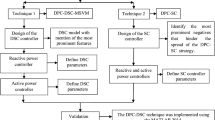

Abstract

Insufficient power grid support for wind turbines has become evident as wind energy use rises, particularly with bigger turbines. This paper introduces a modeling approach for a dual-rotor machine. Furthermore, it proposes a mechanism to integrate the gearbox and synchronous generator with the dual-rotor assembly to serve as a front-end speed control system. The synchronous generator at the end of the drive chain removes the need for a converter to connect electricity to the grid, making dual-rotor wind power production grid-compatible. Given the unique construction of the dual-rotor machine in this proposed system, the conventional mathematical model is no longer suitable for representing such machinery. To solve this problem, a mathematical model is created for the inner rotor of these machines utilizing a “rotating relative coordinate system” and a “relative stationary coordinate system” that stays stationary with the inner rotor while spinning for space. The mathematical model for the dual-rotor system is built on this basis. Final MATLAB simulations prove the unique mathematical model’s viability and the two-rotor wind turbine system’s power production efficiency. This study underscores the potential of this approach in advancing wind energy technology.

Similar content being viewed by others

Introduction

With the expansion of wind power generation share and the increase in single-turbine capacity, several issues concerning wind turbines have become apparent. These issues primarily affect the secure and stable operation of grid networks and the power systems’ power quality. The random fluctuation of wind energy, combined with various grid connection modes and operational characteristics of turbines and related ancillary equipment, leads to voltage flicker, flicker, and current harmonics in wind power output, which can negatively impact the power quality of the system1,2. Additionally, the transient overvoltage resulting from grid instability can cause frequent tripping of wind turbines, posing a danger to the power system’s ability to operate safely and reliably3,4. The need for special generators and complex electronic conversion devices in existing grid-connected wind energy systems adds complexity to the open-loop/closed-loop control of the power generation system. Moreover, the high costs, high failure rates, and operational and maintenance difficulties associated with large-scale converters are persistent problems for extensive-scale turbines5.

Due to the limitations of existing wind power systems’ structural principles, it is challenging to make a significant breakthrough by solely focusing on power electronics technology. Therefore, researchers have proposed the concept of speed-regulating wind turbines6. The synchronous generator and gearbox are connected by means of this speed-regulating device7, bringing the changed pace back to a set rate. As a result, the synchronous generator at the end of the drive chain does not require a converter. This strategy prevents any negative effects on electricity quality and assures the grid’s safe and steady functioning8. Commonly used speed-regulating systems for wind turbines include differential gear trains, hydraulic transmissions, step-less transmissions, and electromagnetic couplers9,10.

Incorporating a speed-regulating mechanism within a traditional wind turbine’s drive chain enables the direct grid connection of the synchronous generator at its end, eliminating the need for a converter. This setup effectively prevents harmonic pollution from electronic devices, thereby enhancing power quality11. Furthermore, in case of a grid failure, these speed-regulating turbines can provide ample reactive power and support low-voltage ride-through, ensuring secure grid operation12. However, wind turbines using differential gear train systems for speed regulation demand high efficiency, strong materials, and temperature adaptability, leading to increased costs13. Similarly, hydraulic drive-based speed-regulated turbines have complex structures, necessitating extensive sealing and higher expenses14. Speed-regulating turbines with Continuously Variable Transmission (CVT) require converters that match their power output, resulting in excessive converter capacity and larger turbine size15. In contrast, electromagnetic coupler systems, functioning as wound asynchronous machines, demand an additional asynchronous machine of equal capacity solely for speed regulation, doubling volume and weight without increasing power generation, posing transportation and hoisting challenges16.

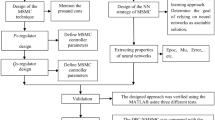

To deal with these challenges, this contribution aims to provide a revolutionary system for wind turbine power generation that incorporates a unique dual-rotor design inspired by speed control turbines. As an initial speed control component, a dual-rotor mechanism is used in this design, which connects the gearbox to an Electrically Excited Synchronous Generator (EESG). This system overcomes the production challenges and high costs associated with differential gears and speed-regulating turbines with hydraulic drives by combining traditional machine components such as a wound rotor, a permanent magnet rotor, and an electrically stimulated synchronous generator. The only device that requires a converter in this suggested arrangement is the dual-rotor machine, which has two rotors: a wound rotor and a permanent magnet rotor. However, because the synchronous generator in this setup runs at a constant speed set by the grid frequency, no converter is needed. As a result, the overall system design is made simpler and the cost of adding more converters is decreased. This efficiently overcomes the issue of large converter capacity in CVT speed-regulating turbines proposed in17. Furthermore, the deep slip design and dual functionalities of the dual-rotor machine, which include regulating speed and generating electricity, address the limitations of a narrow variable-speed, constant frequency operational range, as well as the bulky nature of electromagnetic coupling-based speed regulation turbines. Consequently, this two-rotor wind turbine system provides a fresh and innovative design method for cutting-edge wind turbine power production technology18.

In this work, the system with two rotors for wind power design is presented in Section II. Section III establishes its mathematical model, while Section IV displays the results from MATLAB simulation tests. Finally, Section V draws conclusions based on the findings.

Dual-rotor wind turbine system concept

The suggested wind turbine-producing system is shown in Fig. 1a, while the dual-rotor machine is depicted in Fig. 1b. It’s worth noting that the authors have already published another study detailing the dual-rotor machine’s design and analysis14.

The key component in this system, the dual rotor machine, has a special structure and function. The dual rotor machine is composed of a permanent magnet outer rotor and a wound inner rotor rotating relative to each other, without a stator. In addition, the dual rotor machine has both speed regulation and power generation functions. Before EESG reaches the grid connection condition, the dual rotor machine operates as a motor to achieve synchronous speed matching with the grid, thereby EESG can directly connect to the grid without the need for a converter. After EESG reaches the grid connection condition, the dual rotor machine operates as a generator, and the system supplies power to the grid simultaneously through the dual rotor machine and EESG.

The proposed dual-rotor wind power system offers significant advantages over traditional wind turbines. Conventional turbines, with rigid component connections, especially between the gearbox and generator, are susceptible to damage from impact loads, reducing system reliability. In contrast, the dual-rotor system’s flexible drive chain connection, along with its enhanced system inertia, minimizes damage risks from impact loads, improving turbine system reliability. Furthermore, this technology excels over Doubly-Fed Induction Generator (DFIG) systems by maintaining electric energy quality, offering variable-speed constant-frequency operation, and providing better reactive power control, ensuring efficient wind energy utilization across a wider range of wind speeds.

The dual-rotor wind turbine generating technology is superior to the Permanent Magnet Synchronous Generator (PMSG) in a number of ways. In the first place, it makes use of a partial power converter, which significantly lowers the amount of high-order harmonics in the electricity produced and improves the quality of the energy. This implementation of a partial power converter results in reduced converter costs, smaller converter volumes, and easier and cheaper transportation and installation of the units.

The power-generating dual-rotor wind turbine enhances the chain’s flexibility by securely connecting to the synchronous generator, electrically activated at the drive chain’s end. This feature bolsters unit inertia, partially mitigating the adverse effects of shock loads. Moreover, the End-Effector Synchronous Generator (EESG) at the drive chain’s terminus connects directly to the grid, eliminating harmonic pollution from power electronics and improving electricity quality. EESG’s well-established excitation technology ensures ample reactive power during grid faults, ensuring grid safety.

Additionally, dual-rotor wind turbines employ dual Pulse Width Modulation (PWM) converters, operating back-to-back. These converters, matched to dual-rotor capacities, serve as partial power converters, reducing unit costs. Compared to traditional speed-regulated wind turbines, dual-rotor wind turbines offer combined speed control and electricity generation, flexible operational modes, and variable-speed capabilities across all wind speeds, maximizing energy capture. By utilizing conventional components like permanent magnet and winding rotors, and EESGs, this system tackles cost and complexity issues found in differential gearbox and hydraulic drive wind turbines. Furthermore, only the dual-rotors require converters, eliminating the need for large converter capacities in variable-speed wind turbines. Finally, the dual-rotor system’s combined speed regulation and electricity generation overcome limitations of electromagnetic coupling speed-regulated turbines, including narrow operating ranges and increased size.

Dual-rotor machine modeling

Due to the dual-rotor machine’s distinctive design and functionality, its mathematical model differs from that of existing machines, necessitating a fresh modeling approach19,20,21,22,23. The coordinate transformation system employed for traditional machines is no longer suitable for modeling the device with two rotors. Instead, based on the concept of a “rotating relative coordinate system,” the dual-rotor machine’s wound inner rotor is equipped with relative stationary coordinates in three stages. That is the inner rotor and spinning with respect to the three-phase relative stationary coordinate system a space-time velocity \({\omega _{in}}\) at an electrical angular velocity. Given that the dual-rotor machine’s outer permanent magnet rotor is rotating relative to space at the electrical angular velocity \({\omega _{out}}\), it rotates relative to the system of three-phase relative stationary coordinates on the inner rotor at the electrical angular velocity (\({\omega _{out}} - {\omega _{in}}\)).\({\omega _{out}} - {\omega _{in}}\) is also the speed of electrical rotation of a winding current in the inner rotor generates a magnetic field. The two-phase rotating coordinate system dq can be established on the outer rotor, and the decoupling between windings can be realized. Finally, in the transformation from a nonlinear unsteady system to a linear steady system, one may finish the dual-rotor machine.

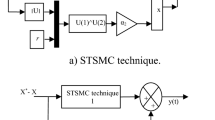

Modeling using a relative stationary three-phase coordinate system

The dual-rotor machine’s inner rotor is wound in three stages, each of which corresponds to a stationary point in the abc system. Electrically, the inner rotor rotates at an angular velocity ωin with respect to space. The inner rotor winding’s AC frequency is \({f_3}={{{\omega _e}} \mathord{\left/ {\vphantom {{{\omega _e}} {2\pi }}} \right. \kern-0pt} {2\pi }}={{\left( {{\omega _{out}} - {\omega _{in}}} \right)} \mathord{\left/ {\vphantom {{\left( {{\omega _{out}} - {\omega _{in}}} \right)} {2\pi }}} \right. \kern-0pt} {2\pi }}\). Given that the dual-rotor machine’s outer rotor revolves at the electrical angular velocity ωout in space and the three-phase winding of the inner rotor revolves at the electrical angular velocity ωin in space, direction of the magnetic field produced by a permanent magnet of the inner rotor winding revolves in relation to the outer rotor at the electrical angular velocity (ωe = ωout -ωin) The amplitude λf is the maximum value of the flux linkage between the magnetic field of the inner rotor’s phase windings and its outer rotor, and \({\theta _e}\) is the angle formed between the inner rotor winding’s phase a and the outer rotor’s magnetic field axis. The dual-rotor machine model in abc coordinates is seen in Fig. 2(a).

The voltage equation for the inner rotor’s three-phase winding is given as follows:

where, ua, ub, uc, & ia, ib, ic, & λa, λb, λc, are the inner rotor’s three-phase winding’s voltage, current, and flux linkage, respectively, and R is the inner rotor’s phase winding resistance.

The flux linkage equation of the three-phase winding of the inner rotor can be expressed as:

where, Laa, Lbb, Lcc, are the inner rotor’s three-phase winding’s self-inductances, Lab, Lba, Lac, Lca., Lbc, Lcb, are the three-phase inner rotor winding’s mutual inductances, λaf, λbf, λcf., are the flux coupling between the inner rotor’s three-phase winding and the outer rotor’s permanent magnet.

Assuming that the spatial magnetic potential and air gap magnetic flux distribution are sinusoidal when the outer rotor rotates relative to the internal rotor at an electrically accelerated angle \({\omega _e}\), the electrical angle of the relative position of the outer rotor will change according to the following formula.

where \({\theta _{e0}}\) is the relative position electrical angle of the outer rotor at \(t=0\). λaf, λbf, λcf., can be expressed as:

The dual-rotor machine adopts the machine with no conspicuous poles, and its air gap geometry does not change with the changes in\({\theta _e}\), so the inner rotor winding’s self-inductance is constant. It can be expressed as:

where, \({L_0}\) is the self-inductance component brought on by the air gap flux in space, and \({L_\sigma }\) is the extra component brought on by flux from armature winding leaking. The three-phase windings on the inner rotor all have the same mutual inductance, which may be written as:

Since the inner rotor current is a three-phase symmetrical AC, thus,

Phase a flux linkage of the inner rotor winding can be expressed as:

Similarly, phase b andc flux linkages are:

If \(\left( {{3 \mathord{\left/ {\vphantom {3 2}} \right. \kern-0pt} 2}} \right){L_0}+{L_\sigma }\) is defined as the inductanceL of the winding within the rotor, the flux linkage equation of the three-phase winding of the inner rotor can be expressed as:

The voltage equation for the inner rotor’s three-phase winding may be written as:

The dual-rotor machine’s mathematical model in the three-phase stationary coordinate system is complex and requires coordinate transformation. This shifts it from a variable coefficient differential equation to a constant coefficient one, while maintaining the magnetomotive force and changing the power.

Modelling in the two-phase relative stationary coordinate system

Select axis α to coincide with axis a, and axis β is 90° ahead of axis α. Since the abc Coordinate System is a three-dimensional relative-stationary coordinate that rotates with the inner rotor relative to space at the electrical angular velocity of ωin, a coordinate system αβ that uses two-phases of relative motion also rotates with the inner rotor relative to space at the electrical angular velocity ωin. The number of windings per phase of the inner rotor three-phase winding abc is denoted by Nr3, and the frequency of AC in the three-phase winding is \({f_3}={{{\omega _e}} \mathord{\left/ {\vphantom {{{\omega _e}} {2\pi }}} \right. \kern-0pt} {2\pi }}\). The number of windings per phase of the two-phase winding αβ of the inner rotor is Nr2, and the frequency of AC in the two-phase winding is\({f_2}={f_3}={{{\omega _e}} \mathord{\left/ {\vphantom {{{\omega _e}} {2\pi }}} \right. \kern-0pt} {2\pi }}\). The voltage and current components of axis α and β of inner rotor winding that uses two-phases are \({u_\alpha },{u_\beta },{i_\alpha },{i_\beta }\), respectively. Figure 2(b) depicts a model of a dual-rotor machine in the coordinate system.

In accordance with the fundamental concept of coordinate transformation, Two-phase relative stationary coordinates (αβ) have the same magnetic field in rotation as three-phase relative stationary coordinates (abc). That is, the components of the synthetic magnetomotive force along the same axis are equal, thus:

Expressed as a matrix:

Since the above formula is not a square matrix and the inverse matrix cannot be obtained, zero axis current \({i_0}\) is introduced. By placing the zero axis at right angles to both the α and β axes, we get the αβ0 coordinate system.

where, K is an undetermined coefficient. Then Eq. (14) can be rewritten as:

Define matrix \({C_{3{s^{\prime}} \to 2{s^{\prime}}}}\) as:

Then the transpose matrix \(C_{{3{s^{\prime}} \to 2{s^{\prime}}}}^{T}\) of \({C_{3{s^{\prime}} \to 2{s^{\prime}}}}\) is:

The inverse matrix \(C_{{3{s^{\prime}} \to 2{s^{\prime}}}}^{{ - 1}}\) of \({C_{3{s^{\prime}} \to 2{s^{\prime}}}}\) is:

After a coordinate transformation, the power remains the same, as stated by the principle of constant power, \(C_{{3{s^{\prime}} \to 2{s^{\prime}}}}^{T}=C_{{3{s^{\prime}} \to 2{s^{\prime}}}}^{{ - 1}}\), so it can be obtained as:

Specifically, the matrix for making the transition from three-phase to two-phase relative stationary coordinates looks like this:

Here is a matrix to transform from two-phase to three-phase relative stationary coordinates:

The equation describing the flux linkage of the dual-rotor machine within the two-phase relative stationary coordinate system is as follows:

where, \({\lambda _\alpha },{\lambda _\beta }\) are the two elements that make up the inner rotor winding’s flux linkage. As part of the two-stage relative stationary coordinate framework, the following equation controls the voltage of the dual-rotor machine:

These formulas reveal complex differential equations with variable coefficients in the two-rotor machine within the two-phase stationary coordinate system, requiring advanced coordinate system transformation techniques for solutions.

Modelling in the system of rotating coordinates

Relative stationary coordinate system αβ for two phases, the AC frequency in the two-phase winding of the inner rotor is \({f_2}={{{\omega _e}} \mathord{\left/ {\vphantom {{{\omega _e}} {2\pi }}} \right. \kern-0pt} {2\pi }}={{\left( {{\omega _{out}} - {\omega _{in}}} \right)} \mathord{\left/ {\vphantom {{\left( {{\omega _{out}} - {\omega _{in}}} \right)} {2\pi }}} \right. \kern-0pt} {2\pi }}\). When the two-phase rotating coordinate system dq (the q axis is 90° ahead of the d axis) rotates relative to the αβ coordinate system at the angular velocity of electricity \({\omega _e}={\omega _{out}} - {\omega _{in}}\), in the dq coordinate system, direct flow makes up the AC component in the inner rotor winding. In other words, the computation is made simpler since there is no connection between the dq coordinate system’s windings. In addition, as a result of the coordinate system αβ with two phases of relative motion rotating with the electrical angular velocity of ωin with the inner rotor relative to space, the dq coordinate system, which has two phases and rotates with the electrical angular velocity of ωo relative to space, that is, the outer rotor and the dq coordinate system both rotate at the same speed. The number of windings per phase of the two-phase winding dq of the inner rotor is N2, and the voltage and current components of the inner rotor winding’s d, q axis are \({u_d},{u_q},{i_d},{i_q}\), respectively. \({\theta _e}\) is the angle between axis d and α. In the dq coordinate system, model of the dual-rotor machine can be found in the supporting information.

The fundamental idea of the coordinate transformation states that two-phase relative stationary αβ coordinates have the same magnetic field as the two-phase rotating dq coordinates. That is, synthetic magnetomotive forces have identical components in every direction, which can be obtained:

A matrix form may be used to represent Eq. (26):

Define matrix \({C_{2{s^{\prime}} \to 2{r^{\prime}}}}\) as:

Since \(\left[ {\begin{array}{*{20}{c}} {\cos {\theta _e}}&{\sin {\theta _e}} \\ { - \sin {\theta _e}}&{\cos {\theta _e}} \end{array}} \right]\) is an orthogonal matrix, \(C_{{}}^{T}=C_{{}}^{{ - 1}}\). Before and after a coordinate transformation, based on the constant power theory, it can be obtained:

The two-phase rotating coordinate system is created by transforming relatively stable two-phase coordinates based on a transformation matrix:

Following that, to convert from a two-phase rotating coordinate system to a two-phase relative stationary one, we use the transformation matrix:

Therefore, two-phase rotational coordinates to three-phase relative stationary coordinates through a transformation matrix:

Then, the matrix representation of the transition from three-phase relative stationary to two-phase rotational coordinates:

According to rotational two-phase coordinates, the dual-rotor machine’s flux linkage equation is:

where, \({\lambda _d},{\lambda _q}\) and \({L_d},{L_q}\) are the flux linkage and inductance of the \({d^{\prime}},{q^{\prime}}\) rotor’s inner winding axis, respectively.

The two-phase rotating coordinate system’s voltage equation for the dual-rotor machine is:

Rewrite the above formula to obtain:

It can be seen from the above formula that when the dual-rotor machine’s electrical angular velocity is constant. The voltage equation is a differential equation with constant coefficients in the two-phase rotating coordinate system, and there is no coupling between the windings, which is easy to solve.

Simulation of the system that powers dual-rotor wind turbines

It is possible to simulate a dual-rotor machine using the well-established mathematical model and the suggested external rotor magnetic chain directed vector control approach, as shown in Fig. 3. The EESG of the system is a mature machine, and its mathematical model and control strategy will not be further elaborated. The focus of this article is on the mathematical model and vector control strategy of the designed dual rotor machine, therefore Fig. 3 only shows the vector control strategy of the dual rotor machine. In order to test the accuracy of the system both before and after grid connection, as well as the accuracy of the dual-rotor machine’s mathematical model and the connection between its rotational velocity, torque, and output power, a MATLAB/Simulink model of the dual-rotor wind turbine generating system was developed. Table 1 lists the specifications of the dual-rotor machine & wind turbines. It should be noted that the selection of wind turbine parameters is based on the parameters of the part of a 2 MW wind turbine that has already been applied in the market.

Synchronous operation control of the dual-rotor device

The dual-rotor machine’s synchronous operation is tested under varying wind conditions with step changes in wind speed and cap wind speed. Before meeting the EESG grid connection criteria, the internal rotor’s speed is synchronized with the EESG using an external rotor magnetic chain directional vector control strategy. This control mechanism combines an outer loop for speed and an inner loop for current, enabling direct grid connection for the EESG without a converter.

Synchronous operation control under step variation in wind speed

The wind speed model depicted in Fig. 4a serves as the basis for validation. The wind speed initially remains constant for the first 0.5 s at 6 m/s. Then, a sharp change happens within 0.5 s, speeding up the wind from 6 m per second to 11. This higher wind speed persists between 0.5 s and 1 s. At 1 s, another abrupt transition takes place, reducing the wind’s velocity from 11 to 6 m/s. The wind then returns to stabilizing at 6 m/s after this. The relationship between wind speed, torque, and power for the dual-rotor machine is shown in Fig. 4b–d.

From Fig. 4b, it is obvious that the dual-rotor machine maintains outer rotor rotational speed is maintained at 125 rpm when the wind is blowing at 6 m/s and 229 rpm when the wind is blowing at 11 m/s. In response to an abrupt shift in wind speed, the internal rotor speed quickly stabilizes at a synchronous velocity of 375 r/min in a time interval of 0.3 s. The magnetic field within the internal rotor winding rotates at -250 r/min when at 6 m/s, the wind is light; at 11 m/s, it becomes a serious threat to life and property, this number drops to -146 r/min. The dual-rotor motor’s exterior and internal rotor speeds are constantly lower than one another over the whole range of wind speeds. A noteworthy difference between the direction of the magnetic field rotation inside the internal rotor winding determines the rotating orientations of the inner and outer rotors. This alignment is numerically compliant with the relationship: nout = nin +ne.

According to Fig. 4c, when the wind speed is 6 m per second, the mechanical torque Tm of the dual-rotor machine is 180 N meters, and when it is 11 m per second, it is 605 Nm. The mechanical torque Ts is stable at -180 Nm when the wind speed is 6 m/s and at -605 Nm when the wind speed is 11 m/s. The electromagnetic torque Te of the stability of the dual-rotor machine at 180 Nm at 6 m/s wind speed and 605 Nm at 11 m/s wind speed. It is clear that mechanical torques are input and output from the dual-rotor machine that are identical in magnitude but opposing in direction over the whole range of wind speeds.

Within Fig. 4d, the mechanical power (Pm) exhibited by the output of the dual-rotor machine, which is only 2355 W at a wind speed of 6 m/s, rises to 14.5 kW at 11 m/s. Meanwhile, the mechanical power (Ps) maintains stability power output is -7065 W at 6 m/s wind speed and − 23.7 kW at 11 m/s wind speed. Correspondingly, the electric power (Pe) remains constant the maximum power output is -4710 W at 6 m/s, and the minimum is -9.2 kW at 11 m/s when the wind speed is 6 m/s. In all wind speed ranges, Pm > 0 represents Pm as the dual-rotor motor’s mechanical input power, Ps < 0 represents Ps as the dual-rotor motor’s mechanical output power, Pe < 0 represents Pe as the dual-rotor motor’s electric input power, and fulfills the connection in terms of numbers Pe = Pm +Ps.

Synchronous operation control under sombrero wind conditions

The validation of the synchronous operating mode of the dual-rotor machine is conducted using wind conditions resembling a Mexican sombrero. This verification employs a 5-second sombrero wind speed profile depicted in Fig. 5a. The relationships between rpm, torque, and output power in a dual-rotor machine under these sombrero wind conditions are showcased in Fig. 5b–d. Remarkably, the inner rotor speed persists at a consistent synchronous rate of 375 r/min across the entire spectrum of wind speeds. Simultaneously, variations in wind speed cause the outer rotor’s speed to change and consistently maintain a lower value than the inner rotor’s speed. Furthermore, it’s noteworthy that the direction of rotation for the inner rotor winding’s magnetic field is in contrast to the rotational directions of the gap in rotational velocity between the two rotors.

Based on the analysis of Fig. 5c, d, it is observed that across the full range of depending on the amount of wind and the dual-rotor machine’s mechanical input and output torques are identical in size but in the opposite direction, and the electromagnetic torque matches the input mechanical torque in value and direction. As Pm > 0, this signifies an input of the dual-rotor machine is powered mechanically. A value of Ps < 0 indicates an output of power generated by the dual-rotor machine. Similarly, since Pe < 0 implies a dual-rotor machine’s electric power input, it suggests that the machine runs in a sub-synchronous mode.

The simulation findings showed that constant operation is possible for the dual-rotor machine under a variety of wind circumstances before being grid-connected and that the inner rotor speed can attain and maintain synchronous speed. Sub-synchronous operation characterizes the dual-rotor machine’s mode of operation; in order to achieve synchronous operation, the in-rotor AC excitation is provided by the converter; the two-spindle motor then draws live power from the grid and operates.

Performance analysis of a series of two-rotor wind turbines

After achieving synchronous operation, the wind turbine generating system’s dual-rotor machine maintains the EESG synchronous speed. Its control objective is to track the ideal speed matching the wind turbine’s peak output at various wind speeds, maximizing wind energy capture. The outer rotor speed is controlled using a vector control method using externally oriented magnetic links. The performance of the dual-rotor machine has been tested using variable wind and combined wind profiles.

Performance under variable wind conditions

The wind speed profile used for performance analysis in variable wind conditions combines step variation and constant variation, as depicted in Fig. 6a. At the same time, Fig. 6b–d illustrate the performance parameters of the dual-rotor device.

In Fig. 6b, initially, the inner rotor magnetic field runs in the opposite direction from the ratio between the two rotors’ speeds, and the outer and inner rotor speeds are lower than each other. After 0.5 s, when compared to the speed of the inner rotor, the outside rotor is moving faster, and the inner rotor magnetic field’s direction coincides with both of these rotor speeds, in accordance with the formula: nout = nin+ne.

In Fig. 6c, it is observed that within the range of wind speeds, the input and output mechanical torques of the machine have equal magnitudes but opposite directions, and the electromagnetic torque is numerically equal to the input mechanical torque and has the same direction. In Fig. 6d, before 0.5 s, the dual-rotor machine utilizes active grid electricity and runs in a sub-synchronous state with Pm> 0, Ps < 0, & Pe < 0. After 0.5 s, the machine outputs active power to the grid and runs in a super-synchronous state. The equation Pe =Pm + Ps is numerically satisfied throughout the range.

Performance of wind conditions with a dual-rotor wind turbine production system

The selected combined wind speed in Fig. 7a is used for 8 s and in Fig. 7b–d, rotor velocity, torque, and output of a dual-rotor machine are shown under this combined wind speed.

Figure 7b, c show how the dual-rotor machine’s outer rotor speed skillfully tracks its ideal value across the range of wind speeds under consideration. The mechanical input torque always stays equal to and opposite to the mechanical output torque, it has been found.

The simulation results in Fig. 7b, d reveal a clear pattern. Before 2.3 s and between 3.7 s and 5 s, the outer rotor lags behind the inner rotor at wind speeds below the synchronous threshold. As a result, the dual-rotor machine absorbs grid electricity, registering as negative electrical power. Conversely, between 2.3 s and 3.7 s, as well as after 5 s, wind speeds exceeding the synchronous level cause the outer rotor to surpass the inner rotor, resulting in positive electrical power output to the grid. Between 2.7 s and 3.3 s, with wind speeds exceeding 12 m/s, the dual-rotor wind turbine system operates with variable pitch control to maintain stability, utilizing its 48 kW rated power from the outer rotor’s constant 575 r/min rotation.

The simulation confirms consistent and stable performance across varying wind conditions once the EESG grid connection is established, effectively harnessing wind energy potential. The machine operates sub-synchronously below the synchronous wind speed, relying on converter-based AC excitation for the inner rotor. In super-synchronous mode, it transfers active electricity to the grid, offering various operational modes under different wind conditions.

Conclusions

This paper presents a dual-rotor wind turbine generation system, offering a significant advancement over traditional wind turbine designs. The key innovation lies in the development of a dual-rotor machine, which integrates a synchronous generator and gearbox to function as a speed control system, eliminating the need for a converter. This design not only enhances the efficiency of wind energy utilization but also improves the stability of the power grid by maintaining high-quality electricity production free from harmonics. The mathematical model developed in this work, particularly the use of rotating and relative stationary coordinate systems, effectively captures the dynamics of the dual-rotor machine, providing a reliable framework for its operation and simulation.

The MATLAB simulations demonstrate that the dual-rotor wind turbine generation system can efficiently operate under various wind conditions, offering both sub-synchronous and super-synchronous modes, with the ability to output power to the grid without requiring large converters. The proposed system’s ability to seamlessly adjust to varying wind speeds while maintaining synchronous operation highlights its potential to optimize wind energy production across a broader range of environmental conditions.

The dual-rotor machine offers a promising advancement in wind turbine technology by addressing some of the challenges found in conventional turbine systems, such as the need for large converters, system complexity, and limited operational flexibility. This work provides a solid foundation for future developments in wind power systems, with the potential to improve the efficiency and reliability of wind energy production while simplifying system design. The proposed dual-rotor machine design represents a step toward optimizing the performance and cost-effectiveness of wind turbine systems.

Data availability

The data that support the findings of this study are available upon request from the corresponding author.

Abbreviations

- CVT:

-

Continuously variable transmission

- EESG:

-

Electrically excited synchronous generator

- DFIG:

-

Doubly-fed induction generator

- PMSG:

-

Permanent magnet synchronous generator

- PWM:

-

Pulse width modulation

- AC:

-

Alternating current

References

Yin, W., Feng, S., Liu, R. P. & Hou, Y. Chance-constrained co‐expansion planning for power systems under decision‐dependent wind power uncertainty. IET Renew. Power Gener. 17 (6), 1342–1357 (2023).

Tsai, W. C., Hong, C. M., Tu, C. S., Lin, W. M. & Chen, C. H. A review of modern wind power generation forecasting technologies. Sustainability 15 (14), 10757 (2023).

Adegbite, A. O. et al. Innovative power management in Electro-Mechanical systems: exploring the new paradigms of energy efficiency and system longevity. Eng. Sci. Technol. J. 4 (6), 401–417 (2023).

Wang, C., Fu, S., Zhang, L., Jiang, Y. & Shu, Y. Optimal control of source–load–storage energy in DC microgrid based on the virtual energy storage system. Energy Rep. 9, 621–630 (2023).

Rajesh Kumar, J. C. & Majid, M. A. Floating solar photovoltaic plants in India–A rapid transition to a green energy market and sustainable future. Energy Environ. 34 (2), 304–358 (2023).

Yin, W., Liu, L., Zhang, W., Li, M. & Guo, Y. Performance improving of wind power generation systems through parameter optimization and dynamic analysis of the Speed-Regulating differential transmission. J. Energy Res. Technol., 145(12). (2023).

Jin, Z., Zhang, J., Wang, S. & Zhang, B. Component-Oriented modeling method for Real-Time simulation of power systems. Energies 16 (6), 2731 (2023).

Wang, S. & Xie, Y. Virtual synchronous generator (VSG) control strategy based on improved damping and angular frequency deviation feedforward. Energies 16 (15), 5635 (2023).

Hu, Z. et al. Harmonic sources modeling and characterization in modern power systems: A comprehensive overview. Electr. Power Syst. Res. 218, 109234 (2023).

Zhu, K. & Ruan, L. Dual active disturbance rejection control of permanent magnet synchronous wind generators. J. Power Electron., 1–12. (2023).

Niu, Y. et al. Research on fault adaptive fault tolerant control of distributed wind solar hybrid generator. Bull. Electr. Eng. Inf. 12 (2), 1029–1040 (2023).

Mostafa, M. A., El-Hay, E. A. & Elkholy, M. M. An overview and case study of recent low voltage ride through methods for wind energy conversion system. Renew. Sustain. Energy Rev. 183, 113521 (2023).

Hannan, M. A. et al. Wind energy conversions, controls, and applications: A review for sustainable technologies and directions. Sustainability 15 (5), 3986 (2023).

Li, Y., Cui, J., Li, H. & Zhao, B. Control strategy of the novel stator free speed regulating wind turbine generation system. PLOS ONE, 19(12). (2024).

Wang, L., Zhang, Z. & Xu, J. Wind turbine blade breakage monitoring with deep auto encoders. IEEE Trans. Smart Grid. 9 (4), 2824–2833 (2018).

Gong, S., Pan, K., Yang, H. & Yang, J. Experimental study on the effect of the blade tip distance on the power and the wake recovery with small Multi-Rotor wind turbines. J. Mar. Sci. Eng. 11 (5), 891 (2023).

Yanan, L. Study of the dual-rotor double machine wind turbine generation system. Energy Rep. 8, 85–95 (2022).

Yanan, L., Jia’an, Z., Zhijun, L., Peng, Y. & Huajun, W. Design and verification of a novel dual-rotor without stator wind turbine generation system. Energy Rep. 7, 161–172 (2021).

Hetyei, C. & Szlivka, F. Review of the aerodynamical load on a Dual-Rotor wind turbine’s blade. Saf. Secur. Sci. Rev. 3 (1), 91–110 (2021).

Li, L., Cao, S., Li, J., Nie, R. & Hou, L. Review of rotor balancing methods. Machines 9 (5), 89 (2021).

Ullah, W., Khan, F., Akuru, U. B., Khan, B. & Khalil, S. A. Evaluation of Counter-Rotating Dual-Rotor Permanent-Magnet Flux-Switching machine with series and parallel stator teeth. Machines 11 (11), 989 (2023).

Jia, L., Lin, K., Lin, M., Le, W. & Wang, S. Comparative analysis of dual-rotor modular stator axial-flux permanent magnet machines with different rotor topologies. IEEE Trans. Appl. Supercond. 31 (8), 1–5 (2021).

Yang, S. H., Pyo, H. J., Jung, D. H. & Kim, W. H. A study on optimal design process of dual rotor Axial-Flux permanent magnet synchronous motors. Machines 11 (4), 445 (2023).

Author information

Authors and Affiliations

Contributions

Conceptualization, Y.L.; methodology, Y.L.; software, Y.L.; validation, Y.L.; formal analysis, Y.L. and H.L.; investigation, Y.L. and J.C.; resources, Y.L. and H.L.; data curation, Y.L.; writing—original draft preparation, Y.L.; writing—review and editing, Y.L.; visualization, Y.L. and B.Z.; supervision, Y.L. and J.C.; project administration, Y.L. and J.C. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Consent for publication

Written consent to publish this information was obtained from study participants.

Use of AI tools declaration

The authors declare they have not used Artificial Intelligence (AI) tools in the creation of this article.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, Y., Cui, J., Li, H. et al. Development and mathematical modelling of a dual-rotor machine for wind turbine power generation system. Sci Rep 15, 30200 (2025). https://doi.org/10.1038/s41598-025-16049-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-16049-7