Abstract

Rolling bearings play a significant role in rotating machinery. Due to the failure of these components, the operations of the whole machinery are compromised and get out of service, which ultimately causes significant workload overhead and monetary loss. Many techniques are proposed for the diagnosis of faults in the rolling bearing; these techniques are manual and require a large amount of time for identification and correction of faults, which is not suitable for routine maintenance and operability of this rotating machinery. Therefore, there is a need for promising techniques for autonomous and reliable fault diagnosis in rolling bearings. Furthermore, the proposed deep learning model for fault diagnosis is not able to provide efficient and reliable results and is vulnerable to degradation problems and lack of multi-scale feature extraction. This proposed model faces the issue of the degradation problem due to the disappearance of the gradient, which ultimately compromises the optimization process. To solve these issues above, the authors proposed a novel three-dimensional (3D) Kronecker convolution feature pyramid (KCFP), which efficiently inputs the acquired data without converting time-frequency domain and pixel loss. In our model, the single dilation rate is replaced by 3D Kronecker convolution, and 3D Feature Selection (3DFSC) is used for the local learning of features. The proposed research enhances feature representation and classification accuracy while mitigating model degradation. Authors evaluate the model on the Paderborn University and MFPT bearing datasets. KCFP achieves round (99.6%) classification accuracy, outperforming the MFF-DRN (98.6%) and standard CNN (97.5%) models for the Paderborn University dataset. KCFP achieves round (97.6%) classification accuracy, outperforming the MFF-DRN (97.0%) and standard CNN (95.7%) models for the MFPT dataset. These results demonstrate the potential of KCFP for reliable and efficient rolling bearing fault diagnosis in industrial applications.

Similar content being viewed by others

Introduction

Due to the digitalization in almost every field of life, it is very significant to ensure the effectiveness and reliability of the mechanical engineering setup across each industry1. The rolling bearings are one of the important components of the mechanical industry; it is very crucial to ensure the efficiency of rolling bearings for the integrity of operations as these components operate under very severe and harsh conditions such as high temperature, continuous usage, high pressure, etc. Due to these harsh conditions, the rolling bearings are vulnerable to different faults such as corrosion, cracks, and inconsistency2. If these issues of rolling bearings are not addressed in a timely manner, then machinery can fail and even cause disastrous accidents. It is the reason that the timely and efficient diagnosis of faults in rolling bearings ensures the integrity of mechanical systems while simultaneously minimizing economic losses3. The traditional methods for fault diagnosis of rolling bearings were dependent on the manual interpretation of waveform signals4. These methods are not only time-consuming but also vulnerable to human errors, which can ultimately lead to the failure in the early identification of rolling bearing faults. Many techniques are proposed for the extraction of multi-dimensional features while utilizing the capabilities of signal processing techniques5. These techniques use the time domain and frequency domain for multi-scale feature extraction. In these traditional techniques, different time-domain statistical features are used for detecting the health of rolling bearings6,7. These traditional techniques are majorly dependent on the experiences and knowledge of domain experts, which is not suitable for complex and large-scale implementation8,9. To solve these issues mentioned above, different techniques are proposed for the extraction of multi-dimensional features while utilizing the capabilities of machine learning and deep learning techniques10,11,12,13.

Due to the advancement of computer technologies, Artificial Intelligence (AI), and deep learning algorithms, the techniques for detecting faults in rolling bearings have gained significant attention14. The AI autonomously captures the most significant features from data without the involvement of domain experts. Furthermore, deep learning models such as Convolutional Neural Networks (CNNs) are showing reliable and efficient results in the diagnosis of diseases such as brain tumor segmentation and breast cancer detection while utilizing medical images15. Similarly, many studies have been conducted by authors to detect faults in rolling bearings and take proactive measures in the mechanical industry to minimize monetary loss. Hakim et al. propose deep learning based on fault diagnosis of rolling bearing while utilizing the capabilities of convolutional neural networks16. Similarly, the frequency spectrum images are used by Li et al. for fault diagnosis while utilizing the capabilities of deep learning networks. Furthermore, the effects of fault diagnosis on the mechanical instruments are minimized while utilizing the capabilities of residual networks and GoogLeNet17. The 1D-vision transformer is used by Xu et al. for the early fault diagnosis of rolling bearings. One-dimensional data is used as input for end-to-end fault diagnosis of fault bearing while simultaneously optimizing the performance of the model by encoder ablation experiments18. Lastly, a machine learning model is proposed by González et al. for the analysis of vibration signals using the CWRU dataset to identify the failure of rolling bearings19. Furthermore, a program is used to achieve an high accuracy by incorporating optimal bandwidth. It is very important to identify the faults in the rolling bearing to improve the efficiency of the system and mitigate the chances of accidents due to mechanical faults. The authors in16 state that existing schemes for the detection of faults in rolling bearings are manual and not able to identify the faults efficiently. This can cause motor failure and result in undesired accidental outcomes. To solve these abovementioned issues, Hakim et al. propose deep learning based on fault diagnosis of rolling bearing while utilizing the capabilities of convolutional neural networks. The proposed model can efficiently identify the faults with a very small computational overhead due to the involvement of several layers of imitations. The authors consider the parameters of fault mode and frequency to evaluate the performance of the proposed model. In the future, the authors plan to integrate the capabilities of transfer learning to reduce the consumption of time and complex operations of deep learning techniques. Similarly, the authors in17 state that deep learning methods are used in fault diagnosis in almost every field of life, like breast cancer detection, brain tumor segmentation, and image deraining. However, its properties and efficiencies in the field of bearing fault diagnosis with the images of frequency spectra have not been explored yet. Therefore, the authors propose a model in which the frequency spectrum images are used for fault diagnosis while utilizing the capabilities of deep learning networks. Furthermore, residual networks and GoogLeNet are used to examine the effects of fault diagnosis on the mechanical instruments. The performance of the proposed model is evaluated by performing a fair comparison between the deep learning techniques using conventional frequency spectrum and discrete random separation. Furthermore, the proposed model is also evaluated while considering the parameters of diagnosis accuracy, amplitude, frequency, and segment length. In the future, the proposed deep learning-based model will be improved with high accuracy while utilizing the capabilities of transfer learning.

Among different deep learning and AI techniques for rolling bearing fault detection, CNN is capable of capturing the most significant features due to its standard convolution and pooling structure. Wu et al. propose a CNN-based residual for detecting the faults of rolling bearings by utilizing the capabilities of feature fusion. The raw signals are used for the extraction of multi-scale features with the feature fusion block20. However, the proposed deep learning model for fault diagnosis is not able to provide efficient and reliable results and is vulnerable to degradation problems and lack of multi-scale feature extraction. This proposed model faces the issue of degradation problem due to the disappearance of gradient, which ultimately compromises the optimization process. Furthermore, the model requires a large number of training cycles and has a slow convergence rate, which ultimately increases the computational overhead of the model. To solve these issues mentioned above, the author proposed a CNN-based Kronecker Convolutional Feature Pyramid (KCFP) network for fault diagnosis in rolling bearings using the Paderborn University dataset and Dataset from the Society for Machinery Failure Prevention Technology (MFPT dataset). The feature extraction capabilities of the model are enhanced, and the degradation problem is solved using multi-scale feature fusion and residual learning techniques. Furthermore, our proposed KCFP model enhances the accuracy of the rolling bearings fault diagnosis process by solving the issues of model degradation and limited diversity of features, which is very important for robust and reliable industrial processes. The main contributions of this paper are given below.

-

An end-to-end fault diagnosis process is proposed by utilizing the capabilities of the CNN-based KCFP model with residual learning for efficiently extracting the most significant features from 1-D raw signals.

-

A feature fusion block for multi-scale feature fusion is proposed for automatically extracting and fusing features of rolling bearings. This feature fusion not only helps in the extraction of diverse and inconsistent features but also enhances the diagnostic accuracy of faults of rolling bearings.

-

A multi-scale pooling layer is used for enhancing the receptive field of the KCFP network, which ultimately ensures the fusion of multi-scale features while simultaneously enhancing the ability of the model to extract the most relevant and significant features across different scales.

The remainder of this paper is organized as follows: section “Related work” presents the related work. Section “Methodology” describes the proposed system model for the diagnosis of faults in rolling bearings and the proposed KCFP network architecture. Section “Results and discussion” presents the experimental setup and evaluation metrics. Section “Conclusion” provides the conclusion and future work of our paper.

Related work

The authors in18 state that when components of roll bearing fail in the mechanical instrument, then it can result in the loss of huge monetary resources and an undesired accidental situation. To efficiently identify the symptoms of failure in large machinery, the authors propose a method in which a 1D-vision transformer is used for the early fault diagnosis of rolling bearings. One-dimensional data is used as input for end-to-end fault diagnosis of fault-bearing. Encoder ablation experiments optimize the performance of the model. The performance of the proposed model is evaluated while considering the parameters of learning rate, average accuracy, training set accuracy, storage occupancy, and noise resistance rate. In the future, the authors plan to extend the proposed 1D-vision transformer on the industrial level to efficiently identify the end-to-end fault diagnosis of rolling bearings. The authors in19 highlighted the same issue that there are the highest chances of rotating machine disasters due to the failure of bearings. Many techniques are proposed in Industry 4.0 for the prediction of deterioration using vibration signals. However, these techniques are not able to efficiently identify predictive maintenance, which can result in undesired outcomes and wastage of resources. To solve these issues mentioned above, the authors propose a machine learning model for the analysis of vibration signals using the CWRU dataset, which ultimately helps in the identification of bearing failures. Furthermore, a program is used to achieve an accuracy of more than 99% by incorporating optimal bandwidth. The proposed model is evaluated while considering the parameters of acceleration, amplitude, window length, and accuracy. In the future, the authors will implement the proposed model on the dataset of Internet of Things (IoT) devices to do real-time prediction for fault diagnosis of bearings. Furthermore, all defects will be detected with more precision and accuracy with the help of different machine learning and deep learning methods. Similarly, the authors in20 state that many deep learning-based techniques have been proposed for the diagnosis of rolling bearing failure. However, these techniques are vulnerable to the degradation problem of the model due to the deepening of the layers of these models. Furthermore, the model has very limited diversity because the features are ignored in these models. To solve the above-mentioned limitations, the authors propose a residual network by utilizing the capabilities of feature fusion to detect the faults of rolling bearings. The raw signals are used for the extraction of multiscale features with the feature fusion block. The authors consider two parameters and evaluate the performance of the proposed model in terms of diagnosis accuracy, mean accuracy, minimum accuracy, average training time, average testing time, and mean frequency. In the future, the proposed model will be extended to remove noise and improve the accuracy of fault detection. The authors in21 state that existing deep learning models like convolutional neural networks for the diagnosis of rolling bearings are not efficient and require large computational overheads. To solve these issues above, the authors propose a convolution network with the integration of a transformer to identify the faults of the rolling bearing while utilizing minimum resources. The bias capacity is integrated with the global information presented by the transformer, which results in the effective extraction of features from the time-frequency representations. The convolutional module and transformer are used for the extraction of local features and global information, respectively. The experimental results show that the proposed mechanism outperforms all the existing benchmark schemes in terms of diagnostic accuracy, prediction of labels, training time, and average loss. In the future, the proposed model will be implemented on diverse and unbalanced datasets. Furthermore, the performance of the proposed model will be evaluated on multi-channel input signals, and optimization of the fault diagnosis process will be enacted. The authors in22 and23 highlight the issues that existing deep learning models for fault diagnosis are not able to perform efficiently with a small amount of data. Therefore, the authors in22 propose a model in which cross-conditional diagnosis of fault diagnosis is performed. Firstly, the preprocessing of vibration signals is performed while utilizing the capabilities of the feature extraction mechanism for the extraction of faulty features. Furthermore, sufficient samples are collected for the training of data while utilizing the capabilities of a deep residual network. The performance of the proposed model is explored in terms of the generalization and adaptability of the pre-trained model. Furthermore, the authors consider the factors of accuracy, test loss, and prediction of labels for evaluating the proposed model. In the future, the authors will implement their proposed model with the data of Industry 4.0 to enhance the generalization of the proposed model. Similarly, the authors in23 propose a mechanism of up-supervised domain adaptation using vibration signals of rolling bearings. Furthermore, the auto-encoder is integrated with a one-dimensional layer of a convolutional network for efficient extraction of depth features. Another mechanism is also proposed for the adaptation of features from the target and source domains. The experimental results show the effectiveness of the proposed model in terms of amplitude, reconstructed signal, variation of features, and mean accuracy. The proposed model is efficient in the diagnosis of faults in rolling bearings. However, there is still a need to enhance the performance of the proposed model by adapting it to different devices with different quality standards. Therefore, the proposed model will be extended to increase the generalization and robustness of the model across different devices. The authors in24 state that deep learning mechanisms for fault diagnosis of rolling bearings are not able to completely remove noise from the data, which ultimately results in the inefficient and unreliable determination of optimal value. Due to this, the overall performances of the deep learning models are compromised. To solve this issue of high noise, the authors use an optimization algorithm named the Sparrow Search Algorithm to remove the noise from fault signals efficiently. Furthermore, a reverse strategy is used to find the location of the initial population, which ultimately enhances the process of global research. Besides this, the Gauss-Cauchy mechanism is introduced in the proposed model to enhance the diversity of the population. Lastly, the hyperparameters are tuned with the help of an optimization algorithm to improve the accuracy of the fault diagnosis process. The experimental results show that the proposed model can outperform all existing rolling bearing fault diagnosis techniques in terms of Gaussian and Cauchy distributions, diagnosis accuracy, optimization curve, and loss value. In the future, the authors plan to enhance the performance of the optimization algorithm by exploring it for different applications and devices with a large sample of images. Studies such as26,27,28, and40 highlight the importance of combining advanced signal processing and optimization techniques for robust fault diagnosis. In our study, the model eliminates the need for manual signal processing and explicitly addresses the degradation using deep learning. Similarly, the authors in25 highlight the issue that existing mechanisms for fault diagnosis of rolling bearings can cause machinery breakdown because these mechanisms are not reliable and efficient. The reason is that they rely on conventional signal processing and feature extraction techniques, which increase the complexity and computational overhead of the system. To solve these issues, the authors propose a mechanism in which 2D images are made from raw signals while utilizing the capabilities of the continuous wavelet transform. This method enhances the feature extraction process and allows users to analyze and interpret raw data further. The authors evaluate the performance of the proposed model in terms of diagnosis accuracy, entropy, precision, recall, and F1 score. In the future, the author will integrate different optimization techniques with the proposed model to enhance the generalization and effectiveness of the diagnosis process.

Methodology

In this section, the author discussed the performance evaluation of the KCFP model, along with the training of datasets and post-processing techniques, is also presented.

Dataset and preprocessing

In this article, authors used two datasets: the Paderborn University bearing dataset30 and the dataset from the Society for Machinery Failure Prevention Technology (MFPT dataset31). There are 32 different bearing conditions in the Paderborn University Bearing Dataset, and different fault and operating conditions are present. The vibration signals indicate three types of faults: inner race, outer race, and rolling element faults. The dataset is recorded under different circumstances, like different speeds and load conditions, which ultimately provide diverse signals that are helpful for rich and reliable analysis. On the other hand, the MFPT dataset is also widely used for fault diagnosis in rolling bearings.

This dataset provides the signals with and without faults and is recorded under diverse conditions. The main property of the MFPT dataset is that it has data with time domain and frequency domain properties. There are three types of faults in the MFPT dataset: inner race, outer race, and ball defects. All these faults are recorded under different loading and speed conditions. First of all, the pre-processing of signals of both datasets is performed to diagnose the fault of the rolling bearing. Standardization ensures consistency of analysis. The Z-score normalization technique is used to minimize the variations in the signals, according to Eq. (1).

Where Z-score is presented by Z, \(\mu\) represents the mean intensity of signals, \(\alpha\) denotes the deviation in the signals, and the value of the signal is shown in X. After performing the pre-processing by using Z-score normalization and partitioning (ratio was approximately 70% training, and 30% testing, depending on the total number of available fault cases) after loading all the signals of both the datasets. The model begins to train while utilizing the capabilities of both datasets, which ultimately helps in enhancing the diagnostic accuracy of the fault detection process. Furthermore, the augmentation of data is performed by a random augmentation process to enhance the generalization capabilities of our proposed KCFP model. The diverse patterns of faults are identified and captured by the random augmentation process, which ultimately helps in improving the accuracy of the proposed model. The augmented data of signals is used to perform reliable and rigorous training for the proposed KCFP model.

Result and discussion

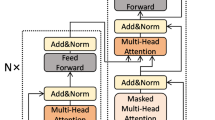

In this paper, the authors used a 3D Kronecker Convolutional Feature Pyramid (KCFP) for fault diagnosis in rolling bearings in an autonomous way. There are three parts of the model, which are 3DFSC for reliable feature selection, feature pyramid for multi-scale feature learning, and 3D component analysis for post-processing with the help of a global threshold, as shown in Fig. 1, as given in Eq. (2).

where, \({\textbf{F}}_{\text {selected}}^{(l)}\) is used to represent the selected features at layer \(l\), the three-Dimensional Feature Selection Component is given by \(\text {3DFSC}\).\({\textbf{X}}\) is the input signal. \(r_1\) and \(r_2\) show the inter-dilation factor, controlling the dilation rates and Intra-sharing factor, respectively. In our proposed model, all the signals that contain significant and essential information are captured for efficient and effective fault diagnosis. The inter-dilation factor r1 controls the dilation rates. At the same time, the size of sub-regions is regulated, and feature vectors are captured by the intra-sharing factor r2, as given in Eqs. (3) and (4).

All the intra-sharing factors are averaged by Kronecker convolution for capturing the significant and partial information that is being missed by Atrous convolution, as shown in Algorithm 1. In our proposed model, the Kronecker convolution functioned at r1 = 5 and r2 = 2, while the Atrous convolution functioned at r1 = 5. Furthermore, the author used the integration of the 3DFSC network associated and a feature pyramid for the generation of multi-scale features, which are ultimately helpful for the fault diagnosis in the rolling bearing, as given in Eq. (5).

The 3DFSC network learns the non-destructive and dense features from the signals. Faults of various magnitudes are handled by utilizing the capabilities of multi-scale features fused by the pyramid. In our proposed model, the problem of gradient vanishing is solved by skip connections, which are responsible for preserving the local features. In this way, it is ensured that there is a proper gradient flow in the network. Besides this, the local features supply the significant and most relevant contextual information, which is used for the determination of boundaries having various faults in the rolling bearings. The context around the regions of faults provides valuable information that is used in the discrimination process of all three fault types and healthy states of rolling bearing. After that, all the valuable features of the fault boundaries are learned after the integration of each feature map, which ultimately helps in enhancing the capabilities of the model for the correct identification of different properties of faults. The proposed KCFP model can propagate significant and complex information efficiently without losing any essential information. Furthermore, our model can diagnose faults while simultaneously ensuring that there is no loss of information without any increase in several parameters. Besides this, the author used a single and efficient model for capturing the relevant and significant information from many signal views, which is ultimately helpful in increasing the accuracy of the fault diagnosis process. The kernel size in our proposed model is adequate for addressing the faults with different magnitudes and sizes of the fault regions. Our proposed model also provides the feature maps for the creation of 3D structure, which is helpful in multi-scale feature learning, as shown in Fig. 1. There is a block at the end of the 3DFSC network, and KCFP is responsible for fusing the local and global features using the pyramid structure. Furthermore, authors used different dilation rates with each pyramid for the generation of three different receptive fields, which is ultimately helpful in capturing the multi-scale faults. The minor faults are diagnosed by the small receptive field of the pyramid, while medium and large receptive fields are responsible for moderate and major faults, respectively. There is a classification layer at the last in the proposed model, which is responsible for the classification of different fault types; this layer uses multi-scale logistic regression in which the probability distribution is used within the range [0, 1], as shown in Algorithm 2.

Furthermore, up-sampling is used to concatenate feature maps at different stages of the pyramid to maintain consistency in the dimensions across branches. Our proposed model also utilized the up-sampling 3D block to scale up the size of different feature maps. Lastly, the author used group normalization for all layers of networks to enhance the performance of our proposed KCFP model.

where \(S\) is the spectrogram input and \(W_{\text {3D}}\) are the 3D convolution weights.

where \(W_{\text {2D}}\) are the 2D convolution weights. For each KCFP block with parameters \(R1\) and \(R2\):

where \(F\) is the input of KCFP. Attention layer output must be written as:

where Attention could be self-attention or channel attention. Entropy Feature map:

where \(p_i\) is the probability of the \(i\)-th feature value in the feature map. Dense connections between KCFP blocks are:

Weight each feature map based on entropy:

Weighted fusion:

Classification layer based on fused features:

Results and discussion

In this section, the authors evaluated the performance of our proposed KCFP model in terms of generalization and effectiveness for fault diagnosis in the rolling bearing. The author utilized two different datasets for performing the experimental analysis: the Paderborn University bearing dataset and the dataset from the Society for Machinery Failure Prevention Technology (MFPT dataset). The authors considered the accuracy for evaluating the performance of our proposed KCFP model for fault diagnosis of rolling bearings. The equation for calculating the accuracy is given below29.

Where a represents the number of correctly identified faults in the rolling bearing, and A shows the total number of test samples. The diagnostic accuracy of our proposed KCFP model and two benchmark schemes, CNN and MFF-DRN, are shown in Figs. 2 and 3 over ten different experiments. It can be observed from the figures that our proposed KCFP model outperforms both benchmark schemes in terms of accuracy. The diagnostic accuracy of the KCFP model is around 99%, and the performance of KCFP is stable across all the experiments. The KCFP model, while slightly more computationally intensive during training due to its 3D architecture and multi-scale processing, achieves competitive inference times, making it suitable for deployment in near-real-time monitoring systems. This capability of KCFP makes it suitable for fault diagnostics in rolling bearings because our proposed KCFP model is capable of capturing and processing the critical and significant features in an effective way for the diagnosis of faults in rolling bearings. The reason is that our proposed model can enhance the receptive field while utilizing the capabilities of Kronecker convolution. Furthermore, the feature pyramid is used to integrate multi-scale features, which ultimately enhances the diagnostic capabilities of our proposed KCFP model.

Furthermore, the performance of MFF-DRN is also efficient and reliable, and it shows an accuracy of around 98% in all the experiments. The performance of the benchmark MFF-DRN scheme is very good; however, it fails to meet the performance of the KCFP model at some points.

The reason is that this model uses deep residual networks and feature extraction with multi-frequency, which are not able to capture minor details along with significant features of the rolling bearing machine. Furthermore, the MFF-DRN model is not able to efficiently integrate low-level and high-level features as compared to our proposed KCFP model. Lastly, Figs. 2 and 3 show that the performance of the CNN model in the diagnosis of rolling bearings is the lowest among all three schemes throughout all ten experiments. The accuracy of CNN in the first five experiments is around 88%, and for the next five experiments, the accuracy is around 94%–96%. The CNN model is very suitable for different applications like brain tumor segmentation, breast cancer detection, etc.; however, it is not suitable for complex fault diagnosis of rolling bearings. The reason is that CNN has very few capabilities to capture multi-scale features compared to other schemes like KCFP and MFF-DRN.

The following training and model parameters were used throughout the experiments for both the Paderborn and MFPT datasets. The model was trained using the Adam optimizer with a learning rate of \(1 \times 10^{-4}\). A total of 100 epochs were executed, with early stopping applied. A dropout rate of 0.3 was applied after dense layers to enhance generalization. ReLU activation was used for all convolutional layers, while the Softmax activation function was employed at the output layer for multi-class classification. The convolutional layers utilized a kernel size of \(3 \times 3 \times 3\), and max pooling was adopted for downsampling. Skip connections were incorporated to preserve gradients and improve the training of deeper layers. Group normalization was applied after each 3D convolutional block to stabilize learning. All experiments were conducted on a system with an Intel Core M-5Y10c @ 1.80GHz CPU and 8GB of RAM. Summary of training and model hyperparameters are shown in Table 1.

There are three types of conditions in both datasets for rolling bearing diagnosis: healthy rolling bearing, bearing faulting with the inner race, and bearing faulting with the outer race. The author conducted different experiments to evaluate the performance of our proposed KCFP with different rotation speeds, load torques, and forces applied to the rolling bearing. In our proposed model, all the signals are divided into smaller chunks of equal size of 5120 and passed as input signals. After this, the normalization is performed to normalize the raw signals.

The diagnostic accuracy of our proposed KCFP model and two benchmark schemes, CNN and MFF-DRN, is shown in Figs. 2 and 3 over ten different experiments. It can be observed from the figures that our proposed KCFP model outperforms both benchmark schemes in terms of accuracy. The diagnostic accuracy of the KCFP model is 99.8%, and the performance of KCFP is stable across all the experiments. This capability of KCFP makes it suitable for fault diagnostics in rolling bearings because our proposed KCFP model is capable of capturing and processing the critical and significant features in an effective way for the diagnosis of faults in rolling bearings. The reason is that our proposed model can enhance the receptive field while utilizing the capabilities of Kronecker convolution. Furthermore, the feature pyramid is used to integrate multi-scale features, which ultimately enhances the diagnostic capabilities of our proposed KCFP model.

Furthermore, the performance of MFF-DRN is also efficient and reliable and it shows the accuracy of around 98% in all the experiments. The performance of the benchmark MFF-DRN scheme is very good; however, it fails to meet the performance of the KCFP model at some points.

The reason is that this model uses deep residual networks and feature extraction with multi-frequency, which are not able to capture minor details along with significant features of the rolling bearing machine. Furthermore, the MFF-DRN model is not able to efficiently integrate low-level and high-level features as compared to our proposed KCFP model. Lastly, Figs. 2 and 3 show that the performance of the CNN model in the diagnosis of rolling bearings is the lowest among all three schemes throughout all ten experiments. The accuracy of CNN in the first five experiments is around 88%, and for the next five experiments, the accuracy is around 94%–96%. The CNN model is very suitable for different applications like brain tumor segmentation, breast cancer detection, etc.; however, it is not suitable for complex fault diagnosis of rolling bearings. The reason is that CNN has very few capabilities to capture multi-scale features compared to other schemes like KCFP and MFF-DRN.

Experimental analysis with Paderborn university bearing dataset

Figure 4 shows the confusion matrix of our proposed KCFP technique and both the benchmark schemes, which are MFF-DRN and CNN. The results indicate that our proposed model outperforms both benchmark schemes in terms of accuracy for fault diagnosis in rolling bearings. The confusion matrix shows that the accuracy of the KCFP matrix is very high, as the diagonal elements show that the KCFP model is consistent in the correct classification of rolling bearing fault diagnosis as it can be seen, the accuracy of KCFP is more than 99% across different classes of rolling bearing faults. Furthermore, the MFF-DRN technique also shows high accuracy of 95%, 92%, and 93% for class 1, class 2, and class 3, respectively. This indicates that the MFF-DRN uses multi-scale frequency, which does not allow for the capture of all significant features. Besides this, CNN is a widely used deep-learning technique for the classification of digital images. This technique shows the lowest accuracy among all three techniques in the diagnosis of rolling bearing faults. The accuracy of CNN is 90%, 88%, and 85% for class 1, class 2, and class 3, respectively. The reason for this low accuracy is that the CNN model is unable to detect the closely related fault types and perform misclassification.

Figure 5 shows the training set accuracy of our proposed KCFP model, MFF-DRN, and CNN model on ten training sets of the Paderborn University bearing dataset. The results show that our proposed KCFP model outperforms both benchmark schemes in terms of accuracy as it achieves the highest accuracy in the phase of training across all datasets of the Paderborn University bearing dataset, as shown in Table 2. These results indicate that our proposed model can learn and generalize all the significant features and fault patterns in the rolling bearing datasets. Furthermore, the performance of MFF-DRN is moderate, with an accuracy of around 98%. Although it outperforms the CNN model, having an accuracy of around 97%, it is unable to beat the higher accuracy of the KCFP model.

Similarly, Fig. 6 also shows the test set accuracy of our proposed KCFP model, MFF-DRN, and CNN model on ten test sets of the Paderborn University bearing dataset. The results show that our proposed KCFP model, with an accuracy of around 98%, outperforms both benchmark schemes in terms of accuracy as it achieves the highest accuracy in the phase of testing across all datasets of the Paderborn University bearing dataset. These results indicate that our proposed model can correctly identify and predict all the significant features and fault patterns in the rolling bearing datasets. Furthermore, the performance of MFF-DRN is moderate, with an accuracy of around 98%. Although it outperforms the CNN model, having an accuracy of around 92%, it is unable to beat the higher accuracy of the KCFP model.

Experimental analysis with machinery failure prevention technology (MFPT dataset)

Figure 7 shows the training set accuracy of our proposed KCFP model, MFF-DRN, and CNN model on five training sets of the MFPT dataset. The results show that our proposed KCFP model outperforms both benchmark schemes in terms of accuracy as it achieves the highest accuracy in the phase of training across all datasets of the MFPT dataset, as shown in Table 3. The accuracy of KCFP is around 98%, and it is the highest among all three schemes. These results indicate that our proposed model can learn and generalize all the significant features and fault patterns in the rolling MFPT dataset. Furthermore, the performance of MFF-DRN is moderate, with an accuracy of around 97%. Although it outperforms the CNN model, having an accuracy of around 95%, it is unable to beat the higher accuracy of the KCFP model.

Similarly, Fig. 8 also shows the test set accuracy of our proposed KCFP model, MFF-DRN, and CNN model on five test sets of the MFPT dataset. The results show that our proposed KCFP model with an accuracy of 99.7% outperforms both benchmark schemes in terms of accuracy as it achieves the highest accuracy in the phase of testing across all datasets of the MFPT dataset. These results indicate that our proposed model can correctly identify and predict all the significant features and fault patterns in the rolling bearing datasets. Furthermore, the performance of MFF-DRN is moderate, with an accuracy of around 99%. Although it outperforms the CNN model, having an accuracy of around 98%, it is unable to beat the higher accuracy of the KCFP model.

Figure 9 illustrates the training and validation accuracy trends over 100 epochs for KCFP, MFF-DRN, and CNN on the Paderborn and MFPT datasets. The KCFP model consistently outperforms the other methods with faster convergence and higher peak accuracy on both datasets. MFF-DRN demonstrates moderate performance, while CNN shows comparatively slower learning and lower final accuracy. The validation curves remain below the training curves. The comparison Table 4 highlights the performance of recent state-of-the-art models applied to the Paderborn and MFPT datasets. The proposed 3D Kronecker Convolutional Feature Pyramid model outperforms previous methods, achieving the highest accuracy of 99.6% by effectively leveraging multi-scale fused features.

Conclusion

Rolling bearings play a significant role in rotating machinery. Due to the failure of these components, the operations of the whole machinery are compromised and become out of service, ultimately causing significant workload overhead and monetary loss. To address these challenges, authors proposed a novel 3D Kronecker Convolution Feature Pyramid (KCFP) model that directly processes raw vibration signals without requiring transformation into the time-frequency domain. By integrating 3D Kronecker convolutions and a 3D Feature Selection Component (3DFSC), our model improves feature learning and overcomes degradation issues typically seen in deep learning architectures. In summary, the KCFP model offers a robust and scalable solution for the autonomous diagnosis of rolling bearing faults, supporting more efficient and reliable maintenance of rotating machinery. In future work, the authors aim to design a custom cost function to address class imbalance and explore variable dilation rates to further enhance performance.

Data availibility

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding authors.

References

Huang, F. et al. A rolling bearing fault diagnosis method based on interactive generative feature space oversampling-based autoencoder under imbalanced data. Struct. Health Monit. 2024, 14759217241248208 (2024).

Senthilnathan, N. et al. Recent advancements in fault diagnosis of spherical roller bearing: a short review. J. Vibr. Eng. Technol. 12(4), 6963–6977 (2024).

Keshun, Y., Puzhou, W., & Yingkui, G. Towards efficient and interpretative rolling bearing fault diagnosis via quadratic neural network With Bi-LSTM. IEEE Internet of Things J. (2024).

Cui, L., Wang, H., Zhao, D. & Hai, X. Synchronous odd symmetric transform for rolling bearing fault diagnosis. Measurement 226, 114184 (2024).

Hou, J. et al. Rolling bearing fault diagnosis method by using feature extraction of convolutional time-frequency image. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 238(9), 4212–4228 (2024).

Pang, B., Liu, Q.i, Sun, Z., Zhenli, X. & Hao, Z.. Time-frequency supervised contrastive learning via pseudo-labeling: an unsupervised domain adaptation network for rolling bearing fault diagnosis under time-varying speeds. Adv. Eng. Inform. 59, 102304 (2024).

Wang, B., Qiu, W., Xiong, H. & Wang, W. A rolling bearing fault diagnosis technique based on recurrence quantification analysis and Bayesian optimization SVM. Appl. Soft Comput. 156, 111506 (2024).

Qin, Y., Liu, H. & Mao, Y. Faulty rolling bearing digital twin model and its application in fault diagnosis with imbalanced samples. Adv. Eng. Inform. 61, 102513 (2024).

Yang, X., Yuan, X., Dong, L., Mei, X. & Chen, K. Manifold assistant multi-modal multi-objective differential evolution algorithm and its application in actual rolling bearing fault diagnosis. Eng. Appl. Artif. Intell. 133, 108040 (2024).

Chang, B., Zhao, X., Guo, D., Zhao, S., & Fei, J. Rolling bearing fault diagnosis based on optimized VMD and SSAE. IEEE Access (2024).

Li, Z. et al. Digital twin-assisted dual transfer: a novel information-model adaptation method for rolling bearing fault diagnosis. Inf. Fusion 106, 102271 (2024).

Li, S. et al. Rolling bearing fault diagnosis under data imbalance and variable speed based on adaptive clustering weighted oversampling. Reliab. Eng. Syst. Saf. 244, 109938 (2024).

Chen, X. et al. A rolling bearing fault diagnosis method via 2D feature map of CSCoh after denoising and MSCNN under different conditions. J. Vib. Control 30(5–6), 1241–1253 (2024).

Zhang, J., Zhang, Q., Feng, W., Qin, X. & Sun, Y. A feature vector with insensitivity to the position of the outer race defect and its application in rolling bearing fault diagnosis. Struct. Health Monitor. 2024, 14759217241236884 (2024).

Xie, M., Liu, J., Li, Y., Feng, K., & Ni, Q. An ensemble domain adaptation network with high-quality pseudo labels for rolling bearing fault diagnosis. IEEE Trans. Instrum. Meas. (2024).

Hakim, M., Omran, A. A. B., Ahmed, A. N., Al-Waily, M. & Abdellatif, A. A systematic review of rolling bearing fault diagnoses based on deep learning and transfer learning: taxonomy, overview, application, open challenges, weaknesses and recommendations. Ain Shams Eng. J. 14(4), 101945 (2023).

Li, Z., Wang, H., Chen, J., Zhou, Z. & Chen, W. Research on rolling bearing fault diagnosis based on DRS frequency spectrum image and deep learning. Int. J. Acoust. Vibr. 28(2), 211–219 (2023).

Xu, P., & Zhang, L. A fault diagnosis method for rolling bearing based on 1D-ViT model. IEEE Access (2023).

Alonso-Gonzalez, M., Díaz, V. G., Perez, B. L., G-Bustelo, B. C. P., & Anzola, J. P. Bearing fault diagnosis with envelope analysis and machine learning approaches using CWRU dataset. IEEE Access (2023).

Wu, X., Shi, H. & Zhu, H. Fault diagnosis for rolling bearings based on multiscale feature fusion deep residual networks. Electronics 12(3), 768 (2023).

Liu, W. et al. A novel fault diagnosis method of rolling bearings combining convolutional neural network and transformer. Electronics 12(8), 1838 (2023).

Han, S., & Feng, Z. Deep residual joint transfer strategy for cross-condition fault diagnosis of rolling bearings. J. Dyn. Monitor. Diagn. 2023, 51–60 (2023).

Zhong, Z., Liu, H., Mao, W., Xie, X.i & Cui, Y. Rolling bearing fault diagnosis across operating conditions based on unsupervised domain adaptation. Lubricants 11(9), 383 (2023).

Ma, G., Yue, X., Zhu, J., Liu, Z. & Shibo, L. Deep learning network based on improved sparrow search algorithm optimization for rolling bearing fault diagnosis. Mathematics 11(22), 4634 (2023).

Wu, G., Ji, X., Yang, G., Jia, Y. & Cao, C. Signal-to-image: rolling bearing fault diagnosis using ResNet family deep-learning models. Processes 11(5), 1527 (2023).

Mishra, R. K. et al. An intelligent bearing fault diagnosis based on hybrid signal processing and Henry gas solubility optimization. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 236(19), 10378–10391 (2022).

Mishra, R. K. et al. A generalized method for diagnosing multi-faults in rotating machines using imbalance datasets of different sensor modalities. Eng. Appl. Artif. Intell. 132, 107973 (2024).

Rezazadeh, N. et al. A transfer learning approach for mitigating temperature effects on wind turbine blades damage diagnosis. Struct. Health Monitor. 2024, 14759217241313350 (2025).

Wu, X., Shi, H. & Zhu, H. Fault diagnosis for rolling bearings based on multiscale feature fusion deep residual networks. Electronics 12(3), 768 (2023).

Lessmeier, C., Kimotho, J.K., Zimmer, D., & Sextro, W. Condition monitoring of bearing damage in electromechanical drive systems by using motor current signals of electric motors: a benchmark data set for data-driven classification. In Proceedings of the European Conference of the Prognostics and Health Management Society*, Bilbao, Spain 17 (2016).

Magar, R., et al. FaultNet: a deep convolutional neural network for bearing fault classification. IEEE Access 9, 25189–25199 (2021).

Khorram, A., Khalooei, M. & Rezghi, M. End-to-end CNN+ LSTM deep learning approach for bearing fault diagnosis. Appl. Intell. 51(2), 736–751 (2021).

Tran, K. et al. A robust deep learning system for motor bearing fault detection: leveraging multiple learning strategies and a novel double loss function. SIViP 19(4), 1–11 (2025).

Mirzaeibonehkhater, M., Labbaf-Khaniki, M.A., & Manthouri, M. Transformer-based bearing fault detection using temporal decomposition attention mechanism. arXiv preprint arXiv:2412.11245 (2024).

Wu, C., & Zheng, S. Fault diagnosis method of rolling bearing based on MSCNN-LSTM. Comput. Mater. Continua 79, 3 (2024).

Zhao, Y. et al. Novelty detection and fault diagnosis method for bearing faults based on the hybrid deep autoencoder network. Electronics 12(13), 2826 (2023).

Liao, J.-X. et al. BearingPGA-Net: a lightweight and deployable bearing fault diagnosis network via decoupled knowledge distillation and FPGA acceleration. IEEE Trans. Instrum. Meas. 73, 1–14 (2023).

Ding, Y. et al. Toward end-to-end bearing fault diagnosis for industrial scenarios with spiking neural networks. arXiv preprint arXiv:2408.11067 (2024).

Li, W. et al. Fault diagnosis using variational autoencoder GAN and focal loss CNN under unbalanced data. Struct. Health Monit. 24(3), 1859–1872 (2025).

Funding

No funding involved in this study.

Author information

Authors and Affiliations

Contributions

Sadia Batool, Muhammad Asif, Abbas Ali Abid, Sagheer Abbas, and Asghar Ali Shah, have collected data from different resources and contributed to writing original draft preparation. Sadia Batool, Khan Muhammad Adnan and Sagheer Abbas performed formal analysis and Simulation, Muhammad Asif, Asghar Ali Shah and Taher M. Ghazal,; writing review and editing, Asghar Ali Shah, and Khan Muhammad Adnan; performed supervision, Sadia Batool, Muhammad Asif and Taher M. Ghazal; drafted pictures and tables, Sagheer Abbas, Ashar Ali Shah and Khan Muhammad Adnan; performed revisions and improve the quality of the draft. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Batool, S., Abid, A.A., Asif, M. et al. Kronecker convolutional feature pyramid for fault diagnosis in rolling bearings. Sci Rep 15, 20735 (2025). https://doi.org/10.1038/s41598-025-08339-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-08339-x