Abstract

With the wide application of large machinery in coal mining, the influence of mine pressure is large and wide. Therefore, it is very important to retain and maintain the strength of coal pillars in the working face section. But the traditional narrow coal pillar grouting technology often causes grouting failure due to slurry leakage. In order to avoid this situation, the pre-grouting solidification technology is put forward. Through theoretical analysis and speculation, numerical simulation, field test and monitoring and other methods, this article discusses the shortcomings of traditional grouting methods, the causes of grouting failure, and the reasons for grouting failure, the characteristics of fracture distribution in narrow coal pillar, the concrete implementation method of pre-grouting solidification technology and the reasonable selection of grouting time. The results show that the high fracture development within the narrow coal pillar has good grouting permeability, and the coal pillar is pre-grouting reinforced before the excavation of the roadway along the goaf, combined with the flexible thin-layer shotcrete layer and reasonable grouting time, the solidification of narrow coal pillar has achieved good results, and has constructed a good surrounding rock environment for excavation and support of roadway.

Similar content being viewed by others

Introduction

China has an abundance of resources for thick and extra-thick coal seams, and many large machines are used in the exploitation of these coal resources1,2,3. The setting of section coal pillar is complex but very important. Its role is to avoid high stress affect the stability of the roadway and isolated from the goaf. The application of large machinery in coal mining makes the strength of mine pressure large and wide. The retention of coal pillars has become a major problem, and the choice of coal pillar width is particularly important4,5,6. When adopting the scheme of wide coal pillar, the roadway is located in the original rock stress zone. Although the roadway maintenance is relatively simple, it causes a waste of resources. When adopting the narrow coal pillar scheme, although the roadway is in the low support pressure area, the influence of mine pressure is enhanced due to the application of large-scale comprehensive machinery, and the plasticization degree of coal pillar is large and some of them are broken. There are still difficulties in practical application7. In view of this problem, many scholars have researched the associated issues with gob-side entry driving. They proposed a number of theories based on the ' triangular block ' and ' beam ' mechanical models. In the surrounding rock control theory of fully mechanized caving roadway, the ' internal and external stress field theory’8 and the ' stress limit equilibrium zone model’9 are proposed. The development of completely automated caving gob-side entry technology is encouraged by these models.

Based on the above model, By analyzing the bearing capacity of the mined-out area, Fan Deyuan et al. proposed the " bolting and grouting roof " control method (BCR-GER), and established the " surrounding rock-support body " model composed of coal wall, roadway support body and coal gangue10. Zhang Hongwei explored the grouting reinforcement of the roadside under the condition of insufficiently stable overburden to prevent system instability11; Zhao Bin et al. studied the deformation and failure law of entry. For the asymmetry of damage, a comprehensive reinforcement method was proposed12. Yan Gang et al. proposed a two-way reinforcement technology, which provides two-way anchoring force for coal pillar and broke through the problem that traditional gob-side entry driving technology could not realize two-way reinforcement of one-side construction of coal pillars13. Chen Dongdong and his team delved into the impact of the primary roadway coal pillar within a double-layer island mining face, specifically under the complex conditions of superimposed mining stresses14. He Wenrui et al. studied the stress characteristics and failure of coal pillars under different coal pillar widths and coal seam thicknesses. It provides a reference for coal pillar setting15. Aiming at the problem of roof subsidence in thick coal seam, Zhao Yiming et al. analyzed the failure characteristics of roof and its discontinuous deformation and failure mechanism16. Qi, Fuzhou et al. studied the technology of roof pre-splitting and filling on the surrounding rock of roadway. The broken rock block is used to fill the goaf, so that the load of the coal pillar is reduced17.

Ensuring that the coal pillar has sufficient strength is an important prerequisite for the roadway. Grouting is widely used as an important means to enhance the strength of coal pillar 18,19. Liu Quansheng proposed a new grouting process to improve the diffusion range of grouting : three-step grouting20. Huang, Shunjie, etc. explored the influence of different ratios on the performance of grouting materials through orthogonal experiments, so that grouting materials can diffuse well in cracks and improve the strength of broken rock mass21. Jiang Zaisheng et al. proposed multi-layer shotcrete pouring, and explored the relationship between concrete thickness and structural bearing capacity22. Many scholars have studied the application of various new materials in shotcrete materials. Liu Qianquan et al. proposed the application of basalt fiber to shotcrete, which effectively improved the bending resistance, toughness and durability of concrete23. Zhao Jinpeng et al. explored the relationship between fiber fracture morphology and mechanical properties of fiber reinforced concrete24. Han Bin et al. established the objective function of particle swarm optimization through artificial neural network model, and obtained the best concrete ratio in less time 25. In order to solve the shortcomings of poor flexibility and no flame retardancy of the traditional shotcrete layer, Chen Jianwei et al. proposed to modify the cement-based materials with fly ash, cellulose and emulsifier to prepare a flexible flame retardant shotcrete layer 26. Through a comprehensive study involving many tests, L. Malmgren analyzed the energy absorption capabilities of shotcrete reinforced with fibers, and steel meshes. This research served as a foundational theoretical framework for the advancement of flexible lining technologies 27

The aforementioned scholars have conducted thorough research on enhancing the stability of gob-side coal roadways, employing a multifaceted approach that includes theoretical analysis, numerical simulations, laboratory experiments, field monitoring, and other methodologies. This work holds significant implications and practical applications in the field. However, the traditional grouting filling method from the roadway side of the coal pillar into the goaf side cannot form a closed grouting space, and there is a phenomenon of slurry leakage. There is still some irrationality in the choice of grouting time, which may lead to grouting failure. Therefore, this paper combines the spatial position characteristics of the goaf in the upper section, and applies the flexible shotcrete technology to close the space. Through the theoretical analysis of the coal pillar disturbance caused by the advancing process of the working face, a reasonable grouting time is selected to pre-grouting the coal body, which improves the strength of the coal pillar, which is of great significance.

Failure mechanism analysis of grouting slurry leakage in narrow coal pillar

Construction of numerical simulation model

Utilizing UDEC (Universal Distinct Element Code) 7.0 software, a numerical simulation model has been developed. The model is used to explore the distribution characteristics of cracks around the roadway. Combined with the shape of goaf, the causes of grouting failure are analyzed.

The length (x) × height (y) of the model is 180 m × 65 m. Under the circumstances of 5 m, 6 m, and 7 m protected coal pillars, the distribution features of the fracture network were examined by simulating the three procedures of mining roadway excavation, working face mining, and gob-side coal roadway excavation.

Analysis of fracture network characteristics

Coal pillar is too narrow to provide adequate support, too wide is likely to cause a waste of resources. The distribution characteristics of fracture under the effect of various coal pillar widths are investigated based on the aforementioned model, and the viability of pre-grouting technology as well as the mechanism of grouting leakage in gob-side entrance are confirmed.

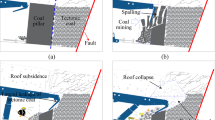

As shown in Fig. 1 (1) 5 m coal pillar: the fracture penetration in the coal pillar area is high, the fracture distribution is dense, and it is seriously broken. The strength of it has been lost; (2) 6 m coal pillar: there is a small range of fracture in the middle of the area, but the degree of fracture development is still at a high level as a whole; (3) There is still no significant change in the degree of fracture development in the width extended to 7 m. Resources will be wasted if it width is increased repeatedly. Therefore, the appropriate width of it should be selected to ensure sufficient strength and not to waste resources.

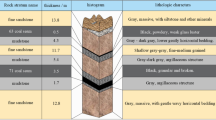

Because the distribution of cracks is complex and uneven, the fractal dimension is used to quantitatively analyze the cracks. It can capture the extent to which shapes occupy space in a non-uniform or fractal manner28. As shown in Table 1, the degree of fracture growth in the area was quantitatively investigated after using ImageJ (image processingand analysis in Java)1.8.0 software to calculate the degree of fracture development of the roof area(a), coal pillar area(b), and roof area(c) of gob-side entry under three conditions.

As shown in Fig. 2, the enhancement in the coal pillar’s width has led to a moderate improvement in the integrity of the roof. However, the fractal dimension, a measure of irregularity, exhibited no discernible pattern of change either in the (b) area or (c) area. The fractal dimension of the fractures in the (b) area is about 1.63, and the degree of penetration is high.

Distribution characteristics of each attribute fracture in coal pillar

The fracture is dominated by slip cracks, which are roughly distributed in the whole coal pillar area under the three kinds of conditions, and the fracture development degree is high. Regarding the simple tensile fractures, their occurrence is quite scarce within the coal pillar region, exhibiting a minimal degree of penetration. In contrast, fractures observed on the goaf side slightly outnumber those on the solid coal side. As for fractures that combine both slip and tensile mechanisms, the degree of development is moderate, characterized by a prominent triangular zone that remains unpenetrated at the base of the area. It is worth noting that as the width increases, the range of this triangular unconnected region expands upward and extends to the top of the region.

In summary, the analysis of the fracture sub-attributes shows that the dominant slip fracture does not show obvious regular changes. Therefore, in the above three cases, the coal in the coal pillar area is seriously broken, the fracture development degree is high, and the connectivity is good, which provides excellent conditions for the diffusion of the slurry. The seriously broken coal on the coal pillar side of the goaf leads to the failure of the traditional grouting scheme to form a closed space, which can easily lead to slurry leakage and cause grouting failure.

Grouting leakage mechanism and goaf shape zoning

Mechanism of grouting leakage

The conventional grouting technique involves injecting grout into the pillar from the side of the gob-side entry. Following the impact of upper curtate mining and the excavation of the coal roadway along the goaf, there is a significant degree of fracture formation within the coal pillar and good slurry fluidity. However, as shown in Fig. 3, a large amount of gangue poured into the roadway from the goaf. The roadway was seriously damaged by multiple disturbances, so the surface of the coal pillar shown in the following figure was seriously broken and there were a large number of cracks. Therefore, under such conditions, the traditional way of injecting grout into the coal pillar can not form a closed space, resulting in serious leakage of grout, a large amount of grout into the roadway and goaf, if the grout is continued to fill the goaf, it is economically costly and the effect of grout diffusion in the coal pillar is not good enough to achieve the expected effect.

Shape characteristics of goaf

According to the location and compaction degree of waste rock, the goaf is divided into: (a) Influx area, (b) Gap area and (c) Compaction area.

The range of broken rock blocks in the goaf into the roadway is slightly different. The degree of rock influx into the roadway is higher in the deep part, and the degree of influx is low near the location of the picture, but there is a lot of unfilled space. The b area, due to the influence of the overlying main roof position, it is connected with the right block, and the waste rock is not fully sunk and crushed, resulting in a large number of gaps between the waste rock. The compacted area is closely arranged between the waste rock due to the falling of the overlying main roof.

In summary, due to the crushing of coal pillars, the deformation of roadways in the upper section, and the large amount of space in the goaf, the traditional grouting technology has the problem of slurry leakage, which leads to grouting failure. Due to the problems existing in the above grouting technology, a new grouting technology is required.

Pre-grouting technology of narrow coal pillar in coal roadway along gob

There are many defects in the control of gob-side entry in traditional fully mechanized top coal caving mining, such as:

-

1.

The coal pillar air leakage, easy to appear goaf toxic and harmful gas leakage, gas disasters and goaf coal natural disasters;

-

2.

Through the influence of mining disturbance and roadway driving, the coal pillar is loose and broken, and the effect of the traditional bolt-cable anchoring method is not good;

-

3.

The traditional method is to select the roadway and then carry out grouting reinforcement. Because the coal pillar is loose and broken, the required slurry is more and the closed space is not formed on the side of the goaf, which is easy to cause a large amount of slurry leakage and cause grouting failure.

The coal pillar area that has been set aside is grouted using pre-grouting solidification technology prior to road excavation. The strength of the coal pillar has been greatly increased, and it is comparatively complete.

In the case of non-pre-grouting reinforcement, the coal pillar is seriously damaged and can not provide enough support protection.

After the mining, the fracture network in coal pillar area has a high degree of development and a high degree of fracture penetration, which provides good conditions for slurry diffusion. It also proves that the coal pillar area is seriously broken, and it is necessary to adopt pre-grouting technology to improve its strength to ensure the smooth progress of the roadway excavation and subsequent support work.

The pre-grouting technology reinforces the coal pillar before tunneling, and improves the stability of the roadway under the support of flexible grouting and segmented independent grouting system.

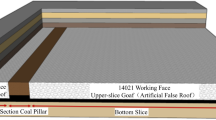

The composition of new grouting technology system

As shown in Fig. 4, Several segmented independent grouting areas are set on the non-mining side of the mining roadway, and several grouting pipes are arranged in each segmented independent grouting area. Each grouting pipe in this area is connected to form a segmented independent grouting system. The flexible shotcrete layer is sprayed in the advanced support area. In the segmented independent grouting area where the goaf lags behind the working face for at least one periodic weighting step, the segmented independent grouting system is connected with a long grouting catheter to reinforce the coal body adjacent to the goaf by segmented independent grouting. The grouting operation is carried out in the sprayed area to improve the overall consolidation and provide good working conditions for the roadway excavation.

Pipe arrangement of grouting system

The pipeline arrangement of the segmented independent grouting system includes two forms: (1) Single-layer pipeline arrangement ; (2) Double-layer pipeline arrangement.

As shown in Figs. 5 and 6, The first arrangement is arranged in a single layer, and the grouting pipe is arranged in a row. Each grouting pipe is at the same horizontal height, so as to realize the uniform diffusion of slurry in the coal pillar; The second arrangement is a double-layer arrangement. The grouting pipes are arranged in two rows, and the upper and lower rows of grouting pipes are connected into one, so that the two rows of grouting pipes are arranged in parallel. This configuration can ensure the diffusion range of slurry in thick coal seam. The segmented independent grouting system is positioned in the center of the height of the mining roadway’s non-mining side under both arrangement types.

As shown in Fig. 7, The two pipeline arrangements are suitable for different coal seam thicknesses to ensure good diffusion of slurry under various coal seam conditions and improve coal strength.

Setting of slurry spraying layer

As shown in Fig. 8, it can be seen that in the case of no shotcrete layer, the coal body above the roadway in the original section is broken and fallen after the mining, which may cause damage to the grouting system. Moreover, if the grouting operation is carried out in this case, due to the destruction of coal pillar wall, a non-closed space is formed by connecting with the roadway. If the grouting is carried out based on this situation, sufficient pressure will not be achieved during the construction process to make the slurry fully diffuse in the coal body, and a large amount of slurry will seep out, resulting in waste of slurry and failure to achieve the expected grouting reinforcement effect.

After increasing the spraying process, the space is closed because of the anti-deformation ability of the spraying layer. The protection of the shotcrete layer has played a certain role in controlling the deformation of the coal pillar, ensuring the normal function of the piping system.

Flexible shotcreting layer

The shotcrete layer adopts flexible materials. Compared with traditional concrete shotcrete, this material is convenient for transportation and low in economic cost due to the thin thickness of the shotcrete layer. The addition of polyethylene fiber improves the anti-deformation ability of the shotcrete layer, reduces the shrinkage rate, improves the waterproofness, and can ensure a closed environment for subsequent grouting operations to prevent slurry leakage.

Shotcrete materials include water, cement, VAE emulsion, polyethylene fiber, fine sand and accelerator. The material matching is shown in Table 2.

Shotcrete process

After the connection grouting pipe is arranged, the grouting is carried out. Because the flexible material is relatively viscous, the secondary spraying process is used to prevent the slurry from flowing around during spraying. The first spraying thickness is 15 ~ 20 mm, waiting for about 2 h, and the second spraying can be carried out after the surface is dry. The second spraying thickness is 20 ~ 25 mm, and the final spraying thickness is about 40 mm. The secondary spraying process is also conducive to covering the cracks caused by uneven surface during the first spraying and strengthening the sealing effect.

Shotcrete indoor test

The indoor test equipment mainly includes hand-held sprayer and electric air compressor. Two kinds of shotcrete materials are configured. Shotcrete material A is the above flexible shotcrete material, and shotcrete material B is the ordinary shotcrete material. Taking compressed air as the power source, the spray effect and performance of two kinds of spray materials are simulated in the laboratory. The experimental equipment is shown in Fig. 9.

The main test process: After the two kinds of shotcrete materials are configured, the air compressor is started and the pressure gauge is observed. When the pressure value reaches 0.8 MPa, the shotcrete material is put into the front bucket of the hand-held shotcrete machine, and the valve is opened for shotcrete operation. The spray material A adopts the secondary spraying process, and the spray material B adopts the ordinary spraying process to spray the same thickness. After drying, the properties of the two materials were compared.

As shown in Fig. 10, the comparison can be seen that the surface of material A is smoother than that of material B. The double spraying process significantly reduces the surface cracks and improves the sealing performance of the coating. The addition of VAE emulsion and polyester fiber further improves the deformation resistance of the shotcrete layer. It can be seen that the performance of material A is more excellent, and it is more suitable for the spray plugging of the surface of the coal pillar.

Selection of grouting time

Because of the different position from the front of the working face, the front and rear of the working face are shown in Fig. 11: (1) Weak mining disturbance area ; (2) Strong mining influence area ; (3) Fracture disturbance area ; (4) Relative stabilized area ; (5) The stability area.

If pre-grouting is selected in (1) and (2), the advanced abutment pressure and mining disturbance make the coal pillar break gradually with the mining. As shown in Fig. 12, a significant amount of new cracks are produced. The original shotcrete layer may be damaged to a certain extent and the coal body that has been grouted and consolidated is broken again, and the effect is poor. In (b) (c) two regions, the coal pillar is undergoing deformation and the internal cracks are continuously expanding. This dynamic condition is not suitable for grouting operations. The overlying strata in (e) area are basically stable, and the damage of coal pillar is basically over.

As the work moves forward, the basic roof collapses, resulting in periodic weighting phenomenon. From the diagram, the cracks in the coal pillar area after periodic pressure are further developed. In order to avoid the re-development of internal cracks after grouting, the grouting time should lag behind at least one periodic weighting step. The grouting area is a blue area like the Fig. 11.

Therefore, the independent segmented grouting system for grouting operation should lag at least one periodic weighting step of the working face, and carry out segmented independent grouting reinforcement of the reserved coal pillar.

After the mining of the working face is completed, the reserved coal column forms a coal body with a certain width that has been grouted and consolidated, and the grouted and consolidated coal pillar is not affected by the advanced strong mining, nor is it affected by the periodic fracture. The overall consolidation is good, and a good surrounding rock environment is constructed for the excavation of entry and support control.

Engineering applications

Based on the above numerical simulation, laboratory test and theoretical analysis, the pre-grouting reinforcement technology is applied in a mine. The thickness is 50 mm, the grouting system is arranged in double layers, the row spacing is 2.4 m, the length of the grouting pipe is 3 m, and the grouting material is P425 cement. The field effect is shown in Fig. 13.

Surrounding rock support of gob-side coal roadway

As shown in Fig. 14, the roof adopts six Φ22mm × 2400 mm left-handed screw thread steel bolts, and the row spacing is 800 mm × 800 mm. The roof anchor cable adopts five Φ18.9 mm × 6300 mm ordinary anchor cables, and the row spacing is 1800 mm. Five Φ22mm × 2400 mm left-handed screw thread steel bolts are used for the two-side bolts, and the row spacing is 800 mm × 800 mm. Three Φ18.9 mm × 6300 mm ordinary anchor cables are used for the anchor cables of the coal pillar side, and the row spacing is 1800 mm.

Surrounding rock displacement monitoring

The measuring point is located at 1.7 m from the roof. The monitoring results show that : (1) The maximum deformation of the solid coal side is 300 mm. (2) The maximum deformation of the coal pillar is 320 mm. The stability, overall strength, and integrity of the coal pillar are all enhanced, and the surrounding rock has less deformation.

Gob-side coal roadway with or without grouting contrast test

The area with a length of an independent grouting system is randomly selected as the test area. The shotcrete process is cancelled when the pre-grouting technology is implemented in this area. The surrounding rock control of the coal pillar side is compared under the same support conditions after the excavation of the gob-side coal roadway is finished.

As shown in Fig. 15, in the test section, a large amount of slurry flows into the goaf, and the slurry does not diffuse inside, resulting in grouting failure. The deformation of one side of the coal pillar is serious, and the deformation reaches 700 mm. The surface is damaged, the internal is loose. and the anchor cable bolt fails, which has an impact on the subsequent production operation. In the normal area of pre-grouting solidification, the surface is complete, the pulling force of the anchor cable is large, the integrity of the coal pillar is improved, the strength is increased, and the stability of the gob-side coal roadway is improved.

In general, after the practical application of pre-grouting reinforcement technology, the grouting effect is basically the same as expected. In the subsequent excavation process of entry, the excavation is stable, the coal pillar is complete and the stability is high.

This technology creates a good surrounding rock environment for the excavation of roadway and support, meets the requirements of safe mining, and has rich application value.

Conclusions

Through the analysis of the fracture development of narrow coal pillar and the influx form of goaf, the failure mechanism of traditional narrow coal pillar grouting leakage is analyzed, which makes up for the defects of traditional scheme, and puts forward a new technology of pre grouting reinforcement and applies it to the field. The key findings derived from this study encompass the following primary conclusions:

-

1.

The UDEC software was used to establish a narrow coal pillar gob-side entry retaining model, and the distribution law of coal pillar cracks under three coal pillar widths of 5 m, 6 m and 7 m was analyzed. In the three cases, the fracture distribution in the range of coal pillar is dense, although its width is increasing, the difference is small.

-

2.

After the mining, gravel in the goaf poured into the roadway, but there is still space in the roadway, and the gangue accumulation density in the shallow part of the goaf is low, and there are a lot of gaps.

-

3.

The traditional roadside grouting technology can not form a closed space. When the coal pillar is destroyed, the slurry will flow into the goaf and cannot be fully diffused i, which is easy to cause grouting failure.

-

4.

Aiming at the defects of traditional roadside grouting technology, pre-grouting solidification technology is proposed. The advantages of this technology mainly include : (a) the flexible grouting ensures the sealing of the grouting space; (b) The segmented independent grouting system and two pipeline layouts ensure the uniformity of slurry diffusion ; (c) Pre-grouting the coal pillar before the excavation of the roadway along the goaf, grouting from the goaf to the coal pillar, and the grouting time lags behind at least one cycle to press the step distance, which reduces the disturbance of the coal pillar again after the grouting operation.

Data availability

Data will be made available on request. If anyone would like to obtain data from this study, please contact Dongdong Chen and Shuaishuai Yue.

References

Dongdong, C. et al. Application of gob-side entry driving in fully mechanized caving mining: A review of theory and technology. Energies https://doi.org/10.3390/en16062691 (2023).

Shengrong, X. et al. Reasonable stopping method and retracement channel support at fully mechanized top coal caving working face of 15 m extra-thick coal seam: A case study. Energy Sci. Eng. https://doi.org/10.1002/ese3.1301 (2022).

Hong, Y. et al. Surrounding rock deformation mechanism of roadways with extra-thick coal seam. Disaster Adv. 6, 226–233 (2013).

Xiang, H. et al. Investigation on rational width of coal pillar and roadway support in isolated panel of extra-thick coal seam. Environ. Inf. Remote Sens. https://doi.org/10.3389/feart.2023.1125678 (2023).

Dongdong, C., Zaisheng, J. & Shengrong, X. Mechanism and key parameters of stress load-off by innovative asymmetric hole-constructing on the two sides of deep roadway. Int. J. Coal Sci. Technol. https://doi.org/10.1007/s40789-023-00635-z (2023).

Deqiu, W. et al. Study on surrounding rock failure mechanism and rational coal pillar width of the gob-side coal roadway under influence of intense dynamic pressure. Energy Sci. Eng. https://doi.org/10.1002/ese3.1416 (2023).

Minggao, Q. & Pingwu, S. Mining Pressure and Strata Control (China University of Mining and Technology Press, 2010).

Zhenqi, S. et al. Theory and application of mining mechanics and strata control. J. China Coal Soc. https://doi.org/10.13225/j.cnki.jccs.2023.1536 (2024).

Yuanxiang, Y. et al. Discussion on determination method of the limit equilibrium zone width based on the deformation analysis of coal wall. J. China Coal Soc. 44, 3340–3348. https://doi.org/10.13225/j.cnki.jccs.2018.1600 (2019).

Deyuan, F. et al. An innovative approach for gob-side entry retaining in deep coal mines: A case study. Energy Sci. Eng. 7, 2321–2335. https://doi.org/10.1002/ese3.431 (2019).

Hongwei, Z., Zhijun, W. & Yuan, Z. Mechanism of grouted-reinforcement in last roadway for pillar in the fully-mechanized gob-side entry. J. Min. Saf. Eng. https://doi.org/10.13545/j.cnki.jmse.2018.03.006 (2018).

Bin, Z. et al. Research on deformation and failure control technology of a gob-side roadway in close extra-thick coal seams. Sustainability. https://doi.org/10.3390/su141811246 (2022).

Bo, W., Changwan, G., Jun, W. & Gang, Y. Bearing capacity experimental study of coal pillar in the gob-side entry driving under the reinforcement of inflatable lock-type anchor. J. China Univ. Min. Technol. https://doi.org/10.13247/j.cnki.jcumt.001125 (2020).

Dongdong, C. et al. Research on the evolutionary patterns and control of surrounding rock superimposed stress field local area loading in double-layer Island face main roadway. Sci. Rep. https://doi.org/10.1038/s41598-024-62466-5 (2024).

Wenrui, H., Fulian, H. & Yongqiang, Z. Field and simulation study of the rational coal pillar width in extra-thick coal seams. Energy Sci. Eng. https://doi.org/10.1002/ese3.538 (2020).

Yiming, Z., Nong, Z. & Jian, W. Failure properties of roadway with extra-thick coal seams and its control techniques. Heliyon https://doi.org/10.1016/j.heliyon.2024.e23990 (2024).

Fuzhou, Q. et al. Stability control mechanism of high-stress roadway surrounding rock by roof fracturing and rock mass filling. Adv. Civ. Eng. https://doi.org/10.1155/2021/6658317 (2021).

Dong, D. C. et al. Evolution law and engineering application on main stress difference for a novel stress relief technology in two ribs on deep coal roadway. J. Cent. South Univ. 30(7), 2266–2283 (2023).

Yanpeng, H. et al. The basic characteristics of paste backfill materials based on highly active mineral admixtures: part I. Preliminary study on flow, mechanics, hydration and microscopic properties. Process Saf. Environ. Prot. https://doi.org/10.1016/j.psep.2024.05.056 (2024).

Quansheng, L., Chaobo, L., Bin, L. & Xuewei, L. Research on the grouting diffusion mechanism and its application of grouting reinforcement in deep roadway. J. Min. Saf. Eng. 31, 333 (2014).

Shunjie, H. et al. Development of cement-based grouting material for reinforcing narrow coal pillars and engineering applications. Processes https://doi.org/10.3390/pr10112292 (2022).

Zaisheng, J., Shengrong, X. & Dongdong, C. Control mechanism and support technology of deep roadway intersection with large cross-section: Case study. Processes https://doi.org/10.3390/pr11051307 (2023).

Qianqian, L. et al. The effect of basalt fiber addition on cement concrete: A review focused on basalt fiber shotcrete. Frontiers https://doi.org/10.3389/fmats.2022.1048228 (2022).

Jipeng, Z. et al. Correlation between the mechanical properties and the fiber breaking morphology of fiber reinforced shotcrete (FRS). Compos. Struct. https://doi.org/10.1016/j.compstruct.2021.114641 (2021).

Bin, H. et al. An optimization method for mix proportion of wet-mix shotcrete: Combining artificial neural network with particle swarm optimization. Appl. Sci. https://doi.org/10.3390/app12031698 (2022).

Jianwei, C. et al. A novel cement-based flexible spray coating for flame retardant. Process Saf. Environ. Prot. https://doi.org/10.1016/j.psep.2023.07.016 (2023).

Malmgren, L. Strength, ductility and stiffness of fibre-reinforced shotcrete. Mag. Concr. Res. https://doi.org/10.1680/macr.2007.59.4.287 (2007).

Yang, B. & Liu, Y. Application of fractals to evaluate fractures of rock due to mining. Fractal Fract. https://doi.org/10.3390/fractalfract6020096 (2022).

Acknowledgements

This research was supported with funding awarded from the Natural Science Foundation of Henan Province (222300420170), the National Natural Science Foundation of China Grant No, 52004286), the Fundamental Research Funds for the Central Universities (Grant No, 2022XJNY02), the China Postdoctoral Science Foundation (Grant No. 2020T130701,2019M650895), the Fundamental Research Funds for the Central Universities (Ph.D. Top Innovative Talents Fund of CUMTB) (No. BBJ2024007), the Doctoral Foundation of Henan Polytechnic University (B2020-35).

Author information

Authors and Affiliations

Contributions

Dongdong Chen: Writing—review & editing, Investigation, Conceptualization, Funding acquisition. Zhixuan Zhang: Writing—original draft, Methodology, Software, laboratory test. Shuaishuai Yue: Writing—review & editing, Investigation, Conceptualization. Chunyang Tian: Methodology. Qingbo Jia: laboratory test, Writing—review & editing. Shengrong Xie: Data curation. Wenkang Zhao: Data curation. Jingchen Chang: laboratory test. Xiangyu Yang: Software. Fuxing Xie: Data curation. Hao Pan: Data curation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chen, D., Zhang, Z., Yue, S. et al. Grouting failure mechanism and new pre-grouting reinforcement technology of narrow coal pillar in fully-mechanized caving gob-side entry. Sci Rep 15, 19897 (2025). https://doi.org/10.1038/s41598-025-03710-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-03710-4