Abstract

Improving the machinability of nickel-based superalloys remains a significant challenge in modern manufacturing, particularly for aerospace and high-performance engineering applications. Excessive friction and elevated temperatures during machining often result in rapid tool wear and reduced efficiency. This study investigates the potential of eco-friendly hybrid nanofluids—engineered by combining nanoparticles with complementary thermal and lubricating characteristics—as a sustainable solution to enhance machining performance. Specifically, the performance of three hybrid nanofluid combinations—hexagonal boron nitride/graphite (hBN/Gr), hBN/molybdenum disulfide (MoS₂), and Gr/MoS₂—was evaluated during the milling of Inconel 601 under varied cutting speeds (30–60 m/min) and feed rates (0.05–0.15 mm/rev). Key machining responses such as cutting force, surface roughness, tool wear, temperature, and tool life were analyzed. Among the tested combinations, the hBN/Gr nanofluid demonstrated superior performance, achieving reductions in cutting force (4.17%), surface roughness (21.05%), cutting temperature (8.57%), and tool wear (19.25%), along with an 11.17% improvement in tool life compared to Gr/MoS₂. These enhancements are attributed to the fluid’s optimal viscosity and exceptional tribological behavior at the tool–chip interface. The study offers a novel, environmentally responsible approach to machining Inconel 601, emphasizing the promising role of hybrid nanofluids—particularly hBN/Gr—as next-generation lubricants in sustainable manufacturing.

Similar content being viewed by others

Introduction

Superalloys, known for their exceptional performance under extreme conditions, play a vital role in modern industries. They are especially crucial in sectors like aerospace, which alone accounts for nearly 70–80% of global superalloy consumption. Among these, nickel-based superalloys are particularly valued for their ability to withstand high temperatures and mechanical stress1,2. One notable example is Inconel 601, widely used in demanding thermal environments such as rocket propulsion systems, turbine engines, and jet engine components. Its popularity stems from its excellent resistance to oxidation and corrosion, along with high fracture toughness3,4. Inconel 601 is commonly found in critical applications across the nuclear, aviation, and power generation sectors. However, the same properties that make it so effective—such as its low thermal diffusivity and high nickel and carbide content—also make it extremely difficult to machine. The intense heat generated during cutting leads to rapid tool wear, reducing machining efficiency and driving up production costs5. Traditionally, industries have relied on conventional cooling and lubrication techniques to counteract these issues and extend tool life. While effective, these methods come with their own set of challenges. Cutting fluids can contribute up to 16% of total manufacturing costs, and improper disposal poses serious environmental risks, including soil and water contamination6,7. As the demand for superalloys continues to rise in aerospace, defense, and space exploration, there’s a growing need to balance high-performance machining with environmental responsibility. This has sparked increased research into sustainable, cost-effective alternatives to traditional cooling and lubrication practices in machining operations.

In recent years, machining research has increasingly turned its attention toward environmentally sustainable cooling and lubrication techniques—especially in the context of machining difficult-to-cut superalloys. While traditional flood cooling methods have long been effective, they are gradually being replaced by greener alternatives such as Minimum Quantity Lubrication (MQL), nano-enhanced MQL, cryogenic cooling, and hybrid nano-lubrication systems. These advanced approaches aim to reduce environmental impact without compromising machining performance8,9,10. MQL, often described as near-dry machining, works by spraying a fine mist of lubricant—created by mixing a small amount of oil with compressed air—directly onto the cutting zone. This method significantly cuts down fluid usage, promotes the use of renewable and biodegradable oils, and delivers precise lubrication and cooling at the tool–workpiece interface11,12. These features make MQL a cleaner and more sustainable alternative to conventional flood cooling. However, under high-stress machining conditions like those encountered with superalloys, MQL alone may not always provide adequate tool life or wear resistance13. To address these limitations, researchers have enhanced MQL systems by adding nano-sized solid particles to the base fluids, creating what are known as nanofluids. These additives—such as hexagonal boron nitride (hBN), molybdenum disulfide (MoS₂), multi-walled carbon nanotubes (MWCNTs), graphite, graphene, and aluminum oxide (Al₂O₃)—offer superior thermal conductivity and lubrication properties. As a result, nanofluids improve heat dissipation and reduce friction more effectively than conventional fluids14,15,16. Considering this, the use of hybrid nanofluids—which combine two or more types of nanoparticles—has gained popularity. These formulations harness the strengths of each individual component, resulting in enhanced cooling, lower friction, and better surface finish. The next section delves into recent studies on both mono and hybrid nanofluid applications in metal cutting, highlighting their promise as high-performance, sustainable solutions for cooling and lubrication in machining operations17,18.

A growing body of research highlights the advantages of nano- and hybrid-based lubrication techniques over conventional methods and basic MQL systems, particularly when it comes to enhancing machining performance. For example, Thakur et al.19 investigated the effectiveness of standard MQL and nano-enhanced MQL using silicon carbide (SiC) nanoparticles during the turning of EN-24 steel. Their findings revealed that the addition of SiC nanoparticles to the MQL fluid led to notable improvements—reducing surface roughness, cutting force, and cutting temperature significantly. Building on this work, Thakur and colleagues20 conducted a comparative study of various advanced cooling strategies. These included cryogenic jet cooling, conventional MQL, nanofluids with either Al₂O₃ or SiC nanoparticles suspended in soluble oil, and a hybrid nanofluid composed of a mixture of Al₂O₃ and SiC. Their study demonstrated that the hybrid nanofluid offered the most balanced performance, combining the thermal conductivity and lubricating strengths of both nanoparticles. This synergistic effect contributed to improved heat dissipation, lower tool wear, and better surface integrity during machining operations. The hybrid nanofluid combination emerged as the most effective, delivering the best overall results in terms of surface finish, tool life, specific energy consumption, and a combined performance index. Abbas et al.21 evaluated dry, wet, and nanofluid-assisted MQL methods during the turning of AISI 1045 steel. Their findings highlighted the superiority of nanofluid-assisted MQL, which notably improved surface finish and reduced power usage compared to dry and conventional wet cooling. Similarly, Rahman et al.22 studied the turning of Ti–6Al–4V ELI under dry, MQL, and nanoMQL conditions using various nanoparticles—Al₂O₃, MoS₂, and TiO₂. Among these, Al₂O₃-based nanoMQL achieved the lowest surface roughness and tool wear, whereas MoS₂-based nanoMQL demonstrated the most effective thermal performance and the highest chip thickness ratio. Yıldırım et al.23 investigated the turning of Inconel 625 using nano-MQL with 0.5 vol% hBN nanoparticles, comparing it to pure-MQL and dry machining. The study evaluated tool life, surface roughness, tool wear, and temperature at the tool-chip interface. SEM and EDX analyses revealed that nano-MQL significantly improved tool life and surface finish while reducing tool wear. Ahsan ul Haq et al.24 investigated the face milling of Inconel 718 under two lubrication conditions: MQL and nanofluid-assisted MQL, aiming to enhance sustainable manufacturing. The study evaluated the effects of feed rate, speed, flow rate, and depth of cut on key metrics like surface roughness, temperature, power, and material removal rate. Empirical models were developed using response surface methodology and validated through ANOVA and experiments. Multi-objective optimization highlighted nanofluid-assisted MQL as the superior approach, achieving reductions in surface roughness (20.1%), temperature (14.7%), and power (13.3%), with higher overall desirability (71.3%) compared to MQL (70.1%). Depth of cut was identified as the most influential parameter. Hegab et al.25 studied the machining of Inconel 718, a difficult-to-cut alloy widely used in aerospace, where high hardness and low thermal conductivity hinder surface quality and tool life. While flood cooling helps, environmental concerns demand greener alternatives. This work evaluated the effectiveness of MQL enhanced with MWCNTs and Al₂O₃ nanoparticles. Experiments varying cutting speed, feed, and nanoparticle concentration showed that nano-fluids improved machining performance, with MWCNTs yielding better results than Al₂O₃.

Sharma et al.26 focused on the machining of AISI 304 steel and compared Al₂O₃-based nanoMQL to a hybrid formulation combining Al₂O₃ and multi-walled carbon nanotubes (MWCNTs). Their hybrid nanofluid not only reduced tool wear by 11% but also lowered nodal temperature by over 27%. In a different study, Singh et al.27 examined the effect of MQL, Al₂O₃ nanoMQL, and an Al₂O₃-graphene hybrid nanoMQL system. The hybrid approach delivered a 20.28% reduction in surface roughness and a 9.94% drop in cutting force compared to the mono-nanofluid setup. Further supporting the benefits of hybrid nanofluids, Sharma et al.28 assessed Al₂O₃ and Al₂O₃-MoS₂ hybrid nanoMQL in turning AISI 304. The hybrid configuration led to decreases in cutting force, feed force, thrust force, and surface roughness by 7.35%, 18.08%, 5.73%, and 2.38%, respectively. Additionally, Sharma and colleagues29 evaluated tribological behavior and fluid spreadability of Al₂O₃-MWCNT hybrid nanofluids at various concentrations using a pin-on-disc test. Subsequent turning experiments confirmed the superior machining performance of the hybrid nanofluid. Lotfi et al.30 investigated sustainable machining of Ti–6Al–4V, a material difficult to machine due to low thermal conductivity. They evaluated Al₂O₃ and CuO-based nanofluids under MQL, both individually and in hybrid form, against pure-MQL, conventional cutting fluid, and dry conditions. The study involved analyzing coolant properties, slot milling performance, and sustainability via the Pugh Matrix. Results showed that Al₂O₃ based MQL had better wettability, and hybrid MQL significantly reduced cutting forces (up to 46.5%), surface roughness (up to 61.2%), and improved surface quality. Hybrid MQL emerged as the most sustainable option for machining Ti–6Al–4V. Namlu et al.31 studied the milling of Inconel 718—a key aerospace alloy known for its high-temperature strength and corrosion resistance but difficult to machine due to poor thermal conductivity and work hardening. To improve machinability, they combined multi-axis Ultrasonic Vibration-Assisted Machining with Hybrid MQL using Al₂O₃–CuO nanofluids. The results showed significant reductions in surface roughness, burr formation, and cutting forces, highlighting this method’s potential for efficient machining of difficult-to-cut materials. In grinding applications, Zhang et al.32 studied nanoMQL and hybrid nanoMQL involving MoS₂, CNTs, and their combination during the machining of Inconel 718. Their results revealed that the hybrid nanofluid offered the finest performance in minimizing machining force, lowering friction, and enhancing surface quality. These studies collectively underscore the growing relevance and potential of hybrid nanofluids as next-generation lubricants for sustainable and high-efficiency machining of difficult-to-cut materials.

Despite substantial progress in the field of nanofluid-assisted machining, the majority of existing research has primarily concentrated on mono-nanofluids, which utilize a single type of nanoparticle. In contrast, limited attention has been given to hybrid nanofluids—engineered fluids that incorporate two or more distinct nanoparticles to exploit their combined thermal and tribological advantages. This underexplored area presents a compelling research gap, particularly in the context of machining nickel-based superalloys, which are notoriously difficult to cut due to their high strength, low thermal conductivity, and tendency to work-harden. Among the wide variety of nanoparticles investigated in previous studies, hBN, Gr, and MoS₂ stand out due to their individual and complementary properties. Specifically, hBN is well known for its superior thermal conductivity, chemical inertness, and ability to form protective films on cutting tools. Graphene exhibits remarkable mechanical strength, thermal conductivity, and ultra-low friction coefficients, while MoS₂ offers excellent solid lubrication and anti-wear characteristics under high loads and extreme conditions. These attributes make them ideal candidates for hybridization, where their combined effects could potentially deliver enhanced lubrication, reduced tool wear, and improved surface integrity. Accordingly, the present study investigates the performance of three hybrid nanofluid combinations—hBN/Gr, hBN/MoS₂, and Gr/MoS₂—under MQL conditions during the milling of Inconel 601, a nickel-based superalloy widely used in aerospace, petrochemical, and high-temperature applications. The study conducts a comprehensive evaluation of key machining performance indicators such as cutting force, surface roughness, cutting temperature, tool wear, and tool life across varying cutting parameters. The novelty of this work lies in its comparative analysis of hybrid nanofluids with strategically selected nanoparticles, contributing to the development of more effective and sustainable cooling and lubrication strategies in precision machining. These findings are expected to support environmentally conscious manufacturing practices while improving process efficiency and tool longevity.

Experimental details

Preparation and characterization of hybrid nanofluids

A sunflower oil with biodegradable properties was chosen as the base fluid for creating hybrid nanofluids due to its environmentally friendly characteristics and absence of harmful substances like chlorine and heavy metals. To enhance the thermal and flow properties of the base oil, three different nanoparticles—hBN, Gr, and MoS₂, each averaging around 80 nm in size—were selected (Table 1), and their SEM images are presented in Fig. 1. These nanoparticles, sourced from Nanografi Company (Turkey), were incorporated into the sunflower oil using the well-known two-step method, which is both efficient and practical. The procedure involved adding the nanoparticles (at a concentration of 0.50% by volume) to the sunflower oil, followed by several stages of mixing: Mechanical stirring at 750 rpm for one hour, ultrasonication at 20 kHz and 200W for 30 min, and magnetic stirring at 1500 rpm for two hours. This method ensured the even distribution of the nanoparticles, leading to the formation of three distinct hybrid nanofluids—hBN/Gr, hBN/MoS₂, and Gr/MoS₂—each with a total nanoparticle concentration of 0.50 vol%. To ensure stability and prevent the settling or clumping of nanoparticles, fresh samples were prepared prior to each experimental test.

The thermophysical behavior of the developed hybrid nanofluids was meticulously evaluated, with a particular focus on two critical properties: Viscosity and thermal conductivity. Viscosity measurements were conducted at 40 °C and 100 °C using a SCHOTT Instruments Ubbelohde capillary viscometer (Germany), following the ASTM D2270 testing protocol. A precision-controlled thermostat bath was employed to maintain the desired temperature during measurements, and calibration was routinely verified by computing the viscosity of distilled water prior to every test session. Thermal conductivity assessments were performed at 20 °C using a TPS 2500 S thermal constants analyzer (Hot Disk, Sweden), equipped with a sensor specifically designed for liquid nanofluid applications (model code 5465). The obtained data offer key insights into the flow and heat transfer characteristics of the hybrid nanofluids, confirming their practical viability for both laboratory-scale experimentation and potential industrial implementation in advanced machining operations.

Tool, workpiece and machining details

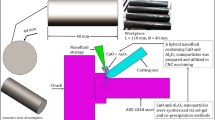

Inconel 601, a nickel-based superalloy, is widely valued for its outstanding high-temperature strength and exceptional oxidation resistance, making it a preferred material in critical sectors such as aerospace, petrochemical, and nuclear industries. However, its low thermal conductivity, high chemical reactivity, and elevated chromium and nickel content pose significant machining challenges, particularly in terms of rapid tool wear and degraded surface quality. To evaluate the machinability of Inconel 601 and identify effective lubrication strategies, face milling experiments were conducted using PVD TiAlN-coated cemented carbide inserts (490R-08T308E-ML S30T, Sandvik, Sweden) with a 4 µm coating thickness. The inserts were mounted on a 25 mm diameter tool holder (model 490-025A20-08L) with an overhang of 40 mm for machining stability. All tests were performed on a DELTA SEIKI CNC-1050 vertical milling machine equipped with an 11 kW spindle motor capable of speeds up to 10,000 rpm.

Three different hybrid nanofluids—hBN/Gr, hBN/MoS₂, and Gr/MoS₂—were supplied using an MQL system (LubriLean Vario, SKF, Germany), operated at 8 bar pressure and 50 mL/h flow rate. A 2 mm nozzle placed 20 mm from the machining zone at a 30° inclination ensured precise delivery of the atomized lubricant mist to the cutting interface. Experiments were conducted across three cutting speeds (80, 100, and 120 m/min) and three feed rates (0.05, 0.10, and 0.15 mm/rev), while keeping the axial depth of cut constant at 0.5 mm and the radial depth at 15 mm. Each combination of cutting speed, feed rate, and nanofluid type was tested in triplicate to ensure repeatability and statistical reliability of the measured machining performance indicators. To eliminate the influence of tool wear between tests, a fresh cutting insert was used for each experimental run. A detailed overview of the machining parameter matrix is presented in Table 2.

Response measurement

The experimental setup for this study incorporated several advanced instruments to ensure precise and reliable measurement of machining responses. For force measurement, the KISTLER 9170A piezoelectric dynamometer was employed, capable of capturing radial, tangential, and axial cutting forces with high precision. It was integrated with a KISTLER 5238B multi-channel charge amplifier and operated using DynoWare software, allowing for real-time force data acquisition at a sampling rate of 10 kHz. This configuration enabled detailed analysis of the dynamic force variations during milling operations. Cutting temperature was monitored using a ThermoPro TP8 thermal imaging camera, which operates across a wide detection range from − 20 °C to 800 °C. The camera provides a thermal resolution of 0.1 °C and an image resolution of 220 × 160 pixels, ensuring accurate real-time visualization of temperature distribution in the cutting zone. An emissivity value of 0.5 was set, as recommended by previous studies, to maintain consistent and accurate thermal measurements. Surface roughness (Ra) was measured using a KLA Tencor MicroXAM-100 3D optical surface profiler, which employs white-light interferometry for high-resolution, non-contact surface characterization. Each sample was scanned over an area of 500 µm × 500 µm at a vertical resolution of approximately 0.1 nm. Ra values were computed using the system’s integrated software after applying Gaussian filtering to eliminate surface waviness. To ensure measurement repeatability, readings were taken at three distinct locations along the feed direction, and the average Ra was reported. Lastly, tool wear was evaluated by measuring flank wear (VB) using a Dino-Lite AM4113ZT digital polarized microscope at 50× magnification, providing clear imaging of the worn tool edge. Measurements were taken at regular machining intervals, and tool life was defined when the flank wear reached 0.3 mm, following standard criteria. For detailed analysis of wear mechanisms, a JEOL scanning electron microscope (SEM) was utilized, offering high-magnification images to identify abrasion marks, adhesion areas, and micro-chipping—thus correlating wear features with tool life progression. An overview of the experimental setup is illustrated in Fig. 2.

Results and discussion

Thermo-physical properties of nanofluids

The performance of nanofluids as cutting fluids heavily depends on their viscosity and thermal characteristics. In this research, viscosity was measured for both the base fluid and hybrid nanofluids at temperatures of 40 °C and 100 °C, using the ASTM D2270 standard. At 40 °C, the base fluid showed the lowest viscosity at 30.5 cSt. However, when nanoparticles were added, there was a significant rise in viscosity. Specifically, the viscosity increased by 37.70%, 46.56%, and 54.75% for hBN/Gr, hBN/MoS₂, and Gr/MoS₂ nanofluids, respectively. The MoS₂-based nanofluids exhibited the highest viscosity due to the higher true density of MoS₂ nanoparticles. While a lower viscosity improves lubrication and helps with nanoparticle movement within the fluid, excessively high viscosity can compromise lubrication efficiency by thickening the lubricating layer33. The viscosity measurements taken at 100 °C revealed a similar trend, though all nanofluids had significantly lower values due to the thinner lubricant film at higher temperatures (Fig. 3a). Among the nanofluids tested, hBN/Gr had the lowest viscosity at both temperatures, followed by hBN/MoS₂ and Gr/MoS₂. These results emphasize the importance of carefully selecting the nanoparticle type to optimize viscosity and enhance tribological performance.

Thermal conductivity is a vital property affecting the heat dissipation performance of nanofluids in machining applications. The addition of nanoparticles to the base fluid significantly improved thermal conductivity due to enhanced phonon transport and increased surface area. Among the tested hybrid nanofluids, Gr/MoS₂ showed the highest thermal conductivity (0.27 W/m K), followed by hBN/MoS₂ (0.26 W/m K) and hBN/Gr (0.23 W/m K), representing enhancements of 50%, 44.44%, and 27.78%, respectively, over the base fluid (Fig. 3b). The superior performance of Gr/MoS₂ is attributed to the exceptionally high intrinsic thermal conductivity of graphene and the layered structure of MoS₂, which facilitates phonon transport. Graphene’s two-dimensional structure with delocalized π-electrons enhances heat conduction, while MoS₂ contributes both thermal and tribological benefits. In contrast, hBN has a lower intrinsic thermal conductivity and is electrically insulating, which may slightly limit its effectiveness when combined with other particles. Other influencing factors include particle morphology, dispersion stability, and interfacial resistance. Nanofluids with well-dispersed particles typically offer better thermal performance. A positive trend was observed between viscosity and thermal conductivity, likely due to higher particle loading and network formation. However, excessive viscosity may hinder fluid penetration at the tool–chip interface, affecting lubrication. Thus, selecting nanoparticles with favorable thermal and physical properties and achieving an optimal viscosity–conductivity balance is crucial for maximizing nanofluid performance in MQL-assisted machining.

Cutting force evaluation

The machining of nickel-based superalloys presents significant challenges due to the high cutting force and friction involved, which negatively impact their machinability34. Accurately measuring cutting forces during machining plays a vital role in evaluating the machinability of advanced materials like Inconel 601. Several factors influence these forces, including cutting tool geometry, workpiece properties, tool–workpiece friction, machining parameters, and the type of cooling-lubrication used. In this study, a precision dynamometer was used to capture cutting force data and examine how various hybrid nanofluid combinations affect machining performance. To determine the resultant cutting force (Fr), the three orthogonal components—Fx (feed force), Fy (radial force), and Fz (main cutting force)—were recorded and combined using Eq. (1). These force components were collected during milling operations under different experimental conditions. Figure 4 presents the variations in cutting force observed across different hybrid nanofluid environments and machining parameters. The results offer valuable insights into how each hybrid lubricant contributes to reducing tool load and improving overall cutting efficiency.

Among the hybrid nanofluids evaluated, the hBN/Gr combination consistently yielded the lowest cutting force values across all cutting speed and feed rate combinations. This was followed by hBN/MoS₂ and Gr/MoS₂, respectively. Notably, hybrid nanofluids containing hBN nanoparticles (i.e., hBN/Gr and hBN/MoS₂) consistently outperformed the Gr/MoS₂ formulation in reducing cutting forces. This distinction became particularly pronounced under intensified machining conditions, specifically at a cutting speed of 60 m/min and a feed rate of 0.15 mm/rev, where hBN/Gr and hBN/MoS₂ exhibited a reduction in cutting force by 4.17% and 2.08%, respectively, compared to Gr/MoS₂. The superior performance of hBN-based hybrid nanofluids can be attributed to the unique morphology and tribological behavior of the nanoparticles. The spherical geometry and lamellar structure of hBN facilitate the formation of a stable, low-viscosity lubrication film35, enhancing penetration at the tool–workpiece interface and reducing friction-induced resistance. In contrast, higher viscosity nanofluids—such as those containing Gr/MoS₂—tend to form thicker lubrication layers that hinder fluid infiltration and elevate interfacial friction, ultimately resulting in higher cutting forces.

The highest cutting temperatures were recorded when using the higher viscosity hybrid nanofluids, specifically hBN/MoS₂ and Gr/MoS₂, thereby reinforcing the earlier explanation regarding their limited lubricating effectiveness. Analysis of cutting force variations under different machining parameters revealed that feed rate exerted the most pronounced influence on cutting force. Across all hybrid nanofluid conditions, increasing the feed rate led to a substantial rise in cutting forces. The maximum cutting force of 480 N was observed under the Gr/MoS₂ condition at a cutting speed of 60 m/min and feed rate of 0.15 mm/rev, whereas the lowest cutting force of 305 N was recorded using hBN/Gr at a cutting speed of 30 m/min and feed rate of 0.05 mm/rev. In contrast, cutting speed had a relatively moderate effect on cutting force. Initially, an increase in cutting speed contributed to a slight decrease in cutting force due to elevated temperatures at the cutting zone, which promoted plastic deformation of the workpiece material and reduced cutting resistance. However, beyond a critical speed threshold, the cutting force began to rise again—an effect likely caused by thermal softening and subsequent deformation of the cutting edge, compromising tool performance. In summary, among all tested conditions, the hBN/Gr hybrid nanofluid demonstrated the most favourable performance, achieving the lowest cutting forces, and thus appears to be the most effective option for reducing cutting loads in the milling of Inconel 601 under MQL-assisted environments.

Cutting temperature evaluation

During metal cutting operations, heat generation originates from multiple sources, primarily due to plastic deformation within the primary, secondary, and tertiary shear zones, as well as frictional dissipation at the tool–chip and tool–workpiece interfaces. The magnitude of cutting temperature is influenced by a range of factors, including cutting parameters, tool geometry and material, and, notably, the type and efficiency of the cooling/lubrication technique employed36. This section of the study aims to investigate the influence of hybrid nanofluid-assisted cooling/lubrication on cutting zone temperatures under varying machining conditions. The experimental findings are illustrated in Fig. 5. Analysis of the results reveals that, across all combinations of cutting speed and feed rate, the hBN/Gr hybrid nanofluid consistently exhibited the lowest cutting temperatures, followed by hBN/MoS₂ and Gr/MoS₂. Notably, the maximum cutting temperature of 175 °C was observed with Gr/MoS₂ at a cutting speed of 60 m/min and feed rate of 0.15 mm/rev. Under identical conditions, the cutting temperatures for hBN/MoS₂ and hBN/Gr were 165 °C and 160 °C, respectively. These values correspond to temperature reductions of 3.03% (hBN/Gr versus hBN/MoS₂) and 8.57% (hBN/Gr versus Gr/MoS₂). Interestingly, despite the expectation that hybrid nanofluids with higher thermal conductivity would facilitate greater heat dissipation and thus lower cutting temperatures, the results demonstrate a contrary trend. This discrepancy implies that thermal conductivity alone is not the dominant determinant of temperature control in high-speed machining environments. Instead, a synergistic interplay of nanoparticle dispersion stability, fluid viscosity, particle morphology, and effective penetration into the cutting interface governs the thermal regulation capability of the nanofluid. The superior performance of hBN/Gr is likely attributed to its lower viscosity and spherical nanoparticle structure, which together enhance film formation and thermal transport at the cutting zone.

The low viscosity of nanofluids used in MQL systems plays a pivotal role in enhancing penetration at the tool–chip interface and improving atomization of the lubricant. This phenomenon is corroborated by the observation that lower cutting temperatures were consistently achieved with low-viscosity hybrid nanofluids. Nevertheless, it is essential to recognize that thermal conductivity and viscosity are not the sole contributors to thermal regulation during machining. Other critical factors, including nanoparticle morphology, dispersion behavior, and interparticle interactions, also influence the cutting temperature. Specifically, hBN exhibits a layered crystal structure bound by weak Van der Waals forces, which facilitates uniform dispersion within the fluid medium. Moreover, hBN contributes to effective lubrication by forming a thin, adherent film at the cutting tool–workpiece interface, thereby reducing both friction and localized temperature. The spherical geometry of hBN nanoparticles is also believed to induce a micro ball-bearing effect, further minimizing mechanical contact and heat generation. In contrast, MoS₂ possesses a higher solid density than both hBN and Gr particles, making it less amenable to aerosolization under MQL conditions. Additionally, the higher viscosity associated with MoS₂-rich nanofluids may lead to the formation of a thicker lubrication film, which can impede effective penetration and reduce cooling performance.

When examining the influence of cutting parameters on temperature, both cutting speed and feed rate were found to exert an effect; however, cutting speed emerged as the more dominant factor. Under hBN/Gr lubrication, for instance, the cutting temperature increased from 105 to 135 °C as cutting speed rose from 30 to 60 m/min at a constant feed rate of 0.05 mm/rev, indicating a 28.57% increase. This temperature rise is attributed to elevated friction and tool wear at higher speeds, which is further substantiated by the corresponding increase in cutting force observed at these parameters. Conversely, the impact of increasing feed rate on cutting temperature was comparatively marginal, suggesting that feed rate plays a secondary role in thermal generation under the conditions studied.

Surface roughness evaluation

Surface finish plays a crucial role in determining the quality of machined components. This aspect becomes especially vital when working with superalloys used in aerospace applications, where achieving both precise dimensions and superior surface quality is essential. In this study, the effect of hybrid nanofluids on the surface texture of Inconel 601—a commonly used superalloy in aviation—is thoroughly examined. Figure 6 presents the correlation between surface roughness, machining parameters, and the application of various hybrid nanofluids. The bar chart analysis highlights that the combination of hBN/Gr results in the smoothest surface finish, outperforming the hBN/MoS2 and Gr/MoS2 blends. The minimum surface roughness recorded was 0.12 μm, achieved under the hBN/Gr condition with a cutting speed of 30 m/min and a feed rate of 0.05 mm/rev. Under identical cutting settings, surface roughness values for hBN/MoS2 and Gr/MoS2 were slightly higher at 0.13 μm and 0.14 μm, respectively. Conversely, the roughest surface, measuring 0.38 μm, occurred with the Gr/MoS2 nanofluid at a higher cutting speed of 60 m/min and feed rate of 0.15 mm/rev. For these parameters, hBN/Gr and hBN/MoS2 yielded lower roughness values of 0.30 μm and 0.32 μm, respectively. This demonstrates that at 60 m/min and 0.15 mm/rev, the hBN/Gr nanofluid reduces surface roughness by approximately 21% compared to Gr/MoS2, while hBN/MoS2 achieves a 6% reduction. The superior performance of the hBN/Gr hybrid is attributed to its lower viscosity and enhanced ability to infiltrate the interface between the cutting tool and the workpiece. These characteristics promote key lubrication mechanisms such as polishing, mending, and rolling, which are critical for maintaining surface quality. Particularly, the spherical morphology of hBN nanoparticles likely facilitates a rolling effect similar to micro ball bearings, reducing friction and improving machining efficiency37.

The hBN nanoparticles are thought to exhibit relatively weak Van der Waals forces, which facilitates their uniform dispersion within lubricating oils. This uniform distribution helps form a protective layer on the contact surfaces between the cutting tool and the workpiece. Evidence for this mechanism comes from observations that the lowest cutting forces and temperatures occurred under cutting conditions involving hBN combined with Gr. As the friction at the interface reduces, the severity of feed marks on the machined surface also decreases, resulting in improved surface finish with lower roughness values. Conversely, elevated friction tends to degrade surface integrity and diminish quality. These trends are corroborated by multiple studies reported in the literature. Regarding machining parameters, the feed rate is especially influential in determining surface roughness outcomes. It has been documented that increasing the feed rate causes a significant increase in Ra value. For example, under the hBN/Gr lubrication setup at a cutting speed of 30 m/min, raising the feed from 0.05 to 0.15 mm/rev led to a 66.67% increase in Ra, from 0.12 to 0.20 μm. This indicates that feed rate exerts a stronger effect on surface roughness than either cutting speed or the lubrication method used. Since feed rate directly controls the formation of surface texture, higher values naturally result in rougher finishes.

Analyzing how cutting speed influences surface roughness reveals that average roughness initially declines but then rises as cutting speed increases. This behavior is linked to the temperature escalation within the cutting zone caused by faster cutting speeds. While a moderate temperature rise facilitates plastic deformation, assisting the tool in chip separation, excessive heat accelerates tool degradation, which in turn deteriorates the surface finish. Among the hybrid cutting scenarios tested, the smoothest surfaces—indicated by the lowest Ra values—were obtained at a cutting speed of 30 m/min combined with a feed rate of 0.05 mm/rev. To better understand the surface features under these conditions, detailed microscopic and three-dimensional surface analyses were conducted (see Fig. 7). These images clearly show that the hBN/Gr hybrid results in fewer feed marks and reduced peak heights compared to the hBN/MoS2 and Gr/MoS2 combinations. This improvement arises from the robust boron-nitrogen bonds in the hBN structure and the lubricating properties of graphite, which together lower friction and enhance the surface quality. Furthermore, the spherical hBN nanoparticles act like tiny rollers within the graphite layers, facilitating smoother interlayer sliding and forming a more operative tribo-film on the workpiece. This effect is more pronounced in hBN/Gr nanofluids than in the MoS2-based hybrids, partly because MoS2 nanoparticles have a higher true density. Additionally, the increased viscosity of Gr/MoS2 mixtures reduces their penetration ability at the cutting interface, limiting their lubricating efficiency and resulting in rougher surfaces. Past research38 has indicated that elevated cutting temperatures can induce thermal distortion, adversely affecting surface finish. Therefore, the relatively lower temperatures achieved using the hBN/Gr nanofluid also play a crucial role in enhancing surface texture alongside the unique lubrication mechanisms.

Tool wear and its mechanism

The wear and durability of cutting tools are critical factors that greatly affect machining productivity, the quality of the final product, and the overall cost of manufacturing. Additionally, the expected tool lifespan is a vital consideration when determining optimal cutting conditions and process parameters39. To assess the effectiveness of hybrid nanofluids in machining applications, multiple tool life experiments were performed. In these tests, the end of a tool’s life was defined by flank wear exceeding a threshold of 0.3 mm. The findings revealed that at a cutting speed of 30 m/min combined with a feed rate of 0.05 mm/rev, the tool life durations under different hybrid nanofluid environments were: 200 min for hBN/Gr, 189.6 min for hBN/MoS2, and 179.9 min for Gr/MoS2. This data demonstrates that the hBN/Gr nanofluid condition enhanced tool life by 5.48% compared to Gr/MoS2, and by 11.17% over hBN/MoS2. Figure 8 depicts the influence of cutting parameters on tool longevity, highlighting the consistent superiority of the hBN/Gr hybrid nanofluid in extending tool life. The superior performance of nanofluids containing hBN particles is attributed to their spherical morphology. In the hBN/Gr hybrid nanofluid, the spherical particles of hBN work in harmony with graphite’s layered structure to deliver multiple tribological benefits. These include surface mending, polishing, a rolling effect, and interlayer sliding—mechanisms that help reduce friction and wear during machining. A similar interaction occurs in the hBN/MoS₂ blend, where hBN particles engage with the layered MoS₂. However, both hBN/MoS₂ and Gr/MoS₂ nanofluids fall short when compared to the hBN/Gr combination, particularly in extending tool life. This performance gap is largely due to the higher density of MoS₂ in the hBN/MoS₂ mixture, which hampers the ability of the hBN particles to slide effectively between MoS₂ layers. Similarly, in the Gr/MoS₂ nanofluid, the dual-layered structures fail to support the rolling action that is crucial for wear reduction, ultimately resulting in diminished tool longevity.

Viscosity plays a critical role in determining tool durability during machining. Among the tested nanofluids, the hBN/Gr hybrid stands out due to its relatively lower viscosity and viscosity index, which help it form a more effective lubricating film at the tool–workpiece interface. This improved lubrication reduces friction, which in turn lowers cutting forces and temperatures—factors that directly contribute to slower tool wear and longer tool life under the given machining conditions. Additionally, the analysis of cutting parameters reveals that increasing the cutting speed has a pronounced negative effect on tool life. Higher speeds lead to elevated temperatures in the cutting zone, which accelerate wear and significantly shorten the lifespan of the cutting tool. Although the feed rate impacts tool life as well—since higher feed rates increase chip size and impose greater stress on the tool—its effect is less significant than that of cutting speed. In summary, cutting speed exerts a more dominant influence on tool lifespan compared to feed rate.

The lifespan of a cutting tool is inherently dependent on the extent of its wear, which can be assessed by analyzing wear characteristics. Effectively understanding and controlling tool wear is critical for extending the tool’s operational life. To explore this relationship, a series of wear experiments were performed to classify the different wear types and the mechanisms causing them. These tests were conducted under defined machining parameters: A cutting speed of 60 m/min, feed rate of 0.05 mm/rev, and a depth of cut of 0.5 mm. In the trials using the Gr/MoS2 cutting fluid, VB reached 0.30 mm after a duration of 30 min, which was used as the benchmark time for subsequent tests. The progression of flank wear over this period under various cutting fluid conditions is illustrated in Fig. 9. After 30 min, flank wear was measured at 0.25 mm for the hBN/Gr condition and 0.28 mm for the hBN/MoS2 condition. These values correspond to a reduction of 19.25% and 9.68% in flank wear, respectively, compared to the Gr/MoS2 baseline. This clearly demonstrates that the hBN/Gr hybrid nanofluid provided superior performance, showing improvements in tool wear, cutting forces, surface finish, and cutting temperature. As highlighted earlier, the relatively lower viscosity of the hBN/Gr nanofluid is considered a crucial factor contributing to decreased tool wear.

To gain deeper insights into how the hybrid nanofluids influence wear types and mechanisms, detailed SEM imaging and EDX analyses were conducted. Figures 10 and 11 display SEM micrographs of tools tested under hBN/Gr, hBN/MoS2, MoS2, and Gr/MoS2 conditions (all at 60 m/min cutting speed, 0.05 mm/rev feed rate after 30 min). The images show that flank wear, nose wear, Built-Up Edge (BUE), and Built-Up Layer (BUL) were the predominant wear modes observed across all hybrid nanofluid environments. The formation of BUL indicates the involvement of adhesion wear processes. Prior studies have established that abrasive wear is prevalent during machining superalloys, primarily due to the hard carbide particles embedded in the material, which induce wear through combined thermal and mechanical loading alongside chip-tool interactions. This is corroborated by EDX results. Notably, BUL was less prominent in the hBN/Gr and hBN/MoS2 scenarios equated to the Gr/MoS2 case, likely owing to the protective tribofilm and lubrication mechanisms provided by the hBN-containing nanofluids, as further supported by elemental mapping and EDX data. Literature suggests that spherical nanoparticles typically demonstrate superior rolling behavior, which can facilitate lubrication. In this context, the spherical hBN particles, situated between the layered Gr and MoS2 nanoparticles, probably promote an interlayer rolling effect that suppresses BUL build up and thus mitigates flaking wear. As tool wear intensifies and thermal stresses rise, chip material tends to adhere to the tool surface. For the Gr/MoS2 hybrid fluid, BUE was visibly formed on the rake face. The detachment of BUE and BUL layers after repetitive cutting cycles can cause flaking, chipping, and micro-chipping wear. While chipping and flaking were detected under hBN/MoS2 and Gr/MoS2 conditions, only BUL was observed in the hBN/Gr condition. This indicates that the hBN/Gr fluid effectively limits excessive BUE and BUL formation—key contributors to flaking wear. The improvement is mainly attributed to the lower viscosity and the efficient tribofilm formed by the hBN/Gr hybrid nanofluid.

Comparison between sustainable lubricating mediums

This section compares the performance of hybrid nanofluid-based Minimum Quantity Lubrication (hybrid-nMQL) with other cooling/lubrication methods, including dry machining, compressed air, and traditional MQL using sunflower oil, in terms of surface roughness, cutting force, cutting temperature, and tool life (Fig. 12). The study shows that hybrid-nMQL, particularly the hBN/Gr combination, offers significant improvements in all these parameters. In terms of surface roughness, hybrid nanofluids resulted in smoother surfaces, with hBN/Gr reducing roughness by up to 33.33% compared to other methods, due to their enhanced lubrication properties. Hybrid-nMQL also demonstrated lower cutting forces, with hBN/Gr reducing cutting force by up to 9.69% under high cutting speeds and feed rates, thanks to more effective lubrication and cooling provided by the nanoparticles. Additionally, cutting temperatures were reduced by up to 31.91% with hBN/Gr, highlighting the better heat dissipation capabilities of hybrid nanofluids compared to dry machining, compressed air, and traditional MQL. Furthermore, hybrid-nMQL significantly improved tool life, especially under the hBN/Gr condition, which showed a 140% increment in tool life compared to dry medium. The moderate viscosity of hybrid nanofluids allowed better fluid penetration and film formation, minimizing friction and heat generation, thereby enhancing tool life. This makes hybrid nanofluids, particularly those incorporating hBN and Gr, a promising alternative to traditional cooling and lubrication techniques in high-performance machining, offering improved machining efficiency.

Conclusion

This work explored the influence of hybrid nanofluids—specifically hBN/Gr, hBN/MoS₂, and Gr/MoS₂—on the machinability of Inconel 601 under MQL conditions. Key machining performance metrics such as cutting force, surface roughness, cutting temperature, and tool wear were analyzed to assess the effectiveness of these nanofluids. The following conclusions are drawn:

-

The hBN/Gr hybrid nanofluid demonstrated the best overall performance, reducing tool wear by 19.25% and 9.68% compared to Gr/MoS₂ and hBN/MoS₂, respectively, over a 30-min machining period. Tool life was extended by 11.17% and 5.48% under hBN/Gr conditions compared to hBN/MoS₂ and Gr/MoS₂, respectively.

-

Under the most demanding machining parameters (cutting speed of 60 m/min and feed rate of 0.15 mm/rev), hBN/Gr achieved a 4.17% and 2.08% reduction in cutting force compared to Gr/MoS₂ and hBN/MoS₂, respectively.

-

The lowest surface roughness of 0.12 μm was achieved with hBN/Gr at 30 m/min and 0.05 mm/rev, outperforming Gr/MoS₂ (0.14 μm) and hBN/MoS₂ (0.13 μm). At higher machining intensity, hBN/Gr still provided up to 21.05% improvement in surface finish over Gr/MoS₂.

-

The cutting temperature was lowest under the hBN/Gr condition, showing reductions of 3.03% and 8.57% compared to hBN/MoS₂ and Gr/MoS₂, respectively, under aggressive machining conditions.

-

Compared to dry, compressed air, and conventional MQL conditions, hybrid-nMQL with hBN/Gr reduced surface roughness by 33.33%, cutting force by 9.69%, cutting temperature by 31.91%, and extended tool life by 140%, demonstrating its superiority as a sustainable and high-performance lubrication strategy.

-

The superior performance of hBN/Gr can be attributed to its low viscosity, enhanced lubrication mechanisms (mending, rolling, polishing effects), and better tribofilm formation, ensuring effective heat dissipation and wear protection at the tool-workpiece interface.

Despite the promising results, several limitations remain. The study was confined to a single material and limited machining conditions. In addition, the long-term stability, dispersion uniformity, and recyclability of hybrid nanofluids were not explored in depth, which are crucial for industrial-scale implementation.

Future research should address these limitations by:

-

Investigating the impact of different nanoparticle concentrations and base fluids.

-

Exploring the stability and degradation behavior of nanofluids during extended machining periods.

-

Extending the methodology to other difficult-to-machine alloys and real-time adaptive MQL systems to facilitate broader industrial adoption, particularly in aerospace and biomedical component manufacturing.

Data availability

Data supporting this study’s findings are available from the corresponding author upon reasonable request.

References

Sen, B. et al. AI-driven wear monitoring of PVD TiAlN coated carbide insert in sustainable machining of Hastelloy C276: An industry 4.0 perspective. Results Eng. 25, 104457 (2025).

Sun, Z. et al. Cutting performance and surface integrity during rotary ultrasonic elliptical milling of cast Ni-based superalloy. J. Mater. Res. Technol. 35, 980–994 (2025).

Özdemir, M. T., Demirsöz, R. & Polat, R. Enhancing wear resistance of inconel 601 through pack alumunizing coating and advanced lubrication environments. Discov. Mater. 5(1), 1–23 (2025).

Öge, T. Ö. et al. Tribological response of pack-boronized inconel 601 superalloy surfaces at elevated temperatures. Tribol. Int. 203, 110387 (2025).

Maruthamuthu, K., Pandi, K., Sathasivam, A. & Palanisamy, P. Recent advancements in machining processes using minimum quantity lubrication and nanofluids. J. Tribol. 147, 1–68 (2025).

Sen, B. et al. Alumina-enriched sunflower bio-oil in machining of Hastelloy C-276: A fuzzy Mamdani model-aided sustainable manufacturing paradigm. Sci. Rep. 14(1), 29194 (2024).

Khanna, N. & Shah, P. Comparative analysis of dry, flood, MQL and cryogenic CO2 techniques during the machining of 15-5-PH SS alloy. Tribol. Int. 146, 106196 (2020).

Khanna, N. et al. Comparison of VT-20 alloy drilling performance evaluation under dry, MQL, EMQL, and hybrid nanoparticle assisted EMQL ecological conditions. Tribol. Int. 199, 110025 (2024).

Shah, R., Shirvani, K. A., Przyborowski, A., Pai, N. & Mosleh, M. Role of nanofluid minimum quantity lubrication (NMQL) in machining application. Lubricants 10(10), 266 (2022).

Kumar, G., Sen, B., Ghosh, S. & Rao, P. V. Strategic enhancement of machinability in nickel-based superalloy using eco-benign hybrid nano-MQL approach. J. Manuf. Process. 127, 457–476 (2024).

Sarıkaya, M., Şirin, Ş, Yıldırım, Ç. V., Kıvak, T. & Gupta, M. K. Performance evaluation of whisker-reinforced ceramic tools under nano-sized solid lubricants assisted MQL turning of Co-based Haynes 25 superalloy. Ceram. Int. 47(11), 15542–15560 (2021).

Sen, B., Mia, M., Krolczyk, G. M., Mandal, U. K. & Mondal, S. P. Eco-friendly cutting fluids in minimum quantity lubrication assisted machining: A review on the perception of sustainable manufacturing. Int. J. Precis. Eng. Manuf.-Green Technol. 8, 249–280 (2021).

Xiao, G., Zhao, B. & Ding, W. Mechanical and tribological properties of porous metallic CBN composites reinforced by graphene nanoparticles. Int. J. Adv. Manuf. Technol. 114, 397–405 (2021).

Zhao, B., Ding, W., Jiang, G., Li, X. & Xu, J. Investigation on microstructure characteristics and tribological properties of self-lubricating metallic composites based on hexagonal boron nitride and molybdenum disulphide. J. Tribol. 143(2), 021902 (2021).

Li, C., Li, X., Huang, S., Li, L. & Zhang, F. Ultra-precision grinding of Gd3Ga5O12 crystals with graphene oxide coolant: Material deformation mechanism and performance evaluation. J. Manuf. Process. 61, 417–427 (2021).

Sen, B., Mia, M., Mandal, U. K. & Mondal, S. P. Synergistic effect of silica and pure palm oil on the machining performances of Inconel 690: A study for promoting minimum quantity nano doped-green lubricants. J. Clean. Prod. 258, 120755 (2020).

Şirin, Ş & Kıvak, T. Effects of hybrid nanofluids on machining performance in MQL-milling of Inconel X-750 superalloy. J. Manuf. Process. 70, 163–176 (2021).

Jamil, M. et al. Effects of hybrid Al2O3-CNT nanofluids and cryogenic cooling on machining of Ti–6Al–4V. Int. J. Adv. Manuf. Technol. 102, 3895–3909 (2019).

Thakur, A., Manna, A. & Samir, S. Multi-response optimization of turning parameters during machining of EN-24 steel with SiC nanofluids based minimum quantity lubrication. SILICON 12(1), 71–85 (2020).

Thakur, A., Manna, A., & Samir, S. Performance evaluation of Al-SiC nanofluids based MQL sustainable cooling techniques during turning of EN-24 steel. Silicon 1–14 (2021).

Abbas, A. T. et al. Sustainability assessment associated with surface roughness and power consumption characteristics in nanofluid MQL-assisted turning of AISI 1045 steel. Int. J. Adv. Manuf. Technol. 105, 1311–1327 (2019).

Rahman, S. S. et al. Tuning nanofluids for improved lubrication performance in turning biomedical grade titanium alloy. J. Clean. Prod. 206, 180–196 (2019).

Yıldırım, Ç. V., Sarıkaya, M., Kıvak, T. & Şirin, Ş. The effect of addition of hBN nanoparticles to nanofluid-MQL on tool wear patterns, tool life, roughness and temperature in turning of Ni-based Inconel 625. Tribol. Int. 134, 443–456 (2019).

ul Haq, M. A. et al. Evaluating the effects of nano-fluids based MQL milling of IN718 associated to sustainable productions. J. Clean. Prod. 310, 127463 (2021).

Hegab, H. & Kishawy, H. A. Towards sustainable machining of Inconel 718 using nano-fluid minimum quantity lubrication. J. Manuf. Mater. Process. 2(3), 50 (2018).

Sharma, A. K., Katiyar, J. K., Bhaumik, S. & Roy, S. Influence of alumina/MWCNT hybrid nanoparticle additives on tribological properties of lubricants in turning operations. Friction 7, 153–168 (2019).

Singh, R. K. et al. Performance evaluation of alumina-graphene hybrid nano-cutting fluid in hard turning. J. Clean. Prod. 162, 830–845 (2017).

Sharma, A. K., Singh, R. K., Dixit, A. R. & Tiwari, A. K. Novel uses of alumina-MoS2 hybrid nanoparticle enriched cutting fluid in hard turning of AISI 304 steel. J. Manuf. Process. 30, 467–482 (2017).

Sharma, A. K., Tiwari, A. K., Dixit, A. R. & Singh, R. K. Measurement of machining forces and surface roughness in turning of AISI 304 steel using alumina-MWCNT hybrid nanoparticles enriched cutting fluid. Measurement 150, 107078 (2020).

Lotfi, B., Namlu, R. H. & Kılıç, S. E. Machining performance and sustainability analysis of Al2O3-CuO hybrid nanofluid MQL application for milling of Ti-6Al-4V. Mach. Sci. Technol. 28(1), 29–73 (2024).

Namlu, R. H., Lotfi, B. & Kılıç, S. E. Multi-axial ultrasonic vibration-assisted machining of Inconel 718 using Al2O3-CuO hybrid nanofluid MQL. Procedia CIRP 123, 89–94 (2024).

Zhang, Y., Li, C., Jia, D., Zhang, D. & Zhang, X. Experimental evaluation of the lubrication performance of MoS2/CNT nanofluid for minimal quantity lubrication in Ni-based alloy grinding. Int. J. Mach. Tools Manuf 99, 19–33 (2015).

Şirin, Ş & Kıvak, T. Performances of different eco-friendly nanofluid lubricants in the milling of Inconel X-750 superalloy. Tribol. Int. 137, 180–192 (2019).

Liu, M., Xie, H., Pan, W., Ding, S. & Li, G. Prediction of cutting force via machine learning: State of the art, challenges and potentials. J. Intell. Manuf. 36(2), 703–764 (2025).

Talib, N. & Rahim, E. A. Performance of modified jatropha oil in combination with hexagonal boron nitride particles as a bio-based lubricant for green machining. Tribol. Int. 118, 89–104 (2018).

Martins, B., Patacas, C., Cavaleiro, A., Faia, P. & Fernandes, F. Real-time temperature monitoring during titanium alloy machining with cutting tools integrating novel thin-film sensors. Mech. Syst. Signal Process. 228, 112444 (2025).

Bermingham, M. J., Kirsch, J., Sun, S., Palanisamy, S. & Dargusch, M. S. New observations on tool life, cutting forces and chip morphology in cryogenic machining Ti-6Al-4V. Int. J. Mach. Tools Manuf. 51(6), 500–511 (2011).

Singh, R. K., Dixit, A. R., Mandal, A. & Sharma, A. K. Emerging application of nanoparticle-enriched cutting fluid in metal removal processes: A review. J. Braz. Soc. Mech. Sci. Eng. 39, 4677–4717 (2017).

Lin, G. et al. Tool wear on machining of difficult-to-machine materials: A review. Int. J. Adv. Manuf. Technol. 134(3), 989–1014 (2024).

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research at Northern Border University, KSA, for funding this work through project number (NBU-FFR-2025-2461-17).

Author information

Authors and Affiliations

Contributions

J.S.C. and S.S. wrote the main manuscript text. V.K.B.R. and N.P. contributed to data collection and analysis. V.S.M. and L.A. prepared figures and helped with manuscript editing. M.K. provided supervision and critical revisions. R.G. conceived the study, coordinated the project, and finalized the manuscript. All authors reviewed and approved the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Consent for publication

All authors have given their consent for the publication of this manuscript.

Author agreement statement

We the undersigned declare that this manuscript is original, has not been published before, and is not currently being considered for publication elsewhere. We confirm that the manuscript has been read and approved by all named authors and that there are no other persons who satisfied the criteria for authorship but are not listed. We further confirm that the order of authors listed in the manuscript has been approved by all of us. We understand that the Corresponding Author is the sole contact for the Editorial process. He/she is responsible for communicating with the other authors about progress, submissions of revisions, and final approval of proofs.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chohan, J.S., Samantaray, S., Bupesh Raja, V.K. et al. Sustainable machining of heat resistant superalloys using hybrid nanofluid based minimum quantity lubrication. Sci Rep 15, 34069 (2025). https://doi.org/10.1038/s41598-025-14204-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-14204-8