Abstract

The correct choice of a stone aggregate for railway ballast is directly related to the stability, safety, efficiency, and maintenance costs of the track. The aggregate must meet several criteria to ensure it is the most appropriate material. Thus, the present study aimed to evaluate four distinct stones: two granites, a diabase, and a basalt, all mined in the eastern region of the state of São Paulo, Brazil, regarding their applicability as ballast. Using Brazilian and ASTM procedures for stone samples, the tests were conducted on 55 and 75-mm specimens, in dry and wet conditions. As a result, all stones met the physical properties established by the standards. Among the mechanical properties, uniaxial compressive strength stood out, with all stones where the tested materials advantageously exceeding the 100 MPa required by the Brazilian standard. Regarding the accelerated weathering test with ethylene glycol, only basalt showed more significant changes, although its resistance to weathering was still lower than 10%. Our findings indicate that these stones perform adequately as ballast for railway applications. The study is expected to contribute to revisions of technical standards and the improvement of a database on Brazilian stone materials for use as railway ballast.

Similar content being viewed by others

Introduction

Most leading countries include railways as a fundamental and efficient method for transporting cargo and passengers on a large scale. Indeed, the railway is of fundamental importance for the functioning of a territory’s economy. As part of the railway, its ballast is mainly composed of stone aggregates, which are responsible for promoting the uniform distribution of stresses and providing the stability, safety, and durability of the track1,2. In more detail, ballast absorbs and transmits to the soil the pressures corresponding to the loads supported by the rails, preventing the development of concentrated pressures, which can lead to soil deformation and track instability. It also provides structural support to the sleepers, preventing them from sinking or moving due to the loads. It also helps to absorb vibrations generated by traffic to reduce material fatigue and extend the useful life of the structure3,4,5.

Several types of stones have been used as ballast material, including granite, gneiss, quartzite, diabase, and basalt, each one with its own specific properties that affect railway performance. The correct choice of stone aggregate is made through the technological characterization of the materials. This involves the stone analysis in terms of their physical, mechanical, chemical, and alterability properties, which compose a database for the selection of the best materials for application as ballast6. The challenge of this analysis is the need to balance several required properties with economic and logistical factors, such as extraction and transportation costs. Some properties like particle size, particle shape, and powdery material are more important for the quality of crushed stone when inspected directly in the stockpiles of quarry processing plants or service railway7,8,9,10. Other characteristics, such as petrographic analysis, physical indices, as well as mechanical and alterability properties, are related to the intrinsic characteristics of the stone material, aiming at its use as ballast aggregate11,12,13,14,15.

In general terms, in the case of aggregates without binders intended for use as ballast, the stone materials must have high compressive strength to withstand the stresses caused by the weight of the vehicles, and adequate particle size and shape to distribute the stresses efficiently to the platform. Furthermore, the material’s behavior when facing harsh weathering conditions must be considered since, under these conditions of use, water exposure might be constant and may result in the decomposition and disintegration of the stone16,17. The uniaxial compressive strength can be estimated by the PLT point load test18,19,20,21,22 or SHR Schmidt hammer rebound23,24,25,26. The PLT has a simpler configuration, is quick to perform, has a low cost, and can be used with prismatic specimens or irregular samples with diametral and/or axial loading. As for the SHR test, it is another classic non-destructive method that can be used to determine an approximate value of the compressive strength. The evaluation of the alterability of stone materials is carried out by means of tests that seek to simulate, in the laboratory, the effects of disintegration caused by physical weathering. This is performed either by the crystallization of salts or expansion of clays by adsorption of ethylene glycol, which, depending on the textural and geochemical conditions of the reactions, can cause expansive disintegration of the crushed stone27,28,29,30.

Based on these perspectives, the present study aimed to determine the physical-mechanical and degradation characteristics of four different types of rocks: two granites, one basalt, and one diabase, and assess their suitability for use as railway ballast. By analyzing properties such as compressive strength, abrasion, and alterability, the present study may support the selection of stones that meet the regulatory requirements for performance and cost-effectiveness, contributing to the optimization of relevant railway infrastructure projects for passenger transport in the eastern region of the state of São Paulo, the richest in Brazil. In this way, the research not only expands the understanding of the properties of ballast materials but also suggests important practical recommendations for the construction and maintenance of railways, contributing to promoting greater safety and operational efficiency.

Materials

The specific stones investigated to compose railroad ballast were: (i) Tres Rios Granite (GRAN1); (ii) Morro do Tico Tico Granite (GRAN2); (iii) basalt (BAS); and (iv) basic intrusives (DIA) related to the Serra Geral Formation. They were selected due to their technological qualities (stones suitable for use as ballast but poorly studied for this purpose), the proximity to the possible routes designed for the part of the São Paulo section of the High-Speed Rail “TAV” and Inter-Cities Train “TIC” that will connect the capital to the city of Americana, in the State of São Paulo, Brazil31,32 and logistical aspects regarding permission to access the quarries. These stones are exploited in several active quarries near existing railroads and have been in operation for decades, contributing to the growth of the metropolitan regions of São Paulo, as well as Campinas and other cities (Fig. 1).

Modified from33.

Location of the area. The three geological units that make up the present study are highlighted in bold in the legend.

Sampling and test methods

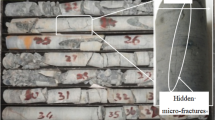

This study began with a detailed geological description of the quarries, especially the heterogeneities of the rock mass regarding the exploitable stones among those existing. Before sampling, geological observations and petrographic descriptions were made on the fronts of the quarries, where stones are extracted for engineering applications to define the portions of the massif with better quality. Stones for ballast are extracted from these portions, where the aggregate is required for its mechanical quality and, especially, for the greater resistance to weathering. Then, new observations were made during technical visits to identify geological exposures, with regard to the integrity found in the diverse dimensions of the disassembled rock, along with the collection of representative blocks and irregular fragments of each stone (Fig. 2). Approximately 150 kg of coarse aggregate in different particle sizes were collected directly from the stockepiles of the processing plant, relating the crushing of the dismantled material of the same origin from the selected faces of the quarries. In the laboratory, cylindrical specimens were prepared with two different diameters, 55 mm, and 75 mm (Fig. 3), while the coarse aggregate was separated into aliquots with a specific mass and particle size range for each characterization test.

Petrographic analyses and physical-mechanical testing procedures were performed by physical indices, UCS uniaxial compression strength, both dry and wet, PLT point load test, SHR Schmidt hummer rebound, LAA Los Angeles abrasion, T Treton toughness index, SC crushing strength and alterability. These procedures followed the guidelines of the ABNT Brazilian Association of Technical Standards34,35,36,37,38 and ASTM American Standard Testing Machines39,40,41. Table 1 presents the synthesis of these tests and their respective technical standards, type/amount of sample, and execution procedures.

The UCS tests were carried out on specimens dried in an oven at 110° C and also on wet specimens, to assess the possible hydraulic weakening of each rock concerning the efforts applied on them. The R hydraulic weakening coefficient42 relates the strength of a dry and saturated material and allows the evaluation of the effect of water on the strength of rocky materials, and is calculated by Eq. 1.

Where σwet and σdry are the tensile strength of the material in wet and dry conditions, respectively.

To check for significant differences in UCS tests on specimens with different diameters, Box Plot graphs were prepared, and statistical analysis compared the difference between the two means using the Statistica software, version 14.0.1.25. The information used were the UCS mean values, their respective standard deviations, and the number of samples studied. All analyses considered a significance level of 5% (α = 0.050). For comparative purposes, PLTs were performed, following all the specifications for equipment and preparation of normative samples, where two types of failures are established for axial tests to be considered valid. Failures other than those established rendered the sample invalid and were disregarded. In the cylindrical specimens prepared for the UCS tests, previous SHR values were also obtained. In sclerometry tests, a Proceq L (0.735 Nm), Digital Silver Schmidt was used.

To obtain information about the weathering of stones, two types of alterability tests were conducted: with sodium sulfate and with ethyleneglycol, all with oven drying. During these cycles, all samples were qualitative and quantitatively evaluated by measuring mass losses, visual examinations, and photographic records of any damages (fissures, cracks, flaking, oxidation, and disintegration) in the specimen.

Results and discussions

The results of the tests performed are presented following the order of the methodology used in the study.

Petrographic analysis and physical indices

The information regarding the degrees of microcracking and stone alteration is discussed below, with the most important petrographic features analyzed at the microscopic level and a summary of the physical indices in Table 2; Fig. 4.

The studied stone materials represent magmatic bodies formed under different genetic conditions, and have homogeneous characteristics, with generally massive and predominantly isotropic structures. The textures vary from inequigranular phaneritic (porphyritic) to fine, to aphanitic terms. In compositional terms, they are two granitoids classified as biotite granites: GRAN1, grayish, and with relatively smaller grains compared to GRAN2, which has whiter tones. The other two stones are basic: a hypabyssal, DIA diabase, extremely compact, fine to medium grain, and an extrusive, the BAS basalt, typically aphanitic. The degree of microcracking is more noticeable in basalt, ranging from moderate to intense, especially in pyroxene crystals. Furthermore, the alteration in this stone appears to be more intense due to the argilization of mafic minerals (pyroxenes) and, secondarily, in plagioclases.

LEFT: Macroscopic appearance of natural stone cylindrical surfaces (Ø 75 mm); RIGHT: Photomicrographs (crossed nicols). GRAN1: mosaic of Qz, Fk, and Pl and a few mafic (biotite). Observe twin crystals of Pl and in the details, on the right, more intense sericitization. GRAN2: clusters of Mu crystals in poikilitic texture. DIA and BAS: subophitic texture with Pl laths surrounded by subhedral crystals of Au/Pg and Op. Minerals key: Au augite, Pg pigeonite, Px pyroxene, Ol Olivine, Mu Muscovite, Qz Quartz, Pl plagioclase and Fk potassic feldspar.

The Brazilian standard for ballast36 recommends minimum apparent specific gravity (ρ) of 2.6 g/cm³, 2.7 g/cm³, and 2.5 g/cm³ for granites, basalts, and other lithologies, respectively. In this context, Table 2 shows that all stones have ρ within the recommended range. Furthermore, as expected, basic stones present the most expressive values of this parameter, due to the higher percentage of ferromagnesian minerals in their composition. The materials studied are also within the maximum limits established for apparent porosity (η) and water absorption (α), being 2% for apparent porosity and 1–2% for water absorption, depending on the lithology. It is worth highlighting the relatively lower values for DIA (compact rock) and the higher values for BAS (thinner stone, but more micro-cracked), still within the limits established by the standard.

In general, stones correspond to the lithological characteristics to which they are associated. They are massive stones, with few voids, as indicated by their apparent specific gravity and low water absorption. The detailed relationship between the mineralogical composition and the main physical properties can be seen in Fig. 5.

Mechanical properties (intact stone)

In terms of the strength of the intact stone, the results of the uniaxial compressive, point load, and rebound hammer tests are presented in Table 3; Fig. 6. The total number of valid tests was 82, 168, and 87, respectively, for UCS, PLT, and SHR tests, taking into account the two diameters of the specimens tested in the present study.

The UCS test results indicate the excellent conditions of the stones for this type of mechanical request, where all presented mean values above the 1 0 MPa required by the Brazilian standard for ballast36 in dry and wet conditions, except for the BAS basalt, which presented an average of 97.5 MPa (slightly below the required limit) of strength in the wet condition for the diameter of 75 mm.

Another significant result is that of DIA diabase, a stone with a massive, homogeneous, very compact structure and fine to medium particle size, which indicated very high strength, up to 260.29 MPa in the 55 mm test specimens, and 251.95 MPa in 75 mm. However, a relatively high standard deviation and coefficient of variation were observed in some cases, reaching 28.3 and 25.7%, respectively, for BAS basalt in the 75 mm diameter, in dry conditions. This is probably due to the textural heterogeneity of the more aphanitic material. The results of GRAN1 and GRAN2 granites generally indicate high strength values (but relatively lower compared to DIA), consistent with what was expected, since the materials are medium-grained rocks and sometimes have a porphyritic texture.

Regarding the values of the hydraulic weakening coefficients (R), all the stones tested presented a decrease in uniaxial compressive strength when analyzed in the wet condition, with reductions in strength between 4% and 18%, on average, and reaching a slightly more pronounced value (27%) in BAS. This behavior was expected, and related to the values of porosity, water absorption, and conditions of microcracking and mineral alteration, as in the case of the more accentuated decay of basalt. In general, R coefficient values were slightly higher in the tests with 75 mm-diameter samples.

The results of the statistical analysis evidenced no significant difference between the two diameters tested (75 mm, as required by the Brazilian standard36, and 55 mm, most used in geomechanical studies) since the p-value found was greater than 0.05. As this value is higher than the stipulated significance level (α = 0.050), it can be concluded that there is no significant difference between performing the test with diameters of 55–75 mm, except for the BAS basalt in the dry condition, which presented a p-value of 0.0233. This result can be justified by the material’s variability. Therefore, it is suggested the use of larger quantities of test specimens to obtain a more representative result of the studied stone. The results provided by the Statistica software (version 14.0.1.25) and the graphs constructed to assist in the analysis can be seen in Table 4; Fig. 6A,B, respectively.

This is a piece of timely information, which should obviously be extended to other types of stone, to collaborate with ABNT, subsidizing a possible shift of the diameter required by standard NBR 556436, from 75 mm to 55 mm. In practical terms, obtaining cylindrical test specimens with a larger diameter is much more expensive, both due to the greater amount of representative stone blocks to be collected in the field, and due to the excessive wear of diamond drill bits, especially in more abrasive stones (quartz-rich), such as granite and other similar materials.

As for PLTs, the results were similar to those obtained from the RCU tests. Where, once again the DIA diabase stood out, with the highest point load strength index, Is(50), in both diameters used, as can be seen in Table 3; Fig. 6C,D.

Regarding hydraulic weakening, an unexpected result was found for granitic stones, where the Is(50) obtained in the wet condition was slightly higher than in the dry condition. Although unexpected, this result can be justified by the material’s variability, as this type of variation is sensitive to the characteristics of the stones. In addition, it is a material with low porosity and water absorption, so somewhat similar results of both conditions are expected.

The D573139 standard allows estimating the UCS from the average values of Is(50) obtained in the PLT. For this purpose, the standard suggests a correlation factor K, determined according to the size (diameter) of the test specimens. In this case, k = 24 is used for 55 mm and k = 24.5 for 75 mm. By multiplying the K factor by the average of Is(50), we obtained the estimate of UCS for each stone. Other references can also be adopted to indirectly calculate the value of the compressive strength from the point load index, such as Al-Harthi (2001)22, who obtained a relatively strong correlation (R² = 0.96) between Is(50) and UCS, made by linear regression analysis. A comparison between the UCS values determined directly by mechanical testing36 and the estimates, either by ASTM (2016)39 or through equations22, can be seen in Table 3.

As mentioned by Wiesner & Gillate (1997)42, correlations between Is(50) and UCS have been proposed by several authors in recent years. In this context, a linear regression analysis was run to obtain equations and correlation coefficients (R²) between these two tests. Attempts were made by grouping the stones of the present study and considering the different diameters and conditions imposed. As illustrated in Fig. 7, a strong to moderate correlation can be noted between these tests, where R² varied from 0.74 to 0.83, with statistical representativeness in the order of magnitude of correlations present in the literature43,44,45.

Sclerometry was previously performed on the specimens intended for the UCS tests. The data in Table 3 list that the average SHR values corresponding to the 75 mm diameter samples are higher than those of 55 mm. This is because, with larger diameters, the samples tend to be more stable during the test, while with smaller diameters, the energy tends to dissipate due to the impact of the hammer, making this discussion more evident when observing Fig. 6E,F.

In addition, the values varied very little between the dry and wet conditions for the two diameters tested. This comparison suggests that the presence of water had little influence on the tests with the materials under study, which is consistent with the data previously shown, such as the physical indices (stones with porosity < 1.96% and water absorption < 0.68% (very low values), as well as the hydraulic weakening calculated from the UCS tests.

Equations to predict the UCS as a function of the SHR value have been proposed by several authors43,44,45,46. In this context, graphs with linear regression and their respective equations were constructed, which relate the UCS test values with SHR. The stones under study were grouped and the different diameters and conditions to which they were subjected were considered. Such graphs can be seen in Fig. 8, with the correlation coefficient R² considered weak for the 55 mm samples and relatively moderate for the 75 mm samples. It is also possible to observe the random distribution of the test points with the smaller specimens, which contributes to the assertion that they tend to be more unstable in the sclerometer test, a fact observed even during the execution of the procedures. The correlation obtained is similar to that found in the literature43, where the authors found a lower R² when grouping all the rocks in the study, compared to analyzing them individually.

The proposed equations for estimating stone parameters from the hammer rebound number can be valuable in the preliminary phase of a project, given that the test is easy to perform and non-destructive. However, the results and comparison with previous studies indicate that the equations should be used with caution and only for the specified type of stone.

Given the sensitivity and limitations of the equations obtained by regression analysis, another alternative method is the use of equations defined by algorithms developed by computational techniques. In this context, after grouping 1,106 data sets from 27 references, Wang and Wan (2019)23 proposed an equation obtained by an optimization algorithm. A comparison between UCS determined by the NBR 5564 test36 and the estimate from the equation of the aforementioned authors is presented in both Table 3; Fig. 9. It shows that the difference between the two methods can reach a significant 100 MPa, as is the case of BAS basalt in the 75 mm samples. Thus, the result confirms that, although the estimation of UCS by SHR is widely used due to its ease of execution and low associated cost, it should be performed with caution, especially in cases where the correlation factor between the tests is considered weak.

The empirical formula proposed by the authors was objectively determined using a large number of data sets and verified by SHR and UCS tests so that it can be applied in engineering projects. However, it should be mentioned that these also have limitations, where the SHR values must be between 10 and 70. In addition, the rebound values are influenced by several factors, such as sample size, rock type, anisotropy, moisture content, and weathering, among others, which can influence the UCS estimate23.

Mechanical properties (coarse aggregate)

Using aggregate samples with different sizes, LAA Los Angeles abrasion test (Gradation F) and T-shock and SC crushing strength tests were performed to verify the mechanical strength of the aggregates.

The general results are illustrated in Fig. 10. Taking into account the Brazilian standard for ballast36, all the stones meet the maximum limit established for the LAA tests. Considering that this test evaluates the durability of stone fragments under friction and impact stresses, the results prove the quality of these materials, especially when it comes to the DIA and BAS basic stones, whose LAA values were significantly lower than the other stones.

Figure 10 also provides information about the T-shock strength obtained through the Treton Impact strength test36. In this case, unlike the basic stones, the GRAN1 and GRAN2 granite stones significantly exceeded the maximum limit of 25% defined by the standard, reaching values above 40%. Although it is a test considered relevant in the selection of ballast material, the Brazilian standard36 defines it as an optional test and indicates that failure to meet the reference values does not imply rejection of the aggregate, leaving the decision at the buyer’s discretion. In addition, some authors10,44 report the limitations of the test due to its manual preparation and the particle size range in which it is performed, which may result in an inappropriate representation of the strength of the materials to the demands for which they are used. Figure 11 presents images of the Treton impact strength test for each stone analysed.

Regarding Re crushing strength, except for GRAN1, all stones were below the maximum recommended limit47,48, highlighting once again the performance of basic stones, which have a mineralogical composition consisting essentially of high-hardness minerals. Especially in the case of DIA diabase, its textural arrangement assented with types of minerals, interlocking, particle size, and microcracking conditions of the minerals, provides more expressive mechanical strength.

In general, the good performance of the igneous stones studied is justified by the type of genesis, being compact, dense, hard, and resistant, which provides the production of excellent aggregates14,49. In addition, the low mass losses are directly associated with the particle size, where stones with fine grains are generally more resistant than those with coarser grains, as is the case of basic stones compared to the granitic stones in the present study50.

Alterability

The accelerated weathering laboratory tests on each material were carried out taking into account three different crushed stone fractions: A (63.5 to 38 mm), B (38 to 19 mm), and C (19 to 12.5 mm). In general, all stones performed well after 5 cycles of immersion in sodium sulfate or ethylene glycol solution followed by oven drying.

The GRAN1 and GRAN2 granite stones, subjected to the sodium sulfate solution, did not show any changes, either in terms of mass loss or any other change visible to the naked eye, even after the final cycle. Given that these stones have low water absorption and porosity indices, the penetration of the saline solution is difficult, preventing the breaking of bonds between particles due to the crystallization of sodium sulfate.

When immersing basic stones in ethylene glycol, DIA diabase also did not show any modification, probably because it is a stone with a compact texture and also little porosity, in addition to a mineralogical composition and alteration products that tend not to react with ethylene glycol. Only BAS basalt exhibited alterations during the tests, with changes observed since the first cycle. Such evidence is because ethylene glycol is one of the products that react with the expansive clays of the montmorillonite group, possible alteration products of BAS pyroxenes and plagioclases, forming a larger volume organo-clay complex, capable of causing the expansive disintegration of the material, as reported in several other studies13,15,28,30,51.

Despite having suffered from changes during the cycles, fraction A of basalt was the only one that slightly exceeded the standard recommendation (10%), reaching 10.52% at the end of the last cycle. The other fractions remained between 3% and 4%, while the weighted average at the end of the five cycles was a weather resistance of approximately 8% for basalt. The complete data are listed in Table 5. Regarding the qualitative analysis, from the end of the first cycle, which involved immersion in ethylene glycol followed by drying in an oven, changes in the fragments due to the reagent were already observed. These changes continued to occur until the last cycle. During the test, it was possible to notice the progression of small fissures to cracks and then to spalling. Table 6 provides a detailed description of each cycle per fraction of the BAS basalt samples.

According to standard NBR 556436, the changes illustrated in Fig. 12 are expected to occur in samples of the same stone when exposed for a long period to wetting and drying cycles in a saturated environment. This may be especially relevant when considering the use of aggregate without binders, as in the case of stone used for railway ballast. However, the results of this test alone are not sufficient to conclude whether the material is satisfactory or not, and it is necessary to take into account the entire context of the technological characterization.

Conclusions

In order to compare and discuss the capabilities and limitations of different stone materials for use as ballast, a careful selection of tests considered essential for technological characterization was carried out. More specifically, the tests selected aimed to compare, on a laboratory scale, granite, diabase, and basalt. The analysis was conducted through petrographic analysis and determination of physical, mechanical, and alterability properties that will dictate the performance of the materials when used in railway works.

The tests showed these are compact stones with low water absorption, correlated to the geological context in which they are inserted. In terms of mechanical strength, basalt, and diabase (Serra Geral Formation) stood out for their high compressive strength, confirmed by UCS, PLT, and SHR strength tests. In addition, there was no significant difference between cylindrical samples of 55 mm and 75 mm in diameter. This comparison is relevant given the practical advantages associated with the smaller diameter, such as sample collection and handling, and less wear on equipment and diamond drills in laboratory demands.

The long-term effects of the tropical climate and the use of aggregates without binders were simulated using accelerated weathering tests, in which all stones, except for basalt, showed good chemical and physical stability. Even though they presented alterations, the tested fractions of the respective basic stone showed resistance to weathering that was still lower than the maximum limit established by the Brazilian standard.

In general, the stones analyzed showed good performance for use as coarse aggregate for railway ballast. These are igneous, compact, resistant stones with low water absorption, which tend to produce high-quality aggregates. Nevertheless, although a large number of tests were performed with representative samples, the results must be considered valid only for the stones evaluated in this research, given the geotechnical variability of the properties of each material. Additionally, although the Brazilian standard stipulates that at least five accelerated weathering cycles must be performed for laboratory tests, future research may expand this approach to include long-term performance assessments, encompassing different climates and environments, to provide a more comprehensive and practical understanding of rock durability in the railway context.

At last, this study is part of broader research that contributes to the development of a more comprehensive database on the properties of stones used as railway ballast in Brazil, serving as a reference for updating technical standards, in addition to supporting the selection of more suitable materials and increasing the efficiency and durability of railway infrastructures.

Data availability

All data generated or analysed during this study are included in this published article.

References

Associação Brasileira dos Transportes Ferroviários (ANTF). Informações gerais - o setor ferroviário de carga brasileiro. Disponível em: https://www.antf.org.br/informacoes-gerais/. [Acesso em: 05 fev]. (2023).

Tutumluer, E., Dombrow, W. & Huang, H. Laboratory characterization of fouled railroad ballast behavior. Transport. Res. Rec. 2117 (1), 93–101. (2009).

Castro, G. B. et al. L. Numerical and experimental study of the unsaturated hydraulic behavior of a railroad track profile considering fouled ballast subjected to tropical climate condition. Adv. Transport. Geotech. IV 467–482 https://doi.org/10.1007/978-3-030-77238-3_36 (2022).

Oliveira Filho, J. J. P., Costa, R., Bernucci, L. B., Motta, R. & Moura, E. Degradação do lastro ferroviário - principais aspectos e estudos de caso. Transportes 25, 21–34. https://doi.org/10.14295/transportes.v25i3.1340 (2017).

Li, D., Hyslip, J., Sussmann, T. & Chrismer, S. Railway Geotechnics 584 (CRC Press, Taylor & Francis Group, 2016).

Selig, E. T. & Waters, J. M. Track Geotechnology and Substructure Management https://doi.org/10.1680/tgasm.20139 (Thomas Telford, 1994).

Varuntanya, K. et al. Laboratory investigation of railway-used ballast morphology using 3D imaging data analyses. Case Stud. Const. Mat. https://doi.org/10.1016/j.cscm.2023.e02272 (2023).

Diógenes, D. F., Castelo Branco, V. T. F. & Motta, L. M. G. Avaliação Da relação entre comportamentos mecânico e hidráulico para lastro ferroviário. Transportes 28 (3), 61–74. https://doi.org/10.14295/transportes.v28i3.1829 (2020).

Pires, J., Costa, R., Bernucci, L., Motta, R. & Moura, E. Degradação do lastro ferroviário – principais aspectos e estudos de caso. Transportes 25 (3), 62–74. https://doi.org/10.14295/transportes.v25i3.1340 (2017).

Indraratna, B., Thakur, P. K. & Vinod, J. S. Experimental and numerical study of railway ballast behaviour under cyclic loading. Int. J. Geomech. https://doi.org/10.1061/(ASGE)GM.1943-5622.0000055 (2010).

Souza, R. N. et al. Comparison of the permeability of potential ballast rocks from Northern Rio De Janeiro state under different fouling rates after sodium sulfate attack. Materials 16, 1–18. (2023).

Guo, Y. et al. Railway ballast material selection and evaluation: a review. Constr. Build. Mater. 344, 128218. https://doi.org/10.1016/j.conbuildmat.2022.128218 (2022).

Santos, R. S., Ribeiro, R. P., Paraguassú, A. B. & Xavier, G. C. Lastro ferroviário de granitos e rocha básica em regiões tropicais: relações entre petrografia, propriedades físico-mecânicas e de alterabilidade. Transportes 29 (2), 2369. (2021).

Esfahani, M. K., Kamani, M. & Ajalloeian, R. An investigation of the general relationships between abrasion resistance of aggregates and rock aggregate properties. Bull. Eng. Geol. Environ. 78 (60), 3959–3968. https://doi.org/10.1007/s10064-018-1366-7 (2019).

Sadegui, J. M., Zakeri, J. A. & Najaer, M. E. M. Developing track ballast characteristic guideline in order to evaluate its performance. Int. J. Railway 9 (2), 27–35. https://doi.org/10.7782/IJR.2016.9.2.027 (2016).

Diógenes, D. F., Castelo Branco, V. T. F., Nogueira Neto, J. A. & Motta, L. M. G. An assessment of the relationship between the petrographic, physical, and morphological properties of aggregates used for railway ballast. Const. Build. Mat. 347, 128345. https://doi.org/10.1016/j.conbuildmat.2022.128345 (2022).

Frazão, E. B. Tecnologia de rochas na construção Civil 132 (ABGE, 2002).

Xie, X. L. et al. A review of test methods for uniaxial compressive strength of rocks: theory, apparatus and data processing. J. Rock. Mech. Geotech. Eng. https://doi.org/10.1016/j.jrmge.2024.05.003 (2024).

Remedio, M. J., Ribeiro, R. P. & Curtis Neto, J. A. Correlations between petrography and technological properties of rocks: application as railway ballast. Geociências 37 (3), 669–681 (2018).

Singh, T. N., Kainthola, A. & Venkatesh, A. Correlation between point load index and uniaxial compressive strength for different rock types. Rock. Mech. Rock. Eng. 45, 259–264. https://doi.org/10.1007/s00603-011-0192-z (2012).

Basu, A. & Aydin, A. Predicting uniaxial compressive strength by point load test: significance of cone penetration. Rock. Mech. Rock. Eng. 39, 483–490. https://doi.org/10.1007/s00603-006-0082-y (2006).

Al-Harthi, A. A. A field index to determine the strength characteristics of crushed aggregate. Bull. Eng. Geol. Environ. 60, 193–200. https://doi.org/10.1007/s100640100107 (2001).

Wang, M. & Wan, W. A new empirical formula for evaluating uniaxial compressive strength using the Schmidt hammer test. Int. J. Rock. Mech. Min. Sci. 123, 04094. https://doi.org/10.1016/j.ijrmms.2019.104094 (2019).

Basu, A. & Aydin, A. A method for normalization of Schmidt hammer rebound values. Int. J. Rock. Mech. Min. Sci. (41), 1211–1214. https://doi.org/10.1016/j.ijrmms.2004.05.001

Yasar, E. & Erdogan, Y. Estimation of rock physicomechanical properties using hardness methods. Eng. Geol. https://doi.org/10.1016/S0013-7952(03)00141-8 (2004).

Tugrul, A. & Zarif, I. H. Correlation of mineralogical and textural characteristics with engineering properties of selected granitic rocks from Turkey. Eng. Geol. 51, 303–317. https://doi.org/10.1016/S0013-7952(98)00071-4 (1999).

Torabi-Kaveh, M., Haidary, F., Khodami, M. & Tajbakhsh, G. Prediction of Durability properties of Igneous Rocks as Railway Ballast by simultaneously considering the petrographical, geochemical, and physical characteristics. J. Mat. Civ. Eng. 36 (1). https://doi.org/10.1061/JMCEE7.MTENG-16370 (2023).

Apaydın, Ö. F. & Yılmaz, M. Correlation of petrographic and chemical characteristics with strength and durability of basalts as railway aggregates determined by ballast fouling. Bull. Eng. Geol. Environ. 80 (6), 4197–4205. https://doi.org/10.1007/s10064-019-01654-4 (2021).

Çelik, M. Y. & Aygün, A. The effect of salt crystallization on degradation of volcanic building stones by sodium sulfates and sodium chlorides. Bull. Eng. Geol. Environ. 78, 3509–3529. https://doi.org/10.1007/s10064-018-1354-y (2019).

Van Blerk, P. G. L., Fletcher, E., Costello, S. B. & Henning, T. F. P. Ethylene glycol accelerated weathering test: an improved, objective aggregate durability test method. Transp. Res. Rec. 2655 (1), 27–35. https://doi.org/10.3141/2655-05 (2017).

Rocha, B. A volta do trem-bala. Revista Ferroviaria (Abril) 26–30. (2023).

Revista Ferroviária. Expansão em passageiros. Maior parte das obras ferroviárias no Brasil é Voltada para mobilidade urbana. Revista Ferroviária 149, 52–69 (2019).

Perrotta, M. M. et al. Geologia e recursos minerais do estado de São Paulo: Sistema de Informações Geográficas - SIG. Rio de janeiro: CPRM, 2006. Programa Geologia do Brasil. https://rigeo.sgb.gov.br/handle/doc/2966

NBR 7389. Aggregates – Petrographic Analysis of Aggregate for Concrete. Part 2: Coarse Aggregate (Brazilian Technical Standards Association, 2009).

NBR 15845. Rocks for Cladding. Part 1: Petrographic Examination (Brazilian Technical Standards Association, 2015).

NBR 5564. Railway – Ballast – Requirements and test Methods (Brazilian Technical Standards Association, 2021).

NBR 16974. Coarse aggregate - Abrasion test in the Los Angeles Machine (Brazilian Technical Standards Association, 2022).

NBR 9938. Aggregates – Determination of Strength to Crushing of Coarse aggregate – Test Method (Brazilian Technical Standards Association, 2013).

D5731. Standard test method for determination of the point load strength index of rock. American society for testing and materials. https://www.astm.org/d5731-16.html. [Accessed in 06 June 2023]. (2016).

D5873. Standard test method for determination of rock hardness by rebound hammer method. American society for testing and materials. https://www.astm.org/d5873-14.html. [Accessed in 06 June 2023]. (2000).

C88. Standard test method for soundness of aggregates by use of sodium sulfate or magnesium sulfate. American standard testing materials, West Conshohocken. https://doi.org/10.1520/C0088_C0088M-18 (2018).

Wiesner, E. & Gillate, S. J. An evaluation of the relationship between unconfined compressive strength and point load strength index. Bull. Int. Eng. Geol. Environ. 56, 115–118 (1997).

Heidari, M., Mohseni, H. & Jalali, S. H. Prediction of uniaxial compressive strength of some sedimentary rocks by fuzzy and regression models. Geotech. Geol. Eng. 36 (1). https://doi.org/10.1007/s10706-017-0334-5 (2018).

Tandon, R. S. & Gupta, V. Estimation of strength characteristics of different himalayan rocks from Schmidt hammer rebound, point load index, and compressional wave velocity. Bull. Eng. Geol. Environ. 74, 521–533. https://doi.org/10.1007/s10064-014-0629-1 (2015).

Basu, A. & Aydin, A. A method for normalization of Schmidt hammer rebound values. Int. J. Rock. Mech. Min. Sci. 42 (2), 215–220. https://doi.org/10.1016/j.ijrmms.2004.05.001 (2005).

Yagiz, S. Predicting uniaxial compressive strength, modulus of elasticity and index properties of rocks using the Schmidt hammer. Bull. Eng. Geol. Environ. 68, 55–63. https://doi.org/10.1007/s10064-008-0172-z (2009).

SABS 1083 - Aggregates from natural sources- South African Bureau standards, (2006).

Frazão, E. B. A importância das características tecnológicas da pedra britada para lastro ferroviário. Solos E Rochas 10 (3), 11–20 (1987).

Langer, W. H. & Knepper, D. H. Geologic characterization of natural aggregate: a field geologist’s guide to natural aggregate resource assessment. In Aggregate Resources (CRC, 2022).

Kazi, A. & Al-Mansour, Z. R. Influence of geological factors on abrasion and soundness characteristics of aggregates. Eng. Geol. 15 (3–4), 195–203. https://doi.org/10.1016/0013-7952(80)90034-4 (1980).

Corrêa, F. A. Contribution to studies on Brazilian rocks for use as railway ballast aggregate: emphasis on geomechanical correlations and alterability tests (MSc dissertation). Eng. School São Carlos Univ. São Paulo 85 https://doi.org/10.11606/D.18.2022.tde-26062023-113050 (2022).

Acknowledgements

The authors would like to thank the Engineering Geology and Road laboratories (EESC-USP) and Geotechnics Laboratory (UFSCar) for the opportunity and for all the infrastructure offered to carry out the physical-mechanical and alterability tests. The authors acknowledge the Brazilian governmental research agencies CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior) and CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico).

Funding

The participation of D.T.A. and R.P.R. was sponsored, respectively, by CAPES research fellowships and by CNPq through the research fellowship PQ2 316330/2021-3.

Author information

Authors and Affiliations

Contributions

Author Contributions: Conceptualization, supervision, writing—review and editing D.T.A. and R.P.R.; formal analysis, investigation, writing—original draft preparation R.P.R., G.C.X. and A.R.G.dA.; writing—review and editing, R.P.R. and S.N.M.; funding acquisition, writing—review and editing S.N.M. and A.R.G.dA.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Statement in the methods

All methods were performed in accordance with the relevant guidelines and regulations.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Alves, D.T., Ribeiro, R.P., de Castro Xavier, G. et al. Technological evaluation of stones from the eastern region of the state of São Paulo, Brazil, for railway ballast. Sci Rep 15, 1444 (2025). https://doi.org/10.1038/s41598-024-83929-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-83929-9

Keywords

This article is cited by

-

X-ray microtomography analysis of weathering-induced porosity changes in LD slag, basalt, and gneiss ballast materials

Bulletin of Engineering Geology and the Environment (2025)