Abstract

This study explores the potential of using waste tires to reinforce silty clay soils for various geotechnical applications. Direct shear tests were conducted to evaluate the cohesion and internal friction angle of the reinforced soil, while California Bearing Ratio (CBR) tests were performed to determine its load-bearing capacity. For the direct shear tests, two types of waste tire aggregates (0/3 mm and 0/6 mm) were added to the soil at different weight percentages: 10%, 20%, 30%, and 40%. In the CBR tests, the percentages used were 2.5%, 5%, 7.5%, 10%, and 12.5%. These tests aimed to assess the soil’s mechanical behavior by analysing changes in cohesion, friction angle, and CBR values-three critical factors for stability and strength. To simulate different compaction intensities, the mixtures were compacted with 11, 25, and 55 blows per layer. The results indicate that adding 40% recycled tire granules significantly improved the soil’s shear resistance, leading to an increase in both cohesion and internal friction angle. Additionally, substantial improvements in CBR values suggest enhanced load-bearing capacity, particularly with higher compaction energies. The study found that a tire content of 7.5% is optimal for maximising CBR values, confirming the effectiveness of tire reinforcement at this level. This research highlights the practicality of using recycled tires for soil reinforcement, demonstrating that while higher reinforcement percentages can be beneficial, their efficiency diminishes beyond a certain threshold. Utilising waste tires in geotechnical engineering not only enhances soil performance but also contributes to sustainable waste management.

Similar content being viewed by others

Introduction

An essential aspect of geotechnical engineering is still soil reinforcement. Enhancing the stability and load-bearing ability of soil structures is crucial for the safe and sustainable construction of infrastructure, including retaining walls, roadways, embankments, and foundations. This field plays a vital role in this process. The primary goal of soil reinforcement is to improve the soil’s mechanical characteristics, such as shear strength, compressibility, and durability. This enables the soil to handle a wider range of structural loads and mitigates issues such as slope instability and soil settlement. To achieve this, various reinforcement materials, such as recycled tires, natural fibers, and geosynthetics, are used. These materials interact with the soil matrix to enhance performance under a range of loads and environmental conditions.

The use of waste tires as a reinforcement material presents a promising solution due to its environmental benefits, cost-effectiveness, and potential to enhance soil mechanical properties1,2. Different types of soil, their density, and the shape of the particles in the soil, along with the waste tires used, can make soil reinforcement work better or worse3,4,5. Studies in the lab have shown that used tires play a big part in geotechnical uses such as stabilizing slopes, retaining wall construction, embankments, foundations, and road subgrades6,7. Several parts of these studies have looked at the shear strength of the soil4,8,9,10,11 and the stabilization of the soil12,13,14. Previous research has focused on the mechanical behavior of waste tire-reinforced soil systems under various loads15,16. These studies help determine the optimal quantity of waste tires required to improve specific physical or mechanical parameters and influence soil behavior in terms of deformation or displacement. Additionally, incorporating tire waste can reduce pavement thickness, thereby lowering project costs17,18.

This study examines the reinforcement of silty clay using backfill deposits mixed with waste tires of two sizes (0/3 mm and 0/6 mm) at various weight percentages. Shear box tests were performed to assess the soil’s friction angle and cohesion, with tire content ranging from 10 to 40% in both reinforced and unreinforced samples. Also, CBR tests were done by adding used tires to the soil at weights ranging from 2.5% to 12.5% and using different levels of compaction (11, 25, and 55 blows). The goal is to assess the effect of waste tire addition on silty clay’s CBR values and shear strength parameters.

Literature review

Shear strength parameter of reinforced soil

Numerous studies have documented the impact of the shear strength characteristics of soils reinforced with materials obtained from tires on soil performance. These investigations have been carried out in tremendous detail. Early studies demonstrated the potential of tire materials to improve soil strength and stability. For instance, Edil and Bosscher19 were among the first to investigate tire shreds’ potential for stabilizing soil, observing notable gains in compaction properties and shear strength. Their ground-breaking work laid the foundation for later studies in this field. In earlier research, Tatlisoz20 observed that sandy silt mixed with 20% tire chips demonstrated greater strength compared to a 10% tire chip mixture, attributed to higher friction angles and cohesion. This preliminary research demonstrated the beneficial effects of tire materials on soil reinforcement. In the early 2000s, Ozkul and Baykal21 showed that clays can improve their ductility, toughness, and resistance to tensile cracking by including short fibers. Tire buffings from tire retreads can be used as fiber reinforcement. The study aimed to investigate the compaction and shear strength properties of clay with tire buffing inclusions. The results showed that clay’s drained shear strength remained constant, but its undrained strength decreased slightly. Mokhtar and Chan22 examined the undrained shear strength of silty soil combined with tire chips and 5% cement under varying stress levels. Similarly, Akbulut et al.23 reported the highest increase in cohesion for cohesive soil with a 2% addition of 10 mm long rubber fibers. Costa et al.24 found that the maximum shear strength improvement occurred with a 40% inclusion of tire buffings. Kalkan25 assessed the cohesion and internal friction angle of clay enhanced with silica fume and rubber fibers using direct shear tests. The addition of silica fume improved both cohesion and friction angle, with the highest values achieved for a mixture containing 20% silica fume and 2% rubber fibers. Sellaf26 measured the cohesion and friction angle of Tizi Tuff and Fergoug sediments mixed with rubber fibers. Their results indicated a gradual decline in cohesion as the rubber fiber content increased in both soil types. Karabash and Cabalar27 examine the impact of tire crumbs and cement addition on Narli sand specimens. The results show that tire crumbs reduce Young’s modulus, deviatoric stress, and brittleness, whereas cement increases deviatoric stress and Young’s modulus. This method could economically and environmentally reduce tire disposal problems and be more beneficial for geotechnical applications, according to the study. The specimens were prepared at 35% relative density, cured overnight, and sheared. Lastly, Yadav and Tiwari28 examine the impact of end-of-life tires (ELT) on the mechanical properties of fine-grained soils. The study reviews existing research on the use of tire waste in various forms (granules, fibers, chips, ash) and their influence on Atterberg limits, compaction, shear strength, permeability, CBR, and other geotechnical parameters. The study concludes that integrating ELT into fine-grained soils has promising potential for civil engineering applications, particularly for road and railway embankments, but emphasizes the need for further in-depth studies to validate their large-scale use.

In an experimental investigation, Daud29 examined the mechanical characteristics and behavior of waste tire mixes with soils. The findings demonstrated that although soil-tire chip combinations respond similarly to pure soils, they are more compressible and need significant deformation to reach their maximum shear strength. A higher friction angle in sandy soil resulted in enhanced shear strength. In the11 study, tire crumbs are combined with varying proportions of sand, fine soil, and sand-fine soil. To prepare mixes, tire crumbs are added in weights of 10%, 20%, and 30%. The ideal water content and maximum unit weight are established. A direct shear test is used to determine mixes’ dilatancy behavior, shear modulus, and shear strength characteristics. Crumbs from tires raise the friction angle and decrease the soil’s unit weight. The ideal percentage of tire crumb is found in 20% of the soil. The effects of tire chips on the shear strength characteristics of high-friction sand are investigated by10. The sand-tire chip combination was mixed at several weight ratios. The standard Proctor test was used to assess the maximum dry density (MDD) and optimum moisture content (OMC) of various sand-tire chip combinations and sand. Sand and mixes of sand and tire chips were subjected to three distinct axial strains in a direct shear box test. Samples were prepared under both OMC and MDD conditions. When the proportion of tire chips reached 5%, cohesiveness dropped by 66.4% and the internal friction angle rose by 13.8%, according to the findings. After this, the internal friction angle dropped, and cohesiveness was marginally improved. They placed our results in the larger perspective of previous studies by pointing out that the kind of tire and the characteristics of the soil might affect tire rubber’s effectiveness.

California bearing ratio (CBR)

The California Bearing Ratio (CBR) is a crucial parameter for assessing the bearing capacity of soil structures, including earth dams, road embankments, and airport pavements. It also plays a key role in determining the required thickness of materials for road construction. The performance and longevity of pavements largely depend on the type and condition of the subgrade soil, which should ideally exhibit low compressibility, sufficient shear strength, efficient drainage, and minimal volume changes under varying weather conditions. Researchers have investigated the impact of incorporating different forms of waste rubber tires such as shreds, granules, fibers, chips, and ash on the CBR of weak or soft soils to enhance their engineering properties and improve pavement stability. Numerous studies have examined the effects of waste tire chips on soil CBR values. Ghazavi and Sakhi30 explored the impact of tire shred aspect ratios on CBR, finding optimal aspect ratios for different shred widths. Rao and Dutta31 found that CBR values increased with scrap tire content up to 5%, then decreased. Oikonomou and Mavridou32 noted that rubber granules (2 mm in size) in sandy-mud mixtures resulted in lower CBR values compared to sandy mud alone, indicating a need for further study. According to33, the maximum CBR and angle of friction values were achieved with 5–6% waste tire rubber chips by volume. Cosentino et al.34 observed that incorporating shredded rubber into the soil reduced the maximum dry density and increased the optimum moisture content, resulting in lower CBR values. Similarly, Hidalgo Signes et al.35 assessed the bearing capacity of sand-granulated rubber mixtures used as sub-ballast layers in new railway lines. Their findings indicated that increasing the content of granulated rubber led to a decrease in the CBR value.

References36,37,38 noted that adding more than 5% shredded rubber decreased CBR values. Sellaf et al.26 reported that intermediate-plasticity clays with up to 1.5% recycled tire fibers showed improved CBR values. Al-Neami2 developed a technique using waste tire chips to improve sandy soil, achieving a CBR value 1.6 times higher than that of pure sand. Narani et al.39 evaluated the effects of waste tire textile fibers (WTTF) on soil properties, noting changes in CBR with varying WTTF contents. Various studies have examined the effects of rubber waste in non-tropical clays. Al-Tabbaa and Aravinthan40 noted increased compressibility and decreased strength in clay mixed with tire shreds, while41 suggested cement addition to mitigate these effects. Edil and Bosscher19 found that compressibility was a critical factor in clay mixtures with tire chips. According to42, increased shear strength was observed up to a certain rubber concentration but decreased maximum dry unit weight with a higher rubber content. Meddah et al.43 explored shredded rubber tire aggregates in roller compacted concrete pavements. Zhang et al.44 discovered that when the amount of granular rubber was higher, the material moved more horizontally and hardened more after being loaded and unloaded many times. However, after repeated loading, compaction affected shear strength. Tabrizi et al.45 demonstrated that the friction angle at the tire strip-sand interface was higher than the internal friction angle of sand. Gao et al.46 investigated the optimal amount of waste tire rubber powder to enhance red clay strength, revealing improvements using triaxial tests and Duncan-Chang models. Recently, Araujo et al.47 looked at how fine lateritic soil mixed with tire-derived aggregates (TDAs) could be used for light-traffic roads. They discovered that the amount of displacement influenced shear strength. More recently, Ghazavi and Khosroshahi48 looked at how much weight circular footings could hold on sand-tire shred (STS) mixtures. They found that the best shred size and content were 2–10 cm and 10% by weight, respectively. Their research revealed that using two-layer STS mixes reinforced with geogrids significantly increased the bearing capacity. This backs up what other studies have found from direct shear and CBR tests. Most of the research examined the physical and mechanical properties of soil under various loads. The soil is mixed with waste tires. The size and amount of rubber in used tires have a big effect on the CBR value of rubber-soil mixtures. This shows how important these factors are for getting accurate results in reinforced soils.

A lot of research has been done on how to strengthen soils using materials from waste tires. The results show big improvements in both shear strength and CBR values, which are important for geotechnical uses. Research has demonstrated that tire-derived materials, such as chips and crumbs, enhance the internal friction angle and cohesiveness of various soils, with optimal results achieved at specific tire content percentages. Similarly, the inclusion of waste tires has a positive influence on CBR values, though the effectiveness depends on factors such as tire granule size, compaction energy, and content percentage. Building on these findings, our study investigates the impact of varying tire granule sizes and compaction energies on silty clay’s shear strength and CBR. We want to find the best conditions for using waste tires to improve the stability and load-bearing capacity of silty clay by doing shear box tests and CBR tests. This will help us come up with more long-lasting and effective ways to strengthen the soil.

Utilizing local backfill and recycled tires for the Batna penetration project

Our research is inspired by the Batna Penetration Project, which was created to link the East–West highway with the city of Batna in Algeria. The project starts at the Chelghoum Laïd highway exit and goes over the Wilaya of Batna. The backfill deposit utilized in the first part of this 22.2 km project is situated in geographic coordinates (N35˚43ˊ23.3˝, E006˚18ˊ25.6˝), which are only a few kilometers from the project’s starting point.

The backfill deposit’s location is depicted in Fig. 1, which provides a precise and comprehensive perspective of the physical site. This visual aid helps to better understand the deposit’s location in relation to the Batna Penetration Road Project. It provides critical geographic context that aids in understanding the backfill source’s proximity and strategic location, which is an important factor in the project’s design and implementation. The exact coordinates reinforce the logistical and practical considerations for using local materials in the project by ensuring an even more accurate identification of the location.

For the Batna Penetration Project’s basal levels, comparatively little earth was removed. These backfills greatly enhance the geotechnical qualities of the soils used in the project. Concurrently, there is a growing need for new tire recycling avenues throughout the world. Shredding is the most promising of the recycling techniques since it turns tires into chips, powder, or granules. Then, these components can be mixed with other materials like concrete, mortar, asphalt, and backfill, or they can be added to playground or athletic surfaces.

According to our proposed procedure, used tires are mixed with soil from the backfill deposit in predetermined ratios. This delivers significant cost reductions in addition to improving the soil’s mechanical and geotechnical qualities. This strategy ought to reassure interested parties about the Batna Penetration Project’s financial sustainability.

Materials and methods

Materials

Soil

The soil used in this study’s experimentation program was silty clay, classified as poorly graded, and was sourced from the backfill deposit in the Batna penetration project area in eastern Algeria. To determine the soil’s properties, a series of laboratory tests were conducted on the samples. Table 1 presents the physico-mechanical properties of the soil used in this study.

Each of these parameters is essential for characterising the physical and mechanical properties of soil in geotechnical engineering. The corresponding French standards (NF) ensure that the tests are performed according to recognised procedures, providing reliable and consistent results.

Waste tire

The waste tires used in this study were obtained from the industry and utilised as provided, without any modifications. We selected these waste tires because they offered several advantages:

-

Low cost and simple availability: The waste tires were supplied by the tire recycling company ELGAZALA, located in Ain Djasser, east Algeria, making them a readily available and cost-effective material for use in this study.

-

Granular classes: The waste tires were processed into two granular classes, 0/3 mm and 0/6 mm, as illustrated in Fig. 2, which were used in the experiments. This granulation allows for better mixing and interaction with the soil, potentially enhancing its mechanical properties.

Tables 2 and 3 provide a detailed overview of the chemical and mechanical properties of the tire sample, as provided by the Laboratory for Physicochemical Analysis of Materials (LACIP GROUP) in Ain M’lila, eastern Algeria. Table 3, in particular, presents essential data on the mechanical properties, offering a deeper understanding of the tire sample’s behavior in various applications, including soil reinforcement.

Silt clay-waste tire mixtures

By incorporating these waste tires, the study aims to explore sustainable and economical solutions for soil reinforcement, contributing to waste management and geotechnical engineering advancements. Figure 3 shows tested materials for soil, waste tires, and silt clay-waste tire mixtures.

This conditioning allowed for the avoidance of the often delicate preparation of waste tire pieces, ensuring relatively excellent homogeneity for the shear test and CBR test. These waste tires, made from natural and synthetic rubber, are classified as granulated waste tires.

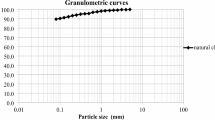

The soil and waste tire particle size distribution (PSD) curves are displayed in Fig. 4. According to GTR nomenclature (standard NF P 11 300), the soil used in this study is classified as A3 (silty clay).

The soil curve reflects the gradation of the soil by showing a variety of particle sizes. The waste tire curve displays peaks that represent the two granular classes, measuring 0/3 mm and 0/6 mm, respectively. Given that these PSD curves have an impact on compaction, strength, and stability, it is essential to comprehend how the materials behave in soil-reinforcing applications. By analysing these curves, geotechnical engineering projects can choose materials that will work better and be more sustainable.

Methods

Direct shear test procedure

In accordance with the French standard NF P94-071, 2 mm sieves were used to ensure soil uniformity and prepare unreinforced soil specimens for the direct shear test. The soil was moistened, thoroughly mixed, and compacted in layers within the shear box. The shear box was cleaned and lubricated to minimize friction between the soil and the apparatus walls. Once assembled, the shear box was subjected to a predefined normal load, applied gradually to simulate field conditions and facilitate specimen consolidation.

To ensure a homogeneous mixture at every stage, the waste tire and soil were meticulously mixed by hand. The experiments were conducted with various combinations of soil and aggregate. The compaction process was kept consistent with the shear box test protocol.

In this investigation, the percentages of granulated rubber in the two granular classes, 0/3 mm and 0/6 mm, were calculated by weight. Each batch’s weights of discarded tires and soil were determined and evenly blended. A testing program was implemented to examine how tire chips, when manually mixed at various percentages (10%, 20%, 30%, and 40%) by weight, affected the properties of silty clay. The proportionate weights of scrap tires and silty clay were specified before mixing to create various samples for use in the direct shear experiments.

Figure 5 illustrates the steps taken to prepare the soil samples reinforced with waste tires for a shear test. The preparation involves mixing soil with different percentages of waste tire granules (0/3 mm and 0/6 mm) to create a homogeneous mixture. The figure would show the process of ensuring uniform distribution of tire particles in the soil before compacting the mixture into the shear box for testing. This preparation is critical to achieving consistent and reliable test results on the reinforced soil’s shear strength parameters.

Sensors measured horizontal displacement and shear force during the test. The test was performed at a constant rate of horizontal displacement until the soil specimen failed. Data on shear force and horizontal displacement were used to determine the soil’s shear strength parameters, specifically cohesion (c) and internal friction angle (φ). The Mohr–Coulomb failure criteria were applied, as illustrated by the following equation

where τ is the shear stress at failure, σ is the normal stress, c is the cohesion, and φ is the internal friction angle. The Mohr–Coulomb failure envelope can be created by charting the shear stress against the normal stress for several tests at various normal loads. The envelope’s intercept on the shear stress axis determines the cohesion (c), while the envelope’s slope indicates the internal friction angle (φ).

For silty clay reinforced with old tires, a series of direct shear tests were conducted to investigate the effect of two granule sizes (0/3 mm and 0/6 mm). The results, shown in Fig. 6, demonstrate the shear strength of silty clay with a 40% waste tire content at both granule sizes. This figure presents a comparison of the shear strength outcomes for the two different granule sizes.

CBR test procedure

To identify and characterise this type of soil, we first conducted a series of laboratory experiments, including modified Proctor tests and CBR testing. Following the results of the CBR tests, we analysed and studied the reinforced soil. To do this, we performed repeatable CBR loading experiments on compacted soil using a 152 mm diameter and 117 mm height CBR mold, following the NF P 94-093 standard. The CBR test, which was done according to NF P 94-093, was used to find out how hard it was for the soil to be broken through at different levels of compaction energy. To find out how strong the tire mixtures made from silty clay were, they were loaded in stages using a standard circular penetration piston with a diameter of 50 mm that moved at a speed of 1.27 mm/min. A surcharge weight consisting of annular weights, each weighing 2.5 kg and with a diameter of 147 mm, was applied to the CBR mold after placing it in the position of the penetration plunger. Loads at 0.625, 1.25, 2, 2.5, 5-, 7.5, and 10-mm penetrations were recorded to establish the stress–strain curve of the silty clay soil.

Using Eqs. (2a) and (2b), we calculated the CBR value from the graph, corresponding to 2.5 mm and 5.0 mm penetrations. We took the maximum value, which can be expressed as follows:

The values of 13.35 kN and 19.93 kN represent, respectively, the forces that cause the piston to sink 2.5 mm and 5 mm on the conventional material of the reference. According to Eqs. (3), the index CBR sought is, by convention, the larger of these two values.

For the CBR tests, we prepared soil-fiber mixtures using waste tire mass percentages of 0%, 2.5%, 5%, 7.5%, 10%, and 12.5%. To ensure uniformity, the samples were moistened to 16% water content and thoroughly mixed. Special care was taken to ensure that the waste tires were randomly distributed within the silty clay mixtures before being placed into a steel CBR mold. We looked at how different levels of compaction (11 blows, 25 blows, and 55 blows) affected the silty clay-granulated waste tire mixtures by using CBR tests to show how reinforcement works. To ensure the reliability and repeatability of the procedure, some experiments were randomly repeated. Figure 7 illustrates the process of preparing the soil samples reinforced with waste tires for the CBR test, highlighting the steps taken to ensure proper sample preparation. The CBR test determines the soil’s bearing capacity and suitability for road construction and other load-bearing applications.

Experimental results and discussions

Shear strength improvement with waste tire reinforcement

In a series of direct shear tests, two different granule sizes (0/3 mm and 0/6 mm) and three different normal loads (100 kPa, 200 kPa, and 300 kPa) were used to determine the shear strength of silty clay mixed with old tires. The reinforcement content used for the tests was 10%, 20%, 30%, and 40%. Figures 8, 9, 10 summarize the findings and display the shear strength behavior for each normal stress level for both granule sizes.

The shear tests on silty clay mixed with tire granules show that the shear strength goes up as both the normal load and the number of granules used go up. Adding 10%, 20%, 30%, and 40% waste tire granules (0/3 mm and 0/6 mm) increased shear strength significantly. The biggest increases were seen at higher percentages for normal loads of 100 kPa, 200 kPa, and 300 kPa. This trend is consistent with the findings of10,21,29, who reported that 10% tire shreds increased shear strength by 30% in clayey soils. Additionally, Karabash and Cabalar27 and Balaban et al.11 support the idea that tire granules can effectively enhance the shear strength of various soil types. These results highlight the adaptability and effectiveness of tire-derived materials for soil reinforcement, showing that different soil types and granule sizes require varying percentages of tire granules. Specifically, adding 40% tire granules of 0/6 mm size to silty clay during direct shear tests makes the shear strength much higher. These findings align with previous studies, reinforcing the potential of used tires as a valuable reinforcement material to improve the mechanical properties of silty clay.

Shear and normal stress in soil reinforced with waste tires

The relationship between shear and normal stress for soil samples reinforced with different percentages of tire granules (0%, 10%, 20%, 30%, and 40%) is shown in Fig. 11. The study includes results for two granular class sizes (0/3 mm and 0/6 mm).

These graphs show how the relationship between shear stress and certain typical stress scenarios changes when tire grains are present. Tire particles are typically responsible for an increase in the soil’s shear strength. Shear stress increases with the rise in normal stress across the different cases studied. At a typical load of 100 kPa, the shear strength of soil lacking tire granules can increase up to 109.6 kPa when 10% tire granules (0/3 mm) are supplied. This demonstrates how important the tire particles are. With 20% tire granules (0–6 mm), the shear strength may only increase up to 101.2 kPa, showing a less noticeable improvement than with finer granules. According to the findings, the shear stress increment is higher when finer tire granules (0/3 mm) are added than when coarser ones (0/6 mm) are added. This occurs because the finer particles interact better with one another and have a larger surface area. For 0% tire granules, shear stresses can be roughly 43.9, 55.3, and 64.9 kPa; for 10% tire granules (0/3 mm), they can reach 109.6, 160.9, and 188.5 kPa; and for 20% tire granules (0/6 mm), they can be roughly 158.1 and 210.8 kPa for normal stresses of 200, and 300 kPa. Several studies support these findings. Bayat et al.9 and Özkul and Baykal21 found that adding shredded tire fibres to sandy soils increased their shear strength by 30–30%. Daud29 found that 30% tire granules worked best for sandy soils. Aksoy et al.10, Karabash and Cabalar27, Balaban et al.11 also found significant increases in shear strength in sandy soils. Additionally, Tajdini et al.49 investigated the shear strength of kaolinite clay mixed with crumb rubber (G30 and G80) through triaxial tests under consolidated drained (CD) and unconsolidated undrained (UU) conditions. Their results showed that incorporating 10% G30 crumb rubber reduced peak shear stress by approximately 78% in UU conditions compared to CD conditions, with a similar reduction observed for 5, 10, and 15% crumb rubber at confining stresses of 100, 200, and 300 kPa. Yadav et al.38 investigated the effects of waste rubber tire granules (Rg) and fibres (Rf) on the mechanical behavior of uncemented and cemented clay soil. Through unconfined compression and splitting tensile tests, the study found that while Rg and Rf reduced shear strength under tensile loads, they enhanced the ductility and strain-hardening behavior of cemented clayey soil. Additionally, the incorporation of Rg and Rf decreased the maximum dry unit weight and water content of the soil. The study recommends limiting the proportions of Rg and Rf to 5% and 7.5%, respectively, for applications in backfilling, embankment construction, and subgrade courses. These references reinforce the conclusions drawn from our experimental results, validating the beneficial impact of waste tire granules on soil shear strength.

Shear strength parameters of soil reinforced with waste tires

For every granule size, the cohesion (c) and internal friction angle (φ) of shear strength were ascertained. As shown in Fig. 12, the corresponding Mohr’s circles and strength envelopes represent the fluctuations in these parameters.

This figure illustrates the effect of different granular sizes (e.g., 0/3 mm vs. 0/6 mm) on shear strength parameters, specifically cohesion (c) and the angle of internal friction (φ). The findings indicate that smaller granular sizes, such as 0/3 mm, generally provide better shear strength compared to larger sizes like 0/6 mm due to their increased surface area and improved inter-particle interaction. For example, incorporating 0/3 mm tire granules into the soil can enhance cohesion from 20 to 48 kPa and increase the angle of internal friction from 12° to 20°. In contrast, with 0/6 mm tire granules, cohesion may only reach 34 kPa, and the angle of internal friction may peak at 33°. According to8, the effective friction angle of clayey soil shows a linear increase with the addition of crumb rubber. Recent studies by4 demonstrated that fine-grained sands reinforced with smaller rubber particles exhibited enhanced shear strength. With 10% tire granules, cohesion increased from 9 to 14 kPa, and the angle of internal friction rose from 29° to 34°. Bayat et al.9 observed similar improvements, with cohesion increasing from 10 to 14 kPa and friction angles increasing from 28° to 33°. The 0/3 mm granular size was found to be most effective for soil reinforcement due to its larger surface area, which facilitates better particle interlock and interaction. Therefore, finer granules (0/3 mm) are more effective at reinforcing soil compared to coarser granules (0/6 mm), as supported by both experimental data and existing literature.

Effect of compaction energy on penetration resistance

The examination of Figs. 13, 14, and 15 presents several significant conclusions about how granule size and compaction energy affect soil reinforcement. Researchers studying the effect of compaction energy on these soils say that the mechanical properties of soils that were strengthened with waste tire granules have gotten a lot better. Our results show that adding two different sizes of tire granules (0/3 mm and 0/6 mm) and pressing them down with 11, 25, and 55 blows makes the silty clay much stronger against penetration. The mechanical properties of the reinforced soil improve as compaction energy increases, confirming the crucial role of compaction in optimizing soil performance. To simulate real-world field conditions, we deliberately applied different compaction energies to assess their effect on the reinforced soil’s behavior. While standardized compaction tests, such as the Proctor test (NF P 94-093), define specific compaction energy levels, our methodology extends beyond these predefined conditions to explore a wider range of compaction scenarios. This method not only helps find the best conditions for compacting tire granulates, but it also provides useful information for civil engineering uses where the amount of energy needed for compacting depends on the tools and the needs of the project. However, we fully acknowledge the importance of standardized testing protocols. Therefore, our study makes sure the methods are sound by using Proctor compaction tests that are in line with NF P 94-093. This procedure makes sure that the results are valid and can be repeated. For example, the stress and penetration resistance are much higher in the presence of tire granules with a compaction energy of 11 blows (Fig. 13). At a compaction energy of 25 blows, this pattern persists and gets stronger (Fig. 14), with 0/3 mm granules performing better than 0/6 mm granules. At 55 blows, soil mixed with 0/3 mm tire granules had the best stress and penetration resistance (Fig. 15), which shows that finer granules work better. These results are consistent with earlier studies. For example, Bayat et al.9 looked at shredded tire fibers in sandy soils with different levels of compaction energy. They discovered that the cohesiveness increased from 10 to 14 kPa, and the internal friction angles increased from 28° to 33°. These comparisons show that shear strength and penetration resistance are greatly enhanced by increasing compaction energy, especially when using finer tire granules. Lastly, the most significant improvements in soil strength occur at the highest compaction energy (55 blows), underscoring the importance of adequate compaction to achieve optimal soil reinforcement. These findings highlight the effectiveness of using waste tire granules, especially finer ones, as reinforcement material for enhancing the structural integrity of silty clay soils. This approach not only improves soil mechanical performance but also contributes to sustainable waste management by repurposing waste tires, demonstrating the potential for integrating recycled materials into civil engineering applications.

Effects of waste tires on soil CBR values at different compaction energies

Figure 16 illustrates the variation in CBR values for 0/3 mm and 0/6 mm granule sizes as a function of compaction energy and the percentage of used tire granules. For 0/3 mm granules with a 7.5% tire content, the CBR values peak at 4.36% under high compaction energy, with lower values recorded under medium and low compaction energies. Conversely, for 0/6 mm granules at the same tire content, the CBR values are lower, ranging from 2.18% to 2.63% across different compaction energies. Additionally, Tafti and Emadi50 reported that sand-tire mixtures achieved CBR values between 30 and 34% under high compaction energy, demonstrating that tire granules can enhance the mechanical properties of soil. These findings support the hypothesis that incorporating used tire granules with appropriate compaction energy can significantly improve soil strength, offering a cost-effective and sustainable solution for various geotechnical applications.

Furthermore, Yadav51 conducted CBR tests following the Indian standard and observed a decrease in CBR values as rubber content increased, particularly for concentrations exceeding 5%. This reduction was attributed to the decline in maximum dry density and the increased compressibility of the mixture. In contrast, in your study, CBR tests were conducted according to the French standard, and the results showed an increase in CBR values with the addition of tire granules, reaching an optimal level at 7.5% rubber content. Specifically, for 0/3 mm granules, CBR values peaked at 4.36% under high compaction energy (55 blows), whereas lower values were observed for 0/6 mm granules. This suggests that both granular size and compaction energy play a critical role in improving CBR values an effect not as distinctly observed in Yadav’s study, likely due to differences in test standards and methodologies.

Conclusion

This research highlights the significant potential of using waste tire granules as a reinforcement material for silty clay in geotechnical applications. The chosen method included direct shear tests to check the cohesion and internal friction angle of the soil, as well as CBR tests to check how much weight the reinforced soil could hold. Two sizes of waste tire granules (0/3 mm and 0/6 mm) were incorporated into the soil at different percentages and compaction levels to assess their impact.

The obtained results demonstrate that the addition of waste tire granules significantly enhances the soil’s shear strength parameters, as evidenced by substantial increases in cohesion and internal friction angle:

-

With 0/3 mm granules, cohesion increased from 20 to 48 kPa, and the internal friction angle rose from 12° to 20°.

-

For 0/6 mm granules, cohesion reached 34 kPa, while the internal friction angle increased to 33°.

The analysis of shear stress also revealed notable improvements:

-

Adding 10% of 0/3 mm granules raised the shear stress from 43.9 kPa (unreinforced soil) to 109.6 kPa when the normal load was 100 kPa. The result is an increase of over 150%.

-

For a normal load of 300 kPa, the increase was even more pronounced, reaching 188.5 kPa with 10% of 0/3 mm granules.

Regarding bearing capacity, the CBR tests demonstrated that adding waste tire granules, combined with optimal compaction, significantly improves penetration resistance:

-

For 7.5% of 0/3 mm granules, CBR values peaked at 4.36% under high compaction energy (55 blows), while lower values were recorded for medium and low compaction energies.

-

In comparison, 0/6 mm granules resulted in slightly lower CBR values, ranging between 2.18% and 2.63%, depending on the applied compaction energy.

These results highlight the dual benefit of using waste tires: on one hand, they enhance the soil’s bearing capacity, and on the other hand, they contribute to reducing tire waste, offering a sustainable and environmentally friendly solution.

Despite these promising results, certain limitations must be considered for large-scale applications. The variability of tire granulates, influenced by their origin and processing method, can affect the performance of the reinforced soil, making standardisation necessary to ensure consistent quality. Additionally, integrating these materials in real-world conditions presents several challenges, particularly in terms of compaction techniques, mixing uniformity, and sensitivity to climatic conditions (rainfall, freeze–thaw cycles). Furthermore, environmental and regulatory considerations must be addressed, particularly regarding the potential leaching of chemical compounds and compliance with applicable construction standards, which may vary by region. To overcome these limitations, further research is needed to develop advanced numerical and experimental models capable of accurately simulating the behavior of reinforced soils under various conditions. Moreover, optimising the incorporation rate and granulometry of waste tires according to soil types and application contexts should be further explored to maximize their effectiveness.

In conclusion, using waste tires to reinforce compressible soils represents an innovative and effective solution from both geotechnical and environmental perspectives. This approach opens promising avenues for the development of sustainable and economically viable solutions in geotechnical engineering.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reason able request.

References

Belabdelouahab, F. & Trouzine, H. Research and enhancement of used tyres, such as material innovative in Algeria. Phys. Procedia 55, 68–74. https://doi.org/10.1016/j.phpro.2014.07.011 (2014).

Al-Neami, M. A. Stabilization of sandy soil using recycle waste tire chips. Int. J. Geomate 15(48), 175–180. https://doi.org/10.21660/2018.48.180228 (2018).

Marto, A., Latifi, N., Moradi, R., Oghabi, M. & Zolfeghari, S. Y. Shear properties of sand-tire chips mixtures. Electron. J. Geotech. Eng. 18(2), 325–334 (2013).

Anvari, S. M., Shooshpasha, I. & Kutanaei, S. S. Effect of granulated rubber on shear strength of fine-grained sand. J. Rock Mech. Geotech. Eng. 9(5), 936–944. https://doi.org/10.1016/j.jrmge.2017.03.008 (2017).

Saberian, M. et al. An experimental study on the shear behaviour of recycled concrete aggregate incorporating recycled tyre waste. Constr. Build. Mater. 264, 120266. https://doi.org/10.1016/j.conbuildmat.2020.120266 (2020).

Ramirez, G. G. & Casagrande, M. D. Experimental study of granular rubber waste tire reinforced soil for geotechnical applications. Key Eng. Mater. 600, 585–596. https://doi.org/10.4028/www.scientific.net/KEM.600.585 (2014).

Hajiazizi, M., Mirnaghizadeh, M. H. & Nasiri, M. Experimental study of sand slopes reinforced by waste tires. Int. J. Min. Geo-Eng. 53(2), 183–191 (2019).

Signes, C. H. et al. Swelling potential reduction of spanish argillaceous marlstone facies tap soil through the addition of crumb rubber particles from scrap tyres. Appl. Clay Sci. 132, 768–773. https://doi.org/10.1016/j.clay.2016.07.027 (2016).

Bayat, O., Askarani, K. K. & Hajiannia, A. Effects of waste tire on the shear strength of sand. Int. J. Struct. Civ. Eng. Res. 8(4), 384. https://doi.org/10.18178/ijscer.8.4.384-389 (2019).

Aksoy, H. S., Taher, N. & Awlla, H. Shear strength parameters of sand-tire chips mixtures. Gümüşhane Üniversitesi Fen Bilimleri Dergisi 11(3), 713–720. https://doi.org/10.17714/gumusfenbil.865490 (2021).

Balaban, E., Smejda, A. & Onur, M. I. Influence of tire crumbs on mechanical properties of sand-fine soil mixtures. Geomech. Geoeng. 17(1), 64–79. https://doi.org/10.1080/17486025.2019.1688870 (2022).

Rahgozar, M. A. & Saberian, M. Geotechnical properties of peat soil stabilised with shredded waste tyre chips. Mires Peat 18, 3 (2016).

Yadav, J. S. & Tiwari, S. K. Assessment of geotechnical properties of uncemented/cemented clayey soil incorporated with waste crumb rubber. J. Mater. Eng. Struct. 4(1), 37–50 (2017).

Mhaya, A. M., Huseien, G. F., Abidin, A. & Ismail, M. Long-term mechanical and durable properties of waste tires rubber crumbs replaced GBFS modified concretes. Constr. Build. Mater. 256, 119505. https://doi.org/10.1016/j.conbuildmat.2020.119505 (2020).

Moghaddas, T. et al. Experimental and numerical investigation of footing behaviour on multi-layered rubber-reinforced soil. Eur. J. Environ. Civ. Eng. 23(1), 29–52. https://doi.org/10.1080/19648189.2016.1262288 (2019).

Mittal, R. K. & Gill, G. Sustainable application of waste tire chips and geogrid for improving load carrying capacity of granular soils. J. Clean. Prod. 200, 542–551. https://doi.org/10.1016/j.jclepro.2018.07.287 (2018).

Ramjiram Thakur, S., Naveen, B. P. & Tegar, J. P. Improvement in CBR value of soil reinforced with nonwoven geotextile sheets. Int. J. Geo-Eng. 12(1), 8. https://doi.org/10.1186/s40703-020-00138-9 (2021).

Guzman, I. L. & Payano, C. Jr. Use of repurposed whole textile for enhancement of pavement soils. Int. J. Geo-Eng. 14(1), 12. https://doi.org/10.1186/s40703-023-00190-1 (2023).

Edil, T. B. & Bosscher, P. J. Engineering properties of tire chips and soil mixtures. Geotech. Test. J. 17(4), 453–464. https://doi.org/10.1520/GTJ10306J (1994).

Tatlisoz, N., Benson, C. H. & Edil, T. B. Effect of fines on the mechanical properties of soil–tire chip mixtures. Testing soil mixed with waste or recycled materials. ASTM Int. 2(2), 40–47 (1997).

Özkul, Z. H. & Baykal, G. Shear strength of clay with rubber fiber inclusions. Geosynth. Int. 13(5), 173–180. https://doi.org/10.1680/gein.2006.13.5.173 (2006).

Mokhtar, M. B., & Chan, C. M. Effect of using cement admixed with rubber chips on the undrained shear strength of soft soil. In National seminar on civil engineering research. University Teknologi Malaysia. http://eprints.uthm.edu.my/4150/ (2007).

Akbulut, S., Arasan, S. & Kalkan, E. Modification of clayey soils using scrap tire rubber and synthetic fibers. Appl. Clay Sci. 38, 23–32. https://doi.org/10.1016/j.clay.2007.02.001 (2007).

Costa, Y. D., Franco, K. B., Jr, O. F. S., & Costa, C. L. Shear strength behaviour of tire derived aggregate—Lateritic soil mixtures. In Geotechnical conference Pan-Am CGS (2011).

Kalkan, E. Preparation of scrap tire rubber fiber-silica fume mixtures for modification of clayey soils. Appl. Clay Sci. 80, 117–125. https://doi.org/10.1016/j.clay.2013.06.014 (2013).

Sellaf, H., Trouzine, H., Hamhami, M. & Asroun, A. Geotechnical properties of rubber tires and sediments mixtures. Eng. Technol. Appl. Sci. Res. 4(2), 618–624 (2014).

Karabash, Z. & Cabalar, A. F. Effect of tire crumb and cement addition on triaxial shear behavior of sandy soils. Geomech. Eng. 8(1), 1–15. https://doi.org/10.12989/gae.2015.8.1.001 (2015).

Yadav, J. S. & Tiwari, S. K. The impact of end-of-life tires on the mechanical properties of fine-grained soil: A review. Environ. Dev. Sustain. 21, 485–568. https://doi.org/10.1007/s10668-017-0054-2 (2019).

Daud, K. A. Soil improvement using waste tire chips. Int. J. Civ. Eng. Technol. 9(8), 1338–1345 (2018).

Ghazavi, M. & Sakhi, M. A. Optimization of aspect ratio of waste tire shreds in sand-shred mixtures using CBR tests. Geotech. Test. J. 28(6), 564–569. https://doi.org/10.1520/GTJ12126 (2005).

Rao, G. V. & Dutta, R. K. Compressibility and strength behaviour of sand–tyre chip mixtures. Geotech. Geol. Eng. 24, 711–724. https://doi.org/10.1007/s10706-004-4006-x (2006).

Oikonomou, N. & Mavridou, S. The use of waste tyre rubber in civil engineering works. In Sustainability of construction materials (pp. 213–238). Woodhead Publishing. https://doi.org/10.1533/9781845695842.213 (2009).

Prasad, D. S. & Raju, G. V. Performance of waste tyre rubber on model flexible pavement. ARPN J. Eng. Appl. Sci. 4(6), 89–92 (2009).

Cosentino, P. J., Bleakley, A. M., Armstrong, A. T., Misilo, T. J. & Sajjadi, A. M. Ground tire rubber as a stabilizer for subgrade soils (No. BDK81 977–03). Florida. Departemnt of Transportation. Research Center (2014).

Signes, H. et al. Characterisation of an unbound granular mixture with waste tyre rubber for subballast layers. Mater. Struct. 48, 3847–3861. https://doi.org/10.1617/s11527-014-0443-z (2015).

Hambirao, G. S. & Rakaraddi, P. G. Soil stabilization using waste shredded rubber tyre chips. IOSR J. Mech. Civ. Eng. 11(1), 20–27. https://doi.org/10.9790/1684-11152027 (2014).

Cabalar, A. F., Karabash, Z. & Mustafa, W. S. Stabilising a clay using tyre buffings and lime. Road Mater. Pavement Des. 15(4), 872–891. https://doi.org/10.1080/14680629.2014.939697 (2014).

Yadav, J. S., Hussain, S. & Garg, A. Geotechnical properties of rubber reinforced cemented clayey soil. Transp. Infrastruct. Geotech. 6, 337–354 (2019).

Narani, S. S., Abbaspour, M., Hosseini, S. M. M., Aflaki, E. & Nejad, F. M. Sustainable reuse of waste tire textile fibers (WTTFs) as reinforcement materials for expansive soils: With a special focus on landfill liners/covers. J. Clean. Prod. 247, 119151. https://doi.org/10.1016/j.jclepro.2019.119151 (2020).

Al-Tabbaa, A. & Aravinthan, T. Natural clay-shredded tire mixtures as landfill barrier materials. Waste Manag. 18(1), 9–16. https://doi.org/10.1016/S0956-053X(98)00002-6 (1998).

Zhang, T., Cai, G., Liu, S. & Duan, W. Laboratory observation of engineering properties and deformation mechanisms of cemented rubber-sand mixtures. Constr. Build. Mater. 120, 514–523. https://doi.org/10.1016/j.conbuildmat.2016.05.123 (2016).

Cetin, H., Fener, M. & Gunaydin, O. Geotechnical properties of tire-cohesive clayey soil mixtures as a fill material. Eng. Geol. 88(1–2), 110–120. https://doi.org/10.1016/j.enggeo.2006.09.002 (2006).

Meddah, A., Beddar, M. & Bali, A. Use of shredded rubber tire aggregates for roller compacted concrete pavement. J. Clean. Prod. 72, 187–192. https://doi.org/10.1016/j.jclepro.2014.02.052 (2014).

Zhang, H. et al. Experimental study on the pullout behavior of scrap tire strips and their application as soil reinforcement. Constr. Build. Mater. 254, 119288. https://doi.org/10.1016/j.conbuildmat.2020.119288 (2020).

Tabrizi, M. K., Abrishami, S., Hosseininia, E. S., Sharifi, S. & Ghorbani, S. Experimental investigation on the behavior of fine-grained soils containing waste rubber tires under repeated and static loading using direct shear apparatus. Constr. Build. Mater. 223, 106–119. https://doi.org/10.1016/j.conbuildmat.2019.06.159 (2019).

Gao, M., Jin, X., Zhao, T., Li, H. & Zhou, L. Study on the strength mechanism of red clay improved by waste tire rubber powder. Case Stud. Constr. Mater. 17, e01416. https://doi.org/10.1016/j.cscm.2022.e01416 (2022).

Araujo, G. L. S., Moreno, J. A. S. & Zornberg, J. G. Shear behavior of mixtures involving tropical soils and tire shreds. Constr. Build. Mater. 276, 122061. https://doi.org/10.1016/j.conbuildmat.2020.122061 (2021).

Ghazavi, M. & Khosroshahi, E. Bearing capacity of circular footings on multi-layered sand-waste tire shreds reinforced with geogrids. J. Rock Mech. Geotech. Eng. 16(3), 1085–1094. https://doi.org/10.1016/j.jrmge.2023.04.026 (2024).

Tajdini, M., Nabizadeh, A., Taherkhani, H. & Zartaj, H. Effect of added waste rubber on the properties and failure mode of Kaolinite clay. Int. J. Civ. Eng. 15, 949–958. https://doi.org/10.1007/s40999-016-0057-7 (2017).

Tafti, M. F. & Emadi, M. Z. Impact of using recycled tire fibers on the mechanical properties of clayey and sandy soils. Electron. J. Geotech. Eng 21(21), 7113–7125 (2016).

Yadav, J. S. Feasibility study on utilisation of clay–waste tyre rubber mix as construction material. Proc. Inst. Civ. Eng. Constr. Mater 176(2), 49–61. https://doi.org/10.1680/jcoma.19.00114 (2023).

Author information

Authors and Affiliations

Contributions

Kamel Bezih: Conceived and designed the study, performed the experiments, analyzed the data and also wrote the main manuscript text . Mohamed Djenane: contributed to the development of the experimental methodology, assisted with data analysis, reviewed the manuscript, and prepared all figures and tables. Mohamed Laouche: provided guidance on the experimental design, contributed to the interpretation of the results, and reviewed the manuscript. Kamel Hebbache assisted with performing the experiments, and provided critical revisions to the manuscript. All authors reviewed and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Informed consent

The human participant appearing in this study provided written informed consent for the publication of their images in this open-access article. No personally identifiable information is included in any figures, tables, or text.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Bezih, K., Djenane, M., Laouche, M. et al. Experimental study of shear strength and CBR improvement of silty clay soil reinforced with waste tires. Sci Rep 15, 16494 (2025). https://doi.org/10.1038/s41598-025-00808-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-00808-7