Abstract

Because the law of slurry diffusion in horizontal grouting holes in deep limestone aquifers is unclear, and the key grouting parameters in grouting design and engineering practice lack a theoretical basis, the grouting process cannot be effectively controlled, and the grouting effect cannot be guaranteed. Therefore, this study comprehensively adopts laboratory tests, theoretical derivation, numerical analysis, comparative verification, and numerical simulation to study the influence characteristics of the theoretically calculated slurry diffusion form and inclination angle, which are similar to those of the physical model test and numerical simulation results. Under different grouting pressures, fracture inclinations (excluding 0°), fracture openings, and slurry water-cement ratios, the slurry diffusion form was approximately oval and symmetrical along the central vertical line, and the maximum and minimum slurry diffusion distances appeared at azimuths of 180°and 0°, respectively. The range of the slurry diffusion trace increased and decreased with an increase in the fracture dip angle in the lower and upper fractures, respectively. Under the same conditions, the slurry diffusion distance in the crack above the horizontal grouting hole was greater than that in the crack below. The crack initiation pressure decreased with an increase in the crack length (0.01–0.5 m), and the decreasing range increased with an increase in the maximum principal stress. Under the same maximum principal stress, the cracking pressure decreases with the increase of crack length. When the crack length is 0.01–0.5 m and the maximum principal stress is 15–25 MPa, the cracking pressure at the top of the Ordovician limestone is 16.73–27.85 MPa. The research results are helpful to provide theoretical support and basis for the practice of grouting reconstruction in the advanced area of karst fractured aquifer in the floor of North China coalfield.

Similar content being viewed by others

Introduction

In the past 10 years, the Carboniferous-Permian coalfield in central and eastern China, as the main coal-producing area, has contributed approximately 13.4 billion tons of coal resources, accounting for approximately 37% of the total coal mining in China1. However, the exploitation of Carboniferous-Permian coal resources has long been threatened by water inrush from the high-pressure aquifer of the underlying Ordovician limestone2,3,4. Due to the exhaustion of the Qianbu coal seam in the central and eastern mining areas of China, most coal mines have successively entered deep mining (800 ~ 1500 m). Therefore, the threat of water inrush in coal mining is becoming increasingly severe because of the complex geological environment, such as high water pressure and high geostress in the deep5. In recent years, many mining areas in central and eastern China have used bedding directional drilling to pre-grout deep limestone in advance areas. This technology has eliminated the constraints of underground conditions, and bedding drilling can expose limestone cracks to the maximum extent. Simultaneously, the ground grouting pressure is high, which can overcome the constraints of high water pressure and high ground stress, effectively improve the fracture filling rate, and enhance the grouting effect6,7. However, in recent years, there have been frequent water inrush accidents in the floor limestone grouting reconstruction working face, such as six water inrush accidents in the Hanxing mining area8 and eight water inrush accidents in the Jiaozuo mining area9. This is because of the lack of understanding of the migration law and final pressure criterion of high-pressure grouting slurry in horizontal holes of deep limestone aquifers, which leads to the lack of theoretical basis for the selection of key parameters such as drilling spacing, grouting pressure, and slurry performance in grouting design, and the scientific and reasonable control of high-pressure grouting process, resulting in long construction period, large grouting amount, and poor grouting effect in advanced area grouting project. Therefore, it is necessary to aim at the migration law of high-pressure grouting slurry in horizontal holes of deep limestone aquifers and the criterion of end pressure to provide a theoretical basis for related grouting engineering practices.

The Ordovician limestone or Taiyuan limestone aquifer is the most developed karst fracture, which is the main channel for groundwater occurrence and migration; therefore, slurry diffusion mainly occurs in the fracture during grouting10. Experts and scholars at home and abroad have done a lot of research on the law of slurry diffusion in fractured rock mass, and have achieved rich results11, but mainly for the slurry diffusion in horizontal fractures of vertical grouting holes, such as Baker12 and Liu Jiacai13 deduced Newton-type slurry diffusion distance formula for smooth horizontal equal thickness fractures; M.Wallner, W.Wittke14, G.Lombardi15 and H. B. Jiabin16 derived the formula of Bingham-type slurry diffusion distance for smooth horizontal equal-thickness fractures; Ruan Wenjun17 constructed Bingham-type slurry diffusion model of smooth fracture considering small opening fracture; Zheng Yuhui18 constructed the slurry diffusion model of Newton fluid and Bingham fluid considering the frequency hydraulic gap width and Bingham fluid seepage law. Zhang Lianghui19 and Zheng Changcheng20 respectively constructed the diffusion distance model of slurry plane fracture considering fracture roughness; Li Shucai21 used the generalized Bingham fluid constitutive equation to study the diffusion mechanism of viscosity-time-varying slurry; Zhang Qingsong22 studied the grouting diffusion mechanism of horizontal fractured rock mass considering the temporal and spatial variation characteristics of slurry viscosity. The hydrodynamic models of slurry diffusion in fractured rock masses established in the above studies are all aimed at slurry diffusion in horizontal fractures, and the influence of slurry gravity was not considered. Xu Bin et al.23 derived the theoretical formula of effective diffusion radius of Bingham fluid slurry in rough inclined fractures by using N-S equation. The hydrodynamic models of slurry diffusion in fractured rock masses established in the above studies are all aimed at slurry diffusion in horizontal fractures without considering the influence of slurry gravity. Zhai et al.24 established a theoretical model of crack grouting diffusion considering the coupling effect of slurry flow and rock mass deformation, analyzed the spatial distribution characteristics of slurry pressure and crack opening in the direction of slurry diffusion, and revealed the influence of the slurry-rock mass coupling effect on slurry diffusion.

However, vertical or inclined cracks in the floor strata are easier to form water channels than horizontal cracks, and horizontal holes can intersect with vertical or inclined cracks when drilling along limestone strata, which is also an outstanding advantage of horizontal holes in limestone strata compared to vertical holes. A few scholars, including Luo et al.25, Pei et al.26,27, and Hu et al.28 explored the slurry diffusion law in inclined fractures by considering the self-weight of the slurry; however, they did not establish a slurry diffusion distance control model in inclined water-bearing fractures by considering the slurry diffusion radiation angle and did not obtain the theoretical trace shape and variation law of slurry diffusion. The coupled numerical model built by Lakirouhani A provides a basic tool for estimating the magnitude of error related to hydraulic fracturing stress measurement under nonideal conditions, and the main discovery of this work is the model-based guide on the values of relevant dimensionless parameters to ensure that the stress estimation using an idealized model is sufficiently accurate29. Ali Lakirouhani et al.30 proposed a plane strain numerical model to calculate the fracture pressure, in which the influence of initial crack length was considered. The calculation results showed that the initial crack length significantly influenced the fracture pressure.

During horizontal hole grouting in a deep limestone aquifer, the grouting end pressure significantly influences the grouting effect. When the grouting pressure is excessively high, it can cause problems such as wastage of construction resources, damage to the target rock stratum, expansion of the grouting scope, and an increase in grouting cost. When the grouting pressure is too low, it can easily cause problems such as insufficient grouting range and crack filling rate, poor grouting effect, and small grouting amount. In the research on grouting termination pressure criteria, domestic and foreign research mainly focuses on injected media such as soil, soft sand layers, and weathered rock layers, and there is little research on high-pressure grouting in deep limestone aquifers. For example, De Pater et al.31 obtained the relationship curve between the cracking pressure of high-pressure grouting in soft sand layer and confining pressure under different confining pressures; Gothäll et al.32 introduced the concept of fracture opening critical pressure, and studied the relationship between slurry pressure and fracture deformation; Li et al.33 and Wang et al.34 respectively studied fully weathered granite and soil, and found that the crack initiation pressure of soil showed a pulse-like change law during high-pressure grouting. Huang et al.35 obtained that the size, position and angle of precast cracks have a decisive influence on the development direction of splitting cracks by using a true triaxial test device, but the literature did not study the influence of factors such as slurry viscosity and stress state on the crack initiation mechanism, but slurry viscosity and stress state played an important role in the crack initiation during splitting grouting, and the precast cracks were simulated by cardboard, which failed to simulate the original void state in the sample. Liu et al.36 studied the influence of precast cracks with different parameters on the propagation of grouting-induced splitting cracks by using a true triaxial physical test platform, and obtained that when precast cracks do not intersect with grouting holes, the propagation of grouting splitting cracks goes through four stages: splitting penetration, slurry filling, splitting and splitting propagation, while when precast cracks intersect with grouting holes, the propagation of splitting cracks only goes through the last three stages. The larger the precast cracks, the easier it is to form a channel between them. However, in this test, the prefabricated cracks were only simulated using cardboard, and the physical and mechanical properties of the samples were not calibrated prior to the test. Moreover, the influence of different water-cement ratio slurries on the crack initiation pressure was not determined. Li et al.37 and others studied the diffusion path, fracturing mode, stress field change and micro seismic monitoring response deviation of grout near faults, and revealed the influence law of different fault distances on the characteristics of grout splitting and diffusion, the direction of fracturing stress and the characteristics of micro seismic monitoring response deviation.

In summary, based on previous research, the author considers factors such as grout weight, fracture dip angle, grout diffusion radiation angle, stress difference between upper and lower fractures of the grouting hole, and hydrostatic pressure of the aquifer, and establishes the grout diffusion control model of inclined fracture of horizontal grouting hole by means of indoor test, theoretical derivation, numerical analysis, comparative verification and numerical simulation, and analyzes and studies the characteristic law of grout diffusion distance and shape changing with influencing factors. To reveal the law of slurry diffusion in horizontal grouting holes in karst fractured aquifers, and compare and verify it through model test and numerical simulation calculation, the criterion of grouting end pressure was studied according to the crack initiation pressure in the grouting process, which provides a basis and reference for grouting transformation in the advanced area of limestone aquifer with floor.

Theoretical model of slurry diffusion in horizontal hole inclined fracture

Rheological characteristics of cement slurry

Considering the cost, environmental protection, slurry performance, and pulping technology, cement slurry is widely used for grouting in the advanced area of the coal seam floor. Its particles are relatively fine and can enter tiny cracks with small crack openings. Viscosity is an important index for determining the fluidity of a slurry. The time-varying characteristics of the cement slurry viscosity with different water-cement ratios were used to assess the type of slurry flow. Therefore, mastering the time-varying law of cement slurry viscosity with different water-cement ratios is the basis for exploring the diffusion law of grouting slurry in horizontal holes in fractured aquifers.

In this study, an RST rheometer was used to test the time-varying viscosity of cement slurry (water cement ratios of 0.6:1, 0.8:1, 1:1, and 2:1) which is widely used in grouting reconstruction in advanced areas. The RST rheometer is a rotating rheometer used to control stress. The instrument uses a high-precision dynamic drive system with an optical encoder to determine the absolute position of the rotor, and the viscosity unit is Pa·s. Table 1 presents the specific test data. By fitting the viscosity data of the cement slurry at different times, the variation law of viscosity with time was obtained (Fig. 1). The viscosity of the cement slurry with water-cement ratios of 0.6, 0.8, and 1.0 shows an exponential change trend with time, whereas the viscosity of the cement slurry with a water-cement ratio of 2 changes slightly with time and remains basically unchanged. Combined with the classification standard of cement slurry flow patterns in the literature11, cement slurry with a water-cement ratio of not more than 1.0 was regarded as a viscous time-varying fluid in this study.

Basic assumptions of model construction

The following derivation should satisfy the following assumptions38,39: (1) The movement of slurry is continuous; (2) The slurry is an isotropic fluid and incompressible, and the bulk density of the slurry remains unchanged during the flow process, and the flow rate is stable; (3) The slurry sidewall meets the non-slip boundary; (4) The upper and lower surfaces of the fracture satisfy the non-slip boundary condition, that is, the slurry flow velocity at the upper and lower surfaces is 0; (5) The crack opening is evenly distributed; (6) The slurry diffusion mode is complete displacement diffusion, regardless of the mixing of water and slurry at the slurry-water phase interface; (7) Slurry flow belongs to laminar flow. The above assumptions and conditions have been discussed or verified by references.

Slurry diffusion model of inclined fracture

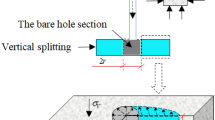

Dissolved fractures are the products of primary structural fractures that are further expanded by erosive flowing groundwater. According to the relationship between fracture extension and rock strata, they can be divided into three types: oblique, vertical, and parallel. Horizontal directional drilling is oblique, vertical, or parallel to fractures when grouting an aquifer in a coal floor (Fig. 2), whereas the vertical and parallel angles between the fractures and strata are 90°and 0°, respectively. Grouting, plugging, and reinforcement of vertical or inclined fractures are crucial for preventing water inrush from the coal floor. Along the vertical section of the horizontal hole, the diffusion section of the slurry in the hole after entering the fracture can be obtained (Fig. 3). Because the aquifer in the seam floor fracture is a confined aquifer, its water level elevation is above the aquifer; therefore, the slurry is resisted by hydrostatic pressure in the fracture above and below the horizontal hole. To facilitate the analysis, the horizontal hole grouting in the fractured aquifer was generalized as a slurry diffusion model of a horizontal grouting hole-inclined fracture, and the slurry micelle moving along the upper and lower fractures was considered as the analysis object. It was determined that the slurry micelle is subjected to mass force, surface pressure, and slurry viscous resistance during the flow process, wherein the surface pressure includes the grouting pressure and hydrostatic pressure (Fig. 4). The X- and Y-axes are established along the direction parallel to the diffusion direction of the slurry micelle and perpendicular to the inclined crack, respectively, with the crack opening being 2 h, the intersection point between the horizontal grouting hole and crack being coordinate 0, the angle between the crack and horizontal hole being α, the hydrostatic pressure being p0, the slurry diffusion distance in the crack above the horizontal hole being Ls, the slurry diffusion distance in the crack below the horizontal hole being Lx, and f being the unit mass force on the slurry.

The basic equations of viscous fluid mechanics, which describe the equilibrium relationship of viscous fluid under various forces, are combined with continuity and constitutive equations to form the basic equations for solving incompressible viscous flow40. The vector equation can be obtained by simplifying the simultaneous equations as follows:

The left side of the equation is the acceleration of the slurry mass micelle under the action of force; the first term on the right side is the unit mass force, the second term is the surface force caused by the pressure gradient, and the third term is the friction force caused by the slurry viscosity.

Because there is an included angle between the fracture and the horizontal hole, the self-weight of the slurry after entering the inclined fracture from the horizontal grouting hole has a component in the direction of the fracture, and this component still has an included angle with the slurry diffusion direction (Fig. 5), and this component presents resistance and dynamic effects in the upper and lower fractures of the horizontal hole, respectively, and this difference can be reflected by the component of the slurry micelle migration direction, so it can be obtained that the slurry unit mass force component in the x-axis direction is:

where θ is the included angle between the direction of slurry micelle migration and the vertical gravity component of α direction, and when θ ∈ (90, 270), the slurry is in the upper crack; When θ ∈ (0, 90) ∪ (270, 360), the slurry is in the lower fracture.

\(\frac{{D{\mathbf{V}}}}{Dt}\) is the rate of change of fluid velocity (\(u,v,w\)) with time, that is, the material derivative of velocity, therefore, its x-direction component is:

gradpis the partial differential component of surface pressurepin three directions in space, and its component inxdirection is \(\frac{\partial p}{{\partial x}}\);

\(\nu \nabla^{2} u^{2}\) is the component of viscous friction along the x direction, where \(\nabla^{2}\) is Laplace operator, \(\nabla^{2} = \frac{\partial }{{\partial x^{2} }} + \frac{\partial }{{\partial y^{2} }} + \frac{\partial }{{\partial z^{2} }}\); \(\nu\) is the coefficient of kinematic viscosity, and its relationship with viscosity μ is \(\nu = \frac{\mu }{\rho }\) that the component of viscous friction in the x-axis direction is:

Substituting formulas (2) and (3), pressure gradient and unit mass force component into formula (1), the scalar equation of Navier–Stokes vector equation in the x direction can be obtained as follows:

In addition, the continuity equation is a mass balance equation based on the law of mass conservation, and the volume expansion rate of incompressible fluid is 0, that is, the divergence of velocity is 0, so the continuity equation can be obtained as follows:

The x direction is the diffusion direction of the slurry micelle, so the flow velocity of the slurry in the y direction and the z direction is zero, which is obtained by combining with Formula (5):

That is, the velocity change along the x direction is 0, which indicates that the slurry micelle flows stably, which is consistent with the previous assumption, that is, the acceleration of the slurry micelle is 0.

Therefore, the Navier–Stokes Eq. (4) in the x direction can be transformed into:

For newtonian fluids

According to the assumption that the slurry sidewall is a non-slip boundary, the boundary conditions can be obtained:

For the lower fracture, according to the boundary condition, the Eq. (6) is solved by integration to obtain the velocity of the slurry micelle along the x direction:

By integrating and averaging Eq. (7) in the direction of fracture opening, the average fluidity of Newtonian fluid slurry in fracture section can be obtained as follows:

In the above formula, the average velocity subscript x represents the lower crack.

Assuming that the grouting pressure at the orifice where the horizontal grouting hole cracks intersect is p1, it will be attenuated after entering the cracks and finally balanced with the hydrostatic pressure. Therefore, assuming that the slurry front pressure is p0 when the diffusion distance in the cracks below the horizontal grouting hole is Lx, that is, the hydrostatic pressure is p0, the boundary conditions can be obtained as follows:

Equation (8) can be transformed into:

The average flow velocity of the slurry in the direction of slurry micro-cluster diffusion on the cross section of the fracture is obtained through the previous derivation, but the slurry shows the phenomenon of peripheral diffusion after entering the fracture, and the θ angle in the flow velocity represents the radiation angle of slurry diffusion, that is, different θ angles represent the flow velocity of slurry micro-cluster in different directions, so the corresponding slurry diffusion distance can be obtained by the slurry micro-cluster flow velocity obtained by the slurry diffusion around a certain period, and the corresponding slurry injection volume can be obtained by the geometric volume calculation method. Let the radius of the horizontal grouting hole be r0, the opening of the fracture be b, and the diffusion distance of the slurry in the fracture below the borehole be x in time t, so the grouting quantity in the fracture below is:

Among them, the subscript x of grouting quantity in the above formula \(Q_{x}\) indicates the lower crack.

Substituting the average flow velocity of grout in the fracture section below the horizontal grouting hole (Eq. 8) respectively, the integral can be obtained:

Among them, the subscript x of grouting pressure px in the above formula indicates the lower crack. According to the pressure p1 at the orifice of horizontal grouting hole:

According to the average speed of diffusion in slurry cracks, the slurry flow can be obtained. When x < 0, the slurry flow in the fracture below the horizontal hole is:

In the above formula (13), the slurry flow \(q_{x}\) subscript x represents the lower crack.

Grouting amount can also be obtained according to the integration of flow rate with time, that is, the amount of grout injected into cracks in a unit time period should be equal to the amount of grout needed to increase the diffusion radius r in this time period, so there are:

By bringing Eq. (13) into Eq. (14), the control equation of diffusion distance in the fracture below Newtonian fluid slurry can be obtained:

Among them, the slurry diffusion distance Lx subscript x represents the lower crack.

However, in the fracture above the horizontal hole (when x > 0), the control equation of average velocity of Newton fluid slurry cross section, grouting pressure and slurry diffusion distance Ls (subscript s indicates the upper fracture) has the same expression as that of the lower fracture, but the difference is θ ∈ (90, 270) in the upper fracture.

Viscous time-varying fluid

When the viscous time-varying fluid flows, there is a flow core phenomenon along the cross section direction of the fracture14, and the height of the slurry flow core is set as b0 (Fig. 6).

According to the velocity expression of the slurry micelle obtained above, the velocity of the upper, middle, and lower parts of the slurry flow cross section is obtained according to the boundary conditions, and the average velocity \(\overline{u}\) of the fracture cross section can be obtained by averaging the cross-sectional integral.

Integrate Eq. (6) and substitute it into the boundary condition:

The velocity distribution at any point in the upper half of the upper core of the cross section \(\left[ {\frac{{b_{0} }}{2},\frac{b}{2}} \right]\) is obtained:

Similarly, the velocity distribution at any point in the lower half of the lower core can be obtained:

Velocity distribution at any point in the core region of the cross section:

The average velocity of the slurry on the cross section can be obtained from the velocity of the upper, middle and lower parts of the fracture section below the horizontal hole as follows:

Therefore, the grouting quantity of the lower fissure in time t is:

From the average velocity of the lower fracture section, we can get:

According to the boundary conditions of grouting orifice \(x = - r_{0} ,p = p_{1}\), the control equation of grouting pressure in the lower fracture is obtained:

According to the average speed of diffusion in slurry cracks, the slurry flow can be obtained. When x < 0, the slurry flow in the fracture below the horizontal hole is:

Similar to Newton’s slurry derivation, the control equation of slurry diffusion distance in the lower fracture can be obtained:

Similar to Newtonian fluid, the governing equations of average velocity, diffusion distance and grouting pressure of viscous time-varying fluid have the same expression. For the upper fracture, θ ∈ (90, 270) is selected. For the lower fracture, θ ∈ (0, 90) ∪ (270, 360) is selected.

Comparison of theoretical calculation with physical model test and numerical simulation calculation results

Comparison with the model test results of related literature

Literature41 carried out model tests on slurry diffusion in horizontal and inclined fractures, and obtained the curve of slurry diffusion distance with time. Based on this model, the paper compared and analyzed the test results with the theoretical calculation results. In this paper, two groups of experiments with different dip angles were carried out. During the experiment, the hydrostatic pressure was zero, the cracks were unsaturated, and the slurry was viscous time-varying slurry with a certain proportion of additives. See Table 1 for other specific parameters. Because the viscosity control equation of the viscosity-time-varying slurry containing additives is not given in the literature, the theoretical calculation is based on the cement slurry whose water-cement ratio is 0.6. Through the slurry diffusion distance control equation (Eq. 23) obtained above, the value of the slurry diffusion distance with time can be obtained by using other parameters in this test, and the comparison curve between the model test results and the theoretical calculation results can be obtained by combining the model test data in this literature (Fig. 7).

Comparison between model test of grout diffusion distance of fracture with different dip angles in literature41 and theoretical calculation results in this paper :(a) grout diffusion distance of fracture with dip Angle of 0°, (b) grout diffusion distance of grout with dip Angle of 10° (grouting pressure of 0.01 MPa), and (c) grout diffusion distance of grout with dip Angle of 10° (grouting pressure of 0.1 MPa).

It can be seen that the slurry diffusion distance of model test is smaller than the theoretical calculation result in the horizontal fracture, but the difference between the model test result and the theoretical calculation result is relatively reduced in the fracture with an inclination angle of 10, and the theoretical calculation result is consistent with the model test result in the initial grouting time (55s horizontally and 200 s vertically), and the theoretical calculation result is larger than the model test result in the later grouting period. The reasons are as follows: the diffusion distance of slurry in horizontal cracks is driven by grouting pressure, and there are differences in viscosity variation between the cement slurry used in the theoretical calculation and the viscosity-time-varying slurry in the literature. According to the literature description, the yield stress increase rate of the viscosity-time-varying slurry is higher than that of the specific cement slurry, so the theoretical calculation result is higher than the model test result. In inclined cracks, the diffusion distance of slurry is driven by both grouting pressure and gravity. The yield stress of viscous time-varying slurry in model test increases slowly at the initial stage of grouting, and gravity counteracts part of the yield stress, so it is close to the theoretical calculation result, and the diffusion distance is smaller than the theoretical calculation result because the yield stress increases rapidly at the later stage.

In addition, based on the model test results, the literature obtained the slurry diffusion patterns at different times and dip angles simultaneously (Fig. 8). According to the relevant parameters in the literature, this study calculated the slurry diffusion trace distribution at different time points when the fracture dip angle was 10°and the slurry diffusion trace distribution at different fracture dip angles (10°, 30°, 50°) for 250 s (Fig. 9). It can be seen that the theoretical calculation results are consistent with the model test results in the literature for the distribution of grout diffusion trace at different times under the same fracture dip angle. At different times, the crack diffusion range above the grouting hole was smaller than that below, and the trace at the same time presented a symmetrical elliptical distribution pattern. However, for the distribution of slurry diffusion traces at the same time point under different fracture dip angles, there are similarities and differences between the theoretical calculation results and the model test results in the literature. The same point is that with an increase in the fracture dip angle, the diffusion distance of the lower fracture increases, and the diffusion distance of the upper fracture decreases. The difference lies in the fact that the transverse width of the lower crack diffusion trace decreases with an increase in the crack dip angle, and the center position of the upper crack diffusion trace is concave. This is because the crack surface was not smooth in the model test, and when the dip angle was small, the self-weight of the slurry as the driving force was smaller than the friction force on the crack surface and the shear force of the slurry, resulting in a smaller gap between the longitudinal and transverse diffusion distances of the slurry. When the crack dip angle increased, the self-weight of the slurry increased, so the longitudinal component increased, resulting in a larger gap between the longitudinal and transverse diffusion distances of the slurry. However, the theoretical calculation assumed that the inner surface of the crack was smooth; therefore, there was a relative lack of friction resistance suppression in the transverse direction, which led to a difference from the model test. In addition, in theoretical calculations, the concave phenomenon of the center position of the upper fracture diffusion trace is mainly caused by the difference in gravity components in different directions; however, it is difficult to capture this phenomenon in model tests because of the restrictions of flow control, acquisition accuracy, and trace distribution. Therefore, the concave phenomenon did not occur.

In the model test of literature41, the diffusion pattern of grout in inclined fractures is (a) at different time, (b) at different dip angles.

In summary, the theoretical calculation results are consistent with the model test results, and the calculation results are reasonable and reliable, which shows that the theoretical control equation of the slurry diffusion distance in a horizontal hole inclined fracture can better reflect the changing characteristics of the slurry diffusion distance in the inclined fracture.

Comparison with numerical simulation results

Model construction and parameter setting

To further verify the applicability and reliability of the theoretical model under certain hydrostatic pressures and different water-cement ratios, this study calculates the slurry diffusion in inclined cracks of horizontal grouting holes based on the numerical simulation software COMSOL, and the obtained results are compared with the theoretical calculation results. The calculation parameters are listed in Table 2.

A three-dimensional crack model was built using COMSOL numerical simulation software. The size of the crack was 3000 mm × 3000 mm × 5 mm, and the grouting hole was located in the upper 2/3 position of the middle. By comparing and optimizing the number of grids, the entire structural system was dispersed into 25,622 units (Fig. 10). The material properties of the injected slurry are listed in Table 2. When setting the boundary, the grouting hole was set as the pressure boundary, and the grouting pressure was 0.15 MPa. According to the pressure state of the crack, the four sides around the crack were set as the pressure boundary, that is, the hydrostatic pressure was set to 0.1 MPa. When calculating the diffusion field of the slurry, the concentration of the slurry was defined by the mass percentage concentration, the concentration at the entrance was 1, and the concentration at the groundwater without slurry was 0. Table 2 lists the other calculation parameters.

Basic control equation

In the numerical calculation of fluid, the flow of fluid should obey the equations of mass conservation and momentum conservation. Among them, the equation of conservation of mass is the continuous equation, which is the mathematical expression of the law of conservation of mass in fluid mechanics, and its integral form is:

The differential expression is as follows:

Because:

Therefore, the differential expression can be abbreviated as:

Where ρ is the fluid density, t is the time, u/v/w is the speed in all directions of x/y/z, and v is the volume of the control unit.

Momentum conservation equation, namely momentum equation, is a mathematical expression of momentum conservation in fluid motion. When considering the viscosity of fluid, momentum equations in x, y and z directions in rectangular coordinate system can be expressed as:

Comparison of calculation results

Through numerical simulation calculations, the slurry diffusion patterns in inclined cracks at different grouting times were obtained (Fig. 11). It can be seen that the slurry diffuses radially around the cracks in inclined cracks, and with the increase of grouting time, the range of the crack diffusion patterns below the grouting hole is larger than that above the grouting hole, and the trace of the slurry diffusion patterns is elliptical. This is consistent with the shape of the inclined fracture slurry obtained by theoretical calculations. Comparing the maximum diffusion distances between the upper and lower cracks in the numerical simulation at different times with the theoretical calculation results (Fig. 12), it was found that the theoretical calculation results of the slurry diffusion distance of cement slurry with different water-cement ratios were consistent with the numerical simulation calculation results, especially for viscous time-varying cement slurry, and their changing trends were similar with time, both of which showed that the growth rate of the slurry diffusion distance decreased gradually with time. The aforementioned slurry diffusion form and numerical calculation results show that the theoretical calculation control model can accurately describe the slurry diffusion form and distance of inclined fractures.

Horizontal grouting holes, inclined fracture, slurry diffusion law

The variation characteristics of the slurry diffusion distance and trace shape with different factors can not only reflect the slurry diffusion law but also have great significance for guiding grouting design and key parameter design in field engineering practice. In fractured aquifers, there are many controlled factors in the slurry diffusion distance, such as the fracture opening, angle between the fracture and grouting hole, grouting pressure, grouting time, slurry viscosity, slurry specific gravity, and grouting quantity. The grouting pressure, grouting time, slurry performance, and grouting quantity are controllable grouting parameters, whereas the fracture opening, angle between the fracture and grouting hole, hydrostatic pressure, and other parameters are the objective properties of the injected media. To quantitatively analyze the influence characteristics of controllable grouting parameters and objective parameters of the injected medium on the slurry diffusion distance and trace shape, the author uses the control variable method to analyze and calculate based on the slurry diffusion distance control equations of Newton fluid and viscous time-varying fluid.

Calculation of working conditions and parameters

MATLAB software is used to analyze and calculate the variation characteristics of grout diffusion distance (L) with grouting time (t) under different grout viscosity (μ), grouting pressure (p1), included angle (α) between cracks and grouting holes, crack opening (b) and hydrostatic pressure (p0), where Newton fluid is based on Formula (15) and viscous time-varying fluid is based on formula (23). And see Table 3, Table 4 and Table 5 for specific parameters and working conditions respectively. Other fixed parameter values, horizontal grouting hole radius r0 is 0.076 m, hydrostatic pressure p0 is 10 MPa, and gravity acceleration g is 9.8 m/s2.

Variation law of slurry diffusion trace and distance under different grouting pressures

Newtonian fluid slurry

Considering the radiation angle of slurry diffusion, the slurry diffusion distance of the Newtonian fluid under different grouting pressures (working conditions 1, 2, 3, and 4) was calculated, and the theoretical trace of the slurry diffusion of the Newtonian fluid under different grouting pressures was obtained (Fig. 13). The analysis shows that, for the same grouting pressure and time, the shape of the slurry diffusion trace presents an approximate oval shape, which is symmetrical along the central vertical line, and the trace in the middle of the upper fracture presents a concave distribution, while the maximum and minimum of the slurry diffusion distance appear in the azimuth angles of 180°and 0°, respectively, that is, in the vertical direction. This is because the self-weight of the slurry plays a resistance and dynamic role in the upper and lower fractures of the borehole, respectively, and this effect decreases to both sides with the vertical line as the symmetry axis. For the same grouting pressure and different grouting times, the grouting of the slurry diffusion trace increased with time, where the increase in the lower crack was greater than that in the upper crack, and the micro-concave characteristics of the trace in the middle of the upper crack gradually weakened. For different grouting pressures and the same grouting time, the shape of the slurry diffusion trace increased with an increase in the grouting pressure, and the range of the trace increased simultaneously.

According to the shape analysis of the slurry diffusion trace, the maximum distance of slurry diffusion was at the position where the θ angle was 0°; thus, the curve of the maximum distance of slurry diffusion with time under different grouting pressures could be obtained (Fig. 14). It can be seen that the maximum distance of slurry diffusion increases with time under different grouting pressures, but the increasing rate gradually decreases; At the same time, the slurry diffusion distance increases with the increase of grouting pressure, and the gap of slurry diffusion distance gradually increases with the increase of time under different grouting pressures, which shows that the influence of grouting pressure on slurry diffusion distance has obvious time effect. By comparing the slurry diffusion distances between the upper and lower cracks of the horizontal grouting hole, it can be determined that the slurry diffusion distance in the lower cracks of the horizontal grouting hole is always greater than that in the upper cracks under the same grouting pressure, and the gap expands with time.

Viscous time-varying fluid slurry

As shown in Fig. 15, the shape and change characteristics of the slurry diffusion trace of the viscous time-varying fluid slurry under different pressures were consistent with those of the Newtonian fluid, and the slurry diffusion trace increased with time. The increase in the trace range increased with the increase in grouting pressure, and the slurry diffusion trace range of the upper fracture was smaller than that of the lower one. However, at the same pressure and time, the diffusion trace range of the viscous time-varying fluid slurry is smaller than that of the Newtonian fluid slurry, and the variation range of the trace is smaller than that of the Newtonian fluid slurry at the same time, and the difference in the diffusion trace range between the upper and lower fractured slurries is smaller than that of the Newtonian fluid slurry under the same conditions.

As shown in Fig. 16, similar to the Newtonian fluid, the diffusion distance of the viscous time-varying fluid slurry increased with the increase in grouting time under different grouting pressures, and the increase rate decreased with the increase in time. In contrast to the Newtonian fluid, the diffusion distance of the viscous time-varying fluid is small under different grouting pressures, and the diffusion distance of the slurry in cracks above and below the horizontal grouting holes is also small. The gap in the slurry diffusion distance tended to be stable with time under different grouting pressures. Under high pressure (2.5 times the hydrostatic pressure), the diffusion distance of the viscous time-varying fluid is also in a relatively low range with time; thus, the viscous time-varying slurry has an obvious influence on the diffusion distance of the slurry. When grouting in an injected stratum with a large void scale, a time-varying viscous slurry can be used for grouting to limit the ineffective diffusion of the slurry.

Variation law of slurry diffusion trace and distance under different fracture openings

Newtonian fluid slurry

As can be seen from Fig. 17 and 13(c), the range of the slurry diffusion trace shows significant changes under different fracture openings, and the range of the slurry diffusion trace increases significantly with an increase in the fracture opening. Simultaneously, the increase range of the slurry diffusion trace increases with time, and the range of the slurry diffusion trace in the lower fracture is larger than that in the upper fracture, and the difference between them increases with the increase in the fracture opening, indicating that the fracture opening has a significant impact on the slurry diffusion trace.

As shown in Fig. 18, the slurry diffusion distance increases with the increase in grouting time under different crack openings, but the increasing rate gradually decreases, and the decreasing range increases with the decrease in crack opening, indicating that the slurry diffusion distance does not change significantly with time under small crack openings. Simultaneously, the slurry diffusion distance increases with an increase in the fracture opening, but the increase range is different, in which the slurry diffusion distance from the micro-tension fracture (1 mm) to the middle-tension fracture (5 mm) increases the most at different times, and the gap gradually expands with time. By comparing the diffusion distance of grout in cracks with different scales, it can be determined that the increase in closed cracks (0.2 mm) or micro-tension cracks is small when the grouting pressure is larger (two times the hydrostatic pressure). Therefore, in the actual grouting process, the grouting time in the booster grouting stage should not be excessively long. However, considering that most closed cracks or micro-tension cracks are developed, high-pressure split grouting should be adopted after short-term booster grouting to realize the expansion and filling of closed cracks or micro-tension cracks. However, the diffusion distance of middle or wide tension cracks (0.01m) can reach thousands of meters or more with time. Reaction injection molding should be used in the early stage grouting process to prevent the slurry from exceeding the designed diffusion range.

By comparing the slurry diffusion distances between the upper and lower fractures of the horizontal grouting holes, it can be determined that the slurry diffusion distance in the lower fracture is larger than that in the upper fracture at the scale of closed, micro-tensile, and middle-tensile fractures, and the gap increases with an increase in the fracture opening. However, in the wide tensile fracture, the slurry diffusion distance in the upper fracture is larger than that in the lower fracture at the beginning of 1500 s, but after 1500 s, the slurry diffusion distance in the lower crack is gradually larger than that in the upper crack, and the gap is multiplied, which is consistent with the phenomenon that the slurry diffusion distance in the upper and lower cracks of the grouting hole is different from that obtained by the slurry diffusion model test in the literature42 with a gap width of 3 mm.

Viscous time-varying fluid slurry

As can be seen from Fig. 19 and 15(c), the fracture opening also has an obvious influence on the range of the slurry diffusion trace of the viscous time-varying fluid; however, it is smaller than that of the Newtonian fluid slurry under the same conditions, mainly because the viscosity of the viscous time-varying slurry increases with time, and the resistance to slurry flow increases gradually.

As shown in Figs. 17 Fig. 20 and that the slurry diffusion distance increases with time under different fracture openings, and the rate decreases with time. Simultaneously, the slurry diffusion distance increases with an increase in the fracture opening, and the increasing range gradually increases, which shows that a larger fracture opening also has an obvious influence on the viscous time-varying fluid. Moreover, for fractures with openings of 0.005 and 0.01 m, the slurry diffusion distance can also reach hundreds of meters or even more with the increase of time under the grouting pressure of twice the hydrostatic pressure. Therefore, it is necessary to control the slurry diffusion range with viscous time-varying slurries for large-scale voids.

Variation law of slurry diffusion trace and distance under different fracture dip angles

Newtonian fluid slurry

From Fig. 13 (c) and Fig. 21, we can obtain the range and shape of the slurry diffusion trace of the Newtonian fluid with fracture dip angles of 30°, 0°, 60°, and 90°. When the fracture dip angle is 0, the slurry diffusion trace is a uniform and symmetrical circle; however, as the fracture dip angle increases, the gap of the slurry diffusion trace range in the upper and lower fractures increases gradually, and the range of the slurry diffusion trace increases in the lower fractures simultaneously. This phenomenon is consistent with the theoretical calculation results of the previous physical model test.

According to Fig. 22, the slurry diffusion distance increases with an increase in the grouting time at different angles between the cracks and grouting holes, and the rate of increase also slows down with an increase in the grouting time. Simultaneously, the slurry diffusion distance in the crack below the horizontal grouting hole increases with an increase in the angle between the crack and the horizontal grouting hole, whereas the slurry diffusion distance in the crack above the horizontal grouting hole decreases with an increase in the angle between the crack and the horizontal grouting hole because the self-weight of the slurry plays different roles in the horizontal grouting hole. Compared with other influencing factors, under the same variable condition, the difference in the slurry diffusion distance between the upper and lower cracks of the horizontal grouting hole is small, which indicates that the angle of the crack influences the slurry diffusion distance, but the influence is relatively small at the crack opening (0.2 mm).

Viscous time-varying fluid slurry

According to Fig. 15(c) and 23, the slurry diffusion trace and shape of viscous time-varying fluid slurry at fracture dip angles of 30°, 0°, 60°, and 90°can be obtained, and the analysis shows that the change of viscous time-varying fluid slurry at different fracture dip angles is consistent with that of Newtonian fluid slurry, but when the fracture dip angle is greater than 0°, the diffusion trace range of viscous time-varying fluid slurry increases slightly with the increase of fracture dip angle. This is mainly because the increase in the viscosity of the viscous time-varying fluid increases the resistance to slurry flow, which counteracts the effect of the increase in the gravity stress component caused by the increase in the inclination angle. Moreover, the crack opening used in the calculation in this study was small (0.2 mm), which further highlights this effect, resulting in a small influence of the fracture inclination angle on slurry diffusion; however, when the crack opening is large, this effect is weakened owing to the increase in the gravity stress component of the slurry, and the range of the slurry diffusion trace is increased owing to the increase in the fracture inclination angle.

It can be seen from the curve of maximum diffusion distance of viscous time-varying fluid slurry with different fracture dip angles in Fig. 24 that, similar to Newtonian fluid, fracture dip angles have relatively little influence on the diffusion distance of viscous time-varying fluid slurry, and compared with Newtonian fluid slurry, the difference of maximum diffusion distance of viscous time-varying fluid slurry with different fracture dip angles at the same time is small, and the difference of maximum diffusion distance of slurry in upper and lower fractures is also small.

The maximum diffusion distance of denatured fluid grout varies with time under different fracture inclination (Note: Ls is the maximum diffusion distance of the grout in the upper fracture, Lx is the maximum diffusion distance of the grout in the lower fracture, and α is the dip Angle of the fracture).

Variation law of slurry diffusion trace and distance under different water-cement ratios

Newtonian fluid slurry

According to the viscosity time-varying test of the cement slurry, when the water-cement ratio is greater than or equal to 2, the cement slurry shows constant viscosity characteristics; thus, it is a Newtonian fluid slurry. From Fig. 13 (c) and 25 (a), we can obtain the diffusion trace and shape of the cement slurry with water-cement ratios of 2:1 and 3:1, respectively. Through comparative analysis, we can know that with the increase in water-cement ratio, the diffusion trace range in the upper and lower cracks of the slurry increases, but the difference between them and the increase amplitude per unit time is small, mainly because the crack opening is small.

As shown in Fig. 26, the slurry diffusion distance increases with an increase in the grouting time under different water-cement ratios, but the increase rate decreases with an increase in time. Simultaneously, the slurry diffusion distance increased with the increase in the water-cement ratio, and the increase range increased with time, which shows that a larger water-cement ratio has a more obvious influence on the slurry diffusion distance. Therefore, for the low-pressure grouting stage, the slurry water-cement ratio should be reduced over time when it lasts for a long time to limit the continuous increase in the slurry diffusion distance with time. In addition, the slurry diffusion distance of different water-cement ratios in the crack below the horizontal grouting hole was larger than that in the crack below, and it increased with time; however, the difference was not obvious at the crack opening (0.2 m).

Viscous time-varying fluid slurry

From Fig. 15(c) and 25(b) and (c), we can obtain the diffusion trace and shape of the cement slurry with water-cement ratios of 0.8:1, 1:1, and 0.6:1, respectively. By comparative analysis, we can know that the diffusion trace range of viscosity time-varying cement slurry is smaller than that of Newtonian fluid slurry, but the diffusion trace range of cement slurry also shows a changing law with the increase in water-cement ratio, and the difference between the diffusion trace range of cement slurry in upper and lower fractures is small.

According to the curve analysis of the diffusion distance of viscous time-varying fluids with different water-cement ratios in Fig. 26, the diffusion distance of viscous time-varying fluids increases with time, and the increasing rate decreases with different water-cement ratios. Simultaneously, the diffusion distance of the viscous time-varying fluid increases with the increase in the water-cement ratio, but the increase rate decreases with the increase in the water-cement ratio, which shows that a smaller water-cement ratio has an obvious influence on the diffusion range of the viscous time-varying fluid. The diffusion distance of viscous time-varying fluids with different water-cement ratios was lower than that of Newtonian fluids.

Criterion of grouting termination pressure in deep limestone aquifer

Stress Intensity factor analysis of the crack tip in grouting formation

According to fracture mechanics, the stress intensity factor represents the strength of the stress field near a crack tip. Although the geometry, crack size, and stress state of the same material are different, as lon as the same stress intensity factor appears at the crack tip, the physical state near the crack tip remains the same. If it is greater than the fracture toughness of the material, the component will be unstable and will fracture. During horizontal hole grouting in a deep limestone aquifer, the horizontal grouting hole and crack tip are subjected to the combined action of geostress and grouting pressure (Fig. 9). Therefore, the total stress intensity factor at the crack tip is equal to the sum of the stress intensity factors of the original rock stress and grouting pressure.

Stress intensity factor of in-situ stress (original rock stress)

The fracture located on the horizontal disk is subjected to principal stresses σ1, σ2, and σ3. Because the direction of action of the horizontal principal stresses σ2 and σ3 is parallel to the fracture surface, the fracture is uniformly compressed by their actions, and there is no singularity at the crack tip, it can be concluded that the horizontal principal stress is K1 = 0. Then, the intensity factor under the action of in-situ stress is equivalent to the stress intensity factor when the disc is compressed in one direction. After checking the stress intensity factor manual, the stress intensity factor of the point on the crack front is expressed as follows:

As shown in Fig. 27, the plane of the circular crack is parallel to the surface of the object, the distance between the crack and the surface is h, the crack is subjected to uniform internal pressure p, and the stress intensity factor of each point at the crack front is expressed as follows:

Where a is the radius of the circular crack, The coefficient m can be obtained from the stress intensity factor manual. Because the ground stress is compressive, the stress intensity factor is negative.

Stress intensity factor of the grouting pressure

During grouting in a fractured rock mass, the slurry flows through the fracture. Under the action of the grouting pressure, the slurry formed a uniform load on the rock walls on both sides of the fracture, which caused the opening of the fracture to change and the stress concentration at the tip. Therefore, the cracks caused by the grouting pressure are classified as open cracks (type I cracks).

As shown in Fig. 28, the infinite generally has an annular crack outside the circular neck with radius a and bears the tension of the normal uniform distribution force acting on a concentric circular area in the crack surface. The inner radius of the annular area is a and the outer radius is r. The total tension distributed over the area of the ring is p. At this time, the stress state is equivalent to the tension of a uniformly distributed normal force on the concentric circular area. According to the stress intensity factor manual43, the stress intensity factor formula for a point on the crack front edge is:

Where: p is the total pulling force distributed over the area of the ring, r is the outer diameter of the ring, and a is the inner diameter of the ring.

Stress intensity factor at fracture tip of injected formation

According to the superposition theorem, the stress intensity factor at the crack tip of the injected stratum is composed of the in-situ stress intensity factor formula and the grouting pressure intensity factor formula:

According to the concentric ring model, when the borehole diameter is r0, \(a=r_0\) , \(r=x+r_0\), where x can be regarded as the length of the fracture. There are:

Criterion of crack initiation pressure at crack tip of high pressure grouting

Therefore, the criterion of fracture instability during grouting is that the stress intensity factor K reaches the critical value KC. KC is a material constant, that is, crack fracture toughness. Its value can be determined by experiments.

Where: e, γ are elastic modulus, Poisson’s ratio, and specific surface energy of rock, respectively. Moreover, according to the basic principle of fracture mechanics, under various loads, the total stress intensity factor at the crack tip is equal to the algebraic sum of each stress intensity factor under each single load. Therefore, the total stress intensity factor can be obtained by superimposing the grouting pressure intensity factor and the in-situ stress intensity factor.

According to Formula 32, let K1 = KIC, that is, the grouting pressure reaches the critical value of the stress intensity factor, and the cracks are cracked, so that the corresponding effective grouting pressure can be obtained. After substitution, the following can be obtained:

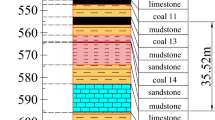

By measuring the critical stress intensity factor of rock samples in the laboratory, the critical effective grouting pressure can be calculated using the crack propagation criterion. Taking the Xingdong Mine as an example, its fracture toughness coefficient KIC = 291.7 N/cm1.5 = 291.7 × 103 N/m1.5, and the maximum principal stress is different under different burial depths. Therefore, according to the maximum principal stresses of 15, 20, and 25 MPa, the critical effective grouting pressures were calculated, and the diameter of the grouting borehole in the horizontal section was 158 mm in engineering practice. The characteristic curves of the critical effective grouting pressure Pc and its variation with the crack length (0.01–0.5 m) were obtained by calculation, as shown in Fig 29,30,31.

From Fig 29,30,31, the curves of the crack initiation pressure of the Xingdong Mine with different maximum principal stresses vary with the crack length in the range of 0.01–0.5 m. The crack initiation pressure decreased with an increase in the crack length (0.01–0.5 m), and the decreasing range increased with an increase in the maximum principal stress. The decreasing range of the crack initiation pressure decreased with an increase in the crack length for the same maximum principal stress. Specifically, it can be obtained that the cracking pressure of Xingdong Mine is 16.74 MPa when the maximum principal stress is 15 MPa, 22.29 MPa when the maximum principal stress is 20 MPa, and 27.85 MPa when the maximum principal stress is 25 MPa.

Conclusion

-

1)

A stress model of slurry diffusion in the horizontal grouting hole of a karst fractured aquifer was developed. The self-weight of the slurry was found to play the roles of resistance and power in the upper and lower fractures, respectively, and hydrostatic pressure played the role of resistance. The diffusion distance control equations for the Newtonian fluid and viscous time-varying fluid slurries in the horizontal grouting hole of the inclined fracture were derived and established.

-

2)

The influence characteristics of the slurry diffusion form and dip angle calculated by theory were similar to those of the slurry diffusion physical model test results and numerical simulation calculation results, and it was found that the slurry diffusion trace shape of the inclined fracture was an approximate ellipse symmetrical along the central vertical line, in which the upper fracture trace range was larger than the lower trace range.

-

3)

Under different grouting pressures, fracture dip angles (excluding 0), fracture openings, and slurry water-cement ratios in a single fracture of karst aquifer, the slurry diffusion form is an approximate ellipse symmetrical along the central vertical line, and the maximum and minimum slurry diffusion distances appear at azimuth angles of 180°and 0°, respectively; the range of slurry diffusion trace increases and decreases with an increase in the fracture dip angle in the lower and upper fractures, respectively. Under the same conditions, the slurry diffusion distance in the crack above the horizontal grouting hole was greater than that in the crack below.

-

4)

The expression of effective grouting pressure based on the stress intensity factor at the crack tip was obtained, and the variation characteristics of the fracture initiation pressure at the top of the Ordovician limestone formation were obtained: the fracture initiation pressure decreased with an increase in the fracture length (0.01–0.5m), and the decreasing range increased with an increase in the maximum principal stress, and the decreasing range of the fracture initiation pressure decreased with an increase in the fracture length under the same maximum principal stress.

Data availability

Data is provided within the manuscript.

References

Lan, H., Chen, D. K. & Mao, D. B. Current status of deep mining and disaster prevention in China. J. Coal Sci. Technol. 44(1), 39–46 (2016).

Xuan, Y. Q. Present situation and countermeasures of coal mine water disaster prevention in Anhui Province. J. Saf. Coal Min. 41(05), 117–119 (2010).

Zhao, Q. B. Ordovician limestone karst water disaster regional advanced governance technology study and application. J. China Coal Soc. 39(6), 1112–1117 (2014).

Bai, H. B. & Miao, X. X. Hydrogeological characteristics and mine water inrush prevention of late Paleozoic coalfields. J. China Univ. Min. Technol. 45(01), 1–10 (2016).

Hu, W. Y. The characteristics of karst and deep coal mine karst water hazardsin eastern North China. J. Coal Geol. Explor. 38(2), 23–27 (2010).

Dong, S. N., Wang, H. & Zhang, W. Z. Judgement criteria with utilization and grouting reconstruction of top Ordovician limestone and floor damage depth in North China coal field. J. China Coal Soc. 44(7), 2216–2226 (2019).

Dong, S. N. et al. Theoretical framework and key technology of advance regional control of water inrush in coal seam floor. J. Coal Geol. Explor. 51(1), 185–195 (2023).

Wang, P. P. et al. Characteristics and control technology of water inrush from deepcoal seam floor above confined aquifer in Xingdong Coal Mine. J. China Coal Soc. 45(7), 2444–2454 (2020).

Xu, Y. C. et al. Evaluation system for floor water inrush risk in grout-reinforced working faces based on grouting boreholes dataset. J. China Coal Soc. 45(3), 1150–1159 (2020).

Pan, W. Y., Liu, X. J. Limestone distribution and karst development characteristics of North China karst coal field. A. Karst and Karst Water in Northern China. C. Beijing: Geological Press (1982).

Collaborative group of "Geotechnical Grouting Theory and Engineering Examples". Geotechnical Grouting Theory and Engineering Practice. M. Beijing: Science Press (2001).

Baker, C. Comments on paper rock stabilization in rock mechanics (Springer-Verlag NY, 1974).

Liu, J. C. Study on the grouting radius of crack grouting // Collection of Scientific Research Papers of China Academy of Water Resources and Hydropower (Water Power Press, 1982).

Nongweile, E. The theory and practice of grouting (Chinese translation) (Northeastern University Press, 1991).

Lombardi, G. The role of the cohesion on cement grouting of rock. A. In Proceedings of the 15th Congress on Large Dams, Lausanne, International Commission on Large Dams (ICOLD)[C]. 235–61 (1985).

Dong, S. N. et al. Technology and application of large curtain grouting water conservation mining based on macroscopic and mesoscopic characteristics of rock mass. J. China Coal Soc. 45(3), 1137–1149 (2020).

Ruan, W. J. Spreading model of grouting in rock mass fissures based on time-dependent behavior of viscosity of cement-based grouts. J. Chin. J. Rock Mech. Eng. 24(15), 2709–2714 (2005).

Zheng, Y. H. Research on grouts and controllable method of grouting in rock mass of fissures (Jilin University, 2005).

Zhang, L. H. et al. Calculation of the parameters of fissure and analysis of grout flowing in the fissure. J. Rock Soil Mech. 19(1), 7–12 (1998).

Zheng, Z. C. Estimation on penetrating radius of stable cement grouts in rock fractures. J. Water Resour. Architect. Eng. 4(2), 1–5 (2006).

Li, S. C. et al. Research on C-S slurry diffusion mechanism with time-dependent behavior of viscosity. J. Chin. J. Rock Mech. Eng. 32(12), 2415–2421 (2013).

Zhang, Q. S. et al. Grouting diffusion mechanism in horizontal crack based on temporal and spatial variation of viscosity. J. Chin. J. Rock Mech. Eng. 34(6), 1198–1210 (2015).

Xu, B. et al. Mechanism of inclined fracture slurry transport based on non-stable Bingham fluid. J. China Coal Soc. 47(11), 4083–4093 (2022).

Zhai, M. L. & Bai, H. B. Research on the mechanism of fracture grouting diffusion and its application based on slurry-rock mass coupling effect. J. Coal Sci. Technol. 52(7), 158–167 (2024).

Ruo, P. P. et al. Theoretical study on flow model for tilted single fracture Binghamian grout. J. Shandong Univ. Sci. Technol. 29(1), 43–47 (2010).

Pei, Q. T., Ding, X. L. & Liu, D. X. Influence of crack occurrence of rock mass on the diffusion characteristics of quick-setting slurry. J. Water Res. Architect. Eng. 16(6), 25–31 (2018).

Pei, Q. T. et al. Grouting diffusion model of quick setting slurry in dip crack rock masses. J. Yangtze River Sci. Res. Inst. 36(12), 83-90’ (2019).

Hu, Y., Liu, W., Shen, Z., et al. Diffusion mechanism and sensitivity analysis of slurry while grouting in fractured aquifer with horizontal injection hole. J. Carbon. Evaporites 35(2) (2020).

Lakirouhani, A., Detournay, E. & Bunger, A. P. A. Reassessment of in-situ stress determination by Hydraulic fracturing. J. Geophys. J. Int. 205(3), ggw132 (2016).

Lakirouhani A, Jolfaei S. Hydraulic fracturing breakdown pressure and prediction of maximum horizontal in situ stress. J. Adv. Civil Eng. (2023).

De Pater, C. J., Dong, Y. & Bohloli, B. Experimental study of hydraulic fracturing in sand as a function of stress and fluid rheology (Society of Petroleum Engineers, 2007).

GOTHÄLL, R. & Stille, H. Fracture dilation during grouting. J. Tunn. Undergr. Sp. Technol. 24(3), 126–135 (2009).

Li, P. et al. Analysis of fracture grouting mechanism based on model test. J. Rock Soil Mech. 35(11), 3221–3230 (2014).

Wang, K. et al. Grouting simulation experiment on reinforcement characteristics of completely decomposed granite. J. Tianjin Univ. (Sci. Technol.) 50(11), 1219–1229 (2017).

Huang, X. S. et al. Research on extension law of grouting induced splitting fractures in materials similar to coal rocks containing different prefabricated fractures. J. Saf. Coal Min. 52(3), 43–48 (2021).

Liu, C. et al. Extension of grouting-induced splitting fractures in materials similar to coal rocks containing prefabricated fractures. J. Geophys. Eng. 17(4), 670–685 (2020).

Li, L. C. et al. Study on induced mechanism of slurry splitting deviation and diffusion in long hole grouting near faults. J. Saf. Coal Min. 56(5), 159–171 (2025).

Zheng, C. C. Simulation study of grouting in fractured rock mass. D. Doctoral Thesis of Central South University of Technology (1999).

Ruan, W. J. Study on basic properties of grout and grouting diffusion of rock fracture. D. Doctoral Dissertation of Jilin University (2003).

Zhang, Z. X., Dong, Z. N. Viscous Fluid Mechanics. M. 2nd Edition. Beijing: Tsinghua University Press (2011).

Zhang, J. X. Study on the Properties of Rheology-Solidification of Time-depending Viscous Grout and Diffusion Mechanism. D. Chengdu University of Technology (2020).

Yu, W. S. et al. Model test research on hydrodynamic grouting for single fracture with variable inclinations. J. Rock Soil Mech. 35(8), 2137–2149 (2014).

China Aviation Research Institute. Handbook of stress intensity factors. M. Science Press. (1981).

Funding

Key projects supported by the National Natural Science Foundation Enterprise Innovation and Development Joint Fund (U24B2041), the National Natural Science Foundation of China (52104240), and the General Project of Basic Research Plan of Natural Science in Shaanxi, China Province (2025JC-YBMS-541).

Author information

Authors and Affiliations

Contributions

Liu Zhaoxing: Supervision, Writing-review & editing,Data curation, Methodology, Writing-original draft, Project administration, Resources, Conceptualization, Writing-original draft. Dong Shuning: Conceptualization, Project administration, Supervision, Project administration, Resources.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Consent to publish

All authors of this article consent to publish.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhaoxing, L., Shuning, D. Research on the migration patterns and termination pressure of grouting slurry in horizontal boreholes within deep limestone aquifers. Sci Rep 15, 25222 (2025). https://doi.org/10.1038/s41598-025-08928-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-08928-w