Abstract

Fissured loess slopes along the railway in the Loess Plateau frequently suffer from disintegration disasters under the coupled effects of rainfall and train vibrations, causing soil collapse that covers tracks and severely threatens railway safety. To reveal the disaster mechanisms, this study conducted water-vibration coupled disintegration tests on fissured loess using the self-developed EDS-600 vibration disintegration apparatus, based on the measured dominant vibration frequencies (12–46 Hz) of the Lanzhou-Qinghai Railway. The influence patterns of vibration frequency (f) and fissure type (t) on disintegration rate (S), disintegration velocity (V), and disintegration velocity growth rate (\(\alpha_{f - t}\)) were systematically investigated, with scanning electron microscopy (SEM) employed to uncover microstructural evolution mechanisms. Results indicate that vibration frequency and fissure type significantly accelerate disintegration: V reaches its maximum at f = 20 Hz, and under the same frequency, V increases with the growth of fissure-water contact area. Under two fissures and f = 20 Hz, V increases by 225% compared to the without vibration and fissures scenario, with the \(\alpha_{f - t}\) value peaking at 137.23% and the synergistic effect index exceeding the single-factor superposition value by 45.99%. Microscopically, water-vibration coupling disrupts clay mineral cementation, reconstructs pore networks, and forms dominant seepage channels, leading to reduced interparticle bonding strength, heterogeneous water film distribution, and stress concentration, thereby inducing fractal propagation of secondary fissures and shortening moisture absorption and softening stages. Combined with unsaturated soil mechanics theory, the study reveals a cross-scale progressive failure mechanism involving simultaneous degradation of matric suction, cementation force, and macroscopic strength. A theoretical framework integrating vibration energy transfer, seepage migration, and structural damage is established, along with a quantitative relation linking vibration frequency, fissure parameters, and disintegration velocity. This provides multi-scale theoretical support for disaster prevention and control of railway slopes and foundations in loess regions.

Similar content being viewed by others

Introduction

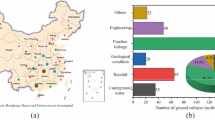

The railway serves as a vital artery of the national economy and is a key component of infrastructure, acting as the backbone of the integrated transportation system. However, during large-scale construction and operation of railways in the Loess Plateau, the coupling effects of multiple disaster-inducing factors—such as locomotive vibrations, intense rainfall and the fissured nature of loess—continually trigger loess disintegration disasters1. Owing to the characteristics of loess, including weak cohesion, high porosity, low strength and strong sensitivity to water and vibration, "long-duration, low-amplitude" locomotive vibration can result in the loosening and cracking of the loess2,3. Concurrently, the multiscale fissure networks within loess provide preferential pathways for rainfall infiltration, triggering intense particle detachment and disintegration through hydrodynamic erosion4,5,6. Water-vibration coupling not only promotes the expansion of primary fissures but also drives the initiation and coalescence of secondary cracks, compromising soil integrity and localizing seepage flows (Fig. 1). These processes exacerbate hydro-mechanical weakening, significantly elevating landslide and subsidence risks7,8,9 (Fig. 2). Representative cases include the 2009 Shitai High-Speed Railway incident, where fissure zone saturation induced "coupled hydro-vibrational collapse" leading to foundation subsidence (Fig. 2a); the 2015 progressive disintegration of a loess slope along the Lanzhou-Qinghai Railway’s eastern Xining section due to irrigation infiltration; and the 2020 Jingguang Railway fissure-controlled landslide (Fig. 2d, e), which resulted in 1 fatality and 123 injuries, underscoring the severity of multi-hazard cascades.

Development of fissures and disintegration disasters in railway slopes and foundations. (a) Damage to railway slopes: (I) development of fissures, formation of cavities and disintegration of loess; (II) expansion of micro-fissures; (III) disintegration of loess at fissure locations; (b) Dense vertical fissures in the foundation along the railway; (c) Merging and expansion of loess cavities; (d) Expansion and penetration of loess fissures.

Geological hazards induced by locomotive vibration, rainfall, and fissure development. (a) Settlement of the roadbed in a certain section along the Shitai Railway; (b) Landslide at the lower slope of Zuitou Village, Baotian section of the Longhai Railway; (c) Landslide in the mountainous section of the Hukun Railway; (d, e) Landslide in the Yonghua section of the Jingguang Railway; (f) Landslide in the Wanyan-Longbizui section of the Jiaoliu Railway; (g) Landslide along the Swiss Railway; (h) Collapse in the Ganluo section of the Chengkun Railway.

Existing studies have systematically revealed the disintegration mechanisms of soil from both intrinsic and extrinsic perspectives. Regarding intrinsic factors, research has confirmed the significant influence of geometric characteristics on disintegration processes, where curvature differences and surface morphology-induced "edge-removal effects" have been experimentally validated10,11. For the dynamic characteristics of loess disintegration, scholars have established a typical three-stage evolution model: immersion (formation of moisture gradients), softening (weakening of structural connections), and collapse (macroscopic instability), which follows a characteristic "S-shaped" curve12,13. Material parameter studies demonstrate significant correlations between initial moisture content13,14, dry density15, and disintegration velocity. At the micro-mechanistic level, carbonate cementation16,17 and clay-organic composite cementation18,19,20 effectively inhibit disintegration by enhancing interparticle bonding strength.

Extrinsic factor studies have uncovered multi-field coupling mechanisms. Chemically, pH reduction21,22,23 accelerates disintegration through mineral dissolution and cementation destruction. Physically, thermally induced stresses from temperature gradients24 and structural fatigue from wet-dry cycles25,26 have been identified as critical drivers. Hydraulically, capillary effects in preferential pathways21 and frost-heave pressures during freeze-thaw cycles27,28 collectively form dynamic destructive systems. Notably, the chemomechanical synergy from rainfall leaching29 exhibits distinct regional characteristics in loess plateau environments.

Microscopic mechanism research has established two classical theoretical frameworks: The pore-air pressure transient theory30,31 provides mathematical models for gas-liquid transport in non-expansive soils, revealing pore-pressure gradients as structural destabilization drivers32,33,34,35. For expansive mineral-containing soils, differential expansion theory36,37 explains particle separation through hydration-induced swelling stresses38,39. However, these theories exhibit limitations in explaining disintegration under prolonged dynamic disturbances.

The impact of dynamic disturbances on disintegration has gained attention in recent years: vibration compaction reduces loess disintegration40, while pre-disturbance accelerates softening41. Xu42 demonstrated 20 Hz vibration significantly enhances disintegration velocity but omitted frequency-response relationships. Although Wang et al.9 and Dang43 conducted multi-frequency experiments, they failed to quantify frequency-disintegration correlations. Lin et al.23 revealed synergistic vibration-chemical effects (20 Hz vibration with low-pH solutions) but provided insufficient mechanistic interpretation. Li et al.44 elucidated micro-scale mechanisms including pore reconstruction and cementation weakening but neglected strength attenuation during vibration. Field investigations along the Lanzhou-Qinghai Railway reveal frequent disintegration in fissured loess areas under combined train vibrations and seasonal rainfall, yet existing research lacks systematic analysis of frequency-dependent disintegration behavior and strength degradation mechanisms.

Therefore, this study innovatively developed the EDS-600 hydro-vibrational coupling apparatus to conduct long-term water-vibration coupling indoor disintegration experiments on fissured loess based on on-site vibration monitoring data from the Lanzhou-Qinghai Railway. By quantifying the effects of vibration frequency (f) and fissure type (t) on disintegration rate (S), disintegration velocity (V), and disintegration velocity growth rate (\(\alpha_{f - t}\)), the study comprehensively reveals the impact of train vibrations and fissure development on disintegration in terms of time progression, morphology, and efficiency. Combining scanning electron microscopy (SEM) technology, the microstructural evolution mechanisms of fissured loess before and after water-vibration interactions are revealed. Finally, the disintegration mechanisms of fissured loess under water-vibration coupling are thoroughly analyzed. The results provide a theoretical basis for disaster prevention and control in railway engineering in fissured loess regions.

Materials and methods

Sample preparation

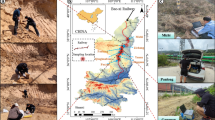

Vibration parameter monitoring and sample collection

This study conducted field investigations and vibration parameter monitoring at three representative sections along the Lanzhou-Qinghai Railway: Lanzhou, Haidong, and Xining (Fig. 3a–e). The tested soil specimens were collected from Q3 Malan loess in fissured zones along the railway corridor at Yongjing County, Gansu Province (102°57′E, 36°06′N) (Fig. 3f). Laboratory tests determined the physical properties and particle size distribution of the loess (Table 1), revealing a sand-dominated composition that enhances susceptibility to structural disintegration under vibrational loading. Fast Fourier Transform (FFT) analysis of vertical acceleration time histories obtained from field monitoring identified a primary vibration frequency band of 12–46 Hz for locomotive-induced excitations (Fig. 3g–j). The maximum vertical acceleration at sampling locations reached 0.06 g (Fig. 3k), with spectral energy density peaking at 30 Hz (Fig. 3l). Considering spatial heterogeneity in monitoring points and topographic influences45, the characteristic frequency range of (20 ± 5) Hz was selected, as it encompasses over 85% of the vibrational energy along the railway corridor, effectively representing regional dynamic characteristics.

Field monitoring and sample collection. (a) Schematic of the working layout of the Lanzhou–Qinghai line; (b) Lanzhou monitoring; (c) Haidong monitoring; (d, e) Xining monitoring; (f) Loess sample collection location; (g) Lanzhou Spectral diagram; (h) Haidong Spectral diagram; (i, j) Xining Spectral diagram; (k) Acceleration time course curve at the sampling location; (l) Spectral diagram.

Sample cutting

To address the challenges of sampling natural fissured intact loess in field conditions, this study employed a remolding method to prepare standardized specimens for simulating the disintegration behavior of natural fissured loess. Specimen preparation strictly followed the Standard for Geotechnical Testing Methods Standard (GB/T 50123 − 2019)46. The detailed procedure included: naturally air-dried field-collected loess was manually crushed and sieved through a 2 mm sieve to remove coarse particles. Distilled water was precisely measured according to Table 1 (natural moisture content: 16.9%) and uniformly sprayed to moisten the soil. The moistened soil was sealed and cured for 72 h (with manual mixing every 24 h to ensure moisture homogeneity) (Fig. 4a, b). Based on the natural dry density (1.55 g/cm³), the required soil mass was calculated and weighed. Specimens were compacted using a static pressing method (cutting ring dimensions: 61.8 mm diameter × 40 mm height) in two layers, with interlayer scarification to eliminate interface effects. The prepared specimens were sealed and cured for 24 h to ensure moisture uniformity (Fig. 4c).

To realistically simulate the disintegration characteristics of fissured loess and provide theoretical basis for related engineering applications, based on the field fissure geometric parameters (fissure lengths < 100 m, average width < 30 cm, varying depths)47, a single through-going fissures (50 mm length × 5 mm width × 15 mm depth) were precision-cut on specimen surfaces. Pre-marked fissure orientations were executed using ultra-fine wire saws to ensure morphological accuracy. Fissure volume ratio (excavated mass to total specimen mass) was controlled to maintain hydro-mechanical response equivalence with in-situ fissures48. Specimen design complied with geometric similarity criteria (diameter/height > 4× fissure spacing)49 to eliminate size effects. Four fissure configurations were prepared: inclined, horizontal, cross, and two fissures (Fig. 4d). Post-cutting specimens were stored in a constant temperature/humidity chamber for subsequent testing.

Testing methods

Disintegration tests

To address the limitations of conventional loess disintegration testing methods (e.g., buoyancy method and mass loss method), such as low accuracy, complex calibration, and significant human error, this study developed a high-precision vibration-disintegration test system based on the EDS-600 vibration platform (Hangzhou Cyber Mechanics Environmental Testing Co., Ltd., China) (Fig. 5). The system comprises a cubic transparent test chamber (inner diameter: 30 cm × height: 30 cm × wall thickness: 1 cm), an EDS-600 servo-controlled vibration platform, a specimen suspension assembly (2 mm aperture stainless steel mesh basket connected by Φ 0.5 mm stainless steel wires), an adjustable support frame (height: 120 cm), a miniature S-type tension load cell (range: 0–500 g, accuracy: 0.01 g, sampling interval: 1 s), and a 4 K high-definition camera. A constant water depth of 20 cm was maintained to enable visual monitoring of the disintegration process. The experimental design included 20 test groups combining vibration frequency gradients (0 Hz, 15 Hz, 20 Hz, and 25 Hz) and fissure types (no fissure, inclined fissure, horizontal fissure, cross fissures, and two fissures). Four interaction categories were established: T0 − 0 (without vibration fissures, control group), Tf−0 (pure vibration group), T0 − t (pure fissure group), and Tf−t (vibration-fissure coupling group), systematically analyzing multifactorial coupling effects. Each group underwent three repeated trials to ensure statistical reliability, with vibration parameters strictly matching field-monitored data (acceleration: 0.06 g).

The disintegration rate (S) and disintegration velocity (V) at any given moment are calculated as shown in Eqs. (1) and (2)12:

where \(M_{\max }\) is the maximum sensor reading (g); \(M_t\) is the sensor reading at time t (g); \(T_{\max }\) is the time corresponding to the maximum sensor reading (s); \(T_{\min }\) is the time corresponding to the minimum sensor reading (s); S is the disintegration rate of the soil sample at time t (%) and V is the disintegration velocity of the soil sample (%/s).

SEM test

Microstructural characterization of four loess specimen types—undisturbed loess (L0), vibration-treated loess (L1), hydraulically modified fissured loess (L2), and water-vibration coupled fissured loess (L3)—were performed using an FEI Quanta 400 FEG SEM. The L1 specimens were subjected to vibrational loading via an EDS-600 servo-controlled vibration platform (acceleration: 0.06 g, frequency: 20 Hz, duration: 24 h). For the L2 specimens, a micro-injection system was employed to deliver 1 mL of distilled water at 1 h intervals into pre-defined fissure nodes until saturation exceeded 95%. The L3 specimens underwent synchronized water-vibration coupling, with vibration timing and water injection processes kept consistent (Fig. 6a). All specimens were sectioned into 1 cm × 1 cm × 1 cm cubes, flash-frozen in liquid nitrogen, vacuum-dried, and gold-coated via ion sputtering, followed by electron microscopy scanning to obtain SEM images (Fig. 6b–e).

Results

Disintegration phenomenon of loess without vibration and fissures

Based on the disintegration stage theory proposed by Wang et al.12 and Li et al.50, combined with experimental observations, the loess disintegration process can be divided into three distinct stages (Fig. 7a): ① Absorption stage (0–50 s): During initial immersion, rapid water absorption occurred, accompanied by gas expulsion from pores. Minor powdery particle shedding was observed on the specimen surface, with negligible mass loss (Fig. 7a1). ② Softening stage (50–200 s): The water content near the immersion surface increased significantly, leading to soil softening. Continuous gas bubble release drove flaky particle detachment from the surface, accompanied by gradual water turbidity development (Fig. 7a2). ③ Collapse stage (200–580 s): Fissures initiated and propagated along the specimen periphery, resulting in blocky collapse (Fig. 7a3). Bubble frequency decreased sharply, while water turbidity intensified significantly. Disintegration velocity peaked during this phase before gradually stabilizing as the specimen disintegrated into residual fragments (Fig. 7a4).

Disintegration phenomenon of fissured loess under water–vibration coupling effect

As shown in Fig. 7, distinct disintegration patterns were observed across experimental groups: ① Pure vibration group (Fig. 7b): Vibrational loading accelerated pore gas-liquid migration, significantly enhancing the water absorption velocity during the absorption stage compared to the control group. The accelerated bubble release velocity triggered granular detachment of soil particles, while the duration of the softening stage was shortened (Fig. 7b1). At 50 s, large-area flake detachment was observed on the specimen periphery, with residual bubble release indicating incomplete water saturation (Fig. 7b2). As immersion and vibration continued, fissures propagated from the periphery to the interior of the specimen by 200 s (Fig. 7b3), ultimately leading to large-volume collapse along the fissures and rapid disintegration until completion (Fig. 7b4). ② Pure fissure group (Fig. 7c): Prefabricated fissures formed preferential seepage channels, causing rapid water saturation upon immersion. Intense bubble release along fissures induced powdered detachment around the fissures (Fig. 7c1). By 50 s, secondary fissures extended along the primary fissures, triggering flaky and blocky collapse at the specimen edges and fissure overhangs. The disintegration progressed inward, rapidly increasing water turbidity (Fig. 7c2). After 200 s, secondary fissures continuously developed, expanded, and interconnected, forming a multi-level fissure network that ultimately fragmented the specimen into small blocks, with subsequent disintegration behavior consistent with the control group (Fig. 7c3, c4). ③ Vibration-fissure coupling group (Fig. 7d): The synergistic effects of vibration and fissures significantly increased water absorption and bubble release velocities, compressing the absorption and softening stages. By 10 s, flaky and blocky collapse occurred at the specimen edges and fissures, accompanied by initial water turbidity (Fig. 7d1). At 50 s, fissure widths expanded to twice the initial values, with micro-fissures initiating and propagating (Fig. 7d2). By 200 s, collapsed debris accumulated along fissures and rapidly disintegrated until termination (Fig. 7d3, d4).

Effects of water–vibration coupling on the disintegration of fissured loess

As shown in Fig. 8a–e, the S-t curves of loess disintegration exhibit significant variations under different vibration frequencies (f) and fissure types (t). The control group (0 Hz, 0 fissures) displays a typical triphasic "S"-shaped curve, whereas single-factor conditions (Tf−0/T0 − t) induce dramatic morphological changes (Fig. 8a–b): the durations of the AB segment (absorption stage) and CD segment (slow collapse stage) shorten significantly, with average disintegration velocities increasing. The prolonged BC segment (rapid collapse stage) indicates accelerated structural destabilization. Under vibration-fissures coupling (Fig. 8c–e), low-frequency vibration (15 Hz) retains the triphasic pattern but shortens both AB and BC durations. High-frequency vibration (25 Hz) further reduces AB and CD durations while increasing the BC segment slope, corresponding to faster disintegration velocities. Notably, under 20 Hz coupling conditions (Fig. 8d), the S-t curve transitions to a quasi-linear pattern, with near-complete elimination of AB and CD segments, signifying immediate entry into rapid disintegration. This effect intensifies with increased fissure-water contact area. Mechanistically, this phenomenon arises from: (1) resonance effects at 20 Hz—matching the loess’s natural frequency (~ 20 Hz)51—which amplify cementation fatigue damage velocities; (2) fissure-induced increases in specific surface area21, enhancing capillary infiltration and gas-liquid phase interactions. These dual mechanisms synergistically elevate pore gas pressure and degrade matrix suction and cementation forces, collectively driving kinetic regime transitions.

The three-dimensional response surface (\(f - t - V\)) constructed from experimental data (Table 2; Fig. 8f) reveals a ridge-like gradient topology. Key points include: baseline point A (0 Hz, 0 fissures, 0.139%/s), representing intrinsic resistance; disintegration velocity (V) progressively increases at point B (20 Hz, 0 fissures, 0.224%/s) and fissure-modified points C (20 Hz, inclined, 0.272%/s), D (20 Hz, horizontal, 0.258%/s), and E (20 Hz, cross, 0.309%/s); with the global maximum at point F (20 Hz, two fissures, 0.313%/s), marking a 125% enhancement over baseline. Surface gradient analysis confirms that the vibration-fissure coupling gradients dominate over single-factor gradients, demonstrating synergistic amplification that surpassing additive effects. This behavior correlates directly with vibration-induced fissure-tip stress concentration and hydraulic permeability enhancement.

Microscopic structural changes of fissured loess under water–vibration coupling effect

Figure 9a illustrates the intact loess L0 with a characteristic honeycomb pore network, where overhead pores and macropores are developed between skeletal particles (Fig. 9a1). Clay particles are discretely distributed as punctate attachments on silt particle surfaces, while coarser clay particles primarily aggregate at particle contact points and pore throats (Fig. 9a2). In the vibration-treated L1 specimen (Fig. 9b), vibrational loading induces structural collapse of overhead pores (Fig. 9b1). Differential inertial motion among particles of varying masses triggers fracture of clay-cemented bridges at contact points, leading to clay particle loosening and detachment. This significantly reduces interparticle bonding strength and promotes microcrack initiation52 (Fig. 9b2). For the hydrated fissured L2 specimen (Fig. 9c), water infiltration induces hydro-collapsible deformation, resulting in reconfigured pore networks dominated by debris-filled collapsed macropores and a predominance of meso-, micro-, and nanopores (Fig. 9c1). Clay mineral dissolution reduces cementation contact points, with liberated clay particles forming colloidal suspensions within pores (Fig. 9c2). Figure 9d L3 specimen reveals the synergistic evolution mechanism of microstructure under hydro-vibrational coupling. The synchronously applied vibrational loading and hydraulic infiltration collaboratively regulate structural changes through dynamic interactions: The vibrational energy continuously acts on the fissure zone, inducing preferential collapse of overhead pores and breakage of cementation bridges between particles, while the formation of new microcracks further expands water infiltration channels44 (Fig. 9d1). Simultaneously, the needle-injected water rapidly migrates along the vibration-extended fissure network, accelerating clay mineral dissolution and cementation weakening. The colloidal suspensions generated by hydration fill the pores, and through the accumulation of pore water pressure and particle lubrication effects, they weaken soil stiffness, further amplifying the transmission efficiency of vibrational energy and exacerbating soil degradation (Fig. 9d2). The coupling effects manifest as vibration-enhanced water penetration into deeper fissures and hydration-induced structural destabilization via mineral dissolution and particle lubrication. Ultimately, this leads to redistribution of free clay particles within pores, forming discontinuous flocculated cementation morphology accompanied by extensive microcracks. These findings demonstrate that hydro-vibrational coupling establishes a self-reinforcing damage pathway through real-time synergy between mechanical destruction and chemical erosion, rather than simple superposition of individual effects. This mechanism provides novel micro-scale insights into the progressive destabilization of cemented structures under dynamic disturbances.

Discussion

Synergistic effect of locomotive vibration and fissures structure on loess disintegration

To effectively analyse the impact of the coupled effects on disintegration, the equation (Eq. (3)) for disintegration velocity growth rate (\(\alpha_{f - t}\))23 is referenced in Table 2.

where f is the vibration frequency (Hz); t is the type of fissure in the soil sample; \(\alpha_{f - t}\) is the disintegration velocity growth rate (%); \(V_{f - t}\) is the disintegration velocity (%/s) and \(V_0\) is the disintegration velocity of the control group (0 Hz, 0 fissures) (%/s).

Based on the loess disintegration velocity growth rate data listed in Table 2, a dual-component column chart was employed to quantify the synergistic effects between fissure types (t) and vibration frequencies (f). In each group of column charts, the left side represents the arithmetic superposition value of pure fissure effect (\(\alpha_{f - 0}\)) and pure vibration condition (\(\alpha_{0 - t}\)), while the right side displays the measured disintegration velocity growth rate (\(\alpha_{f - t}\)) under coupled conditions. A synergistic effect was confirmed when \(\alpha_{f - t} > \alpha_{f - 0} + \alpha_{0 - t}\)53. As shown in Fig. 10, all coupled conditions exhibited significantly higher \(\alpha_{f - t}\) values than the independent factor superposition values, demonstrating consistent patterns: under identical vibration frequencies, \(\alpha_{f - t}\) increased with fissure area expansion; for the same fissure type, the 20 Hz vibration frequency produced the most notable synergistic enhancement (reaching 45.99% in the two fissures case). This trend aligns with the accelerated disintegration curves observed in experiments, where the two fissures and 20 Hz combination achieved a peak \(\alpha_{f - t}\) value of 137.23%, indicating that the coupling of fissure hydraulic conductivity and vibrational energy input intensifies the disintegration dynamics.

Analysis of the disintegration mechanism of fissured loess under water–vibration coupling effect

The disintegration mechanism of loess can be attributed to a two-stage dynamic evolution under water-vibration coupling54 (Fig. 11). During the unsaturated infiltration phase, differential water infiltration through multi-scale pores induces dynamic interplay between pore air pressure (\(u_a\)) and pore water pressure (\(u_w\)): gas compression in closed pores elevates \(u_a\), while capillary-driven heterogeneity in \(u_w\) distribution creates localized matric suction gradients (\(s = u_a - u_w\)). At this stage, the soil follows Bishop’s effective stress theory (Eq. (4)):

Where σ is the total stress and Ψ denotes the effective stress coefficient, governed by pore connectivity and wettability hysteresis. The synergistic effects of pore air pressure buildup and pore water pressure redistribution induce tensile stress concentration at particle contacts, triggering microcrack initiation.

As the soil approaches saturation, cementation dissolution dominates the failure process. Lattice expansion of clay minerals (kaolinite, illite, montmorillonite) and dissolution of soluble salts (e.g., carbonates) collectively weaken interparticle bonding, destabilizing the contact force chain network55. When the effective stress attenuates to \(\sigma^{\prime} < 0\), tensile stress concentration at macropores and microcrack tips initiates chain-like crack propagation. Ultimately, the synergistic effects of pore gas expulsion and cementation dissolution lead to progressive stratified disintegration.

As shown in Fig. 12, the water-vibration coupling effects drive the dynamic evolution characteristics of loess disintegration through multi-physical field synergies. During the initial saturation stage, vibrational loading induces the breakage of cementation bridges and propagation of microcracks in fissured zones via particle inertia differences, forming preferential seepage channels (Fig. 12b). The vibrational energy enhances water kinetic energy43, promoting rapid water migration along vibration-expanded fissure networks while significantly accelerating clay mineral dissolution and weakening cementation strength. During this process, rapid bubble escape along fissure channels leads to preferential flaky or blocky detachment of fissure openings and surface soil56 (Fig. 12d–I). Alternating effects of bubble escape and pore compression cause drastic fluctuations in pore air pressure \(u_a\), while continuous accumulation of pore water pressure \(u_w\) results in marked attenuation of matric suction s (Fig. 12c). When fissures become fully water-saturated, the loss of cementation strength triggers a nonlinear collapse of effective stress σʹ, transitioning the system into the collapse stage. At this stage, pore water pressure \(u_w\) dominates soil behavior, and the interconnection of primary and secondary fissures induces block disintegration (Fig. 12d-II). Microscopic observations reveal that after complete detachment of fine particles from coarse grains, vibration-driven particle rotation and slippage reshape the pore structure into a binary system comprising macropores and enclosed micropores57. The enlarged total pore surface area exacerbates the heterogeneity of water film distribution, amplifying localized stress concentration effects and ultimately triggering fractal propagation of secondary fissures along dominant seepage channels, leading to progressive collapse44(Fig. 12e).

Schematic diagram of disintegration mechanism of fissured loess under water-vibration coupling effect. (a) General mechanisms of loess disintegration; (b) The effect of locomotive vibration; (c) The effect of fissures development; (d) Water-vibration coupling fissured loess disintegration phenomenon: (I) Saturation stage: More bubbles overflow; (II) Collapse stage: Microcracks development; (e) Mechanisms of fissured loess disintegration under water-vibration coupling effect.

Mechanism of strength degradation in fissured loess under water-vibration coupling effect

Based on the analysis of the disintegration mechanisms in fissured loess, the water-vibration coupling effects induce staged degradation of soil strength through multiphysical interactions. Water preferentially infiltrates unsaturated zones along fissure surfaces, leading to the attenuation of matric suction s, while vibrational loads generate alternating tensile-shear stresses that intensify stress concentration at fissure tips. This coupling mechanism creates synergistic damage effects termed the "water wedge effect" and "vibration-induced fatigue", collectively promoting the propagation of microcrack networks within fissured zones. Vibration-induced particle displacement enhances water infiltration through two pathways: (1) Tensile stress concentration at fissure tips increases fissure apertures, thereby accelerating infiltration rates; (2) Particle migration disrupts the original pore structure, forming preferential seepage channels that expedite water migration into deeper regions. Concurrently, water infiltration weakens soil stiffness by dissolving cementing minerals and lubricating particle interfaces, further amplifying the transmission efficiency of vibrational energy. These processes ultimately trigger collapse along weak structural planes. Integrating loess fracture mechanics theory, the disintegration process follows the progressive failure law of the Mohr-Coulomb criterion, with point B marking the critical transition in failure modes. The stress at this point, defined as crack closure stress \(\sigma_B\)58, corresponds to stress components \(\sigma_{1B}\) and \(\sigma_{3B}\), Building on the Griffith-Mohr combined criterion59, the fracture strength of loess is formulated as (Eq. 5):

where \(\sigma_{tf}\) is Tensile strength of loess; \(\sigma_c\) is Uniaxial compressive strength of loess.

During the initial stage (prior to point B), the loess undergoes meso-scale tensile fracture dominated by fissure initiation and propagation. The strength characteristics are primarily governed by the tensile strength \(\sigma_{tf}\). According to the Griffith-Mohr combined criterion, tensile fracture occurs when the minimum principal stress satisfies \(\sigma_3 < - \sigma_{tf}\) under vertical fracture inclination (\(\theta = 0{^{\circ}}\)). In this stage, locomotive vibration accelerates fissure propagation through two pathways: ① Enhanced tensile stress concentration at fissure tips; ② Significant reduction in soil cohesion, matric suction, and tensile strength60, with amplified vibration effects under increasing moisture infiltration44,60 (Fig. 13).

When the stress state exceeds critical point B (crack closure stress \(\sigma_B\)), interconnected fissure networks form, shifting the failure mode from tensile fracture to macroscopic shear fracture. Subsequent strength degradation is predominantly characterized by the deterioration of shear strength parameters, reflecting the transition from localized tensile damage to bulk shear failure. According to the double stress variable theory, the shear strength of soil comprises three components61: effective cohesion, net normal stress and the shear strength induced by matric suction, which can be expressed as follows (Eq. 6):

where \(\varphi^{\prime}\) is the effective friction angle; c′ is the effective cohesion; σ is the normal stress; \(u_a\) is the pore air pressure; \(u_w\) is the pore water pressure and \(\varphi^b\) is the suction friction angle.

The water-vibration coupling effects weaken soil strength through three synergistic pathways: During the initial stage, transient pore-air pressure \(u_a\) surge reduces net normal stress \((\sigma - u_a )\). In the intermediate stage, matric suction \((u_a - u_w )\) undergoes rapid attenuation with increasing moisture content, while further \(u_a\) elevation exacerbates net normal stress reduction. The final stage is marked by structural disintegration of cementation bonds, triggering a sharp decline in effective cohesion cʹ. These progressive degradation mechanisms collectively shift the strength envelope downward, ultimately inducing shear-sliding instability. This triphasic process systematically links pore pressure dynamics, suction evolution, and cementation degradation under coupled hydro-mechanical loading.

The evolution process of loess disintegration hazards in fissure-dense zones under water-vibration coupling follows a progressive damage process (Fig. 14): First, the water-vibration coupling weakens the matrix suction in fissured zones through the "water wedge effect" and "vibration-induced fatigue" mechanisms. The tensile stress generated by vibration induces stress concentration at the fissure tips, promoting the initiation of microcracks in weakly cemented areas. Over time, the pore water pressure and gas pressure gradually increase, accumulating hydraulic fracturing potential. The network of microcracks continuously expands, significantly reducing the soil’s tensile strength, with local tensile failure becoming dominant. As the connectivity of the fissure network increases, the failure mechanism gradually shifts from tensile-dominated to shear-dominated modes, with effective cohesion rapidly decreasing and interconnected shear slip surfaces forming. Finally, strain localization in shear bands triggers progressive collapse along dominant seepage paths, severely reducing the structural integrity of the soil. This leads to differential settlement and slope instability, posing a severe threat to the smoothness of the track and the operational safety of railways.

The study confirms that the hydro-vibrational coupling forms a self-reinforcing damage pathway through real-time interactions between mechanical destruction (pore reconstruction, particle migration) and chemical erosion (mineral dissolution, cementation weakening). Vibration-induced fissures propagation accelerates seepage, while seepage-weakened structural stiffness reciprocally exacerbates vibration-induced damage. Cementation degradation further modulates energy distribution. This multi-field coupling mechanism not only validates the suction-strength coupling mechanism in unsaturated soil mechanics61 but also provides new experimental evidence for the progressive instability mechanisms of fissured loess under dynamic disturbances.

Mitigation strategies for disintegration of fissured loess under water-Vibration coupling effect

To address the disintegration and degradation of fissured loess under water-vibration coupling effect, comprehensive mitigation strategies integrating material modification, structural optimization, and ecological protection are proposed. Material modification methods include traditional cementitious materials such as lime, cement, and fly ash, which enhance soil structural stability through ion exchange and cementation62,63. Microbially Induced Calcium Carbonate Precipitation (MICP) and Enzyme Induced Calcium Carbonate Precipitation (EICP) both utilize biomineralization to generate calcium carbonate cementation, filling fissures and inhibiting their propagation64,65, a method validated in field-scale slope stabilization under rainfall conditions66,67. Sisal fibers and other reinforcement materials form three-dimensional networks to suppress vibration-induced fissures propagation, improving tensile strength and resistance to disintegration68,69. Structural optimization involves constructing a drainage-vibration damping system with gravel blind ditches and geogrid layers to regulate pore water pressure accumulation and disperse vibrational energy70, coupled with a real-time warning system based on hydro-vibrational coupling models that uses sudden changes in pore water pressure and increments in fissure fractal dimensions as predictive indicators. Ecological protection strategies include synergistic bio-mechanical reinforcement through plant root systems combined with MICP71,72, and the use of CN01C superhydrophobic emulsion and other environmentally friendly materials to block water infiltration along fissures through surface hydrophobic modification under rainfall conditions73. For railway engineering, the "MICP + Drainage System" combined scheme is recommended, as it inhibits fissures propagation through bio-cementation while regulating hydro-vibrational coupling paths via drainage structures, ensuring both dynamic load resistance and long-term stability.

Conclusion

This study systematically investigated the vibration propagation patterns along the Lanzhou-Qinghai Railway and the disintegration mechanisms of fissured loess under water-vibration coupling through field monitoring and laboratory experiments. The main conclusions are as follows:

-

1.

Locomotive vibration characteristics: Monitoring data indicate that the dominant vibration frequencies along the Lanzhou-Qinghai Railway range from 12 to 46 Hz. These frequency characteristics are jointly controlled by multiple factors including train speed, loading conditions, and propagation distance.

-

2.

Disintegration dynamics: The water-vibration coupling demonstrates three distinctive effects on fissured loess disintegration: ① The moisture absorption and softening stages duration is significantly reduced compared to the condition without vibration or fissures; ② Under 20 Hz vibration with two fissures, the disintegration curve transitions from an "S" shape to a linear pattern, with disintegration velocity increasing to 225% of the condition without vibration or fissures; ③ The peak disintegration velocity growth rate \(\alpha_{f - t}\) reaches 137.23% under 20 Hz vibration with two fissures, with a synergistic effect index exceeding single-factor superposition values by 45.99%, confirming the coupling enhancement between vibration energy and fissure-induced water transport channels.

-

3.

Micro–macro cross-scale correlation mechanism: SEM analysis demonstrates that water-vibration coupling induces clay mineral cementation failure, pore network reconstruction, and preferential seepage pathway formation. Microstructural evolution governs macroscopic behavior through three key pathways: ① Cementation failure directly weakens interparticle bonding strength, leading to tensile/shear strength reduction and secondary crack initiation; ② Pore structure heterogeneity exacerbates water film distribution non-uniformity, accelerating localized stress concentration and fractal crack propagation; ③ Preferential seepage pathways significantly enhance moisture migration efficiency, shortening the duration of moisture absorption and softening stages.

-

4.

Engineering failure mechanism: Based on unsaturated soil multifield coupling theory, the accelerated pore water infiltration and gas expulsion collectively reduce matrix suction and enhance cement dissolution. This leads to effective stress reduction and simultaneous deterioration of tensile strength and shear strength, rationally explaining the progressive failure patterns along fissure zones in railway slopes.

This study systematically reveals the multi-scale disintegration mechanisms of fractured loess under water-vibration coupling, establishing a coupled theoretical framework encompassing vibrational energy transfer, fluid migration, and structural damage. It clarifies quantitative relationships between vibration frequency, fissure parameters, and disintegration velocities, providing theoretical support for railway slope disaster prevention in loess regions. However, quantitative correlations between microstructural parameters and macroscopic behavior, long-term vibration-induced cumulative damage effects, and coupled environmental factors (temperature, wet-dry cycles) require further investigation. Future work necessitates integrating in-situ monitoring with multiscale numerical simulations to develop a comprehensive predictive model incorporating microstructural evolution, seepage-mechanics coupling, and environmental disturbances, thereby enhancing disaster prevention precision under complex geological conditions.

Data availability

The datasets used or analyzed during the current study available from the corresponding author on reasonable request.

References

Wang, J., Xu, Y., Zhang, D. & Gu, T. Vibration-induced acceleration of infiltration in loess. Sci. China Earth Sci. 64, 611–630. https://doi.org/10.1007/s11430-020-9741-x (2021).

Salehi, A., Pircheraghi, G. & Foudazi, R. Pore structure evolution during sintering of HDPE particles. Polymer 183, 121865–121865. https://doi.org/10.1016/j.polymer.2019.121865 (2019).

Xu, J., Li, Y., Wang, B., Wang, Z. & Wang, S. Microstructure and permeability of bentonite-modified loess after wetting–drying cycles. Int. J. Geomech. 23, 04023052. https://doi.org/10.1061/IJGNAI.GMENG-7726 (2023).

Derbyshire, E., Dijkstra, T. A., Smalley, I. J. & Li, Y. Failure mechanisms in loess and the effects of moisture content changes on remoulded strength. Quatern Int. 24, 5–15. https://doi.org/10.1016/10406182(94)90032-9 (1994).

Wang, N. & Wei, J. Experimental study on disintegration rate of LiShi loess in GuanZhong region of ShannXi pronvince. Eng. Geol. 23, 954–958. https://doi.org/10.13544/j.cnki.jeg.2015.05.019 (2015).

Xu, L., Coop, M. R., Zhang, M. & Wang, G. The mechanics of a saturated silty loess and implications for landslides. Eng. Geol. 236, 29–42. https://doi.org/10.1016/j.enggeo.2017.02.021 (2018).

Pécsi, M. Loess is not just the accumulation of dust. Quatern Int. 7, 1–21. https://doi.org/10.1016/10406182(90)90034-2 (1990).

Peng, J. et al. Distribution and genetic types of loess landslides in China. J. Asian Earth Sci. 170, 329–350. https://doi.org/10.1016/j.jseaes.2018.11.015 (2019).

Wang, X. et al. Formation mechanism of a disaster chain in loess plateau: A case study of the Pucheng County disaster chain on August 10, 2023, in Shaanxi Province, China. Eng. Geol. 331, 107463. https://doi.org/10.1016/j.enggeo.2024.107463 (2024).

Li, X., Wang, L., Yan, Y., Hong, B. & Li, L. Experimental study on the disintegration of loess in the loess plateau of China. Bull. Eng. Geol. Environ. 78, 4907–4918. https://doi.org/10.1007/s10064-018-01434-6 (2019).

Liu, X., Zhang, X., Kong, L., Wang, G. & Lu, J. Disintegration of granite residual soils with varying degrees of weathering. Eng. Geol. 305, 106723. https://doi.org/10.1016/j.enggeo.2022.106723 (2022).

Wang, J., Gu, T., Zhang, M., Xu, Y. & Kong, J. Experimental study of loess disintegration characteristics. Earth Surf. Process. Landf. 44, 1317–1329. https://doi.org/10.1002/esp.4575 (2019).

Li, X. & Yan, Y. On the kinetics of loess disintegration. Chem. Asian J. 23, 3291–3292 (2011). https://www.researchgate.net/publication/298042108

Zhang, Z., Vadim, P., Svetlana, N., Zhang, Z. & Wu, J. Disintegration characteristics of a cryolithogenic clay loam with different water content: Moscow covering loam (prQIII), case study. Eng. Geol. 258, 105159. https://doi.org/10.1016/j.enggeo.2019.105159 (2019).

Wang, N., Wang, Q., Xue, Q. & Liu, X. Experimental study of static disintegration on unsaturated soil. Appl. Mech. Mater. 580, 68–72 (2014). http://dx.doi.org/10.4028/www.scientific.net/AMM.580-583.68

Sadisun, A. I., Shimada, H., Ichinose, M. & Matsui, K. Study on the physical disintegration characteristics of Subang claystone subjected to a modified slaking index test. Geotech. Geol. Eng. 23, 199–218. https://doi.org/10.1007/s10706-003-6112-6 (2005).

Graber, E. R., Fine, P. & Levy, G. J. Soil stabilization in semiarid and arid land agriculture. J. Mater. Civil. Eng. 18, 190–205. (2006).

Kemper, W. D., Rosenau, R. C. & Dexter, A. R. Cohesion development in disrupted soils as affected by clay and organic matter content and temperature. Soil. Sci. Soc. Am. J. 51, 860–867. https://doi.org/10.2136/sssaj1987.03615995005100040004x (1987).

Goebel, M. O., Bachmann, J., Woche, S. K. & Fischer, W. R. Soil wettability, aggregate stability, and the decomposition of soil organic matter. Geoderma 128, 80–93. https://doi.org/10.1016/j.geoderma.2004.12.016 (2005).

Lado, M., Ben-Hur, M. & Shainberg, I. Soil wetting and texture effects on aggregate stability, seal formation, and erosion. Soil. Sci. Soc. Am. J. 68, 1992–1999. https://doi.org/10.2136/sssaj2004.1992 (2004).

Gu, T., Yuan, L., Hu, W., Zhu, L. & Wang, J. Experimental research on disintegration of the Heifangtai loess. Hydrogeol. Eng. Geol. 44, 62–70. https://doi.org/10.16030/j.cnki.issn.1000-3665.2017.04.10 (2017).

Su, X., Tang, H., Huang, L., Shen, P. & Xia, D. The role of pH in red-stratum mudstone disintegration in the three Gorges reservoir area, China, and the associated micromechanisms. Eng. Geol. 279, 105873. https://doi.org/10.1016/j.enggeo.2020.105873 (2020).

Lin, H., Wang, J. & Xu, Y. Synergistic effects and mechanism of locomotive vibration and chemical dissolution on loess disintegration. J. Soil. Sediment. 22, 3106–3118. https://doi.org/10.1007/s11368-022-03302-z (2022).

Gao, W., Xu, L., Zhang, Z., Xiao, T. & Xie, B. Research on influencing factors of red sandstone disintegration during drying-wetting cycles. J. Eng. Geol. 31, 1597–1604. https://doi.org/10.13544/j.cnki.jeg.2021-0198 (2023).

Sun, Y., Liu, Q., Xu, H., Wang, Y. & Tang, L. Influences of different modifiers on the disintegration of improved granite residual soil under wet and dry cycles. Int. J. Min. Sci. Technol. 32, 831–845. https://doi.org/10.1016/j.ijmst.2022.05.003 (2022a).

Selen, L., Panthi, K. K. & Vistnes, G. An analysis on the slaking and disintegration extent of weak rock mass of the water tunnels for hydropower project using modified slake durability test. Bull. Eng. Geol. Environ. 79, 1919–1937. https://doi.org/10.1007/s10064-019-01656-2 (2020).

Wang, L. et al. The effects of freeze-thaw cycles at different initial soil water contents on soil erodibility in Chinese Mollisol region. Catena 193, 104615. https://doi.org/10.1016/j.catena.2020.104615 (2020).

Kong, F. et al. Disintegration characteristics of sodic–saline loessial soil after freeze–thaw and wet–dry cycles. Earth Surf. Process. Landf. 49, 2229–2244. https://doi.org/10.1002/esp.5826 (2024).

Huo, B. et al. Experimental study on the disintegration characteristics of undisturbed loess under rainfall-induced leaching. Catena 233, 107482. https://doi.org/10.1016/j.catena.2023.107482 (2023).

Cernuda, C., Smith, R. M. & Vicente-Chandler, J. Influence of initial soil moisture condition on resistance of macroaggregates to slaking and to water-drop impact. Soil. Sci. 77, 19–28. https://doi.org/10.1097/00010694-195401000-00003 (1954).

Terzaghi, K. & Peck, R. B. Soil mechanics in engineering practice, 2nd edition. New York John Wiley & Sons. 52–65 (1967).

Grant, C. D. & Dexter, A. R. Generation of microcracks in molded soils by rapid wetting. Aust J. Soil. Res. 27, 169–182. https://doi.org/10.1071/SR9890169 (1989).

Zhang, S. & Tang, H. Experimental study of disintegration mechanism for unsaturated granite residual soil. Rock. Soil. Mech. 34, 1668–1674. https://doi.org/10.16285/j.rsm.2013.06.009 (2013).

Qi, Y., Guan, Y., Wang, L., Jiang, P. & Zhang, G. The influence of soil disintegration in water on slope instability and failure. Adv. Civ. Eng. 2020, 8898240. https://doi.org/10.1155/2020/8898240 (2020).

Zhang, P., Tao, K. & Yang, Z. Study on material composition and REE-host forms of ion-type RE deposits in South China. J. Rare Earth. 13, 37–41 (1995).

Tang, L., Xu, H., Liu, Q., Sun, Y. & Wu, Y. Experimental study on disintegration characteristics of improved granite residual soil. China J. Highw. 35, 75–87. https://doi.org/10.19721/j.cnki.1001-7372.2022.10.008 (2022).

Vaisberg, L. A. & Zarogatskii, L. P. Foundations of optimal mineral disintegration. J. Min. Sci. 39, 87–93. https://doi.org/10.1023/A:1025769429101 (2003).

Camacho, P., Déléris, S., Geaugey, V., Ginestet, P. & Etienne, P. A comparative study between mechanical, thermal and oxidative disintegration techniques of waste activated sludge. Water Sci. Technol. 46, 79–87. https://doi.org/10.2166/wst.2002.0295 (2002).

Bissonnais, L. Y. Aggregate stability and assessment of soil crustability and erodibility: I. Theory and methodology. Eur. J. Soil. Sci. 67, 11–21. https://doi.org/10.1111/j.1365-2389.1996.tb01843.x (2016).

Gao, C. et al. Disintegration characteristics of collapsible loess after vibration compaction. P I Civil Eng. Geotec. 176, 86–98. https://doi.org/10.1680/jgeen.20.00137 (2023).

Wu, N. A study on calving property and softening damage parameter of GRS. J. Hebei Inst. Archit. Sci. Technol. 3, 58–62 (2006).

Xu, Y. Study on the four vibration-induced effects of Loess under the effect of locomotive vibration——Promoting cracking, infiltration, disintegration and sliding under the effect of locomotive vibration. dissertation. Northwest University. (2021). https://doi.org/10.27405/d.cnki.gxbdu.2021.002220

Dang, T. Experimental study on the permeability, deformation and disintegration characteristics of remodeled loess under the effect of long-term vibration. dissertation. Xi’an University of Technology. (2023). https://doi.org/10.27398/d.cnki.gxalu.2023.000134

Li, S. et al. Promoting effect and microscopic mechanism of train-induced vibration on loess disintegration. Eng. Geol. 336, 107559. https://doi.org/10.1016/j.enggeo.2024.107559 (2024).

Han, K. et al. Initiation mechanism of shallow loess slope sliding under coupling effect of train vibration and rainfall. Soi L Dyn. Earthq. Eng. 179, 108556. https://doi.org/10.1016/j.soildyn.2024.108556 (2024).

Ministry of Housing and Urban-. Rural Development of the People’s Republic of China. Geotechnical Testing Methods Standard (GB/T 50123 – 2019). (China Planning, 2019).

Yang, Y. Characteristics of cracks in loess landslide and its influence on landslide disasterprone mode: A case study of loess landslide in Jingyang South Plateau. dissertation. Chang’an University. (2016).

Liu, K. Experimental study on triaxial creep properties of fractured Loess. dissertation. Northwest University. (2022). https://doi.org/10.27405/d.cnki.gxbdu.2022.001966

Shen, Z. & Chen, T. Breakage mechanics of geomaterial-structure types and load sharing. CJRME 23 (2004).

Li, X., Huang, R. & Peng, J. Experimental research on disintegration of loess. Chin. J. Rock. Mech. Eng. 28, 3207–3213 (2009).

Wang, J. High frequency hydraulic vibration pile hammer (no resonance construction method). CCES 166–172 (1998).

Yuan, Q., Huang, J. & Chen, M. Energy dissipation characteristics of crushable granules under dynamic excitations. Chin. J. Theor. Appl. Mech. 47, 252–259. https://doi.org/10.6052/0459-1879-14-145 (2015).

Haken, H. Synergetics Phys. Bull. 28, 412 (1977).

Ning, R. Experimental study on the characteristics of loess disintegration and interface effects. dissertation. Chang’an University. (2023). https://doi.org/10.26976/d.cnki.gchau.2023.002427

Sun, Y., Tang, L. & Xie, J. Relationship between disintegration characteristics and intergranular Suction in red soil. Sustainability 14, 14234–14234. https://doi.org/10.3390/su142114234 (2022b).

Jiang, X., Hou, T., Guo, S. & Chen, Y. Influence of cracks on loess collapse under heavy rainfall. Catena 223, 106959. https://doi.org/10.1016/j.catena.2023.106959 (2023).

Hu, R., Lee, C., Wang, S., Zhang, L. & Li, X. Approach to the strength behaviors and microstructural changes of loess under dynamic load. Chin. J. Geotech. 22, 174–181 (2000).

Xing, Y., Luo, Y. & Li, S. The rupture failure strength of loess. J. Hydraul Eng. 4, 36–44 (1999).

Griffith, A. A. Theory of rupture. Proc. First Int. Congr. Appl. Mech. 55–63. https://hal.science/hal-04771599v1 (1964).

Gu, Q. Study on loess monaxial tension properties under train vibration. dissertation. Northwest University. (2017).

Fredlund, D. G., Morgenstern, N. R. & Widger, R. A. The shear strength of unsaturated soils. Can. Geotech. J. 15, 313–321. https://doi.org/10.1139/t78-029 (1987).

Li, H., Yang, M. & Guo, X. Study of the disintegration of loess modified with fly Ash and Roadyes. Sci. Rep. 13, 7253–7253. https://doi.org/10.1038/s41598-023-33434-2 (2023).

Liu, B., Zhou, H., Wang, X., Lian, G. & Yang, B. Effect of modifiers on the disintegration characteristics of red clay. Sustainability. 16, 4511. https://doi.org/10.3390/su16114551 (2024).

Shi, J. et al. Calcareous silt earthen construction using biopolymer reinforcement. J. Build. Eng. 72, 106571. https://doi.org/10.1016/j.jobe.2023.106571 (2023).

Zhao, C., Xiao, Y., He, X., Cui, H. & Liu, H. EICP-enhanced fracture healing: bridging microfluidic observations and macroscale applications. Géotechnique. https://doi.org/10.1680/jgeot.24.01217 (2024).

Xiao, Y., Ma, G., Wu, H., Lu, H. & Zaman, M. Rainfall-induced Eerosion of biocemented graded slopes. Int. J. Geomech. 22, 04021256. https://doi.org/10.1061/(ASCE)GM.1943-5622.0002239 (2022).

Xiao, Y., Zhou, W., Shi, J., Lu, H. & Zhang, Z. Erosion of biotreated field-scale slopes under rainfalls. J. Perform. Constr. Facil. 36, 04022030. https://doi.org/10.1061/(ASCE)CF.1943-5509.0001732 (2022).

Festugato, L. et al. Fibre-reinforced cemented soils compressive and tensile strength assessment as a function of filament length. Geotext. Geomembr. 45, 77–82. https://doi.org/10.1016/j.geotexmem.2016.09.001 (2017).

Jiang, R., Wang, J., Xiao, T. & Zhang, D. Effect of Sisal fibers on the disintegration characteristics of Sisal fiber-amended loess. Constr. Build. Mater. 453, 139032–139032. https://doi.org/10.1016/j.conbuildmat.2024.139032 (2024).

Xu, Z. Macro and Mesoscopic Study of Geogrid Pull-Out Tests Under Static and Dynamic Loading Conditions. dissertation. Shijiazhuang Tiedao University.(2021). https://doi.org/10.27334/d.cnki.gstdy.2021.000284

LV, H. et al. Analysis of slope stability enhanced by plant roots under rainfall condition. Water Resour. Hydropower Eng. 55, 656–660. https://doi.org/10.13928/j.cnki.wrahe.2024.S2.099 (2024).

Xiao, Y. et al. Restraint of particle breakage by biotreatment method. J. Geotech. Geoenviron Eng. 146, 04020123. https://doi.org/10.1061/(ASCE)GT.1943-5606.0002384 (2020).

Chen, W. et al. Research on hydrophobic mechanism and strength evolution characteristics of loess modified with superhydrophobic materials. J. Railw Sci. Eng. https://doi.org/10.19713/j.cnki.43-1423/u.T20241063 (2025).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Numbers: 42027806 and 41630639).

Author information

Authors and Affiliations

Contributions

T.L.: Formal analysis, Methodology, Writing - original draft, Writing - review & editing. J.W.: Conceptualization, Funding acquisition, Project administration. S.J.: Investigation, Resources, Supervision, Validation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Lei, T., Wang, J. & Jiao, S. Research on the disintegration characteristics of fissured loess under water–vibration coupling effect. Sci Rep 15, 17542 (2025). https://doi.org/10.1038/s41598-025-01391-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-01391-7