Abstract

A bacterium showing excellent flocculation performance was isolated from sludge. Through 16S rDNA sequencing, morphological observation, and enzyme characterization, the strain was found to represent a novel bacterium of the Pseudomonas sp., termed Pseudomonas sp. GXUN74702. Pseudomonas sp. GXUN74702 was isolated from the sludge of Siyuan Lake in Guangxi Minzu University. Research showed that strain GXUN74702 had good flocculation performance. After the strain was cultured in fermentation medium (pH 7.0) containing glucose as carbon and urea as nitrogen, shaking at 30 °C 180 rpm for 36 h, the flocculation rate reached 92.5% when treating kaolin suspension with 2 mL of the fermentation broth. The microbial flocculants (MBF) GXUN74702 contained 78.90% total sugars and 6.78% protein. Ion chromatography detection showed that the monosaccharide constituents of MBF-GXUN74702 were most mannose (10.55 µg/mg), glucose (5.34 µg/mg), and glucosamine hydrochloride (1.48 µg/mg). The use of MBF-GXUN74702 for treating aquaculture wastewater was then explored, demonstrating chemical oxygen demand (COD) and biochemical oxygen demand (BOD) removal rates of 52% and 20%, respectively. In summary, Pseudomonas sp. GXUN74702 is a newly identified Pseudomonas sp. strain that shows highly efficient flocculation performance in treating aquaculture wastewater, suggesting its potential value in wastewater treatment applications. The fermentation medium components of Pseudomonas sp. GXUN74702 identified in this study are simple and easy to obtain, and the fermentation conditions of the strain are mild and not harsh, so a large number of fermentation liquid with high flocculation performance can be obtained in a short time. The main component of MBF-GXUN74702 has been proved to be polysaccharides that are superior to inorganic and synthetic organic flocculants owing to their non-toxicity, biodegradability, high efficiency, free secondary pollution, and wide adaption to pH variation. At present, the team has obtained the flocculants powder of the strain under laboratory conditions. The production process of this powder is simple, the yield and flocculation rate are high, and the property is stable and easy to preserve.

Similar content being viewed by others

Introduction

Industrialization and technological progress are associated with the release of toxic waste materials into the environment, causing not only serious pollution but also significant threats to both terrestrial and aquatic habitats, and human health1,2. Flocculation represents a simple and environmentally friendly means for treating contaminated wastewater3. Flocculants promote particle coagulation and sedimentation, allowing separation of solid from liquid materials, and are frequently used for treating wastewater and activated sludge4. There are three types of flocculants, namely, synthetic organic flocculants, such as polyethylene imine and polyacrylamide by-products; inorganic flocculants, such as iron and aluminum sulfates; and biological flocculants, which include natural products5,6,7.

Both organic and inorganic flocculants are used in industrial applications as they are both efficient and cost-effective. However, their extensive use leads to the generation of significant amounts of poorly degradable waste resulting in secondary pollution8,9. Biological flocculants are mainly biopolymers secreted by bacteria, fungi, algae, and yeast into the extracellular space. They are both biodegradable and non-toxic, and are thus more friendly to the environment and human health, and can thus replace the use of other flocculants for treating wastewater10,11,12.

There are also many biological methods applied in sewage treatment. Santosh et al. found that enzymes and energy extracted from sludge could be used for industrial, agricultural, and biofuel production. Karn et al. found that using CER and Triton X-100 with 2000 U/g VSS (volatile suspended solids) could maximize the recovery of amylase from sludge, with a maximum recovery rate of 1.0%13. Canine distemper bacteria exist in soil and water, with flexible metabolism, and can effectively treat wastewater by utilizing their biological adsorption, bioaccumulation, reduction, and precipitation abilities towards various metals14. Zhao et al. discovered the sustainable production of bacterial flocculants by nylon-6,6 microplastics hydrolysate utilizing Brucella intermedia ZL-0615. Leng et al. found that the combination of fungi and microalgae had a complementary effect on pollutant removal from wastewaters16. Microbial flocculants (MBF) are metabolic products that are synthesized and secreted by microorganisms, and are able to coagulate suspended particles in liquids17. Many microorganisms are known to produce bioflocculants, including Azotobacter chloride18, Bacillus subtilis19, Bacillus thuringiensis20, and Pseudomonas aeruginosa21. However, despite their advantages of biodegradability and safety, many natural bioflocculants show relatively poor flocculation ability, low yield and high production cost22,23. Therefore, there has been significant interest in identifying novel bioflocculants that are both biodegradable and show good flocculation capabilities. Pseudomonas sp. bacteria are known to produce a variety of metabolic products with potential biotechnological applications, and thus represent an important source of bioflocculants. Balíková et al. discussed the role and performance of exopolysaccharides in Pseudomonas in remediation technologies, demonstrated the biosynthesis of exopolysaccharides and its application in heavy metal remediation or other environmental applications, such as wastewater treatment and soil remediation through bioflocculation24. Pseudomonas sp. ZC-41 a highly efficient bioflocculant-producing strain, was isolated from activated sludge to produce polysaccharide-based bioflocculant MBF-ZC, which could solve the problem of low flocculation efficiency25. Feng et al. found that bioflocculant produced by Pseudomonas sp. GO2 had the potential to be used in heavy metal treatment from industrial wastewater26.

Here, a novel Pseudomonas sp. strain capable of efficient flocculation was isolated and identified. The strain was termed Pseudomonas sp. GXUN74702 and its flocculation capabilities were investigated, assessing its effectiveness in removing chemical oxygen demand (COD) and biological oxygen demand (BOD) from contaminated aquaculture wastewater. It was found that this strain showed stable and excellent flocculation performance, thus assisting in the development of efficient bioflocculants and providing a theoretical foundation for the use of bioflocculants for treating wastewater.

Materials and methods

Strain and culture medium

Pseudomonas sp. GXUN74702 was isolated from the sludge, and had been deposited in the China General Microbiological Culture Collection Center (CGMCC No. 25238). The bacteria were grown in LB medium containing tryptone 10 g/L, yeast extract 5 g/L, and NaCl 10 g/L, pH 7.0–7.5. The fermentation medium contained glucose 10 g/L, yeast extract 0.5 g/L, urea 0.5 g/L, K2HPO4 5 g/L, KH2PO4 2 g/L, NaCl 0.1 g/L, and MgSO4 7H2O 2 g/L, pH 7.0–7.527.

Determination of flocculation activity

The kaolin suspension included kaolin clay 0.25 g, 1% CaCl2 solution 5 mL in 50 mL of distilled water. The pH of kaolin suspension was adjusted to 7.0–7.5 with NaOH, and 1.5 mL of the fermentation broth was added. After fully stirring for 2 min and standing for 5 min, the liquid at 1 cm below the liquid level was collected and OD550 was measured by a UV spectrophotometer, using untreated kaolin suspension as a control. The flocculation rate was calculated as Eq. (1).

where E represented the flocculation rate, A was the absorbance of the kaolin suspension after treatment of the sample, and B was the absorbance of the control (blank kaolin suspension)28.

Identification of strain GXUN74702

Scanning electron microscopy (SEM) was used to examine the morphology of strain GXUN74702 using SUPRA 55 Sapphire instrument (Carl Zeiss, Germany)29.

The activities of enzymes produced by strain GXUN74702 were evaluated using an API ZYM assay kit (bioMérieux, France)30.

Genomic DNA was isolated from the strain GXUN74702 and the 16S rDNA sequence was amplified using the 27F/1541R and M13F/M13R primers. The 50 µL PCR reaction volume contained 2 × Taq PCR Master Mix 25 µL, forward primer 1 µL, reverse primer 1 µL, genomic DNA 1 µL, ddH2O 22 µL. PCR products were detected by agarose gel electrophoresis, the target band was obtained, and were sent to Shanghai Sangon for sequencing. The results were compared on the Ezibiocloud website, and Mega 11 was used for the construction of the phylogenetic tree31,32,33.

Optimization of cultivation conditions

To optimize the fermentation time, strain GXUN74702 was inoculated into LB medium and grown until OD600 = 1.0. It was transferred to the fermentation medium at a 1% inoculation rate, which was fermented culture at 30 °C, 180 rpm for 96 h. The flocculation rate was assessed at 12 h intervals.

Pseudomonas is mesophile, and the optimum growth temperature is 20–40 °C. To optimization the growth temperature, strain GXUN74702 was grown in LB medium until OD600 = 1.0, which was inoculated (1% inoculation amount) into fermentation medium and cultured at different temperatures (25 °C, 30 °C, 35 °C, 37 °C, 40 °C), shaking at 180 rpm for 36 h. The flocculation rate of fermentation broth was measured.

The minimum growth pH of most bacteria is 3–5, the optimal growth pH is 6.5–7.5, and the highest growth pH is 8–10. To optimize of the initial pH, the pH of fermentation medium was adjusted with 1 moL/L NaOH or HCl respectively, ranging from 4 to 10. The strain GXUN74702 was inoculated into the medium (1% inoculation amount) and grown at 30 °C, 180 rpm for 36 h. Flocculation rate was measured in the different medium.

To optimize the carbon source, strain GXUN74702 was cultivated in fermentation medium with different forms of carbon sources, namely, glucose, maltose, sucrose, fructose, galactose, starch, straw powder, and soybean meal powder. Flocculation rate of the fermentation broth was measured in the different medium.

To optimize the nitrogen source, strain GXUN74702 was grown in fermentation medium with different forms of nitrogen sources, namely, yeast powder, casein, peptone, urea, beef extract, tryptone, and (NH4)2SO4. Flocculation rate of fermentation broth was measured in the different medium.

The suitable shaker speed range of the bacterial culture is usually between 50 and 250 rpm, and for most bacteria, the suitable shaker speed is generally 120–180 rpm. This range ensures a good mix of oxygen and nutrients, while avoiding excessive shear forces that can damage bacteria. To optimize of shaker speed, strain GXUN74702 was inoculated into LB medium and grown until OD600 = 1.0, which were transferred to the fermentation medium (1% inoculation amount). Then they were cultured in shakers with different speeds, namely, 100, 130, 150, 180 and 200 rpm, at 30 °C for 36 h. Flocculation rate of fermentation broth was then measured.

Investigation of the flocculation process

To assess the flocculation properties of MBF-GXUN74702, the influence of fermentation broth dosage, dose of coagulants (1% CaCl2), and settling time on kaolin were assessed. Different fermentation broth volumes (1, 2, 3, 4, and 5 mL) were added to 5 g/L of kaolin suspension, after which flocculation rate was assessed. Varying amounts of 1% CaCl2 (3, 4, 5, 6, 7, 8, 9, and 10 mL) are used to investigate flocculation performance. To determine the effects of time, the kaolin suspension was allowed to stand for varying lengths of time (1, 2.5, 5, 7.5, 10, and 15 min) before the measurement of flocculation rate. Flocculation rates were compared to assess the optimal flocculation conditions of MBF-GXUN74702.

Characteristics of MBF-GXUN74702

To determine the distribution of flocculants, the fermentation broth was centrifuged (8000 rpm, 10 min), and both the bacterial body and supernatants were collected respectively. Equal amounts of ddH2O were added to the bacterial body and mixed well. The kaolin suspension was treated with equal volume fermentation broth (containing bacterial cells), supernatant, and bacterial suspension, and the flocculation rate was measured34.

To identify the flocculants components, total sugar content was assessed using the Phenol sulfuric acid method, with glucose solution as the standard solution. Protein contents were examined using Bradlord assays, with bovine serum protein solution as the standard solution.

Ion chromatography (ThermoFisher, ICS5000) was used to assess the monosaccharide composition of MBF-GXUN74702, using Dionex ICS-5000 + system, Carbo PACTM PA20 (2.0 mm × 150 mm) anion exchange column as analysis column, electrochemical detector, and gradient elution method.

The MBF-GXUN74702 functional groups were assessed using Fourier-transform infrared spectroscopy (FTIR; Thermo Electron Corporation, Waltham, MA, USA) over a wavenumber range of 4000–400 cm−1.

Extraction and purification of bioflocculants

Bacterial cultures were centrifuged (8000 rpm, 10 min), the bacterial cells were removed, 2 volumes of cold ethanol were added to the supernatant, and kept overnight at 4 °C. The resultant precipitate was collected by centrifugation (8000 rpm, 15 min), yielding the crude bioflocculants, which were dissolved in distilled water in a 1:4 (V/V) ratio and freeze-dried35.

COD and BOD removal from aquaculture wastewater

The aquaculture wastewater samples were obtained from fish-farming wastewater of a laboratory in Guangxi Minzu University of China. Aquaculture wastewater comes from water that has been raised for a week. The COD and BOD values of aquaculture wastewater were determined before and following treatment with strain GXUN74702 fermentation broth. COD was determined using the dichromate procedure and BOD by dilution inoculation. Measurements were conducted by the Guangxi Nanhuan Testing Company.

Results and discussion

Isolation and identification of bacteria

Overall, 31 bacterial strains were isolated and purified from sludge in Guangxi Minzu University. Following two rounds of filtering, it was found that one of the strains, termed GXUN74702, showed efficient and stable flocculation capability, with flocculation rate of 72.3%. This strain had been stored in the China General Microbiological Culture Collection Center (CGMCC No. 25238).

16S rDNA sequence of the strain GXUN74702 was amplified, and PCR products were sent to Shanghai Sangon for full-length 16S rDNA sequencing. The sequences were available on the Ezbiocloud website (https://www.ezbiocloud.net). Through BLAST comparison, it was found that the strain resembled Pseudomonas lalkuanensis most closely, with 98.63% similarity. It was thus considered that the strain GXUN74702 belonged to Pseudomonas sp., and was termed Pseudomonas sp. GXUN74702. The 16S rDNA sequence of Pseudomonas sp. GXUN74702 had been uploaded to GenBank: PP446604. A phylogenetic tree was constructed using the neighbor connection algorithm (N-J method) for the 16S rDNA sequence of this strain (Fig. 1).

Morphological observations and biochemical identification

The colonies of Pseudomonas sp. GXUN74702 on LB medium appeared round and light yellow in color, with smooth and moist surfaces, raised centers and neat edges. Scanning electron microscope (SEM) showed that the strain was short rod-shaped. Gram staining showed that the strain was red, indicating that the strain was Gram negative (G-) bacteria (Fig. 2).

The most similar reference strain (Pseudomonas lalkuanensis PE08T) was identified in Ezbiocloud and enzymatic characteristics were compared with those reported in the literature. API ZYM assays (Table 1) showed that the enzymatic properties of Pseudomonas sp. GXUN74702 were not completely identical to the reference Pseudomonas lalkuanensis PE08T, indicating that Pseudomonas sp. GXUN74702 was not the same as Pseudomonas lalkuanensis PE08T.Thus, multiple forms of identification including molecular biology, morphological characteristics, and enzymatic properties, indicated that Pseudomonas sp. GXUN74702 was a novel bacterium belonging to Pseudomonas sp..

Optimal fermentation conditions for bioflocculants production

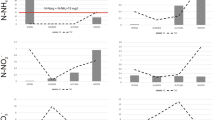

Influence of fermentation time

The growth rate of Pseudomonas sp. GXUN74702 paralleled with the flocculation activity curve. Following fermentation and cultivation, the fermentation broth was used to treat kaolin suspension. This showed that the highest flocculation rate occurred during the stable period (36 h). Prolongation of cultivation resulted in slightly reduced but essentially stable flocculation (Fig. 3A). This indicated that the optimal fermentation time for Pseudomonas sp. GXUN74702 was 36 h.

Flocculation properties of Pseudomonas sp. GXUN74702. (A) influence of fermentation time; (B) influence of fermentation temperature; (C) influence of initial pH; (D) influence of carbon source; (E) influence of nitrogen source; (F) influence of shaker speed. Data represent mean ± standard deviation from three replicates.

Influence of fermentation temperature

Temperature modulates both bacterial growth and enzyme activity36,37. The suitable temperature can promote the growth and reproduction of microorganisms, and make them synthesize and secrete flocculants in large quantities, thus improving the flocculation performance. Inappropriate temperature will inhibit the growth and metabolism of microorganisms, reduce the synthesis and secretion of flocculants, resulting in a decline in flocculation performance. Therefore, the influence of temperature on the flocculation performance of Pseudomonas sp. GXUN74702 was investigated. After fermentation at 30 °C, the flocculation capability was found to be optimal, with a flocculation rate of 82.2%. At fermentation temperatures of 25–40 °C, flocculation performance of this strain was both efficient and stable. However, at temperatures above 40 °C, the flocculation rate of the fermentation broth decreased to 63.1% (Fig. 3B). It was thus concluded that Pseudomonas sp. GXUN74702 exhibited lower coagulation activity during high-temperature fermentation, which might be due to reductions in enzyme activity and biomass.

Influence of initial pH

The initial pH of the fermentation medium is known to directly affect the bioflocculants synthesis38,39. Different microorganisms have their own suitable pH range, and inappropriate initial pH will inhibit microbial growth and flocculants production. Too high or too low pH will change the surface charge of microorganisms, affect the absorption of nutrients, and then affect the flocculation performance. Therefore, the influence of the initial fermentation pH was assessed. As shown in Fig. 3C, when the pH of the fermentation medium was raised from 4 to 7, the flocculation rate of the kaolin suspension treated with the fermentation broth of this strain increased gradually from 44.2% to 88.2%. While further increase in pH led to a gradual reduction in flocculation rate. It was thus concluded that optimal flocculation induced by Pseudomonas sp. GXUN74702 occurred in medium with neutral pH (pH 7.0 ± 0.2).

Influence of the carbon source

Carbon source is essential for microbial growth and reproduction, and is thus closely associated with bioflocculants synthesis. The addition of different carbon sources will regulate the microbial community structure, which will affect the flocculation performance.The application of agricultural waste as a source of carbon for the cultivation of bacterial strains is an effective cost-saving method40,41. Pseudomonas sp. GXUN74702 was inoculated into two common agricultural waste medium (straw powder and soybean meal powder) as carbon sources for fermentation cultivation. The fermentation broth was used to treat kaolin suspension, showing flocculation rate of 57.3% and 63.9%, respectively, indicating reasonable flocculation effects. When the strain was cultured in a medium with glucose as the carbon source, its fermentation broth showed the best flocculation performance, with a flocculation rate of up to 88.2% (Fig. 3D). Therefore, glucose represented the optimal source of carbon for the fermentation culture of Pseudomonas sp. GXUN74702.

Influence of the nitrogen source

The nitrogen source is a crucial nutrient for microbial growth, facilitating the synthesis of proteins, nucleic acids, and other biological macromolecules by microorganisms. A suitable nitrogen source promotes the proliferation of microorganisms and enhances their ability to synthesize and secrete flocculants in large quantities, thereby improving flocculation performance42,43. Therefore, the influence of various nitrogen sources on the flocculants synthesis by Pseudomonas sp. GXUN74702 was investigated. As illustrated in Fig. 3E, yeast powder, peptone, urea, and (NH4)2SO4 as nitrogen sources resulted in flocculation rate of over 80%, while the strain was grown in a culture medium with urea as the nitrogen source, the flocculation rate of the fermentation broth was as high as 90.6%. It could thus be concluded that urea represents the optimal source of nitrogen for fermentation cultivation of Pseudomonas sp. GXUN74702.

Influence of shaker speed

The degree of shaking during cultivation influences the amount of dissolved oxygen in the medium, as well as affecting nutrient uptake and enzymatic activities in the bacteria44,45. The influence of shaker speed on the flocculation performance of Pseudomonas sp. GXUN74702 was illustrated in Fig. 3F, showing that when the shaker speed was 180 rpm, the flocculation rate reached 90.4%. As the speed was raised, the flocculation activity also increased. When the shaker speed exceeded the optimal speed of 180 rpm, the flocculation activity decreased slightly.

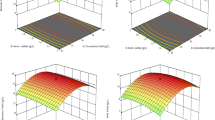

Conditions for optimal flocculation

The effect of fermentation broth dosage on flocculation

It was observed that optimal flocculation occurred at a volume of 2 mL addition amount of fermentation broth. As the addition amount increased, especially when exceeding 3 mL, the flocculation rate decreased significantly (Fig. 4A). It could thus be concluded that bioflocculants performed optimally only at specific concentrations. When the concentration of bioflocculants was too low, the likelihood of collision between particles in the system was reduced, thus affecting flocculation. In contrast, too much bioflocculants could alter colloidal charges, also reducing the flocculation efficiency.

The effect of coagulants (1% CaCl 2 ) dosage on flocculation

In the process of biological flocculation, metal ions need to be added to the kaolin suspension. Cations are useful for neutralizing negative charges on the cation-dependent bioflocculants and kaolin, thereby promoting bioflocculants adsorption to the kaolin and leading to effective flocculation46,47,48. In addition, the cation concentrations also influence flocculation. Here, 1% CaCl2 was used as coagulant aid, with the addition of varying amounts of 1% CaCl2 to the system, and observed the effect of coagulant concentration on the flocculation. The results indicated that the flocculation rate was only 24.8% when 3 mL of 1% CaCl2 solution was added to the flocculation system. As the concentration of the coagulant aid increased, the effect of flocculation became increasingly significant. 10 mL of 1% CaCl2 dosage resulted in a flocculation rate of 90.2% (Fig. 4B).

The effect of settling time on flocculation

Microbial flocculants can promote the interaction, aggregation, and sedimentation of particles. If the settling time is too short, sedimentation is insufficient, while prolonged settling times will increase both the time and economic costs. It was found that standing for 5 min resulted in a flocculation rate of 92.5%, and standing for longer times did not alter the flocculation rate significantly (Fig. 4C).

Characterization of the bioflocculants

Distribution of MBF-GXUN74702

It was found that the fermentation broth of Pseudomonas sp. GXUN74702 was effective for flocculating the kaolin suspension. To improve the yield and flocculation activity of the flocculants, the distribution of MBF-GXUN74702 was investigated. As shown in Fig. 5, the flocculation rate of the bacterial suspension of Pseudomonas sp. GXUN74702 in treating kaolin suspension was only 47.7%, while the flocculation rates of the supernatant and fermentation broth were 90.9% and 91.8%, respectively. These findings indicated that the flocculants secreted by Pseudomonas sp. GXUN74702 were found mainly in the fermentation supernatant. Thus, it could be concluded that Pseudomonas sp. GXUN74702 synthesized and secreted flocculants into the extracellular space during the growth. These flocculants could be isolated by precipitation of the supernatant with ethanol.

Extraction and purification of MBF-GXUN74702

Under the optimal fermentation conditions, 1 L of culture of Pseudomonas sp. GXUN747402 was fermented for 36 h. Ethanol precipitation of the supernatant fraction yielded 8.4 g/L of bioflocculants. After freeze-drying, 2.3 g/L of flocculants product was obtained. Thus, Pseudomonas sp. GXUN74702 produced flocculants with high yields and showed good potential for large-scale industrial production.

Chemical composition of MBF-GXUN74702

This study conducted chemical analysis on the composition of MBF-GXUN74702 and determined its total sugar, monosaccharide, and protein composition. As shown by Phenol sulfuric acid, MBF-GXUN74702 was composed of 78.90% total sugars, and Bradford analysis indicated the presence of 6.78% protein. Ion chromatography analysis indicated that the monosaccharide constituents mostly consisted of mannose (10.55 µg/mg), glucose (5.34 µg/mg), and glucosamine hydrochloride (1.48 µg/mg) (Table 2). These findings indicated that the active components of MBF-GXUN74702 were mainly carbohydrates, and the high sugar levels verified earlier findings that the bioflocculants were thermally stable. Bioflocculants with protein as the main component are sensitive to temperature and are prone to denaturation at high temperatures.

Infrared spectrophotometry (FTIR)

The FTIR results were provided in Fig. 6. Characteristic absorption peaks were observed at 3254, 2363, 1653, and 1081 cm−1, indicating the presence of polysaccharide characteristic groups in the molecule. The absorption peak at 3254 cm−1 was a broad, and was attributed to stretching vibrations of -OH moieties in the sugar ring. The small absorption peak at 2363 cm−1 resulted from C–H stretching vibration, while the absorption peak at 1653 cm−1 indicated C=O asymmetric stretching vibration in –COO–, and the 1081 cm−1 was characteristic absorption peak of C–O of the ether in the polysaccharide ring. These absorption peaks were a typical feature of carbohydrate derivatives49,50, and confirmed that the major components of MBF-GXUN74702 were polysaccharide substances. By infrared spectroscopy analysis and qualitative identification, the MBF-GXUN74702 had the characteristic peak of polysaccharide, which was helpful to further explain the composition of the flocculants. General infrared spectrum refers to the infrared region of the spectrum of 4000–400 cm−1, the spectral region can study the fundamental frequency of the molecular vibration transition of organic compounds, and can obtain molecular structural information, because the characteristic group frequency represents the existence of various functional groups in the molecule, in order to understand the structural characteristics of the entire molecule. The absorption peaks of various polysaccharide functional groups in the infrared spectrum of MBF-GXUN74702 further confirm that the main component of the flocculants is polysaccharide, but the structure and molecular weight of polysaccharide need to be further studied51.

The main component of MBF-GXUN74702 had been proved to be polysaccharide that were superior to inorganic and synthetic organic flocculants owing to their non-toxicity, biodegradability, high efficiency, free secondary pollution, and wide adaption to pH variation52. So MBF-GXUN74702 has a good application prospect in wastewater treatment. MBF-GXUN74702 contained abundant groups (–OH, C–H, C=O, –COO–, C–O) contributing to flocculation, which adsorption and bridging might be considered as the main flocculation mechanism53,54. A novel polysaccharides-based bioflocculants produced by Bacillus subtilis ZHX3 had been used in the treatment of multiple pollutants, and the yield was 3.14 g/L53, which was higher than the flocculants MBF-GXUN74702 yield of 2.3 g/L. In the next step, we will sequence the whole genome of Pseudomonas sp. GXUN747402, find the genes related to polysaccharide synthesis, and use gene engineering to build a strain with high yield of flocculants to improve the yield of flocculants.

Application of MBF-GXUN74702 in aquaculture wastewater

The treatment efficacy of aquaculture wastewater is typically assessed by reductions in the COD and BOD values. High COD and BOD levels in wastewater are not conducive to the growth and reproduction of aquatic organisms, and lead to a foul odor and anaerobic environment, leading to the death of aquatic organisms55. In this study, bioflocculants were used to remove COD and BOD from aquaculture wastewater, showing that MBF-GXUN74702 removed 52% and 20% of COD and BOD, respectively (Table 3).

According to the national sewage discharge standard of China (GB8978-1996), the primary, secondary, and tertiary COD standards are 100, 150, and 500 mg/mL, respectively, while the standards for BOD are 30, 60, and 300 mg/mL, respectively. The results indicated that treatment of aquaculture wastewater with the fermentation broth of Pseudomonas sp. GXUN74702 reached the national discharge level 3 standard for COD and the national discharge level 1 standard for BOD. This indicated that MBF-GXUN74702 had potential application value in the treatment of aquaculture wastewater.

A bioflocculant (MBFA18) was produced by Aspergillus niger (A18) using potato starch wastewater (PSW) as nutrients. During the PSW treatment, 2 mL/L bioflocculant (1.89 g/L) dosage and 0.5 mol/L coagulant aid addition were applied without pH adjustment and 91.15% COD and 60.22% turbidity removal rate could be achieved within 20 min56. A novel bioflocculant ZS-7 produced by Bacillus licheniformis X14 showed good flocculating performance and industrial potential for treatment of low temperature drinking water, and the maximum removal efficiencies of COD (Mn) and turbidity were 61.2% and 95.6%, respectively22. In order to improve the flocculation rate and COD removal rate of MBF-GXUN74702, we must continue to optimize the culture conditions of Pseudomonas sp. GXUN74702 and the flocculation conditions of industrial wastewater treatment, or develop composite flocculants of Pseudomonas sp. GXUN74702 and other flocculating strains.

Conclusions

A novel bacterium strain Pseudomonas sp. GXUN74702 was isolated from the Siyuan Lake in Guangxi Minzu University, and was able to secrete bioflocculants. The fermentation and flocculation conditions were optimized, and pure flocculants were extracted and characterized. Research found that the strain showed the best flocculation effect. The flocculation rate was found to be 92.5%, which was 20.2% higher than that before optimization. The MBF-GXUN74702 had a high yield of 2.3 g/L under optimal fermentation conditions. In addition, chemical analysis showed that the major active ingredient of MBF-GXUN74702 was a safe and non-toxic bio-polysaccharide that produced no secondary pollution. The monosaccharide components of MBF-GXUN74702 were mainly mannose and glucose. FTIR spectra showed that MBF-GXUN74702 molecules contained more polar anionic groups (–OH, COO–), indicating the presence of more active adsorption sites. After treating aquaculture wastewater, the COD and BOD removal rates were 52% and 20%, respectively.

Although microbial flocculants are promising alternatives to chemical flocculants, their high cost and low yield limit their large-scale application in industry. The study demonstrates that MBF-GXUN74702 has efficient flocculation performance and stability, and has good application prospects in wastewater treatment, providing theoretical basis and technical support for the application of microbial flocculants in wastewater treatment. The fermentation medium components of Pseudomonas sp. GXUN74702 identified in this study are simple and easy to obtain, and the fermentation conditions of the strain are mild and not harsh, so a large number of fermentation liquid with high flocculation performance can be obtained in a short time. At present, the team has obtained the flocculants powder of the strain under laboratory conditions. The production process of this powder is simple, the yield and flocculation rate are high, and the property is stable and easy to preserve. Microbial flocculants are mainly studied in the laboratory, and these research results must be scaled up to evaluate the feasibility of using microbial flocculants in large-scale industrial applications. The industrial use of microbial flocculants depends on their long-term stability, and the stability and reusability of microbial adsorbents need to be further studied.

Data availability

The datasets used during the current study available from the corresponding author on reasonable request. Full-length of 16S rRNA gene of Pseudomonas sp. is available under the accession number PP446604 in NCBI GenBank (https://www.ncbi.nlm.nih.gov/nuccore/PP446604).

References

Okaiyeto, K., Nwodo, U. U., Okoli, S. A., Mabinya, L. V. & Okoh, A. I. Implications for public health demands alternatives to inorganic and synthetic flocculants: Bioflocculants as important candidates. Microbiol. Open. 5, 177–211. https://doi.org/10.1002/mbo3.334 (2016).

Fan, W. et al. Preparation and application of composite magnetic flocculants for wastewater treatment: A review. J. Environ. Manage. 377, 124626. https://doi.org/10.1016/j.jenvman.2025.124626 (2025).

Bruno, P., Campo, M. G., Giustra, M., Marchis, M. & Bella, D. Bench scale continuous. Coagulation-flocculation of saline industrial wastewater contaminated by hydrocarbons. J. Water. Process. Eng. 34, 101156. https://doi.org/10.1016/j.jwpe.2020.101156 (2020).

Hyrycz, M., Ochowiak, M., Krupińska, A., Włodarczak, S. & Matuszak, M. A review of flocculants as an efficient method for increasing the efficiency of municipal sludge dewatering: Mechanisms, performances, influencing factors and perspectives. Sci. Total. Environ. 820, 153328. https://doi.org/10.1016/j.scitotenv.2022.153328 (2022).

Porwal, H., Mane, A. & Velhal, S. Biodegradation of dairy effluent by using microbial isolates obtained from activated sludge. Water Resources Ind. https://doi.org/10.1016/j.wri.2014.11.002 (2015).

Dai, D. et al. Performance evaluation of typical flocculants for efficient harvesting of Chlorella sorokiniana under different carbon application modes. Chemosphere 361, 142563. https://doi.org/10.1016/j.chemosphere.2024.142563 (2024).

Zeng, S., Lu, Y., Pan, X. & Ling, X. A novel bioflocculant produced by Cobetia marina MCCC1113: Optimization of fermentation conditions by response surface methodology and evaluation of flocculation performance when harvesting microalgae. Pol. J. Microbiol. 71, 341–351. https://doi.org/10.33073/pjm-2022-030 (2022).

Ngo, H. H. & Guo, W. Membrane fouling control and enhanced phosphorus removal in an aerated submerged membrane bioreactor using modified green bioflocculant. Bioresour. Technol. 100, 4289–4291. https://doi.org/10.1016/j.biortech.2009.03.057 (2009).

Tang, W. et al. Production, characterization, and flocculation mechanism of cation independent, pH tolerant, and thermally stable bioflocculant from Enterobacter sp ETH-2. PLoS ONE 9, e114591. https://doi.org/10.1371/journal.pone.0114591 (2014).

Liu, Y. et al. A bioflocculant from Corynebacterium glutamicum and its application in acid mine wastewater treatment. Front. Bioeng. Biotechnol. 11, 1136473. https://doi.org/10.3389/fbioe.2023.1136473 (2023).

Kurniawan, S. B. et al. What compound inside biocoagulants/bioflocculants is contributing the most to the coagulation and flocculation processes?. Sci. Total. Environ. 806, 150902. https://doi.org/10.1016/j.scitotenv.2021.150902 (2022).

Zhang, S. et al. Recent progress and perspectives of typical renewable bio-based flocculants: Characteristics and application in wastewater treatment. Environ. Sci. Pollut. Res. Int. 31, 46877–46897. https://doi.org/10.1007/s11356-024-34199-5 (2024).

Santosh, K. K. & Awanish, K. Protease, lipase and amylase extraction and optimization from activated sludge of pulp and paper industry. Indian. J. Exp. Biol. 57, 201–205. https://doi.org/10.1007/978-1-4614-8869-9_6 (2019).

Santosh, K. K. Application of cyanobacteria for bioremediation of wastewaters. J. Clean. Prod. 135, 819–820. https://doi.org/10.3389/fenvs.2024.1390660 (2016).

Zhao, H. et al. Sustainable production of bacterial flocculants by nylon-6,6 microplastics hydrolysate utilizing Brucella intermedia ZL-06. J. Hazard. Mater. 465, 133435. https://doi.org/10.1016/j.jhazmat.2024.133435 (2024).

Leng, L. et al. Co-culture of fungi-microalgae consortium for wastewater treatment: A review. Bioresour. Technol. 330, 125008. https://doi.org/10.1016/j.biortech.2021.125008 (2021).

David, O. A., Oluwole, O. E., Ayodele, O. E. & Lasisi, T. Characterisation of fungal bioflocculants and its application in water treatment. Curr. J. Appl. Sci. Technol. https://doi.org/10.9734/cjast/2019/v34i630159 (2019).

Yang, Z. C., Liu, S. Y., Zhang, W. B., Wen, Q. B. & Guo, Y. G. Enhancement of coal waste slurry flocculation by CTAB combined with bioflocculant produced by Azotobacter chroococcum. Sep. Purif. Technol. https://doi.org/10.1016/j.seppur.2018.10.036 (2018).

Jayaprakash, A., Revathy, S., Raj, K. V. A. & Rajesh, E. M. Production and characterization of bioflocculant produced by Bacillus subtilis OL818309 and its flocculating effect on harmful algae. Res. J. Biotechnol. 18, 72–85. https://doi.org/10.25303/1802rjbt72085 (2023).

Zhi, C. Z., Xin, P. W., Chun, Y. W., Yu, J. C. & Che, C. S. Uncovering the flocculating and dye recovery potential of pH-responsive bioflocculant produced by Bacillus thuringiensis. Environ. Prog. Sustain. 43, e14250. https://doi.org/10.1002/ep.14250 (2023).

Ma, L. Z., Wang, D., Liu, Y., Zhang, Z. & Wozniak, D. J. Regulation of biofilm. exopolysaccharide biosynthesis and degradation. Pseudomonas aeruginosa. Annu. Rev. Microbial. 76, 413–433. https://doi.org/10.1146/annurev-micro-041320-111355 (2022).

Li, Z. et al. Production of a novel bioflocculant by Bacillus licheniformis X14 and its application to low temperature drinking water treatment. Bioresour. Technol. 100, 3650–3656. https://doi.org/10.1016/j.biortech.2009.02.029 (2009).

Liu, C., Sun, D., Liu, J., Zhu, J. & Liu, W. Recent advances and perspectives in efforts to reduce the production and application cost of microbial flocculants. Bioresour Bioprocess. 8, 51. https://doi.org/10.1186/s40643-021-00405-2 (2021).

Balíková, K. et al. Role of exopolysaccharides of Pseudomonas in heavy metal removal and other remediation strategies. Polymers (Basel). 14, 4253. https://doi.org/10.3390/polym14204253 (2022).

Chen, W. et al. Production and characterization of efficient bioflocculant in high-turbidity drinking water treatment: Identification of flocculation-related genes. Chemosphere 366, 143452. https://doi.org/10.1016/j.chemosphere.2024.143452 (2024).

Feng, J. et al. Optimal production of bioflocculant from Pseudomonas sp. GO2 and its removal characteristics of heavy metals. J. Biotechnol. 344, 50–56. https://doi.org/10.1016/j.jbiotec.2021.12.012 (2022).

Sepehri, A., Sarrafzadeh, M. H. & Avateffazeli, M. Interaction between Chlorella vulgaris and nitrifyingenriched activated sludge in the treatment of wastewater with low C/N ratio. J. Clean. Prod. 247, 119164. https://doi.org/10.1016/j.jclepro.2019.119164 (2020).

Batta, N., Subudhi, S., Lal, B. & Devi, A. Isolation of a lead tolerant novel bacterial species, Achromobacter sp. TL-3: Assessment of bioflocculant activity. Indian. J. Exp. Biol. 51, 1004–1011 (2013).

Schadler, S., Burkhardt, C. & Kappler, A. Evaluation of electron microscopic sample preparation methods and imaging techniques for characterization of cell-mineral aggregates. Geomicrobiol. J. 25, 228–239. https://doi.org/10.1080/01490450802153462 (2008).

Thorat, V. et al. Pseudomonas lalkuanensis sp. nov, isolated from a bacterial consortia of contaminated soil enriched for the remediation of e-waste. Int. J. Syst. Evol. Micr. 70, 6468–6475. https://doi.org/10.1099/ijsem.0.004559 (2020).

Yoon, S. H. et al. Introducing EzBioCloud: A taxonomically united database of 16S rRNA gene sequences and whole-genome assemblies. Int. J. Syst. Evol. Micr. 67, 1613–1617. https://doi.org/10.1099/ijsem.0.001755 (2017).

Tamura, K., Stecher, G. & Kumar, S. MEGA11: Molecular evolutionary genetics analysis version 11. Mol. Biol. Evol. 38, 3022–3027. https://doi.org/10.1093/MOLBEV/MSAB120 (2021).

Zhang, W. & Sun, Z. R. Random local neighbor joining: A new method for reconstructing phylogenetic trees. Mol. Phylogenet. Evol. 47, 117–128. https://doi.org/10.1016/j.ympev.2008.01.019 (2008).

Jiang, J. P., Liu, L. H., Nie, W., Chen, Y. B. & Wang, Z. Screening of a high bioflocculant-producing bacterial strain from an intensive fish pond and comparison of the bioflocculation effects with Rhodococcus. erythropolis. Aquac. Res. 50, 1047–1056. https://doi.org/10.1111/are.13977 (2019).

Anthony, M. U., John, J. S. & Albertus, K. B. Screening for bioflocculant-producing bacteria from the marine environment of Sodwana Bay. South Africa. Annals. Sci. Technol. 3, 16–20. https://doi.org/10.2478/ast-2018-0010 (2018).

Aljuboori, A. H., Idris, A., Abdullah, N. & Mohamad, R. Production and characterization of a bioflocculant produced by Aspergillus flavus. Bioresour. Technol. 127, 489–493. https://doi.org/10.1016/j.biortech.2012.09.016 (2013).

Xia, S. Q. et al. Production and characterization of a bioflocculant by Proteus mirabilis TJ-1. Bioresour. Technol. 99, 6520–6527. https://doi.org/10.1016/j.biortech.2007.11.031 (2008).

Liu, J. W. et al. Optimized production of a novel bioflocculant M-C11 by Klebsiella sp. and its application in sludge dewatering. J. Environ. Sci. 26, 2076–2083. https://doi.org/10.1016/j.jes.2014.08.007 (2014).

Zhao, H. J. et al. Production of bioflocculants prepared from formaldehyde wastewater for the potential removal of arsenic. J. Environ. Manag. 172, 71–76. https://doi.org/10.1016/j.jenvman.2016.02.024 (2016).

Sheng, Y. L., Zhang, Q., Sheng, Y. R., Li, C. B. & Wang, H. J. Screening and flocculating properties of bioflocculant-producing microorganisms. J. Univ. Sci. Technol. Beijing 13, 289–292. https://doi.org/10.1016/S1005-8850(06)60061-3 (2006).

Deng, S. B., Bai, R. B., Hu, X. M. & Luo, Q. Characteristics of a bioflocculant produced by Bacillus mucilaginosus and its use in starch wastewater treatment. Appl. Microbiol. Biotechnol. 60, 588–593. https://doi.org/10.1007/s00253-002-1159-5 (2003).

Rasulov, B. A. et al. Production, characterization and structural modification of exopolysaccharide-based bioflocculant by Rhizobium radiobacter SZ4S7S14 and media optimization. 3 Biotech. 7, 179. https://doi.org/10.1007/s13205-017-0811-9 (2017).

Zheng, Y., Ye, Z. L., Fang, X. L., Li, Y. H. & Cai, W. M. Production and characteristics of a bioflocculant produced by Bacillus sp. F19. Bioresour. Technol. 99, 7686–7691. https://doi.org/10.1016/j.biortech (2008).

Busisiwe, M. et al. Assessment of Bacillus pumilus isolated from fresh water milieu for bioflocculant production. Appl. Sci. 6, 211. https://doi.org/10.3390/app6080211 (2016).

Tsolanku, S. M. et al. Production and characteristics of bioflocculant TPT-1 from a consortium of Bacillus pumilus JX860616 and Alcaligenes faecalis HCB2. Afr. J. Microbiol. Res. 10, 1561–1575. https://doi.org/10.5897/ajmr2016.8258 (2016).

Kunle, O., Uchechukwu, U. N., Leonard, V. M. & Okoh, A. I. Evaluation of the flocculation potential and characterization of bioflocculant produced by Micrococcus sp. Leo. Appl. Biochem. Microbiol. 50, 601–608. https://doi.org/10.1134/S000368381406012X (2014).

Hasti, D., Mohammad, R., Ahmad, R. Y., Mohammad, A. A. & Qiu, G. L. A comparative study on the toxicity of nano zero valent iron (nZVI) on aerobic granular sludge and flocculent activated sludge: Reactor performance, microbial behavior, and mechanism of toxicity. Process. Saf. Environ. 129, 238–248. https://doi.org/10.1016/j.psep.2019.07.011 (2019).

He, H. J., Wu, B. & Yang, C. P. Effects of fulvic acids and electrolytes on colloidal stability and photocatalysis of nano-TiO2 for atrazine removal. Int. J. Environ. Sci. Te. 16, 7275–7284. https://doi.org/10.1007/s13762-018-2148-2 (2019).

Nwodo, U. U., Agunbiade, M. O., Green, E., Mabinya, L. V. & Okoh, A. I. A freshwater Streptomyces, isolated from Tyume River, produces a predominantly extracellular glycoprotein bioflocculant. Int. J. Mol. Sci. 13, 8679–8695. https://doi.org/10.3390/ijms13078679 (2012).

Guo, J. Y. et al. Characterization and flocculation mechanism of a bioflocculant from hydrolyzate of rice stover. Bioresour. Technol. 177, 393–397. https://doi.org/10.1016/j.biortech.2014.11.066 (2015).

Elkady, M. F., Farag, S., Zaki, S., Gadallah, A. E. & Desouky, A. E. Bacillus mojavensis strain 32A, a bioflocculant-producing bacterium isolated from an Egyptian salt production pond. Bioresour. Technol. 102, 8143–8151. https://doi.org/10.1016/j.biortech.2011.05.090 (2011).

Yang, L. et al. Hyperproduction of extracellular polymeric substance in Pseudomonas fluorescens for efficient chromium (VI) absorption. Bioresour Bioprocess. 10, 17. https://doi.org/10.1186/s40643-023-00638-3 (2023).

Xia, M. et al. A novel polysaccharides-based bioflocculant produced by Bacillus subtilis ZHX3 and its application in the treatment of multiple pollutants. Chemosphere 289, 133185. https://doi.org/10.1016/j.chemosphere.2021.133185 (2022).

Dai, J. et al. A novel polysaccharide-based bioflocculant produced by Bacillus subtilis 35A and its application in the treatment of dye decolorization, heavy metal ion adsorption and meat product wastewater. Front. Microbiol. 15, 1457909. https://doi.org/10.3389/fmicb.2024.1457909 (2024).

Rajwinder, K. et al. Enhanced composting leachate treatment using extracellular polymeric substances as bioflocculant. J. Environ. Eng. 145, 04019075. https://doi.org/10.1061/(ASCE)EE.1943-7870.0001584 (2019).

Pu, S. et al. Isolation, identification, and characterization of an Aspergillus niger bioflocculant-producing strain using potato starch wastewater as nutrilite and its application. PLoS ONE 13, e0190236. https://doi.org/10.1371/journal.pone.0190236 (2018).

Acknowledgements

This work was supported by the Guangxi Minzu University Scientific Research Foundation of China (2019KJQD14).

Author information

Authors and Affiliations

Contributions

G.F.L., S.Q.Q., and Q.L. conceived, constructed, and designed the study. S.Q.Q. isolated and identified the flocculants-producing bacteria. S.Q.Q., and Q.L. optimized the fermentation and flocculation conditions for bioflocculants production. L.Y.W. characterized the bioflocculants. H.M.T., and Y.Y.M. investigated the application of flocculants in aquaculture wastewater. G.F.L., S.Q.Q., and Q.L. analyzed the data and wrote the manuscript. G.F.L. revised the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Qin, S., Li, Q., Wu, L. et al. A novel Pseudomonas sp. strain with high flocculation efficiency for aquaculture wastewater treatment. Sci Rep 15, 23577 (2025). https://doi.org/10.1038/s41598-025-08584-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-08584-0