Abstract

Geopolymer cement represents an innovative and environmentally friendly cement system that utilizes non-portlandite precursors to achieve cement hardening. Unlike traditional Portland cement, which accounts for approximately 5–8% of global CO₂ emissions, geopolymer cement offers a sustainable alternative. While its use has been widely adopted in construction projects, its application in wellbore cementing remains limited. Beyond reducing CO₂ emissions, geopolymer cement optimizes waste management by incorporating rock-based or industrial by-products rich in aluminosilicate content. In this study, Saudi volcanic scoria was developed as the primary binder for lightweight geopolymer wellbore cement. By varying the concentration of sodium hydroxide (NaOH) as an alkali activator from 15 to 40%, lightweight geopolymer cement was produced without the addition of external additives. The geopolymer cement sample containing the optimum concentration of NaOH was then used as a benchmark and compared to traditional Portland cement under identical conditions. Key variables such as mechanical strengths, rheological properties, free water, and sedimentation were analyzed. Experimental results demonstrated that volcanic scoria-based geopolymer cement with 20% NaOH achieved optimal performance, with the highest compressive and tensile strengths of 1798 psi and 73.9 psi, respectively. The results revealed that the geopolymer cement outperformed Portland cement in several aspects. For example, its compressive strength was 56% higher than that of Portland cement. Furthermore, the elastic properties of geopolymer cement were superior, with a 47% lower Young’s modulus than Portland cement. Rheological evaluations indicated that geopolymer cement exhibited excellent pumpability and workability. Despite its plastic viscosity being higher than Portland cement, the geopolymer cement demonstrated 180%, 200%, and 336% higher yield points, 10-second gel strengths, and 10-minute gel strengths, respectively. Geopolymer cement performed exceptionally well in terms of stability, with 96% less free water and a 14% lower density variation than Portland cement. These findings highlight the potential of Saudi volcanic scoria as a primary binder in lightweight geopolymer cement. By applying the one-part method, the volcanic scoria-based geopolymer cement becomes a prospective environmentally friendly cement that can potentially be used in wellbore operations. It offers a viable solution that mitigates the carbon emissions while meeting the technical requirements for wellbore cementing applications.

Similar content being viewed by others

Introduction

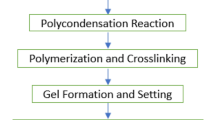

In drilling operations, cement is one of the secondary barriers that should be monitored to prevent the wellbore from any undesirable event such as kick or blowout1. Therefore, choosing pozzolanic material in cementing operations is critical because it can affect the integrity of the cement2,3. Portland has been the main component in cementing operations for several decades. Its ability to provide incredible mechanical strength and durability makes Portland cement the primary choice. However, the dependency on Portland cement can affect the environment. As known, Portland cement contributed to 5% of global carbon emissions4,5. Thus, seeking another alternative cement system is essential to avoid environmental issues but maintain the technical standard. A new cement system called geopolymer cement was first introduced in 1979 by.

Davidovits6. This inorganic cement system developed non-portlandite material as a binder to be a cementitious material7,8. Geopolymer cement has been implemented in several constructions, such as bridges, streets and buildings. Based on this fact, geopolymer cement can be an alternative to Portland cement because it provides impressive durability, mechanical properties and minimum environmental impact.

Several methods can achieve lightweight cement density. The common way to decrease the density of cement in the industry is by adding more water content. However, this method can affect cement quality by reducing its mechanical properties9,10. Therefore, adding some extender (density-reducing additives) can achieve cement stability and higher compressive strength. Generally, the extender was divided into three categories: water extender, low-density aggregates, and gaseous extender11,12,13. As explained previously, a water extender is a viscosifying agent that allows additional water to the slurry without changing the properties of cement. Moreover, low-density aggregates are any additives/materials that have a lower density than the binder. Lastly, the gaseous extender is a gas that can foam the cement slurry. The examples for those categories are bentonite, coal ash powder, and nitrogen or air, respectively14.

A volcanic eruption is a natural disaster that explodes tons of tephra and fragments rocks from the belly of the volcano. In terms of definition, tephra is unconsolidated pyroclastic material that has particle ranges from ash (< 2 mm) and lapilli (2–64 mm) to blocks (dense, angular) such as volcanic (vesicular, rounded) that have more than 64 mm and scoria with the average size diameter of 20–30 cm15,16,17,18. In the Middle East region, Saudi Arabia has identified many possible sources of cement rock that spread in the country’s western region, especially in Taif City, which has a resource belt of more than 90 km in length and 10–15 km wide19. Due to the large amount, volcanic tephra can be utilized as a cement binder material that can take a role as particle replacement or binder material. The potency of Saudi volcanic tephra is tremendous, but research on this material is still limited20. For instance, Alanqari et al. (2022) proposed the methodology, preparation and application of Saudi Volcanic Ash in wellbore cementing operations21. This study investigated the performance of volcanic ash cement slurry in several measurements, including mechanical, physical, and chemical properties, while dissolved in NaOH solution. The result revealed that this cement’s compressive strength and thickening time are affected by alkali concentration and show outstanding performance when compared with Portland cement.

As one of the tephra’s products, the presence of silica and alumina in volcanic ash has added value when incorporated with cement slurry as particle replacement. The study conducted by Kupwade-Patil et al. (2018) mentioned that the additional mixture of silica fume and volcanic ash in Portland slurry up to 40% can be positively affected by showing low porosity and adding more C-S-H and C-A-S-H gels that influence to densification of the microstructure22. Moreover, Celik et al. (2019) investigated the utilization of natural pozzolan (NP) and limestone powder (LP) of volcanic ash as particle replacements for Portland cement23. The study revealed that even if the NP and LP can increase the hydration process, the NP volcanic ash could be beneficial in cement slurry because it can have more effect on the mechanical properties of the cement concrete even though NP increases the setting time. In addition, incorporating NP and LP volcanic ash in cement slurry can increase the water demand. However, several researchers mentioned that volcanic ash can reduce cement quality by decreasing mechanical properties24. It is due to the particle size that used is very fine. Hence, the particle size of volcanic ash should be considered before employing it as a particle replacement or binder in a cement system.

On the other hand, using volcanic scoria can positively affect cement performance. According to Al-Swaidani (2017), using volcanic scoria as particle replacement can improve the durability of concrete cement, especially in acidic environments25. The experimental results reveal that even plain Portland cement has a higher compressive strength than Portland-scoria-based cement, and the durability of Portland-scoria-based binder cement was higher. It is proved by showing higher water and chloride penetration resistance compared to neat Portland cement. In addition, Portland replacement with volcanic scoria can influence the rheological properties of the cement. The study conducted by Tchamdjou et al. (2017) explained the effect of the partial replacement of Portland cement with natural pozzolan generated from volcanic scoria on the workability and flowability of the slurry26. It shows that incorporating volcanic scoria in different percentages of all types almost reduced the cement slurry’s yield stress and plastic viscosity. Utilizing volcanic scoria in different cement products has high potential since it has many sources in many places worldwide27.

This study focuses on developing Saudi volcanic scoria as a lightweight geopolymer wellbore cement binder. Some parameters, such as mechanical and rheological analysis, were conducted to investigate the sample’s durability, flowability, and strength. In addition, the free water and sedimentation tests were elaborated to assess the cement’s stability and integrity. Moreover, a comparison of lightweight geopolymer with traditional cement was added to make the comprehensive analysis. The output of this research is to seek another alternative that can be done for wellbore cementing applications that fulfill the technical requirement but contribute to a green environment.

Materials and methods

Collected material

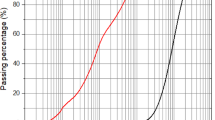

The material used in this study is volcanic scoria collected from the western region of Saudi Arabia. This work prepared the volcanic scoria as the main binder in lightweight geopolymer wellbore cement by grinding the rock materials and sieving them below 106 microns. The X-ray fluorescence (XRF), X-ray diffraction (XRD), and Particle Size Distribution (PSD) tests were conducted to characterize the composition and structural size of the raw materials.

Table 1 shows the XRF result of the volcanic scoria. Based on the measurement test, silicate oxide (SiO2) dominates the composition of the volcanic scoria by 43%, continuing with ferric oxide (Fe2O3) and aluminum oxide (Al2O3) by 20% and 13%, respectively. Moreover, the particle size distribution results in Fig. 1 Shows that the volcanic scoria’s average size (D50) was 10.84 μm.

Sample Preparation

This experiment used volcanic scoria as the primary binder in developing lightweight geopolymer cement. The sodium hydroxide (NaOH) powder, purchased from Sigma-Aldrich, was considered the main alkali activator, as it was agitated with the chemical powder before mixing it with water. To obtain the optimum performance, the sodium hydroxide was varied to analyze the mechanical strength of the volcanic scoria-based lightweight geopolymer cement. On the other hand, a neat Portland cement was considered as representative of the traditional cement. A 300 gr of Class G cement manufactured by Taqa Innovation Centre, Dhahran, Saudi Arabia, was dissolved with 0.293 L of water without any additive materials to make a neat cement slurry. This traditional cement was compared with the optimum geopolymer cement to assess the performance of the green cement system.

As shown by Table 2, the activator compositions of this study ranged from 15% up to 40% by weight of blend (BWOB) with a 5% increment. Moreover, the water components were changed by adding more sodium hydroxide powder to reach a similar density of 13 ppg. The minimum amount of NaOH powder was considered by 15% to improve the mechanical properties of the geopolymer cement. On the contrary, the solid activator was not exceeded by more than 40% due to economic aspects. This study aimed to provide a valuable alternative to wellbore cement without compromising operational expenditure.

Following the American Petroleum Institute (API RP 10B) regulation, the cement slurry was made by mixing for 15 s at 4,000 rpm and then for the next 35 s at 12,000 rpm. The slurry was conditioned for 30 min in an M7200 Atmospheric Consistometer at 120 °F with a rotation speed of 150 rpm. The prepared slurry was subjected to a series of tests to assess its mechanical properties, rheological behavior, free water, and sedimentation.

Properties measurements

After selecting the optimum concentration of NaOH, lightweight geopolymer cement was compared with neat Portland cement of the same density to represent the ability of geopolymer cement to be implemented in shallow formations. Following the American Petroleum Institute Recommendation Practice Standard for Wellbore Cementing (API RP 10B-2), the comparison was investigated by conducting several tests, including mechanical properties, rheological properties, free water, and sedimentation.

Mechanical properties

Three tests were performed to evaluate the mechanical properties of compressive strength, tensile strength, and Young’s modulus. For example, the compressive strength was measured after 24 h of curing using cylindrical cement samples with dimensions of 1.5 inches in diameter and 4 inches in length. The scratch test method involved applying a sharp cutter to the sample’s surface at a consistent depth to estimate its compressive strength.

Tensile strength was assessed under identical curing conditions using a hydraulic press. Cement samples with a diameter of 1.5 inches and a thickness of 0.75 inches were tested via the indirect Brazilian tensile strength method. This approach calculated tensile strength based on the maximum load the sample could withstand before failure. A crushing machine was employed to perform the tensile strength measurements. Similar to compressive strength, the tensile strength of these samples was measured after a 24-hour curing time.

Evaluating elastic properties is one of the crucial aspects of mechanical properties testing, providing insights into the dynamic behavior of cementitious materials. Unlike conventional static strength tests, elastic property analysis determines the material’s response to stress by measuring the propagation velocity of ultrasonic waves. This study assessed the key elastic property of Young’s modulus. The experimental procedure was conducted using the NER Benchtop Velocity system, which measures compressional and shear wave velocities under atmospheric conditions using cylindrical cement samples 1.5 inches in diameter and 4 inches in length.

Rheological behavior

After conditioning, rheological measurements were performed using a viscometer to evaluate critical fluid properties such as plastic viscosity, yield point, and gel strength. The viscometer determined the shear stress at various shear rates (3, 6, 100, 200, and 300 rpm) in ascending and descending sequences, with the results averaged to obtain representative values.

Free water

The static stability of the cement under wellbore conditions was assessed by measuring free water content. Free water content was evaluated by pouring the slurry into a 250 mL cylindrical flask and allowing it to stand for two hours. Any fluid separation was observed to determine the slurry’s static stability during this period. To replicate wellbore conditions, the slurry was conditioned and exposed to elevated temperatures for two hours to simulate its behavior during circulation and evaluate fluid separation within the sample.

Sedimentation test

The static stability of the cement under wellbore conditions was also evaluated by performing a sedimentation test. This test analyzed density variations in cement samples after curing cylindrical specimens for 24 h. The density changes were assessed using direct density measurements. To represent density distribution along the sample, the cured cement cylinders were sectioned into three parts: top, middle, and bottom. Smaller cement cylinders, each measuring 1.5 inches in diameter and 1 inch in length, were cut from these sections to facilitate a precise comparison of density variations. The density of the smaller samples was then calculated based on their specific gravity, providing insights into the uniformity of the cement.

Result and discussion

Mechanical properties

Firstly, sodium hydroxide (NaOH) was commonly used as the main activator in most geopolymer cement. In this part, the effects of several NaOH quantities on the strength properties of lightweight geopolymer cement were evaluated. The formulation varied from 15 to 40% by weight of binder (BWOB). In addition, the samples were cured and tested in the same conditions. Based on the experimental result in Fig. 2, the sample with a 20% alkali activator revealed the optimum compressive and tensile strength. Therefore, the Saudi volcanic scoria-based cement with 20% NaOH will be used as a benchmark in lightweight geopolymer cement.

The compressive strength of the Saudi volcanic scoria-based geopolymer cement exhibits significant variability with changes in NaOH concentration, as depicted in Fig. 2. At the lowest concentration of 15% by weight of binder (BWOB), the compressive strength is measured at 435 psi. This value increases dramatically to 1798 psi at a 20% concentration, marking an increase of 313%. This peak compressive strength at 20% NaOH concentration indicates an optimal point for the geopolymerization process, where the alkali activation of the Saudi volcanic scoria is most effective. However, as the concentration of NaOH increases beyond 20%, there is a noticeable decline in compressive strength. At 25% NaOH, the strength drops to 1189 psi, a decrease of 34% from the peak value. This trend continues with further increases in NaOH concentration, reaching 1001 psi at 30%, 857 psi at 35%, and finally, 725 psi at 40% NaOH concentration. These results suggest that higher concentrations of NaOH may lead to an over-activation of the geopolymer matrix, potentially causing structural weaknesses or inefficiencies in the binding process.

The tensile strength of the geopolymer cement also shows a peak at the 20% NaOH concentration, mirroring the trend observed in compressive strength. Starting at 28 psi for 15% NaOH, the tensile strength increases to 74 psi at 20%, an increase of 239%. This indicates a strong correlation between compressive and tensile strength at this concentration, suggesting an optimal balance in forming the geopolymer network. Subsequent increases in NaOH concentration lead to a decline in tensile strength. At 25%, the tensile strength is 57.9 psi, decreasing by 22% from the peak. The decline continues to 50.8 psi at 30%, 45.3 psi at 35%, and drops to 42.1 psi at 40%. This pattern aligns with the hypothesis that excessive NaOH may disrupt the optimal geopolymer matrix formation, leading to reduced mechanical properties.

The observed trends in compressive and tensile strengths with varying NaOH concentrations highlight the critical role of alkali concentration in the polymerization process of Saudi volcanic scoria-based cement. The peak at 20% NaOH concentration for both strength measures suggests this as the optimal concentration for achieving maximum mechanical properties in this geopolymer system. This finding is consistent with studies by Davidovits (2015)28where the balance between the dissolution of aluminosilicate precursors and the formation of geopolymeric gel is crucial for strength development. Moreover, the decline in strengths at higher NaOH concentrations could be attributed to the formation of excessive sodium silicate gels that may not contribute effectively to the structural integrity of the geopolymer, as suggested by Provis and van Deventer (2009)29. This could also be due to the potential for increased porosity or microstructural defects at higher alkali concentrations, which is a common observation in geopolymer materials, as discussed by Duxson et al. (2007)30.

Mechanical properties are the assessment tests conducted to investigate the integrity of the wellbore cement. Figure 3 examined compressive strength and Young’s modulus to study the mechanical properties of the Saudi volcanic scoria-based geopolymer and Portland cement for lightweight wellbore cementing application. Practically, higher compressive strength can represent good wellbore stability. However, achieving higher compressive strength in shallow formation is not necessary. This is because the cement with high compressive strength might cause problems to the wellbore with lower formation pressure. According to Adjei & Elkatatny (2021), lightweight cement with 50 psi compressive strength can uphold the casing14. Moreover, lightweight cement with a strength ranging from 250 to 1000 psi can be implemented for many shallow-form operations. According to Ahmed et al. (2023), cement materials with good elasticity have a lower Young modulus31. The lower Young’s modulus shows that the cement is more stable under the shear deformation.

Based on the experimental results, the Saudi volcanic scoria-based geopolymer cement exhibited an exceptional result, with excellent compressive strength. For instance, the compressive strength of Portland cement was only 1153 psi, while the volcanic scoria-based geopolymer had a very high compressive strength of 1798 psi, which is 56% higher than Portland cement. This enhancement in strength can be attributed to the unique geopolymerization process where volcanic scoria, rich in aluminosilicate, undergoes alkali activation, forming a robust three-dimensional network of Si-O-Al bonds, as discussed by Davidovits (2015)28.

Moreover, Young’s modulus, a measure of the material’s stiffness, also shows a marked difference between the two types of cement. For example, the Saudi volcanic scoria-based geopolymer cement was more stable during the shear deformation, as represented by its lower Young’s modulus than the Portland cement. For example, volcanic scoria-based geopolymer showed a Young’s modulus of 1.82 GPa, 47% lower than that of Portland cement (3.38 GPa).

The enhanced mechanical properties of the volcanic scoria-based geopolymer cement over Portland cement indicate its potential superiority in wellbore applications requiring high strength and stability under stresses. The significant improvement in the mechanical properties suggests that this geopolymer could be particularly advantageous in wellbore cementing, where durability and resistance to deformation are critical.

Rheological properties

Rheological properties are essential parameters that govern the workability and pumpability of cement slurries. These properties play a key role in improving the durability of the cement and ensuring effective zonal isolation within the wellbore. The design of the rheological behavior of cement slurries must be tailored to the specific wellbore conditions to achieve optimal performance. Furthermore, a properly designed cement slurry should facilitate efficient mud removal, ensure proper slurry placement, and form an impermeable barrier for enhanced well integrity32,33. Yield point and viscosity are crucial for assessing the workability and ease of handling of slurry during cementing processes, particularly in applications involving pumping. Yield point represents the minimum force needed to start the flow of cement slurry, whereas plastic viscosity indicates the slurry’s resistance to flow once movement has begun34.

The Bingham plastic model evaluated the rheological properties of volcanic scoria-based lightweight geopolymer cement. To perform a comprehensive analysis, the rheological behavior of the geopolymer slurry was compared in various activator percentages, as illustrated in Fig. 4. Experimental results revealed several significant findings.

The addition of excess sodium hydroxide powder can significantly reduce the pumpability and workability of geopolymer slurry. This is proved by the sample containing an additional 40% sodium hydroxide, which exhibited a 256% increase in viscosity compared to the 15% NaOH-based sample. Conversely, the yield point of the samples decreased with higher percentages of activator. Among the tested formulations, adding 15% NaOH notably enhanced the yield point of the slurry. Similarly, incorporating lower concentrations of sodium hydroxide positively influenced the gel strength of the geopolymer slurry. The sample with 15% additional NaOH demonstrated the most optimal gel strength at 10 s and 10 min conditions. In contrast, the lowest gel strength was observed in the sample containing 35% NaOH. These findings suggest that the rheological properties of geopolymer cement can be improved by reducing the amount of sodium hydroxide as an activator.

Although the 15% NaOH-based sample achieved better performance than the benchmark sample, the 20% NaOH-based geopolymer cement exhibited an acceptable result when compared to the Portland cement, as illustrated in Fig. 5. Experimental results revealed several significant findings. Despite the plastic viscosity of the geopolymer slurry being approximately higher than that of Portland cement, the geopolymer cement exhibited good pumpability.

The yield point of Saudi volcanic scoria-based geopolymer cement is significantly higher at 28 lb/100 ft² compared to Portland cement’s 10 lb/100 ft². This represents a 180% increase in the yield point of Saudi volcanic scoria-based geopolymer cement relative to Portland cement. A higher yield point indicates that Saudi volcanic scoria-based geopolymer cement possesses greater resistance to initial flow under static conditions, which can enhance its capacity to suspend solid particles, such as aggregates or additives, in the mixture. This behavior is advantageous in applications where sedimentation prevention is critical.

The gel strength of Saudi volcanic scoria-based geopolymer cement is also notably higher than that of Portland cement. The 10-second gel strength for Saudi volcanic scoria-based geopolymer cement is 27 lb/100 ft², while Portland cement shows only 9 lb/100 ft², representing a 200% increase. Similarly, the 10-minute gel strength is 48 lb/100 ft² for Saudi volcanic scoria-based geopolymer cement, compared to 11 lb/100 ft² for Portland cement, which is a 336% increase. This significant enhancement in gel strength demonstrates that Saudi volcanic scoria-based geopolymer cement exhibits superior gelation properties, forming stronger gel structures over time and enhancing resistance to particle settling in static conditions. This characteristic improves the ability to control fluid migration and resist gas intrusion in cementing operations.

Free water

Referring to the API RP 10B-2 standard, this test aims to determine the stability of the wellbore cement in static conditions35. This experiment started by investigating the free water of geopolymer cement in different NaOH compositions, as presented in Fig. 6. It shows that all geopolymer samples exhibited lower free water by obtaining a free fluid of less than 1 ml. The sample activated with 30% obtained the lowest free water after being cured at 50ºC for 2 h by 0.3 ml, while the highest free fluid was exhibited by the 40% NaOH-based sample with 0.7 ml.

In comparison to the benchmarked sample, the 20% NaOH-based sample shows a higher free water content than the 30% NaOH-based sample. It is proved by the free fluid of the benchmarked sample, which exhibited 0.5 ml, 66% higher than the lowest one. However, the 20% NaOH-based geopolymer cement exhibited good stability when compared against Portland cement, as presented in Fig. 7. The free water of Portland cement has been increased significantly by reached the value of 12 ml, which means 2300% increased than geopolymer cement. This test highlights significant difference in water retention characteristics. Free water is not chemically bound or absorbed during cementitious materials’ hydration or activation process.

This vast difference in free water content can be attributed to the fundamental differences in the two cement types’ hydration and chemical reaction mechanisms. Portland cement undergoes a hydration process in which water is consumed to form calcium silicate hydrate (C-S-H) and other byproducts. However, excess water remains unbound and contributes to the free water content. In contrast, Saudi volcanic scoria-based geopolymer cement relies on an alkali-activation process that forms a dense, three-dimensional aluminosilicate network. This network exhibits reduced porosity and a higher capacity to bind water, thereby minimizing the free water content chemically36.

The low free water content of Saudi volcanic scoria-based geopolymer cement has practical implications for its performance characteristics. Reduced free water content enhances the material’s durability and resistance to cracking, shrinkage, and water-related degradation. Additionally, it contributes to lower permeability, which is a desirable property for wellbore cementing applications28. In contrast, the higher free water content in Portland cement can increase porosity, adversely affecting long-term durability and mechanical performance.

Sedimentation test

The sedimentation test also aims to determine the stability of the wellbore cement in static conditions. The test evaluates the homogeneity and stability of the materials, which are critical for ensuring uniform properties and performance in practical applications. This research analyzed the sedimentation of lightweight geopolymer cement in various NaOH contents. Figure 8 demonstrates the density variation and density distributions of the geopolymer cement in three different sections: top, middle and bottom parts. This experiment was conducted by measuring the weight of each section in both dry and wet conditions.

In terms of density variations, the sample activated with 30% NaOH exhibited less segregation by showing a density variation of 2.65%. Moreover, the density of this sample in three different sections was measured as 1.64 g/cm³, 1.69 g/cm³ and 1.68 g/cm³, respectively. The difference between the top and bottom sections was only 0.04 g/cm³. It indicates that the particle of this geopolymer cement was distributed properly.

Compared to the benchmark sample, the 20% NaOH-based sample exhibited the density variations of 4.44%, 1.79% higher than the lowest sample. For the density at each section, the benchmarked sample revealed the density of the top, middle and bottom samples at 1.58 g/cm³, 1.64 g/cm³, and 1.66 g/cm³, respectively. The variation of the top and bottom samples was higher than the previous one by reaching 0.08 g/cm³. Despite exhibiting higher density variation and distribution, the benchmarked geopolymer cement achieved better performance than Portland cement. As presented by Fig. 9, the traditional cement sample exhibited densities of 1.53 g/cm³, 1.58 g/cm³, and 1.61 g/cm³ for the top, middle, and bottom sections, respectively. The density variation in this case was slightly higher, with a difference of 0.08 g/cm³ between the top and bottom sections, corresponding to a density variation of 5.1%.

When comparing the overall density variation, the Saudi volcanic scoria-based geopolymer cement demonstrated 14% less variation than Portland cement, which suggests improved stability and reduced sedimentation within the geopolymer matrix. This reduced variation in geopolymer cement can be attributed to its dense aluminosilicate network formed during the alkali-activation process, which limits particle segregation and enhances structural homogeneity36. However, Portland cement relies on hydration reactions, which may result in greater sedimentation due to particle size and density differences. The average density across all sections for geopolymer cement is 1.63 g/cm³, which is slightly higher than the average of 1.57 g/cm³ for Portland cement. This 3.82% increase in average density indicates that geopolymer cement has a denser matrix overall, which could translate to better mechanical performance and durability in practical applications.

The lower density variation in Saudi volcanic scoria-based geopolymer cement suggests enhanced uniformity, a critical property for lightweight materials. Reduced variation minimizes the potential for weak points caused by segregation, leading to improved mechanical strength and resistance to cracking. Nevertheless, the higher density variation observed in Portland cement could lead to uneven performance. This phenomenon is likely caused by the higher water content and slower hydration process of Portland cement, which allows for greater particle movement and sedimentation during setting28.

Conclusions

This study successfully developed Saudi volcanic scoria as a primary binder in lightweight geopolymer cement. By applying the one-part method, the sodium hydroxide (NaOH) was assessed as the main activator in different percentages to achieve the optimum performance of geopolymer cement. Compared with traditional Portland cement, the mechanical properties, rheological behavior, free water, and sedimentation of geopolymer cement showed promising results. Some key findings are presented in the points below:

-

The 20% of NaOH can contribute to the highest compressive and tensile strength of the volcanic scoria-based lightweight geopolymer cement among the other percentages.

-

Compared to the neat Portland cement, the geopolymer cement exhibited excellent compressive strength and Young’s modulus.

-

The rheological properties of both samples revealed an appropriate result. Even though the plastic viscosity was higher than Portland cement, the yield point and gel strength of geopolymer cement were better than Portland cement, meaning that geopolymer cement has better particle transport and is more resistant in static conditions.

-

The cement stability of geopolymer cement was exhibited more by showing that the free water and density variation of geopolymer cement were lower than Portland cement.

These findings underscore the potential advantages of Saudi volcanic scoria-based geopolymer as a sustainable alternative to Portland cement in wellbore operations. The development of this green cement using an unconventional method not only offers better performance characteristics but also aligns with the broader goal of reducing environmental impacts associated with cement production. This study serves as an initial step toward the adoption and commercialization of Saudi volcanic scoria in geopolymer-based wellbore cement applications. However, further analysis is required to optimize the formulation for lightweight green cement, particularly for use in shallow formations.

Data availability

Due to data privacy, supporting data cannot be made openly available. Contact the corresponding author for further information about the data and conditions for access.

References

Grace, R. D. Blowout and well control handbook. Blowout Well Control Handb. https://doi.org/10.1016/c2016-0-03296-5 (2017).

Patel, H. & Salehi, S. Development of an advanced finite element model and parametric study to evaluate cement sheath barrier. J. Energy Resour. Technol. 141, 092902 (2019).

Fraser, D., Moore, D., Staak, M. & R005 (SPE. Vander. A Barrier Analysis Approach to Well Control Techniques. in SPE/IADC Drilling Conference and Exhibition D021S011, (2015). https://doi.org/10.2118/173153-MS

Czigler, T., Reiter, S., Schulze, P. & Somers, K. Laying the foundation for zero-carbon cement. McKinsey & Company 9, p. 7. (2020). https://www.mckinsey.com/industries/chemicals/our-insights/laying-the-foundation-for-zero-carbon-cement

Griffiths, S. et al. Decarbonizing the cement and concrete industry: A systematic review of socio-technical systems, technological innovations, and policy options. Renew. Sustain. Energy Rev. 180, 113291 (2023).

Davidovits, J. & Synthesis of new high-temperature geo-polymers for reinforced plastics/composites. in (1979).

Heath, A., Paine, K., Goodhew, S., Ramage, M. & Lawrence, M. The potential for using geopolymer concrete in the UK. Proc. Institution Civil Eng. - Constr. Mater. 166, 195–203 (2013).

Mesgari, S., Akbarnezhad, A. & Xiao, J. Z. Recycled geopolymer aggregates as coarse aggregates for Portland cement concrete and geopolymer concrete: effects on mechanical properties. Constr Build. Mater 236, 117571, p. 2. (2020). https://doi.org/10.1016/j.conbuildmat.2019.117571

Blanco, F., Garcı́a, P., Mateos, P. & Ayala, J. Characteristics and properties of lightweight concrete manufactured with cenospheres. Cem. Concr Res. 30, 1715–1722 (2000).

Murthy, R. V. V. R., Mohammad, F. & Chavali, M. Development of innovative lightweight slurry in oil well-cementing operations. Upstream Oil Gas Technol. 7, 100045 (2021).

Bentz, D. P., Coveney, P. V., Garboczi, E. J., Kleyn, M. F. & Stutzman, P. E. Cellular automaton simulations of cement hydration and microstructure development. Model. Simul. Mat. Sci. Eng. 2, 783–808 (1994).

Broni-Bediako, E., Joel, O. F. & Ofori-Sarpong, G. Oil well cement additives: a review of the common types. Oil Gas Res. 2, 1–7 (2016).

Samsuri, A., Junin, R. & Osman, A. M. The Utilization of Malaysian Local Bentonite as an Extender and Free Water Controller in Oil-Well Cement Technology. in SPE Asia Pacific Oil and Gas Conference and Exhibition SPE-68674-MSSPE, (2001). https://doi.org/10.2118/68674-MS

Adjei, S. & Elkatatny, S. Overview of the lightweight oil-well cement mechanical properties for shallow wells. J. Pet. Sci. Eng. 198, 108201 (2021).

Arnalds, O. The influence of volcanic tephra (Ash) on ecosystems. Advances in Agronomy. 121, 331–380. p. 331. Elsevier (2013). https://doi.org/10.1016/B978-0-12-407685-3.00006-2

Elias, S. A. Encyclopedia of Quaternary Science (Elsevier, 2013).

Huff, W. D. & Owen, L. A. Volcanic Landforms and Hazards☆. in Reference Module in Earth Systems and Environmental Sciences B9780124095489096000Elsevier, (2015).

Lowe, D. J. Tephrochronology and its application: A review. Quat Geochronol. 6, 107–153 (2011).

Amin, M. N. & Khan, K. Mechanical performance of High-Strength sustainable concrete under fire incorporating locally available volcanic Ash in central Harrat rahat, Saudi Arabia. Materials 14, 21 (2020).

Celik, K. et al. High-volume natural volcanic Pozzolan and limestone powder as partial replacements for Portland cement in self-compacting and sustainable concrete. Cem. Concr Compos. 45, 136–147 (2014).

Alanqari, K., Al-Yami, A. & Wagle, V. Preparation of a Synthetic Geopolymer Cement Utilizing Saudi Arabian Volcanic Ash for a Sustainable Development: Method, Preparation and Applications. in International Petroleum Technology Conference, IPTC 2022 (2022). https://doi.org/10.2523/IPTC-22617-EA

Kupwade-Patil, K., Palkovic, S. D., Bumajdad, A., Soriano, C. & Büyüköztürk, O. Use of silica fume and natural volcanic Ash as a replacement to Portland cement: Micro and pore structural investigation using NMR, XRD, FTIR and X-ray microtomography. Constr Build. Mater. 158, 574–592, p. 584. (2018). https://doi.org/10.1016/j.conbuildmat.2017.09.165

Celik, K., Hay, R., Hargis, C. W. & Moon, J. Effect of volcanic Ash Pozzolan or limestone replacement on hydration of Portland cement. Constr. Build. Mater. 197, 803–812 (2019).

Hamada, H. M., Abed, F., Beddu, S., Humada, A. M. & Majdi, A. Effect of volcanic Ash and natural Pozzolana on mechanical properties of sustainable cement concrete: A comprehensive review. Case Stud. Constr. Materials 19, e02462, p. 10. (2023). https://doi.org/10.1016/j.cscm.2023.e02462

Al-Swaidani, A. M. Production of more durable and sustainable concretes using volcanic scoria as cement replacement. Materiales De Construcción. 67, 118 (2017).

Tchamdjou, W. H. J., Cherradi, T., Abidi, M. L. & De Oliveira, L. A. P. Influence of different amounts of natural Pozzolan from volcanic scoria on the rheological properties of Portland cement pastes. Energy Procedia. 139, 696–702 (2017).

al-Swaidani, A. M. Volcanic Scoria as Cement Replacement. in Volcanoes - Geological and Geophysical Setting, Theoretical Aspects and Numerical Modeling, Applications to Industry and Their Impact on the Human Health (ed. Aiello, G.)InTech, (2018).

Davidovits, J. Geopolymer Chemistry and Applications Geopolymer Chemistry & Applications. Institute Geopolymer, France vol. (2015). (2011).

Provis, J. L. & Van Deventer, J. S. J. Geopolymers: Structures, Processing, Properties and Industrial Applications (Elsevier, 2009).

Duxson, P., Provis, J. L., Lukey, G. C. & Van Deventer, J. S. J. The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr Res. 37, 1590–1597 (2007).

Ahmed, A., Elkatatny, S. & Adebayo, A. R. Synthetic clay application to reduce the segregation of Barite-Based Oil-Well cement. ACS Omega. https://doi.org/10.1021/acsomega.3c09925 (2024).

Memon, K. R., Shuker, M. T., Tunio, S. Q., Lashari, A. A. & Abbass, G. Investigating rheological properties of high performance cement system for oil wells. Res. J. Appl. Sci. Eng. Technol. 6, 3865–3870 (2013).

Shahriar, A. & Nehdi, M. L. Optimization of rheological properties of oil well cement slurries using experimental design. Mater. Structures/Materiaux Et Constructions. 45, 1403–1423 (2012).

Hwalla, J., El-Hassan, H., El-Mir, A., Assaad, J. J. & El-Maaddawy, T. Development of geopolymer and cement-based shotcrete mortar: impact of mix design parameters and spraying process. Constr. Build. Mater. 449, 138457 (2024).

API, R. P. 10B-2, Recommended Practice for Testing Well Cements (API, 2013).

Provis, J. L. & Bernal, S. A. Geopolymers and related alkali-activated materials. Annu Rev. Mater. 44, 299–327, p. 315. (2014). https://doi.org/10.1146/annurev-matsci-070813-113515

Acknowledgements

The authors would like to acknowledge the College of Petroleum Engineering & Geosciences (CPG) at KFUPM for providing the support to conduct this research.

Author information

Authors and Affiliations

Contributions

S.E. Supervised and reviewed the written manuscript. I. K. R conducted the experimental work and wrote the first draft of the paper. A. A designed the methodology, wrote and revised the manuscript, validation and formal analysis. A. M. A investigation and visualization.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Rahmatullah, I.K., Ahmed, A., Elkatatny, S. et al. Utilizing Saudi volcanic scoria in lightweight geopolymer for enhanced wellbore cementing. Sci Rep 15, 20965 (2025). https://doi.org/10.1038/s41598-025-06865-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-06865-2