Abstract

Multiple roadways have been excavated to form an underground production system, which is used for multi section collaborative mining of room pillar structures, achieving efficient mining of underground inclined and steeply inclined ore bodies; however, due to the combined influence of surrounding rock stress disturbance in the roadway group and lateral stress of the ore room, the dynamic pressure influence of roadway group is prominent in multi section collaborative mining. In this article, a combination of various research methods, such as engineering research, numerical simulation, theoretical analysis, and engineering practice, are adopted with the multi section collaborative mining roadway group in Xifeng Mine as the engineering background; the research work has been carried out on the impact of dynamic pressure manifestation on roadway groups under multi section collaborative mining conditions, the mechanism of dynamic pressure roadway failure and instability, roadway support control strategies, and the design of dynamic pressure roadway group support in Xifeng Mine. Research has shown that: (1) for multi section collaborative mining engineering conditions, a reasonable design of interlayer distance is the key to the surrounding rock stability of the dynamic pressure roadway group, which can reduce the dynamic pressure impact of each middle section roadway on each other, while meeting the mining technology level and efficiency requirements of the ore body; (2) the end of the ore vein mining roadway near the ore room is a key support reinforcement area, which increases the risk of instability of the surrounding rock due to strong mining induced pressure; the secondary support and reinforcement area is the intersection of the ore vein mining roadway and external roadway, as well as the roof of the ore vein external roadway and the side walls near the ore room, which are affected by the risk of shallow loose body collapse; (3) The layout of the roadway group causes uneven disturbance of the surrounding rock stress environment, changes the stable bearing state, and thus intensifies the damage; The mining of the ore room causes the surrounding stress field to be relieved, and the stress imbalance and disturbance of the roadway surrounding rock are more obvious, leading to an increase in the hidden danger of failure and instability; (4) A joint support scheme for dynamic pressure roadway group was proposed (active support with “anchor rod + steel mesh + surface spraying” during the layout stage of the roadway group + passive reinforcement support with “steel arch + metal mesh + surface spraying” during the ore drawing stage), and the on-site support effect was safe and stable.

Similar content being viewed by others

Introduction

Due to the complex geological occurrence conditions, the distribution of inclined and steeply inclined ore bodies is common in underground mining resources. The room column multi section collaborative mining method is often adopted, which excavates multiple roadways to form an underground production system, achieving safe and efficient mining and transportation of mineral resources. For multi section collaborative mining, many engineering safety issues have emerged, such as intensified surrounding rock damage of the ore vein external roadway due to the influence of adjacent roadway layout, intensified deformation of the surrounding rock of the ore vein mining roadway due to mining, and weakened support stability under the conditions of roadway group layout. In practical mining engineering, it is urgent to solve engineering safety issues such as surrounding rock disturbance, mining impact, and support stability of roadway groups under the condition of multi section collaborative mining; therefore, the research on the dynamic pressure influence and support engineering strategy of roadway group under multi section collaborative mining conditions have important engineering guidance significance and scientific research value.

The safe and efficient mining of underground mineral resources has always been widely valued internationally. In terms of the research on the disturbance effects of roadway groups, many scholars have carried out relevant research work from different perspectives of engineering problems, such as analyzing the stress superposition effect of surrounding rock between multiple roadways, analyzing the excavation unloading effect of adjacent roadways surrounding rock, and analyzing the evolution of disturbance and failure of roadway group1,2,3,4,5,6,7. To a certain extent, it has been revealed that the stress disturbance of the roadway group has changed the stress balance of the original roadway, leading to intensified surrounding rock damage. Therefore, a large number of scientific and technological workers have conducted optimization control research on the excavation and support technology of the roadway4,5,6,7,8,9,10,11,12. In the multi section collaborative mining, the safety impact of roadway pressure manifestation in adjacent ore rooms was analyzed, and the impact of roadway dynamic load was analyzed. Relevant studies have revealed the dynamic pressure impact characteristics of multiple intermediate section collaborative mining on adjacent roadway groups13,14,15,16,17. Many research results provide engineering guidance for the subsequent control of roadway surrounding rock. Faced with the engineering problem of multi section collaborative mining roadway group, the disturbance effect characteristics of deep roadway group are analyzed, the influencing factors of multi section collaborative mining roadway group disturbance are analyzed16,17,18,19, the ground pressure changes and rock instability movement characteristics of multi section collaborative mining are analyzed20,21,22,23,24,25,26, and the surrounding pressure instability mechanism and support control of multi section collaborative mining roadway group are studied27,28,29,30. Many research results provide important guidance and valuable engineering experience for ensuring the stability of underground mine roadway support and safe resource extraction. However, there are still some engineering problems that urgently need to be studied and solved, such as the stress mutual disturbance evolution of the surrounding rock of the dynamic pressure roadway group in multi section collaborative mining, and the characteristics of the lateral superposition effect of mining and mining have not been revealed. The key safety impact areas of the dynamic pressure roadway group in multi section collaborative mining have not been clarified, resulting in a lack of guidance direction for the support technology control of the dynamic pressure roadway group and the inability to achieve precise support control.

Therefore, In this article, a combination of various research methods, such as engineering research, numerical simulation, theoretical analysis, and engineering practice, are adopted with the multi section collaborative mining roadway group in Xifeng Mine as the engineering background; the research work has been carried out on the impact of dynamic pressure manifestation on roadway groups under multi section collaborative mining conditions, the mechanism of dynamic pressure roadway failure and instability, roadway support control strategies, and the design of dynamic pressure roadway group support in Xifeng Mine. The research results of this article not only achieve the safety control of dynamic pressure roadway group support in multi section collaborative mining of Xifeng Mine, but also improve the design strategy and engineering reference for dynamic pressure roadway group support in multi section collaborative mining of similar mines.

Engineering impact characteristics of dynamic pressure roadway group in multi section collaborative mining of Xifeng Mine

Project overview

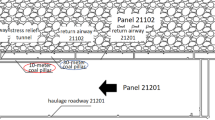

Xifeng Mine belongs to a non-metallic mine, consisting of peaks such as Meiziling, Maogaishan, and Duimenpo. The overall terrain is high in the northwest and northeast, and low in the southeast, belonging to the plateau erosion type of middle mountain, middle low mountain, and valley landforms. During the main mining of the 1 # ore body (740–890 m, with an average thickness of 7.5 m), a 737 main adit was arranged. The rock mass in the mining area is mainly composed of dolomite. Currently, based on the occurrence of the ore body and the mining sequence, the segmented open pit and subsequent filling mining method is adopted. The first mining block is designed for the II-a ore body located in the 740 middle section, with a block length of 30–40 m, a middle section height of 45–70 m, a segmented height of 17.5–22.5 m, a room length of 8–20 m, and a block width equal to the horizontal thickness of the ore body; arrange a cutting courtyard in the middle of the ore room, and arrange segmented rock drilling alleys along the direction of the ore seam veins. Drill rock from the segmented alleys, perform segmented blasting, and extract ore in the middle section. After the mining of a ore room is completed, use waste rock and waste rock cementation to fill the goaf to control ground pressure; to serve the production of the mining area in the 740 middle section of the 1 # ore body, the design and layout of the 740 middle section roadways, 755 section roadways, 770 section roadways, and 785 middle section roadways are connected. The roadway is a three core arch section, section size 4.5 × 4.0 m, the specific layout is shown in Fig. 1.

Safety impact of dynamic pressure roadway group engineering

Through on-site engineering research, the macroscopic mining pressure manifestation of the dynamic pressure roadway group in Xifeng Mine’s multi section collaborative mining was understood. Preliminary analysis was conducted on the safety impact of the dynamic pressure roadway group engineering under the multi section collaborative mining conditions in Xifeng Mine, as follows:

-

(1)

For the multi section collaborative mining conditions of Xifeng Mine, the layout of the multi horizontal sections of the cross vein and cross vein connected roadways is complex, with intersecting and parallel roadways, and there is mutual interference of surrounding rock stress and significant lateral influence of ore room movement.

-

(2)

Under the layout conditions of the roadway group, the top plate and ore body side walls of the outer vein roadway, as well as the top plate and two sides of the cross vein connected roadway are subjected to increased stress and deformation.

-

(3)

During the mining process of the ore room, there are intensified mining pressure effects near the end of the ore room, at the intersection of the through vein connecting roadway and the outside of the vein connecting roadway, on the roof of the outside of the vein connecting roadway, and on the side walls of the ore body, highlighting the safety hazards of the roadway.

-

(4)

The stress mutual disturbance of surrounding rock and the lateral influence of mining action on the dynamic pressure roadway group in multi section collaborative mining have not been revealed, and the influence law of mining pressure manifestation cannot be determined.

-

(5)

The key safety impact areas of the multi section collaborative mining dynamic pressure roadway group cannot be determined, resulting in a lack of guidance direction for the support technology control of the dynamic pressure roadway group and the inability to achieve precise support control.

The dynamic pressure behavior and its impact on the surrounding rock of the multi section collaborative mining roadway group in Xifeng Mine

Numerical model construction and simulation scheme

Using FLAC3D numerical simulation software, based on the engineering overview in Section Project overview, a multi section collaborative mining roadway group model of Xifeng Mine was established, as shown in Fig. 2; model size: 60 m (X) × 75 m (Y) × 100 m (Z), 976,128 zones in total.

Displacement boundary constraints are used around the model and its bottom plate, and stress boundary constraints are used for the top plate. The 740 middle section roadways are located at a depth of 150 m underground, and the original rock stress is about 3.9 MPa (with an average rock mass density of 2600 kg/m3). The simulation plan is designed based on the multi section collaborative mining plan of Xifeng Mine. The excavation sequence of the roadways is as follows: the 740 middle section roadways → the 755 middle section roadways → the 770 middle section roadways → the 785 middle section roadways; the mining sequence of the ore rooms is as follows: 740 section ore room → 755 section ore room → 770 section ore room.

Additional clarification is needed. Considering that roadway support enhances the bearing capacity of surrounding rock and interferes with the failure characteristics of roadway surrounding rock affected by mining, this paper adopts a roadway simulation analysis without support conditions, with the aim of fully revealing the dynamic pressure impact characteristics of roadway groups under multi section collaborative mining conditions.

The failure instability of surrounding rocks in roadway groups under multi section collaborative mining conditions and its influence of dynamic pressure manifestation

-

(1)

Disturbance and failure of surrounding rock under the layout conditions of roadway groups and the influence of mine pressure manifestation.

From the stress damage evolution of the roadway surrounding rock, as shown in Fig. 3, after the excavation of the 755 section roadway, the damage to the roof surrounding rock of the ore vein external roadway and the roof and sides of the ore vein mining roadway in the 740 middle section intensified. After the excavation of the 770 section roadway, the top corner in the ore vein external roadway and the roof and two sides of the ore vein mining roadway in the 755 section intensified, because it was far from the 740 middle section roadway, and there was no disturbance or damage observed in the 740 middle section roadway. After the excavation of the 785 section roadway, the damage to the top corner of the ore vein external roadway and the roof and two sides of the ore vein mining roadway in the 770 section intensified. Due to the long distance between the roadways, there was no disturbance or damage to the roadways in the 755 section and the 740 middle section. The simulation results show that the layout of roadways is complex, with intersecting and parallel arrangements, and the surrounding rock stress is mutually disturbed; when the distance between roadways in a roadway group is relatively close, the later excavation of roadways will cause more severe damage to the first excavation of roadways.

From the stress field evolution of the surrounding rock roadway, as shown in Fig. 4, after the excavation of the 740 middle section roadway, the two sides surrounding rock of the 740 middle section roadway are concentrated in 7.5 ~ 9.5 MPa, and the stress concentration of the surrounding rock roadway at the roadway intersection is severe. After the excavation of the 755 section roadway, the stress environment in the ground changed; although the stress on the surrounding rock of the 740 middle section roadway was slightly relieved, according to the analysis in Fig. 3, it can be seen that the damage to the roadway surrounding rock is intensified due to the unbalanced stress state. After the excavation of the 770 section roadway, the stress transmission effect on the roof of the 755 section roadway changed; although the stress on the surrounding rock of the roadway was slightly relieved, it led to intensified damage to the surrounding rock of the 755 section roadway; due to the distance between the 770 section roadway and the 740 middle section roadway being relatively far, the stress equilibrium state of the surrounding rock in the 740 middle section roadway has not been changed.

As shown in Fig. 5, after the excavation of the 785 section roadway, the stress transmission effect of the 770 section roadway roof changes, and the surrounding rock damage intensifies, but the effect on the stress balance state of the 755 section roadway is not significant. The simulation results show that when the distance between the roadways is close, the effect of later excavation on the stress equilibrium state of the surrounding rock in the first excavation roadway will be significant, the disturbance of surrounding rock stress is the main reason for the intensification of surrounding rock damage in the roadway group; increasing the interlayer distance of the mining level is beneficial for reducing the influence of dynamic pressure on each other in the section roadway, but it is not conducive to the efficient mining of the ore body; reasonable interlayer distance design of the mining level is the key to the surrounding rock stability of the multi section collaborative mining dynamic pressure roadway group.

-

(2)

Dynamic pressure failure of surrounding rock in roadway group and its impact on rock pressure manifestation under multi section collaborative mining conditions.

Under the conditions of multi section collaborative mining, the stress equilibrium state of the surrounding rock of the roadway group has once again changed significantly, and the instability risk of the roadway group has further increased. From the perspective of the evolution of surrounding rock damage caused by lateral mining, as shown in Fig. 6, when the 740 section ore room is mined, the degree of surrounding rock damage to the roof and side walls of the ore vein external roadway in the 740 middle section increases slightly, but the damage to the roof and two sides of the ore vein mining roadway increases significantly, with the most severe damage to the surrounding rock near the end of the ore room. After the mining of the 755 section ore room, the damage to the roof and surrounding rock of the ore vein mining roadway in the 755 section increased significantly, with the most severe damage to the surrounding rock near the end of the mine. The damage to the surrounding rock of the 740 middle section roadway was not significant, but the damage to the surrounding rock near the end of the mine in the cross vein roadway in the 770 section increased.

After the mining of the 770 section ore room, the damage to the roof and surrounding rock of the ore vein mining roadway in the 770 section increased significantly, with the most severe damage to the surrounding rock near the end of the ore room. The damage to the surrounding rock of the 755 section roadway was not significant, but the damage to the surrounding rock near the end of the ore room in the ore vein mining roadway in the 785 middle section increased. The simulation results indicate that due to the large scale of mining, the range of mining impact is large. After the mining of the ore room, the lateral mining stress in the ore room mining goaf is transmitted to the roadways in each horizontal section; the mining pressure near the end of the ore room is particularly evident in the ore vein mining roadway, which is a key support and reinforcement area; the secondary support reinforcement area is the intersection of the ore vein mining roadway and ore vein external roadway, as well as the roof and side walls of the ore vein external roadway and the side of the roadway near the ore room.

From the impact of lateral mining stress field on the roadway group, it can be seen that mining in the ore room leads to significant mining induced pressure relief in the nearby shallow rock layers, while there is a slight increase in the deep rock layers. As shown in Fig. 7, when the 740 section ore room is mined, the stress environment of the surrounding rock in the ore vein mining roadway decreases, but the stress environment of the surrounding rock in the ore vein external roadway increases; the concentration of the surrounding rock in the 740 middle section roadway increases to 8.0-9.9 MPa, and the concentration of the surrounding rock in the 755 section roadway increases to 7.0-8.4 MPa, the stress concentration of the surrounding rock in the roadway at the intersection roadway position is the most severe.

As shown in Fig. 8, when the 755 section ore room is mined, the stress environment of the surrounding rock in the ore vein mining roadway decreases, but the stress environment of the surrounding rock in the ore vein external roadway increases; the stress concentration of surrounding rock in the 740 middle section and 770 section roadways has decreased, but the surrounding rock in the roadway roof and floor has increased; based on the analysis in Fig. 6, it is found that there is no significant damage to the roadway surrounding rock in the area where the stress environment intensifies, but the damage to the surrounding rock of the roadway in the area where the stress environment decreases is more pronounced. The analysis of the reasons suggests that the stress imbalance in the roadway at the location where the stress environment is reduced is severe, and the impact of mining induced pressure relief is relatively more pronounced compared to stress concentration; the uneven stress state of the surrounding rock caused by mining induced pressure relief results in insufficient support strength of the roadway, and there are roof caving and slope fragmentation that cause injury to personnel, and even affect the overall stability of the surrounding rock bearing capacity of the roadway.

Impact of dynamic pressure on roadway group

Through simulation analysis of dynamic pressure behavior of surrounding rock in multi section collaborative mining of roadway groups, the dynamic pressure influence on roadway group is summarized:

-

(1)

For the multi section collaborative mining conditions of Xifeng Mine, For the multi section collaborative mining conditions of Xifeng Mine, the layout of production roadways around the ore body is complex, and the stress of the roadway surrounding rock is disturbed, causing the original stress balance state of the surrounding rock to be disrupted.

-

(2)

At each horizontal section, the roof of the ore vein external roadway and its side wall near the ore body, as well as the roof and two sides of the ore vein mining roadway, are particularly affected by the stress disturbance of the surrounding rock in the upper horizontal section roadway.

-

(3)

From the perspective of roadway layout, increasing the distance between mining horizontal layers can reduce the dynamic pressure impact on each middle section roadway, but the difficulty and efficiency of ore body mining increase; reasonable design of the distance between mining horizontal layers is the key to stabilizing the surrounding rock of multi section collaborative mining dynamic pressure roadway groups.

-

(4)

From the perspective of mining impact, when the ore room is mined, the lateral mining stress in the ore room goaf is transmitted to each horizontal section roadways; the mining pressure is particularly evident at the end of the ore vein mining roadway near the ore room, which is the key support reinforcement area; the secondary support reinforcement area is the intersection of the ore vein mining roadway and the ore vein external roadway, as well as the roof of the ore vein external roadway and its side walls near the ore body.

-

(5)

From the perspective of roadway safety, the area near the end of the ore room, the intersection of the ore vein mining roadway and the ore vein external roadway, as well as the roof of the ore vein external roadway and its side walls near the ore body, are key areas of safety impact, there is a hidden danger of insufficient support strength in the later stage, which can lead to roof collapse and collapse, causing injuries to personnel, and even affecting the overall stability of the surrounding rock bearing capacity of the roadway.

-

(6)

From the perspective of roadway support, it is necessary to pay attention to the reinforcement and support of safety critical areas, and adopt support methods such as hanging metal mesh, anchor cable reinforcement, and anchor cable beam to strengthen the bearing capacity of roadway surrounding rock; at the same time, it is necessary to strengthen the monitoring of mine pressure in safety critical areas of roadways.

The mechanism of the failure and instability of dynamic pressure roadways and control strategy

The impact mechanism of dynamic pressure environment changes on the failure and instability of roadway surrounding rock

According to the mechanical analysis of the failure depth of the surrounding rock under non-uniform dynamic pressure conditions using the Rubinet equation, within the range of plastic fracture zone, the influence of the surrounding rock medium in the limit equilibrium state of the roadway surrounding rock is not significant. The cross-section of the research object’s roadway is an axisymmetric circular cross-section, and the Mohr-Coulomb failure criterion is used to obtain the axisymmetric equilibrium equation for the plastic zone as follows:

Equation organization yields:

At the equivalent roadway boundary position, i.e. when r = R, then \(\sigma _{r} = {P_1}\), the solution is obtained as follows:

Where \({R_0}\)is equivalent roadway radius, m;\({\sigma _r}\)is radial normal stress, MPa;\({\sigma _\theta }\)is the tangential normal stress, MPa, MPa;\({\sigma _c}\)is uniaxial compressive strength, MPa.

Considering the plastic zone distribution calculation equation under non-uniform stress field conditions, according to the Rubinet formula, there are:

Where θ is the angle with the x-axis, °; λ is the lateral stress coefficient; G is the shear modulus of the surrounding rock, MPa; P is the vertical stress load caused by mining, MPa.

Based on the specific engineering overview, roadways in the 740 middle section and 755 section are taken as the research object, the equivalent outer circle radius of the roadway is 2.7 m, the cohesive force inside the surrounding rock is 1.3 MPa, the internal friction angle is 24°, and the temporary support reaction force is 0 MPa. Through numerical simulation, the distribution changes of the ground stress field in the 740 middle section and 755 section are obtained, as shown in Fig. 9; the non-uniform dynamic pressure environment in the numerical simulation is substituted into Eq. 4.6, based on mechanical theory, the influence of dynamic pressure environment changes on the failure and instability of surrounding rock is revealed.

As shown in Fig. 9a, at the position of the ore vein external roadway in the 740 middle section and 755 section, during the disturbance influence stage of adjacent roadway excavation, the vertical geostress decreases to a certain extent and the horizontal geostress slightly increases; during the mining stage, the vertical ground stress increases to a certain extent and exceeds the original rock stress environment; the horizontal ground stress is significantly reduced by the impact of mining induced unloading; the layout of adjacent roadways and the mining of ore rooms have a significant impact on the uneven disturbance of the roadway ground pressure environment. As shown in Fig. 9b, at the positions of the ore vein mining roadways in the 740middle section and 755 section, the closer the distance to the ore room, the more obvious the lateral mining influence on the roadways, and the vertical stress increases to a certain extent, exceeding the original rock stress environment; the horizontal stress is significantly reduced by the mining unloading effect, and the uneven stress environment becomes more obvious.

As shown in Fig. 10, the increase and imbalance of the stress field lead to changes in stress concentration in the roadway surrounding rock, exacerbating the damage of the roadway surrounding rock. For the layout of roadway groups, when the distance between roadways is relatively close, the later excavation of roadways causes changes in the surrounding rock stress field of the first excavation of roadways. The stress disturbance affects the stress state of the surrounding rock of the first excavation of roadways and intensifies their damage. In the process of mining, the impact of mining induced pressure relief is more pronounced than the stress concentration on the stress field imbalance caused by the roadway. This is the reason for the increase in the distance of the ore pressure manifestation near the end of the ore room, the intersection position of the ore pressure manifestation near the end of the ore body, and the depth of surrounding rock damage on the top plate and side walls of the ore body outside the ore body.

In response to the impact of changes in the stress environment of the surrounding rock of the dynamic pressure roadway group in the multi section collaborative mining of Xifeng Mine, taking the roadway bearing rock mass as the research object, based on the active support technology of the roadway to strengthen the stability of the surrounding rock bearing, scientific and reasonable control of the surrounding rock of the dynamic pressure roadway group can be achieved.

Exploration of surrounding rock control strategies for multi section collaborative mining of dynamic pressure roadways in Xifeng Mine

Based on the analysis of the dynamic pressure manifestation and its impact on the surrounding rock of the multi section collaborative mining roadway group in Xifeng Mine, targeted research on the control of surrounding rock will be carried out in key areas of safety impact, namely: the end of the ore vein mining roadway near the ore room, the intersection of the ore vein mining roadway and external roadway, the roof of the ore vein external roadway and its side walls near the ore room. The specific control strategy for the surrounding rock of the roadway group is as follows:

-

(1)

The surrounding rock of the mineral vein outer is mainly affected by the excavation of the roadway from the upper horizontal section, considering that the surrounding rock of the roadway is relatively hard and there are developed cracks to prevent safety hazards of shallow loose body falling, the active support scheme of full section prestressed anchor rods and metal mesh is mainly implemented in the layout stage of the roadway group.

-

(2)

During the layout stage of the roadway group, pre-stressed anchor cables or shed reinforcement support are implemented to control the development of roof cracks and potential instability hazards in key areas of safety impact.

-

(3)

Considering the impact of mining during the ore drawing stage, before the mining of the ore room, anchor beam or shed reinforcement support is implemented near the end of the ore room for the cross vein connecting roadway; by coordinating reinforcement support with active support of anchor rods and metal mesh, the stability control of the surrounding rock is achieved under the condition of strong dynamic pressure disturbance near the end of the ore vein mining roadway.

-

(4)

If conditions permit, metal mesh + surface spraying and grouting technology can be adopted to enhance the surface protection effect of the surrounding rock and enhance the bearing mechanical performance of the surrounding rock.

-

(5)

Scientific and reasonable selection of support components and design of support parameters ensure that the support matches the engineering conditions of the roadway, in order to adapt to the changes in mining pressure of the surrounding rock of the roadway.

-

(6)

Pay attention to the implementation of deformation monitoring in key areas with safety impacts, ensuring stable bearing capacity of surrounding rock and stable working status of supporting components.

Design and engineering application of support for dynamic pressure roadway group in multi section collaborative mining of Xifeng Mine

Support scheme for dynamic pressure roadway group

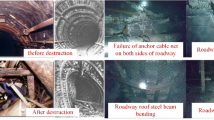

Taking the roadways in the 740 middle sections and 755 sections as examples, combined with the analysis of the dynamic pressure manifestation and its impact on the surrounding rock of the multi section collaborative mining roadway group in Xifeng Mine, as well as the analysis of the control strategy for the surrounding rock of the multi section collaborative mining dynamic pressure roadway group, targeted research on surrounding rock control is carried out. The roadway support scheme in the 740 middle section and 755 section: active support with “anchor rods + steel mesh + surface spraying” during the layout stage of the roadway group, passive reinforcement support with “steel arches + metal mesh + surface spraying” during the ore drawing stage. The specific support plan is as follows:

-

(1)

During the layout stage of the roadway, active support is provided with anchor rods, steel mesh, and surface spraying, as shown in Fig. 11a; the top plate anchor rod adopts Φ 18 × 2000 mm threaded steel anchor rod with a spacing of 1000 × 1000 mm; adopting measures at the roadway roof Φ 6.5 mm steel bars are welded into a steel mesh, with a mesh size of 2000 × 2000 mm and a mesh size of 100 × 100 mm. The mesh overlap is pressed with anchor rods, and the mesh overlap is not less than 100 mm; the use of anchor rods in the roadway Φ 16 × 1500 mm threaded steel anchor rod, with a spacing of 1000 × 1000 mm between rows, and the top row anchor rod at a distance of 600 mm from the top; the surface of the roadway is made of C20 shotcrete with a thickness of 200 mm.

-

(2)

During the ore room mining stage, passive reinforcement support is carried out using steel arches, metal mesh, and surface spraying, as shown in Fig. 11b; considering the intensified instability of the surrounding rock of the roof in the key area affected by the safety of the roadway, as well as the phenomenon of local falling blocks, the key area affected by the safety of the roadway is mainly reinforced with shed support; at the same time, metal mesh and surface spraying are arranged behind the wall to prevent roof caving and strengthen the protective effect of the surface. The steel arch adopts 29 # mining U-shaped steel frame shed support (with a spacing of 1000 mm), and the shed is connected by 10 # channel steel welding (with a spacing of 500 mm). The top of the frame is laid Φ 6 steel mesh pieces are welded to the steel arch; adopt Φ 32 × 1400 mm round steel locking anchor rod (with a spacing of 1000 × 1000 mm) enters the bedrock from the side and is welded to the steel arch as a whole; finally, the surface of the shed section is sprayed with C20 concrete, with a thickness of 350 mm for the upper part and 200 mm for the top plate.

Feedback analysis of engineering practice effects

On-site support design schemes were implemented for the 740 middle section and 755 section roadways. The cross point method was used to monitor the deformation of surrounding rock in key areas of the roadway (the intersection of the external roadway and the end of the ore room through the connecting roadway). The on-site support effect was evaluated based on feedback information, and the support parameters were adjusted appropriately to adapt to the surrounding rock support conditions on site.

As shown in Fig. 12, through long-term monitoring of the deformation of the surrounding rock of the roadway, it can be seen that the subsidence of the roof rock of the roadway is between 70 and 115 mm, and the deformation of the two sides of the rock is between 78 and 140 mm. The current support effect meets the production safety requirements of multi section collaborative mining. The proposed dynamic pressure roadway group combined support scheme has achieved a safe and stable roadway control effect.

Conclusions

-

(1)

for multi section collaborative mining engineering conditions, a reasonable design of interlayer distance is the key to the surrounding rock stability of the dynamic pressure roadway group, which can reduce the dynamic pressure impact of each middle section roadway on each other, while meeting the mining technology level and efficiency requirements of the ore body.

-

(2)

The end of the ore vein mining roadway near the ore room is a key support reinforcement area, which increases the risk of instability of the surrounding rock due to strong mining induced pressure; the secondary support and reinforcement area is the intersection of the ore vein mining roadway and external roadway, as well as the roof of the ore vein external roadway and the side walls near the ore room, which are affected by the risk of shallow loose body collapse;

-

(3)

The layout of the roadway group causes uneven disturbance of the surrounding rock stress environment, changes the stable bearing state, and thus intensifies the damage; The mining of the ore room causes the surrounding stress field to be relieved, and the stress imbalance and disturbance of the roadway surrounding rock are more obvious, leading to an increase in the hidden danger of failure and instability;

-

(4)

A joint support scheme for dynamic pressure roadway group was proposed (active support with “anchor rod + steel mesh + surface spraying” during the layout stage of the roadway group + passive reinforcement support with “steel arch + metal mesh + surface spraying” during the ore drawing stage), and the on-site support effect was safe and stable.

Taking Xifeng Mine as the engineering background, this article studies the changes in stress environment and instability effects of roadway group surrounding rock of under multi section collaborative mining conditions, a targeted roadway support scheme is proposed. However, the stability of the roadway group surrounding rock under the condition of multi section collaborative mining is complex and difficult to analyze due to the comprehensive influence of multiple factors, which leads to shortcomings in the influence laws of various factors. In the subsequent research process, further in-depth research will be conducted on the stability of roadway group surrounding rock under the conditions of multi section collaborative mining, with a focus on revealing the mechanism of roadway safety impact.

Data availability

The datasets used and analysed during the current study available from the corresponding author on reasonable request.

References

Yamaguchi, I., Yamazaki, I. & Kiritani, Y. Study of ground-tunnel interactions of four shield tunnels driven in close proximity. Tunn. Undergr. Space Technol. 13 (3), 289–304. https://doi.org/10.1016/S0886-7798(98)00063-7 (1998). in relation to design and construction of parallel shield tunnels [J].

Ng, C. W., Lee, K. M. & Tang, D. K. W. Three-dimensional numerical investigations of new Austrian tunnelling method (NATM) twin tunnel interactions. Can. Geotech. J. 41 (3), 523–539. https://doi.org/10.1139/t04-008 (2004).

Wanniarachchi, W. et al. Numerical simulation of foam-based hydraulic fracturing to optimise perforation spacing and to investigate effect of dip angle on hydraulic fracturing . J. Pet. Sci. Eng (2019). https://doi.org/10.1016/J.PETROL.2018.09.032.

Xie, G. X., Yuan, A. & Wang, L. Study on Deflection of surrounding rock force chain and disaster mechanism of instability in deep. Stope Shock Vib. (10), 1–12. https://doi.org/10.1155/2020/8883897 (2020).

Trinh, N. & Jonsson, K. Design considerations for an underground room in a hard rock subjected to a high horizontal stress field at Rana Gruber. Norway Tunn. Undergr. Space Technol. Incorporating Trenchless Technol. Res. 38 (09), 205–212. https://doi.org/10.1016/j.tust.2013.07.006 (2013).

Brunton, I. D., Fraser, S. J., Hodgkinson, J. H. & Stewart, P. C. Parameters influencing full scale sublevel caving material recovery at the ridgeway gold mine. Int. J. Rock. Mech. Min. Sci. (04), 647–656 (2010). https://doi.org/10.1016/j.ijrmms.2009.12.011

Osgoui, R. R. & Oreste, P. Convergence-control approach for rock tunnels reinforced by grouted bolts, using the homogenization concept. Geotech. Geol. Eng. 25 (04), 431–440. https://doi.org/10.1007/s10706-007-9120-0 (2007).

Hage Chehade, F. & Shahrour, I. Numerical analysis of the interaction between twin-tunnels: Influence of the relative position and construction procedure. Tunn. Undergr. Space Technol., 23(2), 210–214. https://doi.org/10.1016/j.tust.2007.03.004. (2008).

Li, Q. & Zhu, Q. Control technology and coordination deformation mechanism of rise entry group with high ground stress. Int. J. Min. Sci. Technol. 22 (3), 429–435. https://doi.org/10.1016/j.ijmst.2011.11.002. (2012).

Guo, H., Ji, M. & Zhao, W. Roadway support design based on in-situ stress and lts asymmetrical distributions in a coal mine. Arch. Min. Sci. 65 (02), 299–315 (2020).

Chai, J. et al. Experimental study on a new method to forecasting Goaf pressure based key strata deformation detected using optic fiber sensors. Opt. Fiber Technol. 2021, 102706. https://doi.org/10.1016/j.yofte.2021.102706

Exadaktylos, G. E. & Stavropoulou, M. C. A closed-form elastic solution for stresses and displacements around tunnels. Int. J. Rock Mech. Min. Sci. 39 (07), 905–916. https://doi.org/10.1016/s1365-1609(02)00079-5 (2002).

Jiaguang, K., Peng, W. & Peng, W. Influencing factors of disturbance effects of blasting and driving of deep mine roadway groups. Shock Vib. 2021, 1–11 https://doi.org/10.1155/2021/8873826 (2021).

Yuantian, S. et al. Stability analysis of roadway groups under multi-mining disturbances. Appl. Sci., 11 (17), 7953–7953. https://doi.org/10.3390/APP11177953. (2021).

Liu Shuai, Y. & Ke Tang Chun’an. Research on asymmetric failure mechanism and control of deep mine soft rock downhill roadway group. J. Min. Saf. Eng. 36 (03), 455–464. https://doi.org/10.13545/j.cnki.jmse.2019.03.004 (2019).

Du Lele. Analysis of causes and control techniques for instability of deep well multiple disturbance roadways. (China University of Mining and Technology, 2019).

Qin Min. Research on the application of multi stage enhanced mining ground pressure microseismic monitoring and early warning technology. (Changsha Mining Research Institute, 2013).

Meng Qingbin, S. et al. Research on disturbance effect and control technology of deep well soft rock roadway group excavation. J. Min. Saf. Eng. 38 (03), 496–506. https://doi.org/10.13545/j.cnki.jmse.2020.0046 (2021).

Pan Junfeng, L. et al. Mechanism and prevention of static load induced rockburst in deep panel roadway clusters. J. Coal Sci. 43 (10), 2679–2686. https://doi.org/10.13225/j.cnki.jccs.2018.0016 (2018).

Song Yuanbing, Z. et al. Stability analysis of multi section mining area using Shaba mine. Mod. Min. 27 (12), 17–18 (2012).

Yang Fubo. Research on the influence of multi stage mining on the stability of goaf roof. Min. Technol. 13 (01), 39–40. https://doi.org/10.13828/j.cnki.ckjs.2013.01.029. (2013).

Sheng Jia, C., Bei, L. & Xiangdong, et al. High efficiency mining practice for zoning of gently inclined and Thick ore bodies under multi section group Goafs. Metal Mines 12, 29–32 (2015).

Zhang Jun, Z., Da, W. & Ping Ground pressure monitoring technology for multi section and multi panel deep hole mining. Nonferrous Met. Eng., 5 (S1), 88–92. https://doi.org/10.3969/j.issn.2095-1744.2015.z1.021 (2015).

Yaohua, Z. & Hani, S. Elastoplastic stability analysis of mine haulage drift in the vicinity of mined stopes. Int. J. Rock Mech. Min. Sci. 45 (04), 574–593. https://doi.org/10.1016/j.ijrmms.2007.07.020 (2008).

Cai, M. et al. FLAC/PFC coupled numerical simulation of AE in large-scale underground excavations. Int. J. Rock Mech. Min. Sci. 44 (4), 550–564. https://doi.org/10.1016/j.ijrmms.2006.09.013 (2007).

Xie, C. et al. Numerical. IOP Conference Series Earth and Environmental Science 384, 012047 (2019). https://doi.org/10.1088/1755-1315/384/1/012047

Gaojian, H. et al. Study on the mechanism of surrounding rock failure in multi section mining of Hongling lead zinc mine. Met. Mines 09, 20–24 (2017).

Shiguo, S. & Yinge, M. The impact of multiple middle section overlapping mining on the movement and deformation of overlying rock masses in Macheng mine. Met. Mines. 09, 181–185. https://doi.org/10.19614/j.cnki.jsks.201809033 (2018).

Jia Wenhong, Y. & Longzhe Huang Yongxiang, etc research on deformation and failure characteristics of segmented roadways under multi middle section collaborative mining in Jinchuan mine. Min. Res. Dev. 42 (11), 67–73. https://doi.org/10.13827/j.cnki.kyyk.2022.11.012 (2022).

Qingbin, M., Rui, W. & Lijun, H. etc The disturbance effect of surrounding rock in multi stage joint mining and mining roadway support technology. J. Cent. South Univ. (Nat. Sci. Ed.) 54 (03), 930–943 (2023). https://doi.org/10.13545/j.cnki.jmse.2020.0046

Funding

Guizhou Provincial Science and Technology Plan Project (Guizhou Science and Technology Cooperation Support [2023] General 777); First Class Discipline Research Special Project (YLXKZX-NKD-052).

Author information

Authors and Affiliations

Contributions

ZHENG Yantao conducted engineering research and analysis, managed and analyzed the data, and edited the manuscript. LIU Changwu proposed the research concept. BU Qingwei and TAO Tiejun participated in conducting simulation analysis and conceptual design of technical solutions. ZHAO Chao, JIAN Bingxi, CHEN Yulin, SHI Song , LI Xuanlin participated in the simulation and theoretical analysis of engineering problems.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zheng, Y., Zhao, C., Jian, B. et al. Research on the dynamic pressure influence and support engineering strategy of roadway group under multi section collaborative mining conditions. Sci Rep 15, 19470 (2025). https://doi.org/10.1038/s41598-025-02250-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-02250-1