,16 and so on. For the shaped seeds with lighter quality, if only rely on its own gravity to cast seeds. The casting speed and position fluctuations cannot meet the synchronization of seed casting and affect the quality of single grain precision seeding17,18. The realization of single-grain precision sowing for typical shaped vegetable seeds such as tomato, pepper and eggplant has solid theoretical and practical application value for solving the technical problems of seedling transplantation of vegetables and enriching the application field of air-suction seeder.

Around the vegetable air-suction seeder technology, Xia Hongmei19,20 team of South China Agricultural University has developed air-suction drum-type seeder and air-suction plate-type seeder. And the seed transport law in the process of seed suction and discharge was analyzed by the kinetic method. The seed transport law of cabbage in the stage of seed suction and discharge was analyzed by the kinetic model. Through the one-factor test, the key factors affecting the rate of single grain, multi-grain rate, cavity rate was confirmed. the seeder can be used for pneumatic hole plate seeder for vegetable sowing; Qingxi Liao21,22 team of Huazhong Agricultural University has designed and developed a pneumatic set row type small grain size crop seed precision seeder, single set rower to achieve 9 rows of seeding. It can achieve the small grain size vegetable seed single grain precision seeding through the use of negative pressure seed suction, positive pressure seed casting working principle. Seed has no breakage in the process of seed rowing. It can save seed, greatly reduce the rear period during the seeding and reduce the cost of production.

In the research and development of vegetable seeder, the American Blackmore and SEEDERMAN company, the British Hamilton, the Italian MOSA, the Dutch VISSER, the Australian Williames, South Korea’s Daito Electro-Mechanics, etc23. and other designs of the precision seeder are using the principle of negative pressure adsorption24, with the air needle, the cover and the air suction roller type. Jiangsu Yunma Agricultural Machinery Manufacturing Co., Ltd. have introduced foreign advanced technology and reformed a number of cavity tray seeding precision seeders through the research of cavity tray seeding technology, whose principles are similar to those of foreign countries. In general, foreign vegetable seeding technology and equipment is relatively perfect, the degree of intelligence and productivity is relatively high, but the products are expensive. The adaptability of domestic vegetable seeder to different specifications of cavity trays and different types of seeds is poor, and the sowing precision is low, which restricts the popularization and use of related equipment25.

For the current hole tray seeder exists in the irregular-shaped seed single seed sowing difficulty, different seed adaptability, adjustment difficulty and other issues. This study uses the principle of negative pressure seed suction and positive pressure seed casting combination, designs an irregular-shaped vegetable seed air suction drum type precision seed discharger, elaborates the basic structure of the seed discharger and the principle of work, analyzes the irregular-shaped seed in the precision seeding system in the movement characteristics and internal airflow field distribution and other working mechanisms, carries out seeding technology research and equipment development, focusing on the breakthrough of the seeding technology to improve the efficiency and adaptability of the work of seeders.

Materials and methods

Seeder mechanism and principle of operation

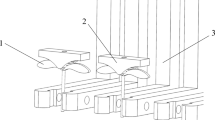

The drum type precision seeder developed in this study mainly consists of drum, left and right side end caps, suction nozzles, compression springs, compression nuts, pulleys, and center drive shafts, etc., and its structure is shown in Fig. 1:

The left and right end caps are tightly attached to both sides of the drum under the action of the pressure spring, and there are three areas on the left end cap, which are the negative pressure seed suction area connected to the negative pressure air source, the positive pressure seed discharge area and the positive pressure hole clearing area connected to the positive pressure air source, as shown in Fig. 2.

Since the left end cover is connected with the drum suction nozzle through hole, the seeding drum is divided into negative pressure seed suction area, positive pressure seed discharge area and positive pressure hole clearing area. When working, the motor drives the drum to rotate through the belt, and at this time the left and right end caps do not rotate with the drum, so the position of the seed suction area, seed discharge area and hole clearing area is fixed, and does not change with the rotation of the drum. There are many rows of suction nozzles distributed along the direction of the busbar outside the drum, the suction nozzles rotate with the drum, and each row of suction nozzles passes through the seed suction area, seed discharge area and hole-clearing area in turn, completing a complete seed discharge process. When the suction nozzle move to the suction area, and the negative pressure air source connected to the suction area for the suction nozzle to provide negative pressure, so that the suction nozzle produces negative pressure airflow, suction nozzle through the seed supply plate, the seed in the suction nozzle under the action of the negative pressure airflow is adsorbed in the suction nozzle; adsorption of the seed adsorption nozzle arrived at the drum above the row of seed area, the suction nozzle and the row of seed area connected to the positive air pressure, the seed by the suction nozzle of the positive airflow falls into the lower part of the hole plate; Finally, the suction nozzle moves to the hole clearing area, which provides a stronger positive pressure airflow for the suction nozzle to clean out any impurities that may be present in the nozzle holes and prepare for the next cycle of seeding.

The adsorption site of the suction head is the ventral surface of the leaflet on the cucumber stem. In order to achieve good adsorption effect, it is necessary to perform a mimic design of the suction head of the cucumber stem. By photographing the image of the cucumber stem leaflet and using MATLAB software for processing21, the ventral curve trajectory of the leaflet under natural state was fitted to provide a theoretical basis for the rational design of the suction head structure of the cucumber stem.

Design of key components

Air suction drum

Air-suction drum is one of the core components of the seeder, and the size design of other components depends on the external dimensions of the air-suction drum. The air suction drum structure sketch is shown by Fig. 3.

Relationship between air suction drum diameter and seed filling time:

Where: t is the seed filling time, s; l is the arc length of the seed filling area, mm; v is the linear speed of the gas suction drum, mm/s; n is the rotational speed of the gas suction drum, r/min.

Obtained from Eq. (1):

From Eq. (2), t is inversely proportional to n, directly proportional to α, and independent of the diameter D.At present, the diameter of commonly used air-suction drum-type seeder is range of 140–260 mm26, in order to meet the conditions of the filling arc length, the larger the diameter D, the greater the number of holes that can be set in the circumferential direction, the lower the speed of the air-suction drum is conducive to improving the performance of the filling of the seed, but the structure of the entire machine increases, and the negative-pressure fan power is increase, and energy consumption increase further, and also make the negative pressure chamber sealing requirements are too high; If the diameter of the air-suction drum is too small, the number of holes that can be set in the circumferential direction is small, and the speed of the drum is high, which is not conducive to seed filling, and the sowing qualification index is reduced. For comprehensive consideration, this paper selects the air suction roller diameter D is 160 mm, the material is 5 mm thick aluminum alloy tube.

The standard specification of the existing vegetable seeding hole tray is 72 holes (6 holes/row×12 rows) of plastic tray, with the size of 540 × 280 × 45 mm and the hole spacing of 42 mm. According to the specification of the seeding hole tray, the number of axial suction holes of air suction roller is determined to be 6, with the hole spacing of 42 mm, and the two ends symmetrically reserved for the fixing position of the end cover of 50 mm, and the length of the air suction roller L is 310 mm.

When designing the number of holes in the circumferential direction of the pneumatic suction drum, theoretically, the minimum number of holes can be designed as 1, and the maximum number of holes can be filled with the whole drum according to the size of the seeds. However, in practice, the arc length between adjacent holes should be at least 2 times larger than the maximum size of the seeds, and the linear velocity of the pneumatic suction drum should be v ≤ 350 mm/s27. Considering that in practice, it is difficult to seamlessly connect two consecutive seeding trays, and the distance between the last hole of the previous tray and the first hole of the next tray is different from the distance between two holes in the same tray, each tray needs to be sown with a tray position sensor to detect the position of the holes to achieve the precise seeding of the holes. In this paper, the number of holes in each row of hole trays is 12, in order to facilitate the servo motor to regulate the speed of the drum, to meet the air-suction drum speed and the coordination of the speed of the hole trays under different productivity, the number of holes in the circumferential direction of the air-absorbing drum is designed to be two times of the number of holes in each row of the seeding hole trays, i.e., Z = 24. At this time, the arc length between adjacent holes T = 20.944 mm, which is more than twice the maximum size of Solanaceae vegetable seeds (the maximum size of Solanaceae vegetable seeds is 3.3–3.8 mm), and when the production rate is 800 trays/h, the linear speed of air-absorbing roller v = 55.85 mm/s<350 mm/s.

Nozzle diameter

Suction nozzle as a direct contact with the seed working parts, its structural size selection will have a great impact on the working performance of the seeder. Suction nozzle diameter empirical formula28, as shown in Eq. 3.

Where: k is nozzle diameter, mm; Dz is seed thickness, mm.

The non-spherical seeds studied in this paper (tomato, pepper, eggplant) are flat, and reseeding is most likely to occur when the edge of the non-spherical seed is adsorbed at the suction nozzle. Therefore, the selection of the diameter of the suction nozzle needs to consider the size of the seed edge thickness. After measurement, the three kinds of seed edge thickness range from 0.59 mm to 0.65 mm, as shown in Fig. 4. Referring to the empirical formula for nozzle diameter, the range of nozzle diameter is 0.378 mm ~ 0.429 mm, and the nozzle diameter of 0.4 mm is selected.

The nozzle hole patterns are mainly categorized into straight holes, countersunk holes and tapered holes according to different shapes. The Fig. 5 shows the schematic diagram of the three hole patterns of the suction nozzle.

Simulation tests

In order to more intuitively understand the design of the three types of holes in the nozzle suction performance, FLUENT fluid simulation software is used on the three types of holes in the nozzle internal flow field simulation, according to the simulation results of the simulation results to analyze each type of holes in the nozzle suction characteristics. SolidWorks is used to establish the internal flow channel model of the three types of nozzles, and then the established internal flow channel model is meshed. The built model will be imported into the ICEMCFD software to create the inlet, outlet and wall, and then mesh, according to the diameter of the suction nozzle to select the maximum mesh size of 0.001 mm. generated mesh is shown in Fig. 6.

The divided mesh is imported into FLUENT simulation software, the k-ε turbulence model is selected, the solution type is selected as pressure-based solver, the fluid type is set as air and incompressible, and the effect of gravity is not considered. Then the boundary conditions are set, the airflow inlet is set as pressure-inlet boundary, and the airflow outlet is set as pressure-outlet boundary. Then the iterative computation is started until the computation converges.

Bench experiments

Test materials and equipment

The test materials were aubergine seeds procured from Shouguang Fangcheng Agricultural Science and Technology Co, with a length×width×thickness of 3.86 × 3.10 × 1.11 mm, a thousand-seed weight of 4.5 g, an impurity content of ≤ 0.1%, and a moisture content of ≤ 5%.The test was carried out on an independently designed vegetable seeding production line, the test bench was equipped with a vacuum pump with a maximum power of 1.5 kW, a maximum negative pressure of 100 kPa, a working voltage of 380 V, a barometric pressure detection device, a data acquisition device, etc. The test setup was shown in Fig. 7.

Test indicators and test methods

The evaluation indexes of this test are based on the Technical Conditions of Greenhouse Vegetable Cavity Tray Precision Seeder (NY/T 1823–2009)29 Y1 reseeding rate, Y2 cavitation rate and Y3 qualification rate are selected as the indexes for evaluating the operational performance of nursery seeder.

Experimental design

According to the previous experimental research, in the case of a certain sowing efficiency, the factors that have a greater impact on the sowing performance are mainly the suction air pressure, clearing air pressure and the vibration frequency of the seed supply box. Therefore, when the sowing efficiency is 800 trays/h and the diameter of suction nozzle is 0.4 mm, the suction air pressure x1, the seed cleaning air pressure x2 and the vibration frequency of seed supply box x3 are selected as the test factors, and each factor is examined at 5 levels, and a quadratic rotated orthogonal combination test is designed, and the factor coding levels are shown in Table 1.

Experiments results and discussion

Analysis of simulation experiment results

According to the above steps, the simulation analysis of the flow field in the flow channel inside the nozzle of three types of holes was carried out respectively, and the airflow velocity vector diagram and airflow velocity cloud diagram of three different types of nozzles were obtained through simulation analysis, as shown in Fig. 8.

The velocity vector diagrams of the flow field and the velocity cloud diagrams of the flow field of the three types of hole-type nozzles are compared and analyzed. It can be seen that the internal flow field of the three types of hole-type nozzles is relatively uniform, but there is uneven airflow velocity at the inlet of the sunken hole and the conical hole, and the flow field is unstable. The flow field distribution at the inlet of the sink hole nozzle is the most uneven, and the flow rate loss is the largest, which is not conducive to seed suction. Tapered hole compared to the sink hole airflow transition is relatively smooth, but the flow rate loss is larger, also not conducive to seed suction. Moreover, the sink hole and conical hole nozzle is characterized by large outside and small inside, the seed will be adsorbed in the process of lateral pressure, especially in the sowing of small non-spherical seeds is easy to cause reseeding or even blocking phenomenon. The straight hole nozzle inlet flow field is stable, the air flow rate loss is minimized, easier to absorb seeds. Therefore, the comprehensive consideration of the selection of straight nozzle.

At present, the commonly used straight-hole suction nozzles have flat holes and raised holes (Fig. 9), both of which are better for round seeds, but for non-spherical seeds, raised holes are better for non-spherical seeds due to the fact that their projections can penetrate deep into the seeds and the contact area is smaller. Moreover, the raised hole suction nozzle prevents falling seeds from knocking down the seeds on the suction nozzle. The raised hole type nozzle structure is the main nozzle type of the current vegetable seeders. Therefore, the raised hole nozzle is selected in this paper.

Analysis of bench test results

The test was conducted according to the three-factor quadratic rotated orthogonal combination test table, five trays were randomly selected as a group of tests during sowing, and each group of tests was repeated three times to take the average value. The experimental program and results are shown in Table 2.

Using Design-Expert10.0 software, the multivariate nonlinear regression models of Y1 reseeding rate, Y2 cavitation rate and Y3 qualification rate on the suction barometric pressure x1, clearing barometric pressure x2 and vibration frequency of seed supply box x3 were established respectively and the significance tests of the models and coefficients were carried out, and the analyses and results were as follows.

Regression modeling of replay rate and significance test

The regression equation for the reseeding rate Y1 is:

The variance scores are as shown in Table 3.The fit of this model was highly significant (P < 0.01). However, the P-value of the interaction term of seed suction air pressure and vibration frequency (X1 × 3), the P-value of the interaction term of seed clearing air pressure and vibration frequency (X2 × 3), and the P-value of the quadratic term of vibration frequency (X32) were all greater than 0.1, which indicated that the interaction term of seed suction air pressure and vibration frequency, the interaction term of seed clearing air pressure and vibration frequency, and the quadratic term of vibration frequency did not have any significant effect on the rate of reseeding, and the F-tests of the rest of the items were all highly significant or significant. By observing the misfit term P = 0.9495, it can be judged that the misfit term is not significant, which indicates that there are no other major factors affecting the performance index.

The test of the regression coefficient of Eq. 4 can be obtained that the factors affecting the seeding re-seeding rate are, from the largest to the smallest, the suction air pressure, the clearing air pressure and the vibration frequency.

Null rate regression modeling and significance testing

The coded regression model for the effects of seed suction air pressure, seed clearing air pressure and vibration frequency of the seed supply cassette on the null rate Y2 can be obtained by fitting multiple regressions to the experimental data, as shown in Eq. (5).

The significance test of the regression model is shown in Table 4.

By looking at Table 4 it can be seen that the fit of this model is highly significant (P < 0.01). However, the P-value of the interaction term between seed suction air pressure and seed clearing air pressure (X1 × 2), the P-value of the interaction term between seed suction air pressure and vibration frequency (X2 × 3), and the P-value of the interaction term between seed suction air pressure and vibration frequency (X1 × 3) were all greater than 0.1, and it could be judged that the effects of the interaction term between seed suction air pressure and seed clearing air pressure, the interaction term between seed suction air pressure and vibration frequency, and the interaction term between seed suction air pressure and vibration frequency on the rate of cavitation were not significant. and the F-tests for the remaining terms were highly significant. By looking at the misfit term P = 0.2547, it is known to be insignificant, which indicates that there are no other major factors affecting the performance index. After eliminating the insignificant factors, the resulting coded regression model is shown in Eq. (6).

Examining the regression coefficients in Eq. 6, it can be obtained that the factors affecting the seeding null rate, from largest to smallest, are the seed-clearing air pressure, the seed-sucking air pressure, and the vibration frequency.

Establishment and significance test of the regression model of passing rate

By fitting multiple regression to the test data, the coded regression model of the effects of seed suction air pressure, seed cleaning air pressure and vibration frequency of seed supply box on the pass rate Y3 can be obtained, as shown in Eq. (7).

The significance test of the regression model is shown in Table 5.

The fit of this model is highly significant (P < 0.01) as can be obtained by looking at Table 5. However, the P-value of the vibration frequency (X3 ), the P-value of the interaction term of suction air pressure and vibration frequency (X1 × 3), the P-value of the interaction term of clearing air pressure and vibration frequency (X2 × 3) are all greater than 0.1, which indicates that the effect of vibration frequency, the interaction term of suction air pressure and vibration frequency, and the interaction term of clearing air pressure and vibration frequency on the pass rate is insignificant, and F-tests of the rest of the items are all highly significant or significant. By looking at the misfit term P = 0.49995, it can be known that it is not significant, which indicates that there are no other major factors affecting the performance index. The coded regression model obtained after removing the insignificant factors is shown in Eq. 8.

The regression coefficients in Eq. 8 are examined, and it can be obtained that the factors affecting the seeding pass rate from the largest to the smallest are the suction air pressure, the clearing air pressure and the vibration frequency, respectively.

Discussion

In order to further explore the factors affecting the experimental results and the degree of influence, this paper chooses to use the response surface method to analyze the influence of the suction air pressure X1, clearing air pressure X2 and vibration frequency of the seed supply box X3 on the sowing qualification rate, reseeding rate and empty hole rate. And through the establishment of the objective function and constraint conditions, the optimal parameter combination of the designed seed discharger is found.

Fixing the vibration frequency and plotting the response surface according to the experimental results, the influence of seed-clearing air pressure and seed-absorbing air pressure on the reseeding rate is obtained as shown in Fig. 10a. By analyzing the response surface, it can be seen that when the vibration frequency is fixed, the reseeding rate will have a positive response to the seed suction air pressure and a negative response to the seed clearing air pressure. By analyzing the extreme values of the response surface, it can be seen that when the suction air pressure is 15KPa ~ 16KPa and the clearing air pressure is 3KPa ~ 4KPa, the seeding reseeding rate appears to be extremely small, below 1%. In the same way the response surface when the seed-clearing air pressure is fixed and the response surface when the seed-absorbing air pressure is fixed can be plotted to obtain the response surface when the seed-clearing air pressure is fixed, as shown in Fig. 10b and c, respectively.

When the seed-cleaning air pressure is fixed, the seed replanting rate will have a negative response to the vibration frequency of the seed supply cassette and a positive response to the suction air pressure. Analyzing the extreme value of this response surface, it can be seen that when the vibration frequency of the seed supply cassette is 49 Hz ~ 55 Hz and the seed suction air pressure is 15KPa ~ 16KPa, the seeding reseeding rate appears to be extremely small value, which is around 1%. And when the suction air pressure is fixed, the sowing reseeding rate has a negative response to both the vibration frequency of the seed cassette and the seed clearing air pressure. When the vibration frequency of the seed cassette is 49 Hz ~ 55 Hz and the seed clearing air pressure is 3KPa ~ 4KPa, the seeding reseeding rate appears to be extremely small, below 1%.

Fixing the vibration frequency and plotting the response surface according to the experimental results, the influence of seed-clearing air pressure and seed-absorbing air pressure on the reseeding rate is obtained as shown in Fig. 11a. By analyzing the response surface, it can be seen that when the vibration frequency is fixed, the seed re-seeding rate will have a negative response to the seed suction air pressure and a positive response to the seed clearing air pressure. By analyzing the extreme values of the response surface, it can be seen that when the seed suction air pressure is 16KPa ~ 17KPa and the seed cleaning air pressure is 2KPa ~ 3KPa, the seeding reseeding rate appears to be a very small value, which is below 1%. In the same way the response surface when the seed-clearing air pressure is fixed and the response surface when the seed-absorbing air pressure is fixed can be plotted to obtain the response surface when the seed-clearing air pressure is fixed, as shown in Fig. 11b and c, respectively. When the seed-cleaning air pressure is fixed, the cavitation rate will have a positive response to the vibration frequency of the seed supply cassette and a negative response to the suction air pressure. Analyzing the extreme value of this response surface, it can be seen that when the vibration frequency of the seed supply cassette is 45 Hz ~ 53 Hz and the seed suction air pressure is 15.7KPa ~ 17KPa, the seeding reseeding rate appears to have a very small value below 1%. And when the suction air pressure is fixed, the response of the cavitation rate to the vibration frequency of the seed cassette is first negative and then positive, while the response to the seed-clearing air pressure is negative. When the vibration frequency of the seed supply cassette is 45 Hz ~ 53 Hz and the seed-cleaning air pressure is 2KPa ~ 3.4KPa, the sowing reseeding rate appears to be extremely small, below 1%.

Fixing the vibration frequency and plotting the response surface according to the experimental results, the influence of seed-cleaning air pressure and seed-absorbing air pressure on the pass rate is obtained as shown in Fig. 12a. By analyzing the response surface, it can be seen that when the vibration frequency is fixed, the seeding reseeding rate will respond to both the suction air pressure and the seed-cleaning air pressure in a positive direction and then in a negative direction. By analyzing the extreme values of the response surface, it can be seen that when the seed suction air pressure is 15.5KPa ~ 16KPa and the seed cleaning air pressure is 3KPa ~ 3.5KPa, the pass rate appears to be a great value, between 96% and 97%. In the same way, the response surface when the seed-cleaning air pressure is fixed and the response surface when the seed-absorbing air pressure is fixed can be plotted as shown in Fig. 12b and c, respectively. When the seed-cleaning air pressure is fixed, the response of the pass rate to the vibration frequency of the seed supply box and the suction air pressure are both positive and then negative. Analyzing the extreme values of this response surface, it can be seen that when the vibration frequency of seed supply cassette is 48 Hz ~ 53 Hz and the seed suction air pressure is 15.5KPa ~ 16KPa, the pass rate appears to be a great value, between 96% and 97%. And when the suction air pressure is fixed, the response of the qualified rate to the vibration frequency of the seed cassette and the seed-cleaning air pressure are both positive and then negative. When the vibration frequency of seed cassette is 48 Hz ~ 54 Hz, and the seed cleaning air pressure is 2.7KPa ~ 3.7KPa, the pass rate appears to be a great value, between 96%~97%.

After obtaining the trend of the influence of the interaction factors on the sowing effect, according to the regression model established from the experimental results, the optimal parameter combinations of the factors were solved using the optimization solution module of the Design-Expert 8.0.6 software in order to achieve the best sowing effect. Where the objective function is:

The constraints are:

The optimal parameter combination of seed suction air pressure 16.0 kPa, seed cleaning air pressure 3.4 kPa, vibration frequency 50 Hz was obtained in Design-Expert software, and the reseeding rate under the optimal parameter combination was 1.5%, the cavity rate was 1.6%, and the qualification rate was 96.4%. According to the optimal working parameters, in the same test environment with the same test method for the planter test, get the reseeding rate of 1.4%, empty hole rate of 1.7%, qualified rate of 96.9%, and the optimization results are basically consistent, indicating that the seed discharger can better meet the agronomic requirements of heterogeneous vegetable seeding and has good adaptability.

Conclusion

In this paper, a irregular-shaped vegetable seed precision seed discharger was designed according to the principle of negative pressure adsorption, the nozzle structure was analysed by fluid simulation, and orthogonal tests were carried out according to the obtained nozzle structure, which led to the following main conclusions:

-

1.

In order to solve the problem of poor seeding performance of irregular-shaped vegetable seed nursery planter seeder, a kind of air suction drum type hole tray seeder was designed. Through fluent simulation experiments, the performance of three different hole types of nozzles was compared, and the results of the simulation experiments show that the straight hole nozzle inlet flow field is stable, the airflow flow rate loss is minimized, it is easier to suck the seeds, and the raised hole nozzle in the straight hole nozzle can prevent the falling seeds from knocking down the seeds on the nozzle, therefore, the device selects the straight hole nozzle with raised holes in order to achieve the uniform seed discharging of the irregular-shaped seeds.The seeding effect of the seed metering device is better than that of similar studies at home and abroad ( such as the pneumatic drum vegetable plug seeder and the pneumatic plate vegetable seeder developed by Xia Hongmei ‘s team ), which can meet the requirements of seedling seeding.

-

2.

In order to obtain the optimal structural parameters and working parameters of the seed displacing device, a quadratic rotating orthogonal combination test method was adopted to analyze the relationship between the main influencing factors of the seed displacing device performance (seed clearing air pressure, seed suction air pressure and vibration frequency of the seed supply box) and the sowing indexes (leakage seeding rate, cavity index and pass rate), and a bench test scheme was designed by applying the methods of regression analysis, response surface and optimization of multi-objective variables. The results of the bench test showed that the optimal parameter combinations of the designed seed discharger were: suction air pressure 16.0 kPa, clearing air pressure 3.4 kPa, and vibration frequency 50 Hz, and the reseeding rate under the optimal parameter combinations was 1.5%, the empty hole rate was 1.6%, and the pass rate was 96.4%. According to the optimal working parameters, in the same test environment with the same test method for the seeder test, get the reseeding rate of 1.4%, empty hole rate of 1.7%, qualified rate of 96.9%, and the optimization results are basically consistent.

Data availability

The data supporting this study’s findings are available from the corresponding author upon reasonable request.

References

Xiaoran, L. et al. General situation of vegetable production and research status of precision seeder in China. J. Agricultural Mechanization Res. 43(05), 263–268 (2021).

Chen, Y. et al. Development report of China vegetable production mechanization in 2020. J. Chin. Agricultural Mechanization 42(6), 1–9 (2021). 34.

Braunack, M. V. et al. Soil temperature and soil water potential under thin oxodegradable plastic film impact on cotton crop establishment and yield. Field Crops Res. 184, 91–103 (2015).

Tiqiong, X. et al. Cost-benefit analysis of vegetable production based on agricultural mechanized production. Trans. Chin. Soc. Agricultural Mach 46(05):75–82 (2015).

Jiajia, Y. et al. Simulation analysis and match experiment on negative and positive pressures of pneumatic precision metering device for rapeseed. Int. J. Agricultural Biol. Eng. 7(3), 1–12 (2014).

Yanan, T. et al. Experimental study on seed compression characteristics of pak choi. Agricultural Mechanization Res. 45(06), 152–158 (2023).

Liu, Y. et al. Research status and development trend of vegetable plug seedling seeder. Trans. Chin. Soc. Agricultural Eng. 8(1), 6–12 (2018).

Sun, H. et al. Improvement of hole pressing roller device and design of the control system for vegetable seedling’s seeding assembly line. Trans. Chin. Soc. Agricultural Eng. 37(22), 41–48 (2021).

Tang, H., Xu, C. S., Wang, Z. M., Wang, Q. & Wang, J. W. Optimized design, monitoring system development and experiment for a long-belt finger-clip precision corn seed metering device. Front. Plant Sci. 13, 814747 (2022).

Dai, Q. et al. Design and test of precision seed metering device for vegetable plug seedling based on air suction needle. J. Agricultural Mechanization Res. 45(5), 117–121 (2023).

Kim, S. J. et al. Development of seeding rate monitoring system applicable to a mechanical pot seeding machine. Agriculture, 13(10): 2000. (2023).

Minghua, Z. et al. Design and experiment of the air suction wheel precision seed metering device for vegeables. Trans. Chin. Soc. Agricultural Eng. 39(7), 98–109 (2023).

Changmin, Y. et al. Research status and development analysis of seed-raising precision seeder. J. Chin. Agricultural Mechanization. 43(4), 183–188 (2022).

Liping, G. et al. Seeding performance of conical-hole seeding plate of the positive and negative pressure combination precision seed metering device for rapeseed. Trans. Chin. Soc. Agricultural Eng. 38(6):22–33 (2022).

Cao, X. et al. Design and experiments of pneumatic roller type precision seed-metering device for rapeseed plug seedlings. Trans. Chin. Soc. Agricultural Eng. 37(2):51–60 (2021).

Tang, H. et al. The Influence of a seed drop tube of the inside-filling air-blowing Precision seed-metering Device on Seeding Quality. Computers and Electronics in Agriculture, 204 (2023).

Liu, R. et al. Optimization and experiment of a disturbance-assisted seed filling high-speed vacuum seedmetering device based on DEM-CFD. Agriculture. 12(9): 1304 (2022).

Hai, L. et al. Design andexperiment of positive and negative pressure combinationprecision metering device for Pakchoi. Trans. Ofthe Chin. Soc. Agricultural Mach. 53(10), 54–65 (2022).

Hongmei, X. et al. Dynamic model building of metering processes for pneumatic plate-type vegetable seed metering device. J. South. China Agricultural Univ. 32(1), 112–116 (2011).

Hongmei, X., Zhiwei, L. & Wenbin, Z. Design and experiment of pneumatic plate vegetable seed arranger. Trans. Chin. Soc. Agricultural Mach. 41(6), 56–60 (2010).

Yitao, L. et al. Investigation on vacuum singulating effect influencing factors of pneumatic precision seed metering device for small particle size of seeds. Trans. Chin. Soc. Agricultural Eng. (Transactions CSAE) 34(24), 10–17 (2018).

Yitao, L. et al. Design and experiment of precision seed placement device for pneumatic needle planetary gear train with narrow row and close planting. Trans. Chin. Soc. Agricultural Mach. 53(11), 86–99 (2022).

Grewal, R. S. & Khurana, R. Development and evaluation of tractor operated inclined plate metering device for onion seed planting. Agricultural Eng. International:CIGR 17(2), 31–38 (2015).

Yazhuo, Q. & Shunan, X. Research status and development trend of vegetable seeder at home and abroad. J. Chin. Agricultural Mechanization 41(1), 205–208 (2020).

Xunlin, Z. et al. Design and simulation analysis of pneumatic mechanical combined single disc and double row seed meter. J. Chin. Agricultural Mechanization 41(3), 30–34 (2020).

Elnesr, M. N. & Alazba, A. A. A spreadsheet model to select vegetables planting dates for maximum yield and water use efficiency. Comput. Electron. Agric. 124, 55–64 (2016).

Yanjun, L. et al. Structural Design and Simulation Analysis of a dual-row Pneumatic Vegetable Precision Planter. Processes 11(6), 1803 (2023).

Jinling, C. Study on Seeding System and Mechanism of Pneumatic Precision Metering Device for Wheat and Rapeseed (Huazhong Agricultural University, 2014).

NY/ & T 1823-. Specifications for hole disk type precise seeder of greenhouse vegetable[S]. (2009).

Funding

This work was mainly supported by the State Key Laboratory of Agricultural Equipment Technology(NKL-2023-006) and Shandong Province Key R&D Program (Major Science and Technology Innovation Project)-Research and Development of High-Efficiency Production Equipment for Specialty Vegetables-2022CXGC010612; Shandong Province Higher Education Institutions Young Innovation Team Talent Introduction Program.

Author information

Authors and Affiliations

Contributions

Conceptualization, Y.L. and Y.N.; methodology, Y.L.; software, Y.L.; validation, Y.L., H.W. and Y.Z.; formal analysis, Y.L.; investigation, H.W.; resources, Y.N.; data curation, Y.L.; writing—original draft preparation, Y.L.; writing—review and editing, Y.L.; visualization, Y.N.; supervision, Y.L.; project administration, Y.Z.; funding acquisition, Y.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, Y., Liu, Y., Ning, Y. et al. Design and experiment of air-suction drum-type seedling seeder for irregular-shaped vegetable seeds. Sci Rep 15, 4694 (2025). https://doi.org/10.1038/s41598-024-83635-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-83635-6