Abstract

This study proposes a model to integrate the Multi-Attribute Decision-Making (MADM) method into the Analysis phase of the Six Sigma (DMAIC) method to improve product quality and optimize processing conditions during high-frequency quenching heat treatment. One of the breakthroughs of the study is the combination of Industry 4.0 technology and the implementation of Shunt Active Power Filter (SAPF) to improve power quality, reduce harmonic distortion (THD), ensure product hardness of 58–62 HRC, and thermal permeability of 1.8–2.2 mm according to standards. Previously, many studies only focused on improving the heat treatment process but did not fully integrate MADM, Six Sigma, and Industry 4.0 technology, nor did any study consider the combination of SAPF to control power quality during high-frequency quenching. Another gap is the lack of quantitative assessment of operator satisfaction after improvement using PLS-SEM. The study applied the Six Sigma DMAIC model combined with MADM to analyze and rank factors affecting product quality. In the improvement phase, the Taguchi method was used to optimize processing conditions, minimizing errors in the production process. At the same time, Industry 4.0 technology and RFID systems were integrated to control production conditions in real time, ensuring the accuracy and reliability of the process. Power quality was improved thanks to the implementation of SAPF, helping to control harmonic distortion (THD) below 5% according to the IEEE 519:2022 standard, minimizing the negative impact of voltage on the heat treatment process. In addition, the study also applied PLS-SEM to measure operator satisfaction after implementing the improved system. The research results show that the rate of substandard products has decreased sharply from 90 to 1%, ensuring hardness of 58–62 HRC and thermal permeability of 1.8–2.2 mm. Power quality is better controlled, with the THD value reduced from more than 34% to less than 5%, meeting the IEEE 519:2022 standard. As a result, production costs are optimized, helping to minimize the waste of raw materials and energy. After implementing the improved system, operators’ satisfaction levels have also increased significantly, reflected in the PLS-SEM measurement indicators. More importantly, this research model is not only effectively applied in the precision engineering industry but also has the potential to be expanded to many other industries, especially small and medium-sized manufacturing enterprises, helping them to increase productivity and improve product quality in the context of Industry 4.0.

Similar content being viewed by others

Introduction

Motivation and background

The manufacturing and processing industry applying science and technology 4.0 to improve production processes is a modern trend1. Many decades ago, Industry 3.0 was developed and put into operation in production processes. In recent decades, along with the development of Internet of Things (IoT) technology, industry 3.0 has turned into Industry 4.02. The production process applies 4.0 technology to help operate more flexibly and bring high efficiency to production3. The rapid development of IoT devices has helped increase the operational flexibility of Industry 4.0 in the manufacturing environment and helped save production costs4. The research question for the production process is whether implementing Industry 4.0 into the production process will help improve operational efficiency and enhance competitiveness in production costs5. The high-frequency quenching heat treatment process is a unique and complex manufacturing environment with uncertain manufacturing conditions. The second research question in this study is the optimal operation of production conditions in the high-stage quenching process, which includes conditions such as the cooling water concentration gradually equaling MG815 and the running current intensity. In the coil, the diameter of the product requiring high-stage quenching heat treatment, the chemical element composition of the SUJ2 raw material, the moving speed of the coil, and the surface gloss of the product help improve production efficiency, save energy, and is easy to operate and control product quality6. Achieving the operating conditions of the high-stage thermal quenching process depends entirely on the condition of the current intensity supplied to the coil. Production costs incurred in the high-stage thermal quenching process arise when the current electricity intensity does not meet the requirements of the IEEE 519:2022 standard and requires a value level to provide amperage for each corresponding product line. The research question is whether power source quality control activities help improve product quality by ensuring product surface hardness from 58 HRC to 62 HRC and the depth of the hardness layer within the standard of 1.8 mm to 2.2 mm7. Improving power quality by implementing and installing active filters is a good method to consider8.

Low-cost production is developed thanks to applying 4.0 techniques and converting semi-automatic structures into automatic ones9. The production conditions of the high-frequency quenching production process are optimized to help save production costs, improve product quality, and improve the company’s production and business efficiency. Technology 4.0 was developed according to the criteria of simple operation, meeting the operator’s needs10. Production costs in the high-stage quenching process are saved. Specifically, MG815 material reduces the rate of evaporation and all current intensity and voltage intensity supplied to the coil, reducing the defect rate. The digital numerical control (DNC) method helps call high-rise heat generator programs using an RFID system linked to the company’s production management system, helping to prevent incorrect program calls, helping to improve safety operations in the process operation of the high-rise thermal quenching process and improve the satisfaction of machine operators and customers regarding product quality perception11. The criteria for developing a production process for decision-makers in a manufacturing company are to develop a production process that is simple to operate, has low production costs, and has flexible operating conditions for each process. Active and safe. Production condition and product quality control data are stored over time, making it possible for different processes to access one source and view results easily. Production data linked between production processes helps improve efficiency in data analysis activities to help decision-makers in the company guide business development strategies12,13,14. An industry 4.0 system designed and deployed at low cost is essential to help small and medium-sized businesses have the opportunity to grow15. Although the low-cost Industry 4.0 system brings economic efficiency when investing for small and medium-sized companies, poor evaluation and monitoring activities of a management department negatively affect the efficiency of operational efficiency of the Industry 4.0 system16,17.

Small and medium-sized companies’ limitations are that their resources are not qualified or aware of Industry 4.0 technology, and their investment capital resources are still weak, so they do not have enough requirements and ability to deploy Industry 4.0 systems18. Another limitation is that decision-makers of small and medium-sized companies are not determined to apply Industry 4.0 technology to improve production processes from Industry 3.0 technology to Industry 4.0 technology19,20. The first research question is whether implementing Industry 4.0 technology to improve production processes brings about improvement in product quality, production process efficiency, and business efficiency in production and business necessity.

All machines in the cashew production process use power to operate, and the quality of the power source positively impacts the machine’s efficiency. The harmonic signal is the agent that causes power quality deterioration in the power supply system for processing machines. Devices using Industry 4.0 technology are the main cause of generating harmonic signals, and devices using high-frequency switching in automatic control include switches, LED lights, tablet screens, and monitors. The second research question is whether harmonic mitigation designed by hardware devices, such as active power filters, is necessary, and the value brought by controlling the THD value in the power source within the IEEE 519:2022 standard is small. More than 5% is essential to help the processing machine ensure accuracy during operation, especially for high-temperature quenching machines.

Manufacturers participating in this project are faced with improving product quality, reducing defect rates, and ensuring stability in mechanical manufacturing processes. The main challenge lies in the fact that factories produce defective products, which affects reputation, costs, and production efficiency. To solve this problem, manufacturers need to perform root cause analysis using tools such as Ishikawa diagrams or Pareto analysis to identify and eliminate the main causes of defects. Next, applying the DMAIC model in Six Sigma and the Taguchi method will help optimize operating parameters, from current intensity and heating time to coil spacing. At the same time, improving power quality by installing adaptive power filters (SAPF) to reduce harmonics and ensure power supplies meet IEEE 519:2022 standards is an important solution. In addition, implementing a real-time monitoring system based on Industry 4.0 technology will help monitor production conditions and product quality. At the same time, employee training programs will improve awareness and skills in quality control. To prevent the recurrence of defects, manufacturers need to store and analyze production data to predict and prevent similar errors in the future, combined with periodic inspection and maintenance of machinery. These solutions not only help reduce defect rates and improve production efficiency but also increase customer satisfaction and improve business reputation, ensuring competitiveness and sustainable development in the long term.

The research question focuses on solving the problem of improving product quality in the manufacturing process by identifying and applying the optimal improvement method and finding the most suitable operating conditions for this method to be effective. The research aims to identify important quality aspects of mechanical products, thereby making quality improvement decisions based on data analysis and modern optimization tools. By applying methods such as DMAIC in Six Sigma, MADM to prioritize issues that need improvement, and the Taguchi method to optimize technical parameters, the research not only focuses on improving the manufacturing process but also ensures that product quality meets strict standards. In addition, modern technologies such as real-time monitoring systems based on Industry 4.0 technology and adaptive power filters (SAPF) are also deployed to control important factors such as power quality and operating conditions. The expected result is not only to improve the quality of mechanical products but also to increase production efficiency, reduce defect rates, and establish a sustainable process, bringing long-term benefits to the manufacturing company.

Eliminating non-value-added activities is a core goal to increase business profits. Managers are always looking for ways to optimize production by applying Industry 4.0 techniques, which help automate processes, shorten processing times, eliminate waste, and improve productivity. This technology not only supports optimizing production activities but also allows for data storage and analysis during processing, flexibly meeting diverse customer requirements, thereby improving management efficiency and business competitiveness.

Power quality plays a critical role in industrial manufacturing, especially in induction heat treatment, where high-frequency currents are required to heat metallic materials in a uniform and controlled manner. However, in modern manufacturing systems, power quality issues such as total harmonic distortion (THDi), voltage fluctuations, low power factor, and voltage imbalance can significantly impact heat treatment performance and product quality. These deviations result in uneven temperature distribution in the material, reducing hardness uniformity, increasing defective product rates, and wasting energy. One of the most common problems in induction heat treatment is current fluctuations, which change the magnetic field strength around the treated material, resulting in unstable temperatures. When THDi exceeds 12%, high-order harmonics can degrade the performance of induction coils, causing energy imbalance and leading to over- or under-heating, directly affecting the material’s hardening depth. This increases the rate of substandard products and reduces the equipment life due to thermal overload, causing production interruptions and increasing maintenance costs. To solve these problems, this study proposes a model combining Six Sigma with Active Power Filter (SAPF) to optimize power quality and strictly control parameters during induction heating treatment. SAPF plays an important role in reducing harmonics, improving power factor, and stabilizing current. At the same time, Six Sigma helps analyze, measure, and optimize the manufacturing process to reduce the rate of defective products. By combining these two methods, the study aims to improve the accuracy of the heat treatment process, significantly reduce the hardness defect rate, and improve production efficiency. This study not only helps improve product quality but also contributes to reducing energy consumption and improving the stability of the production system, helping enterprises better comply with power quality standards such as IEEE 519:2022. In the next section, the study will delve into the methods of analyzing and evaluating the effectiveness of the SAPF + Six Sigma model in controlling power quality and optimizing the induction heat treatment process, thereby proposing strategies to improve production quality in modern industrial environments.

The research is carried out according to the following specific objectives:

-

Build a general model to calculate production costs in the high-rise quenching heat treatment process and the overall production cost.

-

Build the MCDM method model into the defined phase of the Six Sigma method to select problem points to improve the high-rise thermal quenching production process.

-

Design and deploy an active power filter device into the power supply for the high-rise thermal quenching machine to improve the quality of the power source and ensure the cos(φ) coefficient is greater than 0.9, and the THD parameter value is guaranteed according to the IEEE 519:2022 standard, which is less than 5%.

-

Evaluation of low production costs in high-rise quenching heat treatment processes in a competitive environment.

-

Build and deploy an Industry 4.0 technology model to measure and control machining conditions and product quality at the high-rise heat treatment process at a low cost to improve production and business efficiency in small and medium companies.

-

Measuring system user satisfaction after improvement in the heat treatment process confirms the effectiveness and inadequacies in the operation of the continuous improvement system to help improve the efficiency of continuous improvement activities using the PLS-SEM method.

Content, contribution, and organization of this study

This study suggests using the Multi-Attribute Decision Making (MADM) approach to analyze and choose which items require modification to increase stability throughout the Six Sigma method’s analysis phase. The high-rise thermal quenching process’s processing conditions. Proposal to optimize production conditions throughout the high-temperature quenching process and apply the Taguchi method in the Six Sigma improvement phase to meet customer requirements and ensure stable product quality after high-temperature quenching. The depth of penetration is between 1.6 and 2.2 mm. To comply with IEEE 519:2022, suggest a practical power quality measurement at the high-frequency quencher’s source and watch for Total Harmonic Distortion (THD) values under 5%. The Taguchi approach is used to optimize the current intensity (A) to help regulate the energy source utilized by the high-stage quenching machine. In the improvement phase of the Six Sigma method, it is proposed to use a Digital Numerical Control (DNC) system based on the Industry 4.0 technology platform to scan data from RFID objects, retrieve data, and link data between production processes and product quality control results. Implementing system maintenance schedules in the online measurement system is also proposed. According to the technical readiness measurement variables, a PLS-SEM approach is suggested to be deployed during the Control phase of the Six Sigma method to gauge user satisfaction with the upgraded system during the high-rise thermal quenching process. Approaches, information engineering measurement components, and evaluating the utility and usefulness of enhanced systems. In line with the principles of continuous improvement, the author expects that this research article will offer a sample research model in a continuous improvement environment as well as a research model that scales and impacts activities related to continuous improvement in manufacturing businesses. In various industrial firms, the Six Sigma method helps increase productivity and business efficiency while improving the quality of the products and production processes.

In the context of the Industrial Revolution 4.0, which is strongly changing the manufacturing industry, applying advanced technologies to the processing process is an inevitable trend to improve efficiency, optimize costs, and enhance competitiveness. However, the high-frequency quenching process is one of the complex production stages, affected by many factors such as current intensity, chemical composition of the material, coolant concentration, and speed of the induction coil, making it difficult to control product quality. In addition, harmonic distortion (THD) in the electrical system has a negative impact on the hardness and heat permeability of the product, leading to surface defects, deformation, or damage during the processing process. Controlling power quality is an important challenge because unstable power sources can reduce machine performance, waste energy, and increase production costs. On the other hand, small and medium-sized manufacturing enterprises often have difficulty investing in advanced quality monitoring and control systems, making it more challenging to ensure that products meet standards (hardness 58–62 HRC, thermal permeability 1.8–2.2 mm). Therefore, this study aims to integrate 4.0 technology into the production process, helping to automate real-time quality control and propose solutions to optimize processing conditions to reduce product defects, save energy, and improve operating efficiency. In addition, evaluating the satisfaction of operating staff is also an important factor in measuring the effectiveness of the improved system, thereby making appropriate adjustments to improve work efficiency and process stability.

Power quality is an important factor affecting the performance and reliability of industrial manufacturing systems, especially in induction heat treatment. This process requires a high-frequency current to heat metal materials precisely. However, problems such as high harmonic distortion (THDi), voltage fluctuations, low power factor, and voltage imbalance can degrade heat treatment efficiency, leading to uneven temperature distribution, affecting the hardening depth, and increasing the defective rate of products. In many industries, SAPF (Active Power Filter) has been widely used to improve power quality in nonlinear load systems such as variable frequency drives, smart grids, and industrial power systems, but there have been few studies on applying SAPF in induction heat treatment processes. This study’s novelty lies in applying SAPF to control power quality in an induction heating system, which has not been widely explored in previous studies. Unlike traditional SAPF applications that focus on harmonic reduction for induction motors, electronic converters, or microgrid systems, this study focuses on the impact of SAPF on the induced current in the heating coil, a factor that determines temperature stability during material heating. The biggest difference from previous applications is that SAPF is used not only to reduce harmonic distortion (THD) and improve power factor but also to maintain a stable current during short heating cycles, ensuring uniform hardness and optimizing the hardening depth in the metal material. Furthermore, instead of focusing solely on reducing power disturbances in the overall power grid system, this study uses SAPF as part of a manufacturing quality control model, combined with the Six Sigma (DMAIC) method, to measure and optimize the process. This method improves power quality, reduces the defective product rate from 90 to 1%, and improves heat treatment efficiency by strictly controlling current fluctuations, sintering temperature, and hardening permeability. The SAPF + Six Sigma model proposed in this study can be considered a breakthrough in the field of induction heat treatment process optimization, which helps improve product quality, reduce energy consumption, and improve system stability. Compared with previous studies, this study not only considers SAPF as a power electronics solution but also integrates it into the manufacturing quality control system, which helps to improve performance in an industrial field with high requirements for accuracy and stability.

This study chooses fuzzy sets instead of rough sets or extended forms such as IVIFS and q-ROF because fuzzy sets provide better uncertain data handling capabilities, simplify calculations, are easy to deploy in industrial environments, and are suitable for small and medium-sized manufacturing enterprises. This is the optimal choice to help improve production efficiency, minimize product defects, and improve quality in the context of Industry 4.0.

The research paper is organized according to the following structure: Section II: Presenting the content of Raw material and Methodology. Section III: Detailed presentation of the results of the study. Section IV: Show the content of the discussion, and Section V: Present in detail the conclusion of the research paper and future research directions.

Raw material and methodology

Types of manufacturing cost

In production and business, knowing the range of production costs for any product line is essential21. Production cost model during raw material induction heat treatment of the precision mechanical product line’s Suj222. This study model explains two production cost computations: the first precisely characterizes the Suj2 metal product line’s production costs, and the second carries out a particular breakdown of the various cost kinds in the manufacturing process using various cost components. The author of this study focuses on calculating production costs in an induction heat treatment process and estimates the total cost associated with business efficiency in manufacturing a mechanical product line using Suj2 material. These costs may vary depending on the circumstances in each process for the particular production process. Examples include selling expenses, infrastructure management costs, and other utility-related expenses related to the high-rise heat curing process. The goal is to develop a model to determine the associated production cost for the induction heat treatment process. To achieve the objective of increasing production efficiency and the company’s business, however, indirect costs have a substantial impact on the total cost of production and must be carefully considered when analyzing both direct and indirect costs in production.

The production cost model for the induction heat treatment process includes expenditures for machines, materials, debinding, sintering, labor, consumables, and other expenditures.

Formula 1 determines the overall manufacturing cost during the production process.

Where, \(\:{C}_{pc}\): Production cost, \(\:{C}_{ma}\): Machine cost, \(\:{C}_{m}\): Material cost, \(\:{C}_{de}\): De-binding cost, \(\:{C}_{si}\): Sintering cost, \(\:{C}_{la}\): Labor cost, \(\:{C}_{co}\): Consumable cost, and \(\:{C}_{ot}\): Other cost.

The business purchases the processing machines used in the production process through depreciation \(\:{(C}_{dep}:USD\:per\:machine)\)(Eq. 3). The processing equipment runs on three phases of electricity at 230 volts \(\:\left({C}_{en}:USD\:per\:machine\right)\) (Eq. 4) and the business needs to perform weekly, monthly, and other periodic maintenance on the processing machinery \(\:\left({C}_{mai}:USD\:per\:machne\right)\) (Eq. 5) and as advised by the manufacturer, replace the parts (spare parts). When the processing machine is used, the aforementioned costs accumulate over time. Formula (2) computes the overall cost spent on the processing machine.

Where,

Where,\(\:{T}_{p}\left(hours\right)\): Operation time per machine, \(\:{C}_{dep,\:a}\:\left(USD\:per\:years\right)\): depreciation cost, \(\:{U}_{machine}\): Machine uptime between 0 and 1, \(\:\text{P}\text{P}\:\left(\text{U}\text{S}\text{D}\right)\): Machine cost, and \(\:\text{Y}\:\left(\text{y}\text{e}\text{a}\text{r}\text{s}\right)\): Machine lifetime.

Equation 4 calculates the energy cost created at the processing machine based on the machine’s operating hours and the quantity of energy used at the processing machine’s cable supply.

Where, \(\:{T}_{p}\:\left(\text{h}\text{o}\text{u}\text{r}\text{s}\right)\): Operation time of the machine, \(\:{P}_{p}\left(\text{k}\text{W}\text{h}\right)\): The ratio of the consumption power energy of the machine and \(\:{c}_{0}:\left(\text{U}\text{S}\text{D}\:\text{p}\text{e}\text{r}\:\text{k}\text{W}\text{h}\right)\): Energy costs.

Where, \(\:PP\:\left(USD\right)\): Machine unit price, \(\:{MC}_{\%}\): The effective operating hours represent the total hours per year of the Unit and the percentage of maintenance costs per machine.

Formula (6) is used to determine the cost of raw materials used in product production; Formula (7) determines the cost of raw materials used in product manufacturing per unit.

Where, \(\:N\): Number of parts, \(\:{v}_{m}\left({cm}^{3}\right)\): The volume of material, \(\:{c}_{m}\left(USD\:per\:{cm}^{3}\right)\): Cost of material per unit, \(\:{v}_{s}\:\left({cm}^{3}\right)\): Volume of material support, \(\:{v}_{s}\left(USD\:per\:{cm}^{3}\right)\): Cost of volume of material support.

The cost of material lost during the induction heat treatment process due to high temperatures burning or flaking the material’s surface is calculated using the formula (8).

Where, \(\:{V}_{de}\left(liters\right)\): The volume of cooling fluids, \(\:{c}_{de}\left(USD\:per\:liters\right)\): Cost of fluid per unit, \(\:{P}_{de}\left(kW\right)\): Consumed of power, \(\:{T}_{de}\left(hours\right)\): Time, and \(\:{c}_{0}\left(USD\:per\:kWh\right)\): Cost of power per unit.

The Products made with Suj2 materials are subject to stringent controls during production, particularly during the induction heat treatment step. The induction heat treatment process involves numerous input factors, including voltage, amperage, cooling water volume, and concentration. Consequently, all particular aspects must be considered when determining the cost, energy consumption cost, and process protection cooling water cost. This is done using formula (9).

Where, \(\:{V}_{\alpha\:}\left(liters\right)\): Volume of MG815, \(\:{c}_{\alpha\:}\left(USD\:per\:liters\right)\): Cost of MG815 per unit, \(\:{P}_{s}\left(kW\right)\): Consumed power, \(\:{T}_{s}\left(hours\right)\): Time, \(\:{c}_{0}\left(USD\:per\:kWh\right)\): Cost of power per unit, and \(\:{N}_{s}\): Numbers of parts.

The hourly labor rate is used to compute the cost of employing direct labor during office hours and production. Besides the laborers who handle the machine directly during production, additional personnel are responsible for machine maintenance, spare component replacement as necessary, and production management. Formula (10) is used to compute all labor costs.

Where, \(\:{T}_{j}\left(hours\right)\): Operation time, \(\:{c}_{j}\left(USD\:per\:hours\right)\): Cost of operation per unit.

The cost of consumables, including packaging, QR Code stamps, and other supplies, is determined using the formula (11).

Where, \(\:{c}_{i}\left(USD\:per\:unit\right)\): Cost per unit, \(\:{N}_{i}\): Number of units.

In this study, the material used was SUJ2 bearing steel, a low-alloy tool steel with high carbon content commonly used to manufacture ball bearings, camshafts, and high-wear parts in the mechanical industry. SUJ2 steel was selected due to its high hardness, good wear resistance, and especially its mechanical properties, which can be significantly improved after induction heat treatment. Before heat treatment, the chemical composition of SUJ2 steel was determined by optical emission spectroscopy (OES), which showed that the carbon content of 0.95-1.10% enhances the hardness, while chromium (1.3-1.6%) improves the wear resistance. After heat treatment, the mechanical properties of the material changed significantly, with hardness increasing from 20 to 25 HRC to 58–63 HRC, tensile strength more than doubled, but elongation decreased due to microstructural transformation to martensite and dispersed carbides, which improved hardness but reduced ductility. This study’s induction heat treatment process was carried out on a high-frequency heating system with optimized parameters using the Six Sigma method. The sample was heated to 820–850 °C for 6.8–7.2 s, rapidly cooled with polymer solution or oil to form a martensite structure, and then tempered at 150–180 °C for 60 min to reduce residual stress and improve toughness. The key difference between this study and previous studies is the application of Active Power Filter (SAPF) to control the power quality during induction heating, which helps maintain the stability of the current and significantly improves the accuracy of the sintering temperature. Before applying SAPF, the total harmonic distortion (THDi) reached 36.35%, far exceeding the allowable level according to IEEE 519:2022, leading to large temperature fluctuations (± 50 °C) and increasing the defective rate of products up to 90%. After implementing SAPF, the THDi decreased to 5.21%; the sintering temperature was maintained within ± 5 °C, reducing the defective rate to only 1%. This improvement was validated by PLS-SEM, showing a correlation coefficient R² = 0.82, demonstrating that the current stability (improved by SAPF) strongly influences the product hardness after heat treatment. The error between the experimental and predicted model values is only less than 3%, ensuring the system’s accuracy. Thus, this study not only optimizes the induction heat treatment process but also proves that the integration of SAPF helps minimize the negative impact of power quality on product quality, opening a new approach to power control applications in modern industrial production systems.

Multi-attribute decision making (MADM)

Numerous outcomes of the MADM approach are also assessed subjectively in terms of ranking criteria23. Decision-making outcomes for the actual world are further complicated by the decision-making process in an unpredictable setting, as well as the ambiguous surroundings and lack of explicit values in MADM24. To address this shortcoming of MADM, the fuzzy approach was created, and its fuzzification function is also straightforward and not overly complex25. Nevertheless, the uncertainty in the environment with a limited number of samples and the inconsistent member or non-member functions remain, and the trio’s IF function is created to increase the fuzziness.

In this study, the Entropy method was chosen to determine the criterion weights because of its objectivity, independence from subjective assessment, and no comparison matrix required, which saves time and minimizes human error. This method is particularly suitable for MADM and fuzzy sets, supporting the processing of uncertain data in industrial production. In addition, Entropy is simple to calculate, easy to deploy, and suitable for industrial environments, especially small and medium-sized enterprises. Meanwhile, WENSLO is capable of processing highly variable data but requires strict standardization, causing complications in the application process. LOPCOW helps to adjust the weights flexibly but requires regular monitoring and updating, while CRITIC is based on the correlation between criteria but is less effective in production environments without clear linear relationships. Compared to the above methods, Entropy is more optimal because it does not require correlation evaluation between criteria, helping to reduce the complexity of the model. As a result, this method is highly effective in optimizing the decision-making process in a volatile production environment. Choosing Entropy ensures accuracy, simplifies calculations, and increases feasibility in practical applications, improving efficiency and quality in production management.

Entropy has been a key component in fuzzy methods’ development, as it has enhanced accuracy performance when working with data in ambiguous or uncertain environments. Entropy handles measurement data in unclear and practical contexts for optimal performance26. The entropy method implements the divergence approach, which compels us to select the appropriate evaluation criteria. Since the entropy value and the divergence rate are negatively correlated, a high divergence rate will result in a low entropy value. Options with varying weights are indicated by entropy weights. Since the entropy method does not require the implementation of comparison matrices, it is a frequently utilized and user-friendly technique across several sectors27.

The MADM technique aims to identify the best substitute for the current solutions. By multiplying the weights row by column for the matrix containing the matching criterion, the TOPSIS technique computes the weights using a normalized matrix28. Find the Euclidean distance technique between the ideal point and the negative points. Then, compute this distance using the corresponding important criteria for each measurement. For the decision matrix, the Euclidean distance index serves as the decision weight. The TOPSIS approach is incredibly effective at solving complex issues and may be used in various industrial settings29.

In factories that produce mechanical parts, the suggested MADM approach with TOPSIS, used with the entropy of IF specified in the Six Sigma model, achieves a continual improvement of production costs (Shown in Fig. 1).

There are 2 shapes to calculate the IF index: triangular IF number (TIFN) and trapezoidal IF number (IFN). This paper selects a triangular IF number (TIFN) that meets the criteria of simplicity of use, visualization of results, representation of calculations, and simple calculations. The member function IF is calculated according to formula (12).

Where the boundary region values of TIFNs are defined as \(\:(a,\:b,\:and\:c)\), with \(\:a\): Lower limit, \(\:b\): Middle limit, and \(\:c\): Upper limit when \(\:a\le\:b\le\:c\).

The IF index non-member function is calculated by the formula (13)

Where,

The steps in the Hybrid Fuzzy MADM-based entropy model are detailed in Table 1.

In this study, TOPSIS (Technique for Order of Preference by Similarity to Ideal Solution) was chosen as the evaluation method because of its simplicity, objectivity, and ability to quantify the optimality of each option based on the distance to the ideal and less-than-ideal solution. This is especially useful when analyzing conflicting criteria in the system, such as production costs, product quality, energy efficiency, and employee satisfaction. Compared with other methods such as MABAC, VIKOR, MAIRCA, or MARCOS, TOPSIS has the outstanding advantages of being easy to calculate and easy to implement, suitable for real industrial production environments. Although MABAC is flexible with both quantitative and qualitative criteria, the calculation process is more complicated. VIKOR focuses on compromise solutions for conflicting but less-than-ideal criteria to find a clear, optimal solution. MAIRCA balances the ideal and the practical but is less widely used, while MARCOS, an improvement of TOPSIS and VIKOR, requires more complex data normalization. TOPSIS stands out for its simple normalization process and insensitivity to input data errors and has been widely used in Six Sigma research, quality management, and production optimization. Therefore, this method ensures accuracy and reliability and is suitable for evaluating system performance in multi-criteria production environments.

Partial least squares structural equation modeling (PLS-SEM)

In the study, in addition to an SEM model that is used to simulate all the paths simultaneously and in detail, a partial least squares structural equation modeling (PLS-SEM) model also contributes. (1) Despite limitations on sample size, sample size distribution, and sample size imposed by the PLS-SEM technique. (2) The PLS-SEM approach excels in assessing both non-independent variables while delivering reliable and accurate results. (3) PLS offers a strong line of defense against biased data and independent factors. There are two techniques for sampling30. When doing descriptive research and determining causal relationships, the probabilistic sampling method is chosen since it is error-controlled and highly representative of the population. The non-probability sampling method is utilized for visit studies since it saves time and money31. The probability sampling method is employed in this investigation. The quality of the sample size (Eq. 27) and the number of samples (Eq. 28) are factors considered while determining the best sampling technique for the study.

Where: \(\:q\): Shows the occurrence rate of the elements in the sampling unit, exactly as the sampling target \(\:0\le\:q\le\:1\).

Where: \(\:Z\): The statistical value corresponds to the reliability. \(\:s\): The standard deviation of the original sample. \(\:\stackrel{-}{x}\): Average of the original sample. \(\:a\): The sample bias rate depends on the sensitivity of the research results.

Case study for improvement

SUJ2 material has a ductility and hardness of less than 15 HRC before heat and induction heat treatment; the surface hardness increases from 58 HRC to 62 HRC with a low depth of induction heat treatment from 1.7 mm to 22 mm, it is used in the cylinders of the dies of heavy-duty presses due to their ductility and rigidity; SUJ2 Material has excellent bearing properties such as wear resistance, ductility toughness, and hardness. Its workability and fatigue resistance are also excellent. SUJ2 is widely used to produce plastic molds, ball bearings, steel balls, balls, bushings, shafts, guide rods, guide pins, and other mechanical parts. Chemical composition of SUJ2 according to JIS4805 (C(0.95%~1.10%), Cr(1.3%~1.60%), S(0.025%Max), Si(0.15%~0.35%), Mn(0.5%Max) ), P(0.025%Max), Cu(0.20%Max), Ni(0.25%Max), Mo(0.08%Max) and Mechanical properties of SUJ2 material: Compression modulus (140 GPa), Shear modulus (80 GPa) ), Elastic modulus (190–210 GPa), Porosity coefficient (0.27–0.30), Tensile strength (1617 (kgf/mm²)), Bending strength (1176 (kgf/mm²)), Elongation (5%), and Impact strength (28 (J/cm2)).

Thermal engineering has types such as volumetric quenching, performing a thermal process that immerses the entire product in an oil bath and heats it to a temperature of 1200 degrees C, and the material hardness reaches from 58 HRC to 62 HRC for the whole product. The Chikka type surface heat treatment performs a heat process by NITO gas, and surface hardness reaches 75 HCR to 85HRC with the Chikka penetration depth from 1.9 mm to 2.5 mm and induction heat treatment by coil process coil surrounds the product and heats it by current and voltage from the source with surface stiffness ranging from 58 HRC to 62 HRC and penetration depth from 1.7 mm to 2.2 mm.

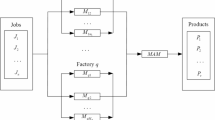

Improving production business efficiency in a mechanical factory means enhancing productivity by reducing production costs at each production process. This study aims to improve the production cost of mechanical products using Suj2 raw material in an induction heat treatment process to improve production efficiency. The content of the stages of establishing criteria to improve the efficiency of the induction heat treatment process with the post-permeation size of 1.7 mm to 2.2 mm and the material hardness after the induction heat treatment. The target is from 58 HRC to 62 HRC responses according to the DMAIC (Define-Measure-Analysis-Improve-Control) cycle. The continuous improvement project of this study includes personnel including mechatronics maintenance: 2 people, high-rise heating machine operator: 4 people, induction heat treatment supervisor: 2 people, high-rise temperature data entry staff (high-rise thermal conditions, induction heat treatment test product quality, order-to-order production data to meet the production plan): 1 person, production manager: 1 person and members in the continuous improvement project under the Six Sigma program (Shown in Fig. 2). 7 criteria for production costs are listed according to the opinion of a member of a Six Sigma project doing brainstorming, including C1: Labor cost, C2: Material cost, C3: De-binding cost, C4: Sintering cost, C5: Machine cost, C6: Consumable cost, and C7: Other cost. The operator on the ground gathers data while the blank product is undergoing induction treatment to identify alternatives. 16 batches of data were gathered at 4 separate time intervals, and in total, 64 products were chosen for study based on the criteria C1, C2, C3, C4, C5, C6, and C7. These study samples were representative of various dates, and the researchers described the sampling procedures, giving instructions to the operator performing sampling during the grinding process and reassessing sample quality. These samples each correspond to 16 different product batches. Both formula A and formula B are applied to the lots. 8 lots were numbered from A1 to A8 for formula A during the study period due to a change in the formula, and the remaining 8 lots were numbered from A1 to A8 and B1 to B8 for formula B.

In line with the Japanese sales criterion that the customer is king, a Japanese foreign direct investment (FDI) company invests in Vietnam and continuously improves efficiency and quality. At a Japanese foreign direct investment (FDI) mechanical manufacturing company in Vietnam, this study carries out continuous improvement efforts under the Six Sigma project. Japan consistently leads the globe in both product quality and user reputation for its mechanical manufacturing sector. Every pale company’s organizational chart has a continuous improvement department working on several aspects of the business, such as improving worker technology proficiency, product quality, manufacturing environments, and processes. The company’s continuous improvement division has always been crucial to raising output and the caliber of the products produced.

The first stage in successfully implementing an improvement project is choosing one, which is essential to project success. If the implementation project is buried, the results will fail to fulfill the actual needs and hinder the company’s future development and present needs. The Six Sigma project is carried out according to the crucial project criteria, which makes it easier for the company’s development strategists to discern between improvement projects that are currently underway and those that have already been completed. Correlation graph tools are used in brainstorming sessions with industry professionals to assess and choose critical project selection criteria.

Five employees of the company in Vietnam and five representatives of the parent company in Japan were among the experts invited to participate in brainstorming sessions and interviews. Every student possesses professional credentials and has worked in the relevant field for projects involving continual development for over 15 years. The suggested key criteria were used to guide the interview and brainstorming sessions by the Critical to Quality (CTQ) approach (Shown in Fig. 3), following 3 specific implementation steps as follows: Step 1: Gathering and outlining the feedback received from customers and adhering to the company’s quality policy criteria. Step 2: Conduct expert brainstorming sessions and interviews to identify the quality program and schedule components. Step 3: Determine and assess performance in achieving the company’s declared objectives and the degree of client satisfaction. Table 2 displays the performance outcomes based on the Critical to Quality (CTQ) chart.

A brainstorming session to gather ideas from relevant members with responsibilities, such as production managers, department heads, machine operators with more than 15 years of experience, and manufacturing experts, is necessary for the Six Sigma method of continuous improvement project to be implemented according to the right goals. The brainstorming session’s output must also meet the previously specified selection and exclusion criteria. These standards were developed to remove the divergent or contradictory viewpoints of specialists who assessed the qualifications of various participants in ideation sessions. Table 3 displays the results using linguistic variables, and Table 4 displays the weighted variables.

The content of giving DM variables to choose ranking criteria for golf variables is displayed in Table 5. The matrix transfer’s analysis results are based on the selection weight criterion, divergence, and entropy methods. Table 6 shows the analysis’s findings and demonstrates that the fifth parameter (Aspects of the content related to environmental consumption. For the continuous improvement project, minimum energy and minimum waste play the most important roles. The second element, which has the least relative relevance, is the downtime cost for content maintenance, activity costs, and breakdown costs.

The function and method for assessing Six Sigma project selection based on the standards decided upon during the brainstorming session are depicted in Fig. 4. Level 1 of the Six Sigma project establishes its objectives. Level 2 refers to the initiatives currently underway and is utilized to choose appropriate projects for improvement implementation based on predetermined standards. Level 3 displays the project possibilities along with the crucial parameters that were previously mentioned. It takes a lot of time and effort to comprehend the model of analysis and project selection based on the levels and the appropriate criteria for each level, necessitating discussion and study of the project by the analyst. Learn the methods and assess each project’s profitability.

The values of the linguistic variables are converted into fuzzy variables, and the set of fuzzy variables’ linguistic variables is created to produce selection performance values for alternatives. Table 7 lists the linguistic factors transformed into fuzzy variables and then used to assess the chosen alternatives. When it comes to choosing options for Six Sigma initiatives based on predetermined criteria, DMs are crucial in the scraper comparison matrices.

Using the Fuzzy TOPSIS method’s analysis results, choose the fifth parameter corresponding to the content’s environmental consumption features. Reducing energy consumption and waste is given top priority to boost the company’s operational effectiveness through Six Sigma method-based continuous improvement initiatives.

In the high-frequency quenching heat treatment process, high current and current intensity are used to pass through the coil to quench the SUJ2 material. Good control of current and voltage factors ensures product quality, that is, no defects arise (parameter P1 (Defects in process and final inspection defects)) and, at the same time, control damaged materials. or avoid wasting raw materials in the high-temperature heat treatment process (parameter P4 (Material waste, non-value activities, and scraps)). In short, implementing good control of power quality will ensure 3 parameters: P5 (Minimum energy consumption, minimum waste), parameter P4 (Material waste, non-value activities, and scraps), and parameter P1 (Defects in process and final inspection defects). The question for this research article is whether to deploy and install a Shunt Adaptive Power filter (SAPF) device system at the source to ensure improvement of power source quality, and ensure the above requirements are an urgent study.

To evaluate the effect of Active Power Filter (SAPF) on the induction heat treatment quality of SUJ2 steel, this study used the Design of Experiments (DOE) method to ensure the objectivity and reliability of the data. The experiment was conducted with 30 SUJ2 steel samples, divided into two groups: the control group (without SAPF) and the test group (with SAPF). Each group consisted of 15 samples, providing sufficient data to evaluate the difference between the two heat treatments. The test samples were randomly selected from the same production batch, with uniform size and shape, to ensure consistency in the experiment. To minimize errors due to systematic fluctuations, each test condition was repeated three times, bringing the total number of treatments to 90 separate measurements. The experiment was conducted using a Randomized Block Design (RBD), in which the position of each sample in the heat treatment system was randomly shuffled to eliminate the influence of differences in the heating process. The measurement and analysis of the results were performed as a single-blind experiment, in which the expert evaluation team did not know in advance which samples were in the control group and which were in the test group. This helped eliminate observer bias and ensure objectivity in data recording. The parameters measured included total harmonic distortion (THDi), sintering temperature, material penetration depth, surface hardness (HRC), and defective product rate. Each parameter was measured at three different times during the production process to evaluate the stability of the heat treatment system. The collected data were analyzed using the Analysis of Variance (ANOVA) method to determine the influence of SAPF on heat treatment quality and using multiple linear regression to evaluate the relationship between factors affecting product quality. All analyses were performed at a significance level of α = 0.05, ensuring statistically significant results. In addition, the study also used an independent t-test to compare the differences between the control and experimental groups to confirm that SAPF has a significant influence on the induction heat treatment quality of SUJ2 steel.

This paper describes in detail the Active Power Filter (SAPF) design and configuration, and how to integrate it into an induction heating system to improve power quality, stabilize current, and enhance product quality. The SAPF in this study is implemented as a three-phase parallel filter, using IGBT (Insulated Gate Bipolar Transistor) technology combined with real-time feedback control, consisting of three main components: a data acquisition and measurement unit to monitor current and harmonics, a DSP (Digital Signal Processor) to analyze real-time data and calculate appropriate compensation current, and an IGBT inverter responsible for generating anti-phase compensation current to eliminate harmonic disturbances in the power system. The SAPF operates on the principle of detecting and compensating harmonics by generating anti-phase current, thereby reducing the total harmonic distortion (THDi) below the IEEE 519:2022 standard. The integration of SAPF into the induction heating process is carried out in a parallel connection model, in which the filter is directly connected to the power supply to the induction coil, which monitors and regulates the current quality without interrupting the operation of the high-frequency heating system. When THDi exceeds the standard level, the IGBT inverter in SAPF generates a compensation current to maintain a stable voltage, thereby helping to precisely control the heating temperature (820–850 °C), heating time (6.8–7.2 s), and cooling rate (20–25 °C/s) during the heat treatment process. Experimental results show that after integrating SAPF, THDi decreased from 36.35 to 5.21%, and the power factor increased from 0.89 to 0.98, helping to maintain a stable sintering temperature with a fluctuation of ± 50 °C to ± 5 °C, thereby reducing the defective product rate from 90% to only 1%. This proves that SAPF not only plays an important role in improving power quality but also helps to improve the heating process accuracy, optimize the hardness and hardenability of materials, reduce energy consumption, and prolong the life of high-frequency sintering equipment. Integrating SAPF into the induction heat treatment process is a breakthrough in combining advanced power filtering technology and optimizing the production process, improving efficiency and quality in the modern metallurgical industry.

Result

Material and induction heat treatment process

The steel being discussed here contains elements like Fe, C, and other alloys like Cr and Mn. The ratio of C components to other alloys will affect the characteristics of steel. The hardness and wear resistance of the material will rise with an increase in carbon content following heat treatment.

Heat treatment indicates that the metal’s structure will alter at temperatures higher than the threshold of 723 °C. It is known as the Ostenite structure at that time (the temperature threshold varies with carbon content). In this scenario, the embryo will harden if the temperature drops abruptly. After that, the material structure becomes a Martensite structure32,33. If the embryo in the aforementioned situation is cooled gradually, it will soften. This is how the RAM works. Ferrite + Cementite is the name of the metal structure.

The alloy used to make SUJ2 steel raw material contains trace carbon and iron. Its inexpensive cost and ability to modify its hardness depending on heat treatment conditions make it suitable for use in various industries34. (Building, auto assembly, molding (screws, screws) (Shown in Fig. 5). Steel with a high carbon content is classified as a toughened material, as are many iron alloys. The company uses SUJ2 material, a type of steel used for induction heat treatment, for alloy forging and bearing steel (Fig. 6). When manufacturing mechanical products, induction heat treatment is considered a unique technique since, following the product’s thermal process, the interior structural components of the product are heated to a certain temperature. After heat processing, the material body changes, and there is no reliable testing apparatus to determine the degree of structural alterations in the material body35,36. Because assuring the thermal process’s quality also ensures the quality of the products, managers must consider this while selecting whether to use the thermal process in the organization.

By carefully applying heat, materials can have their physical and occasionally chemical properties changed37. This process is known as heat treatment. While it can be applied to other materials such as glass and ceramics, its most common application is in metallurgy (Shown in Figure 7). Reducing internal stresses and improving the material’s mechanical properties, such as its strength, toughness, ductility, and hardness, are the main objectives of heat treatment38. The material is heated to a specific temperature, held there for a given period, and then cooled gradually.

Surface treatment hardens the surface to increase wear resistance. The induction heat treatment process is carried out at the company using SUJ 2 material and the induction heat treatment technology. Surface treatment hardens the surface to increase wear resistance. SUJ 2 materials undergo induction heat treatment at the company using the Induction heat treatment method (Shown in Fig. 8). A specific kind of heat treatment called induction heat treatment involves using electromagnetic induction to heat a workpiece and alter its characteristics. Its excellent heat-treatment process control and localized heating make it widely used in industries including manufacturing, aerospace, and the automotive sector.

During induction heat treatment, a copper coil is subjected to an alternating current (AC), creating a rapidly varying magnetic field. The magnetic field creates eddy currents inside a conductive workpiece when inserted into the coil. Because of the material’s resistance, these eddy currents, in turn, produce heat39,40. Among the main benefits of induction heat treatment are Quick and accurate heating: Certain sections of a workpiece can be quickly and precisely heated thanks to induction heating. The heat may be precisely regulated by varying the alternating current’s power and frequency, enabling effective and focused heat treatment39. Energy efficiency: Because induction heating heats the workpiece directly and doesn’t require heating the surrounding area, it is a very efficient method of heating. Compared to traditional methods, it decreases energy loss and allows for faster heating cycles. Decreased distortion: Local heating is usually used in induction heat treatment, which helps to reduce thermal distortion in the workpiece. It lessens the possibility of warping or deformation that might happen with uniform heating techniques by heating particular areas selectively. Automation and process control: Incorporating induction heat treatment into automated production lines is simple. The heating process can be accurately regulated, observed, and modified to guarantee reliable outcomes and satisfy particular needs. Versatility: A large variety of materials, including alloys, polymers, and composites, as well as ferrous and non-ferrous metals, can be subjected to induction heat treatment. It can be applied to several heat treatment procedures, including stress relief, brazing, annealing, tempering, and hardening. Common uses for induction heat treatment include brazing or soldering metal components, heat treating automotive components, including crankshafts and camshafts, and hardening the surfaces of gears, shafts, and tools. It’s important to remember that induction heat treatment calls for specific tools and knowledge. To get the required effects, the heat treatment parameters such as power, frequency, and heating time must be carefully chosen depending on the characteristics of the material and the intended consequences.

Here are some crucial things to consider to guarantee high-quality power for induction heat treatment: Stable voltage: To ensure efficiency and consistency, a power source must be steady for most of the heat treatment process using induction. The voltage must be kept within the designated power supply range for the induction device. It is essential to use a voltage stabilizer or regulator to control and uphold a steady voltage. Correct current: Verify that the induction heat treatment device receives the proper current according to its specifications. It is essential to find the maximum current the device can handle and ensure the power source can supply it without overloading or failing. Stability and quality of the electric current supply are two more crucial elements. The power supply must be able to deliver a steady current without producing any noise or distortion in the current. Power quality can be enhanced by utilizing protective devices like decoupling transformers and noise filters. Power-related factors: When operating, induction heat treatment may need a lot of power. Verifying that the power source can supply enough power for the induction heat treatment device is essential. The effectiveness and outcomes of the heat treatment process may be impacted if the capacity is insufficient. Regular upkeep and inspection: Periodic inspections and maintenance are required to guarantee the power source’s dependability and efficiency. Examine electrical characteristics, including voltage, current, and current quality, to find issues early and take the required maintenance or remedial action. In summary, stable voltage management and maintenance, proper current, current stability and quality, sufficient capacity, testing, and routine maintenance are all necessary to provide power quality for induction heat treatment. This guarantees quality outcomes in the finished product and aids in ensuring efficiency and uniformity in the heat treatment process.

The power supply for induction heat treatment might have several frequent problems. Among these problems are Variations in voltage: Variations in input voltage have the potential to impact the efficacy and uniformity of induction heating. Reduced overall process control, irregular heating periods, and changes in heating patterns can all arise from the unstable voltage applied to the induction heating apparatus. Electricity supply capacity: The electricity needed for induction heat treatment equipment is substantial. Insufficient power supply capacity may result in insufficient heating, sluggish heating rates, or an inability to reach the appropriate temperature. Inadequate power supply capability might also result in equipment failures or circuit breakers tripping. Harmonic distortion: The power supply system may be subjected to harmonic currents from induction heating equipment. This can result in voltage distortion and impact the functionality of other electrical devices connected to the same system. Increased losses, a lower power factor, and interference with other delicate equipment can result from harmonic distortion. Low power factor: The ratio of actual power to apparent power is known as the power factor, and it is frequently low in induction heating systems. A system with a poor power factor requires more current from the power source, which can lead to greater energy expenses and distribution network overload problems. Electrical noise and interference: Induction heating has the potential to produce electromagnetic interference (EMI) and electrical noise that may disrupt nearby communication or other electrical systems or equipment. To reduce electromagnetic interference (EMI) and guarantee that other equipment operates as intended, electromagnetic compatibility (EMC) precautions should be taken. Requirements for the cooling system: Since induction heat treatment equipment produces a lot of heat while operating, sufficient cooling systems are required to keep it operating at peak efficiency and avoid overheating. Inadequate cooling can result in equipment malfunctions, poor performance, and shorter component lifespans. It is critical to have a reliable power source with sufficient capacity for the induction heat treatment equipment to minimize these problems. Reliability and consistency can be ensured through routine maintenance and monitoring of the power supply, which includes harmonic filtering, power factor correction, and voltage regulation. It is also important to use appropriate shielding, grounding, and isolation methods to reduce electrical noise and interference. Furthermore, implementing efficient cooling systems and following advised operating conditions can aid in preventing overheating and equipment malfunctions.

Analysis of the current status of power source quality at induction heat treatment process

The point-of-common coupling (PCC), which is generally defined as the interface between the system owner or operator and user, is where IEEE Std. 519:2022 sets limits for harmonic voltages and currents (Shown in Table 8). The PCC is typically the power system point closest to the user where the system owner or operator could offer service to another user. In this evaluation, the PCC was regarded as the transformers’ outgoing.

The magnitude of each voltage harmonic cannot exceed 3% of the fundamental voltage. The IEEE Std. 519:2022. Table 9 lists the current distortion limits, which differ for each system based on its size relative to the utility system feeding it. The short-circuit ratio (SCR), which is the ratio of the maximum demand load current (IL) to the available short-circuit current (ISC), is used to quantify this relative magnitude. The facility’s size to the system capacity increases with a decreasing SCR value, as do the associated harmonic current limitations. Furthermore, current distortion levels are determined by IL, as opposed to voltage distortion levels, which are determined by the magnitude of the fundamental voltage.

Total current distortion limits are based on the total demand distortion (TDD) level (Eq. 30). Individual current harmonics are also calculated as a percent of the maximum demand current. Nonlinear loads typically produce the maximum amount of harmonic current at peak load levels, so the maximum TDD values are given in IEEE Std. 519:2022 effectively limits the total harmonic current a given facility can inject into the power system. IEEE Std. 519:2022 calls for ID to be calculated based on the peak demand level recorded over the previous 12-month period. Nevertheless, in this assessment, all the loads are assumed to run at full load during the monitoring period. Thus, the value for IL at each location was assumed to be the maximum current drawn by the loads.

The requirements for the 2015 Viet Nam Distribution Code and the 30/2019 requirements. Total Harmonic Distortion (THDV) of voltage (Shown in Table 10) and Current Total Harmonic Demand Distortion TDD (Shown in Table 11).

To control the actual value of the quality of the power supply for the high-stage quenching machine and the power supply directly to the coil used for high-stage quenching for products using SUJ 2 type materials. Results found that the quality of the power supply did not meet IEEE 519:2022 standards. Specific data measured and analyzed at the source are displayed in detail as Current trend (Shown in Table 12; Fig. 9. Current trend), Voltage trend (Shown in Table 13; Fig. 10. Voltage trend), Frequency Trend (Shown in Table 14; Fig. 11. Frequency Trend), Voltage Unbalance (Shown in Table 15; Fig. 12. Voltage Unbalance), THDv (Shown in Table 16; Fig. 13. THD – Voltage), THDi (Shown in Table 17; Fig. 14. THD – Current), Voltage harmonic spectrum from 2nd to 50th (Fig. 15. Voltage harmonic spectrum from 2nd to 50th ), Current harmonic spectrum from 2nd to 50th (Fig. 16. Current harmonic spectrum from 2nd to 50th ), Current harmonic order 5th trend (Fig. 17. Current harmonic order 5th trend), Current harmonic order 7th trend (Fig. 18. Current harmonic order 7th trend), Cos Phi (Fig. 19. Cos Phi trend), and Flicker (Fig. 20. Flicker).

Analyze the total analytical parameters of the quality of the power supply at the source for the high-rise quenching heat treatment machine and the equipment used in the production process. The results show that the actual value of the Current Harmonic THDi parameter is mostly above 34% for all phases and exceeds the allowable standard of the application standard & Evaluation Circular 39/2015 and 30/2019/BCT, which is less than 12%. The actual value of the Individual current harmonic parameter at Order 5th is 33.03%; at Order 7th, it is 10.64%, all of which are larger than the application standard & Evaluation Circular 39/2015 and 30/2019/BCT require smaller. 10% (Shown in Table 18).

The research question that needs to be asked is to design and implement a plan to improve the quality of the power source to eliminate harmonic waves at the source, to help improve the quality of the power source to meet IEEE 519:2022 standards, helping to increase the life of the power source. Operating life and accuracy of processing machines, specifically high-stage quenching heat treatment machines, help ensure product quality, reduce defect rates, and reduce energy loss to help improve operating efficiency, production, and business activities, reducing production costs. A device called SAPF is proposed to be deployed at the source.

A form of surface heat treatment known as induction heat treatment softens the surface of SUJ2 steel material, with penetration sizes ranging from 1.0 to 1.5 mm and hardness levels between 58 and 62 HRC at the penetration depth (Shown in Fig. 21). If the coil receives excessive voltage or current, the hardness in the deep penetration area above the 62 HRC threshold results in surface fractures or cracks on the product. The product will soften and warp if the voltage or current input to the coil is too low, resulting in a deep penetration zone hardness of less than 58 HRC. Two other critical factors influencing the penetration depth and stiffness at the product’s penetration depth area are the heating duration and the separation between the coil surface and the outer body surface during induction. To increase product quality throughout the induction heating process, the ideal conditions for the voltage or current source, timing, and distance must be designed. To determine the ideal Induction heat treatment condition, the author performs experimental optimization analysis using the Taguchi optimization approach41.

Material and experimental method

The Taguchi method is an experimental design technique that aims to minimize the impact of uncontrollable elements and optimize the production process. This technique was created by Japanese statistician and engineer Genichi Taguchi, who maintained that design plays a more significant role in quality control than manufacturing processes to prevent production deviations. Orthogonal sequences are used in experimental planning using the Taguchi method. As a result, this methodology enables the analysis of the influence of parameters on a certain chosen response of a process (or product) with the least amount of tests required, allowing for the fastest possible adjustment of the parameters toward the optimum. The Taguchi method also prioritizes minimizing losses to society from detrimental side effects and considers if a product’s design may have an unfavorable impact.

The procedure of induction heat treatment involves applying an electric current to the carbon structural elements on the surface of SUJ2 material to alter their hardness and the depth to which the heat zone penetrates, hence altering the mechanical properties of the raw material. Hardness, yield strength, and ultimate tensile strength are three variables that influence the effectiveness of this induction process and the requirement for ideal control. By adjusting the input impact parameters, such as electric current (A), coil travel time (T), and contact distance between the coil and the surface of the SUJ 2 material (d), the process of altering the mechanical and physical characteristics of the carbonate component on the material’s surface can be stabilized. Tensile strength (TS), depth case area size (t), and product surface hardness (HRC) are the findings of the product quality assessment following induction. There are two stages to the implementation of the Taguchi optimization method. Because the weak parameters include three condition parameters at each of the three levels, the first stage of handling noisy parameters is conducted in nine experiments using the L9 orthogonal grid criterion. Phase 2 applies the gray relational analysis (GRA) method to multi-objective optimization.

A Chinese source provided the steel material sample used in the type SUJ2 experimental investigation. The chemical element composition is shown in the study paper’s upper section. Stream oil is the coolant utilized in this investigation. Hardness testers, face grinders, and sample cutters are ready for experimental research, and test findings adhere to JIS standards. To conduct an experimental study using 80 A, 90 A, and 100 A as the initial electric current preparation parameters. The coil travel time during induction is 5 s, 7 s, and 10 s, and the coil surface is 3 mm, 5 mm, and 7 mm from the SUJ2 material surface. The product’s hardness, penetration depth, and tensile strength after cooling are the test findings of the mechanical change of SUJ2 material following Induction heat treatment.

According to the JIS hardness measurement value, a hardness test with a 500 N load is conducted for one measurement over a 15-second operating period using the Vicker Laryee HVM-30 hardness tester. The hardness measurement results are determined using Eq. (31), and this hardness value permits the conversion of the unit to hardness using HRC units according to JIS standards.

Where, F: Force (N), D: Diameter (mm), d: average dimension (mm).

Tensile testing is carried out following JIS specifications using the Laryee UE34200 Computer Control Electronic Universal Testing Machine (200KN,0.4%--100% F.S., Floor type). In tensile testing, the product is stretched until it splits into two pieces, at which point the measurement’s experimental outcomes are recorded. Data from tensile measurements is directly entered into the Laryee UE34200 Computer Control Electronic Universal Testing Machine’s specific software.

Two test methodologies are combined with in-depth case testing. One method is to measure the depth case size area at a distance of 0.01 mm using a Vicker hardness tester and analyze the hardness results. The second approach is to examine the raw material composition using an expensive biological microscope with three eyes, an LED Terino 300TC (40X-2000X, with a 5.1 MP high-resolution industrial camera) - Genuine items. To assess the depth size of the depth case, combine the outcomes of the two approaches mentioned above. The results will be skewed because of inaccuracies if the depth case analyst employs one of the aforementioned techniques.

The objective response functional evaluations are used to assess the optimization and design of the experiment. This work needs to optimize three functional parameters: the distance between the coil and the material surface, the coil travel time, and the supply voltage. The three product outputs following induction heat treatment, stiffness, penetration depth dimension, and tensile value, are assessed using the L9 standard orthogonal network. Taguchi calculated functional feedback values in experimental analysis using the formula translated into signal-to-noise (S/N) ratios (Eq. 32).

Where n: number of experiments, \(\:{y}_{i}\): value of characteristics.

A mathematical formula called analysis of variance (ANOVA) is used to assess the association between the parameters of each subject and ascertain the degree to which each parameter in the design interacts with the others. Design of an experimental test. The effects of surface-to-surface distance, travel time, and power supply voltage on the tensile strength, penetration depth, and hardness of the SUJ2 material were examined using ANOVA analysis—heat treatment by induction. The analysis results from the Taguchi approach are more precise since the ANOVA method shows how much attention is placed on the relative importance of each parameter’s effects. The researcher employed Minitab 18.0 software to conduct Taguchi and ANOVA analyses in this investigation.

Using Eqs. (33), (34), and (35), respectively, a confirmation test is run to confirm the accuracy of the output values for the parameters of stiffness, depth case, and tensile strength.

Where \(\:{m}_{h},\:{m}_{y},\:{m}_{u}\): average of the experience test

The Confidence interval (CI) value is used to evaluate the optimal value of the Taguchi experimental study. Confidence interval (CI) values are calculated through two equations, (36) and (37), respectively.

Where \(\:{F}_{\alpha\:,1,{f}_{e}}\): 95% confidence, \(\:{V}_{e}\): variance error, \(\:{n}_{eff}\): number of replications, \(\:{T}_{dof}\): parameters degrees of freedom.

Result and disscusion

The three output parameters, stiffness, depth case, and tensile dimensions, were computed, and the signal-to-noise ratio (S/N) coefficient was examined for the functional feedback parameters in the Taguchi experimental design (Shown in Table 19). Through the Taguchi experimental study, a response (Hardness) analysis is examined in detail and displayed in Table 20 with S/N indexes. Examine the input parameter influence correlation for the hardness output factor based on the experimental study’s input parameter interaction chart. Canbolat et al. (2019) state that the lowest S/N value indicates the least amount of input parameter influence. In other words, the S/N value yields the highest value, indicating that the amount of effect of the input parameter on the output parameter is ideal, and vice versa. The input parameters have a low level of influence on the output parameter hardness. The criterion states that the better the gold, or more precisely, the more optimal the parameter, the smaller the S/N value. The findings of the Taguchi analysis are that the coil travel time needs to reach 10 s, the amperage parameter needs to reach 90 A, and the coil needs to be 5 mm from the product surface. The findings indicate that the coil distance has a product surface size of 5 mm, the coil trip duration is 10 s, and the current value is 100 A. The Taguchi analysis results with the Depth case value impacted by three input parameters. The same analytical results for the tensile value, with the recorded values being the current value of 100 A, the coil moving time of 10 s, and the distance of 10 mm. Following induction heat treatment, the product is in its hardest and most stable state. Table 21 displays the statistical analysis using the ANOVA approach from Taguchi analysis to determine the contribution ratio of each input parameter to the product hardness. The best conditions for using the induction heat treatment machine for products made with SUJ2 material are as follows: the product’s surface distance (5 ± 0.5 (mm) from the coil, a current value of 95 ± 10% A, and a time of 10 ± 2 (2) for moving the coil. These results are based on the results of Taguchi and ANOVA analyses.