Abstract

Aluminium alloy based composites are employed in numerous applications that require outstanding performance due to their superior mechanical characteristics, including higher strength, stiffness, and wear resistance. They are used in engine parts like pistons and connecting rods to improve performance and durability. In this work, Al7075 is employed as the matrix material. Aluminium oxide particulates were chosen as the reinforcing particles. The Al7075–6%Al2O3 composites were manufactured using the stir casting technology. Scanning electron microscopic instrument was employed to investigate the microstructure of Al7075–6%Al2O3 composites. The microstructure analysis of Al7075–6%Al2O3 composites revealed the even dispersion of Al2O3 particulates throughout the Al7075 matrix. The Pin on disc apparatus was utilized to conduct a wear experiment on Al7075–Al2O3 composites. Taguchi methodology was employed to optimize the wear process factors of the produced composites for enhanced performance. According to ANOVA outcomes, the most impacting factor was the sliding distance 87.057% then speed 7.165% and lastly load 0.435%. The R-Sq value and R-Sq (adj) value for wear response obtained using Minitab 16 Taguchi software are 95.05% and 92.08% respectively. The delta values for load, speed and sliding distance are 0.668, 2.830 and 10.734 respectively. The results of this demonstrated that the factor that has the greatest impact is sliding distance. The wear response values provided by OA experimental and regression equation are 3.6131 × 10−3 mm3/m and 3.3062 × 10−3 mm3/m respectively. A difference of 8.49% between the experimental and Taguchi analysis value gives the maximum permissible difference.

Similar content being viewed by others

Introduction

The fabrication of composites involves the mixture of two or more distinct components to form a novel material with superior characteristics. The separate components of these materials are not capable of achieving the properties that are intended to be achieved by these materials alone. Composites comprising metal as a matrix, are a category of advanced materials that can be manufactured by dispersing reinforcing phases into a metal matrix for enhancing the properties of the base material1. They are extremely strong materials that possess the desirable properties of both the matrix phase and reinforcement materials to make them perform better than traditional metals or alloys.

Aluminium alloys are used in vehicle manufacturing to lower vehicle weight and improve fuel economy. Aluminium alloy’s lightweight, durable properties lend themselves to various applications including engine blocks, cylinder heads, and body panels2,3. Because of the beneficial strength to weight ratio, high-strength aluminum alloys are used in the aerospace sector such as example, fuselages and wings.

Aluminium alloys are widely used in industrial machines and equipment for their strength and weight properties. Because of their corrosion resistance and lightweight features, aluminium alloys are used to construct boat hulls and other structures for the marine world, which helps improve performance and the longevity of structures4,5.

Aluminium alloy MMC’s are a class of composites that have aluminium alloys as their matrix material in which various reinforcements are introduced with the purpose of enhancing the characteristics of the base material. The two materials are intended to be used in combination to exploit the advantages of both the aluminium matrix and the reinforcing phase, resulting in improved material properties6. Its application directly includes bending of aircraft structural components. They are used in automotive parts like pistons and braking components to improve performance and fuel economy.

Aluminium composites are lightweight, high-strength materials which are suitable for aerospace, automotive and construction fields. Aluminium composites provide good thermal conductivity and electrical conductivity, which is ideal for heat sinks and electrical components. Unlike other materials, aluminium composite materials are easy to cut, bend and install, providing considerable savings on labor costs and construction time7,8. They can withstand temperature fluctuations, UV rays and moisture, making them perfect for outbound applications.

Aluminium composites can be cost-prohibitive compared to some traditional materials. Aluminium composites are unsuitable for heavy structural loads, unlike solid aluminium or steel. Certain aluminium composites use cores made of plastic or resin, making recycling more challenging than pure aluminium. When heated, aluminium expands, so its correct installation may be complicated, so that over time it does not get damaged or deformed9.

Al7075 alloy is having high strength with good mechanical properties. It is suitable for structural aerospace applications. Its mechanical properties are good for aerospace, automotive and high performance but appropriate handling is necessary to maintain its lower corrosion resistance. Aluminium oxide is a crucial material because of its hardness, stability and available uses. It is a primary ceramic material and also functions in industrial as well as electronic applications. Stir casting is a common method of fabrication for MMC’s in general, but especially when trying to add solid particles into a molten metal matrix10. It is a handy method when it comes to producing composites in mass with substantial ease and at economic rates.

Al7075 alloy is extensively employed as a matrix material in Al7075–Al₂O₃ composites owing to its strength, fatigue resistance, and lightweight properties, rendering it appropriate for applications necessitating structural integrity and performance. The use of Al₂O₃ particles substantially enhances hardness and wear resistance characteristics. It is lighter than steel or other high-strength materials, which are typically desired in applications where weight must be minimized.

The Al₂O₃ reinforcement particles are selected for Al7075–Al₂O₃ composites as they possess better mechanical and thermal, tribological characteristics. The addition of Al₂O₃ particles improves Al7075 matrix’s tensile strength by hindering dislocation motion. The high melting point and superior thermal stability of Al₂O₃ ensure high-temperature retention of strength in the composite. Due to its lower density on a mass basis when contrasted to other ceramic reinforcements, like silicon carbide, aluminium oxide serves as an appropriate choice for lightweight applications without sacrificing strength. Al₂O₃ is widely available and relatively inexpensive volume-adding reinforcement, compared to other ceramic additions such as SiC or B₄C.

The following section present some of the analysis conducted in the literature review to identify work on the various aluminium alloy composites. In addition to this, it presents the previous studies on the utilization of Taguchi method for optimizing the wear factors.

Nagesh D et al. investigated the wear behavior of Al6061 + Graphite + Boron composites. Al6061-Boron intermetallic, Al6061-Graphite and Al6061 + Gr + B MMC’s were successfully manufactured through the stir casting methodology. According to the findings of the investigation, the wear rate of the sample was considerably impacted by the load11. P Muthu et al. investigated wear characteristics of Al6061-titanium carbide-basalt hybrid MMC’s. The ANOVA findings revealed that sliding distance was the leading variable followed by weight and sliding speed12. Mehmet Emin Demir et al.13 conducted research on the mechanical and wear characteristics of AA7075-B4C MMCs. The SEM pictures showed that the probability of agglomeration in the base matrix enhanced as the B4C particulates ratio raised throughout the process. Despite the fact that B4C reinforcement has a tendency to cluster together, it had a favourable impact on the AA7075’s wear resistance.

Biranu Kumsa et al. conducted a wear investigation of MMC’s that were relied on the aluminium alloys. From the S/N ration analysis, it was understood that with the increase of silicon carbide in aluminium matrix, it increases the material strength as well as wear resistance14.

Timish Bhave et al. carried out an experiment which consisted of the fabrication and tribological investigation of AA6061-B4C hybrid MMC’s. ANOVA findings showed that, load is having the major effect on the wear15.The investigation of wear properties of Al6061-TiB2-CeO2 MMC’s were carried out by Sreenivasa et al. by employing Taguchi methodology. It was discovered that, the optimal combination of parameter are 2.5 percent titanium dioxide, 45 Newtons weight and 1250 m sliding distance. Furthermore, this combination resulted in the lowest COF among the MMC’s that were manufactured16.

Mehmet Emin Demir et al.17 investigated the mechanical and wear properties of Al7075–B4C composites. There value of hardness was substantially improved at a reinforcement ratio of 12%, which was observed when the influence of reinforcement ratio was investigated. The 12% B4C was shown to be the most effective in terms of wear resistance, just as it was in terms of hardness. There was an increase in the resistance to wear of the Al7075 matrix owing to the B4C particles.

Padmaraj et al. examined the wear characteristics of Al6061-B4C-Ash MMC’s. Statistical investigation results showed that applied load was affecting the wear rate tremendously18.

Manu Sama et al. examined the wear features of AA6082-3%BN-4%B4C-4%CC composites. The ANOVA findings indicated that, load exerted the maximum impact at 51.6% of the contribution accompanied by sliding distance and speed19. Taguchi analysis was employed for aluminium composites by Ikubanni et al. in order to get superior wear performance. The outcomes showed that, speed is the major important variable20. A wear examination of AA6061-Titanium boride MMC’s was carried out by Santha Rao et al.. The confirmation studies revealed that, the outcomes were within the 10% range of the value that was expected. The ANOVA showed that, the rotational speed is the main important process variable21.

Yahya Hişman Çelik et al.22 conducted a study to investigate the wear behaviour of AlSi7Mg2-SiC composite. According to the findings, the reduction in weight was brought about by raise in the load. The COF and the amount of weight lost both raised as the sliding distance was increased because of the increase. A decrease in weight loss was achieved despite the fact that the COF was enhanced owing to the increase in sliding speed. After analyzing the pictures obtained from the scanning electron microscope (SEM), it was determined that the creation of tribo-surfaces and deformation had a major impact on the decline in weight.

R. Vijaya Kumar et al. conducted a study that utilized the Taguchi methodology to examine the wear study of Al6061-Zircon composites. As per the response table, the most important factor for composites is load23. Pawandeep Singh et al. used Response Surface technique to investigate wear features of Al6061 related composites. According to the ANOVA findings, the crucial factor that affect wear rate is sliding speed24.

Mehmet Emin Demir et al.25 conducted study on the wear characteristics of Al7075–TiO2–Kaoline Composites. When the ratio of kaoline reinforcement was increased, it was discovered that the wear rate was also decreased. A reduction in the wear rate from 2.1 × 10–3 (mm3 m-1) to 1.5 × 10–3 (mm3 m-1) was achieved by incorporating 6 weight percent of kaoline reinforcement into the composite. Within the kaoline-reinforced composites, scanning electron microscopy (SEM) photographs of the kaoline-reinforced composites worn-out surface’s depicted that, the wear scars were narrower, and there were less pits and matrix debris. As a result of sintering and wear, the composite did not exhibit any cracks, as indicated by the findings of the SEM analysis.

Ravi Kuma et al. performed examination on the tribological properties of Al-Si3N4-SSP-RHA composites. Regression analysis was also performed and concluded that there is a high impact of speed followed by load and reinforcement on the individual wear rate26. Narinder Kaushik et al. performed the investigation on the wear behavior of the AMMC’s employing Taguchi approach. The outcomes of the ANOVA indicates that, the process parameters, i.e., sliding distance and SiC weight percentage have major impact on reduction of wear rate27.

A. Baradeswaran et al.28 conducted research on the mechanical and wear properties of Al7075–Al2O3–graphite composites. Furthermore, it was discovered that the incorporation of Al2O3 and Gr particulates leads to an improvement in the composite’s hardness. The hardness of Al7075–Al2O3–Gr composite was more than the Al7075 matrix. The Al7075–Al2O3–Gr composites showed excellent wear-resistance properties.

The research work carried out by B. Manjunatha et al., utilizes the Taguchi approach to examine the impact of quantity of boron carbide particulates on the Al6061 based MMC’s wear rate. From the findings, it was found that speed is the factor which has great impact on composites wear29. The Wear characteristics of Al6082-BN-B4C-Corn Cob Ash composite were investigated by Manu Sam et al. From the ANOVA results, it is found that, load is the major impacting variable representing 51.6% of all30.

The literature survey was conducted in order to examine earlier research on the creation of stir-casting-based aluminium alloy particle reinforced composites. An additional purpose of this literature review was to investigate the distribution of reinforcement particles with the use of a SEM apparatus. The literature review was also carried out to perform wear study of the aluminium alloy particulate reinforced composites. It is also carried out in order to investigate the optimization of the wear process variables comprising of load, speed, and sliding distance, by employing the Taguchi methodology for aluminium alloy particle reinforced composites. It is performed to identify the variable which is having greatest influence on the wear rate.

The preceding literature study indicates that numerous researchers have focused on the aluminum alloy-based metal matrix composites; however, none have investigated the manufacturing and study of properties of Al7075–Al2O3 composites. The use of Taguchi methodology to optimize the variables affecting the wear of composites consisting of Al7075 and Al2O3 is presently in the initial stages. The research on wear features of Al7075–Al2O3 composites for optimization of process parameters using Taguchi approach has also tried to improve the life and efficiency of these composites in engineering applications. This study therefore assists industries in selecting an appropriate process condition for preparing wear-resistant of Al7075–Al₂O₃ composites. It also helps industries to cut down on material degradation, enhance durability, and lower production costs.

The manufacturing and microstructural study of Al7075–Al2O3 composites are the primary focus of the current investigation. In addition to this, this research uses Taguchi method for optimizing the wear variables of Al7075–Al2O3 composites.

Materials and details of experiment

Materials

The high strength aluminium alloy known as Al7075 is a member of the 7xxx series and is largely alloyed with zinc. It is widely utilized in crucial sectors where strength is of the utmost importance. The Al7075 alloy has a density of 2.81 g/cm3. This is used in aircraft structural parts such as wings and fuselage structures and landing gears. It is also used in certain engine components, other suspension parts and wheels where strength and lightweight traits are needed. Because of its strong and light weight properties, it is used in components for satellites and spacecraft.

Alumina, also known as aluminium oxide, is a versatile substance that possesses a variety of characteristics that make it attractive for use in different applications. The size of Al₂O₃ particle used in this study is 40 microns. Its hardness, thermal stability, and electrical insulation characteristics make it ideal for use in abrasives, ceramics, electronics, and catalysis. It is also used for making aluminium metal. Its production is a critical step in many industrial and technological productions. It has a chemical formula of Al2O3. It is commonly found in white ashy solid and bulk forms, as well as crystalline shapes like corundum. Its melting point is roughly 2072 degree centigrade. Because of its excellent hardness, alumina is used in various abrasives, including grinding wheels, sandpapers, and polishing compounds. Alumina is used to manufacture high-performance ceramic materials for applications such as wear-resistant parts, electrical insulators, and refractory materials.

The plan of experiments consists of the following steps.

-

Review of Literature

-

Objectives Formulation

-

Purchase of raw materials like Al7075 and Aluminium oxide particles.

-

Production of Al7075–Al2O3 composite using Stir casting

-

Microstructure analysis using SEM

-

Wear study of Al7075–Al2O3 composites

-

Optimization of wear parameters using Taguchi technique

-

Worn-out surface analysis of Al7075–Al2O3 composite using SEM

-

Results and Discussions

-

Conclusions

-

References

Fabrication of Al7075–Al2O3 particulate composites

Composites made of Al7075 and Al2O3 particles were manufactured by employing the stir casting methodology. The matrix Al7075 alloy was in the form of ingots. The Al7075 ingots were cleaned and melted in a graphite crucible at 750 °C. In order to extract dissolved gases from the molten liquid, the solid form of hexachloroethane (C2Cl6) was utilized31. The overall weight was estimated by computing the weight of Al2O3 particulates at a concentration of 6% weight. The aluminium oxide particulates were heated to 300 degrees Celsius for duration of three hours to mitigate any potential thermal disparity that could arise in the casting procedure. In addition, the removal of moisture from the materials is facilitated by this preheating process32. A continuous stirring process was used to combine the Al2O3 particles that had been warmed with the liquid matrix. The stirring procedure is carried out for ten minutes, and the stirrer is turned at 250 rpm speed to produce a reasonable vortex, which assists in generating a uniform dispersion. A coating made of ceramic was put to the stirrer blades33. This was done in order to limit the amount of iron that was absorbed by the liquid metal from the drums. The molten material was put into the metal mould once the melt had been stabilized, and each of the castings can be created according to the requirements that have been specified. The stirrer was preheated at a low temperature in order to get it ready for insertion into the liquid melt before the moulds were heated to 200 degrees Celsius. This was done before the melt was poured into the moulds34. As a result, Al7075–Al2O3 composites were prepared. The cast samples were in cylindrical shape with a diameter and length of 24 mm and 140 mm respectively. The Al7075–Al2O3 casted composite is shown in Fig. 1.

Wear study

The Pin on Disc instrument is utilized to carry out wear experiments on the composites composed of Al7075 and Al2O3 particles. The wear test was found to have been conducted according to the ASTM G99-95 standard34. The cast samples were then machined in order to acquire samples that had a length of thirty millimetres and a diameter of eight millimetres. For the wear test, a range of speeds, loads, and sliding distances were used35. Wear studies of Al7075–6%Al2O3 composites were conducted and a total of 27 tests were executed using Taguchi technique. For each test, three samples were tested, and an average reading was taken.

6% Al2O3 reinforcement was chosen and kept constant for the wear study of Al7075–Al2O3 composites employing Taguchi methodology. In this study, Al7075–Al2O3 composites were developed with various proportions of Al2O3. The Al2O3 particles were altered at concentrations of 2%, 4%, 6%, and 8%. The hardness test was conducted on Al7075–Al2O3 composites with various proportions of Al2O3 utilizing a Brinell hardness testing apparatus. The hardness test indicated that hardness improved up to 6% of Al2O3, after which it declined. The peak hardness is achieved at 6% Al2O3, measuring 92 BHN.

It is well known that wear and hardness are directly correlated. In order to optimize the wear variables of Al7075–6%Al2O3 composites employing Taguchi technique, 6%Al2O3 was selected and maintained constant depending on the outcomes of the hardness test of the composites. Here, the percentage of Al2O3 remained fixed while the wear process parameters such as load, speed, and sliding distance were changed in three levels.

Figure 2 shows the specimens that were used for the wear test.

Table 1 presents the wear test parameters used in the wear test.

The wear rate which was calculated in the wear tests is based on weight loss. It is calculated by taking the difference between the sample weight after the wear experiment and sample weight before the wear experiment. The wear rate was calculated in the wear tests using Eq. (1).

The experimental density value was taken for the determination of wear rate.

Taguchi methodology for the wear study of Al7075–Al2O3 composites

Taguchi technique was utilized for optimizing the wear performance characteristics. It is carried out by adjusting the design parameters in an appropriate manner36. Minitab software was utilized to optimize the variables of wear. The design variables and the levels that correspond to them are outlined in Table 2. By selecting three levels, it is possible to investigate the impacts of nonlinearity. The response variable that was investigated is the wear.

27 experiments were performed in order to evaluate the impact that various parameters have on the wear examination of Al7075–Al2O3 composites. Table 3 provides findings of these testes. The experimental data was analyzed using Minitab 16 software. The average values of the output values of three samples were taken for the wear test.

Results and discussions

Microstructure study of Al7075–Al2O3 composite

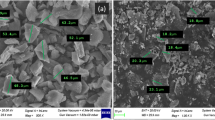

The SEM micrograph of the Al7075 matrix is shown in Fig. 3a. The SEM image of the composite material Al7075–6%Al2O3 is shown in Fig. 3b. Figure 3c,d show the SEM micrographs of the Al7075–6%Al2O3 composite material at a greater magnification.

The microstructure of the Al7075 matrix and Al7075–6%Al2O3 composite was investigated with the use of a scanning electron microscope. The Al7075–6%Al2O3 composite sample and the aluminium matrix were subjected to a particle dispersion research. According to the findings of the microstructure examination, the Al2O3 particles are distributed evenly across the Al7075 alloy matrix37,38. Additionally, these features existed along with the particle reinforcement. The photographs unequivocally illustrate that the Al2O3 particles have a shape that is not consistent through their entirety. The results of the microscopic study suggest that the size of the Al2O3 particles across the composite is very consistent.

Study of worn-out surfaces of Al7075–Al2O3 composites

The SEM pictures of Al7075 matrix and Al7075–6%Al2O3 composites worn-out surfaces are depicted in Fig. 4a–d, correspondingly. SEM pictures of the worn-out surface of Al7075–6%Al2O3 composites are displayed in Fig. 4b. These images were taken when the wear variables, which include load, speed, and sliding distance, were set to 10N, 100 rpm, and 1000 m, correspondingly. Figure 4c depicts the scanning electron microscopic pictures of the Al7075–6%Al2O3 composite’s worn-out surface when the wear variables like load, speed, and sliding distance were 10N, 300 rpm, and 3000 m correspondingly. SEM pictures of the Al7075–6%Al2O3 composite’s worn-out surface are displayed in Fig. 4d when the wear variables, which include load, speed, and sliding distance, are set to 30N, 300 rpm, and 3000 m, correspondingly.

The presence of white particulates in the images obtained using SEM is a technique that may be utilized to ascertain whether or not carbide particulates are present in the material39,40. As can be seen in the images, the existence of reinforcement contributed to a reduction in the width of the grooves. There are signs of delamination, which can be attributed to the occurrence, along with the formation of wear debris, which is also visible. When the composites were subjected to a wear examination, it was observed that their sliding path had grooves that were narrow and tiny, and they included a negligible amount of debris41. SEM images of Al7075–Al₂O₃ composites showed various wear mechanisms depending on load, sliding speed, as well as environmental condition. The SEM images show long parallel grooves in the sliding direction. Strong adhesion causes formation of wear debris. Visible sub-surface cracks or voids lead to material delamination. Large and thin wear debris particles were seen indicating brittle fracture. Isolated Al₂O₃ fragments are dispersed within the matrix42. The tough ceramic particles strengthen the soft aluminum, preventing deep material loss but resulting in more micro-cutting wear. Al₂O₃ particles presence limits metal-to-metal contact however, at high loads, material transfer may occur. Al₂O₃ like particles are helpful to growth of protective oxide film and wear only happened in mild state but brittle destruction occurred in large load. The delamination and wear debris decreases at higher speeds and higher sliding distances. Hence at higher sliding distances and higher speeds, the wear rate also decreases. At higher loads, the delamination and wear debris increases. Hence at higher loads the wear rate also increases43.

Furthermore, the insertion of strong Al2O3 particles lessens the groove width as well as the debris quantity that was formed. This, in turn, led to a reduction in the wear rates that were eventually experienced. As a consequence of the composite material’s improved load-bearing capacities, the material’s abrasion resistance has also improved, which has led to a reduction in the pace at which it wears out.

Wear rate as a response of wear for Al7075–Al2O3 composites

An investigation on the influence that several variables have on the tribological features of Al7075–Al2O3 composites were performed through a total of 27 tests and are indicated in Table 444. The average values of the output values of three samples were taken for the wear test.

The above table illustrates the outcomes of the wear rate response for composites made of Al7075 and Al2O3 particles when employing a L27 orthogonal array.

Table 5 provides the findings of ANOVA. This revealed that, among all the factors adhesive wear test parameters like sliding distance is the major impacting factor45. The presence of Al2O3 ceramic reinforcement in Al7075–6%Al2O3 composites is responsible for the lower influence of load on wear rate in comparison to sliding distance. This reduced influence could be attributed to the ceramic reinforcement’s role in moderating the wear behaviour. Despite the fact that load typically causes an increase in wear as a result of higher contact pressure, the Al2O3 particles have the ability to function as wear-resistant elements, which effectively reduces the total wear rate46. It is possible that this effect will obscure the direct influence that load has on the rate of wear, particularly when the load is smaller.

The Al7075 matrix’s wear resistance is substantially influenced by the Al2O3 particles that are present in the matrix. During sliding contact, these hard particles have the ability to block or minimize the removal of material, which ultimately yields in a decline in the rate of wear47. Although load is having direct influence on wear, the overall wear resistance of the composite is also affected by other factors, such as the presence of Al2O3 particles and how they behave.

Compared to load, sliding distance has a more substantial impact since it directly determines the number of cycles or contact events that contribute to material removal. This means that sliding distance is primarily responsible for determining the cumulative wear over time.

Based on the ANOVA findings, it was found that the sliding distance is the most important variable, accounting for 87.057% followed by speed 7.165% and load 0.435%. Similar results were attained by P Muthu et al.6. Consequently, this variable exemplifies the remarkable enhancement of the outcomes48. The main effect plot (MEP) is depicted in Fig. 5. It is the principal effect that has a direct influence on the variables of the response and the variable that is the dependent.

As shown in the above figure, the wear rate increases in a manner that correlates to the load, speed, and the sliding distance. Regarding the relationship among the speed, load, and the sliding distance, it was discovered that the best average response value for wear rate is level-149. The wear rate diminishes with increasing sliding distance owing to the development of oxide layers, work hardening, compaction of wear debris, and surface smoothing. The wear debris, which consists of Aluminium and Al₂O₃ particles, can become compressed into the wear track by increasing sliding distance, and subsequently create an effective tribo-layer50,51. This layer helps to prevent metal-to-metal contact, thus limiting additional wear. With consistent sliding, the surface asperities disappear and a very smooth surface is created with extremely low friction and low rate of wear.

The wear rate lowers with the rise in sliding speed owing to increased oxide development, less adhesion, transition to mild wear, and the development of a protective tribo-layer. This causes increasing frictional heat at deeper sliding speeds, which will accelerate the generation of the Al₂O₃ oxide layer52. A thicker and more stable oxide layer acts as a protective film, minimizes the extent of metal-to-metal contact, thus reducing the wearing rate. At high speeds, the contact time is short, preventing the amount of sticking and transfer. At high speeds, the wear debris consisting of particles of aluminum and Al₂O₃ is compressed to form a tribo-layer. This surface layer is a full solid lubricant that lowers the friction and wear rates17.

Figure 6 depicts the interaction effect that occurs between several factors and the wear rate. Upon examination of the interaction plot presented below, it becomes evident that the influence of each variable on the rate of wear is more pronounced, while the interaction between the two variables lessens the impact on wear rate.

Table 6 reveals the delta value. It has been determined that, the sliding distance is found to be the main impacting factor in terms of the delta value for wear rate.

The table above illustrates the correlation between S/N ratio and the wear rate. The delta value for load, speed and sliding distance are 0.668, 2.830 and 10.734 respectively. Based on this information, it is found that, the sliding distance is found to be the main impacting factor which affects the wear rate.

Regression analysis

In order to generate the regression equation depending on the significance of individual factors, analysis of variance (ANOVA) is utilized. An illustration of the regression equation for wear rate can be found in Eq. 2.

The R-Sq value and R-Sq (adj) obtained using Minitab 16 Taguchi software are

Confirmation experiment

The confirmation test represents the ultimate phase of the DOE process. Several confirmation test trials were conducted to ascertain the wear rate. To find the optimum values for the variables affecting the signal-to-noise ratio, the MEP was employed. The optimal parameters for confirmatory test are shown in Table 7.

The results of the experiments that were conducted for the confirmatory tests are presented in.

Table 8.

The OA and Confirmatory Experimental Wear rate values are 3.6131 × 10–3 mm3/m and 3.3062 × 10–3 mm3/m respectively. The discrepancy across the experimental and Taguchi analysis value is 8.49%, which falls within acceptable bounds. Similar results were attained by Santha Rao Dakarapu et al.13.

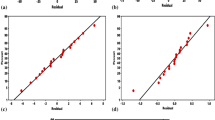

Figure 7 is a visual representation of the normal probability plot. A closer look at this graph reveals that the spots are coming nearer and nearer to the line, which reveals that there are relatively few experimental errors.

The wear behavior was assessed by generating three-dimensional surface diagrams, which are illustrated in Figs. 8 and 9.

The Surface Plot vs. Load and Sliding distance are depicted in Fig. 8. It has been demonstrated that a high load in conjunction with a low speed is having statistically crucial impact on the rate of wear. Figure 9 illustrates how the variables like load, speed and sliding distance strongly impact the wear rate53. Both the increase in load as well as the sliding distance has a substantial impact on the wear rate, which is a positive relationship.

Conclusion

This is a summary of the findings and conclusions that were obtained from the current investigation.

-

The stir casting process has been utilized successfully to synthesize Al7075–6% Al2O3 composites.

-

Microstructural examination of Al7075–Al2O3 composites shows that Al2O3 particles are evenly dispersed in the Al7075 matrix.

-

Based on ANOVA results, it was found that the sliding distance is the most important variable, accounting for 87.057% followed by speed 7.165% and load 0.435%.

-

The R-Sq value and R-Sq (adj) for wear response obtained using Minitab 16 taguchi software are 95.05% and 92.08% respectively.

-

The delta value for load, speed and sliding distance are 0.668, 2.830 and 10.734 respectively. It can be deduced from this that, the crucial factor which affects the wear is sliding distance.

-

The OA and Confirmatory Experimental Wear rate values are 3.6131 × 10–3 mm3/m and 3.3062 × 10–3 mm3/m respectively. The discrepancy across the experimental and Taguchi analysis value is 8.49%, which falls within acceptable bounds.

-

The normal probability graph suggests that there are very few experimental errors because the spots are getting increasingly nearer to the line.

-

The mean response value for wear rate is identified as level-1 concerning speed, load and sliding distance.

-

The Surface Plot vs. load along with the sliding distance reveals that a crucial effect on wear rate is exerted by a combination of high load and low speed.

-

The wear rate is significantly impacted by both the increase in load and the sliding distance.

Data availability

The data sets generated during this research are available from the, corresponding author [Subraya Krishna Bhat], upon a reasonable request.

References

Bhowmik, A., Chakraborty, D., Dey, D. & Biswas, A. Investigation on wear behaviour of Al7075-SiC metal matrix composites prepared by stir casting. Mater. Today Proc. 26, 2992–2995 (2020).

Bulei, C., Stojanovic, B. & Uțu, D. Developments of discontinuously reinforced aluminium matrix composites: Solving the needs for the matrix. In International Conference on Applied Sciences (ICAS 2021), IOP Publishing, Journal of Physics: Conference Series, 2212 (2022) 012029. https://doi.org/10.1088/1742-6596/2212/1/012029.

Sharma, S. K. et al. Progress in aluminum-based composites prepared by stir casting: mechanical and tribological properties for automotive, aerospace, and military applications. Lubricants 12, 421. https://doi.org/10.3390/lubricants12120421 (2024).

Petrova, A., Yaneva, S., Miteva, A., Stefanov, G. & Barbov, B. Study of oxidation kinetics of Al-Si alloys with high concentration of impurities (Fe, Zr, V). Adv. Eng. Lett. 1(1), 1–7. https://doi.org/10.46793/adeletters.2022.1.1.1 (2022).

Krstić, J. et al. Application of metal matrix nanocomposites in engineering. Adv. Eng. Lett. 3(4), 180–190. https://doi.org/10.46793/adeletters.2024.3.4.5 (2024).

Milojević, S. & Stojanović, B. Determination of tribological properties of aluminum cylinder by application of Taguchi method and ANN-based model. J Braz. Soc. Mech. Sci. Eng. 40, 571. https://doi.org/10.1007/s40430-018-1495-8 (2018).

Tenali, N., Ganesan, G. & Babu, P. R. An investigation on the mechanical and tribological properties of an ultrasonic-assisted stir casting Al-Cu-Mg matrix-based composite reinforced with agro waste ash particles. Appl. Eng. Lett. 9(1), 46–63. https://doi.org/10.46793/aeletters.2024.9.1.5 (2024).

Angirekula, R., Manickamn, S. & Ravindra Babu, P. Optimizing process parameters for enhancing mechanical properties of Aa6061 composites reinforced with walnut shell ash and silicon carbide. Appl. Eng. Lett. 9(4), 232–246. https://doi.org/10.46793/aeletters.2024.9.4.5 (2024).

Dey, D., Chintada, S. K., Bhowmik, A. & Biswas, A. Evaluation of wear performance of Al2024-SiC ex-situ composites. Mater. Today Proc. 26, 2996–2999 (2020).

Kumar, V., Nagegowda, K. U., Boppana, S. B., Sengottuvelu, R. & Kayaroganam, P. Wear behavior of Aluminium 6061 alloy reinforced with coated/uncoated multiwalled carbon nanotube and graphene. J. Met. Mater. Miner. 31, 17–24 (2021).

Nagesh, D. et al. Tribological characteristics of Al6061, boron, and graphite hybrid metal matrix composites. Adv. Mater. Process. Technol. https://doi.org/10.1080/2374068X.2021.1946323 (2021).

Muthu, P. An investigation on dry sliding wear behavior of Al6061/Titanium carbide/ Basalt hybrid metal matrix composites. Incas Bull. 13(4), 139–150 (2021).

Demir, M. E., Çelik, Y. H., Kilickap, E. & Kalkanli, A. The effect of B4C reinforcements on the microstructure, mechanical properties, and wear behavior of AA7075 alloy matrix produced by squeeze casting. Proc. Inst. Mech. Eng. Part E 237(6), 2574–2584. https://doi.org/10.1177/09544089221139095 (2022).

Gonfa, B. K. et al. Investigation of mechanical and tribological behaviors of aluminum based hybrid metal matrix composite and multi-objective optimization. Materials 15(5607), 1–18. https://doi.org/10.3390/ma15165607 (2022).

Bhave, T., Borade, A., Bhoye, D., Shaikh, T. & Pawar, S. Fabrication and tribological study of AA601 hybrid metal matrix composites reinforced with B4C nanoparticles. Int. Res. J. Eng. Technol. IRJET 7(6), 779–784 (2020).

SreenivasaIyengar, S. R., Sethuramu, D. & Ravikumar, M. Study on hardness, fracture behavior and optimization of wear characteristics of Al6061/TiB2/CeO2 MMC’s using Taguchi method. Frattura ed Integrità Strutturale 65, 178–193. https://doi.org/10.3221/IGF-ESIS.65.12 (2023).

Demir, M. E., Çelik, Y. H. & Kalkanli, A. The effect of rolling and aging on mechanical and tribological properties in B4C particle reinforced Al7075 matrix composites. Arab. J. Sci. Eng. 47, 16187–16208. https://doi.org/10.1007/s13369-022-06891-6 (2022).

Padmaraj, N. H., Laxmikant, G. K. & Chethan, K. N. Sliding wear characteristics of boron carbide and novel squid quill ash reinforced aluminium 6061 hybrid composites. J. Appl. Eng. Sci. https://doi.org/10.5937/jaes0-34487 (2022).

Manu, S., Radhika, N., Sidvilash, V. & Mohanraj, T. Investigation on the mechanical and wear behaviour of Al-6082-BN-B4C-corn cob ash hybrid composites. Tribol. Ind. 22(2), 294–309. https://doi.org/10.24874/ti.1165.082.21.11 (2021).

Ikubanni, P. P., Oki, M. & Adeleke, A. A. Optimization of the tribological properties of hybrid reinforced aluminium matrix composites using Taguchi and Grey’s relational analysis. Sci. Afr. 12(e00839), 1–9. https://doi.org/10.1016/j.sciaf.2021.e00839 (2021).

Dakarapu, S. R. & Nallu, R. A. Process parameters optimization for producing AA6061/TiB2 composites by friction stir processing. J. Mech. Eng. 67(1), 101–118. https://doi.org/10.1515/scjme-2017-0011 (2017).

Çelik, Y. H. et al. Investigation of wear behavior of aged and non-aged SiC-reinforced AlSi7Mg2 metal matrix composites in dry sliding conditions. J Braz. Soc. Mech. Sci. Eng. 42, 8. https://doi.org/10.1007/s40430-019-2088-x (2020).

Vijayakumar, R. et al. Optimization of wear process parameters of Al6061-zircon composites using taguchi method. Adv. Mater. Sci. Eng. https://doi.org/10.1155/2023/9507757 (2023).

Singh, P. & Gupta, V. Dry sliding wear behaviour of Al6061 hybrid metal matrix composites using response surface methodology. IOP Conf. Ser. Mater. Sci. Eng. 1248, 01207. https://doi.org/10.1088/1757-899X/1248/1/012075 (2022).

Demir, M. E. & Okumu, M. Investigation of microhardness, microstructural, tribological, and thermal properties of Al7075/TiO2/kaoline hybrid metal matrix composites produced by powder metallurgy process. Adv. Eng. Mater. 26, 2401343. https://doi.org/10.1002/adem.202401343 (2024).

Nagula, R. K. & Reddy, K. V. Tribological performance analysis of hybrid Al6061/Si3N4/SSP/RHA composite using Taguchi approach. Int. J. Adv. Res. Eng. Technol. IJARET 11(9), 1272–1286. https://doi.org/10.34218/IJARET.11.9.2020.126 (2020).

Kaushik, N. & Singhal, S. Optimization of wear properties in aluminum metal matrix composites using hybrid Taguchi-GRA-PCA. Int. J. Perform. Eng. 14(5), 857–870. https://doi.org/10.23940/ijpe.18.05.p4.857870 (2018).

Baradeswaran, A. & ElayaPerumal, A. Study on mechanical and wear properties of Al 7075/Al2O3/graphite hybrid composites. Compos. Part B Eng. 56, 464–471. https://doi.org/10.1016/j.compositesb.2013.08.013 (2014).

Manjunatha, B., Niranjan, H. B. & Satyanarayana, K. G. Effect of amount of boron carbide on wear loss of Al6061 matrix composite by Taguchi technique and Response surface analysis. IOP Conf. Ser. Mater. Sci. Eng. 376, 012071. https://doi.org/10.1088/1757-899X/376/1/012071 (2018).

Manu, S., Radhika, N., Sidvilash, V. & Mohanraj, T. Investigation on the mechanical and wear behaviour of Al6082-BN-B4C-corn cob ash hybrid composites. Tribol. Ind. 22(2), 294–309. https://doi.org/10.24874/ti.1165.08.21.11 (2021).

Ranjitha, P., HemanthRaju, T. & Udayashankar, S. Study of wear behavior of silicon carbide and boron carbide reinforced alumiium alloy (Al6061) matrix composites. J. Inst. Eng. India Ser. D https://doi.org/10.1007/s40033-023-00625-0 (2023).

Suresh, V. et al. Mechanical and tribological analysis of C355 aluminium alloy/graphene oxide (GO)/bio-silica (BS) hybrid nanocomposite. Surf. Rev. Lett. https://doi.org/10.1142/s0218625x25500799 (2024).

Arundeep, M., Suresh, V., Srinivasnaik, M. & Yuvaraj, K. P. Effect of nanoparticles reinforcement of Silicon dioxide derived from Prosopis Juliflora on silver-grey magnesium nanocomposite: Utilization of silicon dioxide mechanical and tribological properties. Mater. Res. Express https://doi.org/10.1088/2053-1591/ad7dd6 (2024).

Vijaya Kumar, R., Hemanth Raju, T. & Udayashankar, S. Experimental investigation of Al6063 alloy with zirconium silicate composite. J. Inst. Eng. India Ser. D https://doi.org/10.1007/s40033-024-00643-6 (2024).

Abebe Emiru, A., Sinha, D. K., Kumar, A. & Yadav, A. Fabrication and characterization of hybrid aluminium (Al6061) metal matrix composite reinforced with SiC, B4C and MOS2 via stir casting. Int. J. Metalcast. 17(2), 801–812 (2023).

Arun, K. et al. Applications of artificial neural network simulation for prediction of wear rate and coefficient of friction titanium matrix composites. Mater. Res. https://doi.org/10.1590/1980-5373-mr-2022-0306 (2023).

Naidu, S. C. V. R. M. et al. Effect of graphene and bio silica extract from waste coconut shell and rye grass: Aluminum silicon alloy hybrid composites for energy storage applications. Biomass Convers. Biorefin. https://doi.org/10.1007/s13399-024-05805-w (2024).

Velavan, K., Palanikumar, K., Natarajan, E. & Lim, W. H. Implications on the influence of mica on the mechanical properties of cast hybrid (Al+ 10% B4C+ Mica) metal matrix composite. J. Mater. Res. Technol. 10, 99–109. https://doi.org/10.1016/j.jmrt.2020.12.004 (2021).

Boppana, S. B. et al. Development and mechanical characterisation of Al6061-Al2O3-graphene hybrid metal matrix composites. J. Compos. Sci. 5(6), 155 (2021).

Hillary, J. J. M., Ramamoorthi, R. & Chelladurai, S. J. Dry sliding wear behaviour of Al6061–5%SiC-TiB2 hybrid metal matrix composites synthesized by stir casting process. Mater. Res. Express 7, 126519. https://doi.org/10.1088/2053-1591/abd19b (2020).

Naveed, M. Effect of heat treatment on sliding wear resistance of hybrid aluminum matrix composite. Recent Prog. Mater. 5(2), 1–11. https://doi.org/10.21926/rpm.2302015 (2023).

Teja, M. V., Shaik, B. & Rao, M. M. Influence of graphite in metal matrix composite fabricated by stir casting. IJIEMR 11(10), 131–138. https://doi.org/10.48047/IJIEMR/V11/ISSUE10/16 (2022).

Naidu, S. C. K. V. R. M. et al. Optimization of tribological behavior of Aluminium (A356) composites using TGRA technique. Matéria Rio De Janeiro https://doi.org/10.1590/1517-7076-rmat-2024-0129 (2024).

Jia, X., Madhu, S., Naveen, S., Vellingiri, S. & Arun, J. Utilization of biosilica from Bermuda grass ash on silver-grey magnesium: influence of biosilica on its mechanical and tribological properties. Biomass Convers. Biorefin. https://doi.org/10.1007/s13399-023-04502-4 (2023).

VeereshKumar, G. B. et al. Investigation of the tribological characteristics of aluminum 6061-reinforced titanium carbide metal matrix composites. Nanomaterials 11(3039), 1–17. https://doi.org/10.3390/nano11113039 (2021).

Hugar, N., Narayana, B. V. & Waddar, S. Mechanical behaviour of stir cast TiO2/Redmud/Al6061 metal matrix composites. Mater. Res. Express 9(116509), 1–16. https://doi.org/10.1088/2053-1591/ac9e44 (2022).

Miladinović, S. et al. Tribological behaviour of hypereutectic Al-Si composites: A multi-response optimisation approach with ANN and Taguchi Grey method. Lubricants 12, 61. https://doi.org/10.3390/lubricants12020061 (2024).

Gajević, S. et al. Multi-objective optimization of tribological characteristics for aluminum composite using Taguchi grey and TOPSIS approaches. Lubricants 12, 171. https://doi.org/10.3390/lubricants12050171 (2024).

Gajević, S., Miladinović, S., Guler, O., Ozkaya, S. & Stojanović, B. Optimization of dry sliding wear in hot-pressed Al/B4C metal matrix composites using taguchi method and ANN. Materials 17, 4056. https://doi.org/10.3390/ma17164056 (2024).

Nagaral, M., MuraliMohan, R., Auradi, V. & Bharath, V. Mechanical characterization and fractography of 100–125 micron sized silicon carbide particles reinforced Al6061 alloy composites. Metall. Mater. Eng. Assoc. Metall. Eng. Serbia AMES https://doi.org/10.30544/629 (2022).

Çelik, Y. H. et al. Investigation of wear behavior of aged and non aged SiC-reinforced AlSi7Mg2 metal matrix composites in dry sliding conditions. J Braz. Soc. Mech. Sci. Eng. 42, 8. https://doi.org/10.1007/s40430-019-2088-x (2020).

Demir, M. E., Çelik, Y. H., Kilickap, E. & Kalkanli, A. The effect of B4C reinforcements on the microstructure, mechanical properties, and wear behavior of AA7075 alloy matrix produced by squeeze casting. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. https://doi.org/10.1177/09544089221139095 (2023).

Iyengar, S., Sethuram, D., Shobha, R. & Koppad, P. G. Microstructure, microhardness, and tensile properties of hot-rolled Al6061/TiB2/CeO2 hybrid composites. J. S. Afr. Inst. Min. Metall. 121(10), 543–548. https://doi.org/10.17159/2411-9717/1560/2021 (2021).

Acknowledgements

This work would not have been possible without the support and encouragement extended by the Manipal Institute of Technology, Karnataka-576104. The authors are deeply grateful to these institutions for all that they have done throughout the years.

Funding

Open access funding provided by Manipal Academy of Higher Education, Manipal

This study did not receive any funding from outside sources.

Author information

Authors and Affiliations

Contributions

Concept Design: Vijaya Kumar R, Details of Method: Venugopal M M, Experimentation: Jaya Christiyan K G, Data Analysis: Jagadeesha T, Results and Discussion: Avilasha B G, Drafting of the paper: Shashidhar L C, Software: K. Raju, Resources: Subraya Krishna Bhat, Investigation: Thanuj Kumar M, Visualization: Kanneganti Jyothishya Brahma Chari, Analysis: Hemanth Raju T, Collection of Data: Udayashankar S.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

R, V.K., M M, V., K G, J.C. et al. Study of optimization of process parameters on the wear behaviour of Al7075–aluminium oxide composites using Taguchi approach. Sci Rep 15, 22378 (2025). https://doi.org/10.1038/s41598-025-05188-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-05188-6

Keywords

This article is cited by

-

Machine Learning-Enabled Analysis of Surface Texture Orientation Effects on Wear Debris Morphology and Tribological Performance of High-Density Polyethene (HDPE)

Journal of Bio- and Tribo-Corrosion (2026)

-

Material Classification Using Decision Tree Algorithm, Support Vector Machine, and K-Means Clustering based on Density and Strength

Journal of The Institution of Engineers (India): Series D (2026)

-

Examining dielectric constant improvement techniques for ferroelectric applications using PVDF-HFP/TFO composite films

Journal of Materials Science: Materials in Engineering (2025)

-

Effect of Tungsten Carbide Composites on Al6061 Using Powder Metallurgy Technique: Experimental and Machine Learning Approach

Journal of The Institution of Engineers (India): Series D (2025)