Abstract

Well completion operations involve critical post-drilling processes to enable hydrocarbon extraction, where the selection of completion fluids—such as packer, workover, or fracturing fluids—plays a pivotal role in operational success. In Iran’s oil industry, high-temperature, high-pressure reservoirs necessitate high-density brines like calcium bromide. Reservoirs exceeding 300 °F and 10,000 psi (HPHT conditions) typically require completion fluids with densities above 100 lb/ft3. However, economic constraints and limited domestic bromine resources render such fluids prohibitively expensive, while locally available brines often lack essential completion fluid properties. This study addresses these challenges by synthesizing cost-effective, potassium-based brines using domestically sourced salts and alcohols to enhance density and performance. By incorporating alcohols (40% vol.), the crystallization temperature of medium-density brines was significantly reduced, enabling higher salt dissolution and achieving densities of 93.4, 97.8, 99.2, and 99.4 lb/ft3. Alcohol-free variants (93.4 and 97.8 lb/ft3) and alcohol-enhanced formulations (99.2 and 99.4 lb/ft3) demonstrated alkaline pH stability, low viscosity (Viscosity below 70 cP for pumping downhole using available pumps in Iran), minimal clay swelling (< 5 mL/2 g bentonite), and near-zero corrosion rates, even at 300 °F. Notably, exposure to reservoir rock altered wettability from oil-wet to water-wet, enhancing hydrocarbon recovery. Economically, these fluids leverage Iran’s accessible raw materials, offering a 40% cost reduction compared to calcium bromide. Designed primarily as packer fluids, they ensure well integrity under high reservoir pressures while mitigating formation damage. This research presents a scalable, sustainable solution for Iran’s oil sector, balancing technical efficacy with economic viability in challenging downhole environments.

Similar content being viewed by others

Introduction

The global surge in hydrocarbon demand has intensified the exploitation of high-pressure, high-temperature (HPHT) reservoirs, compelling the oil industry to confront significant operational challenges. Among these, the scarcity of cost-effective, high-density completion fluids capable of meeting HPHT environment demands remains a critical bottleneck. Traditional solutions like bromide-based brines (e.g., calcium bromide) offer high density but prove economically prohibitive in regions like Iran where bromine resources are scarce and import dependence inflates costs1,2,3. Furthermore, reservoir geology variations and temperature/pressure uncertainties complicate fluid selection for optimal well integrity and hydrocarbon recovery4.

Well completion, a pivotal phase following drilling, requires displacing drilling mud with specialized completion fluids to protect equipment, manage reservoir pressure, and minimize formation damage. These fluids - used as packer, perforation or fracturing fluids - must exhibit tailored density, thermal stability, low viscosity, corrosion resistance, and reservoir rock compatibility5,6,7. Historically, solids-laden fluids like bentonite-weighted muds were used, but their pore-throat clogging tendency and degradation caused productivity losses8,9,10. The 1970s introduction of clear brines by Conoco marked a paradigm shift, as solids-free fluids reduced formation damage and enhanced output11. Modern brines formulated with water-soluble salts (e.g., chlorides, formates) now dominate due to their transparency, stability and HPHT adaptability10,12,13,14,15.

In Iran’s predominantly HPHT oilfields, reliance on imported calcium bromide imposes unsustainable costs. While domestic medium-density brines offer cheaper alternatives, their lower solubility limits density adequacy for critical well pressure control. Recent innovations have explored alcohol incorporation to modify brine chemistry. Alcohols reduce true crystallization temperature (TCT), suppress salt precipitation and enable higher salt dissolution. This expands achievable density ranges for domestic salts like potassium carbonate and formate while maintaining alkaline pH, low corrosion rates and ≤ 248 °F thermal stability16.

Alcohols and organic additives in brine systems have attracted significant research attention for balancing density, solubility and environmental sustainability. Early studies demonstrated alcohol-water mixtures could reduce certain salt solubilities (e.g., cesium nitrate, sulfates) due to alcohol’s lower ionic dissolution affinity17,18. These findings revealed system-dependent alcohol impacts necessitating tailored formulations. Subsequent work showed ethylene glycol could enhance calcium bromide brine density (106.2-123.4 lb/ft3) by suppressing crystallization and increasing dissolution19. Isopropyl alcohol and ethanol similarly boosted sodium-based salt solubility in water-glycerol systems20. Further innovations included alcohol polymers (e.g., polyethylene glycol) to triple sodium silicate solubility and sugar/1,3-dicarbonyl additives as eco-friendly zinc-brine alternatives21,22,23. Most recently, alcohol-modified calcium nitrate brines achieved 101.5 lb/ft3 density with improved wettability and thermal stability, though remaining limited to medium-density applications16.

This study introduces a novel class of high-density (≈ 100 lb/ft3), transparent, particle-free completion fluids formulated using alcohol-enhanced systems—specifically ethylene glycol, glycerin, and sorbitol—as solubility-promoting additives. The innovation lies in leveraging alcohols to significantly increase the solubility of salts such as potassium carbonate, potassium formate, and lead nitrate, enabling the production of clear brines with no solid residues, even under HPHT conditions.

Unlike conventional zinc- or bromide-based heavy fluids—which are costly, environmentally hazardous, and prone to precipitation—this system presents a sustainable, scalable, and cost-effective alternative. It eliminates the use of toxic or imported components while maintaining superior physical and chemical stability, especially at elevated temperatures and pressures.

The novelty of this research is threefold:

-

First, it demonstrates, for the first time, the effective use of multi-alcohol systems to boost the solubility of multiple salts beyond traditional limits while maintaining full transparency and thermal integrity.

-

Second, the study presents a unique methodology to formulate fluids that remain Newtonian, corrosion-resistant, and environmentally safe, without compromising on density or downhole performance.

-

Third, it tailors these fluids for practical application in HPHT and tight reservoirs, addressing critical challenges such as formation damage, clay swelling, and wettability alteration—confirmed through experimental evaluations including acid dissolution and contact angle testing.

Materials

Synthesized completion fluids

The completion fluids examined in this study were potassium carbonate (K2CO3) and potassium formate (KCOOH) brines, synthesized using commercially available industrial-grade materials. The potassium carbonate brine was prepared by dissolving potassium carbonate in deionized water at 176 °F, while the potassium formate brine was produced by reacting formic acid (HCOOH) with potassium hydroxide (KOH) in an aqueous solution. Both brines were concentrated at 176 °F to achieve a saturated or near-saturated state, yielding clear solutions with higher densities than those attainable at room temperature. However, upon cooling, these brines showed a tendency to precipitate, restricting their practical use. To overcome this limitation, controlled amounts of alcohols—sorbitol, glycerin, and monoethylene glycol—were added to the brines at 176 °F. These alcohols were chosen for their ability to lower the true crystallization temperature (TCT), thereby preventing precipitation and enabling higher salt solubility. The incorporation of alcohols not only increased the brines’ density but also enhanced their stability and clarity, making them suitable for high-pressure, high-temperature (HPHT) well completion operations.

Formation fluids

The formation fluids used in this study comprised formation water and hydrocarbons from Iran’s Ahvaz oil field and Sarajeh gas field, two major hydrocarbon reservoirs. The formation water samples, representing the aqueous phase in these reservoirs, along with gas condensate from the Sarajeh field, were utilized for key tests such as wettability and compatibility assessments to evaluate the performance of synthesized completion fluids under realistic reservoir conditions. The elemental composition and ion concentration of both the formation waters and hydrocarbon fluids were analyzed using Inductively Coupled Plasma (ICP), a highly precise technique for quantifying trace elements and ions.The results of the ICP analysis, including the percentage composition of elements and the concentration of various ions, are detailed in Tables 1 and 2.

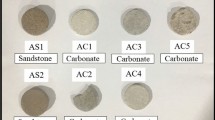

Thin section

For the contact angle and wettability tests, we used carbonate thin sections obtained from an oil field. These thin sections, representing typical reservoir rock, were meticulously prepared to maintain uniformity and consistency throughout the experiments. Figure 1 provides a visual representation of the thin sections used in this study.

Corrosion coupons

The corrosion resistance of the synthesized completion fluids was evaluated using L-80 steel coupons, a widely used material in downhole equipment, ensuring practical relevance to oilfield conditions. The dimensions of the corrosion coupons, including length, width, and thickness, are detailed in Table 3. The steel coupons were immersed in the completion fluids at 300 °F to replicate downhole conditions, with corrosion rates determined through precise weight loss measurements.

Methodology

In this section, a comprehensive flowchart is first presented to visually outline the overall workflow of this study. This flowchart (Fig. 2) serves as a guide to understand the sequence and logic behind the formulation, characterization, and evaluation of the synthesized potassium-based completion fluids. Following the flowchart, each stage of the methodology is described in detail.

Fluid formulation and density measurement

To address the challenging high-pressure, high-temperature (HPHT) conditions prevalent in Iranian hydrocarbon reservoirs (typically > 300 °F(149 °C)), this research focused on formulating high-density completion fluids that effectively maintain wellbore stability with minimal formation damage. The study specifically employed potassium carbonate and potassium formate as base salts, leveraging their dual advantages of superior thermal stability and compatibility with Iran’s indigenous salt deposits. To enhance salt solubility and suppress crystallization, alcohols such as ethylene glycol, glycerin, and sorbitol were incorporated into the brine formulations2,10. Fluid density, a critical parameter for well control, was measured in accordance with ISO 13503-3-2006 standards using a calibrated pycnometer24. The pycnometer was first calibrated with distilled water at 68 °F to determine its exact volume. The density of each brine solution was calculated using the formula:

pH adjustment

This section describes procedures for monitoring and adjusting brine pH to maintain optimal alkalinity (pH 7–9). Using common pH modifiers including NaOH, KOH, NaOCl, NH3, and amines, we evaluated fluid stability under different temperatures. Samples were heated in a controlled oven and pH measurements taken with a calibrated meter to verify performance under simulated downhole conditions.

Viscosity measurement

The flow characteristics of the synthesized completion fluids were assessed through comprehensive rheological analysis at 176 °F (80 °C) using a Brookfield DV-II + Pro viscometer. This industry-standard instrument measured viscosity across a shear rate range of 3-200 rpm, generating complete shear stress-shear rate profiles to fully characterize fluid behavior under simulated operational conditions.

The study categorized fluids based on their flow behavior: Newtonian fluids showed a direct, linear shear stress-shear rate relationship (evidenced by a straight-line graph through the origin), maintaining constant viscosity under varying forces - a critical advantage for stable wellbore flow. Non-Newtonian fluids, however, demonstrated nonlinear responses, typically needing greater force to start flowing. A practical illustration is the cornstarch-water mixture that transitions from liquid-like to solid-like behavior under different stress conditions.

Prior to testing, the viscometer was calibrated with certified reference fluids to guarantee measurement accuracy. For each brine formulation, three consecutive viscosity measurements were performed to verify repeatability. The resulting flow curves were then systematically analyzed to distinguish between Newtonian (constant viscosity) and non-Newtonian (shear-dependent viscosity) behaviors. This fundamental characterization directly informs predictions of hydraulic performance under downhole HPHT conditions, serving as a key quality control parameter for completion fluid design.

Corrosion testing

The corrosion resistance of the synthesized completion fluids was assessed using a standardized test method. For each test, 450 mL of pH-adjusted brine solution (maintained between pH 7–9) was placed in a corrosion cell. A pre-weighed carbon steel coupon, simulating actual downhole materials, was fully immersed in the brine solution. The sealed corrosion cell was then subjected to 72 h of exposure at 300 °F (149 °C) in a precision oven, accurately replicating typical wellbore thermal conditions. After the test period, the coupon was removed, cleaned to remove any corrosion products, and dried. The weight loss of the coupon (W) was measured using a precision analytical balance. The corrosion rate, expressed in mils per year (mpy), was calculated using the following Eq. (13):

.

where:

W = weight loss of the corrosion coupon (grams),

D = density of the coupon material (g/cm3),

A = surface area of the coupon (in2), and.

T = test duration (days).

Thermal stability testing

Low-temperature stability

The low-temperature stability of completion fluids was evaluated by subjecting brine samples to -17 °C (1.4 °F) for 72 h in a controlled freezer, simulating arctic storage conditions. Following this exposure, samples underwent visual analysis for crystallization or phase separation phenomena. Comparative assessment against standard calcium bromide fluids provided critical performance benchmarks for the novel formulations under extreme cold conditions. brines under sub-zero conditions.

High-temperature stability

To assess the thermal stability of completion fluids under simulated HPHT reservoir conditions, brine samples were hermetically sealed in glass vials (wrapped with aluminum foil to prevent evaporation) and subjected to controlled thermal aging in a water bath at six temperatures (77, 104, 140, 176, 212, and 248 °F) for 72 h. Following exposure, comprehensive analyses including pycnometer density measurements, pH monitoring with calibrated meters, and visual clarity inspections were conducted. The results demonstrated exceptional stability, with all tested fluids maintaining their original rheological properties, density (± 0.1 lb/gal), pH stability (± 0.3 units), and optical clarity throughout the extreme thermal cycling, confirming their reliability for demanding HPHT applications in deep reservoirs.

Clay swelling test

The clay swelling test was performed to evaluate the interaction between synthesized completion fluids and clay minerals, a crucial factor in preventing formation damage. According to the ASTM D5890 standard, the test measured the volume change of bentonite clay upon hydration with brine solutions, using distilled water as a reference. In each test, 90 mL of brine was placed in a graduated cylinder, followed by the gradual addition of 2 g of bentonite clay (0.2 g every 10 min over 200 min) to ensure proper dispersion. After a 24-hour hydration period, the final swollen clay volume was recorded. To assess the fluid’s impact on actual reservoir rock, the same procedure was repeated using powdered sandstone samples from the field. Prior to testing, X-ray fluorescence (XRF) analysis was conducted to determine the rock’s mineralogical composition, particularly its clay content, providing critical context for interpreting swelling behavior. The results were compared to the distilled water baseline, with lower swelling volumes indicating better clay hydration inhibition—an essential property for completion fluids to minimize formation damage and preserve permeability. This combined approach of standardized testing and mineralogical analysis ensures a robust evaluation of fluid performance under reservoir conditions.

Wettability assessment

The wettability of reservoir rock surfaces, a critical factor influencing hydrocarbon recovery, was evaluated using a contact angle test. This test measures the affinity of rock surfaces for oil or water, providing insights into the effectiveness of the completion fluids in altering wettability from oil-wet to water-wet states. A 0.0353 ft3 plexiglass cubic container, equipped with two parallel edges spaced 0.065 ft apart and elevated 0.131 ft from the bottom, was used for the test (Fig. 3-A). Thin sections of reservoir rock were first aged in crude oil or gas condensate at 300 °F (149.5 °C) for one week to simulate oil-wet conditions. After aging, the cubic container was filled with hydrocarbon fluid, and the thin section was placed on the edges. A drop of formation water was carefully deposited onto the thin section using a syringe, and the contact angle was measured using DigiMizer software. This initial contact angle provided a baseline for the oil-wetness of the reservoir rock. To assess the impact of the completion fluids on wettability, the thin sections were immersed in the synthesized brines at 300 °F (149.5 °C) for one week. Following this treatment, the cubic container was filled with formation water, and the thin sections were repositioned on the edges. A drop of oil or gas condensate was injected from below the thin section using a curved syringe, allowing it to contact the rock surface. The subsequent contact angle of the hydrocarbon drop was measured using DigiMizer software, indicating the degree of water-wetness induced by the completion fluid. To ensure clear visualization of the contact angles, a bright LED lamp was positioned behind the plexiglass container, illuminating the droplet for high-quality imaging (Fig. 3-B). The curved syringe used for precise droplet deposition is shown in Fig. 3-C. This methodology provided quantitative data on the wettability alteration capabilities of the completion fluids, demonstrating their potential to enhance hydrocarbon recovery by shifting reservoir rock surfaces toward water-wet conditions.

Compatibility of completion fluids with formation water

To evaluate the compatibility of the synthesized completion fluids with formation water—a key factor in preventing formation damage and operational issues—a critical precipitation test was conducted. The study used representative formation water from the oil field to simulate reservoir conditions. The test involved blending the completion fluids with formation water at a 50:50 volume ratio inside high-temperature-resistant bottles (rated for 149.5 °C(300 °F)) to ensure safe testing under extreme conditions. Each bottle was securely sealed with aluminum foil to prevent evaporation and preserve sample integrity. The samples were then aged in an oven at 80 °C (176 °F) for 72 h to replicate downhole thermal exposure. Following incubation, the mixtures were visually examined for precipitate formation. If any solids were detected, further analysis was performed to identify their composition and assess potential risks to reservoir permeability or equipment functionality. This method ensures a reliable evaluation of fluid compatibility under realistic reservoir conditions.

Results and discussion

Fluid Preparation

This study focuses on developing high-performance completion fluids through systematic characterization of potassium carbonate and potassium formate base solutions. The base fluids were prepared under controlled laboratory conditions, with their fundamental properties (density and pH) carefully measured as reference values. To optimize fluid density, three alcohol additives - glycerin, sorbitol, and monoethylene glycol - were selected based on their distinct chemical characteristics and potential to enhance fluid performance. A series of controlled experiments examined how each additive modified the density and pH profiles of the base fluids. This methodological approach provides valuable data for evaluating formulation effectiveness in completion fluid applications. The comprehensive results, presented in subsequent sections, demonstrate significant variations in fluid behavior depending on alcohol type and concentration. These findings contribute to better understanding of fluid modification strategies for well completion operations. The research establishes a foundation for developing optimized completion fluids with tailored physicochemical properties.

Potassium carbonate fluid Preparation and characterization

The potassium carbonate solution was prepared by dissolving 1100 g of salt in one liter of water, reaching its maximum solubility at ambient conditions. The solution remained stable with no sedimentation observed over a 72-hour period at room temperature. Measurements showed the fluid had a density of 93.4 lb/ft3 and a pH of 11, consistent with its highly alkaline properties. These characteristics confirm the solution’s concentrated nature and chemical stability. The results demonstrate the suitability of this formulation for further experimental studies.

To further enhance the density of the potassium carbonate fluid, experiments were conducted using three different alcohols: sorbitol, glycerin, and monoethylene glycol. The results of these experiments are summarized in Tables 4, 5 and 6, respectively.

The addition of sorbitol to the potassium carbonate fluid resulted in a significant improvement in density. Among the tested formulations, Experiment No. 3 yielded the most favorable results, with a density of 99.2 lb/ft3 and a pH of 9.9 (Table 4). This indicates that sorbitol not only enhances the density of the fluid but also slightly reduces its alkalinity, which could be advantageous in certain applications where a lower pH is desirable.

Sorbitol, a sugar alcohol with six hydroxyl groups, exhibits stronger interactions with ionic compounds. Its hydroxyl-rich structure enhances hydrogen bonding with water and ions, improving solubility. This allows sorbitol to stabilize potassium carbonate in solution, leading to a higher density (99.2 lb/ft3) and reduced pH (9.9) in optimized mixtures. Sorbitol’s ability to act as a plasticizer and humectant further contributes to solution stability by preventing salt recrystallization.

The addition of glycerin to the potassium carbonate fluid resulted in a slight increase in density (up to 93.79 lb/ft3) at lower glycerin concentrations, compared to the original density of 93.4 lb/ft3. However, at higher glycerin volume percentages, the density decreased below the baseline value. This dual behavior arises from glycerin’s limited capacity to dissolve potassium carbonate, which is lower than in water. Glycerin (glycerol) is a trihydroxy alcohol with moderate polarity. While it can interact with water molecules, its ability to solvate ionic compounds like potassium carbonate is limited.

The experiments revealed complete incompatibility between monoethylene glycol (MEG) and potassium carbonate brine, resulting in immediate salt precipitation upon mixing. This reaction occurs because MEG’s weak basic nature deprotonates carbonate ions, forming insoluble potassium bicarbonate and other byproducts. Among all tested formulations, the potassium carbonate-sorbitol combination showed superior performance, achieving the highest density while maintaining optimal pH levels. This stable, high-density fluid is particularly suitable for applications requiring precise alkalinity control. The findings demonstrate sorbitol’s effectiveness as a density-enhancing additive for potassium carbonate brines. These results provide valuable guidance for developing optimized completion fluids, with the potassium carbonate-sorbitol mixture emerging as the most promising candidate for field applications requiring both high density and chemical stability. Further research should focus on testing this formulation under simulated downhole conditions to validate its practical performance.

Potassium formate fluid Preparation and characterization

Potassium formate completion fluid was synthesized via a double displacement reaction between industrial-grade formic acid (HCOOH) and potassium hydroxide (KOH). The process began by dissolving potassium hydroxide in distilled water; however, due to the KOH mass exceeding its solubility limit in the given water volume, incomplete dissolution was observed. Formic acid was subsequently added dropwise to the mixture, initiating an acid-base neutralization reaction:

\({\text{HCOOH}}\,+\,{\text{KOH}} \to {\text{HCOOK}}\,+\,{{\text{H}}_{\text{2}}}{\text{O}}\)

The pH of the solution was meticulously monitored and maintained within the range of 8–9, a critical parameter for completion fluids to balance corrosion inhibition and stability. After optimization, the synthesized potassium formate fluid achieved a density of 97.8 lb/ft3 and a pH of 8.3 (Table 7), aligning with industry standards for high-performance completion fluids.

To further improve the fluid density, glycerin, sorbitol, and monoethylene glycol (MEG) were introduced into the optimized potassium formate solution. The results of these experiments are detailed in Tables 8, 9 and 10.

The addition of glycerin to potassium formate fluid resulted in a noticeable decrease in density across all tested volume percentages, with the original density of the potassium formate fluid at high temperature being 105.02 lb/ft3, dropping to a range of 90.8 lb/ft3 to 93.2 lb/ft3 after glycerin addition (Table 8). At 30.67 vol% glycerin, the density decreased to 92.3 lb/ft3, and at 40 vol% glycerin, it further dropped to 90.8 lb/ft3, the lowest observed value. However, at 43.75 vol% glycerin, the density slightly increased to 93.2 lb/ft3, likely due to the absence of sediment (0 g), indicating better solubility and stability at this concentration. Sediment weight decreased as the glycerin volume percentage increased, from 33 g at 30.67 vol% to 0 g at 43.75 vol%, suggesting that higher glycerin concentrations improve the solubility of potassium formate, reducing precipitation. The pH remained stable within the range of 8.1–8.3, indicating that glycerin does not significantly alter the alkalinity of the potassium formate fluid. Mechanistically, glycerin’s lower density compared to the potassium formate solution dilutes the fluid, reducing its overall density, particularly at intermediate glycerin concentrations (30–40 vol%).

The addition of sorbitol to potassium formate fluid demonstrated a significant improvement in density and stability, with the original density of the potassium formate fluid at high temperature being 106.6 lb/ft3 (Table 9). At sorbitol volume percentages ranging from 30.76 to 40%, the final density of the potassium formate-sorbitol fluid remained high, ranging from 97.5 lb/ft3 to 99.5 lb/ft3, with no sediment formation observed in these cases. This indicates that sorbitol effectively stabilizes the potassium formate solution, preventing precipitation and maintaining a dense fluid. However, at lower sorbitol concentrations (25% and 28.5%), complete sedimentation occurred, rendering the fluid unusable. This behavior highlights the critical role of sorbitol concentration in maintaining solution stability. The pH remained stable at 8.1 across all successful experiments, further confirming sorbitol’s compatibility with potassium formate. These results suggest that sorbitol is highly effective at enhancing potassium formate fluid density and stability, particularly at concentrations above 30%, making it a superior additive for high-performance completion fluids.

The addition of monoethylene glycol (MEG) to potassium formate fluid resulted in complete sedimentation across all tested volume percentages (18.18%, 30.76%, and 40%), rendering the fluid unusable (Table 10). The original density of the potassium formate fluid at high temperature was 105.02 lb/ft3, but no final density could be measured due to the complete precipitation of salts. This incompatibility is likely due to MEG’s chemical properties, including its lower dielectric constant compared to water, which reduces ionic dissociation and promotes ion pairing (K+–HCOO− aggregation). Additionally, MEG’s weak basicity may perturb the pH balance, destabilizing the formate ions and triggering salt precipitation. The absence of measurable final volume and density, along with complete sedimentation, underscores MEG’s unsuitability as an additive for potassium formate fluids. As a result, MEG is not a viable candidate for enhancing potassium formate fluid density or stability.

After conducting 52 distinct experiments, the optimal compositions for continuing the research were identified based on their density and pH performance. For the potassium carbonate system, the base fluid exhibited a density of 93.4 lb/ft3 and a pH of 11. The most promising enhancement was achieved in Experiment No. 3, where the addition of sorbitol resulted in a potassium carbonate-sorbitol fluid with a final density of 99.2 lb/ft3. In the potassium formate system, the synthesized base fluid (Experiment No. 38) demonstrated a density of 97.8 lb/ft3, while the sorbitol-enhanced formulation (Experiment No. 43) achieved a density of 99.5 lb/ft3. These optimized compositions were selected for their superior density and stability, making them ideal candidates for further investigation in high-performance completion fluid applications. The results underscore the critical role of alcohol selection and concentration in tailoring fluid properties for specific industrial needs.

Viscosity and rheological behavior of optimized completion fluids

The viscosity and rheological properties of the optimized potassium carbonate and potassium formate-based fluids were evaluated using a Brookfield viscometer. Graphs of viscosity versus speed and shear stress versus shear rate were generated for fluids with viscosities below 70 centipoise, as these met the criteria for practical application in completion fluids. The results are presented in Figs. 4, 5, 6 and 7.

The viscosity test results confirm Newtonian behavior in all tested fluids, demonstrating a linear relationship between shear stress and shear rate. This characteristic provides three key operational advantages: First, the fluid viscosity decreases predictably with increasing shear rate, enabling accurate flow rate calculations. For instance, a fivefold pressure increase results in a proportional flow rate increase. Second, the shear stress curves originate from zero, indicating flow initiation occurs even under minimal pressure - a particularly valuable feature during initial pumping stages. Third, while maintaining Newtonian behavior across most shear rates, the fluids exhibit slight shear-thinning at lower rates, facilitating both easy pump startup and stable high-rate delivery.

These properties make potassium carbonate and potassium formate-based fluids ideal for well completion operations. Their linear, predictable rheology simplifies field implementation while providing precise control under various well conditions. The Newtonian characteristics ensure scalable performance from initial placement to full-rate injection, offering operational flexibility without compromising fluid stability. The combination of immediate flow initiation at low pressures and consistent behavior at high flow rates makes these fluids exceptionally reliable for diverse completion scenarios. This balanced performance profile addresses key operational challenges while maintaining the required stability for downhole applications.

Corrosion behavior of optimized completion fluids

The corrosion behavior of the four optimized fluids (potassium carbonate, sorbitol-enhanced potassium carbonate, potassium formate, and sorbitol-enhanced potassium formate) was evaluated at 300 °F to assess their suitability for high-temperature well applications. Corrosion rates exceeding 5 mils per year (mpy)—a critical threshold for industrial equipment longevity—were mitigated using vanadate-based corrosion inhibitors. The results, summarized in Table 11, highlight the effectiveness of these inhibitors and the inherent corrosion resistance of the fluid formulations.

The base potassium carbonate fluid exhibited a corrosion rate of 330 mpy, far exceeding the acceptable limit of 5 mpy. This high corrosion rate is attributed to the alkaline nature of potassium carbonate (pH 11) and its ionic aggressiveness at elevated temperatures. However, the addition of 0.3 wt% vanadate-based inhibitor reduced the corrosion rate dramatically to 0.9 mpy, demonstrating the inhibitor’s ability to form a protective passivation layer on metal surfaces.

The sorbitol-enhanced potassium carbonate fluid, with a higher salt concentration (65 wt% vs. 52 wt% for the base fluid), showed a slightly elevated corrosion rate of 350 mpy. The increased ionic strength likely accelerates electrochemical reactions, exacerbating corrosion. By incorporating 0.5 wt% vanadate-based inhibitor, the corrosion rate was reduced to 1.5 mpy, underscoring the inhibitor’s scalability even in high-salinity environments.

In contrast, the potassium formate-based fluids exhibited significantly lower corrosion rates. The base potassium formate fluid recorded a corrosion rate of < 1 mpy, while its sorbitol-enhanced counterpart, with a higher salt concentration, showed a marginally increased rate of 2.1 mpy. The inherent corrosion resistance of potassium formate stems from its lower pH (8.3) and the stabilizing effect of formate ions, which reduce oxidative degradation of metal surfaces. The minimal corrosion rates eliminate the need for inhibitors in these formulations, simplifying their field application.

Low-temperature stability of optimized fluids

The low-temperature stability of the four optimized completion fluids (potassium carbonate, sorbitol-enhanced potassium carbonate, potassium formate, and sorbitol-enhanced potassium formate) was evaluated to assess their suitability for cold-environment applications. The fluids were subjected to controlled freezing tests in a refrigerator and freezer, with their crystallization temperatures compared to calcium bromide—a widely used completion fluid in the oil industry (Table 12).

The synthesized fluids demonstrated remarkable cold-weather performance, remaining completely stable at -17 °C (1.4 °F) without any crystallization or precipitation - a significant improvement over conventional calcium bromide solutions which typically freeze at higher temperatures. This superior low-temperature stability stems from two key factors: first, the alcohol additives (particularly sorbitol) function as effective antifreeze agents that prevent ice formation; second, the exceptional solubility of potassium salts in alcohol-water mixtures inhibits salt precipitation even under extreme cold.

These properties give the potassium-based fluids distinct operational advantages for harsh environments. Unlike calcium bromide which risks freezing and causing blockages, the new formulations maintain perfect fluidity in Arctic conditions or deep-sea applications. This reliability prevents equipment damage and operational downtime while ensuring consistent performance where traditional fluids would fail. The combination of advanced chemical formulation and proven field-ready stability makes these fluids particularly valuable for winter operations or offshore drilling in cold climates.

High-temperature thermal stability of optimized fluids

The thermal stability of the optimized completion fluids (potassium carbonate, sorbitol-enhanced potassium carbonate, potassium formate, and sorbitol-enhanced potassium formate) was evaluated at elevated temperatures ranging from 77 °F to 248 °F to simulate reservoir conditions. The fluids were stored in glass vials within a water bath-equipped oven for 72 h, after which their clarity, density, and pH were analyzed. The density and pH profiles as functions of temperature are presented in Figs. 8 and 9, respectively.

A inverse relationship between temperature and fluid density was observed across all tested fluids. As temperature increased from 77 °F to 248 °F, the density of the fluids decreased linearly. This trend aligns with the principle of thermal expansion, where molecular agitation at higher temperatures increases intermolecular spacing, thereby reducing density. Under reservoir conditions (neglecting pressure effects), this implies that fluid density will inherently decrease compared to ambient measurements. Notably, despite this decline, the fluids retained sufficient density for effective wellbore pressure control, a critical requirement for completion fluids. This linear density-temperature relationship allows for accurate density corrections in field applications, ensuring precise hydrostatic pressure control under varying reservoir conditions, while the superior density retention of sorbitol-enhanced fluids highlights their potential for high-temperature environments, where maintaining fluid integrity is critical.

The pH of all synthesized fluids decreased with rising temperature, though they remained within the alkaline range (pH > 7) even at 248 °F. For example, the potassium carbonate fluid’s pH dropped from 11.0 at 77 °F to 9.2 at 248 °F, while the potassium formate fluid’s pH decreased from 8.3 to 7 over the same range. This behavior is governed by Le Chatelier’s principle. The dissociation of water, an endothermic reaction (H2O⇌ H+(aq) + OH−(aq)), shifts toward the products (H+ and OH− ions) at elevated temperatures to counteract the applied thermal stress. The resulting increase in H+ concentration lowers the pH, reducing fluid alkalinity. The consistent alkaline pH across all fluids, even at high temperatures, highlights their robustness in maintaining chemical stability. This is particularly advantageous in high-temperature reservoirs, where acidic conditions could exacerbate corrosion and compromise equipment integrity. The ability of these fluids to retain their alkaline properties under thermal stress further validates their suitability for demanding well-completion applications.

The thermal stability of the synthesized fluids was further quantified by analyzing the magnitudes of density and pH reduction from ambient temperature (77 °F) to 248 °F, as summarized in Table 13.

The potassium formate fluid exhibited the highest density reduction (2.7 pcf), while the sorbitol-enhanced potassium formate fluid showed the smallest decrease (1.97 pcf). This divergence highlights the stabilizing role of sorbitol in mitigating thermal expansion effects. The sorbitol-enhanced formulations likely reduce intermolecular spacing through hydrogen bonding, thereby dampening density loss. In contrast, potassium carbonate-based fluids displayed intermediate reductions, with the base fluid decreasing by 2.15 pcf and its sorbitol-enhanced counterpart by 2.4 pcf. These trends align with the inherent thermal expansion properties of the salts and the solvation effects of sorbitol.

The largest pH reduction occurred in the sorbitol-enhanced potassium carbonate fluid (2.9 pH units), whereas the sorbitol-enhanced potassium formate fluid demonstrated the smallest decline (0.7 pH units). This disparity underscores the influence of the base salt’s chemistry on pH stability. Potassium carbonate’s stronger alkalinity (initial pH ≈ 11) renders it more sensitive to thermal deprotonation via Le Chatelier’s principle, while potassium formate’s near-neutral pH (initial pH ≈ 8.3) provides inherent buffering capacity. Sorbitol’s hydroxyl groups further stabilize the formate system, minimizing H+ ion generation at elevated temperatures.

All fluids maintained transparency without turbidity or precipitation at 248 °F, as evidenced by Fig. 10, which compares fluid clarity in sealed vials before and after thermal exposure. This visual stability confirms the absence of phase separation or salt recrystallization, critical for ensuring consistent fluid performance in high-temperature reservoirs.

-

Formation Damage: Clay Swelling Behavior.

The impact of synthesized completion fluids on formation damage was evaluated through clay swelling tests using bentonite clay and sandstone core samples, with results summarized in Table 14; Fig. 11. For context, the sandstone’s mineral composition, determined via X-ray fluorescence (XRF) analysis, is dominated by SiO2 (90.3 wt%), followed by minor constituents such as Al2O3 (2.2 wt%) and Fe2O3 (1.5 wt%) (Table 15).

All synthesized fluids exhibited significantly lower clay swelling magnitudes in bentonite compared to distilled water (Fig. 11). For example, distilled water caused the highest swelling (25 mm), consistent with its role as a benchmark for osmotic-driven hydration, while potassium carbonate and potassium formate fluids reduced swelling to 4 mm and 3 mm, respectively. Sorbitol-enhanced fluids showed divergent behavior: sorbitol-potassium carbonate further reduced swelling to 3 mm (vs. 4 mm for base potassium carbonate), whereas sorbitol-potassium formate increased swelling to 4 mm (vs. 3 mm for base potassium formate). This behavior is governed by osmotic pressure gradients. Distilled water, with no dissolved ions, creates a steep water concentration gradient across clay platelets, driving rapid hydration and swelling. In contrast, brines like potassium carbonate and formate reduce this gradient due to their ionic strength, suppressing osmosis. Sorbitol’s hydroxyl groups enhance hydrogen bonding in potassium carbonate, stabilizing the fluid-clay interface and further inhibiting swelling. However, in potassium formate, sorbitol may disrupt ion pairing (K+–HCOO−), reducing ionic shielding and allowing partial hydration of bentonite.

Sandstone, with its high silica content (90.3 wt% SiO2), exhibited inherently lower swelling (< 5 mm for all fluids) compared to bentonite, attributed to its low clay mineral content and rigid quartz-dominated matrix, which resists hydration-induced expansion. Practical implications of these findings include the selection of potassium formate (without sorbitol) and sorbitol-enhanced potassium carbonate as optimal fluids for clay-rich formations, minimizing swelling risks. While sorbitol enhances stability in carbonate systems, its use in formate fluids requires caution due to potential swelling aggravation. Brines with high ionic strength, such as potassium carbonate and formate, are superior to freshwater-based systems for mitigating formation damage in sensitive reservoirs. These findings underscore the importance of fluid chemistry in controlling clay swelling and optimizing well-completion strategies, aligning with established principles of osmotic-driven hydration and highlighting the need for tailored fluid formulations based on formation mineralogy.

Formation damage: wettability and wettability alteration

The wettability alteration potential of the synthesized completion fluids was evaluated through a two-stage process: initial oil-wetting and secondary water-wetting, with contact angle measurements used to quantify wettability changes (Figs. 12 and 13; Table 16).

In the initial stage, immersion of thin sections in hydrocarbon fluid for one week induced an oil-wet state, evidenced by large contact angles (49–53°) when formation water droplets were deposited on the surface, with potassium carbonate and potassium formate fluids exhibiting initial angles of 50° and 53°, respectively, and sorbitol-enhanced variants showing slightly lower angles (49° for carbonate-sorbitol; 51° for formate-sorbitol).

During the secondary stage, exposure to the synthesized fluids reversed wettability toward water-wet conditions, with significantly larger contact angles (58–60°) observed when hydrocarbon droplets were introduced beneath the thin sections. Potassium formate achieved the highest secondary-stage angle (60°), while sorbitol-enhanced fluids showed mixed effects: potassium carbonate-sorbitol increased the angle to 58.5° (vs. 58° for base carbonate), and potassium formate-sorbitol slightly reduced it to 59° (vs. 60° for base formate).

This wettability reversal is attributed to chemical adsorption mechanisms at the solid–fluid interface. Specifically, potassium ions (K+) and formate/carbonate anions (HCOO−, CO32−) are believed to adsorb onto the negatively charged rock surfaces, replacing oil-wetting components through ion exchange and surface complexation. These adsorbed ions disrupt the interaction between hydrocarbons and mineral surfaces, facilitating a shift toward a water-wet state26. In addition, sorbitol contributes to wettability alteration by adsorbing via its multiple hydroxyl (-OH) groups, which form hydrogen bonds with silanol or carbonate functional groups on the rock surface. This adsorption enhances the affinity of the surface for aqueous fluids, although its effectiveness appears reduced in formate systems, potentially due to interference with ion pairing or steric hindrance.

While this study focuses primarily on wettability alteration as a fundamental mechanism, its implications for oil production are highly significant. Wettability alteration directly influences hydrocarbon mobility, residual oil saturation, and capillary pressure. Numerous enhanced oil recovery (EOR) studies have demonstrated that converting rock surfaces from oil-wet to water-wet states leads to measurable increases in oil recovery.

For instance, in a hybrid EOR study combining electrical heating (EH) and nanofluid flooding in oil-wet carbonate cores (using Austin chalk as a model), wettability alteration was shown to be the dominant mechanism driving increased oil production. That study reported a contact angle reduction and increased water-wetness, which, in combination with decreased interfacial tension and improved surface charge distribution, enhanced oil displacement. Oil recovery reached 27% with EH alone, and up to 32% when Fe2O3 nanofluid was also introduced. The underlying mechanisms included electrowetting (which increases water droplet spreading) and nanoparticle adsorption, both contributing to improved wettability and oil displacement27.

In line with those findings, the synthesized potassium-based fluids—particularly potassium formate—demonstrated strong potential to reverse oil-wet conditions through ionic and molecular adsorption. This suggests that these fluids can play a critical role in improving oil mobility, minimizing capillary trapping, and enhancing sweep efficiency when applied in actual reservoir settings. The results support the concept that tailored completion fluid formulations, based on controlled chemical interactions and surface adsorption mechanisms, can contribute to enhanced oil production, especially in oil-wet, low-permeability carbonate formations.

Formation damage: compatibility of completion fluid with formation water

Compatibility tests between the synthesized completion fluids and actual formation water were conducted at 1:1 volumetric ratios (50 mL fluid to 50 mL formation water) under ambient temperature and 176 °F conditions, with results summarized in Table 17 and visually documented in Fig. 14.

The potassium carbonate solution showed temperature-dependent instability, becoming completely cloudy at room temperature and forming 3 g of precipitate at 80 °C(176 °F). This behavior stems from carbonate’s characteristic inverse solubility, where heating triggers salt crystallization. The sorbitol-modified version similarly clouded at both temperatures, revealing sorbitol’s ineffectiveness against carbonate precipitation - potentially due to its limited ion-shielding capacity.

Conversely, potassium formate demonstrated superior thermal stability, remaining clear at ambient conditions despite forming about 1 gram of precipitate that fully redissolved at 176 °F. This reversible precipitation confirms formate’s positive temperature-solubility relationship. Most remarkably, the sorbitol-enhanced formate solution maintained perfect clarity across the entire temperature range, proving sorbitol’s hydroxyl groups effectively stabilize formate ions through enhanced solvation. This synergistic combination prevents particle aggregation even under thermal stress, highlighting its advantage over carbonate-based formulations for temperature-variable applications.

Economic evaluation of synthesized completion fluids

The economic viability of completion fluids is a critical determinant for their adoption in the petroleum industry. In the Iranian oil sector, calcium bromide (CaBr2) fluid, priced at 1200$ per barrel, serves as the baseline for cost comparisons. To assess the feasibility of the synthesized fluids, their production costs were evaluated and benchmarked against this standard (Table 18).

New fluids based on potassium carbonate were developed and found to be the most budget-friendly options. They cost 370$ per barrel (basic) and 400$ per barrel (with sorbitol added), which is 69–70% cheaper than calcium bromide. Fluids based on potassium formate were pricier (900$–950$ per barrel) but still 21–25% cheaper than CaBr2. These fluids are better because they tolerate high temperatures, resist corrosion, and work well in formations with high salt content. The price difference between carbonate and formate fluids comes from the higher cost of potassium formate salts. Adding sorbitol slightly increases the cost but improves performance by reducing precipitation and clay swelling. Potassium carbonate fluids are best for shallow, low-temperature wells where cost reduction is key. Potassium formate fluids are recommended for high-temperature, high-pressure wells that need extra stability. All new fluids are cheaper than the 1200$ benchmark. They offer good alternatives to reduce costs without compromising performance, which aligns with global trends in optimizing completion fluid economics.

Conclusion

This study successfully synthesized potassium-based completion fluids tailored for oil and gas operations, demonstrating a combination of superior physical, chemical, and operational properties. The findings support their application as cost-effective, environmentally sustainable alternatives to conventional calcium bromide fluids, particularly suited to Iran’s resource-rich conditions. The main conclusions are outlined below:

-

Optimized Physical Properties:

The synthesized fluids achieved densities up to 99.4 lb/ft3. The inclusion of 40% sorbitol effectively lowered the true crystallization temperature to below 1.4 °F, allowing for greater salt solubility. The fluids exhibited Newtonian behavior with viscosities under 70 cP, which supports efficient pumping. Their transparency and thermal stability up to 120 °C ensure operational reliability in high-temperature downhole environments.

-

Chemical Stability and Compatibility:

The fluids maintained stable alkaline pH values (consistently > 7) and demonstrated low corrosion rates (< 5 mils/year), further reduced by corrosion inhibitors—especially in carbonate-based formulations. Potassium formate-based fluids exhibited zero corrosion at 300 °F, showcasing excellent chemical durability in corrosive environments.

-

Formation Protection and Operational Efficiency:

The fluids significantly minimized formation damage by reducing clay swelling (< 5 mL/2 g bentonite) via controlled osmotic effects. In addition, prolonged exposure to these fluids shifted rock wettability to more water-wet conditions, enhancing hydrocarbon recovery. Their compatibility with formation water further strengthens their potential to preserve reservoir integrity and productivity.

-

Economic and Environmental Viability:

By utilizing locally available raw materials in Iran, the production of these fluids offers a clear cost advantage over imported calcium bromide-based systems. Their low toxicity and environmentally friendly profiles make them aligned with global sustainability goals, offering a green yet effective option for completion operations.

-

Practical Utilization:

These potassium-based fluids are especially valuable for high-temperature, high-pressure (HPHT) reservoirs and environmentally sensitive operations. Their transparent, dense, and stable nature makes them ideal for use in tight formations where minimizing damage is critical. Local production also improves logistical flexibility and reduces dependency on international supply chains.

-

Future Perspectives:

Further research should focus on field-scale deployment to validate performance under real reservoir conditions. Investigations into long-term stability, fluid reuse potential, compatibility with other wellbore chemicals, and behavior in complex multiphase environments are recommended to support broader industrial adoption and regulatory approval.

Data availability

All data generated or analyzed during this study are included in this published article.

Abbreviations

- HPHT:

-

High pressure, high temperature

- TCT:

-

True crystallization temperature

- ICP:

-

Inductively coupled plasma

- XRF:

-

X-ray fluorescence

- MEG:

-

Monoethylene glycol

- mpy:

-

Mils per Year (corrosion rate unit)

- API:

-

American Petroleum Institute

- ASTM:

-

American Society for Testing and Materials

- SiO2 :

-

Silicon Dioxide

- Al2O3 :

-

Aluminum Oxide

- Fe2O3 :

-

Iron oxide

- CaO:

-

Calcium Oxide

- MgO:

-

Magnesium Oxide

- Na2O:

-

Sodium Oxide

- K2O:

-

Potassium Oxide

- TiO2 :

-

Titanium Dioxide

- MnO:

-

Manganese Oxide

- P2O5 :

-

Phosphorus Pentoxide

- LOI:

-

Loss on Ignition

- KOH:

-

Potassium Hydroxide

- HCOOH:

-

Formic Acid

- HCOOK:

-

Potassium Formate

- K2CO3 :

-

Potassium Carbonate

- CaBr2 :

-

Calcium Bromide

- NaOH:

-

Sodium Hydroxide

- NaOCl:

-

Sodium Hypochlorite

- NH3 :

-

Ammonia

- CO3 2− :

-

Carbonate Ion

- HCOO− :

-

Formate Ion

- K+ :

-

Potassium Ion

- H+ :

-

Hydrogen Ion

- OH− :

-

Hydroxide Ion

References

Lee, J., Shadravan, A. & Young, S. (eds) Rheological properties of invert emulsion drilling fluid under extreme HPHT conditions. SPE/IADC Drilling Conference and Exhibition; : SPE. (2012).

Kalatehno, J. M. & Khamehchi, E. A novel Packer fluid for completing HP/HT oil and gas wells. J. Petrol. Sci. Eng. 203, 108538 (2021).

Singh, R., Sharma, R. & Rao, G. R. Investigation of the effects of ultra-high pressure and temperature on the rheological properties of a novel high-density clear completion fluids using magnesium bromide for applications in HPHT reservoirs. Geomechanics and Geophysics for Geo-Energy and Geo-Resources. ;10(1):9. (2024).

Wang, Q. Fluid Chemistry, Drilling and Completion (Gulf Professional Publishing, 2021).

Chandrasekaran, C. Rubber Seals for Fluid and Hydraulic Systems (William Andrew, 2009).

BOUREGA MSE, GOURARI, M. KIHEL N. Drilling Program Elaboration Implemented in Well TOU-15 Gassi Touil Gas-Field 2023.

Khamehchi, E., Khaleghi, M. R., Abbasi, A. & Kalatehno, J. M. Applied Matrix Acidizing of Carbonate Reservoir. Springer.

Allen, T. O. & Roberts, A. P. Production operations: well completions, workover, and stimulation. (No Title). (1982).

Rike, J. L. (ed) The Relationship between Clean Fluids & Effective Completions. SPE Annual Technical Conference and Exhibition? : SPE. (1980).

Mahdavi Kalatehno, J. & Khamehchi, E. Development of a novel Packer fluid for high-temperature and high-pressure oil and gas wells with using design of experiments and artificial intelligence. J. Petroleum Explor. Prod. Technol. :1–25. (2024).

Suman, G. O. World Oil’s Sand Control Handbook (Gulf Publishing Company, 1975).

Rana, A., Murtaza, M., Raza, A., Mahmoud, M. & Kamal, M. S. Application of High-Density Brines in Drilling and Completion Fluids (Current Insights and Future Perspectives. Energy & Fuels, 2024).

Kazemihokmabad, P., Khamehchi, E., Mahdavi Kalatehno, J. & Ebadi, R. A comparative study of Brine solutions as completion fluids for oil and gas fields. Sci. Rep. 14 (1), 12628 (2024).

Crumpton, H. Well Control for Completions and Interventions (Gulf Professional Publishing, 2018).

Sangka, N. B. & Budiman, H. (eds) Application of nitrate based fluid as a completion fluid. Abu Dhabi International Petroleum Exhibition and Conference; : SPE. (2016).

Ebadi, R., Khamehchi, E., Kazemihokmabad, P. & Mahdavi Kalatehno, J. A novel formulation of an eco-friendly calcium nitrate-based heavy completion fluid. Sci. Rep. 14 (1), 21256 (2024).

Hu, M., Jin, L., Jiang, Y., Li, S. & Zhai, Q. Solubility of cesium nitrate in aqueous alcohol solutions at (25, 35, and 45) C. J. Chem. Eng. Data. 50 (4), 1361–1364 (2005).

Wang, P. et al. Ethylene glycol and its mixtures with water and electrolytes: thermodynamic and transport properties. Ind. Eng. Chem. Res. 52 (45), 15968–15987 (2013).

Alleman, D. J. Method of Increasing the Density of a Well Treatment Brine (Google Patents, 2018).

Velez, A. R., Mufari, J. R. & Rovetto, L. J. Sodium salts solubility in ternary glycerol + water + alcohol mixtures present in purification process of crude glycerol from the biodiesel industry. Fluid. Phase. Equilibria. 497, 55–63 (2019).

Topcu, G. et al. Increasing solubility of metal silicates by mixed polymeric antiscalants. Geothermics 77, 106–114 (2019).

Ray, T. G. et al. High Density Clear Brine Fluids (Google Patents, 2018).

Ray, T. G. et al. Crystallization Suppressant Combinations for High Density Clear Brine Fluids (Google Patents, 2020).

API. Testing of Heavy Brines. Recommended Practice RP 13J (American Petroleum Institute, 2014).

ASTM, D. Standard test method for swell index of clay mineral component of geosynthetic clay liners. D5890–D5806. (2006). http://www.astm.org

Gandomkar, A., Kharrat, R. J. E. S., Part, A. & Recovery, Utilization, E. E. Anionic surfactant adsorption through porous media in carbonate cores: an experimental study. ;35(1):58–65. (2013).

Amrouche, F., Blunt, M. J., Iglauer, S., Aiouache, F. & Short, M. J. M. T. S. A novel hybrid enhanced oil recovery technique to enhance oil production from oil-wet carbonate reservoirs by combining electrical heating with nanofluid flooding. ;27:100915. (2024).

Funding

This work has been supported by the Center for International Scientific Studies & Collaborations (CISSC), Ministry of Science Reaserch and Technology of Iran.

Author information

Authors and Affiliations

Contributions

A.N. conceptualized the study, developed the methodology, performed the experimental work, analyzed the data, and wrote the original draft. E.K. supervised the project, managed administration, and provided oversight of the technical direction, as well as review and editing of the manuscript. J.M.K. contributed to laboratory design, validation, and experimental procedures, and participated in manuscript review and editing. A.K. provided technical guidance on enhanced oil recovery and reservoir implications, interpreted wettability alteration and formation behavior, and revised the conclusions and practical implications. All authors reviewed and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Naghipour, A., Khamehchi, E., Mahdavi Kalatehno, J. et al. Experimental study on property enhancement of potassium Brines with alcohol additives for well completion applications. Sci Rep 15, 23264 (2025). https://doi.org/10.1038/s41598-025-06422-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-06422-x