Abstract

Scraper conveyor load prediction is crucial to realize the cooperative speed regulation of coal mining machine and scraper conveyor. In the synthesized mining face, due to the uncertainty of the coal fall, the load of the scraper conveyor fluctuates due to the change of the coal load, which shows a strong nonlinearity and non-smoothness, leading to the difficulty of prediction. To solve this problem, this paper proposes a BP neural network model combined with wavelet transform for scraper conveyor current prediction. By studying the mapping relationship between motor load and current based on the BP neural network algorithm, and taking the scraper conveyor current as the input condition, wavelet decomposition and data reconstruction of historical current data are carried out, and time series prediction is performed on the original data samples and reconstructed data samples, respectively. The simulation results show that the reconstructed BP neural network model using wavelet decomposition has higher prediction accuracy, in which the root mean square error is reduced by 13.26%, the average absolute error is reduced by 14.19%, and the percentage error is reduced by 17.43%. The model meets the accuracy requirements of scraper conveyor load prediction, and can provide theoretical basis for cooperative speed regulation of coal mining machine and scraper conveyor.

Similar content being viewed by others

Introduction

As the most economical and reliable resource of primary energy, coal is a key pillar for ensuring national energy security1. With the coal industry moving towards high-quality development, coal mine intelligentization technology has become the core support to achieve this goal. Among them, as one of the key technologies of coal mine intelligence, integrated mining intelligence is of great significance for enhancing the efficiency and safety of underground mining as well as realizing the less manned and unmanned working face2,3. Scraper conveyor as the key equipment of comprehensive mining working face, its load prediction technology is the basis for realizing the cooperative control of coal mining machine and scraper conveyor, which is the fundamental guarantee for realizing the efficient and safe production of coal mine4.

In recent years, scholars at home and abroad have carried out extensive research in the field of scraper conveyor load prediction and achieved a series of important results. Wang, W.B. et al.5 constructed a prediction model based on the load torque data of scraper conveyor using rough radial basis function neural network (RRBFNN), and realized accurate prediction under complex working conditions. Wang, Y.P. et al.6 proposed a speed regulation strategy based on load analysis, Wang, Y. et al.7 detected anomalies using the YOLO-BS algorithm and proposed a method for calculating the blockage rate, Xia, R. et al.8 monitored and controlled the chain tension and load condition from the relationship between scraper conveyor load and chain mechanics. Yan, X.D. et al.9used neural network to predict the load of scraper conveyor and regulate the speed of the scraper conveyor. Murphy, C.J10designed a new method to monitor the change of the load of scraper conveyor in real time. Hao, Y.Q11obtained sprocket engagement frequency information through sensors, used convolutional neural network to establish a prediction model, combined with fuzzy Proportional Integral Derivative(PID) regulation to achieve the optimization of transportation scheduling of the scraper conveyor to reduce energy consumption and wear. Wang, C.C12constructed a scraper conveyor load prediction model based on wavelet neural network to provide data support for coal mining machine speed regulation, and used Elman neural network to study the speed regulation strategy under different loads. Gao, L.L13synthesized the coal miner and conveyor current changes, combined with AI camera monitoring data, to realize the scraper conveyor load prediction and intelligent speed regulation; Meng, L14 analyzed the relationship between the gear mesh frequency of the gear reducer and the load, and predicted the load of the scraper conveyor based on convolutional neural network; Liu, H. et al.15 utilized convolutional neural network and fuzzy PID control technology to carry out the prediction of the equipment load and regulation and control; Li, L.R. et al.16designed a BP neural network model for load prediction; Wang J17 established a wavelet neural network model to accurately predict the scraper conveyor load, which significantly improved the prediction accuracy.

Although the above studies have made significant progress in the prediction of scraper conveyor loads, there are still some pressing issues that need to be addressed. The limitations of the existing method and the improvement of the proposed method are shown in Table 1.

To address the above problems, this study proposes a scraper conveyor load prediction method based on wavelet transform and BP neural network. Based on the multi-scale analysis capability of wavelet transform, the current data is decomposed in 4 layers by db3 wavelet, which can effectively separate low-frequency trend (reflecting load changes) and high-frequency noise (filtering out electrical interference), and compared with the traditional filtering methods, the wavelet transform has a significant advantage in retaining signal singularity (such as load mutation points). The key advantage of choosing BP neural network is its engineering practicality:

-

1)

Nonlinear mapping ability. BP neural network is able to capture the complex nonlinear relationship between the current signal and the load through the multilayer perceptron structure, and compared with methods such as Support Vector Machine (SVM), there is no need to manually design the features, and the multiscale features after wavelet decomposition can be directly input;

-

2)

Real-time advantage: BP neural network’s forward propagation and back propagation algorithms are mature and computationally efficient, which is suitable for real-time prediction of downhole embedded systems, while recurrent neural network (RNN) is difficult to deal with short-term sudden change signals due to the gradient vanishing problem;

-

3)

Feature inclusion: BP network can simultaneously input the time domain and frequency domain features of the current (e.g., approximate component and detail component after wavelet decomposition), which is more suitable for one-dimensional time series prediction needs compared with convolutional neural network (CNN) and avoids the loss of information in the conversion of two-dimensional images.

Compared with existing methods, the method in this paper achieves noise suppression and feature enhancement through wavelet transform, combined with the nonlinear modeling capability of BP neural network, which significantly improves the prediction accuracy while maintaining real-time performance. This study is of great significance for promoting the intelligent development of comprehensive mining face and realizing efficient and safe production in coal mines.

Methodology

Scraper conveyor load and current relationship analysis

Scraper conveyor is one of the key equipments in the comprehensive mining face. This study takes the SGZ1250/3600 scraper conveyor of a mine as the research object and analyzes the relationship between the load and current of the scraper conveyor. The main structure of this scraper conveyor is shown in Fig. 1.

SGZ1250/3600 type scraper conveyor is used in the working face of medium and thick coal seam mining and is powered by three phase asynchronous motor. The main parameters of the scraper conveyor are shown in Table 2.

Modeling the load-current relationship of a scraper conveyor

The loads of the scraper conveyor drive system can be divided into three categories: friction loads, inertia loads and transportation loads. The friction load mainly includes the load caused by the reverse electromagnetic force and bearing friction; the inertia load covers the transmission gear inertia, load inertia and motor inertia; and the transportation load is generated by the coal being transported.

-

1)

Motor torque analysis:

The electromagnetic torque equation of the motor is19:

where: Te is the electromagnetic torque of the motor, N·m; Jis the overall inertia of the drive system, kg·m2; ω is the rotational angular speed of the motor, rad/s; Tf is the frictional torque of the drive system, N·m; Tc transportation load torque, N·m.

Assuming that the motor runs at a constant speed and the motor inertia is neglected, dω/dt = 0. At this point, Eq. (1)can be expressed as:

According to Eq. (2), when the scraper conveyor is running smoothly, its electromagnetic torque mainly consists of load torque and friction torque. The load torque is generated by the coal-carrying flow of the conveyor, so it is a key factor in load prediction. Vectors such as current, magnetic chain and torque of an electric motor have an important influence on its system operation, and there is an intrinsic connection between the load torque and current of a scraper conveyor, so it must be analyzed in depth. Given that the AC asynchronous motor, as a high-order, multivariable system, has nonlinear and strongly coupled characteristics, multiple factors such as voltage, current, electromagnetic torque and magnetic chain need to be taken into account in the analysis.

-

2)

Stator magnetic field analysis.

Taking the stator magnetic field direction as a reference, its motor vector equivalent circuit is shown in Fig. 2.

According to Kirchhoff’s voltage law (KVL), with clockwise direction as positive, the following relation is obtained20:

where: Rs, is, Ψs, Lsl, us are the vector parameters of the motor stator, the units are Ω, A, Wb, and V; respectively.; Rr, Ψr, Lrl, ur are the vector parameters of the rotor converted to the stator side, the units are Ω, A, Wb, and V.

The voltage equation of AC asynchronous motor can be obtained from Eq. (3) and Eq. (4), as shown in Eq. (5).

where: usα, usβ, urα, urβ are the components of voltage on α-axis and β-axis; isα, isβ, irα, irβ are the components of current on α-axis and β-axis; Ls is the stator inductance; Lr is the rotor inductance; P is the differential operator.

The magnetic chain equation of the motor is shown in Eq. (6).

Due to the interaction of the motor current with the magnetic field generates the electromagnetic torque, this torque affects the interaction relationship between the stator and the rotor and generates the stator magnetic chain, the rotor magnetic chain and the excitation magnetic chain under its action. The electromagnetic torque of an asynchronous motor can be expressed by the fork product of the rotor current and stator current as shown in Eq. (7).

where: np is the number of motor pole pairs.

The relation (8) can be obtained from the magnetic chain Eq. (6):

Substituting Eq. (8) into Eq. (7) yields Eq. (9):

Substituting Eq. (9) into Eq. (1) yields Eq. (10):

From the above derivation, it can be seen that there is not a simple linear relationship between the load and the motor current of the scraper conveyor, and the fluctuation of the motor current can reflect the change of the load. Therefore, this paper chooses the motor current as the key characteristic parameter and adopts the time series prediction method to study the change of the scraper conveyor load.

Scraper conveyor current wavelet processing method

Wavelet analysis is an improvement on the shortcomings of the Fourier transform. The Fourier transform is widely used in the field of signal processing, but its main shortcoming is that it ignores time information, making the transform result unable to indicate the exact time when the signal occurred.

The wavelet transform, as a time-scale analysis method of signals, enables the multi-scale refinement of signals through stretching and translating operations21,22,23. which is shown in Eq. (11):

where: \(\tau\) is the shift factor; \(\alpha\) is the scale factor.

Wavelet transform is categorized into continuous wavelet transform and discrete wavelet transform. Since the time series of scraper conveyor motor current is discrete data, discrete wavelet transform (DWT) is applicable. With DWT, the scraper conveyor current signal can be decomposed into high-frequency (detail) and low-frequency (approximate) components. This decomposition process can be regarded as a process of filtering and convolution, in which the approximate component at the jth decomposition level is obtained by convolving the approximate coefficients at the j-1 th decomposition level with the coefficients of the low-pass filter24. There are many kinds of wavelet basis functions, such as haar wavelet, dbN wavelet, symN wavelet and so on. In this paper, when choosing the wavelet basis function, for the non-smooth characteristics of the scraper conveyor current data, this study selects dbN wavelet as the analysis basis function. dbN wavelet has a tight branching, and it can maintain good localization characteristics in the time and frequency domains, which can accurately capture the local mutations in the current signal, such as the current fluctuations when the load changes suddenly. Its vanishing moments increase with the increase of order N, which can effectively suppress the high-frequency noise and retain the key features to satisfy the demand for noise reduction of current data with more noise interference. Compared with wavelet bases such as biorNr.Nd and coifN, the dbN wavelet support length is shorter and the computational complexity is low, which can improve the computational efficiency and meet the requirements of real-time monitoring and analysis. In addition, the dbN wavelet order can be flexibly adjusted, and the appropriate N value can be selected according to the characteristics of the current data and the purpose of analysis to achieve the optimal analysis effect.

Wavelet decomposition of scraper conveyor current signal

The raw data used in this paper comes from the motor current data of SGZ1250/3600 scraper conveyor in a mine. The data acquisition process is as follows: In the underground production environment of a coal mine, the current data of the scraper conveyor is acquired in real time by installing a high-frequency data collector on the power supply switch. The programmable logic controller (PLC) in the control center of the scraper conveyor downstream channel interacts with the frequency converter through the Profibus-DP communication protocol, and the PLC sends control commands to the frequency converter and receives its feedback signals. The high-frequency collector uploads and stores the collected current data sequence to the computer terminal, thus completing the collection of scraper conveyor current data.

Based on the above characterization of dbN wavelet, dbN wavelet is finally selected as the ideal choice when wavelet decomposition is carried out in this paper. Considering that the differences in the effects presented by dbN wavelets of neighboring orders are not significant in practical applications, this study decides to adopt the db3 wavelet base after prudent consideration. It is mainly based on the following three reasons:

-

1)

Vanishing moments and noise reduction capability. Different wavelet bases have different numbers of vanishing moments. The more vanishing moments, the better the wavelet function can suppress the high-frequency noise in the signal and better retain the low-frequency trend in the approximated signal. For the scraper conveyor load current signal, db3 has three vanishing moments, which can better capture the main change characteristics of the load current while suppressing high-frequency noise. And as N increases (e.g., db4, db5, db6, db7), etc., although there are more vanishing moments and the noise reduction ability may be stronger, the signal may be overly smoothed in some cases and some useful detailed information is lost, resulting in the inability to accurately reflect the sudden changes of the load current.

-

2)

Tightness of wavelet bases. Wavelets with good tight support have shorter support intervals in the time domain and are able to maintain good localization properties in both the time and frequency domains. db3 has good tight support and is able to detect and analyze the local mutations in the load current signal effectively. In contrast, some other wavelet bases may have longer support intervals in the time domain, which is not conducive to the accurate capture of localized features of the signal.

-

3)

Computational complexity. The complexity of wavelet bases affects the computational efficiency. db3 is computationally simpler compared to other higher-order dbN wavelets (e.g., db4 - db7), as well as wavelet bases such as sym5 and coif3. For signals such as scraper conveyor load current, which need to be analyzed in real time or quickly, lower computational complexity can reduce the computation time and improve the analysis efficiency.

When making the selection of the number of wavelet decomposition layers, a four-layer wavelet decomposition was chosen for the following reasons:

-

1)

Feature extraction requirements. The 4-layer decomposition can decompose the scraper conveyor load current signal into subbands of different frequency ranges, which can correspond to different load features respectively. For example, the low-frequency approximation component can reflect the long-term trend of the load, while the high-frequency detail component can capture the short-term fluctuations and sudden changes of the load. In general, the subbands obtained by 4-layer decomposition can already cover the main characteristic information of the load current, and further increasing the number of decomposition layers may not bring more valuable features, but rather increase the complexity of the analysis.

-

2)

Computational resources and efficiency. Each additional layer of decomposition will significantly increase the computational amount. For large-scale load current data, too many decomposition layers will lead to long computation time and higher demands on computational resources. In practical applications, it is necessary to balance between the completeness of feature extraction and computational efficiency. 4-layer decomposition can meet the real-time requirements of practical engineering with a relatively small amount of computation under the premise of ensuring that enough features can be extracted.

-

3)

Data length and noise impact. The length of the scraper conveyor load current data is limited. As the number of decomposition layers increases, the length of each sub-band will gradually decrease, and when the number of decomposition layers is too high, the number of data points in the sub-band will become very small, which may lead to unstable statistical characteristics of the signal and be easily affected by noise.4 Layer decomposition strikes a better balance between the data length and the influence of noise, and can ensure the stability and reliability of the sub-band data.

Therefore, db3 wavelet is finally used in this study to decompose the time series in 4 layers, where a3 represents the low-frequency signals, and d1, d2 and d3 correspond to high-frequency signals at different scales, and the decomposition results are shown in Fig. 3.

Scraper conveyor load prediction model based on DWT-BP neural network

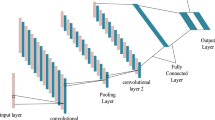

BP neural network structure

BP neural network is a multi-layer feed-forward neural network, whose main features include forward transmission of signals and back propagation of errors. In the forward propagation process, the signal goes from the input layer through the hidden layer and finally reaches the output layer; in the error back propagation process, the error propagates from the output layer to the hidden layer and then reaches the input layer, and the weights and biases from the hidden layer to the output layer and from the input layer to the hidden layer are adjusted in order to make the predicted output of the BP neural network gradually close to the expected output, the topology of the BP neural network is close to the expectation25, to make the predicted output of the BP neural network gradually close to the desired value, the topology of the BP neural network is shown in Fig. 4.

As can be seen from Fig. 4, the network is mainly composed of three parts: input layer, hidden layer and output layer. uN is the input value of the Nth neuron in the input layer; the hidden layer contains L neuron nodes, and θj denotes the threshold of the neuron in the hidden layer; yM is the output value of the Mth neuron in the output layer, and θk denotes the threshold of the neuron in the output layer. ωij denotes the connection weights between neuron in the input layer and neuron in the hidden layer; and ωjk denotes the connection weights between the connection weights between the hidden layer neurons and the output layer neurons.

DWT-BP neural network combined prediction models

Given that the noise in the electrical system of the scraper conveyor affects the accuracy of the scraper conveyor load current prediction, this paper introduces the wavelet decomposition and reconstruction method on the basis of the traditional BP prediction model. Through wavelet decomposition, the original data is decomposed into low-frequency and high-frequency components, where the high-frequency component corresponds to the detail component and the low-frequency component corresponds to the approximation component. Since the noise is mainly concentrated in the detail component, in this paper, the high-frequency component is denoised, while the low-frequency component is kept unchanged. The processed individual components are predicted separately and the predictions are summed up to obtain the final prediction. This method effectively solves the problem of noise in the signal, thus improving the accuracy of load prediction.

The DWT-BP neural network prediction process is shown in Fig. 5.

Modeling of DWT-BP scraper conveyor load current prediction

Based on MATLAB software, a DWT-BP neural network prediction model is established for the short-term current prediction problem of scraper conveyor asynchronous motor to carry out simulation experimental research. In the prediction method, this paper takes the historical current data as input, constructs and optimizes the neural network model by introducing a large number of training samples (including the original data before sequence decomposition and the data after decomposition and reconstruction), and then compares and analyzes the prediction accuracy under different data conditions. The specific load prediction steps are as follows:

-

1)

Sample data preprocessing. Data standardization processing, as a key preprocessing link in industrial equipment condition monitoring, is very important in scraper conveyor load current analysis. Due to the operation of scraper conveyor, its three-phase motor load current signal is affected by coal flow, operating resistance, voltage fluctuations and other factors, the raw data will have numerical differences or differences in the scale. Therefore, the mapminmax function is chosen to normalize the samples and normalize the data to the interval of [0, 1], which can effectively eliminate the magnitude difference of the data samples, improve the training efficiency, enhance the stability of the model and improve the generalization ability of the model. In addition, the method retains the original distribution characteristics of the data and is simple and efficient to realize through linear transformation, which is especially suitable for engineering signals with clear extreme value ranges such as scraper conveyor current data. Compared with Z-score normalization, it avoids the bias caused by data distribution assumptions (e.g., normal distribution) and does not require additional storage of mean and variance parameters, making it more suitable for model deployment and updating in downhole real-time monitoring scenarios.

-

2)

Data set division. A total of 1000 sets of data samples were selected for load prediction in this study. In constructing the dataset, based on the engineering consideration of the dynamic characteristics of the scraper conveyor load, the first 10 sets of currents were selected as inputs for predicting the 11 th current parameter, and so on to finalize the construction of the dataset. This time window can capture the short-term trend of current signals (e.g., periodic fluctuations during coal miner cutoff) and avoid the computational delay caused by too long a window, which is in line with the time constraints of real-time underground control.

Based on the proportion of typical engineering practice, the training set accounts for 70% and the test set accounts for 30% when dividing the dataset. While ensuring the generalization ability of the model, overfitting due to insufficient data volume is avoided. For 1000 sets of current data, the division can cover the complex working conditions of underground (such as different coal seam thicknesses and rock mixing), and also meet the basic needs of BP networks for sample size.

-

3)

Determination of network structure. According to the overview of the BP neural network in the previous section, it is determined that it is a three-layer neural network structure, and in accordance with the method of sample set division, it is determined that the input layer is 10 neuron nodes and the output layer is 1 neuron node. Based on the nonlinear mapping theory, a single intermediate layer structure can realize complex feature expression.

The number of neurons in the hidden layer is determined based on the empirical formula (shown in Eq. 12and the trial-and-error method. Too few neurons will lead to model underfitting (e.g., failing to capture the multi-scale features of current signals), while too many is prone to overfitting (e.g., amplifying noise interference). It is experimentally verified that 10 neurons strike a balance between model complexity and generalization ability, and can effectively extract current features (e.g., high-frequency mutation components) after wavelet decomposition.

where: m and n are the number of neurons in the output and input layers, respectively, \(a \in (1,10)\).

-

4)

Neural network training and parameter setting. Before the Matlab prediction simulation, the network parameters need to be set systematically to adapt the scraper conveyor current data characteristics. First of all, the hidden layer function is logsig, because its output range (0,1) is highly matched with the normalized data characteristics, which can effectively transfer the nonlinear mapping relationship and avoid the saturation of the activation value. Secondly, the output layer adopts the tansig function, whose (−1,1) output characteristics can meet the continuous numerical demand of load prediction, and can restore the real value through the inverse normalization, while retaining the sensitivity to small load changes. In order to meet the training requirements of non-smooth signals in downhole, traingdx is chosen as the training function, which combines the momentum factor and the adaptive learning rate adjustment strategy to effectively inhibit the gradient oscillations caused by noise and accelerate the convergence, and compared with the traditional traingd function, its dynamic adjustment of the learning rate is more adaptive to the training requirements of non-smooth load signals, which is in line with the fast response of real-time monitoring in downhole. The traingd function is more adaptive to the training needs of non-smooth load signals than the traditional traingd function, which is in line with the fast response requirements of real-time downhole monitoring. On this basis, the training number is set to 10,000 times, and the threshold is determined based on the trial training results to ensure that the model converges to the target error within reasonable iterations. In order to balance the control accuracy and computational resources, the target error is set to 0.00001, which avoids the control lag caused by too high an error and prevents the resource consumption caused by too low an error. Finally, the initial learning rate is set to 0.01, which is an empirical value to avoid parameter oscillations and ensure the update speed at the early stage of training, and combined with the adaptive mechanism of traingdx, the convergence process can be further optimized.

-

5)

Prediction and evaluation: the constructed neural network is utilized to predict the latter 30% of the collected data, the sim function is called to generate the prediction results, and the comparison graph between the predicted and actual values is plotted. At the same time, the comparison graph between the prediction of the data after wavelet transform and the prediction of BP neural network is plotted, and the average absolute percent error is calculated to evaluate the prediction accuracy.

Results

Simulation analysis and performance evaluation

In this study, the author constructed a neural network load prediction model, which was designed with 10 input nodes and 1 output node. The general idea is to use the first 10 data points to predict the 11 th data point, and keep iterating to construct the data set, which consists of 700 sets of training samples and 300 sets of test samples. A certain simulation training is shown in Fig. 6. During the training process, the model reaches the set target of 0.00001 in error value after 7 iterations, and the training process then ends.

During model training, the mean square error iteration curve is shown in Fig. 7. The number of iterations in the training process is related to the number of training samples, and the mean square error of the network gradually decreases when the number of iterations gradually increases. After 7 iterations, the mean square error value converges to the optimal level, and the model converges to the optimal when the number of iterations reaches 7, which indicates that the model has high operational efficiency and reduces the consumption of computational resources when solving the load prediction problem. The fast convergence performance is suitable for real-time load prediction in the synthesized mining face, which can meet the requirements of the scraper conveyor on the prediction time implementation. In the figure, training data is training data, validation data is validation data, and test data is test data. The comparison of the predicted current value curve with the actual value curve is shown in Fig. 8.

For the prediction of the sample data after wavelet decomposition, the same 1000 sets of samples were used, and the DWT-BP neural network was built for the prediction of each component sample after decomposition, respectively, and the current curves obtained from the prediction were compared with the actual values, and the results are shown in Figs. 9, 10, 11 and 12.

After completing the prediction of each component, the predicted values of each component are accumulated to obtain the reconstructed values. The reconstructed predicted value curves are compared with the actual value curves and the results are shown in Fig. 13.

Comparison of BP neural network prediction and DWT-BP neural network prediction results is shown in Fig. 13, from which it can be seen that the black dotted line is the actual value of the current, the blue dotted line is the predicted value of the DWT-BP neural network, and the red dotted line is the predicted value of the BP neural network. Through the analysis, it can be seen that both the BP neural network and DWT-BP neural network prediction curves maintain a high degree of synchronization with the trend of the actual working conditions, and the prediction trajectory of the DWT-BP neural network (blue dotted line) is closer to the curve of the actual current value, and its amplitude deviation is significantly lower than that of the prediction value of the BP neural network model, which indicates that the prediction error of the DWT-BP neural network load prediction model is smaller, better prediction performance.

The waterfall plot of amplitude prediction using BP neural network and DWT-BP neural network is shown in Fig. 13, where blue represents the predicted value of BP neural network, blue represents the predicted value of DWT-BP neural network, and green represents the actual current value, in order to analyze the accuracy of the prediction results and clearly evaluate the prediction results, this paper selects the prediction mean square error (RMSE, Root Mean Square Error), mean absolute error (MAE, Mean Absolute Error), Mean Absolute Error (MAE, Mean Absolute Percentage Error), and Mean Absolute Percentage Error (MAPE, Mean Absolute Percentage Error) were chosen as the evaluation criteria for the two prediction methods. The three reflect the overall prediction of the deviation status, the closer the three values converge to 0 the better the prediction. At the same time, the fit of the model is calculated, and the closer the fit is to 1, the better the fit is.

The calculation formula is shown in Eq. (13)-Eq. (16):

where:\({y_t}\)is the true value of the sample data;\({\hat {y}_t}\)is the predicted value output by the neural network prediction model; \(n\) is the number of samples.

After calculation, the evaluation indicators of the prediction results are shown in Table 3.

The RMSE, MAE, and MAPE of the BP neural network model are 0.5534, 0.4537, and 0.5491, respectively, and in comparison, the corresponding errors of the DWT-BP neural network prediction model are 0.4208, 0.3118, and 0.3748, respectively, and comparing the two sets of data, it can be seen that all the evaluation indexes of the DWT-BP neural network prediction model are better than the BP neural network model, in which the root mean square error is reduced by 13.26%, the average absolute error is reduced by 14.19%, and the percentage error is reduced by 17.43%. Through the analysis and discussion of the prediction model error, the prediction error of the DWT-BP neural network model is smaller, which indicates that the predicted value of the optimized model has a smaller deviation from the actual value.The DWT-BP model is able to fully reveal the changing law of the current in the load prediction model of the scraper conveyor. The DWT-BP model can fully reveal the change rule of current in the prediction model, and the load prediction accuracy is higher. The fitting degree of the two neural network models is 0.9311 and 0.9554 respectively, and the fitting degree is above 0.90, and the difference is not big, which indicates that the model fits better before and after wavelet transform, and the fitting effect is better, and there is no phenomenon of overfitting and underfitting.

Since this paper cannot quantitatively describe the influence of complex working conditions such as gangue and bottom plate flatness on the load current of scraper conveyor, the prediction may have a relative lag when the current changes abruptly. However, overall, the prediction results of the network can basically reflect the change trend of the scraper conveyor load current, and the prediction effect is good.

Conclusion

(1) In this study, the three-phase asynchronous motor-driven scraper conveyor is taken as the object of study, and the intrinsic correlation between the load and current of the conveyor is analyzed in depth, and the corresponding mathematical model is established;

(2) The db3 wavelet is used to decompose the original current signal in 4 layers, and its tight branching and vanishing moment properties are utilized to effectively separate the low-frequency trend from the high-frequency noise, which improves the integrity of the data in terms of retaining the load mutation characteristics as compared with the traditional filtering methods. Combined with the multilayer perceptron structure of BP neural network, the model is able to capture the complex nonlinear relationship between current signal and load;

(3) A scraper conveyor load prediction method based on wavelet transform and BP neural network is proposed. Under normal mining conditions, the model is more suitable for extracting the nonlinear information in the short-term load of the scraper conveyor, and the future load trend can be indirectly reflected by predicting the current value; the simulation results show that compared with the traditional BP neural network prediction method, the wavelet transform-based BP neural network prediction method shows higher prediction accuracy. Among them, the root mean square error is reduced by 13.26%, the average absolute error is reduced by 14.19%, and the percentage error is reduced by 17.43%. The method can effectively meet the accuracy of scraper conveyor load prediction;

(4) This study reveals the correlation between the multiscale characteristics of the scraper conveyor current signal and the load fluctuation, and the proposed joint prediction model is universal in the field of nonsmooth signal processing;

(5) Despite the milestones achieved in this study, the following limitations still exist: ①the robustness of the model to extreme working conditions (e.g., large gangue jam) needs to be further verified;②the occupancy of computational resources need to optimize the footprint of computing resources. Future research will combine edge computing technology to develop lightweight prediction models, while exploring multi-source data fusion (e.g., vibration signals, coal volume monitoring) to improve prediction accuracy.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Wang, G. F. et al. Research and practice of coal mine intelligentization (Primary Stage). Coal Sci. Technol. 47 (8), 1–36 (2019).

Wang, G. F. Discussion on the latest technological progress and problems of coal mine intelligentization. Coal Sci. Technol. 50 (1), 1–27 (2022).

Wang, G. F. & Zhang, D. S. Coal intelligent synthesis mining technology innovation practice and development prospect. J. China Univ. Min. Technol. 47 (3), 459–467 (2018).

Wang, G. F. et al. New progress of intelligent mining in coal mines. Coal Sci. Technol. 49 (1), 1–10 (2021).

Wang, W. B. et al. Research on speed control method of scraper conveyor based on load prediction and energy consumption optimization. Coal Sci. Technol. Preprint at (2025). https://link.cnki.net/urlid/11.2402.td.20250116.1411.002. 1–10.

Wang, Y. P. & Wang, S. Y. Coordinated speed planning strategy of scraper conveyor and Shearer based on scraper conveyor loads analysis. IOP Conf. Ser. Earth Environ. Sci. 267 (4), 42–44 (2019).

Wang, Y. et al. A big coal block alarm detection method for scraper conveyor based on YOLO-BS. Sensors 22 (23), 9052–9052 (2022).

Xia, R., Liang, C. & Wang, X. W. Study on dynamic characteristics of scraper conveyor under various scraper configurations. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 09544089231224903 (2024).

Yan, X. D. et al. Posture monitoring method of scraper conveyor based on adaptive extended kalman filter. In: 2022 International Conference on Sensing, Measurement & Data Analytics in the era of Artificial Intelligence (ICSMD). IEEE. 1–6 (2022).

Murphy, C. J. & Bliss, R. E. Method and apparatus for belt conveyor load tracking. US19930137846, (1993).

Hao, Y. Q. Operation control system of scraper conveyor based on load prediction. Energy Energy Conserv. 12, 163–165 (2024).

Wang, C. C. Upgrade of speed regulation control of shearers based on load prediction. Energy Energy Conserv. 12, 295–298 (2024).

Gao, L. L. Intelligent speed regulation of scraper conveyors based on load prediction. Energy Energy Conserv. 11, 103–105 (2024).

Meng, L. Research on load prediction and variable frequency speed regulation of scraper conveyor. Autom. Appl. 64 (13), 120–122 (2023).

Liu, H. et al. Design and application of speed control system of scraper conveyor based on load prediction. Energy Environ. Prot. 44 (10), 239–243 (2022).

Li, L. R., Ma, J. H. & Chang, J. F. Optimization research of frequency conversion system for scraper conveyor using BP neural network. Coal Technol. 41 (5), 187–189 (2022).

Wang, J. Research on load forecasting method of scraper conveyor. Coal Sci. Technol. 41 (1), 32–35 (2020).

Guo, G. et al. Load prediction method of scraper conveyor based on rough RBF neural network. Coal Eng. 56 (2), 138–145 (2024).

Cui, J. Z. Research on torque ripple suppression of double salient pole permanent magnet Motor. Ph.D. thesis, China University of Mining and Technology, (2023).

He, H. T. Research on cooperative control method of ming equipment based on coal flow measurement and scraper conveyor load prediction in fully mechanized mining face. Ph.D. thesis, Xi’an University of Science and Technology, (2022).

Farghaly, I. S. et al. Enhancing spectral efficiency using a new MIMO WPT - NOMA system based on wavelet packet transform and convolutional complex neural network. Phys. Commun. 69, 102617 (2025).

García, S. et al. A data-driven topology identification method for low - voltage distribution networks based on the wavelet transform. Electr. Power Syst. Res. 243, 111517 (2025).

Xia, H. J. et al. Capacitor parameter Estimation based on wavelet transform and Convolution neural network. IEEE T Power Electr. 39 (11), 14888–14897 (2024).

Yuan, Z. H. et al. Hierarchical characterization joint surface roughness coefficient of rock joint based on wavelet transform. J. Coal Sci. 47 (7), 2623–2642 (2022).

Wang, F. G. et al. Method and application of slope stability prediction based on GA-BP neural network. China Saf. Prod. Sci. Technol. 20 (6), 161–167 (2024).

Funding

Te funding was provided by Heilongjiang Province Leading Science and Technology Research Project (2021ZXJ02 A01)&Natural Science Foundation of Heilongjiang Province (LH2022E106).

Author information

Authors and Affiliations

Contributions

D.Z. is mainly responsible for the manuscript & apos’s creation of ideas, structure, establishment of theoretical models, analysis of results. J.Q. is mainly responsible for establishing theoretical models and simulation models, conducting simulation and writing manuscripts. W.W. is mainly responsible for the establishment of theoretical models, support for project funds, and language polishing of manuscripts. Y.Z and W.G. are mainly responsible for collecting on-site data and analyzing simulation data.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, D., Qin, J., Wu, W. et al. Research on scraper conveyor load prediction method based on wavelet transform and BP neural network. Sci Rep 15, 15367 (2025). https://doi.org/10.1038/s41598-025-00333-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-00333-7