Abstract

This research offers a simple and convenient strategy for surface decoration of polyurethane sponge foam through the covalent attachment of 5,5-dimethylhydantoin as an N-halamine precursor using 1,6-hexamethylene diisocyanate as a crosslinking agent. After hypochlorite bleach treatment, the N-H bonds in the 5,5-dimethylhydantoin moieties on the polyurethane sponge foam surface change into N-Cl bonds. This modification enhances antibacterial performance against both Gram-positive and Gram-negative bacteria. The washing stability of the prepared Cl-DMH-PUSF substrates was studied after 20 rinsing cycles using the DPD tablet test. The results showed that no active chlorine was released from the Cl-DMH-PUSF substrate after multiple washing processes, implying the strong stability of the active chlorine on the N-halamine surface. To characterize the synthesized antiseptic samples, field emission scanning electron microscopy (FESEM) and energy dispersive X-ray analysis were applied. FESEM images revealed a collection of needle-shaped nanoparticles on the Cl-DMH-PUSF surface, which could act as a needle in contact with bacteria and contribute to pathogen death. This approach is innovative as it uses commercial polyurethane sponge foam modified under mild conditions to produce rechargeable antibacterial substrates with unique nano-coral structures, enabling both chemical and mechanical antibacterial actions.

Similar content being viewed by others

Introduction

Water contamination and freshwater scarcity remain major global challenges. Rapid urbanization and industrial growth have intensified these issues1,2. Inadequate access to clean drinking water was among major public health deficits of the 20th century3. Release of contaminants into natural water bodies has reduced the quantity of freshwater despite the increasing demand4,5. Despite environmental regulations, both groundwater aquifers and surface water reservoirs are still contaminated with various inorganic and organic pollutants, including heavy metals, dyes, and phenolic compounds6,7. Besides chemical pollutants, water often carries microorganisms and pathogens that cause various acute and chronic diseases8,9. Contaminated drinking water has been linked to a broad array of health issues, including skin irritation, allergies, headaches, vomiting, and even cancer10,11. The urgent need for antibacterial and disinfectant compounds to combat pathogens is more critical than ever12. However, one of the primary concerns in this field is the increasing resistance of bacteria and pathogens to conventional disinfectants and antibacterial agents13. Waterborne pathogens torment nearly half of the population in developing countries, with over 3 million people dying annually because of filthy water and ineffective disinfection systems14. To address this issue, a series of antibacterial reagents have been synthesized, among which biocidal polymers, such as N-halamine-based polymers, have gained extensive attention in recent years15,16. Wang et al.17 synthesized mesoporous composite-supported N-halamines (MCSNs) for water treatment and reported that 60% of formaldehyde was decomposed within 10 min under alkaline conditions. MCSNs showed great antibacterial activity, reducing S. aureus and E. coli O157:H7 by over 7 logs within 1 min, highlighting their potential for environmental remediation. In another related research, Zhu et al.18 synthesized antibacterial N-halamine polymer materials based on protein gelatin sponges (GS-Cl) with oxidative chlorine as the active agent. The GS-Cl materials demonstrated high antibacterial efficiency against E. coli and S. aureus, with adjustable chlorine content and good biocompatibility, effectively promoting wound healing in bacterial infection models. Also, Wu et al.19 developed a multifunctional antibacterial cotton fabric (QACs/Hals@cotton-Cl) via in-situ free radical copolymerization. The modified cotton exhibited strong antibacterial properties, eradicating S. aureus and E. coli within 10 min, promoting wound healing, and maintaining durability after multiple uses. The fabric exhibited excellent hydrophobicity and could be easily recharged with chlorine, indicating its potential for medical and hygiene applications. In another study, Sun et al.20 prepared N-halamine-based polyurethane films with rechargeable antimicrobial properties. However, their approach involved laboratory-prepared films, while our study focuses on modifying commercial polyurethane sponge foam with a simpler, scalable method and unique morphological features suitable for practical applications.

N-halamines are known for their long-term stability in both dry environments and aqueous solutions, effectively eliminating a wide range of microorganisms21,22. These compounds can rapidly kill infectious agents, including bacteria, viruses, fungi, and other microorganisms, through the action of halogen atoms within their structure that leading to the inactivation of the N-halamine molecule23. N-halamine compounds disinfect through two primary mechanisms. The first involves the direct transfer of an oxidized halogen (Cl+ or Br+) from the N-Cl or N-Br groups to the cell walls of microorganisms, causing oxidative damage and cell death. The second mechanism involves the breaking of N-Cl or N-Br bonds, releasing Cl+ or Br+ ions into water, which penetrate the microorganism and cause further oxidative damage24,25. According to the Kirby–Bauer test, both mechanisms are believed to occur simultaneously26,27. Traditional water treatment methods often rely on large volumes of chlorine or hypochlorite solutions, which have strong odors and corrosive properties. When these compounds interact with organic matter in water, they can produce carcinogenic by-products such as trihalomethanes28. One promising solution to mitigate these risks is the use of insoluble or immobilized disinfectants. Organic N-halamine compounds, in particular, offer a safer alternative, as they can perform effective disinfection without releasing harmful by-products29. These compounds are available in both solid and water-soluble forms and are known for being stable, odorless, non-corrosive, and non-toxic, making them ideal for disinfecting a wide range of pathogens30,31.

In this study, organic N-halamine compounds were used to functionlize the surface of polyurethane sponge foam (PUSF) for efficient water disinfection. This approach presents a versatile strategy for surface functionalization by covalently attaching 5,5-dimethylhydantoin (DMH) using 1,6-hexamethylene diisocyanate as a crosslinking agent. Upon exposure to hypochlorite bleach, the N-H bonds in DMH moieties were converted into N-Cl bonds, resulting in durable oxidizing agents capable of eliminating bacteria. The synthesized antiseptic substrates were characterized by energy-dispersive X-ray analysis and field emission scanning electron microscopy. Antibacterial performance tests of the chlorinated DMH-PUSF substrates demonstrated excellent activity against both Gram-positive and Gram-negative bacteria. Additionally, the durability and rechargeability of the Cl-DMH-PUSF substrates were evaluated, with active chlorine content assessed through both quantitative and qualitative methods. The bonds of N-H in the DMH moieties be converted into bonds of N-Cl upon exposure to hypochlorite bleach treatment, which turns into durable oxidizing agents versus bacteria. The characterization of the prepared antiseptic substrates was evaluated by energy dispersive X-ray and field emission scanning electron microscopy. The results of the antibacterial performance evaluation of the chlorinated DMH-PUSF shown that these prepared substrates possessed great antibacterial activity against Gram-positive and negative bacteria. The durability and rechargeability of the Cl-DMH-PUSF substrates toward rinsing were studied. The active chlorine content of the disinfected samples was also measured by both quantitative and qualitative methods.

Experimental procedures

Materials

1,6-Hexamethylene diisocyanate (HDI), 5,5-dimethylhydantoin (DMH), and triethylamine (TEA) were obtained from Sigma–Aldrich. Toluene (Merck, p.a.) was used without further purification. Sodium hypochlorite solution (10% NaOCl), diethyl-p-phenylenediamine (DPD), potassium iodide, sodium thiosulfate standard solution, and starch powder were purchased from Yijishiye Company. The polyurethane sponge foam (PUSF) substrate was supplied by Dow Chemical Company. The bacterial strains used in this study, Escherichia coli and Staphylococcus aureus, were obtained from clinical isolates.

Preparation of the DMH grafted PUSF (DMH-PUSF) substrate

The surface of the polyurethane sponge foam (PUSF) substrate was functionalized to impart disinfectant properties using 5,5-dimethylhydantoin (DMH) as a modifying agent and 1,6-hexamethylene diisocyanate (HDI) as a crosslinking agent. First, 5 g of PUSF was cut into small pieces and placed under reflux in a balloon flask. Then, 40 ml of toluene, 4 ml of HDI, and 1 ml of triethylamine (TEA) catalyst were added. The mixture was refluxed under a nitrogen atmosphere at 60 °C for 20 min. The polyurethane segments were then removed, washed with toluene, and dried. In the next step, the PUSF pieces were placed in a separate reflux balloon containing 100 ml of methanol and 10 g of DMH. The mixture was refluxed for 2 h at 60 °C. The resulting product was separated, washed with methanol, and dried20.

Preparation of the chlorinated DMH grafted PUSF (Cl- DMH-PUSF) substrate

To activate the hydantoin-containing polyurethane surface and form N-Cl bonds within the hydantoin structure, the final product (DMH-PUSF) was immersed in a sodium hypochlorite solution (10% NaOCl) for 2 h at room temperature and pH = 7. The activated DMH-PUSF was then washed with distilled water, heated at 45 °C, and dried to remove excess chlorine32,33. Schematics of the performed reactions are shown in Fig. 1. These reactions were conducted in three distinct ways, with variations in the amount of TEA catalyst, reaction time, and reflux temperature.

In Step 1, the commercial polyurethane sponge foam (PUSF) is first cleaned with ethanol to remove surface contaminants and dried to prepare for functionalization. In Step 2, the PUSF is treated with a solution containing 1,6-hexamethylene diisocyanate (HDI) and dibutyltin dilaurate (DBTDL) catalyst in toluene. The HDI reacts with hydroxyl groups present on the PU surface through its isocyanate groups (-NCO), forming covalent urethane linkages and leaving free terminal isocyanate groups for further reaction. In Step 3, 5,5-dimethylhydantoin (DMH) is added, and its active amide N-H groups react with the remaining free -NCO groups of the PU-HDI intermediate, forming a stable covalent bond and anchoring DMH molecules onto the sponge surface. Finally, in Step 4, the functionalized DMH-PUSF is treated with sodium hypochlorite solution under mild conditions, converting the N-H groups of DMH into N-Cl bonds, thus producing the Cl-DMH-PUSF substrate with antimicrobial properties due to the oxidative chlorine atoms bound to the hydantoin rings.

Characterization techniques

Field emission scanning electron microscopy (FESEM, Hitachi S-4160, Japan) was used to characterize the morphological structure of the prepared antiseptic Cl-DMH-PUSF substrates. Energy-dispersive X-ray spectroscopy (EDX, LEO 1530) was employed to perform elemental analysis and detect the presence of chlorine (Cl), oxygen (O), nitrogen (N), and carbon (C) on the surface of the substrates. To evaluate the antibacterial performance and determine the percentage inhibition of bacterial growth, a microplate reader (ELISA) was used for optical density measurements of the prepared samples.

Measurement of active chlorine in disinfectant samples

The active chlorine content in the N-halamine compounds of the disinfected samples was measured using both quantitative and qualitative methods.

The qualitative measurement of the active chlorine with DPD tablets

The chemical method for measuring chlorine levels in water is more practical compared to electronic methods due to its simplicity, cost-effectiveness, and sufficient accuracy. This method allows for the easy determination of both free chlorine and total chlorine concentrations. In the chemical chlorine measurement test, diethyl-p-phenylenediamine (DPD) was used as a reagent. In the presence of chlorine, the DPD reagent changes color, and the chlorine concentration is determined based on the intensity of the resulting dye. Three tests were conducted to evaluate the release of active chlorine from the Cl-DMH-PUSF samples:

In the first test, a small piece of the Cl-DMH-PUSF sample was immersed in 10 ml of distilled water for 2 h. After the sponge sample was removed, the remaining water was tested with a DPD tablet to measure chlorine levels.

In the second test, a DPD tablet was dissolved in 10 ml of distilled water, and a small piece of the Cl-DMH-PUSF sample was immersed in the solution to observe the chlorine release.

In the third test, a DPD tablet was dissolved in 10 ml of distilled water, and a small piece of the Cl-DMH-PUSF sample, previously dried after undergoing 20 washing cycles, was immersed in the solution to assess the stability of active chlorine content.

The quantitative measurement of the active chlorine amount by iodometric Titration

Iodometric titration was used to measure the active chlorine content of the disinfectant solid samples. First, 1 g of potassium iodide was dissolved in 40 ml of distilled water, and the pH of the solution was adjusted to 4. Then, 0.05 g of the solid disinfectant sample was added to the solution and stirred continuously at room temperature for 1 h. The iodine (I₂) produced in the reaction was titrated with a 0.01 mol/L standardized aqueous solution of sodium thiosulfate in the presence of a starch reagent to determine the active chlorine content of the Cl-DMH-PUSF substrate34.

Each measurement was repeated three times, and results are presented as mean ± standard deviation (SD). Paired t-tests were used to analyze differences in chlorine content before and after washing cycles, with p-values < 0.05 considered statistically significant.

This protocol was also performed with the unchlorinated DMH-PUSF substrate as a control. The active chlorine content of the Cl-DMH-PUSF substrate was calculated using the following equation34:

Where VCl is the consumed sodium thiosulfate volume (ml) in the Cl-DMH-PUSF titration. V0 and WCl are the consumed sodium thiosulfate volume (ml) in the unchlorinated DMH-PUSF titration and the Cl- DMH-PUSF weight (g), respectively.

Antibacterial functions evaluation

To evaluate the antibacterial activity of the Cl-DMH-PUSF substrate, clinical isolates of Escherichia coli and Staphylococcus aureus were used as models for Gram-negative and Gram-positive bacteria, respectively. The bacterial isolates were cultured in a nutrient medium in a rotary incubator at 150 rpm and room temperature until they reached the mid-exponential growth phase. The bacterial cells were then harvested by centrifugation at 600 rpm for 10 min and washed three times with phosphate buffer solution35. The washed cells were re-suspended in buffer solution to a final concentration of approximately 10⁸ CFU/ml. A portion of the solid disinfectant sample was cut into smaller pieces, added to distilled water, and placed in an ultrasonic bath to achieve a homogeneous distribution. For the antibacterial test, 50 µl of the bacterial suspension was added to 500 µl of the disinfectant solution and mixed thoroughly. As a control, 50 µl of the bacterial suspension was added to 500 µl of nutrient culture medium without the disinfectant sample. The optical density (OD) of the solutions was measured at 630 nm using a microplate reader36 before incubation (T₀). The culture media were then incubated at 37 °C for 24 h with constant shaking. After incubation, the OD of the solutions was measured again37. The percentage of antimicrobial activity was calculated using the following equation38:

All antibacterial experiments were performed in triplicate, and results are reported as mean ± standard deviation (SD). Statistical analysis was conducted using one-way ANOVA, with p-values < 0.05 considered significant.

Results and discussion

Characterization of the disinfectant Cl-DMH-PUSF substrates

Figure 2 depicts the molecular structure and digital microscope images of the synthesized Cl-DMH-PUSF sponge foam sample. The porous structure of the sponge foam has a skeleton approximately 100 μm thick, with most pores being open while some are closed. The polyurethane structure of this sponge foam is covalently bonded to dimethylhydantoin (DMH) molecules through the crosslinking agent diisocyanate. Upon reaction with sodium hypochlorite (NaOCl), N-halamine structures are formed within the hydantoin moieties.

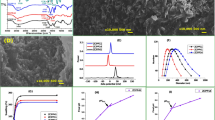

Also, Fig. 3 shows the FE-SEM images of the disinfectant Cl-DMH-PUSF substrates at various magnifications. The images reveal both open and closed pores with a thin layer of polyurethane covering the surface. The main walls of the sponge foam are approximately 100 μm thick, while the thin film covering the pores is about 1–2 μm thick. At higher magnifications, smaller particles can be observed on the polyurethane surface, where needle-shaped nano-corals are visible. These nanoparticles are formed during the chlorination reaction of hydantoin compounds on the surface in the NaOCl solution. These nano-coral assemblies serve as the active disinfectant components on the sponge surface. Figure 4 shows higher magnification images of the N-halamine nano-corals on the sponge surface, which resemble marine corals in morphology. The needle-shaped nanoparticles are approximately 100 nm in length and 20 nm in thickness, with tips measuring about 19 nm in diameter. Also, the size of various microorganisms and pathogens is shown in Fig. 3. Given that the size of bacteria ranges from 1 to a few micrometers and viruses range from 50 to 800 nm, these coral-shaped nano-needles can interact with bacteria or viruses, penetrating their cell bodies and releasing stabilized N-halamine chlorine, leading to pathogen death. The unique nano-coral morphology of these hydantoin compounds provides a high surface area for chlorine uptake, allowing them to store chlorine on the surface for extended periods. One significant advantage of these chlorinated N-halamine compounds is that they eliminate the need for high concentrations of free chlorine in water. Instead, the activated chlorine is stabilized within the solid substrate and is only released upon contact with bacteria. This reduces the risk of forming carcinogenic halo-methane compounds in water. The Cl-DMH-PUSF substrates retain sufficient stabilized chlorine for water disinfection, and when depleted, they can be easily recharged. Figure 5 presents the X-ray map and EDX analysis of the Cl-DMH-PUSF surface, showing the elemental distribution of key elements, including Cl, O, N, and C. The elemental distribution is represented by colored dots, where each color corresponds to a specific element on the surface of the substrate. The map was obtained from a Cl-DMH-PUSF sample after 20 washing cycles. As seen in the image, chlorine is uniformly and abundantly distributed across the polymer surface, confirming the stability of N-Cl compounds even after repeated washing. Additionally, the Cl-DMH-PUSF substrates appear yellow in color due to the presence of the chlorinated hydantoin layer, which is a direct result of the chlorination process. The yellow color forms as a visual indicator of the N-Cl bonds created during the reaction with NaOCl, demonstrating the successful formation of the active chlorine layer on the polyurethane sponge surface. Notably, the yellow color did not fade after multiple washing cycles, indicating the stability and durability of the Cl-DMH layer on the polyurethane sponge foam surface9. The remaining chlorine content in the Cl-DMH-PUSF structure after 20 washing cycles, according to its EDX spectrum, was approximately 11.83% by weight, which shows that it did not decrease significantly compared to the initial chlorine content of the Cl-DMH-PUSF sample (15.4%).

Microscopic digital images and molecular structure of Cl-DMH-PUSF sample (3D image created with image created with Adobe photoshop Version 2019 https://www.adobe.com/products/photoshop.html).

Figure 6 shows the X-ray map images and EDX spectrum of the pristine polyurethane sponge foam sample. Based on the molecular structure of polyurethane, the main elements for distribution analysis in these tests are C, N, and O, while the distribution of chlorine (Cl) is essential for comparison with hydantoin-modified samples. As seen in Fig. 6, a small amount of chlorine (Cl) with blue highlights is detected in the map images and the EDX spectrum (0.27%), which could be due to impurities or even instrumental measurement errors.

Figure 7 shows the X-ray map images and EDX spectrum of the N-halamine-functionalized polyurethane sponge foam sample (Cl-DMH-PUSF). In the MAP images for chlorine, a high and uniform concentration of Cl atoms is observed, resulting from the formation of N-Cl structures. The chlorine content in these images is 15.4% by weight, which is significantly higher compared to the control sample. However, it should be noted that the element content obtained from EDX analysis is approximate and not highly precise, with the exact value measurable by titration. In Figs. 6 and 7, the scale bar of the X-ray map images is approximately 200 μm. These analyses confirm the highly uniform distribution of dimethylhydantoin molecules on the sponge foam surface.

Figure 8 illustrates the FTIR spectra of (a) dimethylhydantoin (DMH), (b) polyurethane sponge foam (PUSF), and (c) DMH-functionalized sponge foam (DMH-PUSF) for comparison.

In spectrum (a) corresponding to DMH, the amide carbonyl (C = O) stretching vibrations appear as strong peaks in the range of 1690–1770 cm–1 (highlighted in green areas). Two types of amide carbonyl groups show absorption peaks in this region. The absorption peak in the 3000–3300 cm–1 region corresponds to the amide N–H stretching vibrations. The absorption peaks in the 2800–2972 cm–1 region are related to the stretching vibrations of the C–H bonds in aliphatic methyl groups. The out-of-plane bending (OOP) vibrations of amide N–H bonds appear in the 500–800 cm–1 region, highlighted in yellow.

In spectrum (b), the polyurethane structure is clearly identified. Notably, the presence of some unreacted isocyanate (N = C = O) groups in the polyurethane sponge foam structure is observed at 2273 cm–1. The amide carbonyl absorption peaks at 1639 and 1716 cm–1 indicate the connection of these groups to aromatic benzene rings.

In spectrum (c), the structure of the DMH-functionalized sponge foam is well confirmed. The appearance of characteristic DMH peaks, highlighted in yellow and green, confirms the successful functionalization of the sponge foam structure. Additionally, the reduction in intensity of the isocyanate peak at 2273 cm⁻¹ further confirms the reaction of these N = C = O groups with DMH molecules.

The active chlorine content of antiseptic compounds

In the qualitative method to detect the content of the active chlorine in the synthesized antiseptic product, the versatile DPD tablet test was applied. The DPD tablet test is a simple and economical approach to detect the presence of active chlorine in disinfectant materials or water. Since the use of rechargeable disinfection N-halamine systems requires determining the exact time of disinfectant substrate inactivation to reactivate the system with sodium hypochlorite, using the DPD test can be very effective and attractive. DPD tablets are commercially available in various packages and are very affordable. The compound Diethyl-p-PhenyleneDiamine (DPD), in contact with chlorine (N-Cl), quickly changes from a colorless state to a pinkish solution, with the intensity of the color change directly related to the concentration of active chlorine. In commercial samples of DPD tablets, a color change chart in terms of chlorine concentration (ppm) is provided with the product, allowing the operator to determine the approximate chlorine concentration by comparing the solution’s color with the chart. The DPD tests were performed on the disinfectant Cl-DMH-PUSF substrate before and after the washing process.

In the first case, a small piece of the Cl-DMH-PUSF sample was immersed in 10 ml of distilled water for 2 h. After removing the sponge sample, the remaining water was tested with a DPD tablet. No color change was observed upon dissolving the DPD tablet in this sample, indicating the absence of free active chlorine (Cl+) in the water. Therefore, no active chlorine leaks from the solid polyurethane sample. This confirms that the Cl-DMH-PUSF substrates do not leach chlorine into water under normal usage conditions, ensuring safety for disinfection applications without releasing harmful free chlorine.

In the second case, one DPD tablet was dissolved in 10 ml of distilled water, and a small piece of the Cl-DMH-PUSF sample was dipped into it. After about 30 s, the solution turned pink due to the contact of DPD molecules with the active surface of N-halamine in the sponge. Figure 9 shows the color change of the solutions in the presence of a polyurethane piece. By comparing the displayed color with the reference color chart, the amount of active chlorine was estimated to be about 0.5 ppm.

To investigate the covalently bound stability of chlorine in the prepared Cl-DMH-PUSF substrate, the sample was rinsed 20 times, dried, and then tested with the DPD solution. Almost the same amount of discoloration was observed after 30 s (with the active chlorine content estimated to be about 0.5 ppm). According to the obtained active chlorine content, it was found that no active chlorine was released from the Cl-DMH-PUSF substrate after multiple washing processes. This test demonstrates the complete stability of the active chlorine on the N-halamine surface, which is not released by washing and only reacts to release Cl+ upon contact with bacteria and organic molecules39.

Additionally, to evaluate storage stability, the Cl-DMH-PUSF samples were stored at room temperature in sealed containers for one month. The active chlorine content and yellow coloration remained unchanged, indicating good storage ability under ambient conditions.

The accurate measurement of active chlorine content in synthesized disinfectant compounds is possible using iodometric titration. In this method, a potassium iodide solution of a certain concentration reacts with N-halamine active chlorine to form iodine (I2), and the exact amount of active chlorine is determined by titration with a standard sodium thiosulfate solution40. The results of the active chlorine content in Cl-DMH-PUSF samples obtained from iodometric titration are presented in Table 1. A non-functionalized PUSF sample exposed to chlorination by NaOCl solution, according to the previously mentioned methods, was prepared and examined as a blank sample33. The titration results showed that no active chlorine was present on the non-functionalized PUSF surface, indicating that the polyurethane sponge foam could not be chlorinated alone. The functionalized Cl-DMH-PUSF sample was titrated before and after 20 washing cycles (20w). The results (Table 2) indicated that multiple washes did not cause a significant reduction in chlorine content. The slight decrease in chlorine content after the 20 washing cycles may be attributed to the separation of thin and brittle polyurethane layers formed on the closed pores. During the washing process, some of these brittle films were lost, resulting in a slight reduction in active chlorine content. This issue can be addressed by using stronger foam filters to enhance durability.

Furthermore, rechargeability tests showed that after re-chlorinating the washed Cl-DMH-PUSF samples with hypochlorite solution, the active chlorine content was effectively restored to near-original levels. This demonstrates that the prepared substrates can be reactivated and reused for multiple antibacterial applications.

Antibacterial activity

To investigate the antibacterial potential of the fabricated Cl-DMH-PUSF substrates, the antibacterial activity of these chlorinated N-halamine compounds was evaluated against the Gram-negative bacterium E. coli and the Gram-positive bacterium S. aureus. The obtained results are listed in Tables 3 and 4, respectively. According to the results, the amount of antiseptic substance used affected the percentage of final antimicrobial activity. As observed, increasing the amount of the substance from 0.16 to 0.21 g caused an increase in antimicrobial activity from 46.43 to 48.87%. With higher concentrations of the synthesized substrates, the antimicrobial property increased significantly and could even reach 100%. This effect can be attributed to the presence of vacant spaces and porous walls in the polyurethane sponge foam, which create a large specific surface area for the binding of N-halamine compounds and act as barriers to the biocidal agent’s attack41,42.

It is worth noting that while N-halamine compounds generally demonstrate rapid and complete bacterial inactivation, the antibacterial inhibition observed in this study was approximately 50% under static test conditions. This relatively moderate effect may be attributed to (i) limited exposure area of the Cl-DMH-PUSF sample relative to the bacterial suspension volume, (ii) partial surface coverage with active N-Cl groups, and (iii) the lack of mechanical agitation to promote direct contact between bacteria and the sponge surface. Therefore, the antibacterial mechanism here primarily depends on physical contact with N-halamine active sites, and increasing the grafting density or implementing dynamic flow systems is expected to enhance antibacterial performance in practical applications.

To achieve the optimal amount of catalyst, the antimicrobial properties of the synthesized samples were evaluated with varying catalyst amounts. The results showed that the optimal catalyst content was 0.2 ml. The synthesized antiseptic substrate demonstrated almost identical antimicrobial activity against both Gram-positive and Gram-negative bacteria. This can be attributed to the high disinfection power of N-halamine compounds, which results in a broad-spectrum extinction of pathogenic agents43.

Antiseptic and rechargeability mechanism of the Cl-DMH-PUSF substrates

The antibacterial mechanism of N-halamine-based polymers involves two primary pathways. First, the direct transfer of oxidative halogen atoms (Cl+) from the N-Cl bonds on the polymer surface to bacterial cell walls occurs upon contact, leading to oxidation of essential cellular components such as proteins, lipids, and nucleic acids, resulting in rapid cell death. Second, if N-Cl bonds are hydrolyzed, free halogen ions (e.g. Cl+) may be released, which can penetrate bacterial cells and cause further oxidative damage internally. However, in the Cl-DMH-PUSF substrates prepared in this study, the DPD tests confirmed that the antibacterial effect occurs mainly through the surface contact mechanism without chlorine leaching, ensuring safe disinfection performance. Additionally, the unique nano-coral morphology formed on the polymer surface may enhance antibacterial efficacy by physically disrupting bacterial membranes.

In general, N-halamine compounds are divided into three categories: amine, amide, and imide compounds. The molecular structures of these compounds are shown in Fig. 10. Amine compounds do not have any C = O electron-withdrawing groups, making their N-Cl bonds very stable and resistant to Cl+ release31. On the other hand, imide compounds, due to the presence of two adjacent C = O groups near the nitrogen atom, have very weak N-Cl bonds, which are easily broken to release Cl+. Among these categories, amide N-halamine compounds exhibit moderate stability with only one adjacent C = O group. In these amide compounds, the stability of the N-Cl bond is sufficient to maintain its disinfectant properties over time while remaining reactive enough to release Cl+ quickly in the presence of bacteria—a balance not achieved in amine or imide compounds44. Also, Fig. 10 illustrates the order of stability and the release rate of activated chlorine in these different compounds. Amide N-halamines, such as DMH, are more stable than imide compounds but react more effectively with bacteria. The synthesis of the disinfectant Cl-DMH-PUSF substrates is based on the use of HDI as an intermediate agent. This HDI compound forms a strong covalent bond with the polyurethane chain through one of its isocyanate groups, facilitated by the alkaline catalyst TEA. The other isocyanate group of HDI, which is highly reactive, binds to the DMH compound. The N-H bonds in the DMH moieties are converted into N-Cl bonds upon exposure to hypochlorite bleach treatment, resulting in durable oxidizing agents effective against bacteria.

Figure 11 schematic representation of the antibacterial mechanism of Cl-DMH-PUSF sponge foam. The synthesized N-halamine structure can release positive chlorine ions (Cl+) upon contact with microorganisms and bacteria. DPD test analyses showed that N-halamine does not break down or release active chlorine ions in contact with water alone. Only upon contact with DPD molecules or microorganisms does the N–Cl bond break ionically, releasing Cl⁺, which can react with DPD molecules or penetrate microorganisms. The positive chlorine ion can enter bacterial cells through ion channels and attack internal components such as DNA. The reaction of active chlorine with bacterial DNA causes severe damage, leading to bacterial death. Finally, the inactivated hydantoin sites can be recharged with sodium hypochlorite (NaOCl) solution, making them ready for subsequent uses.

According to the results obtained from Sect. 3.2, it can be concluded that the disinfection mechanism of this system operates through direct contact with bacteria without releasing chlorine into the water. Therefore, to determine the exact time of inactivation of the disinfectant substrate in continuous disinfection systems, the user can simply remove a piece of the polyurethane sponge from the disinfection tank and test it with DPD tablets. If necessary, the disinfection tank can be recharged using a NaOCl solution.

Schematic representation of the DMH molecule attaches to the surface of polyurethane foam and its antibacterial mechanism (3D images created with image created with Adobe photoshop Version 2019 https://www.adobe.com/products/photoshop.html).

In addition to the theoretical understanding of N-halamine classes presented above, the experimental data in this study provide further mechanistic insights into the antibacterial and rechargeability performance of Cl-DMH-PUSF substrates. Specifically, the FESEM images (Figs. 3 and 4) confirmed the formation of unique needle-shaped nano-coral structures (~ 100 nm in length and ~ 20 nm in thickness) on the sponge surface, which can physically puncture bacterial membranes, leading to direct mechanical damage in combination with oxidative stress from chlorine. The DPD tests (Sect. 3.2) showed no detectable release of free chlorine into water after immersion of the samples, indicating that the antibacterial effect operates mainly through a surface contact mechanism whereby Cl + is transferred from covalently bound N-Cl groups to bacterial cell walls upon direct contact, causing rapid inactivation. Moreover, iodometric titration results (Table 1) demonstrated that after 20 washing cycles, the active chlorine content was only slightly reduced and could be effectively restored to near-original levels by re-chlorination, confirming the practical rechargeability of these substrates for repeated disinfection applications. Thus, the antibacterial mechanism of Cl-DMH-PUSF involves both physical disruption by nano-coral structures and chemical oxidation by N-Cl bonds, supported by experimental evidence of their stability and rechargeability.

Conclusion

In this research, the N-halamine precursor of the 5,5-dimethylhydantoin was covalently grafted onto the surface of polyurethane sponge foam using 1,6-hexamethylene diisocyanate as a crosslinking agent. Upon hypochlorite bleach treatment, the N-H bonds in the 5,5-dimethylhydantoin moieties on the surface of the polyurethane sponge foam were converted into N-Cl bonds, providing rechargeable, durable, and powerful antimicrobial activity against both Gram-positive and Gram-negative bacteria. After multiple rinsing processes, the chemical method using Diethyl-p-PhenyleneDiamine (DPD) tablets was employed to evaluate the washing stability of the prepared Cl-DMH-PUSF substrates. The results showed that no active chlorine was released from the antiseptic Cl-DMH-PUSF substrate after repeated washing, indicating robust stability of the active chlorine on the N-halamine surface. The prepared antiseptic substrates were characterized through FESEM, EDX, DPD tests, and iodometric titration. Notably, the antimicrobial samples prepared in this work are rechargeable, and the inactivation time of the antiseptic substrates can be easily monitored using DPD tablets. If the samples become inactive, they can be recharged via additional chlorination treatments. The obtained results suggest that the prepared antiseptic Cl-DMH-PUSF substrates have significant potential for long-term antimicrobial applications. In addition, the prepared substrates demonstrated good storage stability for at least one month, effective rechargeability after multiple uses, and no chlorine leaching into water, confirming their suitability as safe, durable, and reusable solid-phase disinfectants for practical water treatment.

The key novelty of this study is the successful modification of commercial polyurethane sponge foam to produce rechargeable antibacterial substrates with unique nano-coral structures, enabling dual-action antibacterial mechanisms and offering a scalable and practical solution for water disinfection, which distinguishes this work from previous studies using laboratory-synthesized polyurethane films.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Change history

06 November 2025

A Correction to this paper has been published: https://doi.org/10.1038/s41598-025-26661-2

References

Oulad, F. et al. Fabrication and characterization of a novel Tannic acid coated boehmite/pes high performance antifouling NF membrane and application for licorice dye removal. Chem. Eng. J. 397, 125105 (2020).

Sudhaik, A. et al. Review on fabrication of graphitic carbon nitride based efficient nanocomposites for photodegradation of aqueous phase organic pollutants. J. Ind. Eng. Chem. 67, 28–51 (2018).

Shandilya, P. et al. Fabrication of fluorine doped graphene and SmVO4 based dispersed and adsorptive photocatalyst for abatement of phenolic compounds from water and bacterial disinfection. J. Clean. Prod. 203, 386–399 (2018).

Sudhaik, A. et al. Magnetically recoverable graphitic carbon nitride and NiFe2O4 based magnetic photocatalyst for degradation of Oxytetracycline antibiotic in simulated wastewater under solar light. J. Environ. Chem. Eng. 6 (4), 3874–3883 (2018).

Sakthisharmila, P., Palanisamy, P. & Manikandan, P. Removal of benzidine based textile dye using different metal hydroxides generated in situ electrochemical treatment-A comparative study. J. Clean. Prod. 172, 2206–2215 (2018).

Naseem, K. et al. Removal of congo red dye from aqueous medium by its catalytic reduction using sodium borohydride in the presence of various inorganic nano-catalysts: a review. J. Clean. Prod. 187, 296–307 (2018).

Zinadini, S., Zinatizadeh, A. A. & Derakhshan, A. A. Novel (4, 4-diaminodiphenyl sulfone coupling modified PES/PES) mixed matrix nanofiltration membranes with high permeability and anti-fouling property. Separ. Purif. Technol. 236, 116292 (2020).

Siddiqui, S. I. & Chaudhry, S. A. Nigella sativa plant based nanocomposite-MnFe2O4/BC: an antibacterial material for water purification. J. Clean. Prod. 200, 996–1008 (2018).

Oulad, F. et al. Preparation and characterization of loose antifouling nanofiltration membrane using branched aniline oligomers grafted onto polyether sulfone and application for real algal dye removal. Chem. Eng. J. 401, 125861 (2020).

Siddiqui, S. I. & Chaudhry, S. A. Nanohybrid composite Fe2O3-ZrO2/BC for inhibiting the growth of bacteria and adsorptive removal of arsenic and dyes from water. J. Clean. Prod. 223, 849–868 (2019).

Siddiqui, S. I. et al. Nigella sativa seed based nanocomposite-MnO2/BC: an antibacterial material for photocatalytic degradation, and adsorptive removal of methylene blue from water. Environ. Res. 171, 328–340 (2019).

Kenawy, E. R., Worley, S. & Broughton, R. The chemistry and applications of antimicrobial polymers: a state-of-the-art review. Biomacromolecules 8 (5), 1359–1384 (2007).

Ringot, C. et al. Triazinyl porphyrin-based photoactive cotton fabrics: preparation, characterization, and antibacterial activity. Biomacromolecules 12 (5), 1716–1723 (2011).

Gleick, P. H. Dirty-water: Estimated Deaths from water-related Diseases 2000–2020 (Citeseer, 2002).

Hui, F. & Debiemme-Chouvy, C. Antimicrobial N-halamine polymers and coatings: a review of their synthesis, characterization, and applications. Biomacromolecules 14 (3), 585–601 (2013).

Kocer, H. B. et al. A novel N-halamine acrylamide monomer and its copolymers for antimicrobial coatings. Reactive Funct. Polym. 71 (5), 561–568 (2011).

Wang, Y. et al. Preparation of N-halamine-based mesoporous composites for decontamination of formaldehyde and simultaneous deactivation of bacteria. Colloids Surf., A. 700, 134664 (2024).

Zhu, J. et al. Preparation of N-Halamine gelatin sponge and its application in the treatment of skin infection. Polymers 16 (18), 2579 (2024).

Wu, K. et al. Fabrication of multifunctional cotton fabrics with quaternized N-halamine endowing the synergetic rechargeable antibacterial, wound healing and self-cleaning performances. Int. J. Biol. Macromol. 275, 133493 (2024).

Sun, X. et al. An N-halamine-based rechargeable antimicrobial and biofilm controlling polyurethane. Acta Biomater. 8 (4), 1498–1506 (2012).

Chang, J. et al. Alkyl substituted hydantoin-based n-halamine: preparation, characterization, and structure–antibacterial efficacy relationship. Ind. Eng. Chem. Res. 55 (35), 9344–9351 (2016).

Lan, S. et al. Electrospun sesbania gum-based polymeric n-halamines for antibacterial applications. Polymers 11 (7), 1117 (2019).

McCann, B. W. et al. Inter-and intramolecular mechanisms for Chlorine rearrangements in Trimethyl-Substituted N-Chlorohydantoins. J. Phys. Chem. A. 116 (26), 7245–7252 (2012).

Liang, J. et al. Polymerization of a hydantoinylsiloxane on particles of silicon dioxide to produce a biocidal sand. J. Appl. Polym. Sci. 97 (3), 1161–1166 (2005).

Lin, J., Cammarata, V. & Worley, S. Infrared characterization of biocidal nylon. Polymer 42 (18), 7903–7906 (2001).

Bauer, A. et al. Antibiotic susceptibility testing by a standardized single disk method. Am. J. Clin. Pathol. 45 (4_ts), 493–496 (1966).

Chen, Z., Luo, J. & Sun, Y. Biocidal efficacy, biofilm-controlling function, and controlled release effect of chloromelamine-based bioresponsive fibrous materials. Biomaterials 28 (9), 1597–1609 (2007).

Black & Corporation, V. White’s Handbook of Chlorination and Alternative Disinfectants (Wiley, 2011).

Dong, A. et al. Chemical insights into antibacterial N-halamines. Chem. Rev. 117 (6), 4806–4862 (2017).

Ahmed, A. E. S. I. et al. New approach to produce water free of bacteria, viruses, and halogens in a recyclable system. Appl. Environ. Microbiol. 77 (3), 847–853 (2011).

Akdag, A. et al. The stabilities of N – Cl bonds in biocidal materials. J. Chem. Theory Comput. 2 (3), 879–884 (2006).

Cao, Z. & Sun, Y. Polymeric N-halamine latex emulsions for use in antimicrobial paints. ACS Appl. Mater. Interfaces. 1 (2), 494–504 (2009).

Luo, J. & Sun, Y. Acyclic N-halamine‐based fibrous materials: preparation, characterization, and biocidal functions. J. Polym. Sci., Part A: Polym. Chem. 44 (11), 3588–3600 (2006).

Yao, J. & Sun, Y. Preparation and characterization of polymerizable hindered amine-based antimicrobial fibrous materials. Ind. Eng. Chem. Res. 47 (16), 5819–5824 (2008).

Akujobi, C. & Njoku, H. Bioassay for the determination of microbial sensitivity to Nigerian honey. Global J. Pharmacol. 4 (1), 36–40 (2010).

Kuda, T., Shimizu, K. & Yano, T. Comparison of rapid and simple colorimetric microplate assays as an index of bacterial count. Food Control. 15 (6), 421–425 (2004).

Patton, T. et al. Use of a spectrophotometric bioassay for determination of microbial sensitivity to Manuka honey. J. Microbiol. Methods. 64 (1), 84–95 (2006).

Sarker, S. D., Nahar, L. & Kumarasamy, Y. Microtitre plate-based antibacterial assay incorporating resazurin as an indicator of cell growth, and its application in the in vitro antibacterial screening of phytochemicals. Methods 42 (4), 321–324 (2007).

Cao, Z. et al. Rechargeable infection-responsive antifungal denture materials. J. Dent. Res. 89 (12), 1517–1521 (2010).

Cao, Z. & Sun, Y. N-halamine‐based chitosan: preparation, characterization, and antimicrobial function. J. Biomed. Mater. Res. Part A 85 (1), 99–107 (2008).

Denyer, S. P. Mechanisms of action of antibacterial biocides. Int. Biodeterior. Biodegrad. 36 (3–4), 227–245 (1995).

Larson, M. A. & Mariñas, B. J. Inactivation of Bacillus subtilis spores with Ozone and monochloramine. Water Res. 37 (4), 833–844 (2003).

Liang, J. et al. N-halamine/quat siloxane copolymers for use in biocidal coatings. Biomaterials 27 (11), 2495–2501 (2006).

Li, X. et al. Biocidal activity of n-halamine Methylenebisacrylamide grafted cotton. J. Eng. Fibers Fabr. 10 (2), 155892501501000217 (2015).

Author information

Authors and Affiliations

Contributions

Ali Ashraf Derakhshan was the primary author of this study.Ali Akbar Zinatizadeh was the supervisor of this study.Ali Rostami wrote and edited the article and checked the data’s validity. Fariba Oulad, Khosro Chehri, and Mozhgan Fathi Delphani also edited the article.All authors reviewed and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this Article was revised: The original version of this Article contained an error in the Figures, where Figure 7 was a duplication of Figure 6.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Derakhshan, A.A., Zinatizadeh, A.A., Rostami, A. et al. Preparation and characterization of a novel rechargeable antibacterial polyurethane sponge foam substrate modified with chlorinated N-halamine for efficient disinfection. Sci Rep 15, 30605 (2025). https://doi.org/10.1038/s41598-025-16711-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-16711-0