Abstract

During the filling process of LNG tank trucks, due to the long-term operation of filling equipment in low temperature and high-pressure conditions, the sealing parts in the equipment are prone to failure, leading to leaks. The reasons for the leakage of LNG filling equipment were analyzed, and the diffusion of LNG after different equivalent leakage hole diameters and different wind speeds were numerically analyzed. A gas leak monitoring system suitable for LNG filling stations was established based on TDLAS technology. The analysis results show that when the equivalent leakage hole diameter is greater than 4 mm, the height of natural gas diffusion will exceed 5 m within 2 s without wind; the concentration of natural gas above the leakage point is inversely proportional to the height, and the decrease in concentration at a height of 5 m is between 50% and 60% compared with a height of 0.5 m; the wind will bend the natural gas diffusion shape downwind, and the degree of bending decreases as the equivalent leakage hole diameter increases; the optimal laser incidence angle of the laser gas sensor is between 30° and 50°, and the theoretical effective monitoring area width of the sensor when the installation height is 5 m is 4.46 m within the optimal laser incidence angle range.

Similar content being viewed by others

Introduction

With the growing demand for energy and the increasing awareness of environmental protection, the consumption of natural gas has been increasing year by year1,2. Natural gas is a clean energy with the characteristics of high combustion heat value and less pollution3. However, due to its large gaseous volume, transportation and storage are inconvenient, so it needs to be liquefied. After liquefaction, the volume of LNG is reduced by 625 times compared to the same amount of gaseous natural gas, providing a safer and more economical way for the transportation and storage of natural gas4,5. Tank truck transportation is an important part of LNG land transportation, and LNG is transported to various receiving stations through tank truck transportation6. Currently, LNG filling stations generally use filling arms to fill LNG from the storage tank to the tank truck. During the tank truck filling process, the sealing parts of the filling arm are easily damaged due to long-term operation in low-temperature and high-pressure conditions, leading to LNG leakage and serious safety accidents7. After an LNG leak occurs, the valve of the filling arm should be immediately closed to prevent the accident from spreading. Establishing a gas leak monitoring system at an LNG filling station can monitor the gas leakage in real time. When the system detects the presence of natural gas leakage in the monitoring area, it can alert the station staff and automatically close the valve of the filling arm, which is of great significance for improving the safety of filling operations.

Ehsan et al.8 conducted a simulation analysis of the gas leakage process after pipeline damage using the CFD method, studying the effects of pipeline pressure, leakage hole diameter, wind speed, and soil porosity on the diffusion of natural gas after leakage. Abdolrahim Moghadam Dezfouli et al.9 proposed a method for detecting the leakage rate of low-flow natural gas pipelines by using a strong airflow to pass through the gas leakage hole, producing a mixture of natural gas and air, and determining the natural gas leakage rate by measuring the volumetric flow rate and natural gas concentration of the mixture. Riaz et al.10 developed a nonlinear adaptive model for the location of oil and gas pipeline leaks, based on the characteristic changes in pressure and flow at the entrance and exit of the pipeline to locate the pipeline leakage position. Zhang et al.11 conducted a simulation analysis of the diffusion situation after equipment leaks at an LNG gas station using the FLACS 3D simulation software, studying the accident range caused by natural gas leakage to provide a reference for the installation location of natural gas leakage detection devices. Yan et al.12 developed a sensor system for detecting trace levels of methane in the atmosphere using TDLAS technology and obtained gas concentration data using the LabVIEW platform. They also proposed a method for locating mobile gas leaks by combining gas turbulence models and particle swarm optimization algorithms and tested its reliability.

In this study, our research object is the manual LNG loading station. Based on the fluid computing software Fluent, the diffusion state of LNG leakage under different equivalent leak aperture and different wind speed was analyzed. Based on the numerical simulation results of gas diffusion, a gas leakage monitoring system is established based on TDLAS technology.

Analysis of leakage causes in LNG filling equipment

During the LNG tanker filling process, LNG leakage is the most common accident that occurs at the filling station13. Because the filling arm is connected to the various pipelines and rotary joints through flanges and runs in low-temperature conditions for a long time, it is very easy to cause the sealing failure of the connections, resulting in LNG leakage14. During the use of the filling arm, if the installation specifications are not followed or the filling arm is not inspected and maintained according to the operating instructions, it is easy to cause damage to the filling arm pipeline, resulting in LNG leakage from the pipeline cracks. According to the actual situation of the LNG filling station, the common leakage forms that can be summarized include flange leakage, low-temperature rotary joint leakage, valve leakage, and pipeline leakage.

Flange leakage

The connections between the pipes in the loading arm are mainly achieved through flanges, so flange leakage is the most common form of leakage during filling. The sealing of flange connections mainly relies on the application of a certain pre-tightening force to the bolts, thereby compressing the gasket to achieve sufficient sealing pressure to seal the fluid medium15. For LNG liquid, due to its low-temperature characteristics, the sealing performance of the sealing elements in the low-temperature state decreases. If the sealing elements are not replaced for a long time, their spring force will weaken, causing seal failure. During the filling process of the tanker, there will be vibration, which may also cause seal failure between the flanges and cause leakage.

Low-temperature rotating joint leakage

The low-temperature rotary joint serves as the moving joint for the filling arm, supporting the movement of the filling arm. The quality of the rotary joint not only affects whether the filling arm can perform the specified movement but is also one of the common factors that cause leaks in the filling arm16. The main reason for the leakage of the rotary joint is damage to the sealing element. During assembly, hard particles or roughness that do not meet the required specifications in the sealing surface can cause damage to the sealing element, resulting in a loss of sealing effect.

Valve leakage

In LNG filling equipment, cryogenic ball valves are the most widely used valves. Cryogenic ball valves are affected by the temperature, pressure, and vibration of LNG during filling, as well as the defects they have during production, and there is a risk of leaking over a long period of use17. The sealing of cryogenic ball valves mainly consists of three parts, including the packing seal of the valve stem, the seal between the valve seat and the valve ball, and the seal between the valve body and the connection, which are the most common locations for cryogenic ball valves to leak.

Pipe leaks

The leaks in the pipelines of the LNG fueling arm are mainly caused by processing defects and improper installation. Defects such as cracks, pores, incomplete fusion, and incomplete penetration in the pipe processing process may cause leak accidents. During the installation of the fueling arm, if the installation specifications are not followed, it is easy to cause uneven load on the fueling arm, resulting in a situation where the pipeline in a certain area is subjected to greater force, thereby damaging the pipeline and causing a leak accident.

Mathematical model for gas diffusion

When LNG leaks into the atmospheric environment, it will quickly vaporize and form a methane gas cloud that disperses around. Due to the influence of the atmospheric environment, methane gas diffuses irregularly in the air, which is a typical turbulent flow. In Fluent, the standard k-ε turbulence model is used for calculation, as shown in Eqs. 1 and 218.

Where: k is the turbulent kinetic energy, m2/s2; ε is the dissipation rate of turbulent kinetic energy, m2/s3; σk is the Prandtl number corresponding to the turbulent kinetic energy k; The Prandtl number corresponding to the dissipation rate ε of turbulent kinetic energy; µ is the dynamic viscosity, Pa⋅s; µt is the dynamic turbulent viscosity, Pa⋅s; Gk is the generation term of turbulent kinetic energy k caused by the average velocity gradient, kg/(m⋅s3); Gb is the generation term of turbulent kinetic energy k caused by buoyancy, kg/(m⋅s3); YM is pulsation expansion in compressible turbulence, kg/(m⋅s3); C1ε, C2ε and C3ε are empirical constants. Sk is the defined turbulent energy term, kg/(m⋅s3); Sε is the defined turbulent kinetic energy dissipation source term, kg/(m⋅s4).

Numerical simulation and analysis of gas diffusion

Physical modeling

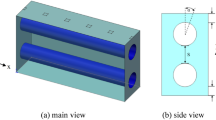

Taking the on-site layout of the LNG loading arm as a reference, the space occupied by the pipelines for the loading arm was simplified into a rectangular space measuring 6 m in length and 5 m in width. The two-dimensional plane gas diffusion model established is shown in Fig. 1. Since the top of the loading arm on-site has a canopy, the top of the calculation model was set to a fixed wall condition, and the ground and pipeline walls were also set to fixed wall conditions. A simulated leak point was set on the pipeline, and the grid was densely spaced at the leak point during grid division.

Boundary conditions

The pressure of the medium in the LNG fueling arm pipeline is 1 MPa, and the pipe diameter is 50 mm. Assuming that all the LNG leaks and vaporizes into methane gas, the methane gas inlet at the leak point is set as the mass flow inlet type, and the mass flow rate Q of methane gas can be calculated by Eq. 319:

Where: Cd is the leakage coefficient; A is the equivalent leakage hole area, m2; ρ is the density of LNG, kg/m3; g is the acceleration of gravity 9.8 m/s2; h is the height difference between the leakage point and the liquid surface, m; P is the pressure in the pipeline, Pa; P0 is the atmospheric pressure, Pa.

Since the LNG filling process is continuous, it can be assumed that the height difference between the leak point and the liquid surface remains unchanged. When the medium pressure is 1 MPa, the mass flow Q of methane gas calculated by taking different equivalent leakage pore sizes is shown in Table 1:

The inlet of the wind is of the velocity inlet type, and considering the working environment of the filling station, the wind speed from 0 to 8 m/s is set to 5 gradients for calculation. The right boundary of the calculation model is set to a pressure outlet type, with an exit pressure of atmospheric pressure.

Limitations of the computational model

(1) When LNG leaks through a small hole, LNG will quickly vaporize when it comes into contact with the external environment, forming a methane gas cloud to spread around. Because the vaporization time is very short, the calculation model ignores the vaporization process of LNG, so the model is only suitable for analyzing the diffusion law of LNG after leakage through small holes.

(2) The influence of the shape of the leak hole is ignored in the calculation model, and the shape of the leak hole is assumed to be circular.

(3) The calculation model ignores the change of wind speed at different altitudes, and assumes that the wind speed is constant at different altitudes in the LNG loading station.

Analysis of computation results

Figure 2 shows the variation curve of natural gas concentration at a height of 2 m above the leak point with different equivalent leakage diameters. After the leak occurs, the gas cloud reaches a height of 2 m within 0.1s, and the natural gas concentration in the vicinity of the leak point increases proportionally with the leakage time. As the natural gas gradually diffuses, the natural gas concentration in the leakage area gradually approaches a constant value. Because natural gas is diffused in the atmosphere in a turbulent form, as the height increases, the diffusion of natural gas to the surrounding gradually increases, so the change in the volume concentration of natural gas at the center line of the leak location is not linear. When the concentration value in the leakage area reaches the detection threshold set by the natural gas leakage monitoring system, the system will alert the station personnel and close the valve of the loading arm. Therefore, the monitoring system should be able to close the valve within a short time after the leak occurs to prevent the leak accident from expanding. As shown in Fig. 2, the natural gas concentration value in the leakage area exceeds 10% after 2 s of LNG leakage, reaching the monitoring range of the monitoring system. Therefore, analyzing the diffusion of natural gas 2 s after the LNG leakage can provide a basis for the design of the natural gas leakage monitoring system.

In the absence of wind, the concentration distribution of natural gas diffused from different equivalent leakage hole diameters after 2 s of LNG leakage is shown in Fig. 3. As the equivalent leakage hole diameter increases, the range of natural gas diffusion gradually expands. The natural gas concentration at different heights along a path perpendicular to the leakage point is shown in Fig. 4, where the natural gas concentration decreases as the height increases. Compared with the natural gas concentration at a height of 0.5 m above the leakage point, the natural gas concentration at a height of 5 m decreases by 50–60%. When the equivalent leakage hole diameter is 2 mm, the maximum diffusion height of natural gas after 2 s of leakage is 3.6 m. When the equivalent leakage hole diameter is between 4 mm and 10 mm, the maximum diffusion height of natural gas will reach 5 m, and due to the blocking effect of the roof above the loading skid, natural gas will accumulate below the roof. Therefore, when the equivalent leakage aperture is greater than 4 mm, the maximum height of the gas cloud is the height of the ceiling due to the obstruction of the ceiling. The volumetric fraction of natural gas below the roof is between 13.1% and 16% when the equivalent leakage hole diameter is between 4 mm and 6 mm, and the natural gas concentration is within its explosive limit at this time.

In the conditions of equivalent leakage orifice diameters of 2 mm, 6 mm, and 8 mm, the concentration distribution of natural gas leaked for 2 s under different wind speeds is shown in Fig. 5. After the natural gas leakage, the shape of the gas diffusion gradually bends downwind under the influence of wind. As the wind speed increases, the degree of bending also increases. Under the influence of wind, the diffusion of natural gas after the leakage is different at different equivalent leakage orifice diameters. When the equivalent leakage orifice diameter is small, the mass flow rate of natural gas leaked is relatively small, causing the gas cloud after the leakage to be more affected by the horizontal wind force, so the more the equivalent leakage orifice diameter is small, the more significant the influence of wind on the diffusion of natural gas. Figure 6 shows the concentration of natural gas above the leakage point at a height of 0.5 m at different wind speeds. Under the influence of wind, the natural gas cloud gradually diffuses downwind, and in the process of diffusion, it gradually dilutes, resulting in an inverse proportional relationship between the concentration of natural gas above the leakage point and the wind speed, compared with the condition without wind, the concentration of natural gas at the same position above the leakage point presents a downward trend.

Gas leak monitoring system design

The related technologies of gas leakage monitoring mainly include TDLAS technology, infrared imaging technology, acoustic imaging technology and passive fiber laser technology. Table 2shows the advantages and disadvantages of each of these technologies. Considering the characteristics of various technologies and the actual situation of LNG loading station, it is the best technical scheme to establish leakage monitoring system of LNG loading station based on TDLAS technology20,21.

Tunable diode laser absorption spectroscopy (TDLAS) technology is often used for the detection of gas concentrations and has the advantages of high detection accuracy and strong resistance to interference22. In this paper, a gas leakage monitoring system for LNG filling stations is designed based on TDLAS technology, and the installation of the laser gas sensor is based on the diffusion conditions of LNG after leakage during the filling process of the tanker.

Principles of TDLAS technology

TDLAS technology primarily utilizes the principle of infrared spectral absorption of gases to achieve the detection of gas concentrations. According to the Lambert-Beer law:

Where: v is the incident light frequency; I(v) is the remaining light intensity after the laser passes through the gas to be measured; I0(v) is the original light intensity of the laser; P is the pressure of the gas; S(T) is the characteristic spectral line intensity of the gas, which is mainly related to the temperature of the gas. φ(v) is a linear function, which describes the shape of the gas absorption spectral line, mainly related to the temperature and pressure of the gas. C is the volume concentration of the gas to be measured; L is the propagation distance of laser in gas.

System working principle

Figure 7 shows the working principle diagram of the natural gas leakage monitoring system, where the laser gas sensor is installed in the loading area of the tank truck, and the data of natural gas leakage detected by the laser detection module and the scene monitored by the video surveillance module are transmitted to the terminal PC via optical fiber. When the sensor detects the existence of natural gas leakage in the loading area, the warning light alerts the personnel at the station. At this time, the operator can close the valve through the arm valve control system to prevent the accident from expanding. The rotating pan-tilt module in the laser gas sensor can make the sensor swing and tilt, and the personnel at the station can remotely control the position and trajectory of the sensor through the terminal PC and set the pre-flight route. In case of emergency, the sensor’s movement attitude can be manually controlled by the personnel.

According to the relevant provisions of combustible gas detection, when the concentration of combustible gas reaches 1.25%, the alarm instrument needs to issue an alarm. Since natural gas is a flammable and explosive gas, in order to ensure the safe filling of LNG, the alarm threshold set by the sensor should be lower than 1.25%. Combined with the characteristics of the scanning laser gas sensor, the alarm threshold of the leakage monitoring system is set to 5000ppm·m, which can be adjusted according to the application situation.

Laser gas sensor layout for refilling stations

Figure 8 shows the geometric relationship of the laser gas sensor arrangement. For the determination of the sensor installation height, three factors should be mainly considered: Firstly, the laser gas sensor emits laser, and the light path L0 should be less than the rated detection distance of the sensor to ensure that the laser can form a closed loop after passing through the natural gas cloud. Secondly, the vertical distance h between the light path and the leak point should be less than the vertical diffusion height HN of the natural gas cloud or the distance L2 between the leak point and the reflective surface should be less than the horizontal diffusion distance LN of the natural gas cloud, to ensure that the laser can detect the natural gas cloud after the pipeline leaks. Thirdly, it should be avoided that there are obstacles on the light path. Since the top of the loading skid usually has a canopy, the laser gas sensor should be installed so that the laser can pass through the underside of the canopy to prevent it from being obstructed.

Different laser incidence angles will result in different detected gas concentration values. Different equivalent leak apertures show similar rules, so we take 6 mm equivalent leak apertures as an example to analyze the difference of gas concentration detected by different laser incident angles. Figure 9 shows the distribution law of natural gas concentration in optical paths with different laser incidence angles when the equivalent leakage aperture is 6 mm under the condition of no wind. Due to the blocking effect of the natural gas cloud under the loading platform, natural gas accumulates below the blocking structure, so the difference in natural gas concentration along the initial light path is small when different incidence angle lasers enter the detection area. As the light path extends, the difference in natural gas concentration along the light path gradually increases near the leak point. Because the vertical distance from the leakage position is different when the laser with different incidence Angle passes through the gas cloud, the gas concentration in the optical path with different incidence Angle is different. When the laser incidence angle is less than 50°, the detection light path will pass above the leak point, and the high concentration region of natural gas on the detection light path is mainly located near the leak point. As the detection light path is above the leak point, the larger the laser incidence angle, the closer the light path will be to the leak point. When the laser incidence angle is between 30° and 50°, the light path can pass above the leak point, and the light path formed at this angle is shorter, allowing it to form a loop after passing through the natural gas cloud. Therefore, when the sensor is installed at a height of 5 m, the optimal scanning angle of the sensor is between 30° and 50°.

Figure 10 shows the concentration distribution of natural gas along the optical path at different laser incidence angles when the equivalent leakage orifice diameter is 6 mm and the wind speed is 4 m/s. Due to the influence of wind, the gas plume disperses downwind from the leak point, resulting in the absence of detectable natural gas concentrations on the upwind side of the leak point. The gas concentration is relatively higher on the downwind side of the leak point. Under a wind speed of 4 m/s, the laser incidence angle is between 30° and 50°, and the sensor can still effectively monitor the natural gas concentration values in the leak area.

Figure 11 shows the main monitoring area of the laser gas sensor. Since the filling arm is the most likely equipment to leak during the filling process of the tanker, the focus of the natural gas leak monitoring system is mainly the filling area of the tanker by the filling arm. The sensor can be installed in the position facing the tanker filling area. The monitoring area can be periodically scanned by rotating the pan-tilt module to adopt different laser angles. When the installation height of the sensor is 5 m and the laser incidence angle is between 30° and 50°, the theoretical width of the effective monitoring area d is 4.46 m.

Possible challenges in installing a leak monitoring system

We propose a leak monitoring system for LNG loading stations, which may present the following challenges when deploying such a system:

(1) Due to the differences in the construction structure of LNG loading stations, it is necessary to make reasonable planning according to the construction pattern of LNG loading stations when installing gas sensors.

(2) In the construction stage of leakage monitoring system of LNG loading station, more funds need to be invested.

(3) In bad weather conditions, the detection accuracy of the sensor may be affected, so the filling operation should be avoided in bad weather conditions.

Conclusion

In this paper, the diffusion state of LNG leakage under different equivalent leakage pore size and different wind speed is analyzed. Based on TDLAS technology, a natural gas leakage monitoring system suitable for LNG tanker loading station was established, and the following conclusions were reached:

(1) During the filling process of LNG tank trucks, the main locations where LNG filling equipment is prone to leakage are the flange connections, low-temperature rotary joints, low-temperature valves, and defects in pipelines. Therefore, these locations should be checked in daily maintenance.

(2) Under no-wind conditions, when the equivalent leakage diameter is greater than 4 mm, the diffusion height will exceed 5 m. Due to the blocking action of the top canopy of the loading skid, the natural gas cloud will accumulate below the canopy. When the equivalent leakage diameter is between 4 mm and 6 mm, the fractional volume of natural gas below the canopy is between 13.1% and 16%. The concentration of natural gas above the leakage point decreases as the diffusion height increases. Compared with the concentration at a height of 0.5 m above the leakage point, the concentration at a height of 5 m decreases by 50–60%.

(3) Under windy conditions, the shape of the gas plume after natural gas diffusion tends to curve downwind, and the degree of curvature increases as the wind speed increases. The more windy it is, the more significant the influence of wind on natural gas diffusion becomes, especially for smaller equivalent leakage diameters.

(4) Numerical analysis of the gas diffusion situation after the leak can provide a reference for the design of the natural gas leak monitoring system. The installation position of the laser gas sensor should be based on the layout of the filling station and follow a reasonable geometric relationship. When the installation height of the sensor is 5 m, the optimal scanning angle of the sensor is between 30° and 50°. At this time, the theoretically effective monitoring area width of the laser gas sensor is 4.46 m.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Liu, H. et al. Research on China’s natural gas development strategy under the constraints of carbon peak and carbon neutrality. Strategic Study Chin. Acad. Eng. 23 (06), 33–42 (2021).

Yang, F., Deng, L., Luo, T. & Zhang, J. Design and flow field analysis of high-pressure natural gas wellhead drop separation device. Drill. Prod. Technol. 46 (05), 113–118 (2023).

Federica, R., Marta, G. & Laura, A. Green vs fossil-based energy vectors: a comparative techno-economic analysis of green ammonia and LNG value chains. J. Environ. Chem. Eng. 12 (1), 111723 (2024).

Wu, Y. et al. Research on digital twin based temperature field monitoring system for LNG storage tanks. Measurement 215, 112864 (2023).

You, Y., Kim, S. & Lee, J. Comparative study on ammonia and liquid hydrogen transportation costs in comparison to LNG. Int. J. Naval Archit. Ocean. Eng. 15, 100523 (2023).

Li, X., Zhang, Y., Wang, T. & Li, C. Risk assessment of LNG tanker based on particle swarm optimization Analytic Hierarchy process. Saf. Environ. Eng. 29 (02), 9–15 (2022).

Zhou, J., Li, C., Pu, H. & Liang, G. Numerical simulation of LNG leakage due to joint seal failure in loading and unloading operation. Oil Gas Chem. Ind. 50 (05), 104–112 (2021).

Ehsan, Z. et al. Numerical study of gas leakage from a pipeline and its concentration evaluation based on modern and practical leak detection methods. J. Loss Prev. Process Ind. 80, 104890 (2022).

Abdolrahim, M., Reza, S., Morteza, B. & Maziar, C. Experimental and numerical investigation on development of a method for measuring the rate of natural gas leakage. J. Nat. Gas Sci. Eng. 104, 104643 (2022).

Riaz, M., Ahmad, I., Khan, M., Mond, M. & Mir, A. Volumetric flow and pressure gradient-based leak detection system for oil and gas pipelines. Int. J. Oil Gas Coal Technol. 25 (3), 340–356 (2020).

Zhang, Y., Li, Y., Dang, W., Wang, Y. & Liu, D. Study on leakage simulation and detection coverage of typical LNG filling station. China Saf. Sci. J. 32 (S1), 108–113 (2022).

Yan, G. et al. Mid-infrared methane sensing system for gas leakage detection and its application. Chin. J. Lasers. 49 (18), 118–126 (2022).

Shu, Y., Chen, H., Zhang, J. & Tang, E. Numerical simulation of LNG leakage risk of tank car in an LNG loading area. Fire Sci. Technol. 41 (02), 221–225 (2023).

Fan, Z. & Cheng, G. Application of passive low temperature leakage protection on liquefied natural gas steel structure. Electroplating Finish. 39 (22), 1550–1555 (2020).

Nelson, N., Prasad, N. & Sekhar, A. Structural integrity and sealing behaviour of bolted flange joint: a state of art review. Int. J. Press. Vessels Pip. 204, 104975 (2023).

Yan, Y., Miao, H., Sun, F., Zhang, C. & Yuan, R. Research and design of low temperature resistant Rotary Joint for LNG handling arm. Agricultural Equip. Technol. 43 (01), 40–41 (2017).

Chen, Q. et al. Failure analysis of deflected seal of ultra-low temperature valve spool based on ABAQUS. J. Tsinghua Univ. (Science Technology). 62 (12), 1996–2002 (2022).

Li, Y., Wang, Z. & Zheng, S. Analysis and prediction of hydrogen-blended natural gas diffusion from various pipeline leakage sources based on CFD and ANN approach. Int. J. Hydrog. Energy. 53, 535–549 (2024).

Wang, Z. Research on Leakage Diffusion and Explosion Suppression of LNG Storage tank (Southwest Petroleum University, 2018).

Yang, D., Oh, J., Lee, G., Lee, S. & Choi, S. Detection of hydrogen gas leak using distributed temperature sensor in green hydrogen system. Int. J. Hydrog. Energy. 82, 910–922 (2024).

Yan, Z., Cui, X. & Gao, Y. Acoustic injection method based on weak echo signals for leak detection and localization in gas pipelines. Appl. Acoust. 211, 109577 (2023).

Zhao, L., Zhang, Q., Wang, Z. & Dai, J. A highly sensitive low-pressure TDLAS sensor for detecting dissolved CO and CO2 in transformer insulating oil. Opt. Laser Technol. 174, 110622 (2024).

Author information

Authors and Affiliations

Contributions

L. S.: Conceptualization, Methodology, Project Administration. T. Y.: Writing - Original Draft Preparation, Visualization, Visualization, Formal Analysis. C. H.: Validation, Writing - Review & Editing, Investigation. H. Z.: Resources, Supervision, Funding Acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Song, L., Yin, T., Han, C. et al. Leakage analysis and leakage monitoring system design for LNG tanker filling process. Sci Rep 14, 32152 (2024). https://doi.org/10.1038/s41598-024-84173-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-84173-x