Abstract

The development trend of high precision of mechanical equipment, the reliability of bearings work increasingly demanded. Therefore, it is crucial for the reliable operation of mechanical equipment to evaluate the health status of bearings. It combines IDBO (Improved Dung beetle optimizer) optimised VMD (Variational mode decomposition) and CNN-BiLSTM (convolutional neural network-Bi-directional Long Short-Term Memory) to achieve rolling bearing conformity fault diagnosis and damage assessment. Chaotic mapping, Golden sine algorithm and cosine iteration strategy are introduced to improve the performance of DBO, and the hyperparameters of VMD are optimised using IDBO to improve the signal pre-processing. Feature extraction and fault classification of signals using CNN-BiLSTM is used to compensate for the poor diagnosis of CNN timing signals by BiLSTM instead of Softmax classifier. The HUST dataset is used to discuss the application of signal processing methods and neural network models in bearing composite fault diagnosis. The advantages of the proposed scheme in bearing composite fault and damage assessment are verified, effectively solving the challenge of rolling bearing composite fault diagnosis.

Similar content being viewed by others

Introduction

As an important part of mechanical equipment, rolling bearings are widely used in aerospace equipment, transportation tools and wind power equipment1. Affected by many factors such as design scheme, processing and manufacturing, and service conditions, bearings often become the source of mechanical faults2. For most machinery, it has been demonstrated that the initial damage to the bearings is minimal3. With the continuous operation of faulty bearings, a single weak early fault gradually evolves into a composite fault with a greater degree of harm4. Furthermore, the operation of the fault bearing results in the gradual expansion of the defect, owing to factors such as fatigue damage, wear, and eccentric damage, amongst others5. In the event that bearings are found to be non-compliant with the established scrapping standards, the prevailing practice among industry entities is to continue utilising them until such time as the defective bearing is deemed unsuitable for further use5. Consequently, it is imperative to devise methodologies that facilitate the expeditious identification and analysis of both singular and compound faults in bearings, irrespective of their respective defect severity levels. This approach is of paramount importance in ensuring the optimal functionality of the bearings in service6. At present, the primary objective of most bearing fault diagnostics is to achieve fault classification at different rotational speeds7. However, the rotational speed of most machines, including machine tools and engines, remains essentially constant during the majority of their operational time. Consequently, conventional single-fault diagnosis schemes are inadequate for compound fault diagnosis, particularly in scenarios where different defect levels coexist at the same rotational speed.

After the signal of the fault bearing is collected by the sensor, it will be interfered by a large number of irrelevant signals8. In order to obtain more pure fault information, it is necessary to preprocess the original signal to separate the fault signal from the interference signal. The commonly used signal processing methods include wavelet transform (WT)9, empirical mode decomposition (EMD)10, and local mean decomposition (LMD)11. The utilisation of these methodologies facilitates the segregation of bearing fault signals from noise signals. WT cannot decompose signals adaptively and requires the wavelet basis function to be set in advance. Similarly, EMD and LMD, along with their improved algorithms, cannot solve the fundamental problems of modal overlap and boundary effects12. Dragomiretskiy proposed a new non-stationary signal processing method: variational mode decomposition (VMD)13, which avoids the problems of endpoint effect and false component in the iterative process. Zhang et al.14 used VMD to process the bearing fault signal to remove the interference of irrelevant signals and accurately extract the fault characteristics. Li et al.15 pretreated the bearing fault signal by VMD, and then diagnosed the bearing fault by multiple classifiers. The results show that the fault classification accuracy is significantly improved compared with the fault signal without VMD preprocessing.

However, it is important to note that the effect of signal decomposition of VMD is directly related to the number of modes and penalty factors16. Setting the number of modes too high may result in false modes, whereas setting it too low may result in under-decomposition. A smaller penalty factor may result in mode overlap, whereas a larger penalty factor may result in the loss of local signal information. To achieve optimal signal decomposition, it is necessary to adjust the parameters7. Xing et al.17 investigated the correlation coefficient, the kurtosis index and the spectrum graph. They explored the influence of decomposition effect and applied it to the decomposition of bearing simulation signals. This was achieved by examining the parameter range under different engineering backgrounds. The results were satisfactory18. It is possible to determine the value of the modal number by means of the centre frequency and spectrum of the decomposed signal19. However, it is difficult to determine the specific value of the penalty factor20. Also the method requires expert experience and computational resources and is not adaptive21. In order to solve the problem of VMD parameter selection, Wang et al.22 employed the swarm intelligence optimisation algorithm (SSA) to adaptively optimise the parameters of the VMD and process the bearing fault signal, achieving favourable outcomes. The population structure of SSA is characterised by homogeneity, which may result in the convergence of solutions to complex optimisation problems prior to the completion of the full iteration process23. The Dung beetle optimizer(DBO) algorithm is an emerging swarm intelligence optimisation algorithm that employs simulation modelling of four species of dung beetle to complete optimization24. The population structure is complete and suitable for dealing with complex optimization problems25. However, like other swarm intelligence algorithms, DBO must improve the convergence accuracy to complete convergence when dealing with complex problems26.

Following signal pre-processing, the efficient classification of faults in various signals is required to achieve bearing fault diagnosis27. With the development of deep learning theory, its excellent data processing and information mining capabilities have been continuously and successfully applied to various engineering cases28,29. It is essential to explore the potential application of deep learning theory in bearing fault diagnosis30. Choudhary et al.31 input the thermal images of rolling bearings in six states into CNN, and this non-contact fault diagnosis can detect early bearing faults in time. In their study, Tang et al.32 constructed the feature set of bearing fault signals by means of a stacked auto-encoder (SAE) network. Utilising a long short-term memory (LSTM) network to learn the feature set and predict the performance of the bearing, the efficacy of the proposed method is demonstrated to exceed that of the conventional approach. Guo et al.33 proved the feasibility of the method by combining CNN and BiLSTM to diagnose the faulty bearing signals, and achieved high accuracy. The effectiveness of the aforementioned methods in the field of bearing fault diagnosis using neural networks has been exhaustively documented34,35. However, it is important to acknowledge the inherent limitations of these methods, which include the potential loss of critical fault information due to structural constraints inherent in the network design and the undue influence of factors such as network parameters on the diagnostic results36,37,38.

In addressing the aforementioned issues, this paper proposes a novel approach to diagnose rolling bearing faults at constant speeds. This method integrates IDBO-VMD and CNN-BiLSTM, leveraging their individual strengths to enhance the accuracy and efficiency of the diagnosis process. The study introduces the chaotic mapping algorithm and the Golden sine algorithm to optimise the DBO algorithm, with the objective of enhancing its convergence speed and robustness. The integration of CNN and BiLSTM neural network models results in the development of the CNN-BiLSTM fault diagnosis model.In summary, the principal contributions of this study can be categorized as follows:

-

1.

The design of a bearing compound fault diagnosis model based on IDBO-optimised VMD denoising combined with CNN-BiLSTM.

-

2.

An improved Dung beetle optimizer algorithm is proposed. Use chebyshev chaotic mapping to initialize the population, introduce Golden sine algorithm to improve its convergence speed and accuracy.

-

3.

The validation of the efficacy of data pre-processing for the diagnosis of bearing compound faults through the analysis of the results of the diagnosis. The following conclusions were drawn: The accuracy of fault diagnosis was significantly improved by appropriate data pre-processing.

-

4.

The effectiveness of the Dung beetle optimiser algorithm was confirmed through the analysis of the results of bearing fault diagnosis.The advantages of the method of signal processing and the neural network were studied through the analysis of bearing fault diagnosis cases with the same speed and different fault dimensions.

Composite fault diagnosis process and method

Fault bearing fault diagnosis process

Step 1 Vibration acceleration signals of compound fault bearing with different defect degree are presented in data acquisition test bench. Step 2 The key hyperparameters of VMD are optimized by IDBO using enveloping entropy as fitness function. The optimized VMD is used to preprocess the fault signal and obtain multiple IMF components39. Step 3 The sensitive IMF components are screened by the minimum envelope entropy, and the time-frequency characteristics of the reconstructed signals are calculated to construct the feature set. Step 4 The feature set is input into CNN-BiLSTM for feature extraction and fault diagnosis, and the diagnosis results are shown in matrix graph. Figure 1 shows a composite fault diagnosis flow chart.

VMD algorithm

The VMD signal decomposition method has a rigorous mathematical reasoning formula, and is widely used in the processing of non-stationary and nonlinear signals because of its advantages of mode variation adaptation and complete recursion. By transforming the signal decomposition problem into the construction and solution of variational problem, and by constraining the mode center frequency, the mode mixing phenomenon of EMD is avoided, which has better convergence and stability. The detailed steps of the algorithm can be referred to Reference13.

Improved dung beetle optimizer

Dung beetle optimizer

The DBO algorithm draws inspiration from five distinct behaviors of dung beetles—ball-rolling, dancing, foraging, reproduction, and theft—to establish five corresponding update rules. By iteratively updating the positions of the beetles based on these behaviors, the algorithm continuously refines and outputs the current optimal solution along with its fitness value until the iteration process is complete, ultimately delivering the global optimal solution and its associated fitness value. For detailed information on the DBO algorithm, please refer to Reference24. Similar to other swarm intelligence optimization algorithms, the DBO algorithm faces challenges in balancing global exploration and local exploitation, determining appropriate population size, and ensuring adequate coverage of the initial population25. During iterative optimization, the algorithm is susceptible to converging prematurely on local optima. In this study, we enhance the exploration capabilities of the DBO algorithm by optimizing the initialization of the population and improving the coordination between global and local search strategies.

-

(1)

Perturbation strategy based on chebyshev chaotic map.

The diversity and quality of the initial population is one of the factors affecting the performance of swarm intelligent optimization algorithms, although DBO has four populations, the initialisation inputs of different populations are more homogeneous and of lower quality. Chaos theory is a kind of non-linear theory to study complex systems, with the characteristics of non-periodicity, unpredictability and randomness, and its high sensitivity to the initial conditions has a great advantage in the initial population input of intelligent optimisation algorithm.

Chaotic mapping is a way to generate chaotic mapping operator, Chebyshev mapping is a kind of chaotic mapping based on Chebyshev polynomials40. Compared with other chaotic mapping, Chebyshev mapping has the characteristics of high stochasticity, sensitivity to the initial state and low susceptibility to periodic state, so in this paper, We introduce the chaotic mapping operator for the initial population inputs, and the chaotic variables linearly mapped to the parameter domain, using the chaos equation to initialise the population inputs, to increase the population diversity, to improve the global search ability of the algorithm, and to prevent the algorithm from falling into the local optimum. The initialisation of the k-order Chebyshev mapping is defined as in Eq. (1).

$$\:{x}_{n+1}=\text{cos}\left({karccos}{x}_{n}\right)$$(1)where \(\:{x}_{n}\)∈[-1,1], and when the order k ≥ 2(in this paper, we take k = 4),no matter how similar the choices of the initial values are, the sequences iterated out are uncorrelated with each other, i.e., they are chaotic and ergodic in this range. Chaotic mapping can make the initial population inputs of dung beetles more random, which is conducive to improving the accuracy of the algorithm and accelerating its convergence.

-

(2)

Golden Sine Strategy dung beetle position updates.

Golden sine algorithm (Gold-SA) coordinates global and local searches by using periodic fluctuations of the sine function and the golden ratio coefficient. This significantly improves the accuracy and convergence speed of the algorithm when finding the optimal solution. The details of the GSA algorithm can be found in the through Reference41. The positional update of the Gold-SA is shown in Eq. (2).

$$\:\begin{array}{c}{X}_{i}^{t+1}={X}_{i}^{t}\times\:\left|\text{sin}\left({R}_{1}\right)\right|+{R}_{2}\times\:\text{sin}\left({R}_{1}\right)\times\:\\\:\left|{x}_{1}{P}_{i}^{t}-{x}_{2}\times\:{X}_{i}^{t}\right|\end{array}$$(2)where \(\:{X}_{i}^{t}\) denotes the position of i in the t-th iteration, \(\:{P}_{i}^{t}\) is the optimal position of i in the t-th iteration, \(\:{R}_{1}\)∈[0,2\(\:\pi\:\)] determines the operator’s move distance in the next iteration, and\(\:{\:R}_{2}\)∈[0,\(\:\pi\:\)] determines the direction of the next move, \(\:{x}_{1}\)and \(\:{x}_{2}\)are obtained by the golden section coefficient τ coefficient.

In the DBO algorithm, the ball-rolling dung beetle searches for potential optimal solutions in the solution space through ball-rolling behaviour is the core and foundation of the operation of the DBO algorithm, and the efficiency and accuracy of the ball-rolling behaviour affects the overall convergence speed of the algorithm and the accuracy of the solution, while the direction of the ball-rolling behaviour is affected by the intensity of sunlight \(\:{\Delta\:}x\) and the coefficient b. Although the algorithm will continue to move away from the worst position, there is a certain probability that the algorithm iteration will become slower and fall into the local optimum. To improve the rolling behaviour and population interaction of the ball rolling dung beetle, the golden sine strategy is used to optimise the rolling behaviour and improve the stability of the convergence of the algorithm, and the improved position update formula for the rolling behaviour is shown in Eq. (3).

$$\:\begin{array}{c}{x}_{i}\left(t+1\right)={x}_{i}\left(t\right)\times\:\left|\text{sin}\left({R}_{1}\right)\right|+{R}_{2}\times\:\text{sin}\left({R}_{1}\right)\times\:\\\:\left|{x}_{1}{P}_{i}^{t}-{x}_{2}\times\:{x}_{i}\left(t+1\right)\right|\end{array}$$(3) -

(3)

Non-linear cosine change convergence factors.

The adaptation factor R is a key factor affecting the global exploration and local exploitation of the DBO, which changes linearly with the number of iterations through Eq. (4). The algorithm limits the region to the current optimal solution by the adjustment factor to complete the mutation operation, and the non-linear convergence factor cannot fully reflect the optimisation search process.

$${\text{R}} = {\text{1}} - {\text{t}}/{\text{M}}$$(4)where t is the current number of iterations and M is the maximum number of iterations. Therefore, in order to achieve a well-coordinated development, the corrected convergence factor is varied with iterations through Eq. (5) by introducing a non-linear, cosine-varying convergence factor that mimics the cosine variation42.

$$\:\left\{\begin{array}{c}{R=R}_{\text{f}}+\left({R}_{\text{i}}-{R}_{\text{f}}\right)\frac{1+{\left|\text{cos}\left(\frac{\left(t-1\right)\pi\:}{\left(\text{M}-1\right)}\right)\right|}^{\text{n}}}{2},\\\:t\le\:\frac{1}{2}M\\\:{R=R}_{\text{f}}+\left({R}_{\text{i}}-{R}_{\text{f}}\right)\frac{1-{\left|\text{cos}\left(\frac{\left(t-1\right)\pi\:}{\left(\text{M}-1\right)}\right)\right|}^{\text{n}}}{2},\\\:\frac{1}{2}M<t\le\:M\end{array}\right.$$(5)Where \(\:{R}_{\text{i}}\) and \(\:{R}_{\text{f}}\) are the initial and final values of the convergence factor R. The corrected convergence factor decreases slowly in the early stages of the iteration to maintain excellent global exploration capability, and decreases faster in the later stages of the iteration so that the algorithm maintains excellent localisation exploration capability.

-

(4)

Algorithmic efficiency.

To demonstrate the algorithmic efficiency of IDBO, IDBO and the optimisation algorithms SSA, DBO, IVY43 and HO44, whose algorithmic efficiency has been proven in other engineering optimisation domains, were used to find the optimum of the standard test function. Due to space limitations, the single peak test function F1 what test the global development ability of the algorithm, the multi-peak test function F2 what test the exploration ability of the algorithm, and the fixed peak test function F3 what test the coordination ability of the algorithm45. The specific information of the function corresponds to Table 1.

The results of optimisation algorithms are shown in Fig. 2, IDBO has the smallest function value and the best optimisation result in the test of single-peak function, which demonstrates the improvement of the improved strategy on the local exploration ability of DBO; in the test of multi-peak function, except for DBO, the rest of the algorithms output the optimal function value, among which IDBO has the smallest value of the initial iteration, which verifies the validity of the chaotic strategy in the initial population optimisation; in the test of fixed-peak function, except for SABO, the rest of algorithms output the optimal function value. Finally, compared with the test results of DBO, the improvement effect of IDBO algorithm is more obvious.

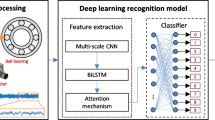

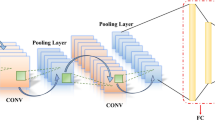

CNN

Convolutional neural network is a kind of feed-forward neural network with convolutional operation and deep structure, which mainly consists of convolutional layer, pooling layer and fully-connected layer27. CNN with its powerful potential features feature mining ability achieved a great success in the field of image and natural language processing, It is now widely used in the field of signal processing, and the related technology is gradually maturing. Although CNN have achieved good results in signal processing, their fixed convolution kernels can cause issues such as the loss of historical signal information when processing time-series signals, which can seriously affect processing performance in applications such as bearing fault detection.

BiLSTM

Recurrent neural networks (RNNs) are extensively utilised in the processing of bearing timing signals due to their capacity to store timing signal history information. However, issues such as gradient vanishing have been observed in classical RNNs, leading to the storage of information that is often of a short-term nature during the back-propagation process within the network.

Long Short Term Memory Neural Network (LSTM) is a kind of improved RNN used to solve the problem of gradient disappearance, its structure is similar to RNN46. LSTM introduces the ‘gate’ mechanism to regulate the flow of information on the basis of RNN. This strategy of selectively storing temporal information solves the problem of gradient vanishing in RNN. LSTM gate control is completed by the input gate, oblivion gate, and output gate, the specific information transfer process can be seen in Fig. 3. The input gate is responsible for filtering the information fed into the network. It consists of sigmoid layer and tanh layer, the former is responsible for screening the information and the latter is responsible for inputting the information into the network.

The Oblivion Gate determines the amount of information that has been input to this unit by the network in the previous moment.

The output gate determines the amount of information fed into the network at the next moment and determines the network state through a sigmoid layer.

Where \(\:{i}_{t}\), \(\:{f}_{t}\:\)and \(\:{o}_{t}\) denote the switching state of the corresponding gate, \(\:{\widehat{C}}_{t}\) is the replacement state, \(\:{C}_{t}\) is the current state, \(\:{h}_{t}\:\)is the hidden state at the current moment, \(\:{y}_{t}\) is the current time series, \(\:W\) and \(\:b\) are the weights and biases, \(\:\sigma\:\) is the sigmoid activation function, \(\:\text{t}\text{a}\text{n}\text{h}\) is the hyperbolic tangent function.

Although LSTM can predict the next moment of data from the previous moment of data, the current time information of the time series signal is not only related to the previous moment of information but also related to the historical information. BiLSTM (Bi-directional Long Short-Term Memory) considers the historical information and the local information of the previous moment through the positive and negative information streams. Enhancing the network’s ability to process long sequence signals. The structure of BiLSTM is shown in Fig. 4.

CNN-BiLSM

Within the CNN-BiLSTM diagnostic model, efficient signal feature capture is achieved through CNN, and the deficiency of CNN in temporal signals is perfected through BiLSTM’s excellent ability to store temporal information47. Specifically, CNN is responsible for extracting the potential information of bearing fault signals and reducing the dimensionality of the signals; BiLSTM is responsible for achieving fault classification by exploiting the temporal sequence of the signal features.

The integration of CNN and BiLSTM applies the advantages of a singular neural network model to the composite fault diagnosis of bearings to improve the diagnostic accuracy and efficiency. In addition, in order to improve the efficiency of fault diagnosis, the filtered sensitive IMFs are generally subjected to feature extraction. In order to verify the generality of the proposed model, this paper adopts the common time-frequency features: variance, peak, crag, RMS, peak factor, impulse factor, waveform factor, margin factor, centre frequency, average frequency, root mean square frequency, standard deviation of frequency, a total of nine time-domain indicators and four frequency-domain indicators.

Experimental validation and analysis

In order to verify the effectiveness of the proposed method in the bearing composite fault diagnosis under the constant speed operation environment, this paper firstly processes the composite fault signal through signal processing methods such as time-frequency analysis of the fault signal and envelope spectral analysis, to investigate whether the composite fault diagnosis of the bearing can be realised only through signal processing; in order to highlight the necessity of the VMD’s pre-processing of the fault signal and the validity of the intrinsically proposed model, the comparison method based on the CNN-LSTM48, CNN-BiLSTM49 and VMD-CNN-LSTM comparison methods.

In order to evaluate the model more objectively, the results are evaluated by the Average Accuracy (AA), Macro Precision (MP), Macor Recall (MR) and Macro F1-measure (MF) metrics calculated by Eq. (11)50,51,52.

Where \(\:l\) denotes the total number of sample categories, \(\:i\) denotes the category of the current sample, and \(\:N\) denotes the total number of samples. True Positive (TP) denotes the number of samples predicted correctly for the current sample, True Negative (TN) denotes the number of samples predicted correctly for the non-current sample, False Positive (FP) denotes the number of samples predicted as the current sample for the non-current sample, and False Negative (FN) denotes the number of samples predicted as non-current for the current sample.

Dataset overview

The composite fault signals of rolling bearings were selected from HUSTbearing53. The test bearing model is ER-16 K and the fault data were obtained from 9 healthy bearings operating under 11 different operating conditions. The test bench is shown in Fig. 5 and consists of speed control, motor, shaft, acceleration sensor, bearing, and data acquisition board. The nine health states of the bearing can be seen in Fig. 6 as normal, moderate and severe inner ring, outer ring and ball failures, and moderate and severe combined inner and outer ring failures. The dimensions of the faults are as follows: moderate and severe inner and outer ring faults measure 0.15 mm and 0.30 mm, respectively; moderate and severe ball faults measure 0.25 mm and 0.50 mm. The 11 test environments used were bearing running speeds of 20 Hz, 25 Hz, 30 Hz, 35 Hz, 40 Hz, 60 Hz, 65 Hz, 70 Hz, 75 Hz, 80 Hz, and 0-40-0 Hz.The sampling frequency was set to 25.6 kHz.

References22,23 selected 30 Hz as the bearing operating speed. Consequently, nine sets of composite fault data were selected for experimental verification at a speed of 30 Hz for healthy states. The classification of the degree of bearing fault defects and the steady speed collection are more in line with the normal bearing operation to the failure process, which also leads to a reduction in the effect of the neural network model based fault diagnosis54. It is beneficial to explore the effectiveness of the proposed model.

Signal processing methods

In order to explore the effectiveness of signal processing methods in the diagnosis of composite bearing faults, the common signal processing methods of time-frequency signal analysis and envelope spectral analysis are used to process the composite bearing fault signals. The faulty bearing is the bearing of Fig. 6(9) with a rotational speed of 30 Hz and the detailed parameters are shown in Table 2. The failure frequency of the inner ring of the bearing can be calculated by Eq. (12)55 and the outer ring by Eq. (13)56. In this case, bearing theory outer ring failure frequency is about 3.5744fr that is 102 Hz, outer ring theory failure frequency is about 5.4256fr that is 162hz. The result of the composite fault signal processing is shown in Fig. 7.

Composite fault simple signal analysis results are shown in Figs. 5, 6, from the time-frequency analysis i.e. Figure 7(a)(b) can be observed in the bearing there is a shock corresponding to the preliminary judgement that the bearing is faulty. In order to confirm the bearing fault site, the fault signal envelope spectrum analysis results are shown in Fig. 7(C). Rotational frequency f and the outer ring fault frequency fo and its multiplier frequency can be clearly observed, the inner ring fault frequency fi due to modulation and noise and other reasons may be ignored. It is very convenient to conclude that only the outer ring of the bearing is faulty.

The programme proposed in this paper

From the results of the signal analysis, it is very difficult to determine the location of the bearing fault by signal analysis alone. In addition, the signal analysis method cannot determine the degree of bearing failure. The rolling bearing composite fault diagnosis scheme combining signal analysis and network model proposed in this paper is used to process the signals to achieve bearing composite fault diagnosis and defect size assessment.

The composite fault diagnosis of bearings is carried out using several models mentioned above, and the fault feature set is divided into training set and test set according to 7:3. The bearing consists of 120 samples per state and each sample consists of 2048 sampling points. After VMD preprocessing and time-frequency feature extraction, it is input to the above diagnostic model.

The composite fault diagnosis confusion matrix is shown in Fig. 8 and the related metrics are shown in Table 3. In this composite fault diagnosis case, the proposed scheme has the highest diagnostic accuracy of 95%, the second accuracy of VMD-CNN-LSTM is 81%, CNN-BiLSTM is 99% and CNN-LSTM is 99%. The rest of the evaluation metrics are VMD-CNN-BiLSTM > VMD-CNN-LSTM > CNN-BiLSTM > CNN-LSTM. A higher MP is indicative of an effective false positive control mechanism, while a higher MR is indicative of a high false negative control mechanism. The MF indicator is a measure of the overall performance of the proposed model.

Discussion

In the task of rolling bearing composite fault diagnosis and damage assessment, composite fault diagnosis cannot be accurately accomplished only by time-frequency analysis and envelope spectral analysis. Due to the interference of extraneous factors such as noise, composite faults are easily misjudged as but one fault resulting in serious accidents. After that the above task is carried out by diagnostic model. CNN-LSTM combines the ability of CNN feature extraction and LSTM to memorise temporal relationships. However, the diagnostic performance is greatly limited due to the strong interference of the signal and the similarity of the signals at different levels. CNN-BiLSTM improves the diagnostic accuracy due to the mechanism of positive and negative information flow. But overall these two models are not able to perform the composite fault diagnosis task.

The diagnostic efficiency and accuracy of CNN-LSTM are significantly improved by means of signal preprocessing such as VMD noise reduction and making feature sets.MP indicators for the four kinds of indicators the highest indicates that the diagnosis of the error of the samples is mainly to diagnose the positive samples of the normal bearings as negative. The accident rate is reduced to a certain extent. But the low accuracy rate is still a defect of this model. The proposed model in this paper continues the advantages of VMD-CNN-LSTM and improves the diagnosis accuracy. By processing the time-frequency feature set, the diagnosis task is completed efficiently and accurately, which proves the effectiveness of the improved strategy adopted in this paper.

Conclusion

A novel diagnostic scheme for composite fault diagnosis of rolling bearings has been developed, incorporating the IDBO algorithm to enhance the VMD decomposition effect and a combined neural network diagnostic model. Through a comparative and evaluative analysis with other diagnostic schemes, it has been demonstrated that this scheme can achieve efficient rolling bearing composite fault diagnosis. Secondly, the paper employs signal analysis methods such as time-frequency analysis and envelope spectral analysis to process composite fault signals. The results indicate that the failure of composite fault diagnosis is only attributable to the scheme applicable to the analysis of a single fault signal. Furthermore, under steady-speed operating conditions, the proposed model can efficiently identify the bearing damage level by evaluating and classifying the damage. However, in order to demonstrate the generality of the proposed scheme, strategies such as the creation of special feature sets and the use of multi-layer neural network mechanisms to improve diagnostic accuracy are not employed. In future work, the model will be improved and applied to the fields of migration learning and small sample diagnosis.

Data availability

Data availabilityThe HUST bearing failure dataset used in this paper is a publicly available dataset that can be downloaded from the following website: https://github.com/CHAOZHAO-1/HUSTgearbox-dataset. All data generated or analysed during this study are included in this published article.

References

Chen, X., Yang, R. & Xue, Y. Deep transfer learning for bearing fault diagnosis: A systematic review since 2016. IEEE Trans. 72, 1–21. https://doi.org/10.1109/TIM.2023.3244237 (2023).

Salunkhe, V. G. et al. A novel incipient fault detection technique for roller bearing using deep independent component analysis and variational modal decomposition. ASME J. Tribol. 145, 7. https://doi.org/10.1115/1.4056899 (2023).

Zhou, X. et al. Fault diagnosis method of rolling bearing based on improved VMD spectrogram and FCM. Mach. Tools Hydraul. 51, 206–211. https://doi.org/10.1007/s11042-020-09534-w (2023).

Cheng, X. et al. Gearbox fault diagnosis method based on lightweight channel attention mechanism and transfer learning. Sci. Rep. 14, 743. https://doi.org/10.1038/s41598-023-50826-6 (2024).

Jin, X. H., Zhao, M. B., Chow, T. W. S. & Pecht, M. Motor bearing fault diagnosis using trace ratio linear discriminant analysis. 61, 2441–2451. https://doi.org/10.1109/TIE.2013.2273471 (2014).

Salunkhe, V. G. & Desavale, R. G. An intelligent prediction for detecting bearing vibration characteristics using a machine learning model. ASME J. Nondestructive Evaluation. 4, 3. https://doi.org/10.1115/1.4049938 (2021).

Wang, Q., Hu, S. & Wang, X. Detection of incipient rotor unbalance fault based on the RIME-VMD and modified-WKN. Sci. Rep. 14, 4683. https://doi.org/10.1038/s41598-024-54984-z (2024).

Mao, M. et al. Application of FCEEMD-TSMFDE and adaptive catboost in fault diagnosis of complex variable condition bearings. Sci. Rep. 14, 30448. https://doi.org/10.1038/s41598-024-78845-x (2024).

Yan, R. Q., Shang, Z. G., Xu, H. & Wen, J. C. Wavelet transform for rotary machine fault diagnosis:10 years revisited. Mech. Syst. Signal. Proc. 00, 110545. https://doi.org/10.1016/j.ymssp.2023.110545 (2023).

Randall, R. B. & Antoni, J. Why EMD and similar decompositions are of little benefit for bearing diagnostics. Mech. Syst. Signal. Proc. 192, 110207. https://doi.org/10.1016/j.ymssp.2023.110545 (2023).

Cheng, Y. & Zou, D. Complementary ensemble local means decomposition method and its application to rolling element bearings fault diagnosis. Proc. Inst. Mech. Eng. O 233, 868–880 (2019).

Wang, Z., Yang, J. & Guo, Y. Unknown fault feature extraction of rolling bearings under variable speed conditions based on statistical complexity measures. Mech. Syst. Signal. Proc. 72, 108964. https://doi.org/10.1016/j.ymssp.2022.108964 (2022).

Dragomiretskiy, K. & Zosso, D. Variational mode decomposition. IEEE Trans. Signal. Process. 62, 531–544. https://doi.org/10.1109/TSP.2013.2288675 (2013).

Zhang, S., Wang, Y. & He, S. Bearing fault diagnosis based on variational mode decomposition and total variation denoising. Meas. Sci. Technol. 27, 075101. https://doi.org/10.1088/0957-0233/27/7/075101 (2016).

Li, K., Su, L., Wu, J. & Wang, H. A. Rolling bearing fault diagnosis method based on variational mode decomposition and an improved kernel extreme learning machine. Appl. Sci. 7, 1004. https://doi.org/10.3390/app7101004 (2017).

Yuan, Y. et al. Noise reduction and feature enhancement of hob vibration signal based on parameter adaptive VMD and autocorrelation analysis. Meas. Sci. Technol. 33, 125116. https://doi.org/10.1088/1361-6501/ac8e23 (2022).

Xing, Y. & Jian, R. Features method for selecting VMD parameters based on spectrum without modal overlap. J. Phys. Conf. Ser. 1605, 012002. https://doi.org/10.1088/1742-6596/1605/1/012002 (2020).

Zhong, X., Xia, T. & Mei, Q. An effective centre frequency selection scheme based on variational mode extraction and its application to gear fault diagnosis. Insight-Non-Destructive Test. Condition Monit. 64, 155–163. https://doi.org/10.1784/insi.2022.64.3.155 (2022).

Li, H., Liu, T., Wu, X. & Chen, Q. An optimized VMD method and its applications in bearing fault diagnosis. Meas 166, 108185. https://doi.org/10.1016/j.measurement.2020.108 (2020).

Zhang, X., Miao, Q., Zhang, H. & Wang, L. A parameter-adaptive VMD method based on grasshopper optimization algorithm to analyze vibration signals from rotating machinery. Mech. Syst. Signal. Proc. 108, 58–72. https://doi.org/10.1016/j.ymssp.2017.11.029 (2018).

Jin, Z., He, D. & Wei, Z. Intelligent fault diagnosis of train axle box bearing based on parameter optimization VMD and improved DBN. Eng. Appl. Artif. Intell. 110, 104713. https://doi.org/10.1016/j.engappai.2022.104713 (2022).

Wang, X. et al. Fault diagnosis method of rolling bearing based on SSA-VMD and RCMDE. Sci. Rep. 14, 30637. https://doi.org/10.1038/s41598-024-81262-9 (2024).

Tang, J., Liu, G. & Pan, Q. A review on representative swarm intelligence algorithms for solving optimization problems: applications and trends. IEEE-CAA J. AUTOMATIC. 8 (10), 1627–1643. https://doi.org/10.1109/JAS.2021.1004129 (2021).

Xue, J. & Shen, B. Dung beetle optimizer: A new meta-heuristic algorithm for global optimization. J. Supercomput. 79, 7305–7336. https://doi.org/10.1007/s11227-022-04959-6 (2023).

Kong, W. et al. PID control algorithm based on multistrate-gy enhanced Dung beetle optimizer and back propagation neural network for DC motor control. Sci. Rep. 14, 28276. https://doi.org/10.1038/s41598-024-79653-z (2024).

Tang, X., He, Z. & Jia, C. Multi-strategy cooperative enhancement Dung beetle optimizer and its application in obstacle avoidance navigation. Sci. Rep. 14, 28041. https://doi.org/10.1038/s41598-024-79420-0 (2024).

Li, X. et al. A review on convolutional neural network in rolling bearing fault diagnosis. Meas. Sci. Technol. 35, 1. https://doi.org/10.1088/1361-6501/ad356e (2024).

Salunkhe, V. G. et al. Vibration dynamic analysis of the bearing parameters in steam turbine bearing systems in sugar refinery. ASME J. Tribol. 148, 13. https://doi.org/10.1115/1.4068559 (2025).

Ruan, D. W., Han, J. Z., Yan, J. P. & Guehmann, C. Light convolutional neural network by neural architecture search and model pruning for bearing fault diagnosis and remaining useful life prediction. Sci. Rep. 13, 1. https://doi.org/10.1038/s41598-023-31532 (2023).

LeCun, Y., Bengio, Y. & Hinton, G. Deep learning. Nature 521, 436–444. https://doi.org/10.1038/nature14539 (2015).

Choudhary, A., Mian, T. & Fatima, S. Convolutional neural network based bearing fault diagnosis of rotating machine using thermal images. Meas 176, 109196. https://doi.org/10.1016/j.measurement.2021.109196 (2021).

Tang, G., Zhou, Y., Wang, H. & Li, G. Prediction of bearing performance degradation with bottleneck feature based on LSTM network. IEEE Int. Inst. Meas. Tec. Conf. 1–6. https://doi.org/10.1109/I2MTC.2018.8409564 (2018).

Guo, Y., Mao, J. & Zhao, M. Rolling bearing fault diagnosis method based on attention CNN and BiLSTM network. Neural Process. Lett. 55, 3377–3410. https://doi.org/10.1007/s11063-022-11013-2 (2023).

Zhang, Y. et al. Attention activation network for bearing fault diagnosis under various noise environments. Sci. Rep. 15, 977. https://doi.org/10.1038/s41598-025-85275-w (2025).

Salunkhe, V. G. et al. Rolling element bearing fault diagnosis by the implementation of Elman neural networks with long Short-Term memory strategy. ASME J. Tribol. 147, 8. https://doi.org/10.1115/1.4067382 (2025).

Saeed, A., Khan, A. & Akram, M. Deep learning based approaches for intelligent industrial machinery health management and fault diagnosis in resource-constrained environments. Sci. Rep. 15, 1114. https://doi.org/10.1038/s41598-024-79151-2 (2025).

Chen, X., Zhang, B. & Gao, D. Bearing fault diagnosis base on multi-scale CNN and LSTM model. J. Intell. Manuf. 32, 971–987. https://doi.org/10.1007/s10845-020-01600-2 (2021).

Nacer, S. M. et al. A novel method for bearing fault diagnosis based on BiLSTM neural networks. Int. J. Adv. Manuf. Technol. 125, 1477–1492. https://doi.org/10.1007/s00170-022-10792-1 (2023).

Salunkhe, V. G. et al. Unbalance bearing fault identification using highly accurate Hilbert–Huang transform approach. J. Nondestr Eval Diag. 6, 3. https://doi.org/10.1115/1.4062929 (2023).

Yıldız, B. S., Kumar, S., Pholdee, N. & Yildiz, A. R. A new chaotic lévy flight distribution optimization algorithm for solving constrained engineering problems. Expert Syst. Appl. 39, 12992. https://doi.org/10.1111/exsy.12992 (2022).

Tanyildizi, E. & Demir, G. Golden sine algorithm: A novel Math-Inspired algorithm. Adv. Electr. Comput. Eng. 17, 71–78. https://doi.org/10.4316/AECE.2017.02010 (2017).

Seyedali, M. SCA: A sine cosine algorithm for solving optimization problems. KNOWL-BASED SYST. 96, 120–133. https://doi.org/10.1016/j.knosys.2015.12.022 (2016).

Ghasemi, M., Zare, M. & Trojovský, P. Optimization based on the smart behavior of plants with its engineering applications: Ivy algorithm. Knowl.-Based Syst. 295, 111850. https://doi.org/10.1016/j.knosys.2024.111850 (2024).

Amiri, M. H. et al. Hippopotamus optimization algorithm: a novel nature-inspired optimization algorithm. Sci. Rep. 14, 5032. https://doi.org/10.1038/s41598-024-54910-3 (2024).

Xin, Y., Yong, L. & Guang, L. Evolutionary programming made faster. 3, 102. https://doi.org/10.1109/4235.771163 (1999).

Wang, Y. H. et al. Degradation trend prediction of hydropower units based on a comprehensive deterioration index and LSTM. Energies 15, 6273. https://doi.org/10.3390/en15176273 (2022).

Jiang, Z. et al. A fault detection of aero-engine rolling bearings based on CNN-BiLSTM network integrated cross-attention. Meas. Sci. Technol. 35, 12 (2014).

Dao, F. et al. Wear fault diagnosis in hydro-turbine via the incorporation of the IWSO algorithm optimized CNN-LSTM neural network. Sci. Rep. 14, 25278. https://doi.org/10.1038/s41598-024-77251-7 (2024).

Li, X. et al. An improved sparrow search algorithm and CNN-BiLSTM neural network for predicting sea level height. Sci. Rep. 14, 4560. https://doi.org/10.1038/s41598-024-55266-4 (2024).

Salunkhe, V. G. et al. An integrated dimension theory and modulation signal bispectrum technique for analyzing bearing fault in industrial fibrizer. J. Nondestr Eval Diag. 7, 3. https://doi.org/10.1115/1.4065545 (2024).

Song, Q. et al. Fault diagnosis of HVCB via the Subtraction average based optimizer algorithm optimized multi channel CNN-SABO-SVM network. Sci. Rep. 14, 29507. https://doi.org/10.1038/s41598-024-80954-6 (2024).

Xiao, Q. et al. Feature decoupling integrated domain generalization network for bearing fault diagnosis under unknown operating conditions. Sci. Rep. 14, 30848. https://doi.org/10.1038/s41598-024-81489-6 (2024).

Zhao, C., Zio, E. & Shen, W. Domain generalization for Cross-Domain fault diagnosis: an Application-oriented perspective and a benchmark study. Reliab. Eng. Syst. Safe. 245, 109964. https://doi.org/10.1016/j.ress.2024.109964 (2024).

Jagadeesha, T. et al. Investigation of Crack Detection Technique in a Rotating Shaft by Using Vibration Measurement 631–645. https://doi.org/10.1007/978-981-15-4739-3_54 (AIME, 2021).

Song, J. et al. Reliability analysis of gear-bearing drive systems considering gear manufacturing and installation errors. Sci. Rep. 15, 23301. https://doi.org/10.1038/s41598-025-06446-3 (2025).

Salunkhe, V. G., Desavale, R. G. & Jagadeesha, T. A numerical model for fault diagnosis in deep groove ball bearing using dimension theory. Mater. Today Proc. 47, 3077–3084. https://doi.org/10.1016/j.matpr.2021.06.072 (2021).

Acknowledgements

This work is supported by grants from the National Natural Science Foundation of China (51805151).

Funding

This work is supported by grants from the National Natural Science Foundation of China (51805151).

Author information

Authors and Affiliations

Contributions

Lihai Chen: Conceptualization, Formal analysis, Funding acquisition, Project administration, Investigation, Methodology, Resources, Validation, Writing – review & editing. Xiaolong Bai: Data curation, Formal analysis, Investigation, Software, Validation, Visualization, Writing – original draft. Yonghui He: Formal analysis, Resources, Writing – review & editing. Dong Jia: Data curation, Resources, Writing – review & editing. Yican Li: Investigation, Software. Zhenshui LI: Data curation, Software. All authors reviewed the manuscript, Methodology, Software, Conceptualization, Supervision, Funding acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chen, L., Bai, X., He, Y. et al. Multi-fault diagnosis and damage assessment of rolling bearings based on IDBO-VMD and CNN-BiLSTM. Sci Rep 15, 31121 (2025). https://doi.org/10.1038/s41598-025-17177-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-17177-w