Abstract

In this study, self-developed intelligent detection equipment was used to quickly detect the key parameters of peripheral eyes and scan the cross-section over-excavation based on the double-track tunnel project at Chongqing University Town. The correlation between the two was clarified using ANSYS/LS-DYNA finite element methods and then, the blasting drilling scheme was optimized. Three-dimensional imaging technology Integrated with high-precision laser scanning and an intelligent positioning system, is employed to acquire precise data regarding the excavation of the cross-section. The three-dimensional imaging technology intuitively represents the actual outline of the surrounding rock by creating a three-dimensional model of the tunnel excavation cross-section. The intelligent positioning system tracks the spatial coordinates of the blasthole in real time to ensure the accuracy of the position parameters of the peripheral eye. The results show that the positional deviation of the borehole in the perimeter eye can lead to significant over-excavation of the tunnel section, especially in the tunnel top and shoulder area. The field data show that when the average position deviation range of peripheral eyes is 17–23 cm, the over-excavation circumference of the tunnel measures 25.55–35.39 cm. The numerical simulation shows that the over-excavation caused by the spatial position deviation of the peripheral eye is approximately 2–3 times more than that caused by angular deviation, with average over-excavation in the top and shoulder areas of the tunnel reaching 45 cm and 18 cm, respectively. By implementing an optimized drilling strategy, the position deviation can be reduced to within 10 cm and the angular control can be improved, hence reducing the average over-excavation to 5 cm. The result serves as a benchmark for the further development of intelligent tunnel construction technology and the optimization of blasting construction under similar geological conditions.

Similar content being viewed by others

Introduction

There are two main objectives in tunnel blasting construction: to achieve a faster tunneling speed and to minimize the damage to the surrounding rock mass1. Owing to its advantages of high efficiency, economy and good applicability, the drilling and blasting method is the primary construction method for tunnel excavation at home and abroad2. However, there are some problems in the current tunnel construction by drilling and blasting method, such as the difficulty of accurately estimating the blasting load and the low technical level of construction personnel3. These problems make the blasting effect difficult to meet the design requirements, resulting in an excessive damage range to the surrounding rock, and the phenomenon of over-excavation and under-excavation is serious. Excessive excavation may destroy the stability of surrounding rock and increase the difficulty and cost excavation. Under-excavation affects the effective cross-section of the tunnel and compromises the subsequent safety of construction and use4,5,6. Therefore, it is of great importance to analyze the influence of the position parameters around the tunnel blasting hole on the over-excavation and under-excavation of the tunnel to improve the safety and efficiency of mountain tunnel construction, together with the economy and quality of the project.

To control over-excavation of tunnel blasting, many scholars conducted numerous studies and technical investigations with various methods and achieved some research results. Gong et al.7 effectively controlled the problem of over- and under-excavation in cutting blasting excavation of long footage straight holes in a medium section tunnel by adjusting the charge of the cutting hole and surrounding eye and improved the efficiency and quality of the blasting. Chen et al.8 proposed a blasting scheme with a density coefficient of 1.0 and a blocking length of 30 cm as parameters, which effectively solved the problems of over-excavation and under-excavation in the blasting of a full-section tunnel of hard granite. Yu et al.9 achieved a good blasting effect, effectively controlled the over-excavation and under-excavation, and improved the flatness of blasting contour by setting the offset hole with an offset hole angle of 15°. Salum et al.10 effectively controlled the over-excavation caused by blasting by rationally designing the blasting mode and minimizing the charge of the peripheral eye, and characterizing the rock in combination with ground vibration monitoring. Mao et al.11 proposed a method for detecting over-excavation and under-excavation in tunnels based on a high-density point cloud to quickly and effectively determine the centerline of the tunnel. They also investigated the optimal way of to set the sampling parameters under point cloud. Carter-Greaves et al.12 developed a new method that can improve the degree of automation and intelligence level of in detecting over- and under-excavation in the tunnel construction stage by combining 3D laser scanning technology with other information technologies.

Previous studies have shown that the parameters of the peripheral borehole play a key role in tunnel excavation in the drill and blast process to approximate the excavation profile to the positive section. The most important parameters are the angle of the blast hole, the charge of the blast hole, the position of the blast hole. According to the statistical analysis in “Technical Rules for Highway Tunnel Construction” (JTG/T F60-2009), among many factors affecting over-excavation and under-excavation, drilling accuracy and blasting technology have the greatest influence, which are 44.2% and 20.3% respectively. etc.13. The angle of the blast hole determines the direction of the cracks and debris created by the blast. By adjusting the angle of the blast hole, the direction and range of the blast can be controlled. The charge determines the strength and effect of the blast. Reasonable adjustment of the charge can fulfill the purpose of controlling the blast to control the situation of over-excavation and under-excavation. The position of the blast hole determines the stress concentration area generated by blasting, and by reasonably selecting the position of the blast hole, uniform rock crushing can be achieved14,15,16. Therefore, accurately determining the position of the blasthole according to the geological conditions and engineering conditions before blasting can effectively avoid over-excavation or under-excavation. However, with the existing equipment, it is difficult to quickly and accurately measure the exact parameters of peripheral eyes and analyze their influence on over-excavation and under-excavation during blasting.

Based on a double-track tunnel in Chongqing, this paper examines the influence of peripheral eyes on blasting over-excavation. First, the working principle of the self-developed automatic detection system for the effects of tunnel blasting is introduced. The system consists of two types of core equipment: a device for detecting blasthole parameters and a device for scanning the blast excavation profile. The blasthole parameter detection device can measure the position, angle and depth of the blasthole in real time, while the blasting excavation contour scanning device is used to obtain the tunnel section after blasting and accurately record the over-excavation data. In combination with these measurements, the finite element software ANSYS/LS-DYNA (Ansys LS-DYNA 19.0, URL link: https://www.ansys.com/zh-cn/products/structures/ansys-ls-dyna) is used to perform numerical simulation analysis of the correlation between the parameters of the peripheral hole and the over-excavation, and the influence of the deviation from the position of the blasthole and the angle on the over-excavation caused by the blasting is compared and analyzed. The research results can be used to optimize the blasting drilling strategy used in tunnel engineering.

System for detecting the effects of tunnel blasting

At the tunnel construction site, the blasthole parameters and over-excavation data acquired with the help of the self-developed system for the detection of blasting effects. The system mainly consists of a device for detecting blasthole parameters and a device for blast excavation profile scanning.

Blasthole parameter detection equipment

The blasthole parameter detection equipment mainly consists of five parts, which can measure blastholes with different size parameters and determine the actual position of the blasthole opening, charge, and opening angle. The detection equipment is shown in Fig. 1, and the composition of the functional modules of the detection equipment is shown in Fig. 2.

The working principle of the main components of the functional module is as follows: the detection tube is the core component extending into the blast hole and is used to measure the blast hole data. When measuring, the end of the detection tube protrudes into the actual depth of the blast hole, and its length can be adjusted by the telescopic connecting tube. The laser measurement module integrates a high-precision 3-axis accelerometer, 3-axis gyroscope, 3-axis magnetometer and a laser infrared detector. It uses a cutting-edge microprocessor, advanced dynamic calculation system and a Kalman dynamic filtering algorithm, which can quickly obtain and analyze the position and elongation of the detection device in real time to accurately measure the actual depth and angle of the blast hole. The module can also record the relative position of each blast hole, and automatically output the three-dimensional (X, Y, Z) coordinates of each blast hole to the industrial flat plate for comparative analysis of the planned blast hole position. The measurement accuracy reaches ± 0.1 mm, and the user interface is shown in Fig. 3. The data processing terminal integrates the battery module, display, wireless receiver, main circuit board and data storage and analysis module. It is responsible for receiving and processing the data transmitted by the measurement module and shows the actual angle and depth of the blast hole on the display with an accuracy of ± 0.1° and ± 0.1 mm respectively.

Blasting excavation contour scanning equipment

The blasting excavation contour scanning equipment can accurately scan the actual contour line of the mountain tunnel excavation section after blasting construction. The device adopts hybrid solid-state lidar for radar scanning and uses modular transmission and reception technology. The data acquisition speed can reach 430,000 points per second, the measurement range is 20 m, and the upward angle is 120° horizontally. The equipment can automatically scan the blasted contour line in a fixed state and generate a three-dimensional contour model. After the scanning is completed, the equipment calculates the data for the over- and under-excavation position data according to the design plan with one click, and analyzes these positions to draw the over- and under-excavation situation of each position. The equipment can comprehensively evaluate the blasting effect of each excavation cycle, as shown in Fig. 3, and the composition of the functional module is shown in Fig. 4.

The blasting excavation contour scanning equipment also consists of five parts: expression layer, interface layer, application layer, service layer and equipment layer. It scans the tunnel section after excavation and locates and analyzes the position and degree of over-excavation in combination with the parameters of the design section. The working principle of its main components is as follows: the presentation layer presents the scanning and analysis results intuitively, mainly on industrial tablets and PCs. The function of interacting with the blasthole parameter detection equipment is realized in the application layer, which mainly includes the interaction with the front-end blasthole detection equipment, three-dimensional model presentation and blasting plane presentation. The service is able to draw the cross-section profile of the excavated tunnel layer quickly and accurately with the help of advanced image synthesis and analysis engine Many key components are integrated in the device layer, including lidar scanners, intelligent positioning devices, and communication devices. The lidar scanner can accurately scan the tunnel excavation section after blasting, the intelligent positioning equipment can ensure that the equipment can accurately locate the contour in complex environments, and the communication equipment ensure real-time data interaction and remote control of the equipment.

Measurement of peripheral tunnel parameters

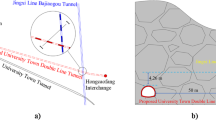

Project overview

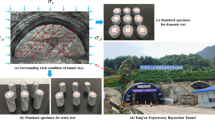

The supporting project is a double-track tunnel project in Chongqing. The total length of the tunnel is approximately 4075 m, with a two-hole separate layout and six lanes in both directions. The surrounding rock passing through the tunnel is mainly Class IV surrounding rock. According to the conditions of the surrounding rock, the two-step method and blasting excavation are mainly adopted to cooperate with the excavation. With the self-developed intelligent equipment to detect the blasthole parameters, 50 m before and after the intersection of the double-track tunnel in University Town and Chengdu-Chongqing Passenger Dedicated Line Tunnel are monitored. The left and right lines are detected every 10 m, and the data of 20 excavation sections are collected. In this paper, three sections with serious over-excavation and under-excavation (the average over-excavation thickness is 20 cm) are analyzed and investigated, namely DK4 + 125. 600 –DK4 + 210. 30, and all experimental sections are grade IV surrounding rock. According to the TSP advanced geological prediction of the tunnel project, the parameters of the surrounding rock are listed in Table 1.

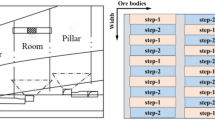

The optimal excavation footage of the two-step method is suggested: in poor geological conditions, an excavation footage of 2.0 m is recommended. In favorable geological conditions are preferred, it is recommended to increase the excavation footage by 4.0 m17,18,19,20. Due to the high demands on the objects to be protected in this project, the blasting cycle size of the cutting bench construction surface is designed to be no more than 1.5 m, and the blasting cycle size of the non-cutting bench working surface is designed to be no more than 2.0 m. The length of the peripheral blast hole is 1.6 m, and the charge of a single hole is 0.2 kg.

In view of the fact that the research focuses on tunnel excavation and forming but does not consider the influence of support stage, the upper step was selected as the main research object in this study. A short footage cycle is used in the construction, and the cycle footage is strictly limited to 1.5 m. The economic and technical indicators of blasting excavation are listed in Table 2, and the blasting parameters are listed in Table 3.

In the process of tunnel construction, it is very important to accurately measure the position of the surrounding eyes and to dynamically correct the construction scheme to control the over-excavation and under-excavation of the tunnel.

Study factor selection

In the actual blasting construction of a mountain tunnel, the over-excavation and under-excavation of the tunnel mainly consists of two parts: one is the surrounding rock damage caused by blasthole blasting, and the other is the surrounding rock caving height of the excavation section caused by surrounding eye parameters (the research object of this paper). As shown in formula (1).

where h is the overall over-excavation of the tunnel, units:m; Rl is the damage range of surrounding rock caused by blasting, units: m; Rh is the caving height of surrounding rock caused by the blast hole, units: m.

When performing perimeter hole drilling, the drilling rig should usually drill holes parallel to the design contour. However, due to the limitation of working space, the drilling direction may deviate from the outside of the design contour at a certain angle, which is referred to as the extrapolation angle a. When calculating the over-excavation height Rh caused by surrounding rock caving in China, it is calculated according to the extrapolation angle A of the peripheral hole, the opening offset e, and the depth L of the borehole, as shown in formula (2).

where L is peripheral blast hole length, units:m; a is peripheral eye angle, according to the measured value, units: °; e is Blast hole position and design error (opening error), units: m.

In essence, the theoretical model shows that the angle deviation mainly affects the deviation of the end point of the blast hole, while the position deviation affects the initiation coverage of the whole tunnel, and the two have superimposed effects on the surrounding rock disturbance. Therefore, this paper primarily examines the position and angle deviation of the peripheral hole from two perspectives: over-excavation and under-excavation.

Collection of the measured parameters of the blasthole

The self-developed intelligent blasthole parameter acquisition equipment was used to monitor the data of the IV surrounding rock excavation area from section DK4 + 125. 600 to section DK4 + 210. 30 of the double-track tunnel in University Town. Three groups of tests were conducted on the left and right lines in each excavation area in five construction cycles, and a total of three groups of six excavation sections were collected, namely test section “System for detecting the effects of tunnel blasting”, test section “Measurement of peripheral tunnel parameters” and test section “Numerical simulation”. The actual spatial positions and blast hole angles of the peripheral eyes of six groups of excavation sections were obtained, and the scan diagrams of the peripheral eyes are shown in Figs. 5, 6 and 7.

Peripheral eye scan of test section “System for detecting the effects of tunnel blasting” (unit: cm).

Peripheral eye scan of test section “Measurement of peripheral tunnel parameters” (unit: cm).

It can be seen from Fig. 6 that for test section “System for detecting the effects of tunnel blasting” (left line), based on the idea of “ Ning Chao owes nothing”, the overall opening positions of the peripheral eyes of the test section are located outside the design excavation contour line, and the opening error is 0–22 cm. In the test section “System for detecting the effects of tunnel blasting” (right line), the blast holes in areas a, b and c are located outside the design excavation contour line, and the error range with the design is 7–55 cm, which can easily lead to over-excavation. The position of the peripheral eye opening in area d is in good agreement with the design excavation contour.

It can be seen from Fig. 7 that in test section “Measurement of peripheral tunnel parameters” (left line), the position of the blast holes in areas a and b is located outside the design excavation contour line, and the error range with the design is 9–45 cm, which can easily lead to over-excavation; The opening position of the peripheral eye in areas c and d is located inside the design excavation contour, and the opening error is 0–5 cm, which is easy to cause under-excavation. In test section “Measurement of peripheral tunnel parameters” (right line), the positions of peripheral holes in areas a, c and d are in good agreement with the design excavation contour. The positions of the peripheral holes in the vault and area b are located outside the design excavation contour, with an opening error of 25–38 cm, which can easily lead to over-excavation.

Figure 8 shows that the positions of the blastholes in areas a, b and d of test section “Numerical simulation” (left line) are all located outside the design excavation contour line, and the error range with the design is 1–64 cm, which can easily lead to over-excavation; The opening position of the peripheral eye in area c is within the design excavation contour line, and the opening error is 0–3 cm, which can easily lead to under-excavation. For test section “Numerical simulation” (right line), the blast holes in areas a and b are located outside the design excavation contour line, and the error range with the design is 0–55 cm, which can easily lead to over-excavation. The positions of the peripheral eyes in areas c and d are in good agreement with the designed excavation contour.

Peripheral eye scan of test section “Numerical simulation” (unit: cm).

In Fig. 9 shows the difference between the measured and designed eye positions around the tunnel, especially in the top area. The comparison shows that the borehole in the left section deviates from the outside of the design contour line. At the same time, there are deviations in the design contour in some areas, leading to under-excavation. There are many deviations between the pink and red points, indicating that over-excavation may occur during actual construction. The blue dot is slightly below the design line in area c, which indicates under-excavation.

Comparison of the peripheral eyes on the left line of sections “System for detecting the effects of tunnel blasting” to “Numerical simulation”.

The comparative analysis in Fig. 10 shows that the top area a and b: the pink and red points deviate more from the design line, resulting in a large amount of over-excavation, indicating that the vault and right shoulder are poorly controlled during construction. Side wall areas c and d: the blue point is slightly below the design line in area c, indicating under-excavation. The deviation in area d is small and control is better.

Comparison of eyes around the right line of sections “system for detecting the effects of tunnel blasting”–“Numerical simulation”.

Overall, the top is clearly over-excavated and the side walls are relatively stable. The pink and red points in the vault area of the left line (area a) deviate greatly from the design line, and the over-excavation deviation can be up to 0–64 cm, while the blue points on the left wall (area c) show slight under-excavation (deviation 0–5 cm). The pink and red points on the right shoulder of the right line (area b) are more obviously over-excavated and have a large deviation, while the data on the right side wall (area d) is closer to the design outline. In general, the phenomenon of over-excavation in the top area (areas a and b) is widespread, which illustrates the influence of the positional deviation of the peripheral eye on the construction accuracy. Particular attention should be paid to optimal control of the vault and shoulder area during construction.

Data collection of over- and under-mining

After blasting, the surrounding rock can be affected by vibrations, crack increase, etc., which reduces its stability and poses a risk of collapse, so it is considered dangerous rock. After blasting, the dangerous rock attached near the tunnel face does not fall automatically. To prevent falling rock from hitting the operators, it is necessary to manually process the tunnel face (as shown in Fig. 11) to obtain a clean excavated section without gravel. Based on the results of the 3D laser scanner, the detailed point cloud image of the tunnel face is created, as shown in Figs. 12, 13 and 14.

Measured diagram of experimental section “System for detecting the effects of tunnel blasting”.

Measured diagram of experimental section “Measurement of peripheral tunnel parameters”.

Measured diagram of experimental section “Numerical simulation”.

If the actual opening position of the peripheral hole deviates from the planned excavation position, over- and under-excavation can easily occur. The drilling deviation includes the deviation and dislocation between the drilling axis and the preset design path during the drilling process, which directly leads to the inconsistency between the results of the blasting operation and the original design scheme. The over-excavation range of the section is compared, as shown in Fig. 15.

According to the analysis of Figs. 12, 13 and 14, the average deviation between the actual drilling position and the design hole position of the peripheral hole of test section “System for detecting the effects of tunnel blasting” is 17 cm, and the average over-excavation thickness is 25.55 cm. The average deviation between the actual drilling position and the design hole position of the peripheral hole in test section “Measurement of peripheral tunnel parameters” is 18 cm, and the average over-excavation thickness is 26.31 cm. The average deviation between the actual drilling position and the design hole position of the peripheral hole in test section “Numerical simulation” is 23 cm, and the average over-excavation thickness is 35.39 cm. Given the low stability of the surrounding Class IV rock, any small deviation in borehole positioning can significantly affect the uniformity of tunnel blasting. This heterogeneous blasting effect tends to cause excessive blasting force to be released in some local areas, while in other areas the blasting effect may weaken due to insufficient energy. This effect directly exacerbates the probability of over- and under-excavation during tunnel excavation.

. Numerical simulation

Creation of a numerical calculation model

This time, the ANSYS/LS-DYNAMIC program is used to simulate the tunnel blasting excavation. The parameters of the peripheral eye have a considerable influence on the damage to the surrounding rock and the over-excavation. Therefore, the influence of peripheral eye blasting on over-excavation of tunnel is particularly considered, while the influence of the cut hole and the auxiliary hole is ignored. Except for the tunnel face, the rest are set as a non-reflecting boundary. In the finite element model, the peripheral eye is determined using only the measured parameters of the blasthole. The specific model is shown in Fig. 16.

Material model and parameter determination

Rock mass material model

In this paper, the HJC model is used, which can be used for concrete subjected to large strain and high pressure and can reflect damage failure. The parameters of the surrounding rock parameters are set according to Table 4 and defined as *MAT_JOHNSON_HOLMQUIST_CONCRETE.

Explosive material model and equation of state

The peripheral eye assumes an uncoupled charge structure, and the radial uncoupling coefficient is 2.63. The explosive material is defined by the high-energy explosive model * MAT_HIGH_EXPLOSIVE_BURN embedded in LS-DYNA. The pressure–volume relationship of the detonation product of the explosive adopts the JWL equation of state as shown in formula (3), and the gun mud adopts the same material as the medium. The specific parameters of emulsion explosive No. 2 are shown in Table 5.

where: Pc is the pressure of the detonation generator, GPa; V is the relative volume; E0 is the initial specific internal energy; A, B, R1, R2 and ω are constants.

Air material model and equation of state

Air was described using the NULL material model while the LINEAR_POLYNOMIAL equation of state was used. The linear polynomial equation of state is as follows:

where: \(P\) is the detonation pressure; \(E\) is the internal energy per unit volume; \(V\) is the relative volume; For the air model, the parameters of the polynomial equation of state are: \(C_{0} = C_{1} = C_{2} = C_{3} = C_{6} = 0\), \(C_{4} = C_{5} = 0.4\). The air density is assumed to be 1.225 kg/m3, and the initial relative volume \({V}_{0}\) is assumed to be 1.0.

Analysis of simulation results

In this paper, the design blasting scheme without deviation of insertion angle and borehole position is called scheme A, and the actual blasting scheme with deviation of insertion angle and borehole caused by the construction level of drilling and blasting personnel is called scheme B to study the blasting effect under the scheme. In addition, two groups of models are created, one group with only the borehole position deviation, referred to as scheme C, and the other group with only the extrapolated angle deviation, referred to as scheme D. The data of extrapolated angle deviation of blast hole position deviation under schemes C and D are all from section “System for detecting the effects of tunnel blasting”. In the period from 0 to 400 ms, after the initiation of the cut hole, the damage degree and scope of the surrounding rock expand rapidly, and the auxiliary hole, peripheral hole and bottom plate hole are initiated in sequence according to the design sequence, and the damage extent of the rock mass gradually increases. After 800 ms, the damage area of the peripheral hole is basically penetrated, and the energy generated by blasting is concentrated in the penetrating crack, forming the blasting profile. As shown in Fig. 17, the degree of damage and the extent of surrounding rock are represented by different colors (Table 6). The color changes from blue to red to indicate that the degree of damage is gradually getting deeper, blue indicates no damage, green indicates partial damage, and red indicates complete damage20.

Influence of parameter deviation on over- and under-excavation

Using the example of test section “System for detecting the effects of tunnel blasting” (left line), the influence of peripheral eye parameters on the over- and under-excavation is analyzed, and the measured peripheral eye parameters are listed in Table 7.

From the above, it can be seen that the intelligent blasthole parameter detection equipment has the characteristic of displaying the actual spatial position of the surrounding blasthole in real time. At the same time, in conjunction with the use of a three-dimensional laser scanner, high-precision cross-section measurement data can be obtained, and the inclination angle is shown in Fig. 18.

Comparison of the peripheral eye inclination angle and design inclination angle of test section “System for detecting the effects of tunnel blasting” (left line).

From the data in the chart, it can be seen that the horizontal inclination deviation range between the hole positions 1–8 (area c) and the design hole position is − 12°–9.3°, the vertical inclination deviation range is − 7.8°–10.0°, the range of horizontal inclination deviation range between hole positions is 9–16 (area a) and the design hole position is − 17.9°–11.9°, the range of horizontal inclination deviation between hole positions 17–24 (area b) and the design hole position is − 36.7°–10.3°, and the range of vertical inclination deviation is 11.4°–27.4°.

As the over- and under-excavation is mainly closely related to the parameters of the peripheral eye, it is only modeled according to the actual parameters of the peripheral eye, and the cut hole and auxiliary hole are modeled according to the ideal state. To compare the weights of the deviation of the drilling position and the extrapolation angle on the blasting over-excavation, the simulation results of scheme A are compared with those of scheme C and D, respectively, and the historical damage variables of the model can be obtained by entering the keyword * DATABASE_EXTENT_BINARY in the K file. To better examine the blasting over-excavation and intercept the damage of the bottom section of the blasthole, Fig. 19 shows the historical damage variables of the model output by the HJC model in the K-file by defining the keyword.

It can be seen from Fig. 19 that the numerical simulation systematically predicts the distribution law of over-excavation under different deviation conditions, and that both the position deviation (scheme C) and the inclination deviation (scheme D) have a significant influence on the over-excavation of the tunnel. The phenomenon of over-excavation caused by the position deviation is particularly pronounced, especially in the vault and spandrel areas, where the over-excavation amount is significantly higher than the inclination deviation. The simulation results are compared in detail, as shown in Fig. 20. By comparing the over-excavation range and the damage distribution, the influence of over-excavation and under-excavation can be evaluated under different deviation conditions.

Figure 20 shows the over-excavation range and the damage distribution of the deviation of the blast hole position and angle by the numerical simulation. From the distribution, it can be seen that the tunnel excavation caused by the positional deviation is more obvious and has the same inhomogeneity especially in the vault and vault shoulder area, where the phenomenon of over-excavation is concentrated. In contrast, the influence of the angular deviation is small, and it mainly tends to be slightly over-excavated or under-excavated locally, and the flatness is good overall.

Figure 21 further provides the comparison data of over-excavation and under-excavation in different areas. It can be seen from the dotted diagram that in the vault area, the average over-excavation caused by the positional deviation of the blast hole reaches about 45 cm, while the angular deviation is 18 cm; In the spandrel area, the over-excavation of position deviation is about 38 cm, while the angular deviation is 15 cm. For the side wall and arch foot area, the influence of positional deviation and angular deviation is small, and the over-excavation and under-excavation amount is kept within 10 cm.

Overall, the influence of the positional deviation of the blast hole on over-excavation is more obvious than the influence of the angular deviation, and the amount of over-excavation caused by the positional deviation is 2 to 3 times that of the angular deviation in the key areas (vault and spandrel). Therefore, precise positioning technology should be prioritized to reduce the deviation of blast hole position during construction, especially in the vault and spandrel areas. At the same time, by further optimizing the inclination deviation, the local over-excavation can be reduced and the overall flatness of the tunnel can be improved.

Comparison between simulation and measured results

In order to study the phenomenon of tunnel over- and under-excavation under position deviation, inclination deviation and actual parameters, it is known from the above that the deviation of blasthole position has a greater influence on over- and under-excavation. Next, the blasthole position deviation scheme, which has a greater influence on over- and under-excavation and the actual blasting scheme are discussed and studied. Figure 22 is the diagram of the effective damage cloud, and Fig. 22 is the historical damage variables of the actual parameter model.

Figure 22 shows the spatial distribution characteristics of the damage based on the diagram of the effective damage cloud. It is evident that the vault and spandrel areas are the most concentrated damage locations, and the red areas have a large area and considerable depth, indicating that these parts were exposed to a large blast energy. In contrast, the damage on the side walls and arch foot area is minor and shows green or blue areas. Figure 23 shows the development of the damage to the surrounding rock. With the release of blasting energy, the damage expands outwards from around the area of the blasthole and finally forms a penetrating damage zone in the area of the vault and the spandrels.

Figures 22 and 23 show the damage during blasting and its spatial distribution. It is clear that the vault and spandrel areas are the most serious parts of the over-excavation. The red damage profile is plotted in Fig. 24 to further analyze the influence of this damage distribution on the excavation profile of the tunnel, and the numerically simulated over-excavation amount is shown in Fig. 25.

Figure 24 shows the comparison of the red lesion profile under the two schemes of modeling the actual parameters of the peripheral eye and the modeling considering only the position offset. The results show that the damage profile modeled by the actual peripheral eye parameters deviates more significantly from the design profile, especially in the vault and spandrel areas, and that the phenomenon of over-excavation is more severe than in the scheme that considers only the positional offset modeling. This shows that in addition to the position offset, other parameter deviations (such as inclination deviation) also have an important influence on the tunnel profile and further increase the extent and depth of over-excavation.

Figure 25 compares the over-excavation and under-excavation of the two schemes in different areas through quantitative analysis. The data shows that the over-excavation of the vault of the reaches about 50 cm when modeling the actual parameters, which is significantly higher than the 45 cm when modeling the positional offset. The over-excavation in the spandrel area is approximately 42 cm and 38 cm, respectively, and the over-excavation in the modeling of the actual parameters is even greater. In the sidewall and arch foot regions, the actual parametric modeling scheme still has a larger amount of over-excavation or under-excavation, but the difference is relatively small.

It can be seen from Figs. 24 and 25 that the actual situation leads to the existence of the over-excavation phenomenon, and the surface of the tunnel contour is mainly dominated by the over-excavation phenomenon. Compared with the ideal scheme (scheme A), the average over-excavation amount of the model (scheme b) modeled according to the actual parameters is obviously higher than that of the blast hole position deviation scheme (scheme c), and the phenomenon is more prominent in areas A, b and d. The overall comparison can approximately show that the influence of peripheral hole position offset and inclination offset on over- and-under-excavation is orthogonal, that is, the influence of peripheral hole parameters on over- and-under-excavation is: angle deviation + position deviation > position deviation > angle deviation.

Verification of the applicability of the numerical simulation

To check the applicability of the numerical simulation for predicting over-excavation and under-excavation, Fig. 26 shows the comparison and verification process between the results of the numerical simulation and the actual blasting effect. Combining the field situation with the damage range nephogram obtained by the simulation (Fig. 26a), Fig. 26b shows the red damage depth profile of the numerical simulation. Three-bit cloud maps with over- and under-excavation of the tunnel are generated by using blasting excavation contour scanning equipment, and the over- and under-excavation of the section is derived, as shown in Fig. 26c, d. The measured excavation profile (Fig. 26d) is compared with the damage profile diagram of the tunnel section obtained by numerical simulation (Fig. 26b). The results are shown in Fig. 26e. The measured over-excavation profile range essentially matches the damage profile obtained by the simulation. In order to further verify the accuracy of the numerical method in predicting over-excavation and under-excavation, the measured data of five sections (test section “System for detecting the effects of tunnel blasting” (right line), test section “Measurement of peripheral tunnel parameters” (left and right lines) and test section “Numerical simulation” (left and right lines)) of DK4 + 125. 600 to DK4 + 210. 30 of the double-track tunnel in University Town were collected, and the detailed point cloud image of the tunnel face was obtained based on the operation results of the 3D laser scanner. Based on the actual situation, the blast hole model is created, and the over- and under-excavation amount is predicted by numerical simulation. The results of the numerical simulation are compared with the measured results. The comparison chart is shown in Fig. 26.

Figure 27a shows that the measured results clearly exceed the blue design outline in most sections, especially in the vault and spandrel areas, which indicates that there is considerable over-excavation at these points. However, in the arch foot and some side wall areas, the measured results are sometimes below the blue design line, demonstrating the phenomenon of under-excavation, which is consistent with the distribution law of the peripheral eye opening position. In particular, the trend of over-excavation in the vault area and under-excavation in the arch foot area is in good agreement. However, in the vault and side wall areas, the over-excavation amplitude of the measured results is greater than that of the numerical simulation, which may indicate that the blasting energy of the peripheral hole exceeds the design value in actual construction or the strength of the surrounding rock is lower than the value specified in the simulation. In the arch foot area, the phenomenon of under-excavation is sometimes more obvious in the measured results than in the numerical simulation, which may be related to over-protection of the design contour or insufficient blasting during construction. From the over-excavation volume in Fig. 27b, it is evident that the over-excavation volume in the numerical simulation is lower than the measured result. It may be that only a single blasting cycle is performed in the numerical simulation, and the over-excavation phenomenon is more serious after multiple blasts and stress release on site. However, the measured results are generally consistent with the tendency of numerical simulation, which can better reflect the distribution law of over-excavation and under-excavation.

Comparison between measured results and numerical simulation of sections “System for detecting the effects of tunnel blasting” to “Numerical simulation”.

Engineering applications

Blasting design scheme

From the preceding analysis, it is clear that the main factor leading to significant over-excavation on site is the position and angular offset of the peripheral hole. Considering the feasibility and practicability of the optimization scheme on the construction site, the change of the original scheme should be minimized under the premise of ensuring the optimization effect, and the drilling scheme can be improved by reducing the opening position offset of the peripheral hole and the inclination angle deviation of the blast hole. The improvement scheme for the peripheral eye construction is shown in Fig. 28 below.

Due to on-site construction habits, the vertical inclination angle of the peripheral hole at the vault can easily be too large, resulting in an uneven blasting profile and local over-excavation, leading to in stress concentrations. Therefore, the actual opening position at the vault is shifted inwards by 10 cm, the horizontal inclination angle is controlled to 0°, the vertical inclination angle is < 0°, and the opening positions of the other locations remain unchanged. At the same time, the horizontal inclination angle of the borehole on the side wall is controlled to < 0°, and the horizontal inclination angle and the vertical inclination angle at the spandrel are both < 0° to ensure that there is no local excessive over-excavation.

Results of the blasting optimization

After the adjustment of the drilling technology and construction management, the blasting construction was carried out again and the data of over- and under-excavation were collected for simulation analysis. After the blasting of the test section was completed, the intelligent scanning equipment of the blasting excavation profile was used to scan the contour line of the excavation section after slag removal. The whole scanning process took about 5 min. Under the condition of certain parameters such as charge, uncoupling coefficient and diameter of the blast hole, the calculation model for the optimized blast hole layout scheme was created in ANSYS/LS-DYNA software by using the model parameters listed in Tables 4 and 5.

Figure 28 shows the scanned map of the optimized test section, the field map and the comparison of the numerical simulation results. It can be seen from Fig. 28a, b that the flatness of the optimized excavation section profile is significantly improved overall. In particular, the actual excavation contour of the side walls on both sides has a high degree of fit with the design contour. The over-excavation range of the optimized test section is reduced to − 0.11 to 0.29 m, and the average over-excavation amount is 0.05 m, indicating that the over-excavation control has achieved certain results. Due to the relatively broken surrounding rock structure in the right spandrel area, the local over-excavation amount is slightly larger, but compared with the measurement data before optimization, the over-excavation range has been reduced considerably.

It can be seen from Fig. 29c, d that the distribution trend of over-excavation predicted by the simulation is in high agreement with the actual scan results, especially in the side wall and vault areas, where the agreement between the simulated contour and the measured contour is high. To further quantify the optimization effect, Fig. 29d shows the comparison of over- and under-excavation. The consistency between the numerical simulation and the measured results is further evidence of the feasibility of the optimization scheme.

Conclusion

Based on the double-track tunnel project in Chongqing, combined with intelligent detection equipment and numerical simulation, the influence of peripheral eye parameters on over-excavation of blasting was analyzed in depth in this study, and the four main conclusions can be summarized as follows:

-

(1)

The integrated 3D laser scanning technology and blast hole parameter detection device used in this study demonstrates the ability to quickly complete section measurement, peripheral eye parameter extraction and accurate calculation of over-excavation and under-excavation at the tunnel construction site and confirms the high efficiency and practicability of the technology.

-

(2)

This study showed that the positional deviation and the angular deviation of the peripheral eye have a significant influence on the phenomenon of over- and under-excavation in tunnel blasting. The combined effect of both factors aggravates the over- and under-excavation of the excavation profile, especially in the tunnel top and shoulder area. The field data showed that the average positional deviation of the peripheral eyes was between 17 and 23 cm, resulting in overcut thicknesses between 25.55 and 35.39 cm. In contrast, angular deviation had little effect on the overcut, and the amount of overcut was usually between 15 and 18 cm.

-

(3)

The measured and numerical simulations are in good agreement: Considering the complexity and variability of the surrounding rock properties, there are inevitably differences between the over- and under-excavation in actual tunnel construction and the numerical simulation. Nevertheless, numerical simulation shows that it is capable of to effectively predicting over- and under-excavation in mountain tunnels. The analysis shows that the average over-excavation predicted by the numerical simulation is 45 cm in the vault area and 38 cm in the spandrel area, while the measured average over-excavation is 50 cm and 42 cm, respectively, and the relative errors are about 10% and 9.5%, respectively. The simulated and measured values of over-excavation in the side wall and arch foot area are both within 10 cm, and the error is controlled to be less than 15%.

-

(4)

In this study, an optimized drilling scheme that focused on reducing the positional deviation of the peripheral eye and improving angular control was proposed. By controlling the position deviation within 10 cm and controlling the inclination angle more precisely, the average over-excavation was effectively reduced to 5 cm, which significantly improved the excavation accuracy, especially in the upper part of the tunnel and the shoulder area, where the maximum deviation was reduced to within 29 cm.

This study focuses on the three-dimensional over- and under-excavation phenomenon in a single construction cycle, while in the real engineering environment, multiple over- and under-excavation areas may be accumulated in continuous blasting sections. Therefore, future research needs to be further expanded to the superposition scenario of over- and under-excavation, and systematically evaluate its compound effect on the overall stability and long-term safety of the project, in order to provide more comprehensive and detailed scientific guidance for tunnel design and construction.

Data availability

The datasets used or analysed during the current study are available from the corresponding author on reasonable request.

References

Guan, L. M. et al. Research and application of large section blasting excavation of inclined shaft in weak surrounding rock_GUAN LIMING. Highw. Transp. Sci Technol. 40(02), 145–152 (2023).

Song, S. S. & Huo, R. K. Optimization research and application of linear cutting blasting scheme for railway tunnel hollow_SONG Sensen. Blasting 40(04), 66–72 (2023).

Hu, G. B. Study on the influence of blasting parameters of marl tunnel on over- and under-excavation_HU Guibin. Eng. Blasting 30(02), 78–87 (2024).

Shi, J. B. et al. Design and application of three-dimensional scanning detection system for tunnel excavation and underexcavation_Shi Jiabin. Railw. Constr. 63(04), 81–83 (2023).

Chen, Z. et al. Cause analysis and control measures of over-and under-excavation of underground tunnel_Chen Zheng. Sichuan Arch. 43(05), 155–157 (2023).

Wei, Z. et al. Detection method of railway tunnel over-excavation and under-excavation based on overall analysis of 3D laser scanning point cloud_Wei Zheng. Acta Railw. Sinica 45(01), 135–140 (2023).

Gong, W. Y. et al. Field test of long footage straight hole cutting blasting excavation and over-and under-excavation control in medium section tunnel. 2–14.

Yun, J. C. et al. Optimizing blasting schemes: A comprehensive approach through macro-micro simulation and field experiment. Geotech. Geol. Eng. 42, 3877–3896 (2024).

Yu, S. S., Wang, W. & Li, Y. W. Q. Research and application of design optimization of peripheral eye offset hollow hole blasting_YU Shaoshan (1). J. Railw. Sci. Eng. 1–10.

Amiri, H. S. & M, V. M. S. R. Optimising blast pulls and controlling blast-induced excavation damage zone in tunnelling through varied rock classes. Tunn. Undergr. Space Technol. 85, 307–318 (2019).

Mao, Q. Z. et al. On-site detection of over-and under-excavation of tunnels under construction using high-density point clouds_MAO Qingzhou (1). Wuhan Univer. J. 1–12.

Carter-Greaves, L. E. et al. Algorithm development for automated key block analysis in tunnels from LiDAR point cloud data. Tunn. Undergr. Space Technol. 132, 104787 (2023).

Ruan, D. S. Study on the influence of peripheral hole blasting parameters on tunnel over-and underexcavation and parameter optimization_Ruan Dixin (Chongqing Univ., 2021).

Yan, D. M. et al. Study on two-step excavation footage of grade IV surrounding rock tunnel_YAN Dumin. Railw. Stand. Des. 60(09), 99–103 (2016).

Liu, X. Y. et al. Numerical analysis of surrounding rock damage caused by millisecond delayed blasting of tunnel peripheral hole_Liu Xiangyu. Vib. Shock 42(24), 8–15 (2023).

Li, J. H. et al. Research progress and prospect of blast hole optimization and control technology for tunnel smooth blasting_Li Jinhang. Mod. Tunn. Technol. 61(01), 36–47 (2024).

Hou, F. Determination of HJC model parameters and optimization of blast hole spacing in tunnel smooth blasting_HOU FEI. Value Eng. 42(34), 81–83 (2023).

Wang, Z. L. et al. Finite element analyses of constitutive models performance in the simulation of blast-induced rock cracks. Comput. Geotech. 135, 104172 (2021).

A computational constitutive model for glass subjected to large strains, high strain rates and high pressures.

Luo, Y. B. et al. Small section water diversion based on GSI classification. Research on underexcavation prediction and optimization of drilling and blasting parameters_Luo Yubo. J. Rock Mech. Eng. 1–12.

Funding

The Key Research and Development Program of MCC(ZGZY-ZDYF-SJY-2024-01); National Postdoctoral Management Committee Project-Supported by China Postdoctoral Science Foundation (2022M720594); Chongqing Municipal Housing and Urban-Rural Development Commission (Chengkezi 2023 No. 1-1);Chongqing Science and Technology Bureau-Chongqing Natural Science Foundation (General) (CSTB2022NSCQ-MSX0518);Chongqing Urban Construction Investment (Group) Co, Ltd. (COCT-JSA-GC-2021-0138);The Chongqing University of Science & Technology Graduate Innovation Program Project (YKJCX2420642).

Author information

Authors and Affiliations

Contributions

Zi-qiang Li: Preservation of the original data on which the paper is based, verification that the figures and conclusions accurately reflect the data collected and that manipulations to images; Acquisition of the financial support for the project leading to this publication. Guiquan-Ma: Preparation, creation and/or presentation of the published work, specifically writing the initial draft (including substantive translation), Preparation, creation and/or presentation of the published work, specifically visualization/ data presentation. Ze-lin Zhou: Oversight and leadership responsibility for the research activity planning and execution, including mentorship external to the core team. Jia-shuai Zhang: Application of statistical, mathematical, computational, or other formal techniques to analyze or synthesize study data. Sheng-peng Pu: Management activities to annotate (produce metadata), scrub data and maintain research data (including software code, where it is necessary for interpreting the data itself) for initial use and later reuse. Zi-yi Zheng: Management activities to annotate (produce metadata), scrub data and maintain research data (including software code, where it is necessary for interpreting the data itself) for initial use and later reuse.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Informed consent

For the information contained in this manuscript that may lead to the identification of the study participants, as well as the images shown in Fig. 11, the authors have legally obtained explicit informed consent from the relevant study participants. Before obtaining consent, the study participants have fully known the purpose and publication form of the information and images, and clearly understood that this publication is an open-access online publication. Its contents can be freely consulted, downloaded, and disseminated by the public, and the public voluntarily agrees to use the relevant information and images for the publication of this online open-access publication.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, Zq., Ma, Gq., Zhou, Zl. et al. Study on the influence of peripheral eye on over-excavation during mountain tunnel blasting construction. Sci Rep 15, 28257 (2025). https://doi.org/10.1038/s41598-025-13682-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-13682-0

Keywords

This article is cited by

-

Application of CO₂ fracturing blasting in mountain tunnel construction adjacent to existing structures

Scientific Reports (2025)

-

Study on the spatial relationship between potential and actual rockbursts in a deeply buried hard rock tunnel

Bulletin of Engineering Geology and the Environment (2025)