Abstract

To delve into the adaptability of the full section SBM boring process during its inaugural application, this paper innovatively put forward an adaptability evaluation model for the SBM shaft boring within composite deep strata. This model is with the degree of adaptability T as the quantitative criterion. Initially, the evaluation index system of SBM boring adaptability is established. The determination of the adaptive standard for evaluation indexes and the calculation parameters of the model is based on a comprehensive approach that encompasses rock abrasion testing and extensive field investigations. Furthermore, based on the principle of AHP, the weight total ranking of SBM boring adaptability evaluation indexes is given under this method. Ultimately, fuzzy mathematics theory is introduced, and the fuzzy comprehensive evaluation and its verification is conducted. The results show that: the five factors that have the greatest influence on the adaptability of SBM boring in composite deep strata are, in order: I3 > I5 > I4 > I6 > I11. Based on the adaptability evaluation model of SBM boring and by the principle of weighted average, the adaptability of the SBM boring process response is “strong adaptability”. Through the engineering case, the scientific rationality of the SBM adaptability evaluation method in the composite deep strata has been verified.

Similar content being viewed by others

Introduction

The shaft presents significant development prospects, serving as an essential and vital conduit in underground spaces. Its applications span various engineering fields, including mining engineering, transportation tunnels, underground parking facilities, hydroelectric power stations, waste material storage, deep flood drainage systems, sewage management and other large-scale projects1,2,3,4,5. Currently, the conventional shaft drilling method is widely utilized in shaft drilling. It employs drilling and blasting techniques for rock fragmentation. However, this approach presents several drawbacks, including occupational injuries, safety risks, as well as noise and air pollution6,7,8,9,10. With the advancement of industrial science and technology, shaft and counter shaft drilling machines have emerged as two mechanical methods for rock breaking that do not require personnel to descend into the shaft. This greatly reduces the harm of traditional drilling and blasting methods.

Nevertheless, the shaft drilling method has inherent limitations, such as its tendency towards small diameters and low efficiency. This method often necessitates the assistance of traditional drilling methods for the lower sections. Furthermore, the counter shaft drilling method exposes the shaft slope to prolonged periods of high stress, surge water layers, and even the risk of rock explosions. Thereby this method increases the possibility to accidents. To address the shortcomings of these two mechanical rock-breaking methods, domestic efforts have intensified in researching and developing major SBM equipment. The adaptability evaluation of SBM equipment construction is an urgent problem to be solved at the present stage. Consequently, there is an urgent need to conduct relevant research on the adaptability of emerging shaft boring machines in the construction process response.

The current research undertaken by scholars both domestically and internationally on the adaptability of boring machines primarily encompasses three key aspects. It includes the geological adaptability of the machines11,12,13,14,15,16,17,18,19, the adaptability of the boring parameters20,21,22,23,24and the construction adaptability25,26,27,28,29. Cai et al.30 aiming at the adaptability of the boring machine to clay formation, revealed the physical deformation and response rules of formation parameters and engineering effects on surface settlement, building inclination and deformation, conducted sensitivity analysis on deformation effects. Based on boring parameters such as jack speed and torque, Kilic et al.31 used a machine learning model to study the complex dynamics that affect the advancing rate parameters of boring machine, and established a strong correlation between operator behavior and logging data. Wang et al.32focusing on the adaptability of double-shield construction vibration to the surrounding environment on urban subway, installed vibration sensors on the construction site for vibration measurement, studied the vibration characteristics of the machine construction, the influence range on the environment and the factors affecting the vibration. While the evaluation methodologies pertaining to the rock-breaking adaptability of boring machines within the domains of engineering economics33,34and construction risk35,36,37,38,39,40 have also garnered certain achievements. Currently, both domestic and international scholars have yet to embark on research evaluating the adaptability of SBM equipment during the boring process. When confronted with various equipment response issues during SBM shaft construction, there is a relative scarcity of engineering experience and countermeasures to draw upon. As such, conducting adaptive research on the response of the SBM boring process becomes paramountly necessary. This research will not only help to enrich mechanical shaft formation methods, but also provide valuable insights into enhancing the performance and reliability of SBM technology.

This research aims to comprehensively evaluate the overall performance and applicability degree of shaft boring machines when operating in complex, deep strata environments. By this study, the potential of SBM to break the limitations of traditional drilling methods and enhance safety and efficiency can be better understood in shaft boring projects. Drawing upon the Volcano Tunnel Shaft Engineering located in Sichuan Province, China, this paper puts forward the fundamental definition of SBM shaft boring adaptability. It subsequently establishes the evaluation index system alongside a comprehensive evaluation model for evaluating the adaptability of SBM boring in deep strata. This model is then applied to practical engineering project, with the findings validating the scientific rationality of the adaptability evaluation model for shaft boring machines in composite deep strata. Furthermore, this research significantly contributes to enriching the theoretical foundation of mechanical methods for shaft construction.

Adaptability evaluation theory and method

Definition of adaptability

In the field of system science, adaptability signifies the capacity of a system object to successfully accommodate and evolve in concert with external influencing factors. The definition of SBM adaptability presented in this paper pertains to the quantification of the process response exhibited by SBM shaft boring in deep, composite strata. It evaluates the level of mutual compatibility between the boring machine and its relevant influencing factors during shaft excavation, employing an adaptability degree T as quantitative criterion. Additionally, it identifies specific elements and their corresponding indexes that characterize these elements. They contributes to the construction of an evaluation index system tailored for assessing the adaptability of shaft boring operations in deep strata.

Principles of the evaluation system

The evaluation index system is established based on specific evaluation problems and must follow the principles of hierarchy, validity and simplicity. The scope of the adaptability evaluation of SBM shaft boring has multi-level characteristics, and the evaluation system structure as shown in Fig. 1 is formed for the adaptability problems of SBM deep boring.

Fuzzy comprehensive evaluation method

Generalization and selection of evaluation methods

The model is a generalization of reality12. The adaptability evaluation model encompasses a diverse array of methodologies, including Failure Mode and Effects Analysis, Delphi Method, Monte Carlo Simulation, Neural Network Method, Expert Review Method, Fuzzy Comprehensive Evaluation Method, Accident Tree Analysis, Impact Graph Method, and Event Tree Analysis, among others. Each of these evaluation approaches possesses a unique scope of applicability and inherent limitations. It necessitates a tailored selection process based on the specific requirements and characteristics of the evaluation scenario.

Many qualitative and quantitative uncertain factors must be considered comprehensively for evaluating the adaptability of shaft boring machine in deep ground construction. Fuzzy Comprehensive Evaluation Method provides a proper mechanism to deal with these uncertainties. It allows a comprehensive evaluation of things affected by multiple factors. Based on the actual situation and the comparison and analysis of different adaptive evaluation methods above, it is particularly appropriate to choose Fuzzy Comprehensive Evaluation Method to study the adaptive evaluation of SBM shaft boring process response.

Evaluation method

As the core of fuzzy comprehensive evaluation method, fuzzy mathematics has formed a set of scientific evaluation process. The steps of fuzzy evaluation method are as follows:

(1) Establishment of factor sets.

A factor set consisting of various factors affecting the object of evaluation, i.e.

In Eq. (1), U is the factor set; ui represents the influencing factors (i = 1,2,…,p-1,p), which have different degrees of ambiguity; p is the number of influencing factors.

(2) Establishment of evaluation sets.

The evaluation set is the collection of all evaluation results made by the decision maker on the object to be evaluated, with the evaluation value range interval as the evaluation objective, usually expressed as:

In Eq. (2), V is the evaluation set; v is the evaluation index, which is described by fuzzy language, such as "excellent, good, average, bad, very bad". The membership function is quantified by the value of [0,1] range interval in fuzzy mathematics.

(3) Single factor evaluation matrix.

After constructing the evaluation set, determine the membership degree of factor set U to evaluation set V, and calculate the single factor evaluation matrix:

(4) Weight set of influencing factors.

A weight is a quantity characterized by the importance corresponding to the rank of the influencing factor. if the corresponding weight of ui is ai, i = 1,2,…,p−1,p, then the set of rank weights A of ui is:

Normalizing for ai yields:

(5) Fuzzy comprehensive evaluation.

The fuzzy set A on the factor set U is transformed into the fuzzy set B on the evaluation set V by the single-factor evaluation matrix R. If A and R are known, then B is obtained from the fuzzy transformation as:

In Eq. (6), B represents the fuzzy subset on the evaluation set V; bj represents the membership degree of the corresponding hierarchical fuzzy subset B of the evaluated object, j = 1,2,…,q-1,q. Finally, the membership level of the evaluated object is determined based on the principle of maximum membership.

Determining the membership function

The key to effective evaluation using the Fuzzy Comprehensive Evaluation Method lies in the construction of an objective reality-based membership function. In this paper, the semi-trapezoidal and triangular distribution types are used to establish the membership function of the quantitative indexes. The formulas are as follows:

Weight determination method

The methods for determining weights include Fuzzy Relation Equation, Delphi Method, Analytic Hierarchy Process, Statistical Method, etc. Among them, the Analytic Hierarchy Process (AHP) has the advantages of short scoring time, easy understanding and mastery, small data volume, and low computational complexity. Therefore, in the adaptive fuzzy comprehensive evaluation of the response during the deep SBM shaft boring process, the Analytic Hierarchy Process is used to calculate the weights.

Principles of AHP

Assuming that the actual net weights of q objects are γ1,γ2,…,γq−1,γq, a weight ratio matrix G is formed after calculating the weight ratio of two two objects:

The weight ratio matrix G is left-multiplied by the net weight vector of the object W = (γ1,γ2,…,γq−1,γq)T , which is then obtained:

In Eq. (11), the vector W is the eigenvector of the comparison judgment matrix G corresponding to q. It is in terms of the net weights of q objects as components. In the matrix relation, q is the unique largest characteristic root of the weight ratio matrix G non-zero. W is the corresponding eigenvector of q.

Steps of AHP

(1) Building a hierarchical structure model.

The evaluation problem is decomposed hierarchically and a hierarchical structure model is established. It is divided into target layer, criteria layer and index layer.

(2) Constructing judgment matrix.

Assuming that it is now necessary to compare q factors H = {h1,h2,…,hq} to the degree of influence on factor Y. A pairwise comparison matrix is established by comparing the factors two by two. It improves the reliability of the data. Each time to take two factors hi, hj, aij to indicate the influence ratio of hi and hj on Y, with matrix G = (aij)q×q to indicate the results, said G for the judgment matrix between Y-H. Then the influence ratio of hj and hi on Y that is aji = 1/aij. Such as Table 1 lists the meaning of references to 1 to 9 and its reciprocal, with the number of aij as a scale to determine the value of aij.

(3) Hierarchical single ordering and consistency tests.

The eigenvector W corresponding to the largest eigenvalue λmax of the judgment matrix G is normalized to obtain the sorting weights of factors at the same layer for a factor at the upper layer. This process is known as hierarchical single sorting. If the comparison results are consistent, then the elements of the matrix G should then satisfy:

A matrix G of order q is consistent if and only if the largest eigenroot λmax = q of the positive reciprocal inverse matrix G. When there is an error in consistency, there must be a largest eigenroot λmax > q of G. The larger the error is, the larger the value of λmax-q is.

By calculating whether λmax is equal to q one can test whether the judgment matrix G is a consistent matrix. Because the characteristic root λ always depends on aij, when λmax is much larger than q, not only the non-consistency degree of judgment matrix G is more serious, the normalized eigenvectors corresponding to λmax are also less able to practically reflect the influence weight of H = {h1,h2,…,hq}’s weight of influence on factor Y. For this reason, it is necessary to perform a consistency test on the judgment matrix to determine whether it is acceptable or not. For example, the following is the consistency test of judgment matrix:

1)Calculation of consistency index CI

2)For q = 1,2,…,9, Table 2 can be checked to determine the value of the average random consistency index RI:

Generate 500 sample matrices based on a randomized method, construct the positive reciprocal inverse matrix by choosing any number from 1 to 9 and its reciprocal, and compute the average value of the largest eigenroot λ’max, then there are:

3)Calculation of the consistency ratio CR

If CR < 0.1, the consistency of the judgment matrix is acceptable, otherwise the judgment matrix should be corrected in some way.

4)Calculation of eigenvectors and maximum eigenvalues λmax.

The square root method is used, and the calculation process is as follows:

The first step is to find the elements’ product hi of each row in the judgment matrix.

In the second step, normalize hi(i = 1,2,…,q) is normalized to find the eigenvector corresponding to the maximum eigenvalue λmax:

In the third step, from Wi(ω1,ω2,…,ωq) we know that the largest eigenvalue λmax of the judgment matrix G satisfies: GW = λmaxW, which leads to:

In the fourth step, the maximum eigenvalue λmax of the judgment matrix is computed:

(4) Hierarchical total ordering and consistency test.

Assuming that the upper layer (layer A) has A1,A2,…,Ap total p factors with hierarchical total ranking weights a1,a2,…,ap, then assume that the subsequent lower layer (layer B) has q factors B1,B2,…,Bq, whose hierarchical single-ranking weights for Aj are b1j,b2j,…,bqj. If Bi is not associated with Aj, bij = 0.

Now the weights of the factors in the demand layer B for the total objective, i.e., the hierarchical total ordering weights of the factors in layer B b1,b2,…,bq. The weight synthesis method is shown in Table 3.

According to Table 3, it can be calculated that:

Assuming that the pairwise comparison judgment matrix of factors related to Aj in layer B, the consistency test yields a single-ordering consistency index of CI(j)(j = 1,2,…,q). The corresponding average random consistency index is RI(j). CI(j) and RI(j) have been obtained at the layer single-ranking. The total ranking random consistency ratio of B layer is:

If CR < 0.1, the results of the hierarchical total ranking can be considered to be consistent. The result is accepted.

Adaptability evaluation model of SBM in deep strata

Establishment of adaptability evaluation indexes

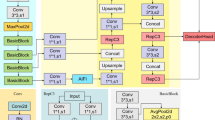

Introducing fuzzy mathematical theory to evaluate the adaptability of SBM boring in composite deep strata, the first problem to be solved is to screen and determine the evaluation indexes. According to the principle of establishing the adaptability evaluation system, and combined with the SBM construction parameters and field survey data, the evaluation system of SBM adaptability in composite deep strata is established as shown in Fig. 2.

The target layer is Degree of SBM boring adaptability. It is used to reflect the degree of adaptability between SBM boring in composite deep strata and each influencing factors. It is denoted by T. The criteria layer includes SBM boring, Geological conditions, Geological problems, and Construction organization. They are expressed as C1, C2, C3, and C4, respectively. The index layer covers 18 indexes I1 ~ I18.

The specific physical dimension of each evaluation index at the index layer of the system is shown in Table 4 below.

Adaptability evaluation criteria

The fuzzy mathematical theory is used to establish the membership function to standardize and quantify the determined evaluation indexes. Any value in the interval of [0,1] is used to represent the adaptability degree between SBM and each influencing factor. For each evaluation index, this paper categorizes the evaluation criteria of membership function into four adaptive levels: no adaptability, basic adaptability, more adaptability and strong adaptability. In the process of selecting the quantitative value for evaluation indexes, the quantitative criterion expresses the function range and interval size of each index as accurately as possible, as shown in Table 5 for the evaluation criteria of the adaptability of SBM boring.

Evaluation index weights

Hierarchical single-ordered evaluation

The nine-scaled method in hierarchical analysis was used to analyze the weights of the SBM adaptability evaluation indexes. In order to reduce the bias caused by subjectivity, the relative importance of each evaluation index was assigned by expert seminars, on-site surveys and e-mail consultation. According to the feedback to determine the values of index weights, the comparison judgment matrix of the evaluation indexes at each layer was calculated. The calculation results are shown in Table 6.

The maximum eigenvalue λmax = 4.174, consistency index CI = 0.058 and the corresponding eigenvector ω1 = (1.617,1.410,0.690,0.283) of this judgment matrix are obtained after calculation. The relative weights of evaluation indexes of this layer are shown in Fig. 3 after normalization.

Consistency test for judgment matrix: when q = 4, check Table 2 to get the average random consistency index RI = 0.89, and then based on Eq. (15) to get the consistency ratio CR = 0.065 < 0.1, the consistency test result passed.

This method is used to calculate the judgment matrix for criteria layer SBM boring C1, Geological conditions C2, Geological problems C3, and construction organization C4. The criteria layer C1, C2, C3, C4 single layer comparison judgment matrix for the adaptability evaluation indexes of shaft boring is as follows:

\(GC1 - I = \left[ {\begin{array}{*{20}c} 1 & 3 & {1/6} & {1/3} \\ {1/3} & 1 & {1/5} & {1/5} \\ 6 & 5 & 1 & 1 \\ 3 & 5 & 1 & 1 \\ \end{array} } \right]\); \(GC2 - I = \left[ {\begin{array}{*{20}c} 1 & 6 & 7 & 7 & 7 & 7 \\ {1/6} & 1 & 6 & 9 & 9 & 5 \\ {1/7} & {1/6} & 1 & 4 & 4 & 1 \\ {1/7} & {1/9} & {1/4} & 1 & 1 & 5 \\ {1/7} & {1/9} & {1/4} & 1 & 1 & 5 \\ {1/7} & {1/5} & 1 & {1/5} & {1/5} & 1 \\ \end{array} } \right]\);

\(GC3 - I = \left[ {\begin{array}{*{20}c} 1 & 2 & 3 & 4 & 7 & 8 \\ {1/2} & 1 & 2 & 3 & 6 & 5 \\ {1/3} & {1/2} & 1 & 2 & 5 & 5 \\ {1/4} & {1/3} & {1/2} & 1 & 6 & 5 \\ {1/7} & {1/6} & {1/5} & {1/6} & 1 & 2 \\ {1/8} & {1/5} & {1/5} & {1/5} & {1/2} & 1 \\ \end{array} } \right]\); \(GC4 - I = \left[ {\begin{array}{*{20}c} 1 & 3 \\ {1/3} & 1 \\ \end{array} } \right]\)

Calculate single layer comparison judgment matrix for the criteria layer of SBM adaptability evaluation system. The maximum eigenvalue λmax, corresponding eigenvectors ω, the consistency indexes CI and CR values are shown in Table 7.

As shown in Table 7, the CR values of the consistency check on the judgment matrix are all less than 0.1. It indicates that the consistency check results of the evaluation indexes for the shaft boring criteria layer are passed. After normalization, the relative weights of the evaluation indexes in the criteria layer are shown in Fig. 4.

Hierarchical total ranking evaluation

In Table 8, the ranking of indexes obtained from different levels can further calculate the total weight ranking of SBM deep adaptability evaluation indexes on the target layer T. It is shown in Fig. 5.

The total ranking consistency ratio CR of index layer I to target layer T is calculated according to Eq. (20):

The overall consistency test results of the hierarchy indicate that the sorting has good consistency. So far, based on the overall ranking of hierarchical weights determined by Analytic Hierarchy Process, the weight order of the adaptability evaluation indexes for SBM boring can be obtained as follows: I3 > I5 > I4 > I6 > I11 > I17 > I1 > I12 > I7 > I13 > I2 > I8 > I9 > I14 > I18 > I10 > I15 > I16.

Engineering evaluation

Aiming at the adaptability evaluation system for the response of SBM boring process in composite deep strata, an adaptability evaluation model is established based on AHP-Fuzzy theory. By using this model, the construction adaptability of the support project is evaluated quantitatively.

Engineering conditions

Stratigraphic lithology

The ground elevation of the shaft entrance is 2140m. The roadway elevation at the bottom of the shaft is 1847.5m. The inner diameter of the shaft is 8.3m. The boring depth is about 292.5m. The strata lithologies traversed by the shaft are mainly sandstone, carbonaceous shale and granodiorite, etc. The lithological characteristics are shown in Table 9. The physical and mechanical indexes and lithological indexes of rocks are shown in Table 10.

As shown in Fig. 6, the rock abrasion test was carried out with the help of the rock abrasion test system. Using a 90° conical head steel needle (Fig. 7) under a load of 70N, the steel needle into the fixture tightened, and then the test rock sample into the work platform, turn the lift handle to clamp the rock sample, slowly rotate down the host load, so that the tip of the steel needle and the surface of the test block contact.

Through the workpiece control equipment, the steel needle at a speed of 10mm/min in the rock surface after sliding 10mm, the loss of the steel needle diameter is used to calculate the abrasion coefficient CAI, the calculation method is shown in Eq. (21).

In Eq. (21), CAI is the coefficient of abrasion, d is the diameter (mm) of the steel needle being worn as in Fig. 8, and c is the correction factor (taken as 1 mm).

The rock samples were cylinders with a diameter of 50 ± 1mm and a height of 25 ± 1mm (Fig. 9), the upper and lower end faces were kept parallel, the flatness tolerance of the end faces was less than 0.05mm, and the deviation of the end faces from the perpendicularity to the axis of the cylinder was less than or equal to 0.25°. Each rock sample surface test 3 times, with 0.1mm as the basic unit, the measured value will be converted to the steel needle abrasion value, the arithmetic average of the three test values converted to the final rock sample CAI abrasion value.

The degree of wear of the steel needles after the rock sample abrasivity test is shown in Fig. 10 (taking the observation angle of 0° as an example), and the CAI abrasion values of the test rock samples converted by the abrasion diameters of the steel needles are shown in Table 11.

As can be seen from Table 11, the range of CAI abrasion values of granodiorite is [0.9, 1.4]. The test values, average values and CAI scatters are plotted according to the parameters in the table, as shown in Fig. 11.

According to classification based on rock abrasion level (0.0 to 0.3 is extremely low, 0.3 ~ 0.5 is very low, 0.5 ~ 1.0 is slightly low, 1.0 ~ 2.0 is medium, 2.0 ~ 4.0 is very high, and 4.0 ~ 6.0 is extremely high), the rock abrasion level of the shaft construction through the mountain is medium. The rock abrasion coefficient of the adaptability evaluation index is taken to be 1.2 by statistical analysis.

Unfavorable geology

Usually, the temperature inside the wells also increases with the increase of underground depth, but the warming is small. While temperature anomalies may occur in some fracture structure sites, such as outcropping the surface in the form of hot springs. As shown in Fig. 12

, the derrick supports the bucket into the shaft. It is used to lift and discharge the rock slag in the slag bin. The shaft wall adopts the anchor mesh supporting structure.

According to the results of temperature monitoring in the well, the temperature gradient near the well test area is low, less than the normal ground temperature gradient of 3℃/100m, and no abnormal geothermal activity phenomenon is found. No hot springs were found on the nearby surface, indicating that there is no in-well temperature anomaly in this area. The temperature inside the wells at the maximum buried depth in this engineering area is 20℃ ~ 25℃, and the temperature inside the wells is not high. Table 12 lists other adverse geological problems.

Boring parameters

SBM adopts circular full section boring with excavation diameter D = 9.53m. Disk hob, that is, cutter. Figure 13 shows the cutter structure, rock breaking principle, and cutter ring failure mode. As a consumable part, the cutter is the main working part of the shaft boring machine to break rock. Its overall steel structure is composed of high-strength steel plate welding with material characteristics of no less than Q355NC. Its main role is to cut the circular shaft section and stir the slag rock residue.

System condition monitoring utilizes a data acquisition system to obtain all condition parameters, including speed, torque, operating status, pressure, stroke, thrust, velocity, penetration, etc. They are displayed on a touch-screen control panel in the operator’s room through the PLC system.

Construction organization

Volcano Tunnel Shaft Engineering is constructed by China Railway Construction Heavy Industry Corporation Limited. It owns the special production qualification of tunnel boring machine enterprise. The group’s headquarter is located in Changsha, Hunan Province, China. Figure 14 shows the operating floors of the SBM and lifting system.

Considering that although the construction unit enterprise level is high quality, but the shaft is the first application of the domestic full-section SBM. So for the shaft engineering SBM boring technology level and construction organization evaluation criteria for 0.8. Then based on the establishment of the membership function, the two adaptability evaluation indexes correspond to no adaptability, basic adaptability, more adaptability and strong adaptability evaluation criteria, respectively, take the value of 0, 0, 0.8, 0.2.

Evaluation of boring adaptability

Evaluation index values

Based on the geological characteristics and the construction monitoring data of the Volcano Tunnel Shaft Engineering, considering the average value and the most unfavorable conditions, the evaluation index values of SBM boring adaptability in the composite deep strata for this case are listed. They are shown in Table 13.

Model calculation

The fuzzy relationship matrix of adaptability evaluation indexes in each layer is given by the established index membership function as follows:

\(r1 = \left[ \begin{gathered} 0 \hfill \\ 0 \hfill \\ 0 \hfill \\ 0 \hfill \\ \end{gathered} \right.\begin{array}{*{20}c} {0.3} \\ {0.95} \\ 0 \\ {0.7} \\ \end{array} \begin{array}{*{20}c} {0.7} \\ {0.05} \\ 0 \\ {0.3} \\ \end{array} \left. \begin{gathered} 0 \hfill \\ 0 \hfill \\ 1 \hfill \\ 0 \hfill \\ \end{gathered} \right]\); \(r2 = \left[ \begin{gathered} 0 \hfill \\ 0 \hfill \\ 0 \hfill \\ 0 \hfill \\ 0 \hfill \\ 0 \hfill \\ \end{gathered} \right.\begin{array}{*{20}c} 0 \\ 0 \\ 0 \\ 1 \\ {0.83} \\ 0 \\ \end{array} \begin{array}{*{20}c} {0.49} \\ {0.6} \\ {0.75} \\ 0 \\ {0.17} \\ 0 \\ \end{array} \left. \begin{gathered} 0.51 \hfill \\ 0.4 \hfill \\ 0.25 \hfill \\ 0 \hfill \\ 0 \hfill \\ 1 \hfill \\ \end{gathered} \right]\); \(r3 = \left[ \begin{gathered} 1 \hfill \\ 0 \hfill \\ 0 \hfill \\ 0 \hfill \\ 0 \hfill \\ 0 \hfill \\ \end{gathered} \right.\begin{array}{*{20}c} 0 \\ 0 \\ 0 \\ 0 \\ 0 \\ 0 \\ \end{array} \begin{array}{*{20}c} 0 \\ 0 \\ 0 \\ 1 \\ {0.5} \\ 0 \\ \end{array} \left. \begin{gathered} 0 \hfill \\ 1 \hfill \\ 1 \hfill \\ 0 \hfill \\ 0.5 \hfill \\ 1 \hfill \\ \end{gathered} \right]\); \(r4 = \left[ \begin{gathered} 0 \hfill \\ 0 \hfill \\ \end{gathered} \right.\begin{array}{*{20}c} 0 \\ 0 \\ \end{array} \begin{array}{*{20}c} {0.8} \\ {0.8} \\ \end{array} \left. \begin{gathered} 0.2 \hfill \\ 0.2 \hfill \\ \end{gathered} \right]\)

Above r1, r2, r3 and r4 denote the fuzzy relationship matrix of evaluation indexes corresponding to the C1, C2, C3 and C4 in the criteria layer, respectively. Accordingly, the membership degree of each SBM adaptability evaluation indexes corresponding to the membership function is further presented. The weight values and membership degrees of the evaluation indexes obtained are substituted into the Eq. (6). The calculated result is shown below.

It can be seen from the calculated result that the SBM shaft boring corresponds to the membership degree of the membership function. Then according to the principle of maximum membership degree, the maximum membership degree can be determined to be 0.4149. So the adaptability of the SBM shaft boring is evaluated as “strong adaptability”.

Evaluation verifying

In order to further verify the scientific rationality of the evaluation result, the quantitative evaluation grading standard of SBM boring adaptability in deep strata is proposed, as shown in Table 14.

Based on the weighted average principle, calculate the degree of SBM boring adaptability T as follow:

In Eq. (22): Bi = (0.0672,0.1892,0.3288,0.4149). xi corresponds to the four grades, respectively. The values of 0.25, 0.5, 0.75, and 1 are assigned to x respectively to be substituted into the above equation. The degree of SBM boring adaptability is calculated as:

According to the proposed Table 14, the adaptability of SBM in this shaft engineering case is “strong adaptability”. Therefore, the result of evaluation model based on AHP-Fuzzy theory is consistent with the evaluation verifying. It should also be noted that this study proposes this grading standard to initially categorize the SBM adaptability evaluation into five grades. Its reasonableness needs to be further examined by more actual engineering cases.

Conclusion

Focusing on the application of SBM mechanical rock breaking in shaft construction, this paper presents a foundational definition of the adaptability of SBM shaft boring in deep strata. It verifies the scientific rationality of the proposed evaluation model through the analysis of engineering case. The main conclusions of the research are as follows:

-

(1) Based on the definition of adaptability of SBM shaft boring in deep strata, the adaptability evaluation indexes were identified and screened, and the evaluation index system was established. The degree of SBM boring adaptability T covered 4 criteria layer indexes C1~C4 and 18 evaluation indexes I1~I18. Through the rock abrasion test and field investigation, the evaluation parameter values of 18 evaluation indexes under the adaptability evaluation criteria are determined.

-

(2) Based on the principle of AHP, the comparative judgment matrix of each layer in the shaft boring adaptability evaluation index system is constructed. The weight values of evaluation index is calculated, and it gives the total ranking of the index weight in the evaluation system as follows: I3>I5>I4>I6>I11>I17>I1>I12>I7>I13>I2>I8>I9>I14>I18>I10>I15>I16. Thus, the five factors that have the greatest influence on the adaptability of SBM construction are determined, i.e., the total thrust, the rock uniaxial compressive strength, the boring speed, the rock integrity coefficient and the width of fracture zone.

-

(3) The fuzzy mathematical theory is introduced to determine the membership function of the adaptability evaluation indexes of the SBM construction. It further establishes the evaluation model combined with the adaptability evaluation index system. According to the principle of maximum membership, the adaptability of SBM boring in this shaft construction is determined as “strong adaptability”. By the principle of weighted average, the degree of SBM boring adaptability T is calculated as 0.7729. The result of evaluation model based on AHP-Fuzzy theory is consistent with the evaluation verifying.

-

(4) The evaluation result and verifying indicate that the adaptability of full section SBM construction method to shaft boring is strong, and it proves the engineering applicability and scientific rationality of the adaptability evaluation model proposed in this paper. The study can better solve the adaptability evaluation problem of SBM mechanical rock breaking process response, and has certain engineering application value and scientific guiding significance.

Data availability

The data that support the findings of this study are available on request fromthe corresponding author. The data are not publicly available due to privacy orethical restrictions.

References

Li, Z. Q., Lai, J. X., Ren, Z. D., Shi, Y. F. & Kong, X. G. Failure mechanical behaviors and prevention methods of shaft lining in China. Eng. Fail. Anal. 143, 106904 (2023).

Liu, Z. Q. Shaft boring machine drilling technology 1–287 (China Coal Industry Publishing House, 2018).

Guo, L. H. et al. CFD–DEM method is used to study the multi-phase coupling slag discharge flow field of gas-lift reverse circulation in drilling shaft sinking. Sci. Rep. 14, 13853 (2024).

Zhao, J. L., Ma, C., Han, J. N., Xiao, X. M. & Jiang, Y. Q. Research of deformation law about guide rails under the action of mining deformation in mine vertical shaft. Sci. Rep. 13, 5604 (2023).

Gurkalo, F., He, C. F., Poutos, K. & He, N. Effects of innovative reinforced concrete slit shaft configuration on seismic performance of elevated water tanks. Sci. Rep. 14, 6113 (2024).

Lee, S. J., Kim, B. R., Choi, S. O. & Kim, N. S. Evaluation of blasting vibration with center-cut methods for tunnel excavation. Geomech. Eng. 30(5), 423–435 (2022).

Kim, T. K., Kim, S. K. & Lee, J. M. Dynamic response of drill floor considering propagation of blast pressure subsequent to blowout. Appl. Sci.-basel 10(24), 8841 (2021).

Choudhary, B. S. & Agrawal, A. Minimization of blast-induced hazards and efficient utilization of blast energy by implementing a novel stemming plug system for eco-friendly blasting in open pit mines. Nat. Resour. Res. 31(6), 3393–3410 (2022).

Ding, X. H. et al. Research on blasting mechanism and blasting effect of aqueous media in open pit coal mines. Sci. Rep. 13, 19140 (2023).

Hosseini, S., Pourmirzaee, R., Armaghani, D. J. & Sabri, M. M. S. Prediction of ground vibration due to mine blasting in a surface lead–zinc mine using machine learning ensemble techniques. Sci. Rep. 13, 6591 (2023).

Zhao, J., Gong, Q. M. & Eisensten, Z. Tunnelling through a frequently changing and mixed ground: A case history in Singapore. Tunn. Undergr. Sp. Technol. 22(4), 388–400 (2007).

Hassanpour, J., Rostami, J. & Zhao, J. A new hard rock TBM performance prediction model for project planning. Tunn. Undergr. Sp. Technol. 26(5), 595–603 (2011).

Ribacchi, R. & Lembo Fazio, A. Influence of rock mass parameters on the performance of a TBM in a gneissic formation (varzo tunnel). Rock Mech. Rock Eng. 38(2), 105–127 (2005).

Gong, Q. M., Zhao, J. & Jiao, Y. Y. Numerical modeling of the effects of joint orientation on rock fragmentation by TBM cutters. Tunn. Undergr. Sp. Technol. 20(2), 183–191 (2005).

Xia, Y. M. et al. Geological adaptability matching design of disc cutter using multicriteria decision making approaches. J. Cent. S. Univ. 25(4), 843–854 (2018).

Qi, W. C., Wang, L. H., Zhou, S. Y., Kang, Y. L. & Zhang, Q. Total loads modeling and geological adaptability analysis for mixed soil-rock tunnel boring machines. Undergr. Sp. 7(3), 337–351 (2022).

Wan, C. D. & Jin, Z. Y. Adaptability of the cutter-head of the Earth Pressure Balance (EPB) shield machine in water-rich sandy and cobble strata: a case study. Adv. Civ. Eng. 2020, 8847982 (2020).

Li, T., Zhan, J. W., Li, C. & Tan, Z. S. Evaluation of the adaptability of an EPB TBM to tunnelling through highly variable composite strata. Math. Probl Eng. 2021, 5558833 (2021).

Newman, T., Bellhouse, M., Corcoran, J., Sutherden, R. & Karaouzene, R. Discussion: TBM performance through the engineering geology of the Lee Tunnel. Proc. Inst. Civ. Eng.-geotech. Eng. 169(3), 299–313 (2016).

Mitsutaka, S. & Aphichat, S. Theoretical model of shield behavior during excavation. J. Geotech. Geoenviron. Eng. 128(2), 138–155 (2002).

Sapigni, M., Berti, M., Bethaz, E., Busillo, A. & Cardone, G. TBM performance estimation using rock mass classifications. Int. J. Rock Mech. Min Sci. 39(6), 771–788 (2002).

Qian, W. F. et al. Adaptability of earth pressure balance shield tunneling in coastal complex formations: a new evaluation method. Geomech. Eng. 27(4), 425–440 (2021).

Nagrecha, K. et al. As-encountered prediction of tunnel boring machine performance parameters using recurrent neural networks. Transp. Res. Rec. 2674(10), 241–249 (2020).

Yang, F. W., Su, W. L., Yang, Y. & Cao, Z. G. Analysis of load and adaptability of disc cutters during shield tunneling in soft-hard varied strata. Front. Struct. Civ. Eng. 17(4), 533–545 (2023).

Lu, Z. L., Wang, X. C., Zhou, G. H., Feng, L. & Jiang, Y. S. Investigation on vibration influence law of double-shield TBM tunnel construction. Appl. Sci.-basel 12(15), 7727 (2022).

Jung, Y. R. et al. Analysis of correlation between shield TBM construction field data and settlement measurement data. J. Korean Tunn. Undergr. Sp. Assoc. 24(1), 79–94 (2022).

Liu, Z. B. et al. Hard-rock tunnel lithology prediction with TBM construction big data using a global-attention-mechanism-based LSTM network. Autom. Constr. 125, 103647 (2021).

Kong, S. M., Byun, Y., Choi, S. I., Kim, C. Y. & Lee, S. W. A study of vibration reduction effects of TBM and NATM parallel construction methods according to tunnel depth and size. Appl. Sci.-Basel 13(6), 3492 (2023).

Zhang, Z. X. et al. Safety-risk assessment for TBM construction of hydraulic tunnel based on fuzzy evidence reasoning. Processes 10(12), 2597 (2023).

Cai, L. P. et al. Research on the deformation laws of buildings adjacent to shield tunnels in clay strata. Sci. Rep. 14, 265 (2024).

Kilic, K., Narihiro, O., Ikeda, H., Adachi, T. & Kawamura, Y. Soft ground micro TBM jack speed and torque prediction using machine learning models through operator data and micro TBM-log data synchronization. Sci. Rep. 14, 9728 (2024).

Wang, Z. Y., Jiang, Y. S., Shao, X. K. & Liu, C. L. On-site measurement and environmental impact of vibration caused by construction of double-shield TBM tunnel in urban subway. Sci. Rep. 13, 17689 (2023).

Elyasi, S. Developing an evaluation model for economic feasibility analysis of using mechanical boring machines (TBM vs Roadheader) in one of the largest coal reserves in Iran. Min. Metall. Explor. 38(2), 1081–1094 (2021).

Einstein, H. Decision aids for tunneling: update. Transp. Res. Rec. 1892, 199–207 (2004).

Liu, D. H., Xuan, P., Li, S. & Huang, P. Z. Schedule risk analysis for TBM tunneling based on adaptive CYCLONE simulation in a geologic uncertainty-aware context. J. Comput. Civ. Eng. 29(6), 04014103 (2015).

Chung, H., Lee, I. M., Jung, J. H. & Park, J. Bayesian networks-based shield TBM risk management system: methodology development and application. KSCE J. Civ. Eng. 23(1), 452–465 (2019).

Lu, F. et al. Risk analysis and countermeasures of TBM tunnelling over the operational tunnel. Front. Earth Sci. 11, 1103405 (2023).

Wang, P., Xue, Y. G., Su, M. X., Qiu, D. H. & Li, G. K. A TBM tunnel collapse risk prediction model based on AHP and normal cloud model. Geomech. Eng. 30(5), 413–422 (2022).

Lin, P., Xiong, Y., Xu, Z. H., Wang, W. Y. & Shao, R. Q. Risk assessment of TBM jamming based on Bayesian networks. Bull. Eng. Geol. Environ. 81(1), 47 (2022).

Yang, Y. L. et al. Research on prevention and control technology of classified rockburst in TBM construction of deeply buried tunnels. Sci. Rep. 14, 333 (2024).

Funding

This work was supported by the National Key Research and Development Program of China (Grant No. 2021YFB3401504) and the National Natural Science Foundation of China (Grant Nos. 52074009 and 52104116).

Author information

Authors and Affiliations

Contributions

Suqian Ni (First Author): Conceptualization, Methodology, Software, Investigation, Formal Analysis, Data Curation, Writing—Original Draft; Ying Xu (Corresponding Author): Conceptualization, Funding Acquisition, Resources, Supervision, Writing—Review & Editing; Peiyuan Chen: Visualization, Investigation; Jinjin Ge: Resources, Visualization; Rongzhou Yang: Supervision, Investigation; Ziyi Yang: Software, Validation; Guang Yang: Writing—Review & Editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ni, S., Xu, Y., Chen, P. et al. Adaptability evaluation model and experiment of full section SBM in deep strata based on AHP-fuzzy theory. Sci Rep 15, 521 (2025). https://doi.org/10.1038/s41598-024-84123-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-84123-7

Keywords

This article is cited by

-

China’s environmental governance efficiency evaluation based on novel cross-efficiency network DEA model

Scientific Reports (2025)