Abstract

Pea-gravel grouting (PGG) is a composite material backfilled between segment and surrounding rock of a shield tunnel, requiring balanced mechanical properties and impermeability. However, the practice always faces an issue of the defects of harden PGG with local cavity, less dense or insufficient strength. In this paper, an experimental study was firstly carried out on the grouting slurry to determine its mix proportion by evaluating the workability and density, which showed that the rational w/b = 0.5 and 0.6 with a sodium bentonite content within 5 ~ 15%. A method was developed to simulate the construction process of PGG to cast the blocks with a size of 900 mm×500 mm×250 mm. Using the samples drilled from the blocks, the cylinder specimens with a diameter of 100 mm and a height of 200 mm were manufactured for testing the axial compressive strength and the modulus of elasticity of PGG, while those with a diameter of 170 mm and a height of 150 mm were repaired to be the circular truncated conic specimens for testing the PGG impermeability. Results show that whatever the w/b, the axial compressive strength and the modulus of elasticity of PGG decreased while the impermeability increased with the increase of sodium bentonite content. The increase of w/b results in the decrease of mechanical properties and impermeability of PGG. The optimal content of sodium bentonite with different w/b can be selected in a range of 5 ~ 15% regarding for the practical requirements and the economic feasibility and beneficial effect on environment protection. Formulas are proposed for predicting the axial compressive strength and the modulus of elasticity of PGG in practical application.

Similar content being viewed by others

Introduction

To meet the requirement of water supply in different regions of China, long distance water delivery projects have been built with a feature of crossing different underground geological conditions. In these projects, the hydraulic tunnels have been constructed by the tunnel boring machine (TBM) in recent years1,2. Compared with traditional drilling and blasting construction method, the TBM tunnel is constructed with the advantages of high construction efficiency and safety, small disturbance to surrounding rock, low project cost and beneficial environmental protection2,3,4.

During the construction of TBM tunnel, tunnelling, segment lining and pea-gravel grouting (PGG) are significant taches controlling project quality4,5. The PGG is hybrid with pea-gravel and grouting slurry, which is backfilled under a certain pressure to the annular gap between segment and surrounding rock. This forms a steady transition layer with adaptable modulus of elasticity to let compatible deformation of segment to surrounding rock, providing an effective impermeability to prevent water leakage6,7,8. During the backfilling process, many adverse conditions exist including tunnel boring machine operation5,7, surrounding rock deformation9,10, segments assembly11,12 and grouting slurry variation13,14,15,16. This makes the PGG face an issue of quality control in practice. The insufficient backfilling of PGG produces the defects of local cavity, less dense or insufficient strength, which may cause the deformation and settlement, even cracking of segment lining8,13,14,15,16. Meanwhile, the segment deformation and cracking can be caused by uneven grouting pressures, especially that the difference between the grouting pressures at the top and bottom of the tunnel has a significant impact on the overall deformation and opening of the joints between the segments16. As the results, the segment cracking and the joints opening can result in a water leakage of hydraulic tunnel, whereas the internal water leakage will cause the soften of surrounding rock to raise a safety problem of the tunnels15. Moreover, the internal water leakage will reduce the water delivery efficiency of tunnels, even result in the change of underground environment along the water delivery project. Therefore, a second slurry grouting increases the construction procedure, and the project inspection quantity and cost. Therefore, the countermeasures are always needed to improve the PGG backfilling technique9,10,16,17. Meanwhile, the PGG properties should be changed to fit for the requirement of different hydraulic shield tunnels. For examples, for the No. 1 tunnel in north route of Wanjiazhai Yellow River Diversion Project, the PGG had an axial compressive strength of 15 MPa and the permeability coefficient less than 1.0 × 10− 5 cm/s17, whereas for the tunnel of Tao River Division Project, the PGG was demanded an axial compressive strength of 15 MPa, and the dense mortar at bottom inverted segment18. Moreover, the PGG quality relies on the mix proportion and preparation of grouting slurry19,20. This promotes the optimal investigations of mix proportion considered effects of pea-gravel particles21, superplasticizer22, gypsum dehydrate23 or soluble glass24. Generally, increasing pea-gravel particle size will decrease the PGG strength, adding superplasticizer and gypsum dehydrate will improve the slurry fluidity to make a dense PGG, and admixing soluble glass can enhance the slurry strength. Based on the constituents of grouting slurry, the PGG can be categorized into three main groups namely cement-based grouts with cement as binder, lime-based grouts with lime as biner, and bi-component grouts with cement or lime and other mineral admixtures, chemical additives as the binders25.

Meanwhile, the concept of plastic concrete has been applied in the PGG preparation. This comes from the same characteristics of them having low strength with a rational modulus of elasticity to transfer a larger deformation26,27, and low permeable coefficient to ensure water impermeability28,29. Except for common constitutes of plastic concrete, bentonite is always used to replace partial cement to reduce grouting cost, and maintain steady to avoid pump-pipe blocking during grouting30. The plastic concrete presents a decrease in workability, density, strength, and modulus of elasticity with the increase of bentonite content31,32,33, while the long-term strength trends to have a high development with the curing age over than 56 days34,35. Comparatively, sodium bentonite is better than calcium bentonite to improve the mechanical property and impermeability of plastic concrete, since the filling effect of fine grains of sodium bentonite on the pores of plastic concrete36,37. Therefore, referenced the studies of plastic concrete, sodium bentonite can be used as an admixture to prepare grouting slurry for the PGG construction.

In view of the importance of PGG in the TBM tunnel construction, the study on grouting slurry is still necessary to ensure the filling quality into the close packing pea-gravel. Meanwhile, how to manufacture the specimens in lab to simulate the PGG construction is a gap that has not been involved previously. Therefore, the rational water to binder ratio (w/b) and sodium bentonite content were firstly studied to determine the mix proportion of grouting slurry with reasonable workability. A method simulated the practical backfilling process of PGG was developed to produce the PGG blocks, and the core cylinder samples were drilled from the blocks to manufacture the PGG specimens for testing the axial compressive strength, the modulus of elasticity and the impermeability. Test results are analyzed and discussed to get the adaptable PGG for engineering application. The predicted method for the axial compressive strength and the modulus of elasticity are also proposed for practical design.

Materials and methods

Raw materials

The cement was P·O 42.5 common Portland cement produced by Weihui Tianrui Cement Co. Ltd, Henan, China. The properties were measured according to the specifications of China code GB 17538, and summarized in Table 1.

The sodium bentonite was produced by Xinyang Zhongshan Bentonite Co. Ltd. Henan, China. The product specification was 200 mesh in accordance with China code JB/T 922739, the physical properties are summarized in Table 2. Except the apparent density was measured in this study, other properties were provided by the manufacture.

The polycarboxylic acid superplasticizer was produced by Yuncheng Niji Factory, Shanxi, China. The properties were measured according to the specifications of China code GB 807640, results are presented in Table 3. The admixing water was the tap water of Zhengzhou city, China.

The pea-gravel was the crushed stone with a particle size of 5 ~ 10 mm in continuous grading, which was tested in accordance with the China code SL/T 35241. Results are summarized in Table 4.

Test methods for grouting slurry

The workability of grouting slurry was expressed by the indices of fluidity, bleeding rate and setting time. Rational fluidity provides a filling ability of grouting slurry among pea-gravel particles under a certain pressure, which is measured using the cone slump flow test in accordance with the specifications of China code SL/T 35241. Lower bleeding rate makes a steady grouting slurry with a little free water separated from the solid grains, is determined using the measuring cylinder method specified in China code SL/T 6242. Proper setting time ensures a necessary time for the grouting slurry reached a certain area from the grouting point, and then remained steady without a continue flowing, which is measured using the needle penetration method specified in China code GB/T 134643.

The pure cement slurry was firstly tested to select a rational range of w/b in view of the requirement with the compressive strength of PGG over 10 MPa at a curing age of 28 days. The tested water to cement ratio was from 1.2 to 0.5, resulting that the bleeding rate decreased from 24.8 to 10.4%, the final setting time shortened from 23.0 h to 14.2 h, while the compressive strength increased from 10.3 MPa to 40.0 MPa. As is known, the bleeding rate represents a volume percent of bleeding water to total slurry at initial setting period, which should be restricted to avoid a heavy separation of water from solid grains into sedimentation or layering the slurry. Therefore, to get a steady grouting slurry, the cement slurry with a content of sodium bentonite less than 20% was further studied using the w/b = 0.5 and 0.6, considered possible strength reduction of grouting slurry with the admixing of sodium bentonite44,45,46. Based on previous researches summarized, the w/b values fall into the rang of 0.4 ~ 1.1 for cement-based and lime-based grouts, and close to 0.5 for bi-component grouts25. This indicates the rationality of w/b = 0.5 and 0.6 used in this study.

Test methods for PGG

Preparation of specimens

For each PGG that formed using the stacked pea-gravel filled with grouting slurry, the number and size of test specimens were in accordance with the specifications of China codes GB 5008147 and GB 5008248. Two groups of six cylinders with a diameter of 100 mm, three as a group, were used for testing the axial compressive strength and the modulus of elasticity, one group of six cylinders with a diameter of 170 mm were used for measuring the impermeability. Therefore, twelve specimens were tested for each PGG.

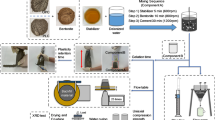

To simulate the PGG used in engineering, a block was firstly produced to create all specimens of each PGG. As shown in Fig. 1, the block with the operation space of drilling machine was designed with a size of 900 mm long, 500 mm wide and 250 mm high. The ϕ100 mm cylinder samples were drilled at two end-parts, and the ϕ170 mm samples were drilled at the central part.

The production of a block followed the process that simulates the backfilling of PGG in annular gap between segment lining and surrounding rock, details are stated as below:

-

(1)

A mould was formed with three steel plates as the formworks of width and bottom, and three acrylic plates as the formworks of length and top. The grouting hole was at the center of bottom formwork. This simulates the formation of gap and the grouting hole on segment.

-

(2)

The mould was fully filled with the pea-gravels, as shown in Fig. 2a), and then the top formwork was fixed. This simulates the backfilling of pea-gravel in the gap.

-

(3)

The grouting slurry was grouted from the grouting hole into the mould under a pressure of 0.8 MPa, as shown in Fig. 2b), until it fully filled into the gaps of pea-gravel. Through the transparent acrylic plates, the filling status of grouting slurry among pea-gravel particles could be viewed, and the quality of PGG could be controlled in the backfilling process of grouting slurry. This simulates the backfilling of grouting slurry into the gap under a rational pressure.

-

(4)

After formation of a block for 24 h, the mould was removed, as shown in Fig. 2c), and covered with a plastic film for 6 days. This simulates the formed pea-gravel grouting that naturally cured in the gap in a condition without underground water passed through surrounding rocks.

-

(5)

The cylinder samples were drilled from the block using the core drilling machine, as shown in Fig. 3. This is a special step added for drilling samples for testing.

-

(6)

The ends of samples with a diameter of 100 mm and 150 mm were cut and parallelly planished to be the specimens with a height of 200 mm and 170 mm, respectively for the tests of mechanical properties and the impermeability. All specimens were cured for another 21 days in a standard curing room at a temperature of (20 ± 5) oC and a RH ≥ 95% before testing. Therefore, the mechanical properties and impermeability of PGG were measured at the age of 28 days. The curing condition was basically a standard curing that simulated the backfilling of PGG without the influence of underground water pass through surrounding rocks.

Test for mechanical properties

Test for mechanical properties of PGG specimens was conducted using the computer controlling WAW-600 electro-hydraulic servo universal testing machine produced by Shanghai Longhua Testing Machine Co. Ltd. China. Due to the standard size of specimens for concrete is specified as ϕ150 mm×300 mm, test results of axial compressive strength in this study were multiplied a coefficient of 0.9547.

Test for impermeability

As specified in China code GB/T 5008248, the specimen for testing the concrete impermeability is a circular truncated cone with diameters of 175 mm at top surface and 185 mm at bottom surface, and a height of 150 mm. Therefore, how to reform a ϕ170 mm cylinder specimen to be a standard circular truncated cone is a key technique that determines the success of testing. In this aspect, several kinds of materials were explored to fill the gap between the cylinder specimen and standard mould, including the epoxy resin mortar, the quick setting cement with sealing rubber ring, the structural adhesive with quick setting cement and cement butter mixture, and the structural adhesive with quick setting cement and paraffin. Finally, the last one was used in this study. As presented in Fig. 4a), a cylinder specimen was firstly coated with a thin layer of neutral silicone structural adhesive. Waiting for the adhesive dried, the specimen was set into a standard steel mould, and the filling material was filled in the gap to form a standard specimen. One day later, the mould was removed, the standard specimen was formed, as shown in Fig. 4b).

The impermeability of specimens was measured on an impermeability meter with a step pressure method48. Six specimens as a group were wrapped respectively with liquid paraffin, and pressed into a testing steel mold. After held the pressure for 5 min, the hardened paraffin could seal the surface of specimens to the testing steel mold. After that, the steel mold was fixed on the test instrument, and the water pressure was exerted until the water seepage took place on two of the six specimens. The impermeability class of PGG is determined using formula (1) as follow,

Where, W is the impermeability class of PGG, MPa; H is the water pressure when the water seepage takes place on two of six specimens, MPa.

Properties of grouting slurry

Workability

As mentioned earlier, the indices of fluidity, bleeding rate and setting time was used to express the workability of grouting slurry. As presented in Fig. 5 for the test results of the fluidity, it is easy to understand that the grouting slurry with a higher w/b had a larger fluidity, owing to that more free water was provided in the slurry. The presence of sodium bentonite created a continuous decrease of the fluidity with the increase of sodium bentonite content. When the sodium bentonite content reached 20%, a sharp decrease of fluidity took place, especially on the grouting slurry with a w/b = 0.5. This may attribute to the high absorption of the main component of sodium bentonite, the montmorillonite with looseness structure. With the increase of sodium bentonite content, a larger amount of mixing water was absorbed by the montmorillonite, resulting in an increase of slurry consistency. At the same time, the irregular grains of sodium bentonite made them easily gather to increase the friction between grains, leading to a further decrease of fluidity45.

The measured bleeding rate are presented in Fig. 6. The presence of sodium bentonite obviously improved the bleeding of grouting slurry. When the w/b = 0.5, the bleeding rate was below 1% even with a sodium bentonite content of 5%. When the w/b = 0.6, the bleeding rate decreased to be 2% with a sodium bentonite content of 10%. This indicates that the free water in grouting slurry can be retained by the montmorillonite of sodium bentonite with better water absorption47.

As shown in Fig. 7 for the test results of the setting time of grouting slurry, both the initial and the final setting time of grouting slurry could be shortened by admixing sodium bentonite even at a content of 5%, which could be continuously shortened with the increase of sodium bentonite content. Meanwhile, the grouting slurry with a low w/b had a shorter setting time. This contributes from the hydration of cement which releases calcium ion Ca2+ adsorbed effectively by the grains of sodium bentonite with negative charges on surfaces. In this process, the exchange absorption takes place between Ca2+ and Na2+, leading to the spacing reduction between montmorillonites and the releasing of bound water35,36,37. The released water promotes the hydration of cement to shorten the initial and the final setting time. On the other hand, the slurry with a low w/b gives a large amount of cement grains to produce much more hydrates to shorten the setting time.

Density

Table 5 summarizes the test results of the density of grouting slurry, presenting a higher density for the grouting slurry with a low w/b = 0.5. Meanwhile, the density of grouting slurry tended to decrease with the increase of sodium bentonite content, while it had a larger decrement with a low w/b. This attributes to the composition of grouting slurry. Since sodium bentonite is lighter than cement about 16.8% in this study, as presented in Tables 1 and 2, a greater volume than the replaced cement can be given in a same mass, leading to a decrease of the density of grouting slurry.

Practical mix proportion used for Preparing PGG

Based on above experimental study, the sodium bentonite content was rational within 5 ~ 15% that replaces cement in an equal mass. For the pea-gravel with a bulk porosity of 40%, the cement dosage was 1072 kg/m3 or 1200 kg/m3 in grouting slurry with a w/b of 0.6 or 0.5. With a content of superplasticizer at 1% mass of binder, the practical mix proportion of grouting slurry used for preparing PGG are summarized in Table 6. In which the pure cement slurry was also included for the comparison in this study.

Properties of PGG

Axial compressive strength

The failure patterns of specimens under uniaxial compression are exhibited in Fig. 8. For the PGG with different w/b, similar failure pattern appeared on specimens with the same sodium bentonite content. When loaded up to 80% the ultimate, some concrete debris felled off the specimen surface. At the failure state, a wider vertical crack while a sounder burst appeared on the specimens without sodium bentonite, the specimen is poor in entirety. With the increase of sodium bentonite content, the specimens presented notable improvement in brittleness with multi vertical cracks and better entirety. This shows that with the increase of sodium bentonite content, the transversal deformation increased on the specimens, which was dispersed with multi cracks to avoid a sudden broken.

Test results of the axial compressive strength of specimens varied with w/b and sodium bentonite content are drawn in Fig. 9. Whatever the w/b, the axial compressive strength of specimens decreased with the increase of sodium bentonite content, and a higher decrease took place at 5% sodium bentonite content. This indicates that the admixing of sodium bentonite changed the composition of binder, resulting in a different hydration process of binder compared to pure cement. The sodium bentonite mainly contributes to the filling effect in PGG, which does not fully possess the binder property although can be weakly reacted with the byproducts of cement hydrates49. Meanwhile, the sodium bentonite has a higher water absorption, which may absorb large amount water to disturb the hydration of cement, leading to insufficient water for cement hydration50. Undoubtedly, the specimens with a higher w/b presented a lower axial compressive strength.

Fitting analysis is done based on test results, a formula is built for predicting the axial compressive strength of PGG with the influences of w/b and sodium bentonite content as follow,

.

Where, fc is the axial compressive strength of PGG, MPa; w/b is the water to binder ratio; Rsb is the sodium bentonite content, %.

The comparisons of test results to calculated ones using formula (2) are shown in Fig. 10. The correlation coefficient R2 = 0.943 and 0.980 respectively for the PGG with w/b = 0.5 and 0.6, when the sodium bentonite content varies from 0 to 15%.

Fitness of test data using formula (2) for the axial compressive strength.

Modulus of elasticity

Test results of the modulus of elasticity of specimens varied with w/b and sodium bentonite content are drawn in Fig. 11. Whatever the w/b, the modulus of elasticity of specimens decreased with the increase of sodium bentonite content, and a higher decrease took place at 5% sodium bentonite content. This is similar to the variation of axial compression strength of specimens discussed above, owing to the positive relationship between modulus of elasticity and axial compressive strength.

Fitting analysis is done for the test results, a formula is built for predicting the modulus of elasticity in relation to the axial compressive strength of PGG as follow,

.

Where, Ec is the modulus of elasticity of PGG, MPa; fc is the axial compressive strength of PGG, MPa; Rsb is the sodium bentonite content, %.

The comparisons of test results to calculated ones using formula (3) are shown in Fig. 12. The correlation coefficient R2 = 0.743 for the PGG with w/b = 0.5 and 0.6, when the sodium bentonite content varies from 0 to 15%.

Fitness of test data using formula (3) for the modulus of elasticity.

Impermeability

Test results of the impermeability of specimens varied with w/b and sodium bentonite content are drawn in Fig. 13. Although the impermeability class was the same at W4 for PGG without admixing sodium bentonite, the PGG with w/b = 0.5 presented a longer time to resist the pressure of 0.5 MPa than that with w/b = 0.6. This indicates that the PGG with a lower w/b gave a real higher impermeability. With the increase of sodium bentonite content, the impermeability of PGG increased, and the PGG with 5% and 10% sodium bentonite presented a high increment, while those with 15% sodium bentonite reached the highest of W9 and W8. This was owing to the finer grains of expansive montmorillonite which can effectively fill the pores and extrude surrounding compositions to form a compacted structure51. Meanwhile, through the interaction of positive and negative charges, sodium bentonite grains can adsorb a large number of free water molecules, which further reduces the free water to enhance the impermeability of PGG. When the w/b varied from 0.5 to 0.6, the PGG decreased in impermeability. This attributes to the higher volume free water in PGG, which forms many micro-pores that can be connected during the hardening process52.

General discussion

Based on the test results of mechanical properties and impermeability of PGG, the addition of sodium bentonite decreases the axial compressive strength and the modulus of elasticity, and conversely increases the impermeability. This means that the optimal content of sodium bentonite should be selected according to the requirement of real project, since different PGG is needed for the tunnels of water delivery under different surrounding rocks and underground water condition20,25. In addition, the economic feasibility should be concerned about for the PGG with cement replaced by bentonite substitution. With current market prices of cement and sodium bentonite and referencing the mix proportion of Table 6, the cost of PGG has an increase of 5.8%~19.3% with a 5%~15% content of sodium bentonite. However, the use of sodium bentonite has a favorable effect on the environmental protection since the production of sodium bentonite is simple by natural mineral without hazardous substances.

Conclusions

Based on the study of this paper, conclusions can be made as follows:

-

(1)

The optimal content of sodium bentonite was 5%~15%, based on a series of experiment study on the properties of grouting slurry with w/b = 0.5 and 0.6. The grouting slurry had a good flowability which presented a less decrease with the increased content of sodium bentonite, while the water bleeding rate presented a markable reduction, and the initial setting time changed from 10.3 h to 6.5 h while the final setting time changed from 12.1 h to 7.5 h. This ensures the grouting slurry was better in workability for practical application. Meanwhile, the density of grouting slurry also decreased with the increase of sodium bentonite content.

-

(2)

The axial compressive strength of PGG decreased with a higher w/b and an increased content of sodium bentonite. The axial compressive strength of PGG with w/b = 0.5 decreased from 16.1 MPa to 11.6 MPa with the increased content of sodium bentonite from 5 to 15%, while that of PGG with w/b = 0.6 decreased from 14.9 MPa to 8.1 MPa. Similar variations existed on the modulus of elasticity with the sodium bentonite content and w/b.

-

(3)

For testing the impermeability of PGG, a method was developed for mending the PGG cylinder samples drilled from the simulated PGG block to be the standard specimens of circular truncated cone. The impermeability of PGG with w/b = 0.5 increased from W6 to W9 with the sodium bentonite content increased from 5 to 15%, while that of PGG with w/b = 0.6 increased from W5 to W8. Therefore, the addition of a rational content of sodium bentonite can effectively improve the impermeability of PGG.

-

(4)

The optimal content of sodium bentonite with different w/b can be selected regarding for the practical usage of PGG in water delivery tunnels, concerning about the economic feasibility and the beneficial effect on environment protection.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reason able request.

References

Du, L. Progressions, challenges and countermeasures for TBM construction technology in China. Tunn. Constr. 37 (9), 1063–1075 (2017).

Liu, Q. et al. Application and development of hard rock TBM and its prospect in China. Tunn. Undergr. Space Technol. 57, 33–46 (2016).

GB/T 51438 – 2021. Standard for Design of Shield Tunnel Engineering (China Building Industry Press, 2021).

GB 50446 – 2017. Code for Construction and Acceptance of Shield Tunnel (China Building Industry Press, 2017).

Zhang, Z. et al. Safety risk assessment of TBM tunnel construction based on fuzzy evidence reasoning. Processes 10 (12), 2597 (2022).

Zhao, D., Jing, L. & Yang, W. Numerical analysis of segment linings in deep and long tunnels of West route of south-to-north water transfer project. Chin. J. Rock. Mechan Eng. 24 (20), 81–86 (2005).

Shaterpour-Mamaghani, A., Tumac, D. & Avunduk, E. Double shield TBM performance analysis in difficult ground conditions: a case study in the gerede water tunnel. Turk. Bull. Eng. Geol. Environ. 75 (1), 1–12 (2016).

He, Y. et al. Case study of the impacts of pea-gravel grouting defects on loading responses of TBM tunnel segment lining with different surrounding rocks. Results Eng. 27, 105807 (2025).

Liu, L. Pea-gravel backfilling grouting technology of TBM construction, water resour. Hydropower Eng. 43 (6), 63–66 (2012).

Jin, C. & Gao, Z. Analysis and countermeasure of pea gravel backfilling grouting for TBM pipe with double shield. Yunnan Water Power. 37 (7), 181–118 (2021).

Li, F., Si, P., He, Y., Wang, H. & Zhang, Z. Case studies of the load-bearing performance of shield tunnel segment with misaligned defects. Sci. Rep. 14, 17370 (2024).

Li, F. et al. Numerical analysis of the single-directionally misaligned segment behavior of hydraulic TBM tunnel. Buildings (14), 2198 (2024).

Zhang, J., Huang, Q., Wang, X., Hu, C. & Zhang, S. Study on engineering influence of defects in pea gravel backfilling and grouting layer. Mod. Tunn. Technol. 58 (6), 163–172 (2021).

Yang, F., Jin, J. & Yang, F. Influence of backfill grouting property and compactness of TBM pea-gravel on supporting effect. Yellow River. 46 (1), 139–145 (2024).

Zhao, S. et al. Bearing performance of shield tunnel lining segments affected by softened base due to internal water leakage. J. Water Resour. Water Eng. 35 (3), 201–206 (2024).

Liu, T., Zhang, S., Yu, K. & Liu, H. Tunnel lining segment deformation and cracking mechanisms during tunneling in complex mixed grounds with the combined mining and shield tunneling method. KSCE J. Civ. Eng. 27 (1), 399–416 (2023).

Zheng, R. Design and construction of pea-gravel grouting for 1 tunnel in North route of Wanjiazhai yellow river diversion project. Water Resour. Hydropower Eng. 38 (5), 39–40 (2007).

Fan, C. Analysis on key points to control engineering quality of tunnel constructed by TBM in Tao river delivery project and the countermeasure. Shanxi Hydrotechnics. 3, 64–65 (2008).

Wang, F. Application of filling grouting into pea gravel of tunnel constructed by TBM. Shanxi Hydrotechnics. 3, 33–34 (2009).

Jiang, X. et al. A state-of-art review on development and progress of backfill grouting materials for shield tunneling. Develop Built Environ. 16, 100250 (2023).

Yu, S. Quantitative Analysis of the Morphological Characteristics of Pea-gravel and Its Simulation Test of Backfill Grouting. Thesis for Master Degree, Chengdu University of Technology, (2019).

Wang, Y. & Gao, Q. Exploration of TBM grouting construction for CCS project of Ecuador. Sichuan Water Power. 33 (4), 36–39 (2014).

Chen, M. Research and Development of TBM Tunnel Bean Gravel Backfill Grouting Material and Its Hydration Mechanism, Thesis for Master Degree, North China University of Water Resources and Electric Power, China (2023).

Shi, H. Discussion on construction technology of pea gravel backfill grouting in TBM water tunnel. Water Resour. Hydropower Northest. 39 (9), 16–18 (2021).

Mohammadzamani, D., Lavasan, A. A. & Wichtmann, T. On design and assessment of tail void grouting material in mechanized tunneling: a review. Geotech. Geol. Eng. 41 (7), 4233–4255 (2023).

Sadrekarimi, J. Plastic concrete mechanical behaviour. J. Institution Eng. India Civ. Eng. Div. 82, 201–207 (2002).

Gao, D. & Song, S. Performance and strength calculation model of plastic concrete under conventional tri-axial stress. J. Hydroelectric Eng. 33 (2), 201–207 (2014).

Zhang, L., Tang, J. & Yang, M. Research on impermeability of plastic concrete. Concrete 2, 1–3 (2010).

Li, Q. & Zhang, P. Experiment on impermeability of plastic concrete. Indust Constr. 4, 48–51 (2007).

Lima-Guerra, D. J., Mello, I., Resende, R. & Silva, R. Use of bentonite and organobentonite as alternatives of partial substitution of cement in concrete manufacturing. Intern. J. Concr Struct. Mater. 8 (1), 15–26 (2014).

Memon, S. A., Arsalan, R., Khan, S. & Lo, T. Y. Utilization of Pakistani bentonite as partial replacement of cement in concrete. Constr. Build. Mater. 30, 237–242 (2012).

Zhang, P., Guan, Q. & Li, Q. Mechanical properties of plastic concrete containing bentonite. Res. J. Appl. Sci. Eng. Technol. 5 (4), 1317–1322 (2013).

Taklymi, S. M. Q., Rezaifar, O. & Gholhaki, M. Investigating the properties of bentonite and Kaolin modified concrete as a partial substitute to cement. SN Appl. Sci. 2 (12), 1–14 (2020).

Liang, M., Lv, X., Gao, D., Yan, K. & Song, S. Analysis of the influence of clay dosage and curing age on the strength of plastic concrete. Adv. Mater. Res. 936, 1433–1437 (2014).

Mesboua, N., Benyounes, K. & Benmounah, A. Study of the impact of bentonite on the physico-mechanical and flow properties of cement Grout. Cogent Eng. 5 (1), 1446252 (2018).

Song, Q. Influence of bentonite types on the properties of plastic concrete. J. Hydroelectric Eng. 28 (3), 112–116 (2009).

Tang, B., Cui, W., Zhang, B. & Jiang, Z. Effect of bentonite on mechanical properties of plastic concrete and its microscopic mechanism. J. Build. Mater. 26 (12), 1254–1261 (2023).

GB 175–2007. Common Portland Cement (China Standard Press, 2007).

JB/T 9227 – 2013. Bentonite for Foundry (Mechanical Industry Press, 2014).

GB 8076 – 2008. Concrete Admixtures (China Standard Press, 2008).

SL/T 352–2020. Specifications for Test Methods of Hydraulic Concrete (China Hydropower Press, 2020).

SL/T 62-2020. Technical Specification for Cement Grouting of Hydraulic Structures (China Hydropower Press, 2020).

GB/T 1346–2011. Test Methods for Water Requirement of Normal Consistency, Setting time and Soundness of the Portland Cement (China Standard Press, 2011).

DL/T 5786 – 2019. Code for Mix Design of Hydraulic Plastic Concrete (China Electric Power Press, 2019).

Chen, L., Lu, J., Zhang, Y. & Cui, D. Experimental study on ratio and performance for bentonite cement slurry. EWRHI 42 (3), 55–60 (2021).

Fei, Z., Wu, J., Ming, H., Ke, R. & Shi, C. Study of ratio of cement-bentonite slurry and its applicability. J. China Three Gorges Univ. (Nat Ed). 41 (4), 51–54 (2019).

GB/T 50081 – 2019. Standard for Test Methods of Physical and Mechanical Properties on Concrete (China Building Industry Press, 2019).

GB/T 50082 – 2009. Standard for Test Methods of Long-term Performance and Durability of Ordinary Concrete (China Building Industry Press, 2009).

Ding, G., Jiang, L. & Zhang, J. Influence of bentonite on hydrating and hardening of cement. J. Wuhan Univ. Technol. 34 (4), 20–23 (2012).

Kong, X., Lu, Z. & Zhang, C. Recent development on Understanding cement hydration mechanism and effects of chemical admixtures on cement hydration. J. Chin. Ceramic Soci. 45 (2), 274–281 (2017).

Han, X. Research on mix proportion design of concrete based on workability. Concrete 2, 60–66 (2022).

Wang, Y., Li, J., Zhu, G. & Zhou, S. Characteristics of plastic concrete for impervious core wall of TGP cofferdam II. J. Yangtze River Sci. Res. Inst. (1), 31–34 (2001).

Acknowledgements

This study was financially supported by the Fund of First-class Discipline Innovation Team of Henan, China (CXTDPY-6), and the Key Sci-Tech Project in University of Henan, China (22A560012).

Author information

Authors and Affiliations

Contributions

C.L., Y.Y. and B.Z. wrote the main manuscript text and C.L. revised the manuscript, K.W. and Y.H. participated the investigation and analyzed test data, S.Z. proposed the methodology of research and supervised the research. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, C., Yang, Y., Zhou, B. et al. Preparation and properties of pea-gravel grouting with sodium bentonite for hydraulic shield tunnel. Sci Rep 15, 26776 (2025). https://doi.org/10.1038/s41598-025-12061-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-12061-z